Study on Multi-Pollutant Test and Performance Index Determination of Wet Electrostatic Precipitator

Abstract

1. Introduction

2. Materials and Methods

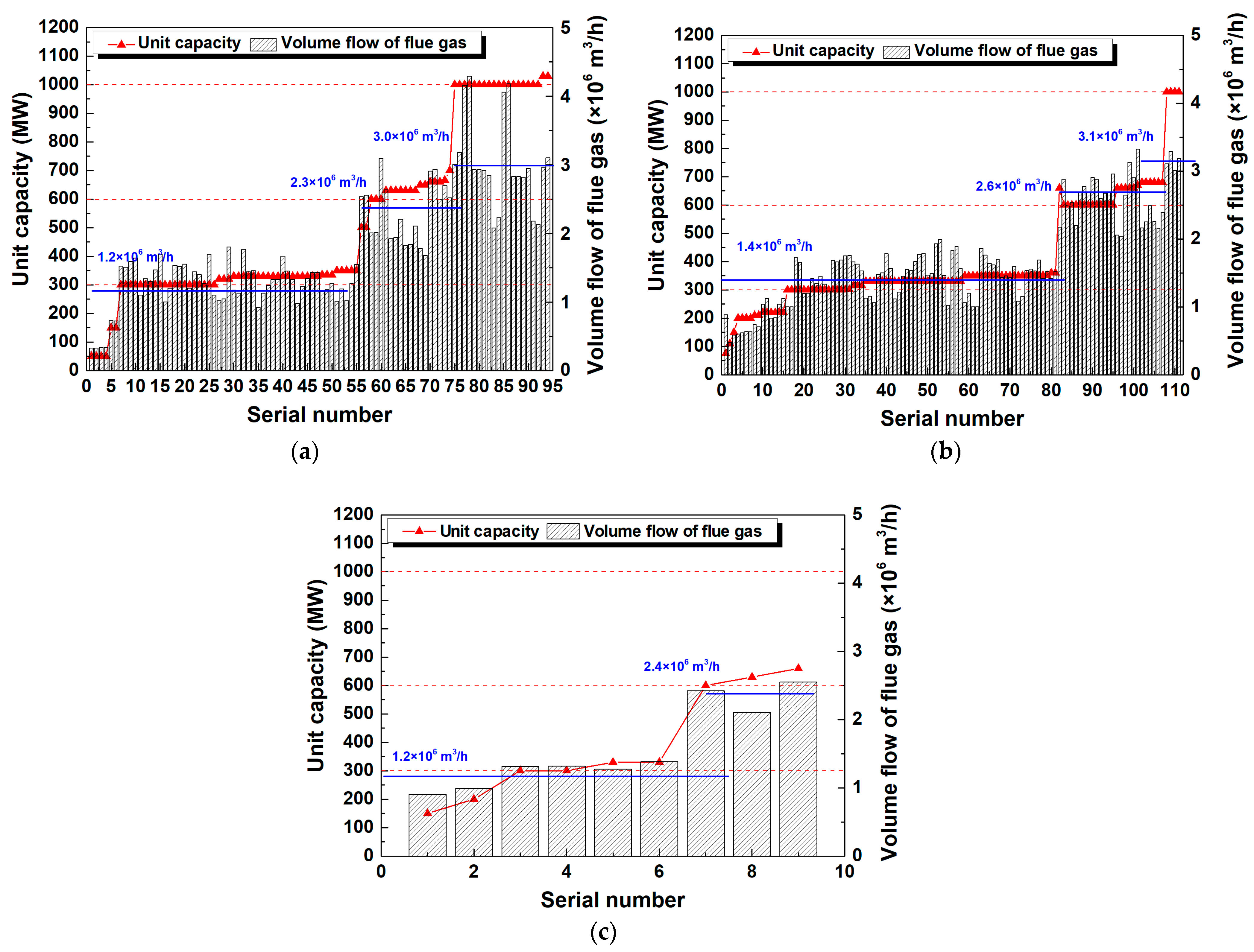

2.1. Research Object

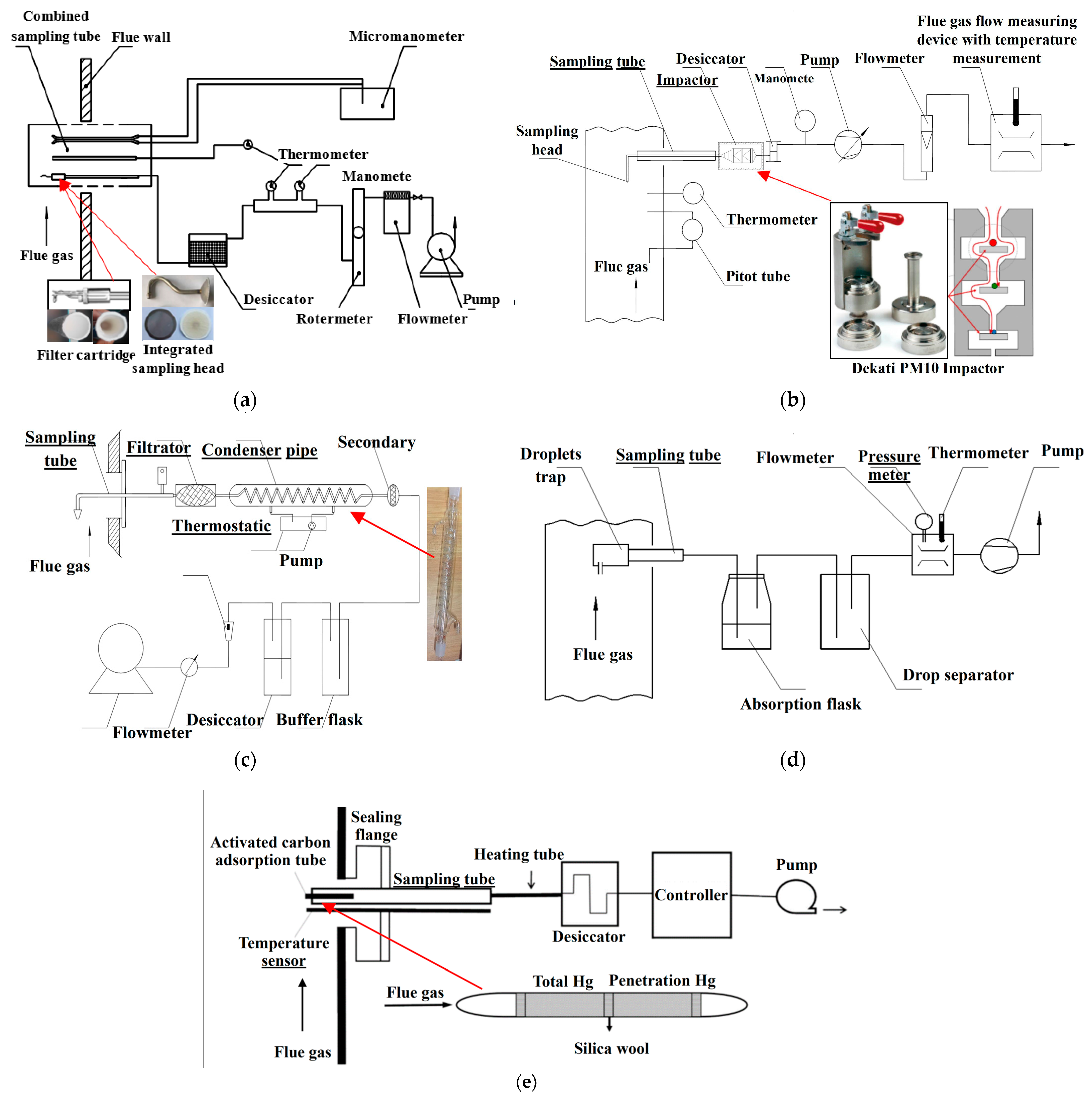

2.2. Test Methods

3. Results

3.1. Pollutant-Removal Performance

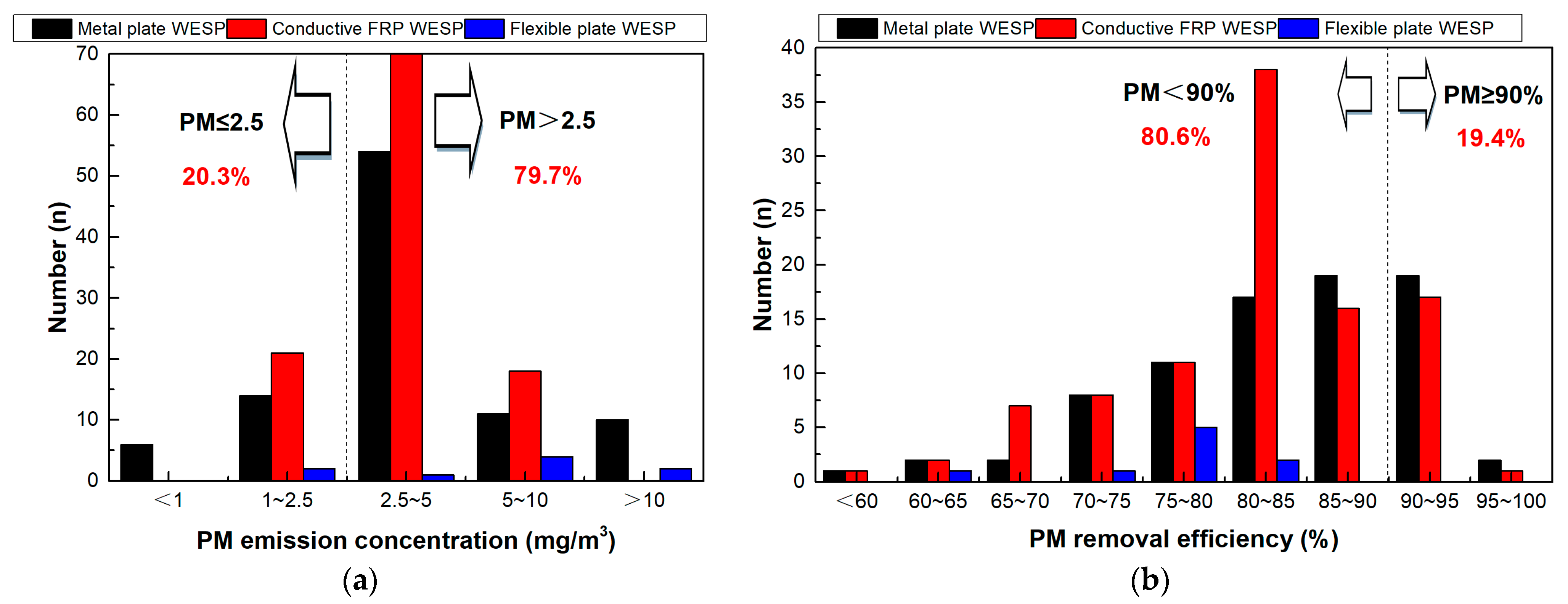

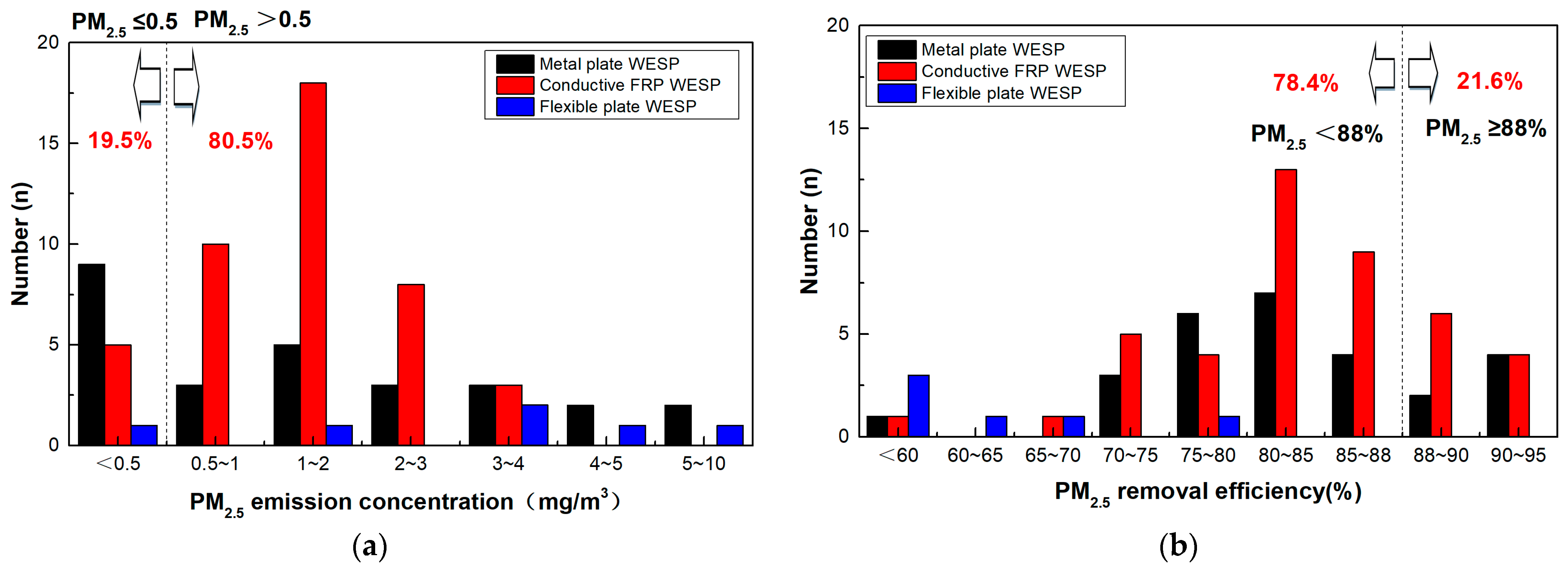

3.1.1. PM and PM2.5

3.1.2. Non-Conventional Pollutant

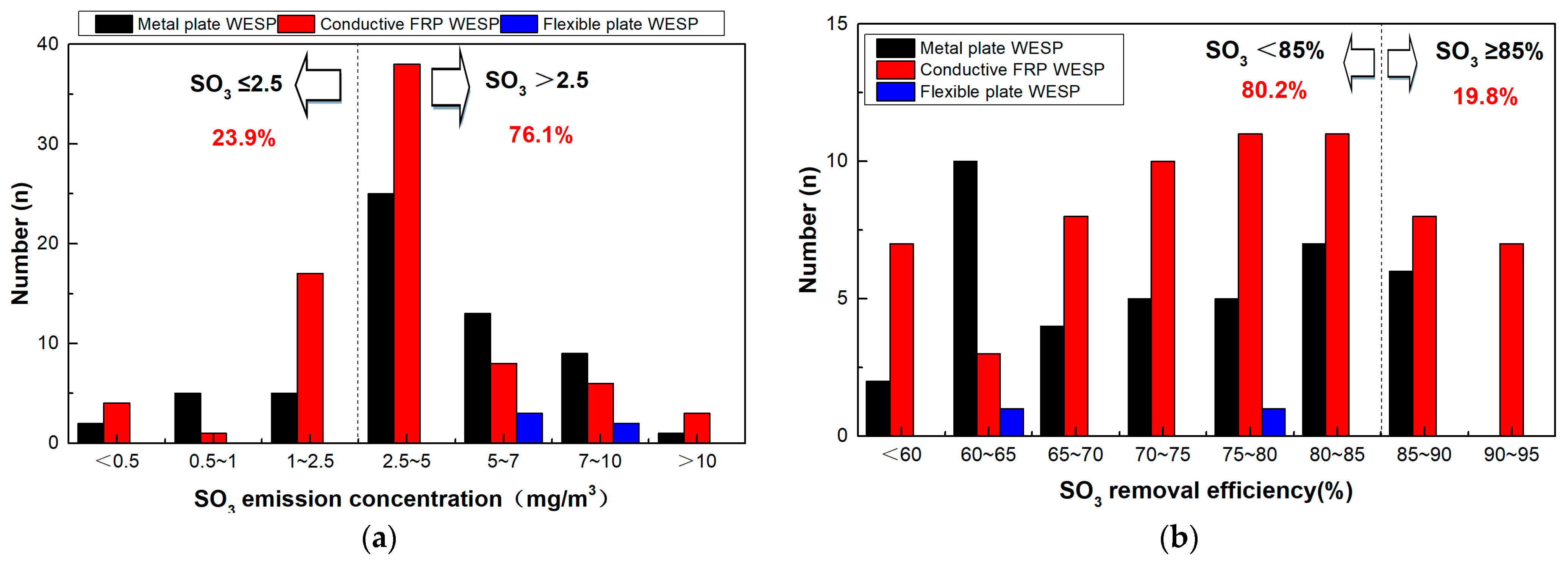

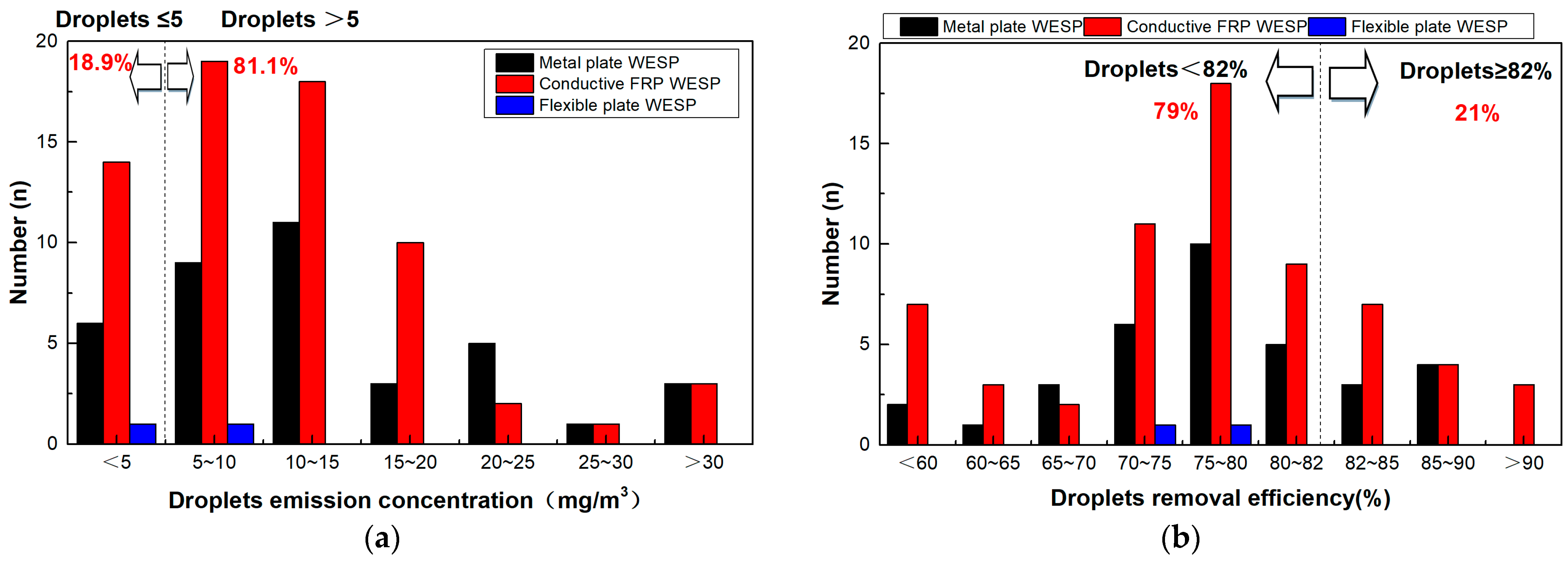

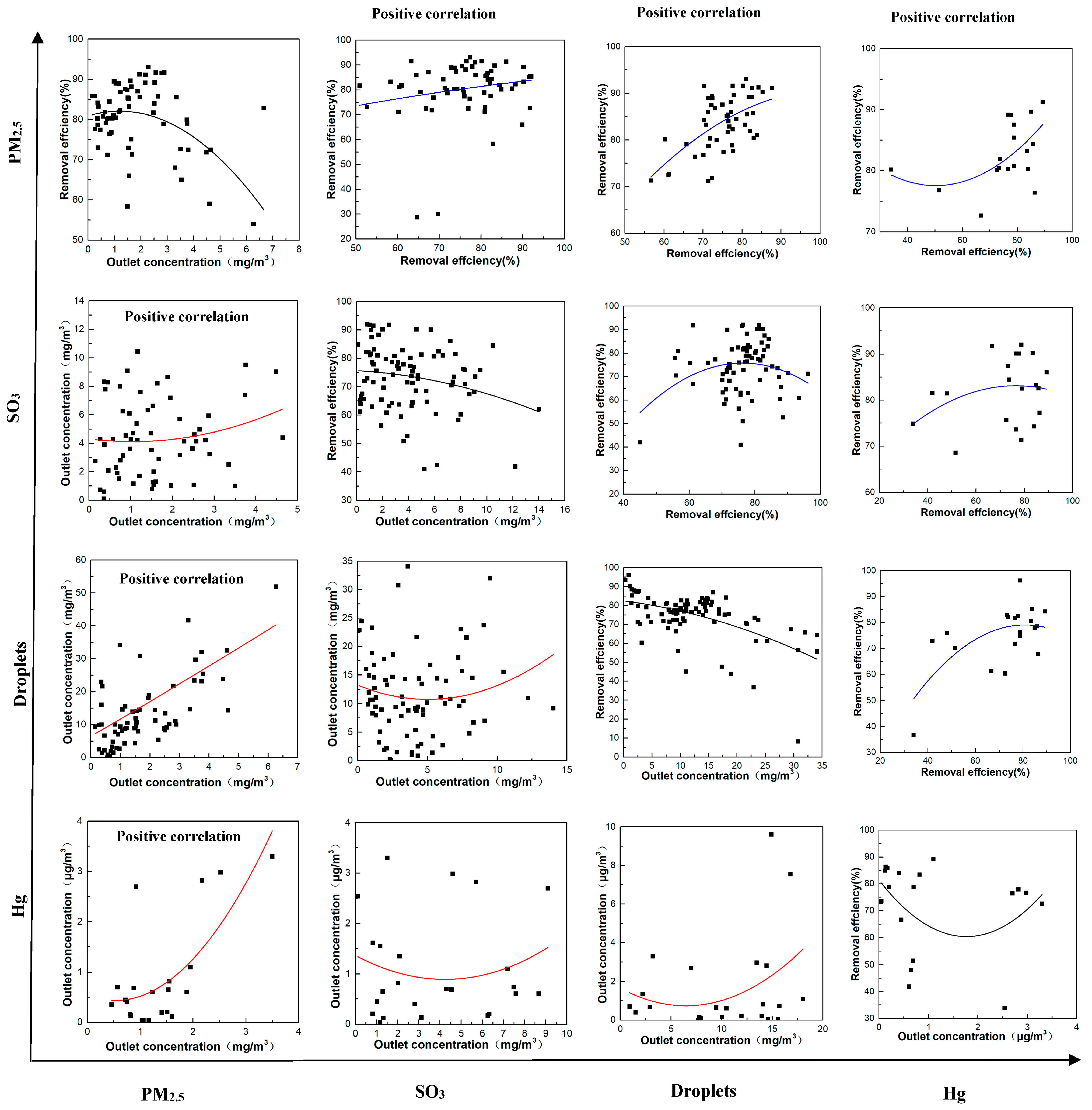

3.1.3. Correlation Analyses of Multiple Pollutant Removal Performance

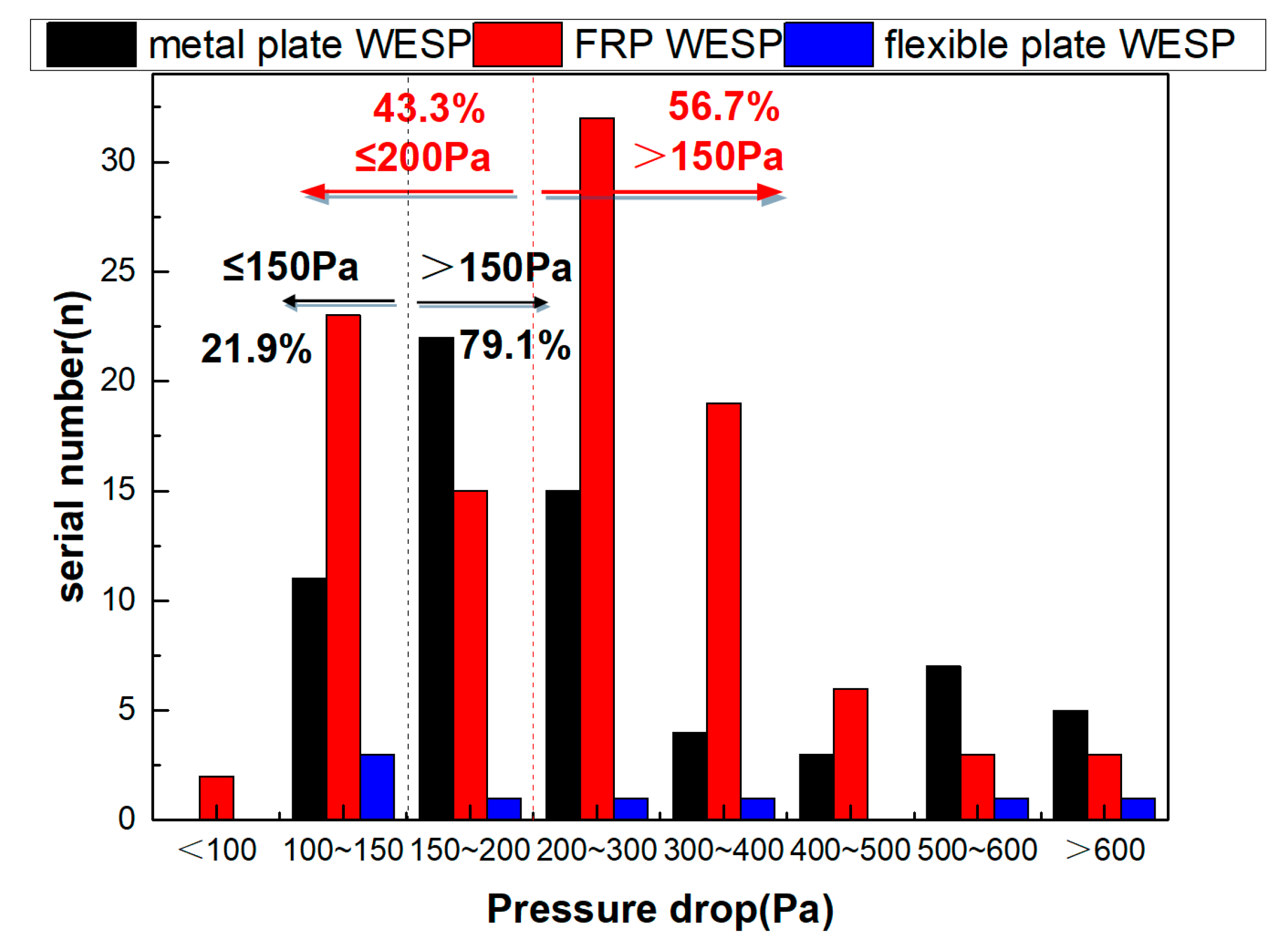

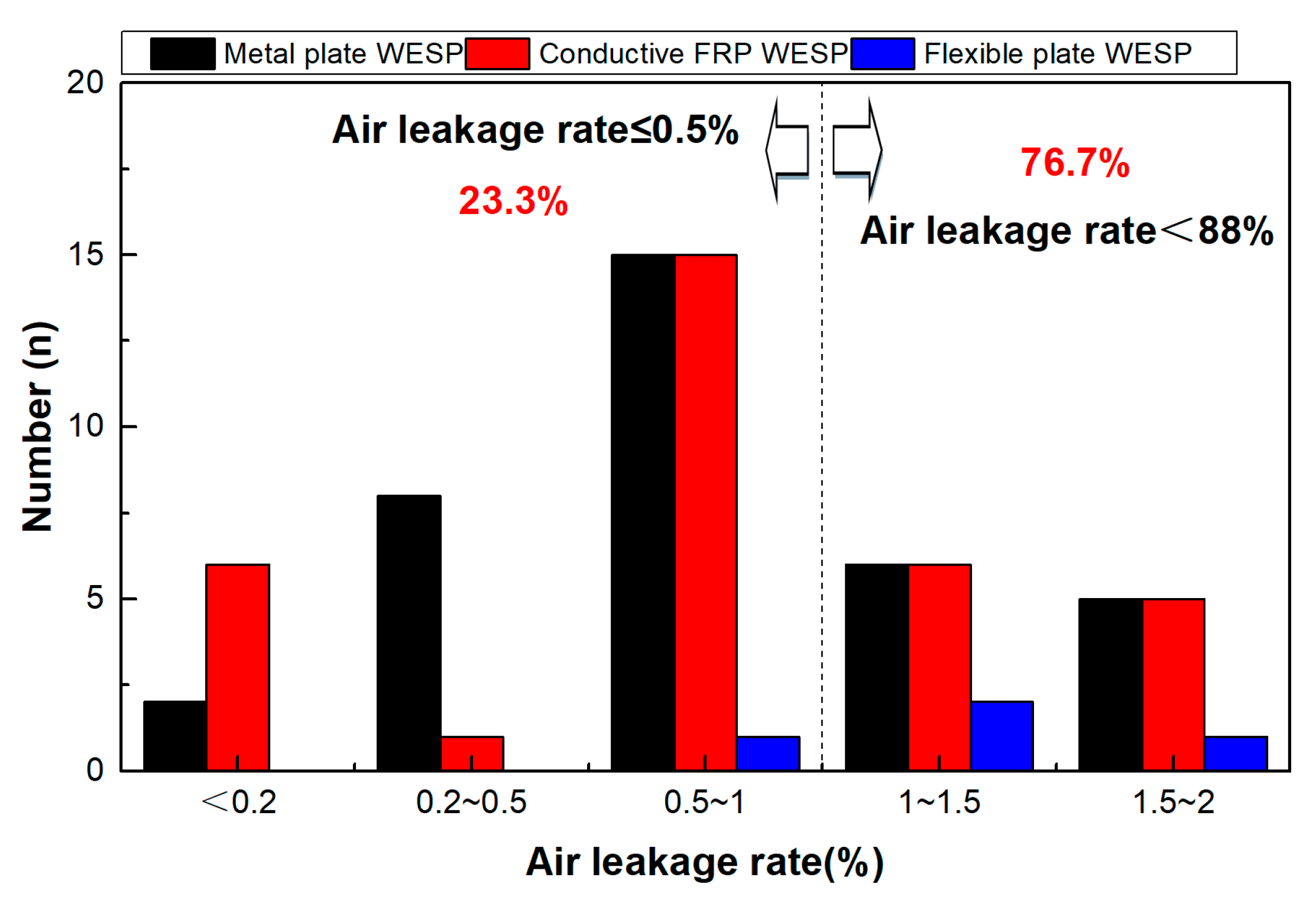

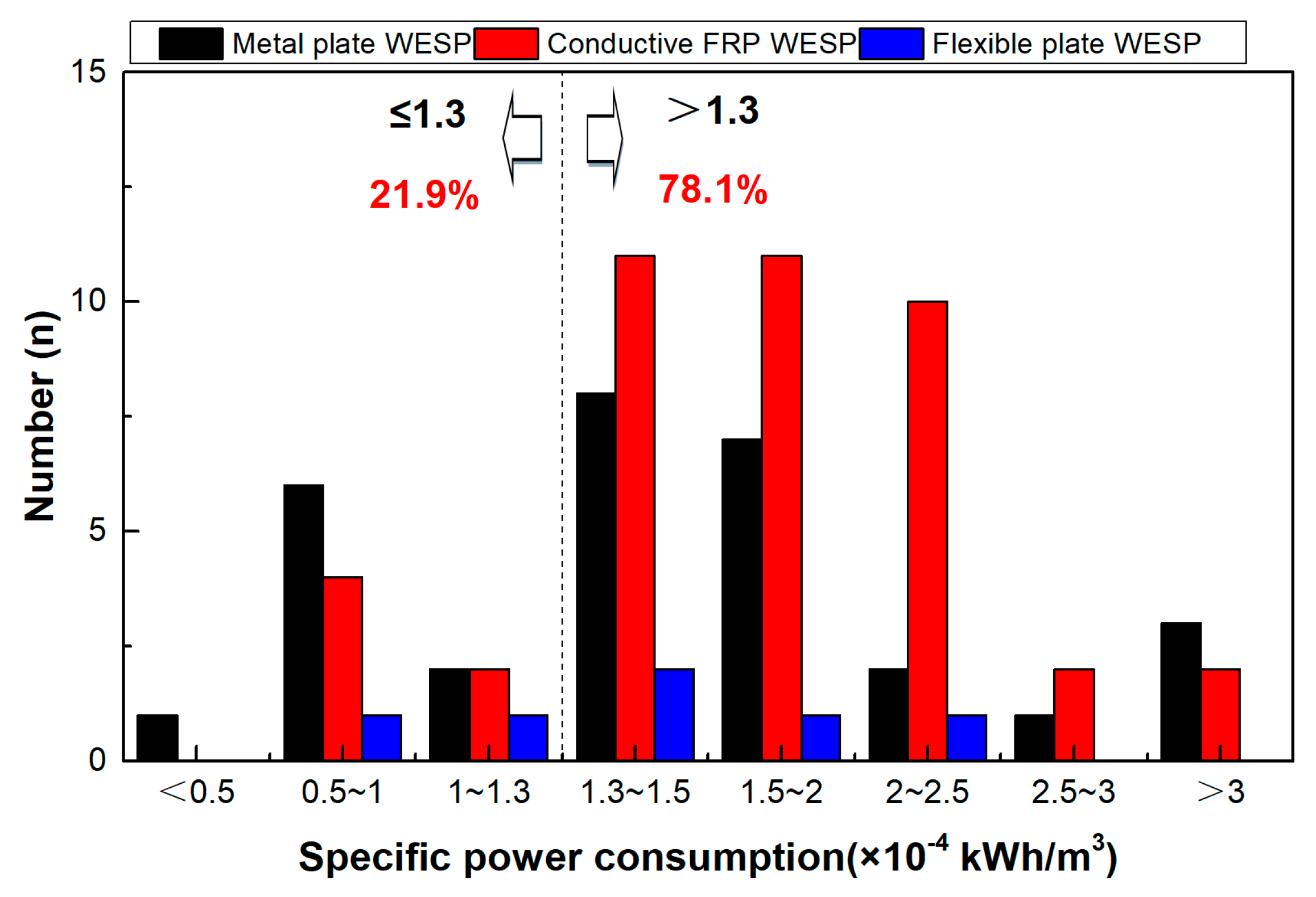

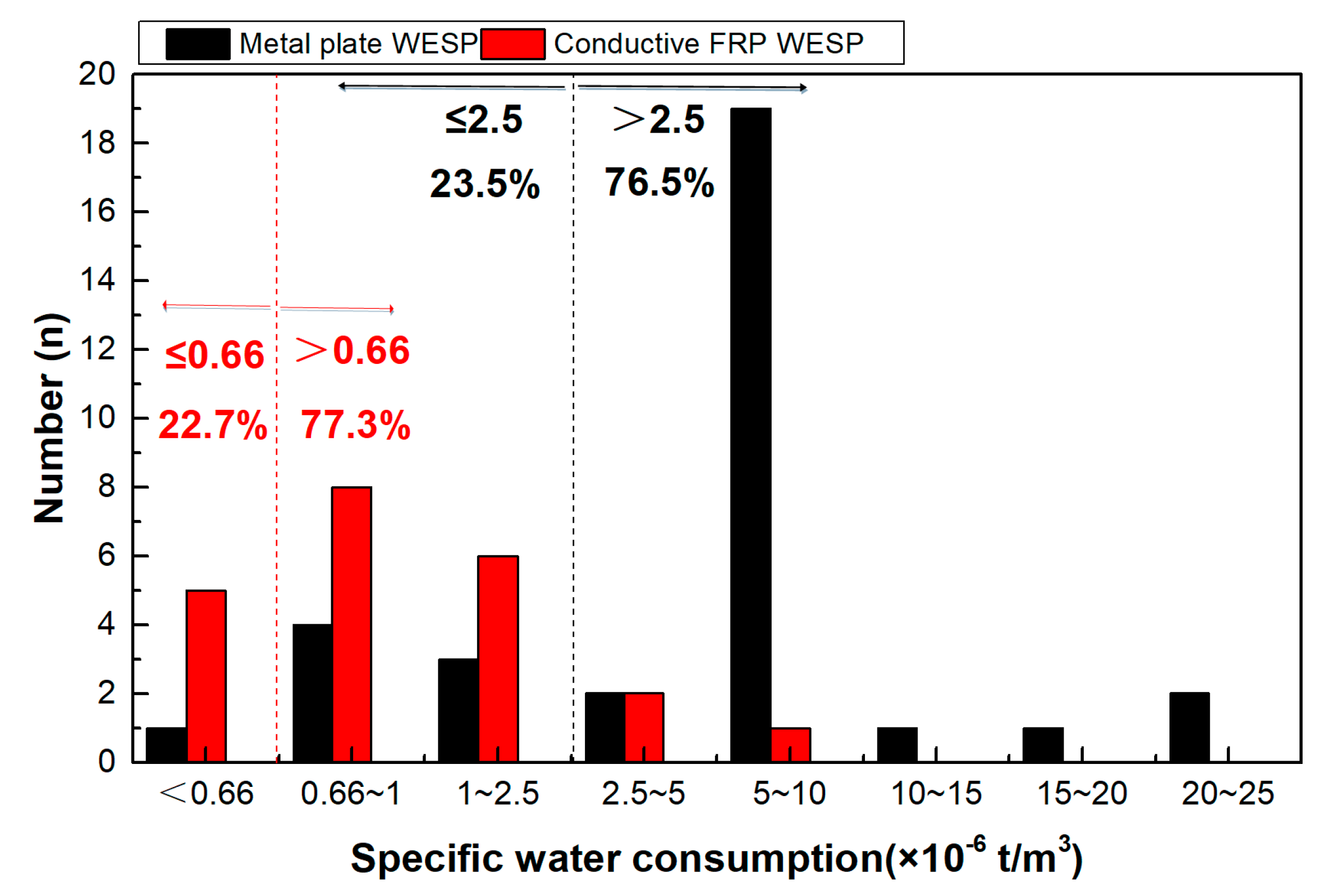

3.2. Performance Indexes

3.3. Energy-Efficiency Characteristics

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Xu, M.; Wang, W.; Wen, C.; Yu, D.; Liu, X. Research development of precipitation technology to accomplish the ultra-low emission from coal-fired power plants. Proc. CSEE 2019, 39, 6627–6639. [Google Scholar]

- Ren, Y.; Wu, Q.; Wen, M.; Li, G.; Xu, L.; Ding, X.; Li, Z.; Tang, Y.; Wang, Y.; Li, Q.; et al. Sulfur trioxide emissions from coal-fired power plants in China and implications on future control. Fuel 2020, 261, 11638. [Google Scholar] [CrossRef]

- Liu, H.; Zhu, S.; Yao, Y.; Li, J.; Chen, Z.; Chen, L.; Fang, X. Experimental research on the PM2.5 in inlet and outlet flue gas using ELPI for WESP of “ultra-clean emission” power plants. Electr. Power 2014, 47, 37–41. [Google Scholar]

- Liu, H.; Chen, Z.; Wang, S.; Cai, X.; Guo, G.; Shen, M.; Zhou, B. Emission characteristics and removal technology of SO3 from coal-fired power plants. Chin. J. Environ. Eng. 2019, 13, 1128–1138. [Google Scholar]

- Yang, F.; Liu, H.; Feng, P.; Li, Z.; Tan, H. Effects of Wet Flue Gas Desulfurization and Wet Electrostatic Precipitator on Particulate Matter and Sulfur Oxide Emission in Coal-Fired Power Plants. Energy Fuels 2020, 34, 16423–16432. [Google Scholar] [CrossRef]

- Flagiello, D.; Tammaro, D.; Erto, A.; Maffettone, P.L.; Lancia, A.; Di Natale, F. Foamed structured packing for mass-transfer equipment produced by an innovative 3D printing technology. Chem. Eng. Sci. 2022, 260, 1–14. [Google Scholar] [CrossRef]

- Jens, P.; Sven, A.; Linda, B.; Michael, S. Investigation of the Collection Efficiency of a Wet Electrostatic Precipitator at a Municipal Solid Waste-Fueled Combined Heat and Power Plant Using Various Measuring Methods. Energy Fuels 2019, 33, 5282–5292. [Google Scholar]

- Xu, Y.; Liu, X.; Cui, J.; Chen, D.; Xu, M.; Pan, S.; Zhang, K.; Gao, X. Field measurements on the emission and removal of PM2.5 from coal-fired power stations: 4.PM removal performance of wet electrostatic precipitators. Energy Fuels 2016, 30, 7465–7473. [Google Scholar] [CrossRef]

- Pan, D.; Gu, C.; Zhang, D.; Zeng, F. Removal Characteristics of Sulfuric Acid Aerosols in the Wet Electrostatic Precipitator System. Energy Fuels 2019, 33, 7813–7818. [Google Scholar] [CrossRef]

- Yang, Z.; Zheng, C.; Zhang, X.; Chang, Q.; Weng, W.; Wang, Y.; Gao, X. Highly efficient removal of sulfuric acid aerosol by a combined wet electrostatic precipitator. RSC Adv. 2018, 8, 59–66. [Google Scholar] [CrossRef]

- Peng, Y. Application of energy-saving technology in electro-static precipitator. Recycl. Resour. Circ. Econ. 2016, 9, 42–44. [Google Scholar]

- Zhang, B.; Qi, J.; Shao, J. Electricity saving technology for electrostatic precipitator in coal-fired power plant. Thermal Power Generation 2007, 36, 61–63. [Google Scholar]

- Liu, H.; Li, J.; Yao, Y.; Zhong, J.; Du, Y.; Du, Y. The Energy Efficiency Evaluation of Electrostatic Precipitator in Coal-fired Power Plant. Electric Power 2017, 50, 22–27. [Google Scholar]

- JB/T 11638-2013; Wet Electrostatic Precipitator. Technical Committee on Environmental Protection Machinery of Standardization Administration of Machinery Industry: Beijing, China, 2013.

- JB/T 12532-2015; Top Mounted Wet Electrostatic Precipitator. Technical Committee on Environmental Protection Machinery of Standardization Administration of Machinery Industry: Beijing, China, 2015.

- JB/T 12593-2015; Wet Electrostatic Precipitator Installed at the Downstream of the Coal-Fired Flue Gas Wet Desulphurization Equipment. Technical Committee on Environmental Protection Machinery of Standardization Administration of Machinery Industry: Beijing, China, 2015.

- T/ZZB 0161-2016; Wet Electrostatic Precipitator. Zhejiang Manufacture Brand Construction Promotion Association: Hangzhou, China, 2016.

- GB/T 13931-2017; Methods of Performance Tests for Electrostatic Precipitator. National Technical Committee on Environmental Protection Products Standardization: Beijing, China, 2017.

- ISO 12141-2002; Stationary Source Emissions-Determination of Mass Concentration of Particulate Matter (Dust) at Low Concentrations—Manual Gravimetric Method. International Organization for Standardization: Geneva, Switzerland, 2002.

- GB/T 15187-2017; Measuring Method for Performances of Wet Dust Collectors. National Technical Committee on Environmental Protection Products Standardization: Beijing, China, 2017.

- HJ 836-2017; Stationary Source Emission-Determination of Mass Concentration of Particulate Matter at Low Concentration-Manual Gravimetric Method. Ministry of Environmental Protection: Beijing, China, 2017.

- DB37/T 2706-2015; Technical Specification for Monitoring Low Concentration Emission of Waste Gas from Fixed Sources. Technical Committee of Environmental Protection Standardization of Shandong Province: Jinan, China, 2015.

- Liu, H.; Yao, Y.; Li, J. Study on Blank Test of Low-Concentration Particulate Matter Gravimetric Testing for Coal-Fired Power Plants. Electr. Power 2017, 50, 115–121. [Google Scholar]

- Liu, H.; Yao, Y.; Li, J.; Zhao, X.; Fang, X.; Guo, Y. Research of low concentration test method of PM for ultra-low emission. China Power Sci. Technol. 2017, 23, 49–53. [Google Scholar]

- ISO 23210:2009; Stationary Source Emissions-Determination of PM10/PM2.5 Mass Concentration in Flue Gas-Measurement at Low Concentrations by Use of Impactors. International Organization for Standardization: Geneva, Switzerland, 2009.

- DL/T 1520-2016; Specifications for Fine Particles (PM2.5) Monitoring in the Thermal Power Plants-Gravimetric Method. Technical Committee on Environmental Protection of Electric Power Industry of Standardization Administration: Beijing, China, 2016.

- Decati Ltd. Dekati® PM10 Impactor USER MANUAL, Version 3.2; Decati Ltd.: Bologna, Italy, 2015.

- Liu, H.; Yao, Y.; Li, J.; Ding, H.; Chang, Q.; Zuo, P. The Constract of PM2.5 Test Method and PM2.5 Emissions Characterization Research for Coal-fired Power Plant. China Power Sci. Technol. 2017, 23, 34–39. [Google Scholar]

- Liu, H.; Yao, Y.; Li, J.; Chen, Z.; Fang, X. Research of Classification Dust Removal Efficiency and Pollutant Emission Characteristics for WESP in Coal-fired Power Plant. Electr. Power 2017, 50, 178–184. [Google Scholar]

- Zheng, C.; Wang, Y.; Liu, Y.; Yang, Z.; Qu, R.; Ye, D.; Liang, C.; Liu, S.; Gao, X. Formation, transformation, measurement, and control of SO3 in coal-fired power plants. Fuel 2019, 241, 327–346. [Google Scholar] [CrossRef]

- GB/T 21508-2008; Performance Test Method for Coal-Fired Flue Gas Desulphurization Equipment. National Technical Committee on Environmental Protection Products Standardization: Beijing, China, 2008.

- DL/T 998-2006; Performance Test Code for Wetlimestonegypsum Flue Gas Desulphurization. Technical Committee on Environmental Protection of Electric Power Industry of Standardization Administration: Beijing, China, 2006.

- DL/T 1990-2019; Determination of Sulfur Dioxide in Flue Gas from Thermal Power Plants Controlled Condensation Technique. Technical Committee on Environmental Protection of Electric Power Industry of Standardization Administration: Beijing, China, 2019.

- Liu, H.; Yao, Y.; Li, J.; Fang, X.; Li, B.; He, D.; Yao, B. The Study of SO3 Measurement Method at Low Concentration for Stationary Source. Environ. Eng. 2017, 35, 90–109. [Google Scholar]

- Zhang, D.; Liu, H.; Zhao, L.; Yuan, W.; Fang, X.; Xu, D.; Luo, J. Study on the Method of Sampling of Coagulated Particulate Matter (SO3) in Coal-Fired Power Plants. Electr. Power 2018, 51, 33–36. [Google Scholar]

- EPA Method 30B-2008; Determination of Total Vapor Phase Mercury Emissions from Coal-Fired Combustion Sources Using Carbon Sorbent Traps. Environmental Protection Agency: Washington, DC, USA, 2008.

- GB/T 40505-2021; Wet Electrostatic Precipitator—Methods of Performance Tests. National Technical Committee on Environmental Protection Products Standardization: Beijing, China, 2021.

- Teng, C.; Li, J. Experimental Study on Particle Removal of a Wet Electrostatic Precipitator with Atomization of Charged Water Drops. Energy Fuels 2020, 34, 7257–7268. [Google Scholar] [CrossRef]

- Anderlohr, C.; Schaber, K. Direct Transfer of Gas-Borne Nanoparticles into Liquid Suspensions by Means of a Wet Electrostatic Precipitator. Aerosol Sci. Technol. 2015, 49, 1281–1290. [Google Scholar] [CrossRef][Green Version]

- Electrostatic Precipitator Committee of China Environmental Protection Industry Association. Technology of Flue Gas Ultra-low Emission for Coal-fired Power Plants; China Electric Power Press: Beijing, China, 2015. [Google Scholar]

- Chang, J.; Dong, Y.; Wang, Z.; Wang, P.; Chen, P.; Ma, C. Removal of sulfuric acid aerosol in a wet electrostatic precipitator with single terylene or polypropylene collection electrodes. J. Aerosol Sci. 2011, 42, 544–554. [Google Scholar] [CrossRef]

- Zhao, S.; Pudasainee, D.; Duan, Y.; Gupta, R.; Liu, M.; Lu, J. A review on mercury in coal combustion process: Content and occurrence forms in coal, transformation, sampling methods, emission and control technologies. Prog. Energy Combust. Sci. 2019, 73, 26–64. [Google Scholar] [CrossRef]

- Zhao, S.; Duan, Y.; Yao, T.; Liu, M.; Lu, J.; Tan, H.; Wang, X.; Wu, L. Study on the mercury emission and transformation in an ultra-low emission coal- fired power plant, emission and control technologies. Fuel 2017, 199, 653–661. [Google Scholar] [CrossRef]

- Peng, Y.; Shi, N.; Wang, J.; Wang, T.; Pan, W. Mercury speciation and size-specific distribution in filterable and condensable particulate matter from coal combustion. Sci. Total Environ. 2021, 787, 1–8. [Google Scholar] [CrossRef]

- Liu, H.; Wu, L.; Zheng, C.; Li, J.; Lu, J.; Liu, X.; Chen, Z. Investigation of pollutant-removal performance and energy efficiency characteristics of wet electrostatic precipitator. Greenh. Gases Sci. Technol. 2022, 4, 520–536. [Google Scholar] [CrossRef]

- GB/T 33017.1-2016; General Principle of Assessment Technical Requirements for High Efficiency Air Pollution Control Equipment. National Technical Committee on Environmental Protection Products Standardization: Beijing, China, 2016.

| First Level Index | Second Level Index | Unit | Evaluation of Requirements | |

|---|---|---|---|---|

| Metal Plate WESP | FRP WESP | |||

| Environmental index | PM emission concentration | mg/m3 | ≤2.5 | |

| SO3 emission concentration | mg/m3 | ≤2.5 | ||

| Technical performance index | PM removal efficiency | % | ≥90 | |

| SO3 removal efficiency | % | ≥85 | ||

| Pressure drop | Pa | ≤200 | ||

| Air leakage rate | % | ≤0.5 | ||

| Energy consumption index | Specific power consumption | 10−4 kWh/m3 | ≤1.3 | |

| Specific water consumption | 10−6 t/m3 | ≤2.50 | ≤0.66 | |

| Contrast Item | Unit | Standards and Indicators | Advanced Index | |

|---|---|---|---|---|

| PM emission concentration | mg/m3 | GB/T 40514-2021 | Meet the design requirements | ≤2.5 |

| DL/T 514-2017 | Reach the guaranteed value stipulated in the contract | |||

| HJ 2053-2018 | ≤10, can be less than 5 | |||

| JB/T 12593-2016 | Meet the design requirements | |||

| JB/T 13556-2018 | ≤10 | |||

| SO3 emission concentration | mg/m3 | GB/T 40514-2021 | not specified | ≤2.5 |

| DL/T 514-2017 | ||||

| HJ 2053-2018 | ||||

| JB/T 12593-2016 | ||||

| JB/T 13556-2018 | ||||

| PM removal efficiency | % | GB/T 40514-2021 | ≥70%, can reach more than 90% | ≥90% |

| DL/T 514-2017 | Reach the guaranteed value stipulated in the contract | |||

| HJ 2053-2018 | 70~90% | |||

| JB/T 12593-2016 | not specified | |||

| JB/T 13556-2018 | not specified | |||

| SO3 removal efficiency | % | GB/T 40514-2021 | It should not be less than 60% | ≥85% |

| DL/T 514-2017 | not specified | |||

| HJ 2053-2018 | not specified | |||

| JB/T 12593-2016 | not specified | |||

| JB/T 13556-2018 | not specified | |||

| Pressure drop | Pa | GB/T 40514-2021 | ≤250 Pa | ≤200 |

| DL/T 514-2017 | Reach the guaranteed value stipulated in the contract, and ≤250 Pa if not stipulated in the contract | |||

| HJ 2053-2018 | ≤250 (Plate type) ≤300 (Tubular type) | |||

| JB/T 12593-2016 | ≤250 | |||

| JB/T 13556-2018 | ≤300 | |||

| Air leakage rate | % | GB/T 40514-2021 | ≤1% | ≤0.5% |

| DL/T 514-2017 | Reach the guaranteed value stipulated in the contract, and ≤2.5% if not stipulated in the contract | |||

| HJ 2053-2018 | ≤1% (Plate type) ≤2% (Tubular type) | |||

| JB/T 12593-2016 | ≤2% | |||

| JB/T 13556-2018 | ≤2% | |||

| Specific power consumption | 10−4 kWh/m3 | GB/T 40514-2021 | not specified | ≤1.3 |

| DL/T 514-2017 | ||||

| HJ 2053-2018 | ||||

| JB/T 12593-2016 | ||||

| JB/T 13556-2018 | ||||

| Specific water consumption | 10−6 t/m3 | GB/T 40514-2021 | not specified | ≤2.50 (Metal plate WESP ≤0.66 (FRP WESP) |

| DL/T 514-2017 | ||||

| HJ 2053-2018 | ||||

| JB/T 12593-2016 | ||||

| JB/T 13556-2018 | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, H.; Luo, S.; Yu, L.; Zhao, H.; Liang, J.; Guo, Y.; Cui, Y.; Shan, S.; Liu, X.; Li, J. Study on Multi-Pollutant Test and Performance Index Determination of Wet Electrostatic Precipitator. Separations 2023, 10, 536. https://doi.org/10.3390/separations10100536

Liu H, Luo S, Yu L, Zhao H, Liang J, Guo Y, Cui Y, Shan S, Liu X, Li J. Study on Multi-Pollutant Test and Performance Index Determination of Wet Electrostatic Precipitator. Separations. 2023; 10(10):536. https://doi.org/10.3390/separations10100536

Chicago/Turabian StyleLiu, Hanxiao, Shuiyuan Luo, Liyuan Yu, Haibao Zhao, Jun Liang, Ying Guo, Ying Cui, Sike Shan, Xiaowei Liu, and Jianguo Li. 2023. "Study on Multi-Pollutant Test and Performance Index Determination of Wet Electrostatic Precipitator" Separations 10, no. 10: 536. https://doi.org/10.3390/separations10100536

APA StyleLiu, H., Luo, S., Yu, L., Zhao, H., Liang, J., Guo, Y., Cui, Y., Shan, S., Liu, X., & Li, J. (2023). Study on Multi-Pollutant Test and Performance Index Determination of Wet Electrostatic Precipitator. Separations, 10(10), 536. https://doi.org/10.3390/separations10100536