Prediction of the Vanadium Content of Molten Iron in a Blast Furnace and the Optimization of Vanadium Extraction

Abstract

:1. Introduction

2. Methods and Principles

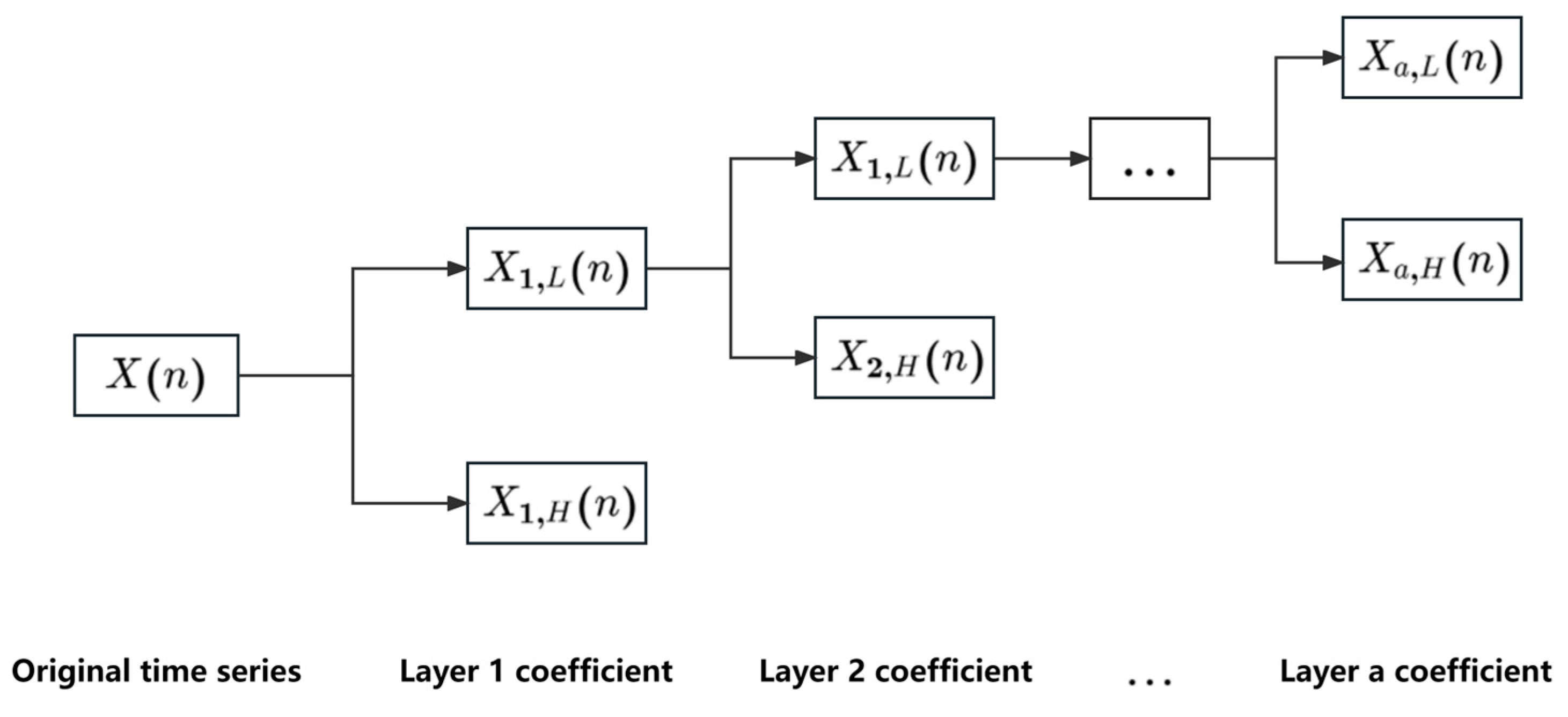

2.1. Wavelet Transform

2.2. Temporal Convolutional Networks

2.2.1. Causal Convolution

2.2.2. Dilated Convolution

2.2.3. Residual Connection

3. Data Preparation

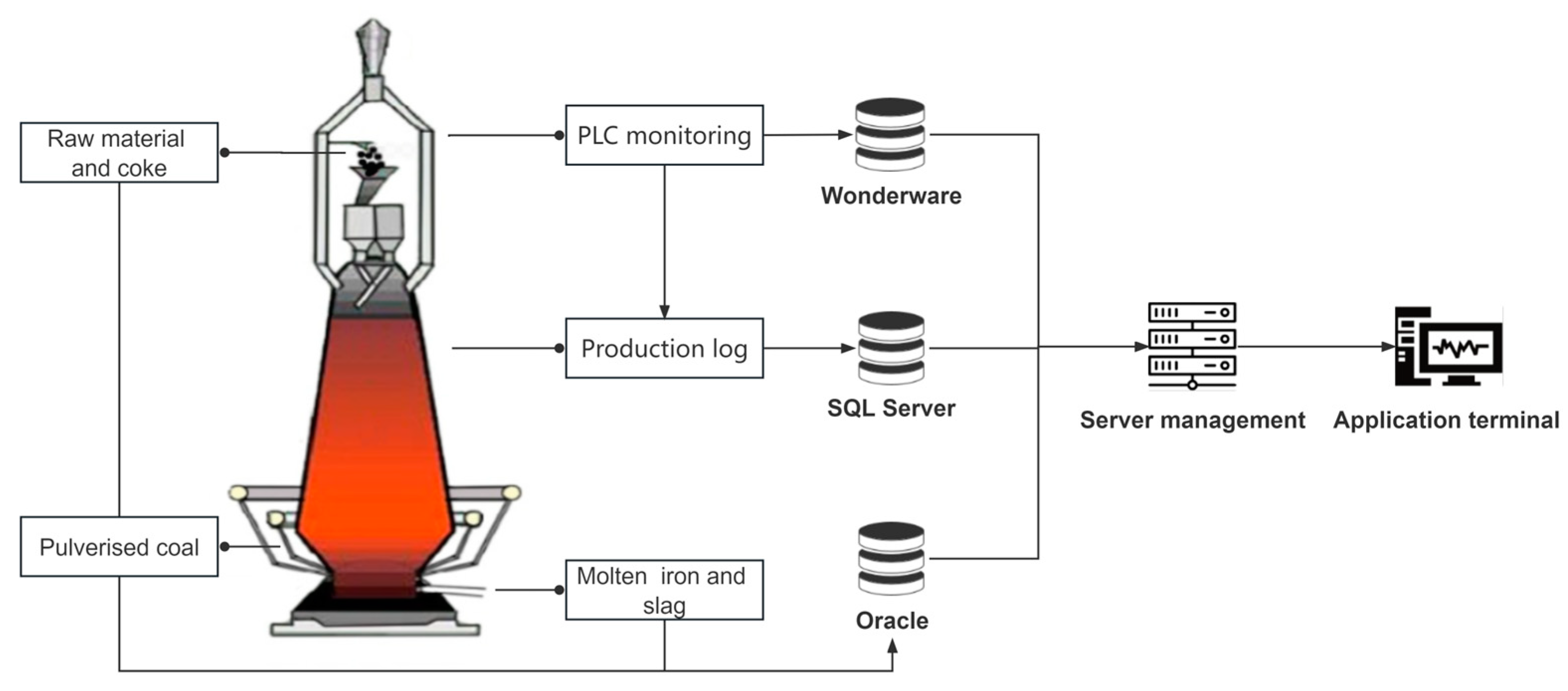

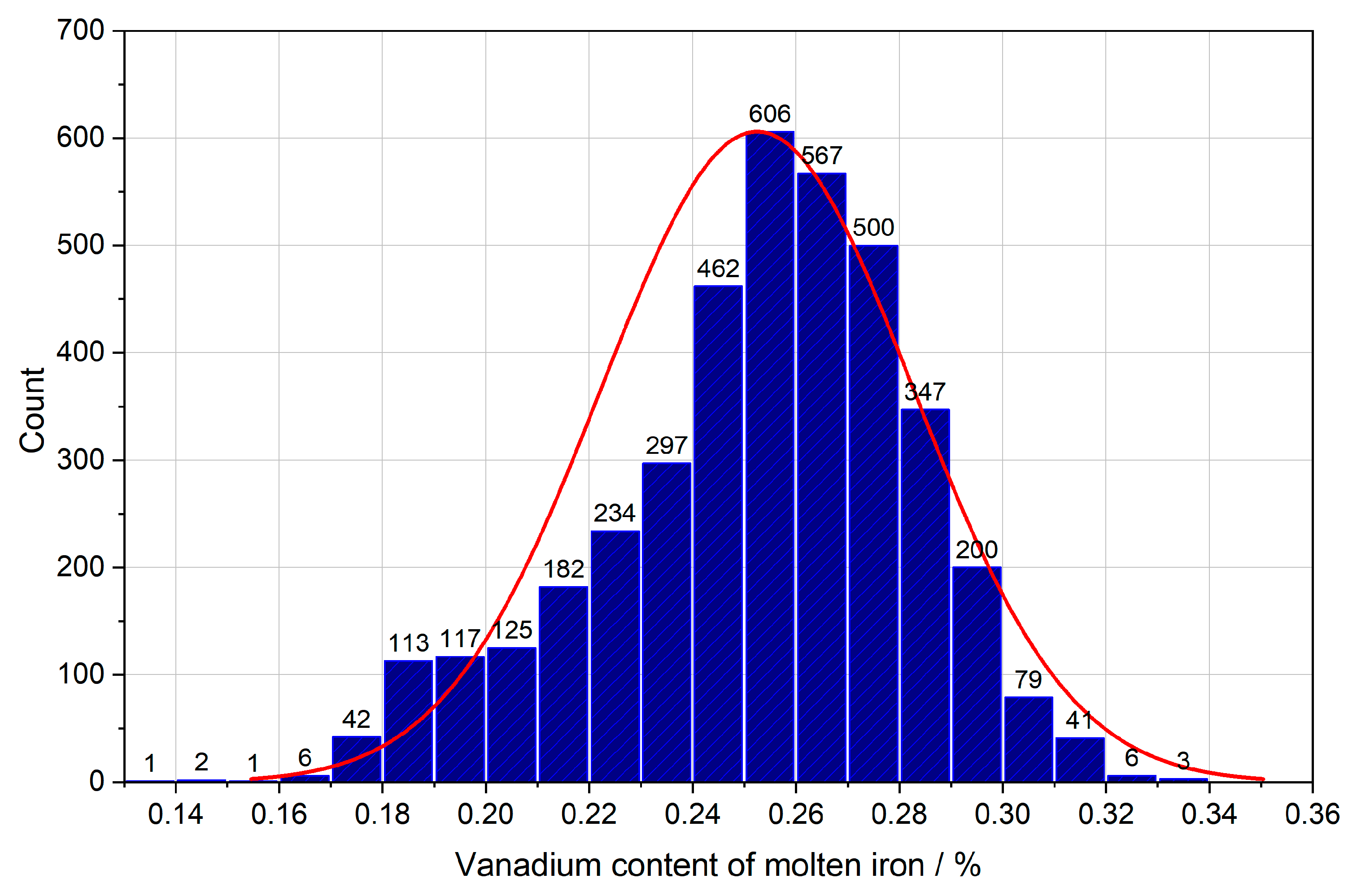

3.1. Data Collection

3.2. Data Processing

3.2.1. Missing Data Processing

3.2.2. Outlier Data Processing

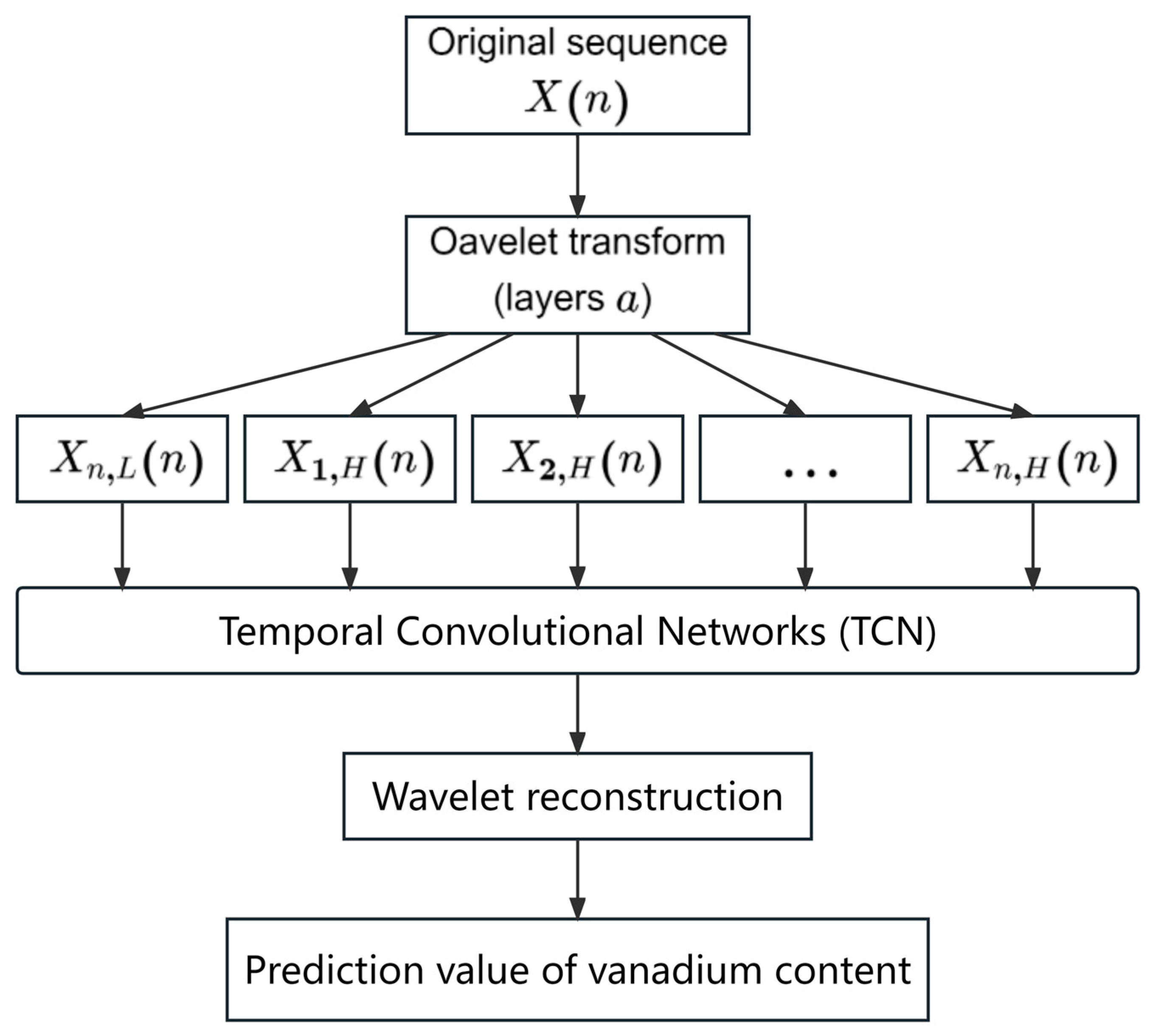

4. Wavelet-TCN Prediction Model

4.1. Analysis of the Forecast Data

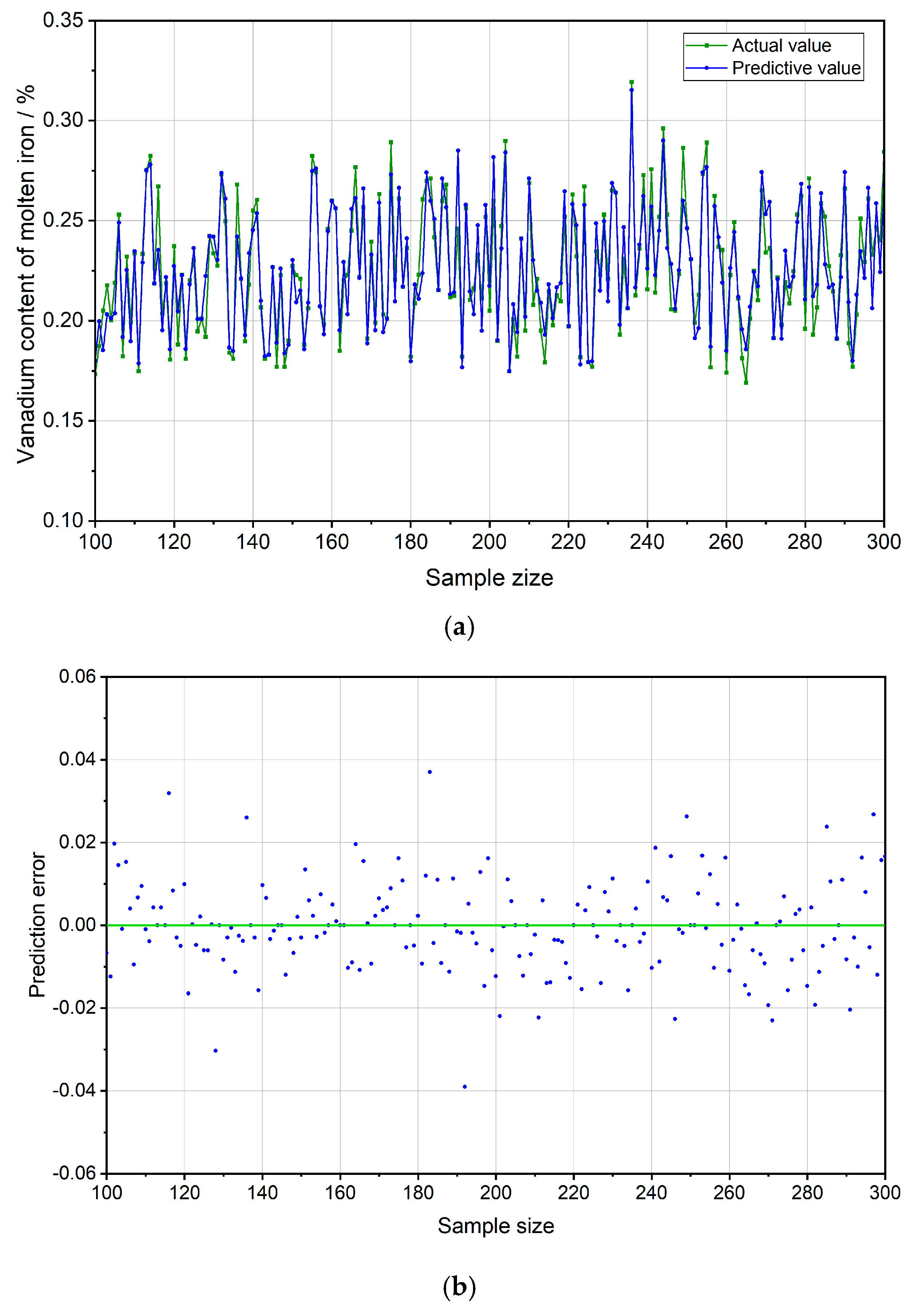

4.2. Results and Analysis

4.2.1. Wavelet Transform Layers Selection

4.2.2. Modeling Results

5. Optimization of Vanadium Extraction Operations

5.1. Limitations of Vanadium Content Enhancement

5.2. Measures for Increasing Vanadium Content

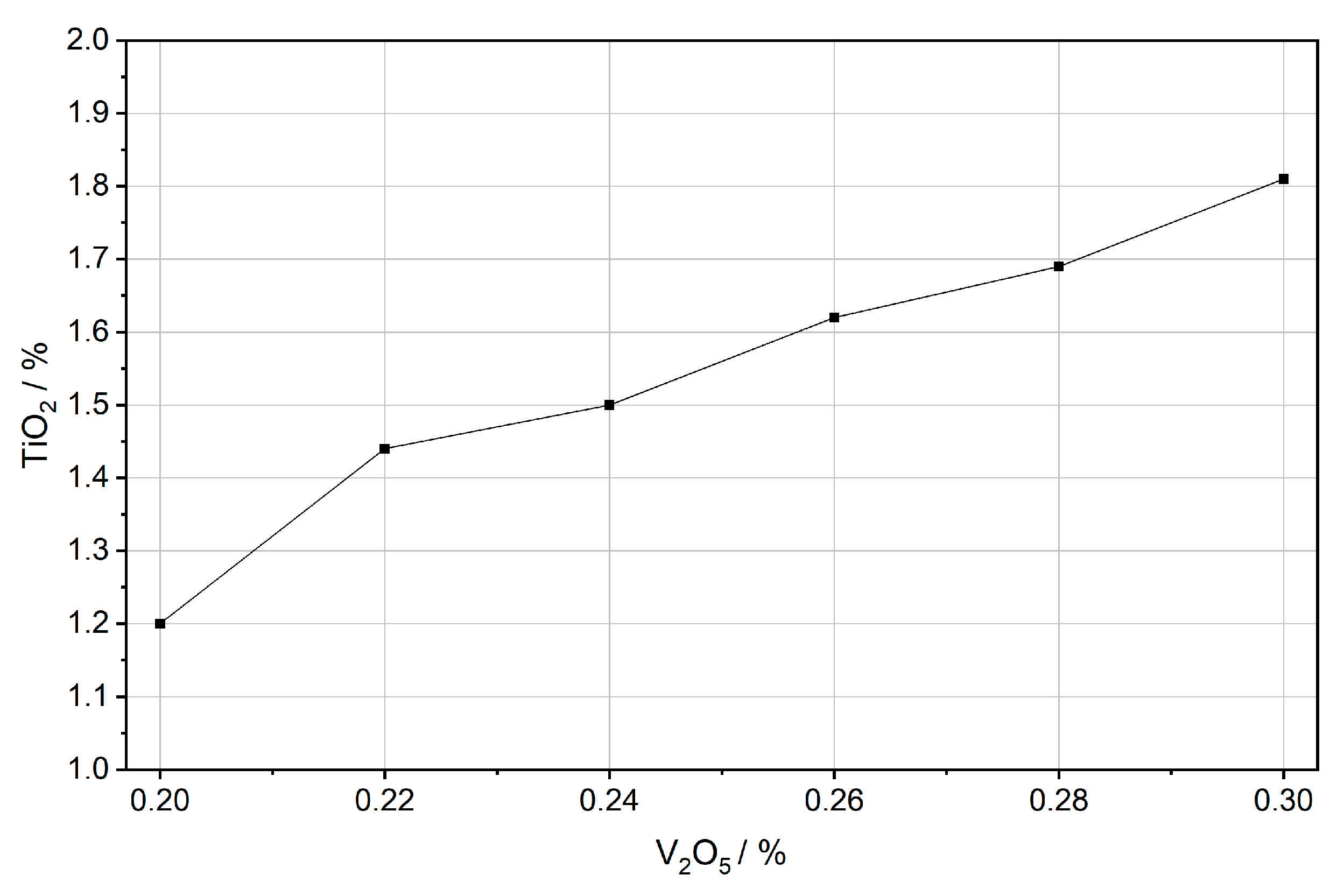

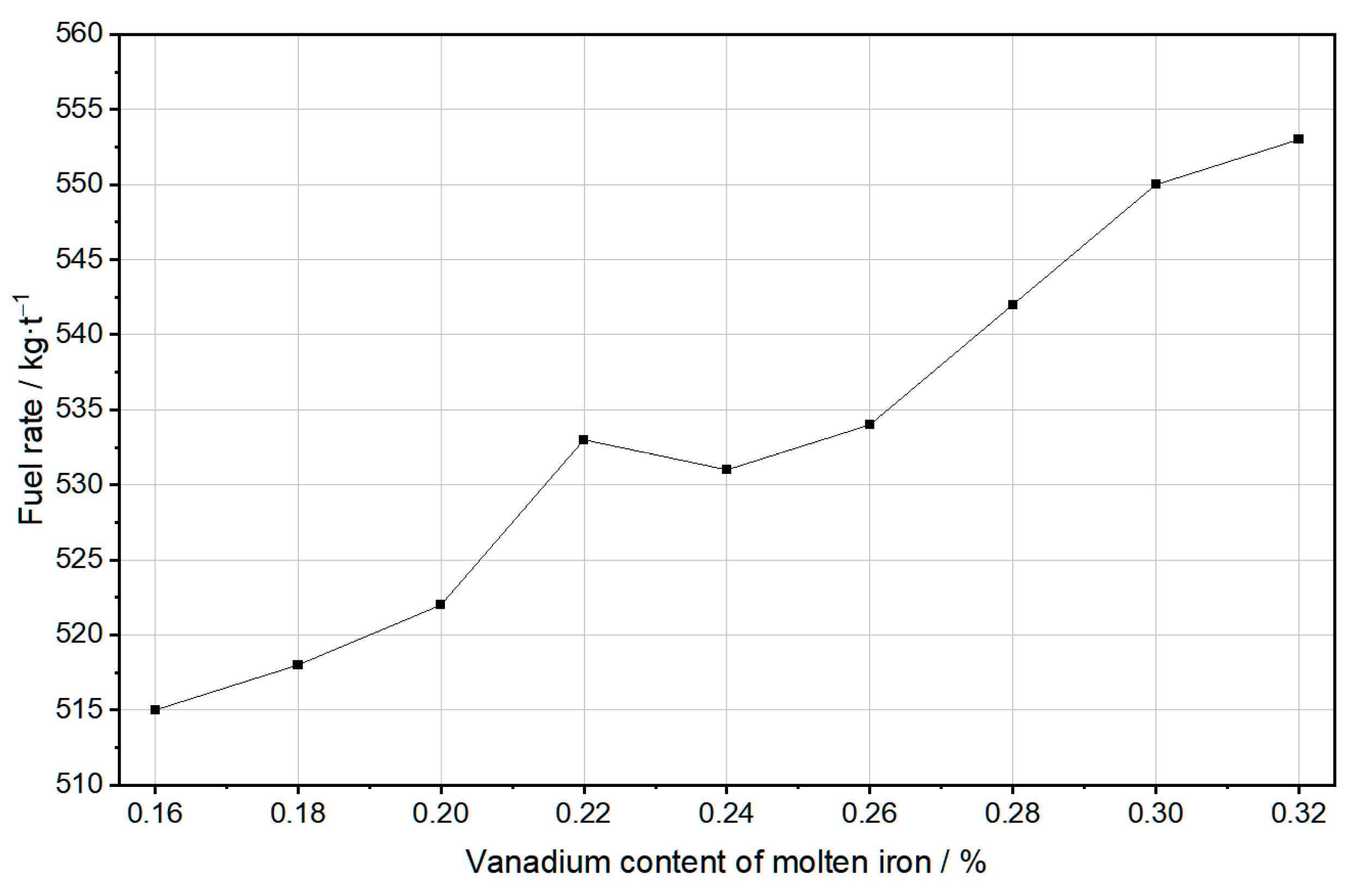

5.2.1. Increasing the Vanadium Load of Raw Materials of Blast Furnace

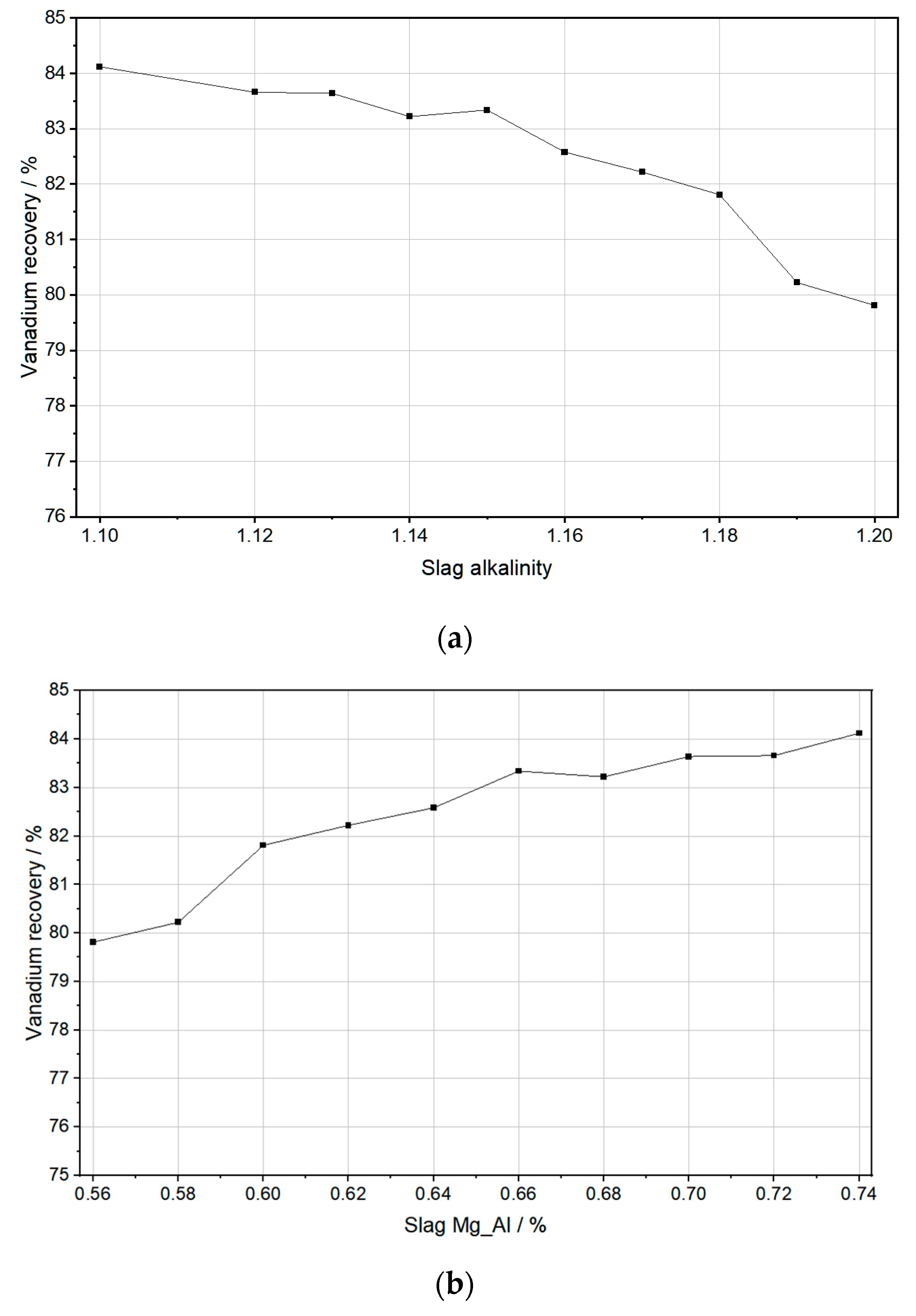

5.2.2. Furnace Temperature and Slag Composition Control

6. Conclusions

- (1).

- Based on the data resources of blast furnace ironmaking, the raw data related to the blast furnace parameters were selected, and the clean data were obtained by processing the missing data and outlier data. The data processing process improved the usability of the data and provided a good database for data mining analysis and model development.

- (2).

- A combined wavelet-TCN method was selected to predict the vanadium content of molten iron in a blast furnace. The wavelet transform layered sequence features are stable, and TCN has the advantages of less parallel training time, strong generalization ability, and complete feature extraction. The results show that compared to single models, such as LSTM, LSTM with attention, and TCN, the combined model based on wavelet-TCN (a = 5) had an improvement of about 11~17% in R2, and the prediction accuracy was high and stable, which met the practical requirements of blast furnace production. This guaranteed the subsequent high efficiency and stability of the vanadium extraction.

- (3).

- Aiming at the complexity of selecting the number of wavelet transform layers, the average Hurst index was proposed to characterize the predictability of the sequence after the wavelet transform, which was used as a reference index for the combined model to select the number of wavelet transform decomposition layers. The average Hurst index simplified the process of wavelet transform layer selection and reduced the model computation time.

- (4).

- Based on the historical data of vanadium blast furnace smelting, the factors affecting the vanadium content of molten iron were analyzed and the measures to increase the vanadium content were summarized to provide the production guidance for operators. Ensuring the stable and smooth operation of the blast furnace was the necessary condition for increasing the vanadium content of molten iron. Increasing the vanadium load of the blast furnace and avoiding increasing the TiO2 load, as well as maintaining the corresponding blast furnace operating parameters in the appropriate range to achieve the optimization of vanadium extraction from molten iron.

- (5).

- The prediction model for the vanadium content of molten iron achieved a satisfactory predicative performance. However, there are still some further optimization works to be carried out. We can try to make predictions for the next two or three hours to obtain a longer-term trend of the vanadium content of molten iron.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, X.; Han, Y.X.; Li, Y.J.; Gao, P. Research Status on Comprehensive Development and Utilization of Vanadium-Titanium Magnetite. Met. Mine 2019, 6, 33–37. [Google Scholar] [CrossRef]

- Zhang, Y.M.; Wang, L.N.; Chen, D.S.; Liu, H.Y.; Zhao, H.X.; Qi, T. A method for recovery of iron, titanium, and vanadium from vanadium-bearing titanomagnetite. Int. J. Miner. Metall. Mater. 2018, 25, 131–144. [Google Scholar] [CrossRef]

- Li, Z.K.; Liu, X.J.; Hao, L.Y.; Lyu, Q.; Li, H.W. Prediction Model of Vanadium in Blast Furnace Molten Iron Based on AdaBoost Algorithm. J. N. China Univ. Sci. Technol. (Nat. Sci. Ed.) 2020, 42, 20–28. [Google Scholar]

- Zhang, Y.S. Introduction to Blast Furnace Smelting Technology for Vanadium-Titanium Magnetite Iron Ores. China Steel Focus 2021, 5, 7–8. [Google Scholar]

- Xue, F. 1080 m3 Blast Furnace Fast Recovery Vanadium and Titanium Ore Smelting Practice. Metall. Mater. 2020, 40, 79–82. [Google Scholar]

- Yan, C.J.; Chen, S.J.; Zhao, X.J.; Li, F.M.; Lyu, Q.; Qie, Y.N. Experimental Study on Reduction of Vanadium Oxides in Blast Furnace Hearth. Iron Steel Vanadium Titan. 2017, 38, 22–26. [Google Scholar]

- Li, L.F.; Zhang, G.X.; Zhang, Y.H.; Yi, F.Y.; Hao, L.Y. Chengsteel 2500 m3 Blast Furnace Iron-Vanadium Smelting Practice. Ironmaking 2021, 40, 37–40. [Google Scholar]

- Zhang, W.X.; Li, Z.C.; Rao, J.T.; Fan, Y.D.; He, S.G. Factors Influencing Vanadium Content in Hot Metal Smelted in Pangang Blast Furnace. Iron Steel Vanadium Titan. 1999, 20, 52–57. [Google Scholar]

- Deng, Y.; Lyu, Q. Establishment of Evaluation and Prediction System of Comprehensive State Based on Big Data Technology in a Commercial Blast Furnace. ISIJ Int. 2020, 60, 898–904. [Google Scholar] [CrossRef]

- Liu, X.J.; Deng, Y.; Li, X.; Hao, L.Y.; Liu, E.H.; Lyu, Q. Prediction of Silicon Content in Hot Molten of Blast Furnace Based on Big Data Technology. China Metall. 2021, 31, 10–16. [Google Scholar] [CrossRef]

- Jiang, K.; Jiang, Z.H.; Xie, Y.F.; Pan, D.; Gui, W.H. Online Prediction Method for Silicon Content of Molten Iron in Blast Furnace Based on Dynamic Attention Deep Transfer Network. Acta Autom. Sin. 2021, 49, 949–963. [Google Scholar] [CrossRef]

- Jiang, Z.H.; Xu, C.; Gui, W.H.; Jiang, K. Prediction Method of Hot Metal Silicon Content in Blast Furnace Based on Optimal Smelting Condition Migration. Acta Autom. Sin. 2022, 48, 194–206. [Google Scholar] [CrossRef]

- Tang, W.W.; Li, X.; Liu, X.J.; Li, H.Y.; Zhang, S.H. Intelligent Application of Big Data Enabling Blast Furnace ironmaking. Metall. Ind. Autom. 2022, 46, 11–22. [Google Scholar]

- Liu, X.J.; Li, X.; Liu, E.H.; Liu, S.; Lyu, Q. Research Status and Prospect of Big Data Technology in Blast Furnace Ironmaking Production. Multipurp. Util. Miner. Resour. 2021, 4, 91–96. [Google Scholar]

- Han, Y.; Hu, Z.B.; Yang, A.M.; Li, J.; Zhang, Y.Z. Intelligent Recommendation Model for Reducing Silicon Deviation Fluctuation of Hot Metal in BF and Application. Iron Steel 2023, 58, 30–38. [Google Scholar] [CrossRef]

- Liu, B.; Wang, M.S.; Li, Y.; Chen, H.L.; Li, J.Q. Deep Learning for Spatio-Temporal Sequence Forecasting: A Survey. J. Beijing Univ. Technol. 2021, 47, 925–941. [Google Scholar] [CrossRef]

- Li, P.F.; Hua, P.; Gui, D.W.; Niu, J.; Pei, P.; Zhang, J.; Krebs, P. A Comparative Analysis of Artificial Neural Networks and Wavelet Hybrid Approaches to Long-term Toxic Heavy Metal Prediction. Sci. Rep. 2020, 10, 13439. [Google Scholar] [CrossRef]

- Alhnaity, B.; Kollias, S.; Leontidis, G.; Jiang, S.Y.; Schamp, B.; Pearson, B. An autoencoder wavelet based deep neural network with attention mechanism for multi-step prediction of plant growth. Inf. Sci. 2021, 560, 35–50. [Google Scholar] [CrossRef]

- Chen, K.; Laghrouche, S.; Djerdir, A. Prognosis of fuel cell degradation under different applications using wavelet analysis and nonlinear autoregressive exogenous neural network. Renew. Energy 2021, 179, 802–814. [Google Scholar] [CrossRef]

- Band, S.S.; Heggy, E.; Bateni, S.M.; Karami, H.; Rabiee, M.; Samadianfard, S.; Chau, K.W.; Mosavi, A. Groundwater level prediction in arid areas using wavelet analysis and Gaussian process regression. Eng. Appl. Comput. Fluid Mech. 2021, 15, 1147–1158. [Google Scholar] [CrossRef]

- Li, B.; Chen, X.F. Wavelet-based numerical analysis: A review and classification. Finite Elem. Anal. Des. 2014, 81, 14–31. [Google Scholar] [CrossRef]

- Ma, H.; Chen, C.; Zhu, Q.; Yuan, H.T.; Chen, L.M.; Shu, M.L. An ECG Signal Classification Method Based on Dilated Causal Convolution. Comput. Math. Methods Med. 2021, 2021, 6627939. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, K.R. Smart Pothole Detection Using Deep Learning Based on Dilated Convolution. Sensors 2021, 21, 8406. [Google Scholar] [CrossRef] [PubMed]

- Shafiq, C.; Gu, Z.Q. Deep Residual Learning for Image Recognition: A Survey. Appl. Sci. 2022, 12, 8972. [Google Scholar] [CrossRef]

- Deng, W.; Guo, Y.X.; Liu, J.; Li, Y.; Liu, D.G.; Zhu, L. A missing power data filling method based on improved random forest algorithm. Chin. J. Electr. Eng. 2019, 5, 33–39. [Google Scholar] [CrossRef]

- Dai, H.; Kan, J.F.; Li, W.R.; Zhou, W.D. Outlier detection for sliding window of multi-variable time series. J. Nanjing Univ. Inf. Sci. Technol. (Nat. Sci. Ed.) 2014, 6, 515–519. [Google Scholar] [CrossRef]

- Zhao, J.; Chen, S.F.; Liu, X.J.; Li, X.; Li, H.Y.; Lyu, Q. Outlier screening for ironmaking data on blast furnaces. Int. J. Miner. Metall. Mater. 2021, 28, 1001–1010. [Google Scholar] [CrossRef]

- Soheila, A.T.; Sabzevari, V.R. Early arrhythmia prediction based on Hurst index and ECG prediction using robust LMS adaptive filter. Signal Image Video Process. 2021, 15, 1813–1820. [Google Scholar]

| Type of Data | Data Content | Data Frequency | Number |

|---|---|---|---|

| Non-real-time discrete data | Test data of raw material and fuel | Batches | 60 |

| Test data of slag and iron | Furnaces | 21 | |

| Manually entered production data | Hours | 13 | |

| Real-time continuous data | Operating parameters | Seconds, hours | 69 |

| Temperature of the hearth and bottom | Seconds | 156 | |

| Temperature, pressure, and flow volume of cooling stave | Seconds | 216 |

| Model | MAE | MSE | R2 | Time | Accuracy (±0.025/%) |

|---|---|---|---|---|---|

| Wavelet-TCN (a = 1) | 0.0132 | 0.01004 | 0.8364 | 121 s | 84.62 |

| Wavelet-TCN (a = 2) | 0.0124 | 0.00961 | 0.8562 | 154 s | 86.98 |

| Wavelet-TCN (a = 3) | 0.0123 | 0.00963 | 0.8578 | 193 s | 88.17 |

| Wavelet-TCN (a = 4) | 0.0116 | 0.00886 | 0.8643 | 241 s | 89.05 |

| Wavelet-TCN (a = 5) | 0.0111 | 0.00810 | 0.8847 | 295 s | 90.53 |

| Wavelet-TCN (a = 6) | 0.0109 | 0.00803 | 0.8871 | 371 s | 90.83 |

| Wavelet-TCN (a = 7) | 0.0109 | 0.00804 | 0.8884 | 598 s | 91.12 |

| Model | MAE | MSE | R2 | Accuracy (±0.02/%) |

|---|---|---|---|---|

| Wavelet-TCN (a = 5) | 0.0111 | 0.00810 | 0.8847 | 90.53 |

| TCN | 0.0148 | 0.01030 | 0.7935 | 82.54 |

| LSTM with attention | 0.0150 | 0.01045 | 0.7888 | 81.66 |

| LSTM | 0.0160 | 0.01269 | 0.7587 | 78.11 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, H.; Li, X.; Liu, X.; Bu, X.; Chen, S.; Lyu, Q.; Wang, K. Prediction of the Vanadium Content of Molten Iron in a Blast Furnace and the Optimization of Vanadium Extraction. Separations 2023, 10, 521. https://doi.org/10.3390/separations10100521

Li H, Li X, Liu X, Bu X, Chen S, Lyu Q, Wang K. Prediction of the Vanadium Content of Molten Iron in a Blast Furnace and the Optimization of Vanadium Extraction. Separations. 2023; 10(10):521. https://doi.org/10.3390/separations10100521

Chicago/Turabian StyleLi, Hongwei, Xin Li, Xiaojie Liu, Xiangping Bu, Shujun Chen, Qing Lyu, and Kunming Wang. 2023. "Prediction of the Vanadium Content of Molten Iron in a Blast Furnace and the Optimization of Vanadium Extraction" Separations 10, no. 10: 521. https://doi.org/10.3390/separations10100521

APA StyleLi, H., Li, X., Liu, X., Bu, X., Chen, S., Lyu, Q., & Wang, K. (2023). Prediction of the Vanadium Content of Molten Iron in a Blast Furnace and the Optimization of Vanadium Extraction. Separations, 10(10), 521. https://doi.org/10.3390/separations10100521