Safety Compliance in a Sample of Italian Mechanical Companies: The Role of Knowledge and Safety Climate

Abstract

:1. Introduction

The Antecedents of Safety Compliance

2. Materials and Methods

2.1. Participants and Training Intervention

2.2. Instruments

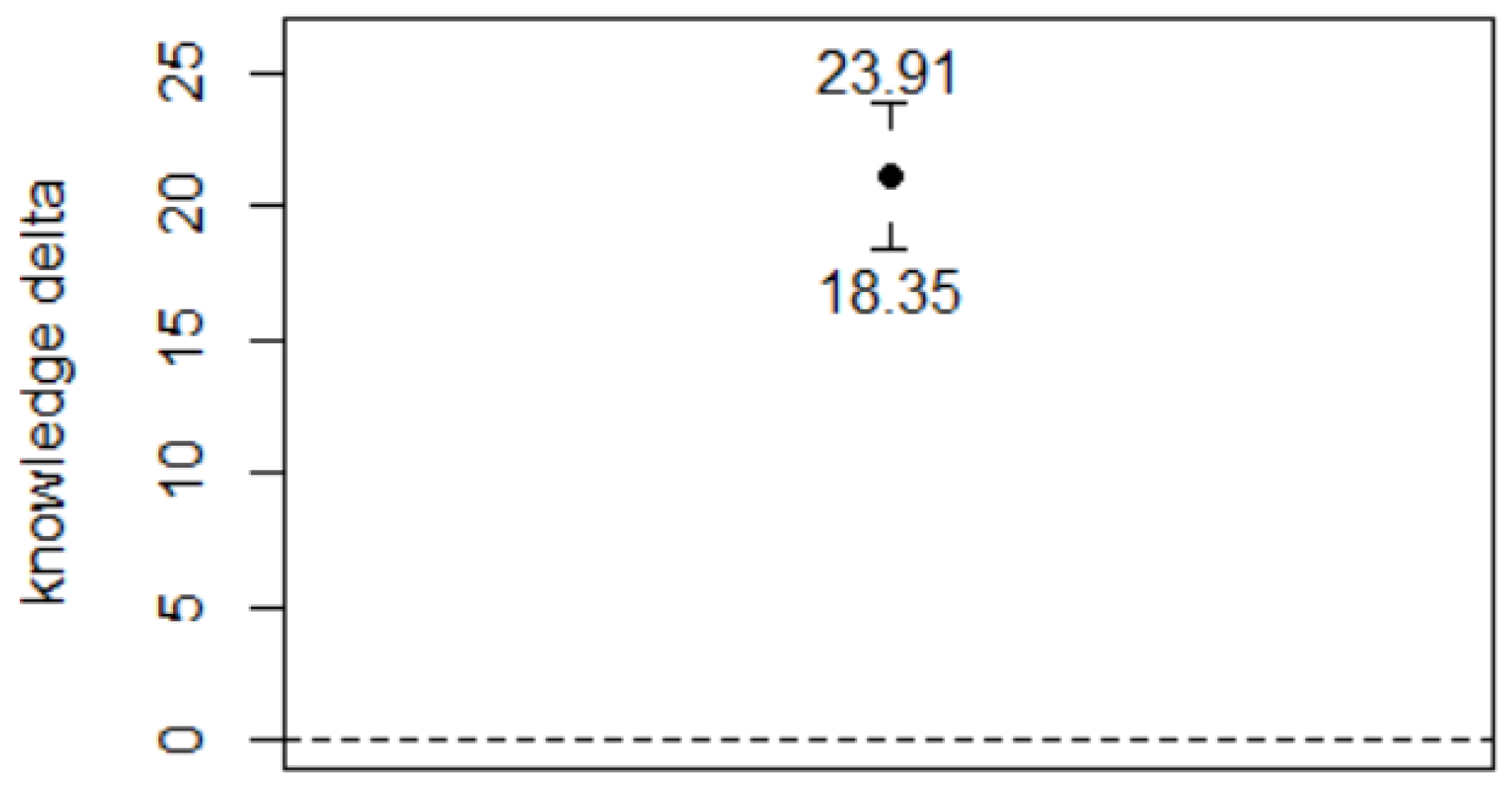

- Knowledge: An adapted version of the scale proposed by Ricci et al. [47] composed of 20 items characterized by different formats: two items concerning the recognition of safe behaviours presented as a photographic stimulus (e.g., safety signage), with three alternatives and only one correct answer; 15 items requiring the production—with paper and pencil—of the correct answers to questions on the role of prevention and the safety procedures to apply (e.g., “What is the safest behaviour to use in the event of an earthquake tremor?”); three items requiring the recognition of the correct answer, among four alternatives, on the obligations and sanctions that the law imposes on workers (e.g., “Breaking the obligation to correctly use the working equipment and the means of transport, as well as the safety equipment, will be punished with:”).

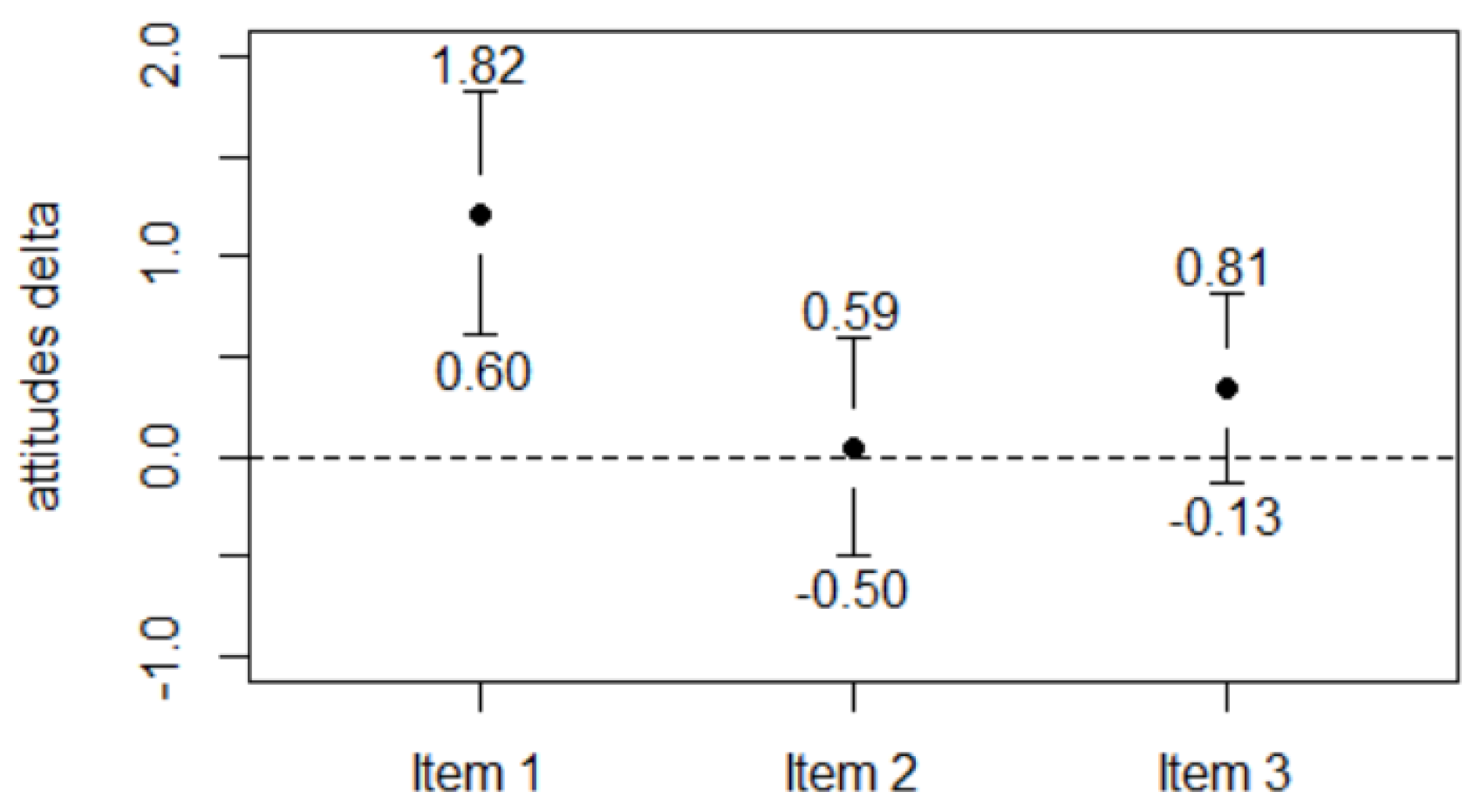

- Attitudes towards safe practices: A self-evaluation questionnaire consisting of three items (e.g., “People get hurt because they don’t apply the procedures”), adapted from Ricci et al. [47], with responses given on a 10-point Likert-type scale (from 1 “completely disagree” to 10 “completely agree”). Reliability value result (Cronbach alpha coefficient): 0.64 [43].

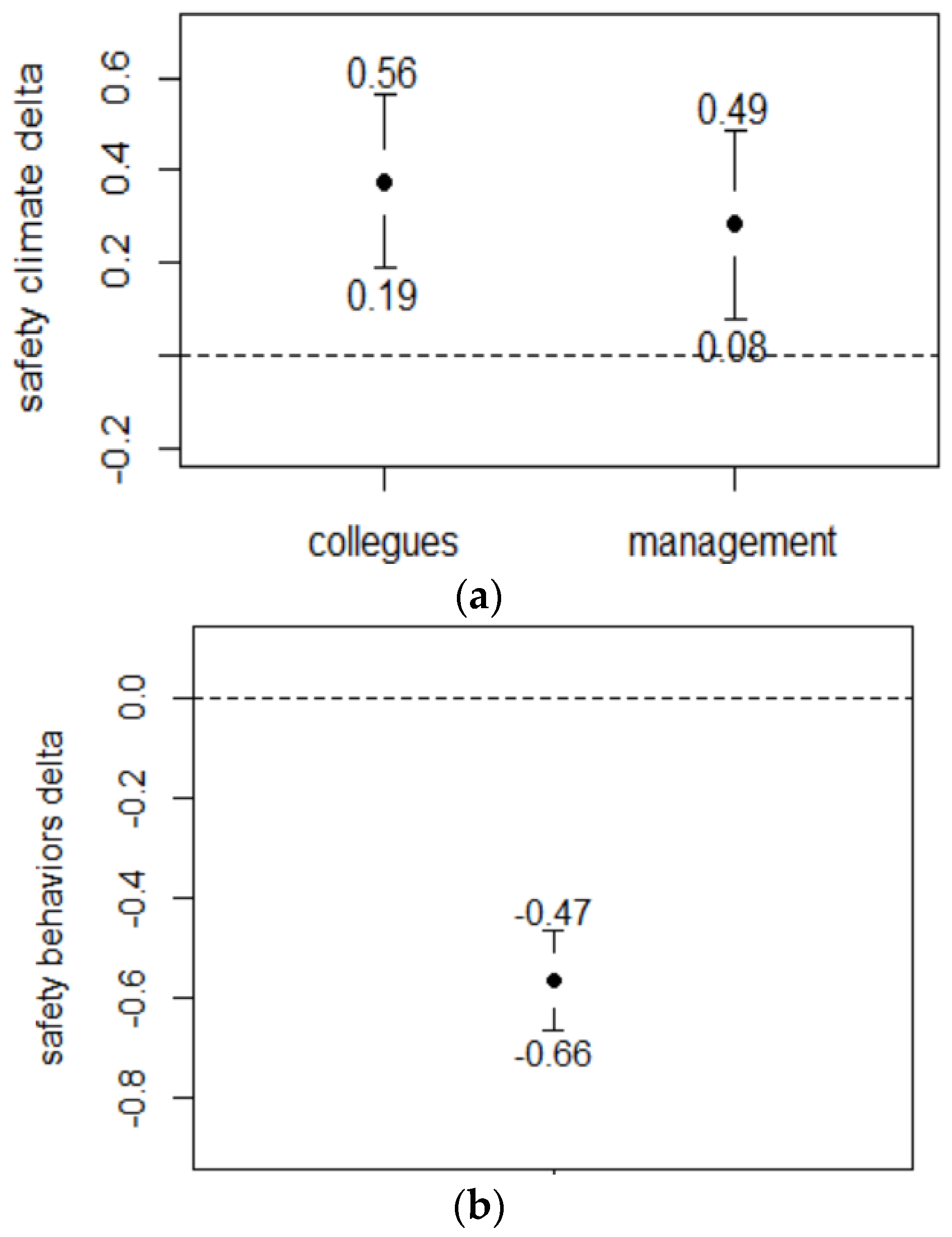

- Safety climate: The Italian version, in reduced form, of the NOSACQ-50 [48], with seven verbal items rated on a 7-point Likert scale (from 1 “completely disagree” to 7 “completely agree”). The items measured the workers’ perception of the actions taken by the management (e.g., “the management involves the workers in decisions concerning safety”) and by their colleagues (e.g., “the workers of this company help one another to work safely”). Reliability value result (Cronbach alpha coefficient): 0.83 [43].

- Behaviours: An original observation checklist containing four parameters (personal protective equipment, manual handling of loads, posture at work, and pace of work). For each parameter, four indicators were identified: 1 = very good; 2 = quite good; 3 = relatively wrong; and 4 = completely wrong. The survey was completed by personnel with experience in observation tasks, who were trained by the lead researcher before proceeding with the scheduled activities.

2.3. Procedure

2.4. Data Analysis

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Eurostat. Data Browser. 2021. Available online: https://ec.europa.eu/eurostat/databrowser/view/hsw_mi01/default/table?lang=en (accessed on 11 September 2021).

- Eurostat. Non-Fatal Accidents at Work, 2017 and 2018. 2020. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=File:Non-fatal_accidents_at_work,_2017_and_2018_(standardised_incidence_rates_per_100_000_persons_employed)_AAW2020.png (accessed on 11 September 2021).

- Eurostat. Accidents at Work Statistics. 2020. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php/Accidents_at_work_statistics#Standardised_incidence_rates (accessed on 11 September 2021).

- Beus, J.M.; McCord, M.A.; Zohar, D. Workplace safety: A review and research synthesis. Organ. Psychol. Rev. 2016, 6, 352–381. [Google Scholar] [CrossRef]

- Chmiel, N.; Taris, T. Safety at work. In Introduction to Work and Organizational Psychology. A European Perspective; Chmiel, N., Ed.; Blackwell Publishing: Oxford, UK, 2000; pp. 255–271. [Google Scholar]

- Griffin, M.A.; Neal, A. Perceptions of safety at work: A framework for linking safety climate to safety performance, knowledge, and motivation. J. Occup. Health Psychol. 2000, 5, 347–358. [Google Scholar] [CrossRef] [PubMed]

- Kalteh, H.O.; Mortazavi, S.B.; Mohammadi, E.; Salesi, M. The relationship between safety culture and safety climate and safety performance: A systematic review. Int. J. Occup. Saf. Ergon. 2021, 27, 206–216. [Google Scholar] [CrossRef] [PubMed]

- Seo, H.C.; Lee, Y.S.; Kim, J.J.; Jee, N.Y. Analyzing safety behaviors of temporary construction workers using structural equation modeling. Saf. Sci. 2015, 77, 160–168. [Google Scholar] [CrossRef]

- Kapp, E.A. The influence of supervisor leadership practices and perceived group safety climate on employee safety performance. Saf. Sci. 2012, 50, 1119–1124. [Google Scholar] [CrossRef]

- Christian, M.S.; Bradley, J.C.; Wallace, J.C.; Burke, M.J. Workplace safety: A meta-analysis of the roles of person and situation factors. J. Appl. Psychol. 2009, 94, 1103. [Google Scholar] [CrossRef]

- Burke, M.J.; Sarpy, S.A.; Tesluk, P.E.; Smith-Crowe, K. General Safety performance: A test of a grounded theoretical model. Pers. Psychol. 2002, 55, 429–457. [Google Scholar] [CrossRef]

- Morrow, S.L.; Koves, G.K.; Barnes, V.E. Exploring the relationship between safety culture and safety performance in US nuclear power operations. Saf. Sci. 2014, 69, 37–47. [Google Scholar] [CrossRef]

- Garbarino, S.; Tripepi, G.; Magnavita, N. Sleep health promotion in the workplace. Int. J. Environ. Res. Public Health 2020, 17, 7952. [Google Scholar] [CrossRef]

- Hollnagel, E.; Wears, R.L.; Braithwaite, J. From Safety-I to Safety-II: A White Paper; The Resilient Health Care Net; University of Southern Denmark: Odense, Denmark; University of Florida: Gainesville, FL, USA; Macquarie University: Sydney, Australia, 2015. [Google Scholar]

- Robson, L.S.; Stephenson, C.M.; Schulte, P.A.; Amick III, B.C.; Irvin, E.L.; Eggerth, D.E.; Grubb, P.L. A systematic review of the effectiveness of occupational health and safety training. Scand. J. Work Environ. Health 2012, 38, 193–208. [Google Scholar] [CrossRef] [Green Version]

- Burke, M.J.; Sarpy, S.A.; Smith-Crowe, K.; Chan-Serafin, S.; Salvador, R.O.; Islam, G. Relative effectiveness of worker safety and health training methods. Am. J. Public Health 2006, 96, 315–324. [Google Scholar] [CrossRef] [PubMed]

- Ricci, F.; Chiesi, A.; Bisio, C.; Panari, C.; Pelosi, A. Effectiveness of occupational health and safety training: A systematic review with meta-analysis. J. Workplace Learn. 2016, 28, 355–377. [Google Scholar] [CrossRef]

- Bena, A.; Berchialla, P.; Coffano, M.E.; Debernardi, M.L.; Icardi, L.G. Effectiveness of the training program for workers at construction sites of the high-speed railway line between Torino and Novara: Impact on injury rates. Am. J. Ind. Med. 2009, 52, 965–972. [Google Scholar] [CrossRef]

- Cavazza, N.; Serpe, A. The impact of safety training programs on workers’ psychosocial orientation and behaviour. Rev. Int. Psychol. Soc. 2010, 23, 187–210. [Google Scholar]

- Guldenmund, F.W. The nature of safety culture: A review of theory and research. Saf. Sci. 2000, 34, 215–257. [Google Scholar] [CrossRef]

- Zohar, D.; Luria, G. A multilevel model of safety climate: Cross-level relationships between organization and group-level climates. J. Appl. Psychol. 2005, 90, 616. [Google Scholar] [CrossRef] [PubMed]

- Hu, X.; Griffin, M.A.; Bertuleit, M. Modelling antecedents of safety compliance: Incorporating theory from the technological acceptance model. Saf. Sci. 2016, 87, 292–298. [Google Scholar] [CrossRef]

- Smith-Crowe, K.; Burke, M.J.; Landis, R.S. Organizational climate as a moderator of safety knowledge–safety performance relationships. Int. J. Ind. Occup. Organ. Psychol. Behav. 2003, 24, 861–876. [Google Scholar] [CrossRef]

- Fugas, C.S.; Silva, S.A.; Meliá, J.L. Another look at safety climate and safety behavior: Deepening the cognitive and social mediator mechanisms. Accid. Anal. Prev. 2012, 45, 468–477. [Google Scholar] [CrossRef]

- Shin, M.; Lee, H.S.; Park, M.; Moon, M.; Han, S. A system dynamics approach for modeling construction workers’ safety attitudes and behaviors. Acc. Anal. Prev. 2014, 68, 95–105. [Google Scholar] [CrossRef]

- Wong, B.M.; Etchells, E.E.; Kuper, A.; Levinson, W.; Shojania, K.G. Teaching quality improvement and patient safety to trainees: A systematic review. Acad. Med. 2010, 85, 1425–1439. [Google Scholar] [CrossRef] [PubMed]

- Eagly, A.H.; Chaiken, S. The Psychology of Attitudes; Harcourt Brace Jovanovich College Publishers: San Diego, CA, USA, 1993. [Google Scholar]

- Clarke, S. Safety climate in an automobile manufacturing plant: The effects of work environment, job communication and safety attitudes on accidents and unsafe behaviour. Pers. Rev. 2006, 35, 413–430. [Google Scholar] [CrossRef]

- Zohar, D. Safety climate in industrial organizations: Theoretical and applied implications. J. Appl. Psychol. 1980, 65, 96–102. [Google Scholar] [CrossRef] [PubMed]

- Jiang, L.; Yu, G.; Li, Y.; Li, F. Perceived colleagues’ safety knowledge/behavior and safety performance: Safety climate as a moderator in a multilevel study. Accid. Anal. Prev. 2010, 42, 1468–1476. [Google Scholar] [CrossRef] [PubMed]

- Reason, J. Human Error; Cambridge University Press: Cambridge, UK, 1990. [Google Scholar]

- Ajzen, I. The theory of planned behavior. Organ. Behav. Hum. Decis. Process. 1991, 50, 179–211. [Google Scholar] [CrossRef]

- Hacker, W. Activity: A fruitful concept in industrial psychology. In Goal Directed Behavior: The Concept of Action in Psychology; Frese, M., Sabini, J., Eds.; L. Erlbaum Associates: Mahwah, NJ, USA, 1985; pp. 262–284. [Google Scholar]

- Frese, M.; Zapf, D. Action as the core of work psychology: A German approach. Handb. Ind. Organ. 1994, 4, 271–340. [Google Scholar]

- Zacher, H.; Frese, M. Action regulation theory: Foundations, current knowledge, and future directions. In The SAGE Handbook of Industrial, Work and Organizational Psychology; Ones, D.Z., Anderson, N., Viswesvaran, C., Sinangil, H.K., Eds.; SAGE Publications: London, UK, 2018; Volume 2, pp. 80–102. [Google Scholar]

- Meliá, J.L.; Silva, S.; Mearns, K.; Lima, M.L. Exploring the Dimensionality of Safety Climate in the Construction Industry. In Proceedings of the Fourth International Conference on Occupational Risk Prevention, Sevilla, Spain, 10–12 May 2006; Available online: https://www.prevencionintegral.com/canal-orp/papers/orp-2006/exploring-dimensionality-safety-climate-construction-industry (accessed on 11 September 2021).

- Vinodkumar, M.N.; Bhasi, M. Safety climate factors and its relationship with accidents and personal attributes in the chemical industry. Saf. Sci. 2009, 47, 659–667. [Google Scholar] [CrossRef]

- Johnson, S.E. The predictive validity of safety climate. J. Saf. Res. 2007, 38, 511–521. [Google Scholar] [CrossRef]

- Lu, C.S.; Tsai, C.L. The effects of safety climate on vessel accidents in the container shipping context. Accid. Anal. Prev. 2008, 40, 594–601. [Google Scholar] [CrossRef]

- Ajslev, J.; Dastjerdi, E.L.; Dyreborg, J.; Kines, P.; Jeschke, K.C.; Sundstrup, E.; Andersen, L.L. Safety climate and accidents at work: Cross-sectional study among 15,000 workers of the general working population. Saf. Sci. 2017, 91, 320–325. [Google Scholar] [CrossRef]

- Singer, S.; Lin, S.; Falwell, A.; Gaba, D.; Baker, L. Relationship of safety climate and safety performance in hospitals. Health Serv. Res. 2009, 44, 399–421. [Google Scholar] [CrossRef] [PubMed]

- Brondino, M.; Silva, S.A.; Pasini, M. Multilevel approach to organizational and group safety climate and safety performance: Co-workers as the missing link. Saf. Sci. 2012, 50, 1847–1856. [Google Scholar] [CrossRef]

- Ricci, F.; Nucci, M. Safety Integrated Model-training (SIM-t) and its evaluation: A safety training proposal for mechanical companies. Saf. Sci. 2022, 146, 105538. [Google Scholar] [CrossRef]

- Magnavita, N. Medical surveillance, continuous health promotion and a participatory intervention in a small company. Int. J. Environ. Res. Public Health 2018, 15, 662. [Google Scholar] [CrossRef] [Green Version]

- Castaneda, D.E.; Organista, K.C.; Rodriguez, L.; Check, P. Evaluating an entertainment–education telenovela to promote workplace safety. SAGE Open 2013, 3, 2158244013500284. [Google Scholar] [CrossRef] [Green Version]

- Peters, E.; Lipkus, I.; Diefenbach, M.A. The functions of affect in health communications and in the construction of health preferences. J. Commun. 2006, 56, S140–S162. [Google Scholar] [CrossRef]

- Ricci, F.; Pelosi, A.; Panari, C.; Chiesi, A. Safety Value in Practice for an Effective Occupational Health and Safety Training. In Proceedings of the Organization 4.1: The Role of Values in the Organizations of the 21st Century ISSWOV (International Society for the Study of Work and Organizational Values), Trieste, Italy, 1–4 July 2018. [Google Scholar]

- The Nordic Council of Ministers. NOSACQ 50item, Italian Version. Available online: https://nfa.dk/da/Vaerktoejer/Sporgeskemaer/Safety-Climate-Questionnaire-NOSACQ50/NOSACQ50-translations (accessed on 28 June 2021).

- Hurvich, C.M.; Tsai, C.L. Regression and time series model selection in small samples. Biometrika 1989, 76, 297–307. [Google Scholar] [CrossRef]

- Ricci, F.; Bravo, G.; Modenese, A.; De Pasquale, F.; Ferrari, D.; Bello, M.; Gobba, F. Risk Perception and Ethnic Background in Construction Workers: Results of a Cross-Sectional Study in A Group of Trainees of a Vocational School in Italy. Eur. J. Investig. Health Psychol. Educ. 2021, 11, 96–111. [Google Scholar] [CrossRef]

| Model: Predictor(s) | df | Loglikelihood | AICc | AICc Delta | Weight |

|---|---|---|---|---|---|

| M12: knowledge plus management safety climate | 4 | −63.289 | 135.0 | 0.00 | 0.524 |

| M1: knowledge | 3 | −63.270 | 137.1 | 2.16 | 0.178 |

| M13: knowledge interacting with management safety climate | 5 | −65.928 | 138.1 | 3.12 | 0.110 |

| M10: knowledge plus colleague safety climate | 4 | −65.327 | 139.0 | 4.08 | 0.068 |

| M11: knowledge interacting with colleague safety climate | 5 | −65.317 | 141.2 | 6.26 | 0.023 |

| M14: knowledge plus attitudes plus colleague safety climate plus management safety climate | 8 | −62.645 | 142.7 | 7.78 | 0.011 |

| M8: knowledge plus attitudes | 6 | −65.007 | 142.8 | 7.88 | 0.010 |

| M9: knowledge interacting with attitudes | 17 | −59.802 | 160.4 | 25.44 | 0.000 |

| M7: management safety climate | 3 | −78.645 | 163.5 | 28.56 | 0.000 |

| M6: colleague safety climate | 3 | −80.211 | 166.7 | 31.69 | 0.000 |

| Null model | 2 | −81.278 | 166.7 | 31.70 | 0.000 |

| M2: attitude, item 1 | 3 | −80.671 | 167.6 | 32.61 | 0.000 |

| M4: attitude, item 3 | 3 | −80.919 | 168.1 | 33.10 | 0.000 |

| M3: attitude, item 2 | 3 | −81.192 | 168.6 | 33.65 | 0.000 |

| M5: attitudes: item 1 + item 2 + item 3 | 5 | −80.064 | 170.7 | 35.75 | 0.000 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ricci, F.; Panari, C.; Pelosi, A. Safety Compliance in a Sample of Italian Mechanical Companies: The Role of Knowledge and Safety Climate. Eur. J. Investig. Health Psychol. Educ. 2022, 12, 281-294. https://doi.org/10.3390/ejihpe12030020

Ricci F, Panari C, Pelosi A. Safety Compliance in a Sample of Italian Mechanical Companies: The Role of Knowledge and Safety Climate. European Journal of Investigation in Health, Psychology and Education. 2022; 12(3):281-294. https://doi.org/10.3390/ejihpe12030020

Chicago/Turabian StyleRicci, Federico, Chiara Panari, and Annalisa Pelosi. 2022. "Safety Compliance in a Sample of Italian Mechanical Companies: The Role of Knowledge and Safety Climate" European Journal of Investigation in Health, Psychology and Education 12, no. 3: 281-294. https://doi.org/10.3390/ejihpe12030020

APA StyleRicci, F., Panari, C., & Pelosi, A. (2022). Safety Compliance in a Sample of Italian Mechanical Companies: The Role of Knowledge and Safety Climate. European Journal of Investigation in Health, Psychology and Education, 12(3), 281-294. https://doi.org/10.3390/ejihpe12030020