Service Life Prediction of Concrete Coated with Surface Protection Materials by Ultrasonic Velocity in Cold Region

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Experimental Procedures

2.2.1. Water Absorption Test

2.2.2. Rapid Freeze–Thaw Test

3. Results

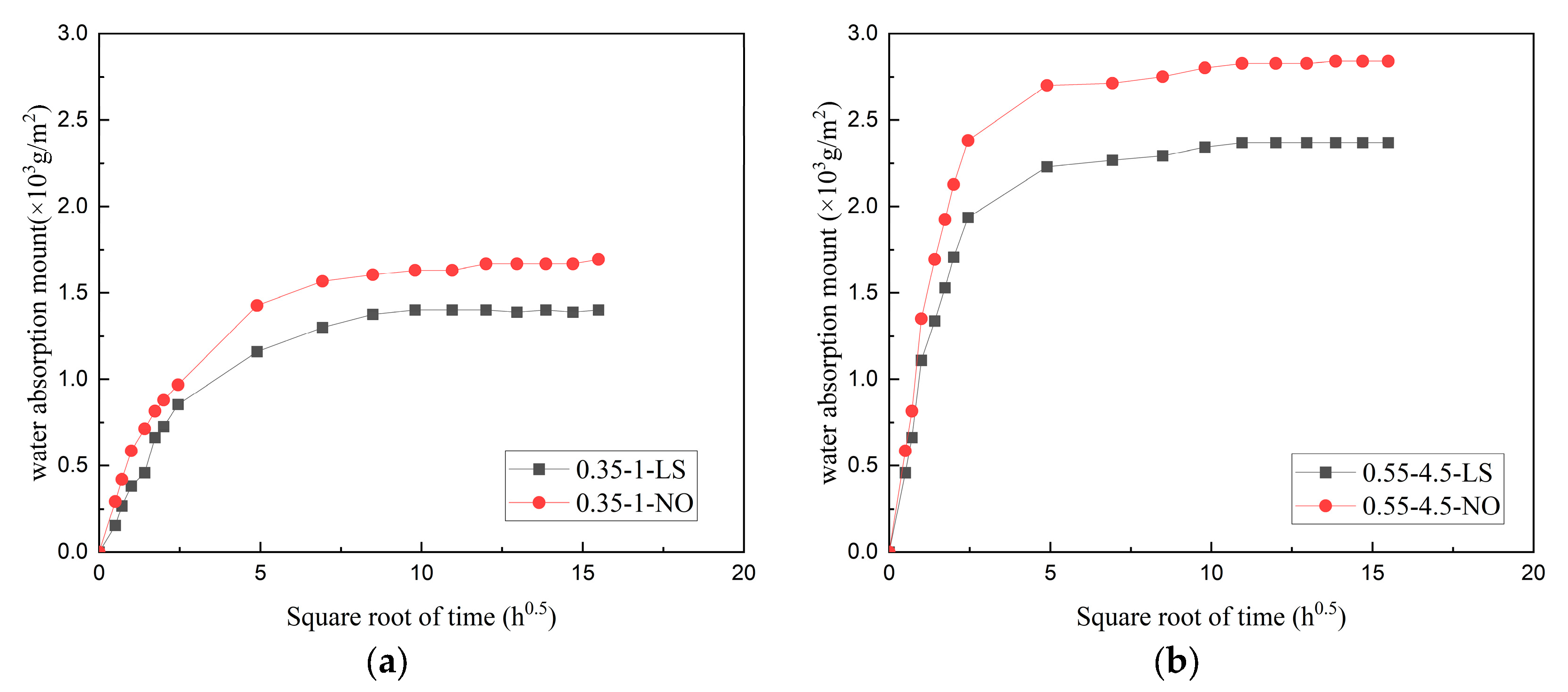

3.1. Results of the Water Absorption Test

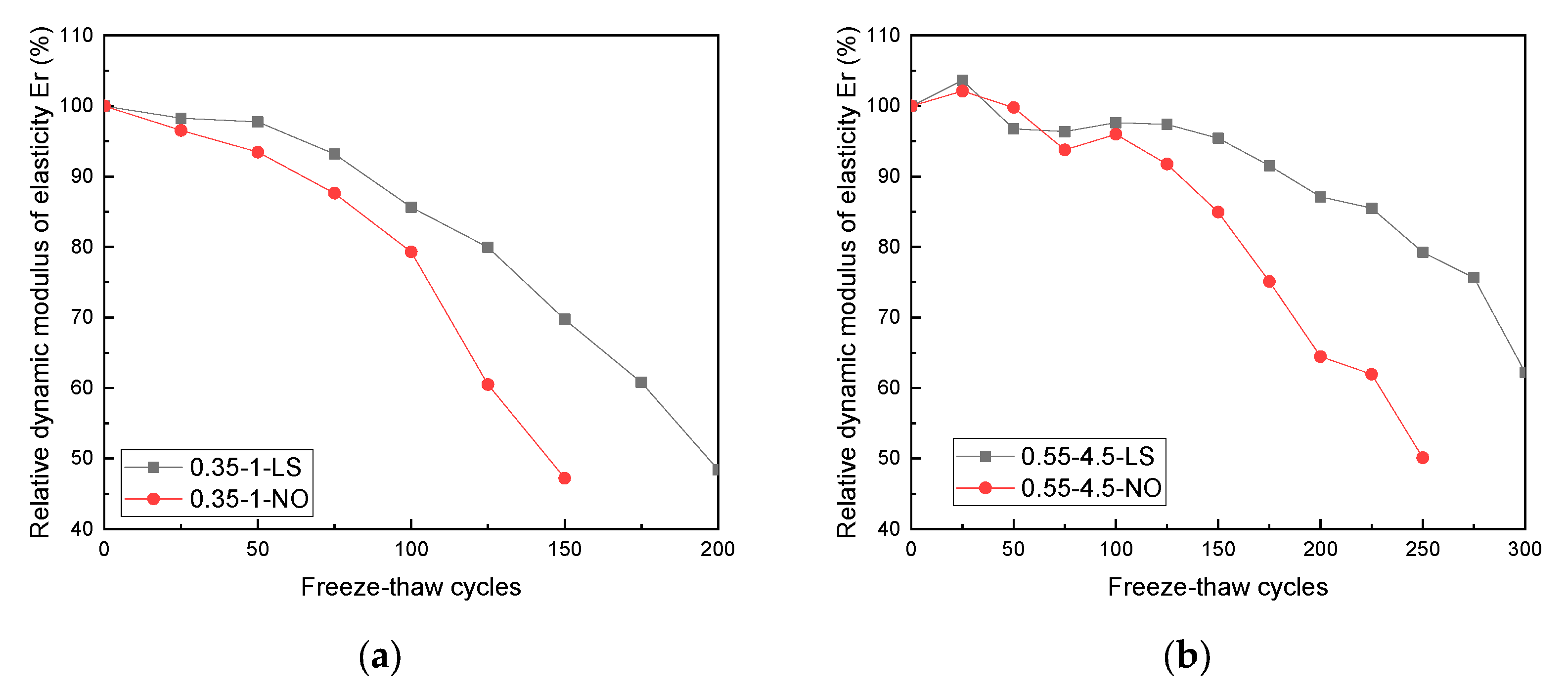

3.2. Results of the Relative Dynamic Modulus of Elasticity

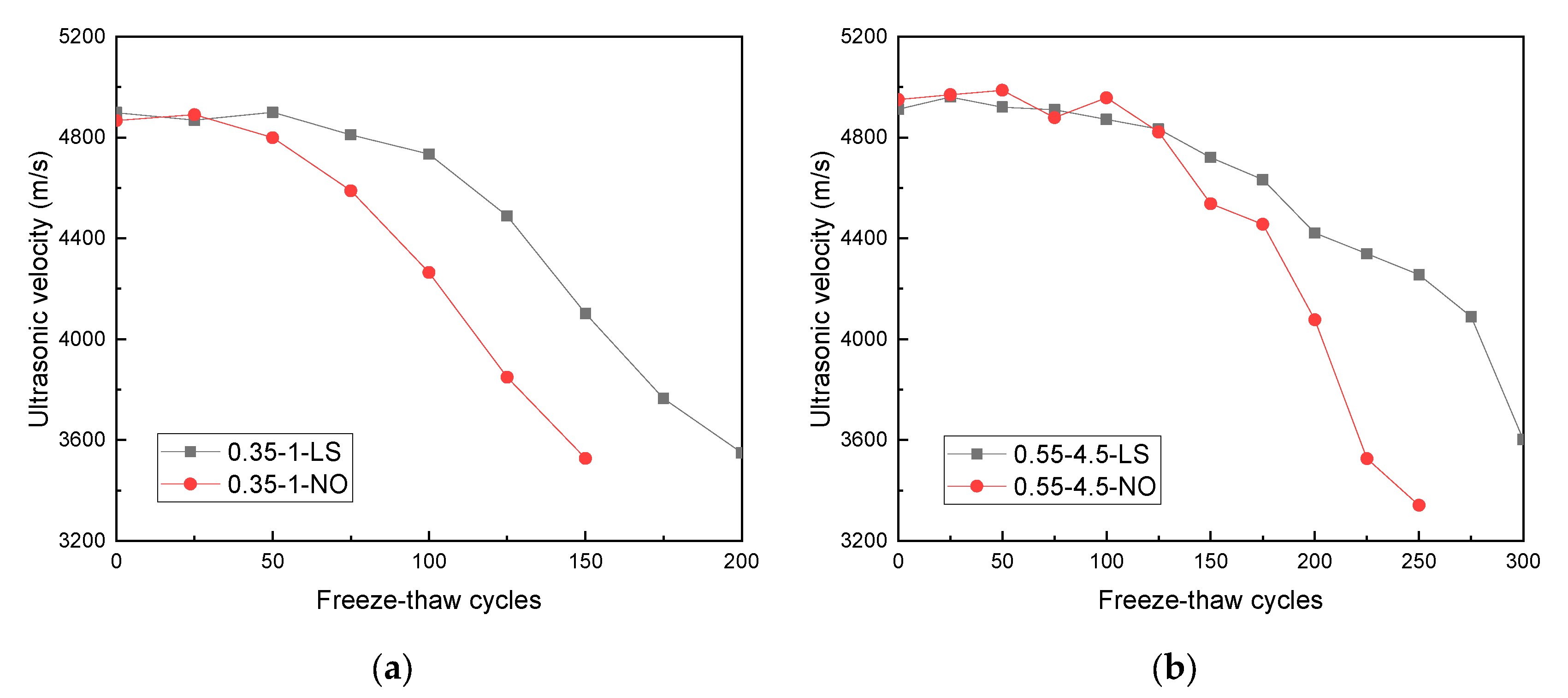

3.3. Change in the Ultrasonic Velocity

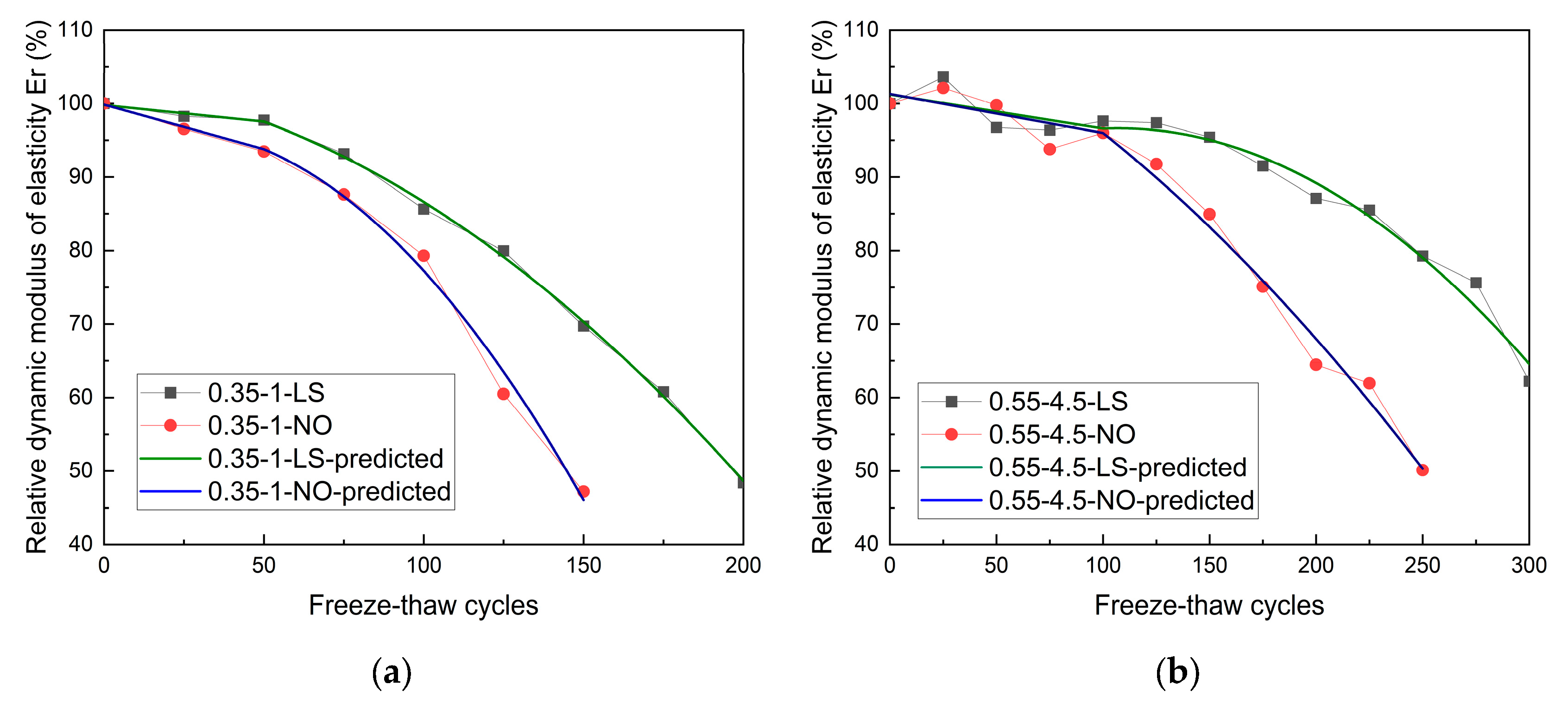

3.4. Prediction of Relative Dynamic Modulus of Elasticity

- (1)

- In the first segment ①, the velocity and acceleration are shown as follows:

- (2)

- In the second segment ②, the velocity and acceleration rate are exhibited as below:

3.4.1. Prediction of the Relative Dynamic Modulus of Elasticity Er

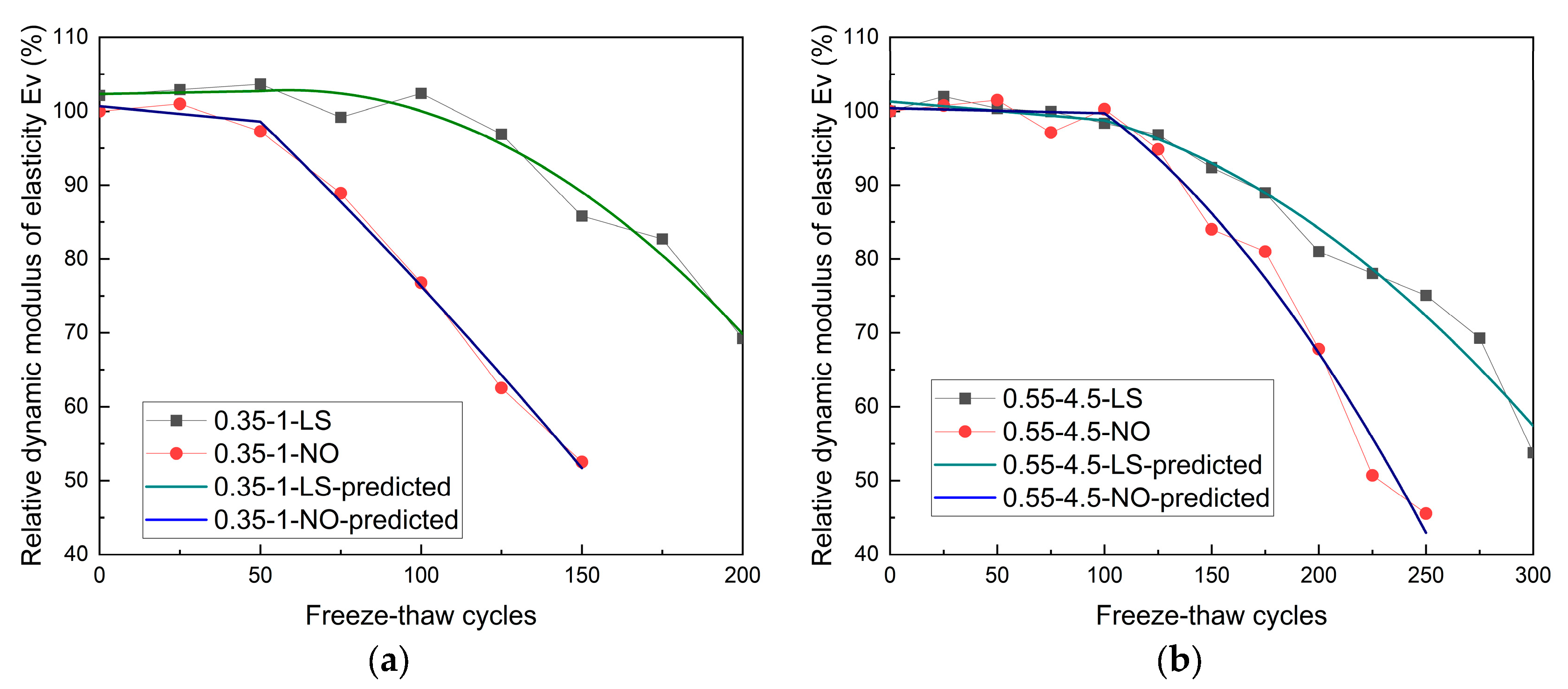

3.4.2. Prediction of Relative Dynamic Modulus of Elasticity Ev

3.5. Calculation of the Service Life by the Two-Segment Damage Model

4. Conclusions

- The use of LS reduced the initial coefficient of water absorption (Bini) and the total water absorption amount in both kinds of concrete specimens.

- LS improved the concrete freeze–thaw resistance in both kinds of concrete specimens. The Er of the 0.35–1–NO specimens was 46.06% at 150 cycles, while the Er of the 0.35–1–LS specimens was 48.62% at 200 freeze–thaw cycles. The Er of the 0.55–4.5–LS specimens at 300 freeze–thaw cycles was 62.23%, while the value of the 0.55–4.5–NO specimens was below 60%. The Er of the 0.35–1 specimens decreased slightly before 50 cycles and then it showed a dramatic decrease, whereas the changing point for the 0.55–4.5 specimens was 100 cycles. The Ev, calculated by ultrasonic velocity, was also evaluated. The changes in Ev were similar to those in Er, where the changing points for the 0.35–1 and 0.55–4.5 specimens were 50 and 100 freeze–thaw cycles, respectively.

- The two-segment mathematical model consisted of a straight line and a univariate quadratic polynomial. The two-segment model was employed to predict Er and Ev, respectively. The goodness of fit values were above 0.97 and 0.98, respectively, representing high prediction reliability. In addition, Er and Ev were used to verify the service life predictions for the two types of concrete specimens during the freeze–thaw cycles. Except for the 0.35–1–LS specimens showing an error of 24.28%, the errors for the other three types of concrete specimens were within 8%. Therefore, the Ev could be used to accurately predict the service life of concrete.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Medina, C.; De Rojas, M.S.; Thomas, C.; Polanco, J.A.; Frías, M. Durability of recycled concrete made with recycled ceramic sanitary ware aggregate. Inter-indicator relationships. Constr. Build. Mater. 2016, 105, 480–486. [Google Scholar] [CrossRef]

- Liu, Y.; Jia, M.; Song, C.; Lu, S.; Wang, H.; Zhang, G.; Yang, Y. Enhancing ultra-early strength of sulphoaluminate cement-based materials by incorporating graphene oxide. Nanotechnol. Rev. 2020, 9, 17–27. [Google Scholar] [CrossRef]

- Liu, Y.; Tian, W.; Wang, M.; Qi, B.; Wang, W. Rapid strength formation of on-site carbon fiber reinforced high-performance concrete cured by ohmic heating. Constr. Build. Mater. 2020, 244, 118344. [Google Scholar] [CrossRef]

- Liu, Y.; Yu, K.; Lu, S.; Wang, C.; Li, X.; Yang, Y. Experimental research on an environment-friendly form-stable phase change material incorporating modified rice husk ash for thermal energy storage. J. Energy Storage 2020, 31, 101599. [Google Scholar] [CrossRef]

- Liu, Y.; Xie, M.; Xu, E.; Gao, X.; Yang, Y.; Deng, H. Development of calcium silicate-coated expanded clay based form-stable phase change materials for enhancing thermal and mechanical properties of cement-based composite. Solar Energy. 2018, 174, 24–34. [Google Scholar] [CrossRef]

- Júnior, N.A.; Silva, G.A.O.; Ribeiro, D.V. Effects of the incorporation of recycled aggregate in the durability of the concrete submitted to freeze-thaw cycles. Constr. Build. Mater. 2018, 161, 723–730. [Google Scholar] [CrossRef]

- Yu, K.; Jia, M.; Yang, Y.; Liu, Y. A clean strategy of concrete curing in cold climate: Solar thermal energy storage based on phase change material. Appl. Energy 2023, 331, 120375. [Google Scholar] [CrossRef]

- Basheer, L.; Cleland, D.J. Freeze–thaw resistance of concretes treated with pore liners. Constr. Build. Mater. 2006, 20, 990–998. [Google Scholar] [CrossRef]

- Zeng, Y.; Zhou, X.; Tang, A. Shear performance of fibers-reinforced lightweight aggregate concrete produced with industrial waste ceramsite-Lytag after freeze-thaw action. J. Clean. Prod. 2021, 328, 129626. [Google Scholar] [CrossRef]

- Luo, S.; Bai, T.; Guo, M.; Wei, Y.; Ma, W. Impact of Freeze–Thaw Cycles on the Long-Term Performance of Concrete Pavement and Related Improvement Measures: A Review. Materials 2022, 15, 4568. [Google Scholar] [CrossRef]

- Powers, T.C. A working hypothesis for further studies of frost resistance of concrete. J. Proc. 1945, 41, 245–272. [Google Scholar]

- Ebrahimi, K.; Daiezadeh, M.J.; Zakertabrizi, M.; Zahmatkesh, F.; Korayem, A.H. A review of the impact of micro-and nanoparticles on freeze-thaw durability of hardened concrete: Mechanism perspective. Constr. Build. Mater. 2018, 186, 1105–1113. [Google Scholar] [CrossRef]

- Gong, F.; Jacobsen, S. Modeling of water transport in highly saturated concrete with wet surface during freeze/thaw. Cem. Concr. Res. 2019, 115, 294–307. [Google Scholar] [CrossRef]

- Falchi, L.; Müller, U.; Fontana, P.; Izzo, F.C.; Zendri, E. Influence and effectiveness of water-repellent admixtures on pozzolana–lime mortars for restoration application. Constr. Build. Mater. 2013, 49, 272–280. [Google Scholar] [CrossRef]

- Liu, Z.; Chin, C.S.; Xia, J. Novel method for enhancing freeze–thaw resistance of recycled coarse aggregate concrete via two-stage introduction of denitrifying bacteria. J. Clean. Prod. 2022, 346, 131159. [Google Scholar] [CrossRef]

- Hoła, J.; Bień, J.; Schabowicz, K. Non-destructive and semi-destructive diagnostics of concrete structures in assessment of their durability. Bull. Pol. Acad. Sci. Tech. Sci. 2015, 63, 87–96. [Google Scholar] [CrossRef]

- Shang, H.S.; Yi, T.H.; Guo, X.X. Study on strength and ultrasonic velocity of air-entrained concrete and plain concrete in cold environment. Adv. Mater. Sci. Eng. 2014, 2014, 706986. [Google Scholar] [CrossRef]

- Yan, W.; Wu, Z.; Niu, F.; Wan, T.; Zheng, H. Study on the service life prediction of freeze–thaw damaged concrete with high permeability and inorganic crystal waterproof agent additions based on ultrasonic velocity. Constr. Build. Mater. 2020, 259, 120405. [Google Scholar] [CrossRef]

- Fagerlund, G. Frost destruction of concrete–a study of the validity of different mechanisms. Nord. Concr. Res. 2018, 58, 35–54. [Google Scholar] [CrossRef]

- Cho, T. Prediction of cyclic freeze–thaw damage in concrete structures based on response surface method. Constr. Build. Mater. 2007, 21, 2031–2040. [Google Scholar] [CrossRef]

- Yu, H.; Ma, H.; Yan, K. An equation for determining freeze-thaw fatigue damage in concrete and a model for predicting the service life. Constr. Build. Mater. 2017, 137, 104–116. [Google Scholar] [CrossRef]

- Chen, F.; Qiao, P. Probabilistic damage modeling and service-life prediction of concrete under freeze–thaw action. Mater. Struct. 2015, 48, 2697–2711. [Google Scholar] [CrossRef]

- Lu, W.P.; Wittmann, F.H.; Wang, P.G.; Zaytsev, Y.; Zhao, T.J. Influence of an applied compressive load on capillary absorption of concrete: Observation of anisotropy. Restor. Build. Monum. 2014, 20, 131–136. [Google Scholar] [CrossRef]

- Castro, J.; Bentz, D.; Weiss, J. Effect of sample conditioning on the water absorption of concrete. Cem. Concr. Compos. 2011, 33, 805–813. [Google Scholar] [CrossRef]

- Litvan, G.G. Phase transitions of adsorbates. V. Aqueous sodium chloride solutions adsorbed of porous silica glass. J. Colloid Interface Sci. 1973, 45, 154–169. [Google Scholar] [CrossRef]

- Zhang, P.; Wittmann, F.H.; Vogel, M.; Müller, H.S.; Zhao, T. Influence of freeze-thaw cycles on capillary absorption and chloride penetration into concrete. Cem. Concr. Res. 2017, 100, 60–67. [Google Scholar] [CrossRef]

- Zhang, W.; Pi, Y.; Kong, W.; Zhang, Y.; Wu, P.; Zeng, W.; Yang, F. Influence of damage degree on the degradation of concrete under freezing-thawing cycles. Constr. Build. Mater. 2020, 260, 119903. [Google Scholar] [CrossRef]

- Baltazar, L.; Santana, J.; Lopes, B.; Rodrigues, M.P.; Correia, J.R. Surface skin protection of concrete with silicate-based impregnations: Influence of the substrate roughness and moisture. Constr. Build. Mater. 2014, 70, 191–200. [Google Scholar] [CrossRef]

- Liu, W.D.; Sun, W.T.; Wang, Y.M. Research on damage model of fiber concrete under action of freeze thaw cycle. J. Build. Struct. 2008, 29, 124–128. [Google Scholar]

- Yu, H.F. Study on High Performance Concrete in Salt Lake: Durability, Mechanism and Service Life Prediction; Nanjing University: Nanjing, China, 2003. (In Chinese) [Google Scholar]

- Ababneh, A.N. The Coupled Effect of Moisture Diffusion, Chloride Penetration and Freezing-Thawing on Concrete Durability. Doctoral Dissertation, University of Colorado, Denver, CO, USA, 2002. [Google Scholar]

- Sun, L.F.; Jiang, K.; Zhu, X.; Xu, L. An alternating experimental study on the combined effect of freeze-thaw and chloride penetration in concrete. Constr. Build. Mater. 2020, 252, 119025. [Google Scholar] [CrossRef]

- Lin, H.; Han, Y.; Liang, S.; Gong, F.; Han, S.; Shi, C.; Feng, P. Effects of low temperatures and cryogenic freeze-thaw cycles on concrete mechanical properties: A literature review. Constr. Build. Mater. 2022, 345, 128287. [Google Scholar] [CrossRef]

- Wu, P.; Liu, Y.; Peng, X.; Chen, Z. Peri-dynamic modeling of freeze-thaw damage in concrete structures. Mech. Adv. Mater. Struct. 2022, 1, 1–12. [Google Scholar] [CrossRef]

- Chen, X.; Lam, K.H.; Chen, R.; Chen, Z.; Qian, X.; Zhang, J.; Zhou, Q. Acoustic levitation and manipulation by a high-frequency focused ring ultrasonic transducer. Appl. Phys. Lett. 2019, 114, 054103. [Google Scholar] [CrossRef]

| Chemical Composition (wt.%) | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Oxides | CaO | SiO2 | Al2O3 | Fe2O3 | SO3 | MgO | Na2O | K2O | Others |

| Content | 61.10 | 22.70 | 6.85 | 2.86 | 3.61 | 0.95 | 0.36 | 0.28 | 3.88 |

| Mix | Mix Proportion (kg/m3) | External Coating | |||

|---|---|---|---|---|---|

| Cement | Sand | Limestone | Water | ||

| 0.35–1.0–LS | 471 | 827 | 978 | 165 | LS |

| 0.35–1.0–NO | None | ||||

| 0.55–4.5–LS | 313 | 843 | 949 | 172 | LS |

| 0.55–4.5–NO | None | ||||

| Sample | α | β | Bini = α × β | Total Water Absorption (%) |

|---|---|---|---|---|

| 0.35–1–NO | 1.45 | 0.80 | 1.16 | 1.69 |

| 0.35–1–LS | 1.30 | 0.58 | 0.75 | 1.40 |

| 0.55–4.5–NO | 2.82 | 0.64 | 1.80 | 2.84 |

| 0.55–4.5–LS | 2.34 | 0.60 | 1.40 | 2.34 |

| Specimen Type | Segment 1 | Segment 2 | Goodness of Fitting (R2) | |

|---|---|---|---|---|

| Velocity | Damage Velocity | Damage Acceleration | ||

| 0.35–1–LS | 0.045 | 0.0577 + 0.0022 × N | 0.0022 × N | 0.9989 |

| 0.35–1–NO | 0.1215 | −0.1095 + 0.0058 × N | 0.0058 × N | 0.9939 |

| 0.55–4.5–LS | 0.0463 | −0.1838 + 0.0018 × N | 0.0018 × N | 0.9721 |

| 0.55–4.5–NO | 0.0532 | 0.1330 + 0.0022 × N | 0.0022 × N | 0.9858 |

| Specimen Type | Segment 1 | Segment 2 | Goodness of Fitting (R2) | |

|---|---|---|---|---|

| Initial Velocity | Damage Velocity | Damage Acceleration | ||

| 0.35–1–LS | −0.0079 | −0.1934 + 0.0034 × N | 0.0034 × N | 0.9697 |

| 0.35–1–NO | 0.0417 | 0.3749 + 0.0010 × N | 0.0010 × N | 0.9958 |

| 0.55–4.5–LS | 0.0254 | −0.0356 + 0.0012 × N | 0.0012 × N | 0.9804 |

| 0.55–4.5–NO | 0.0068 | 0.0011 + 0.0024 × N | 0.0024 × N | 0.9853 |

| Specimen Type | Service Life of Concrete Specimens (Freeze–Thaw Cycles) | ||

|---|---|---|---|

| Er | Ev | Error (%) | |

| 0.35–1–LS | 173 | 215 | 24.28 |

| 0.35–1–NO | 131 | 132 | 0.76 |

| 0.55–4.5–LS | 302 | 293 | 2.98 |

| 0.55–4.5–NO | 222 | 205 | 7.66 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, D.; Yang, F.; Mo, Y.; Yang, S.; Guo, C.; Wang, F. Service Life Prediction of Concrete Coated with Surface Protection Materials by Ultrasonic Velocity in Cold Region. Separations 2023, 10, 328. https://doi.org/10.3390/separations10060328

Ma D, Yang F, Mo Y, Yang S, Guo C, Wang F. Service Life Prediction of Concrete Coated with Surface Protection Materials by Ultrasonic Velocity in Cold Region. Separations. 2023; 10(6):328. https://doi.org/10.3390/separations10060328

Chicago/Turabian StyleMa, Dequn, Fan Yang, Yeqiang Mo, Shichao Yang, Chengchao Guo, and Fuming Wang. 2023. "Service Life Prediction of Concrete Coated with Surface Protection Materials by Ultrasonic Velocity in Cold Region" Separations 10, no. 6: 328. https://doi.org/10.3390/separations10060328

APA StyleMa, D., Yang, F., Mo, Y., Yang, S., Guo, C., & Wang, F. (2023). Service Life Prediction of Concrete Coated with Surface Protection Materials by Ultrasonic Velocity in Cold Region. Separations, 10(6), 328. https://doi.org/10.3390/separations10060328