Development of Solar Powered Biodiesel Reactor for Kuwait Sheep Tallow

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental Procedures

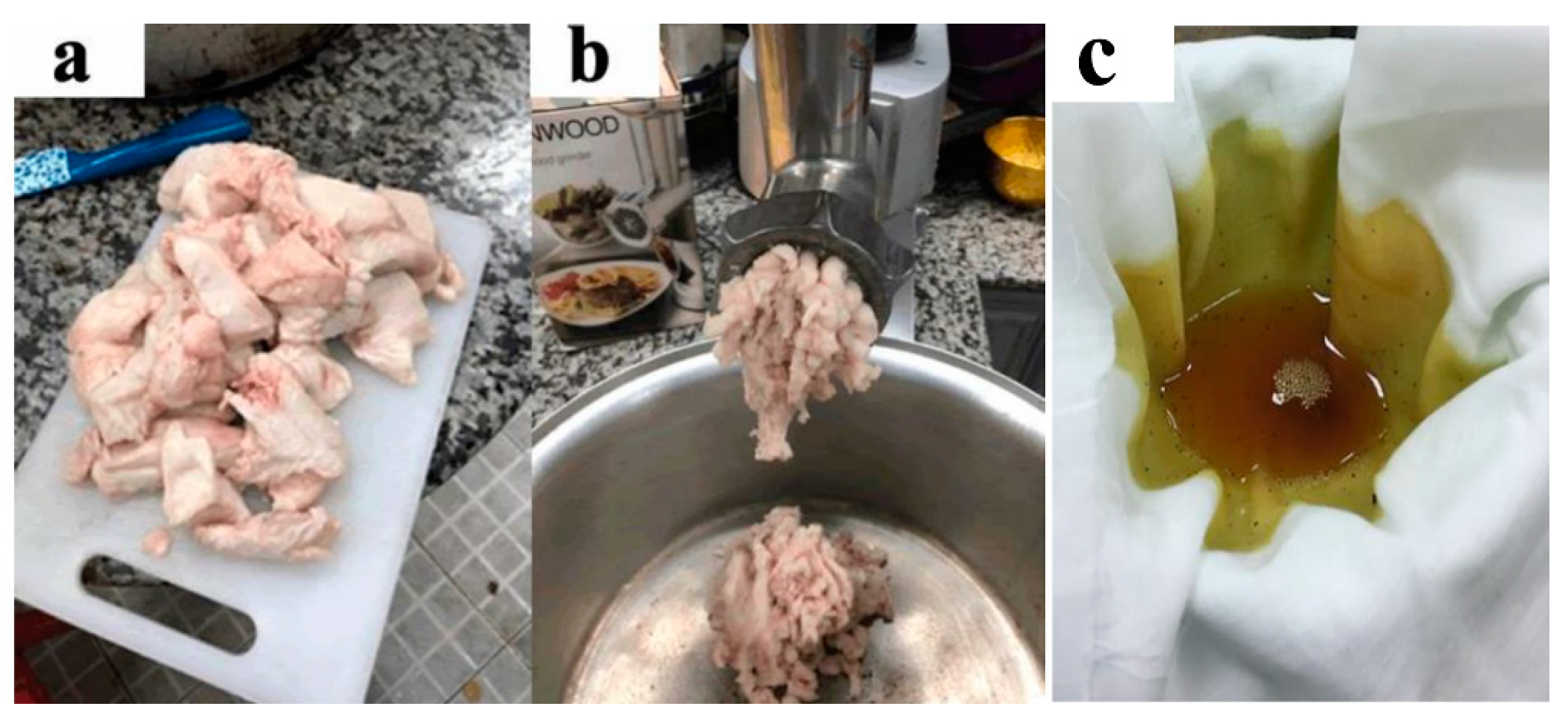

2.2. Extraction of Fat from Sheep

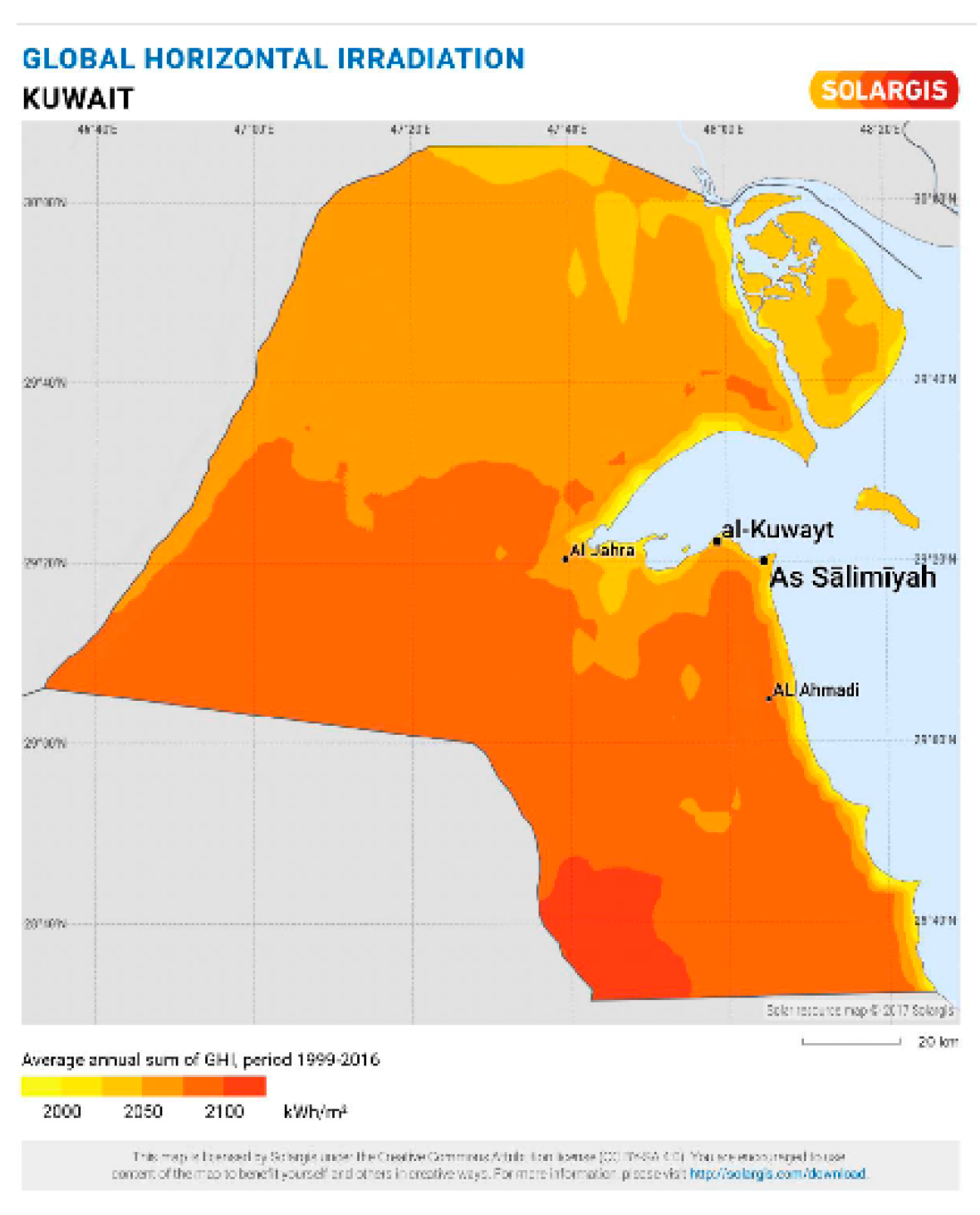

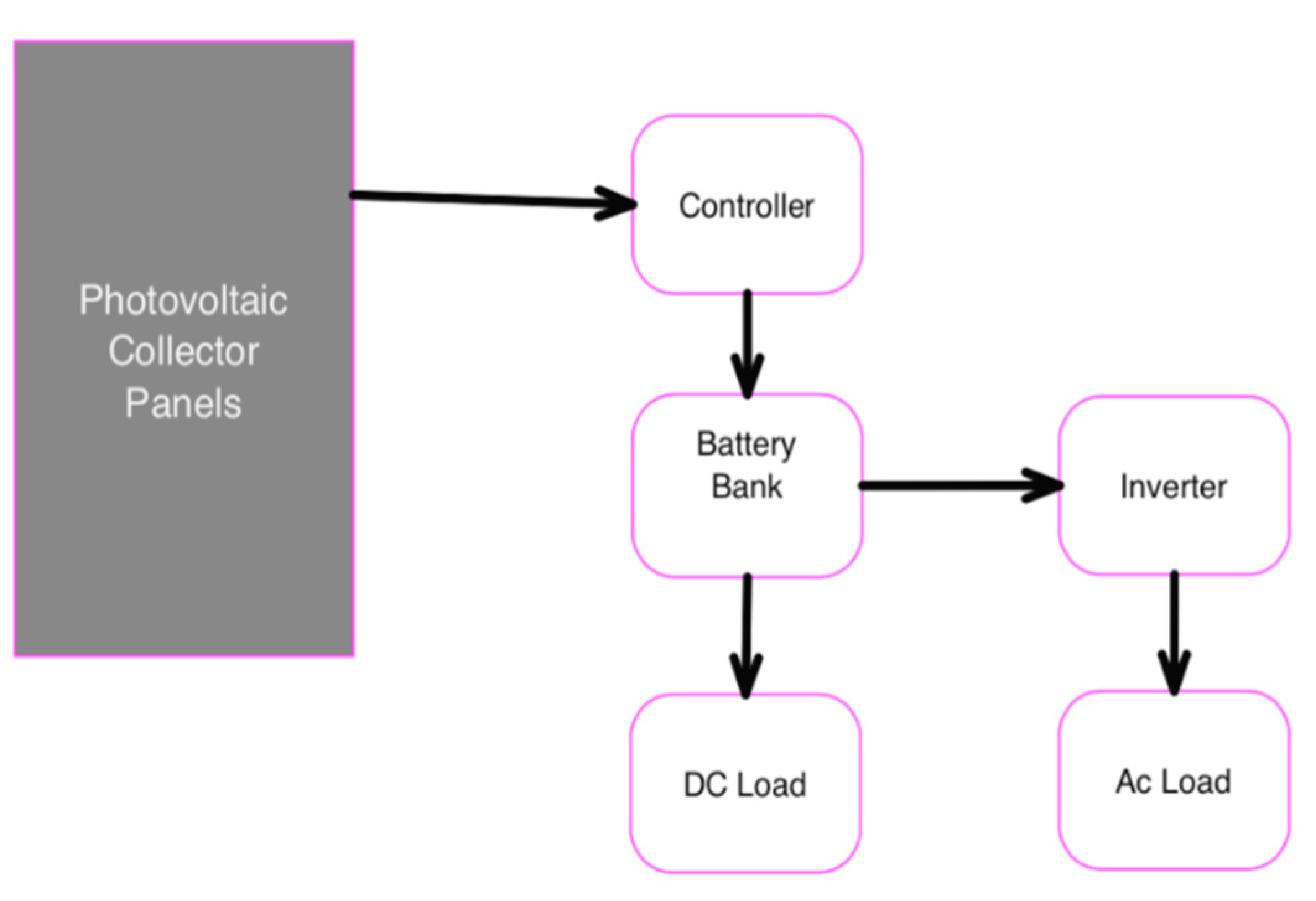

2.3. Solar Power System Design and Calculations

- a

- PV Collector

- b

- Bank of Batteries

- c

- Solar charge controller

- d

- Inverter

- e

- Loads

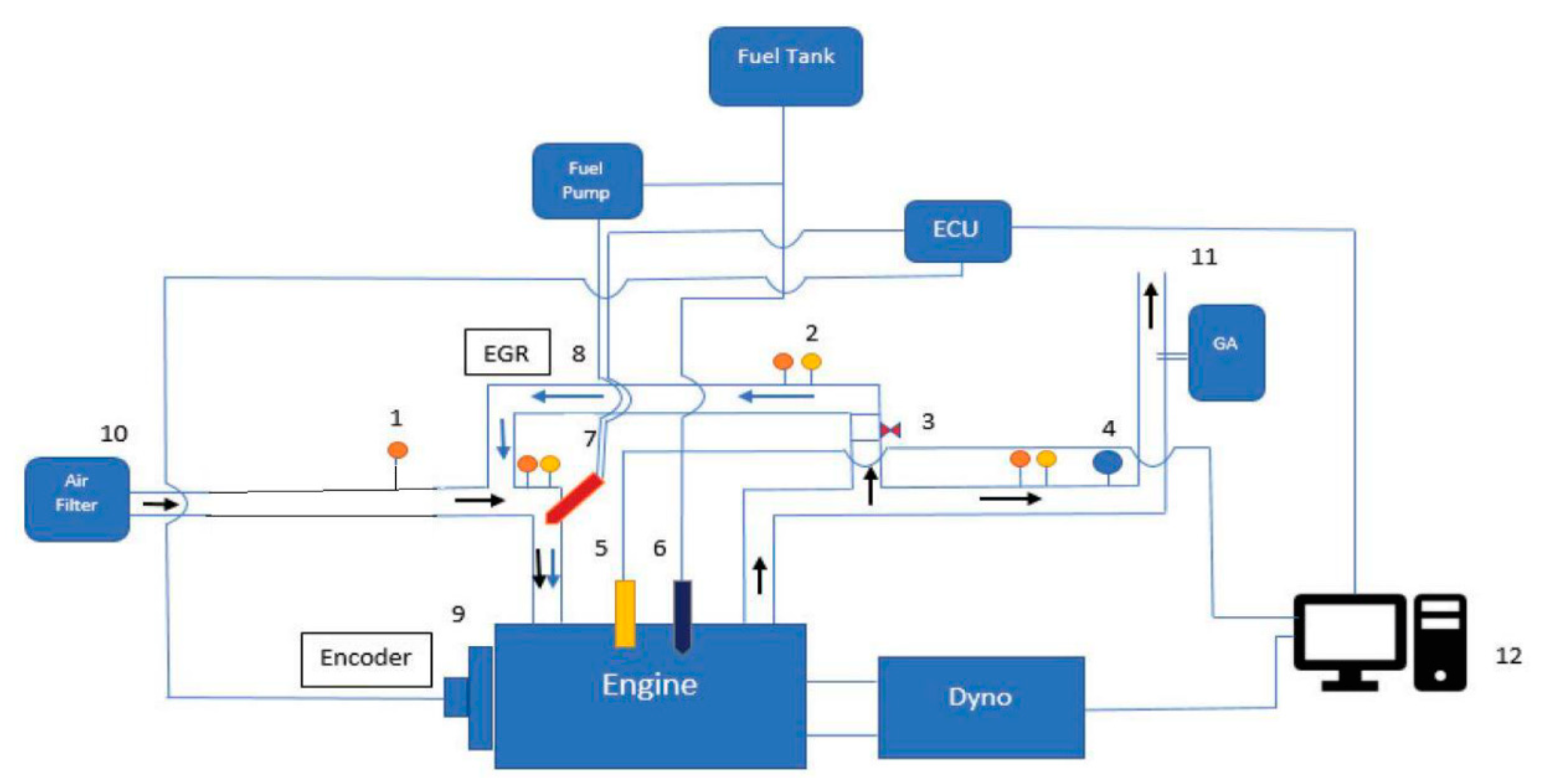

2.4. Diesel Engine Instrumentations

2.5. Exhaust Emissions Measurement

2.6. Calculation Methods

3. Results and Discussion

3.1. Characterization of Sheep Fat Biodiesel and Blends

3.2. Emission Characteristics

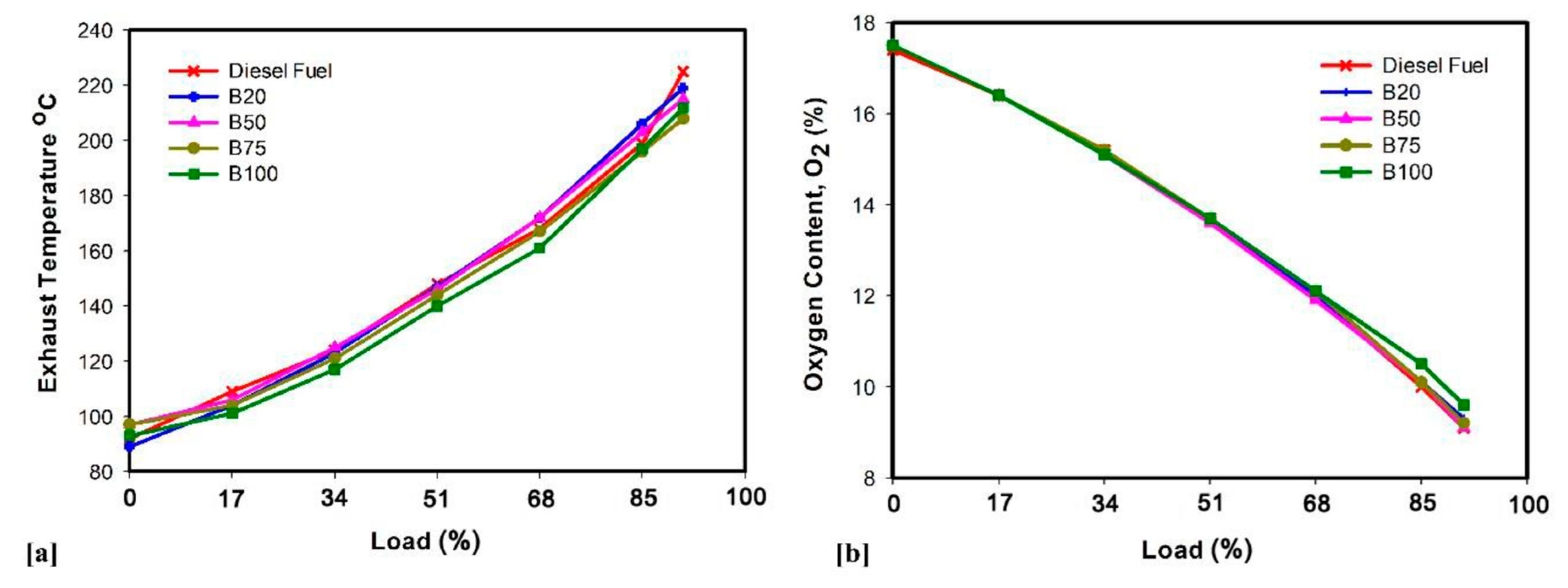

3.2.1. Temperature of Cooled Exhaust Gases

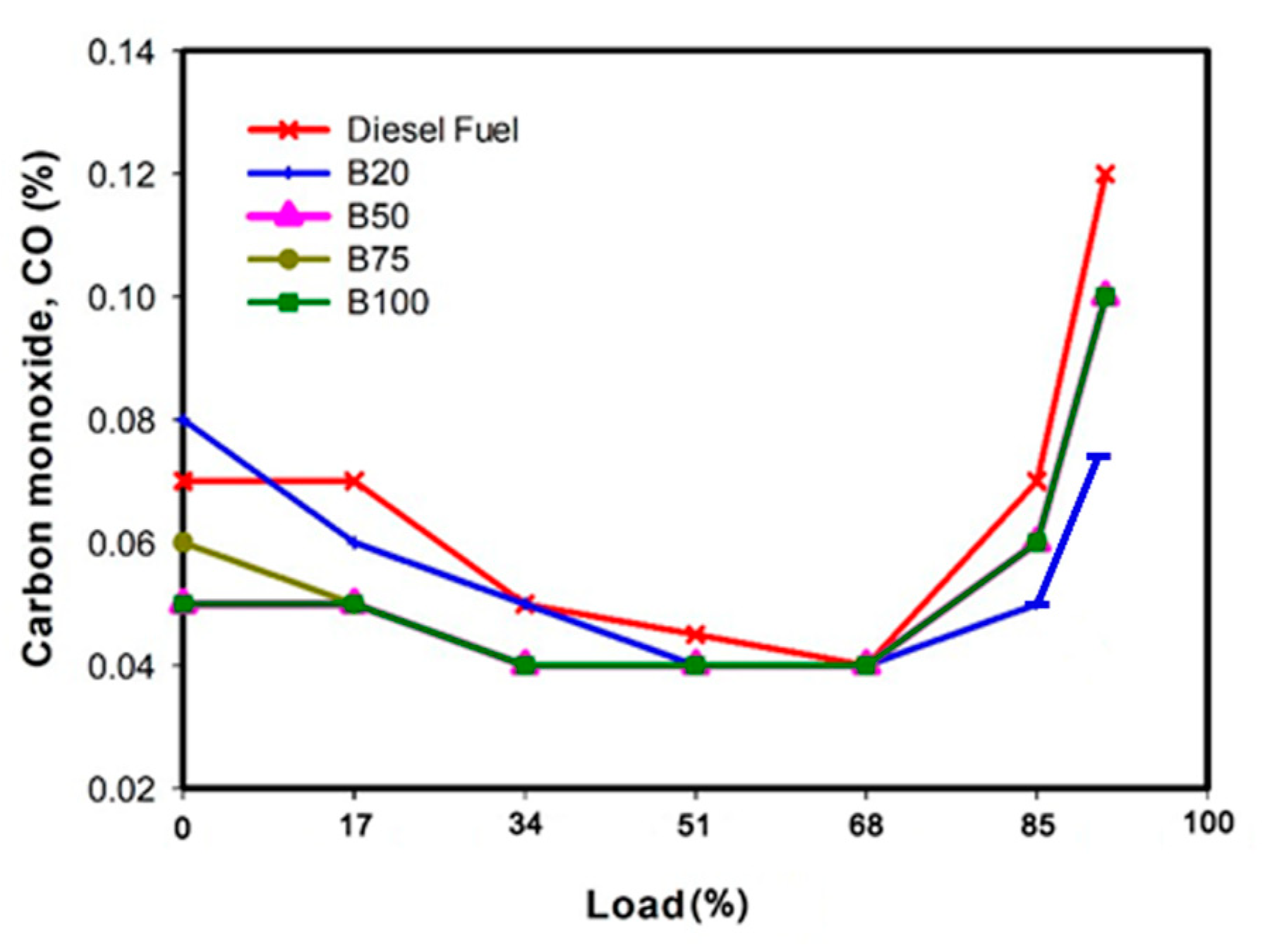

3.2.2. Carbon Monoxide (CO)

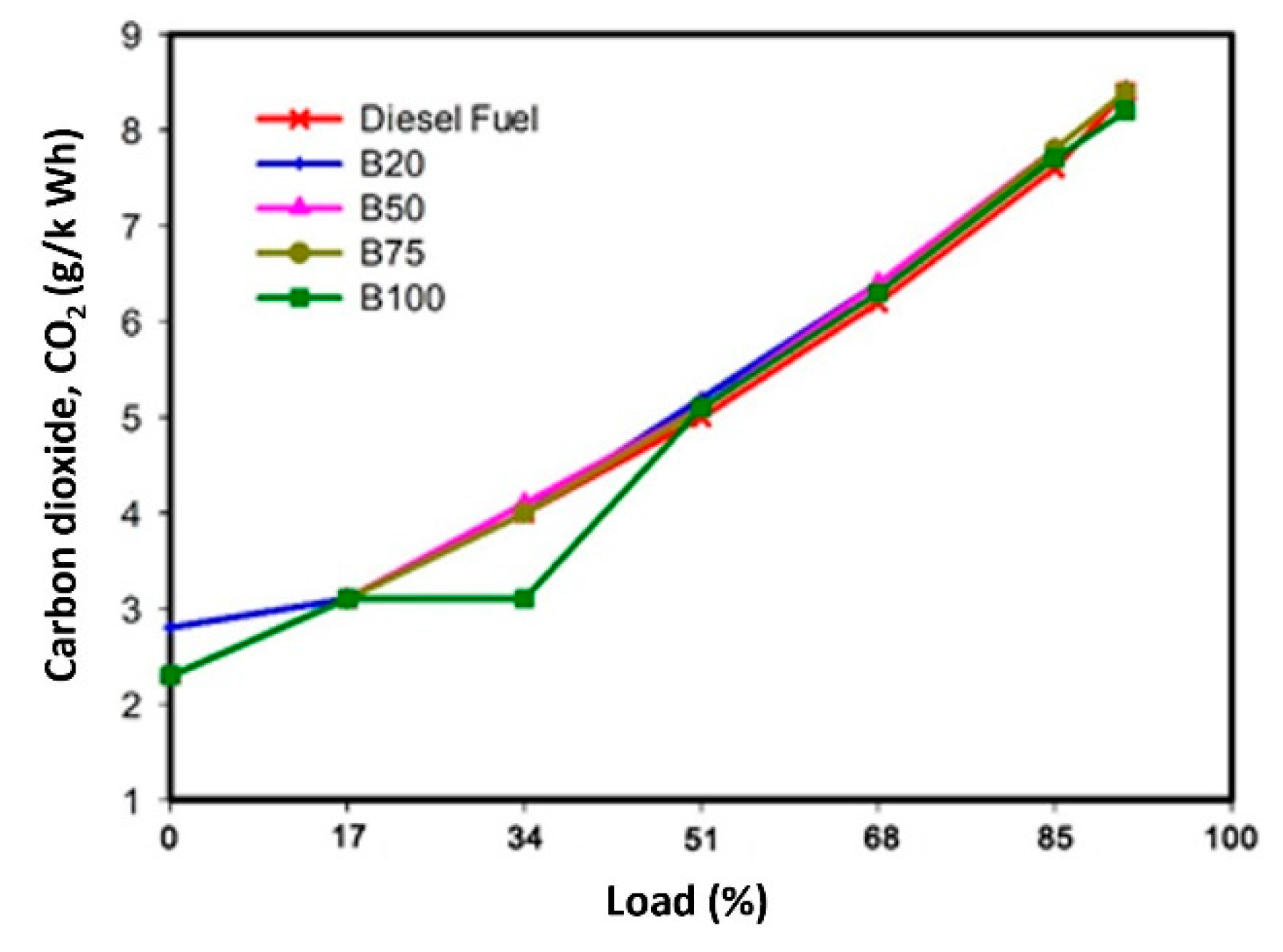

3.2.3. Carbon Dioxide (CO2)

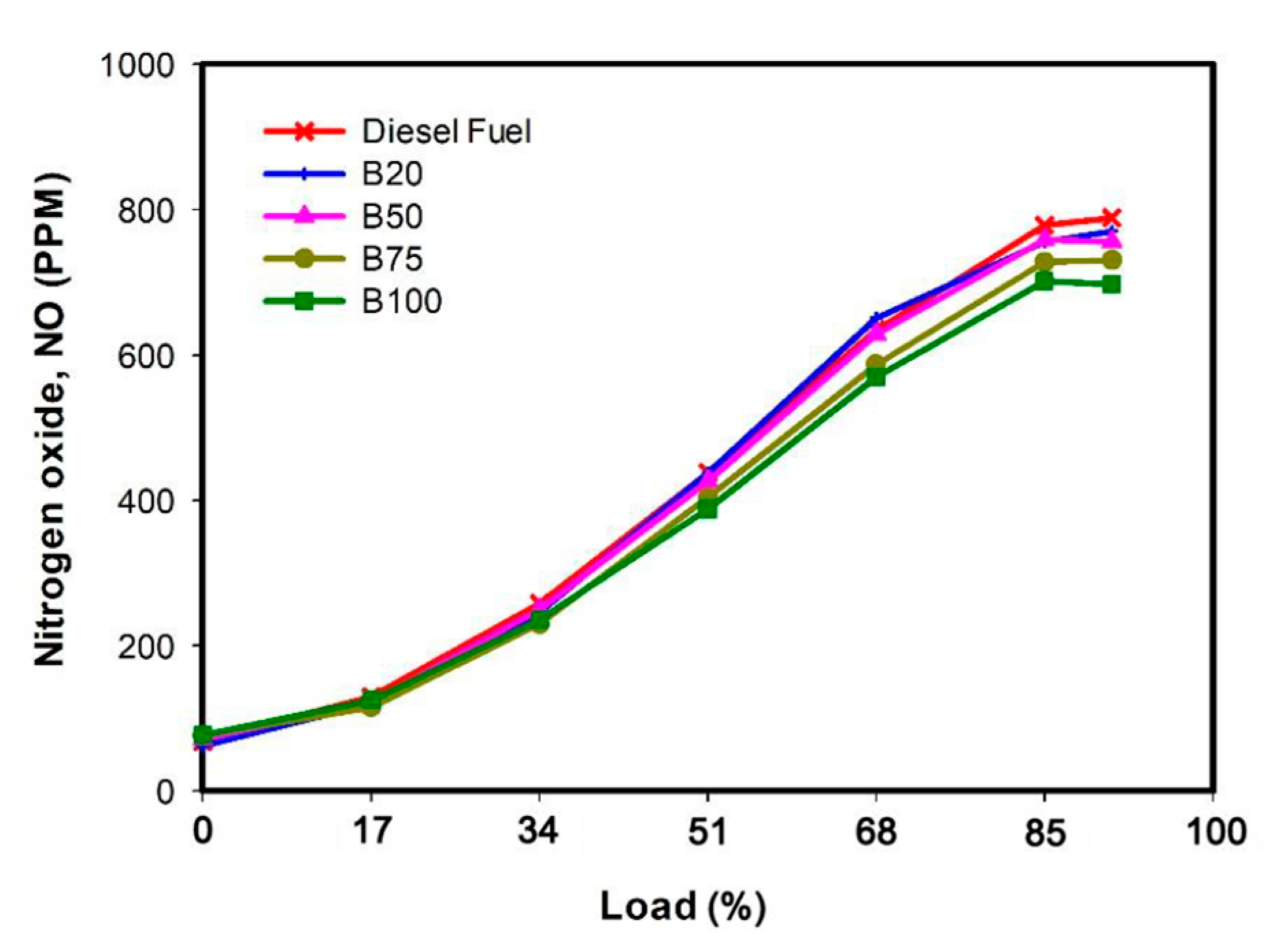

3.2.4. Nitrogen Oxide (NOx)

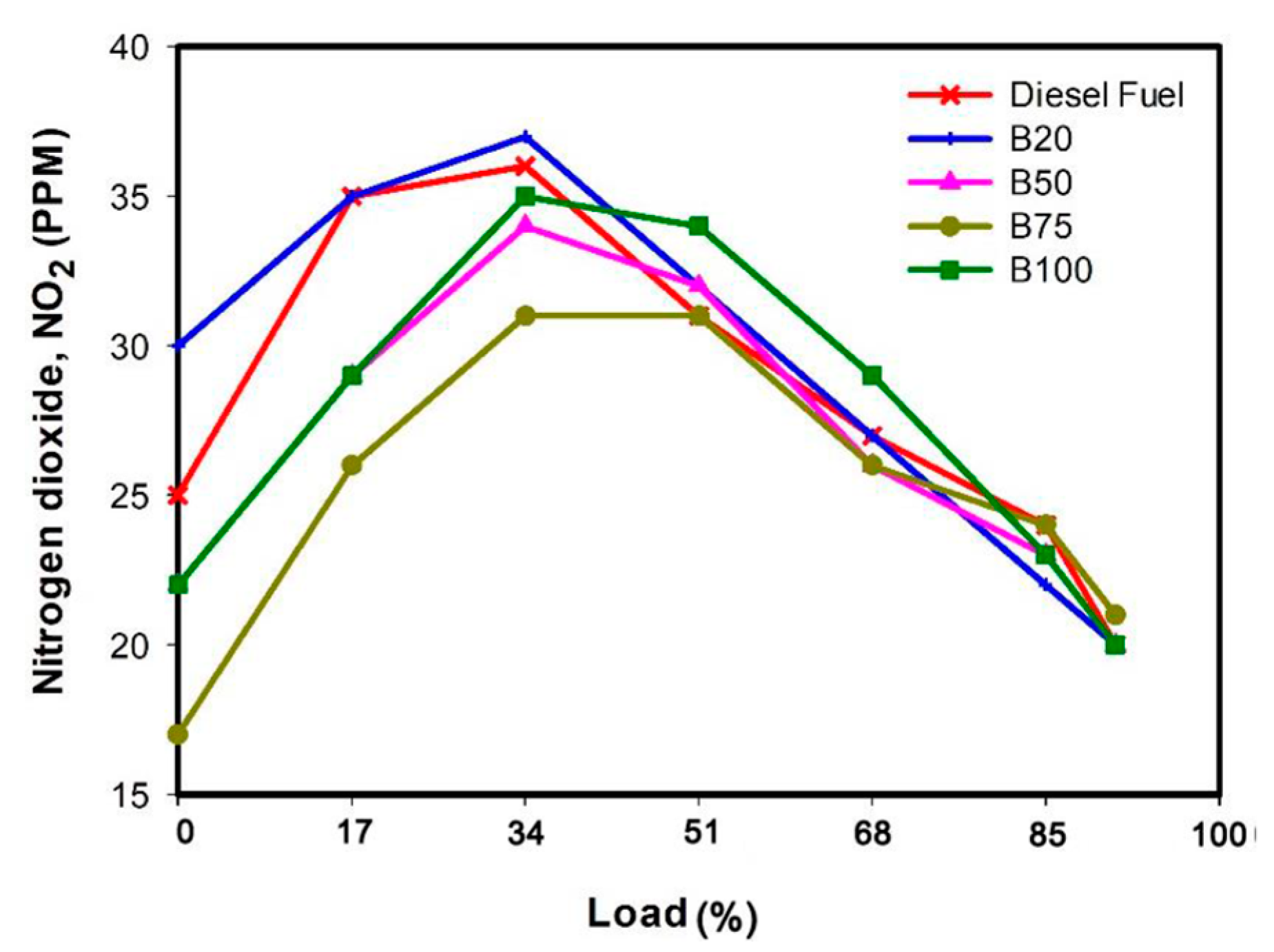

3.2.5. Nitrogen Dioxide (NO2)

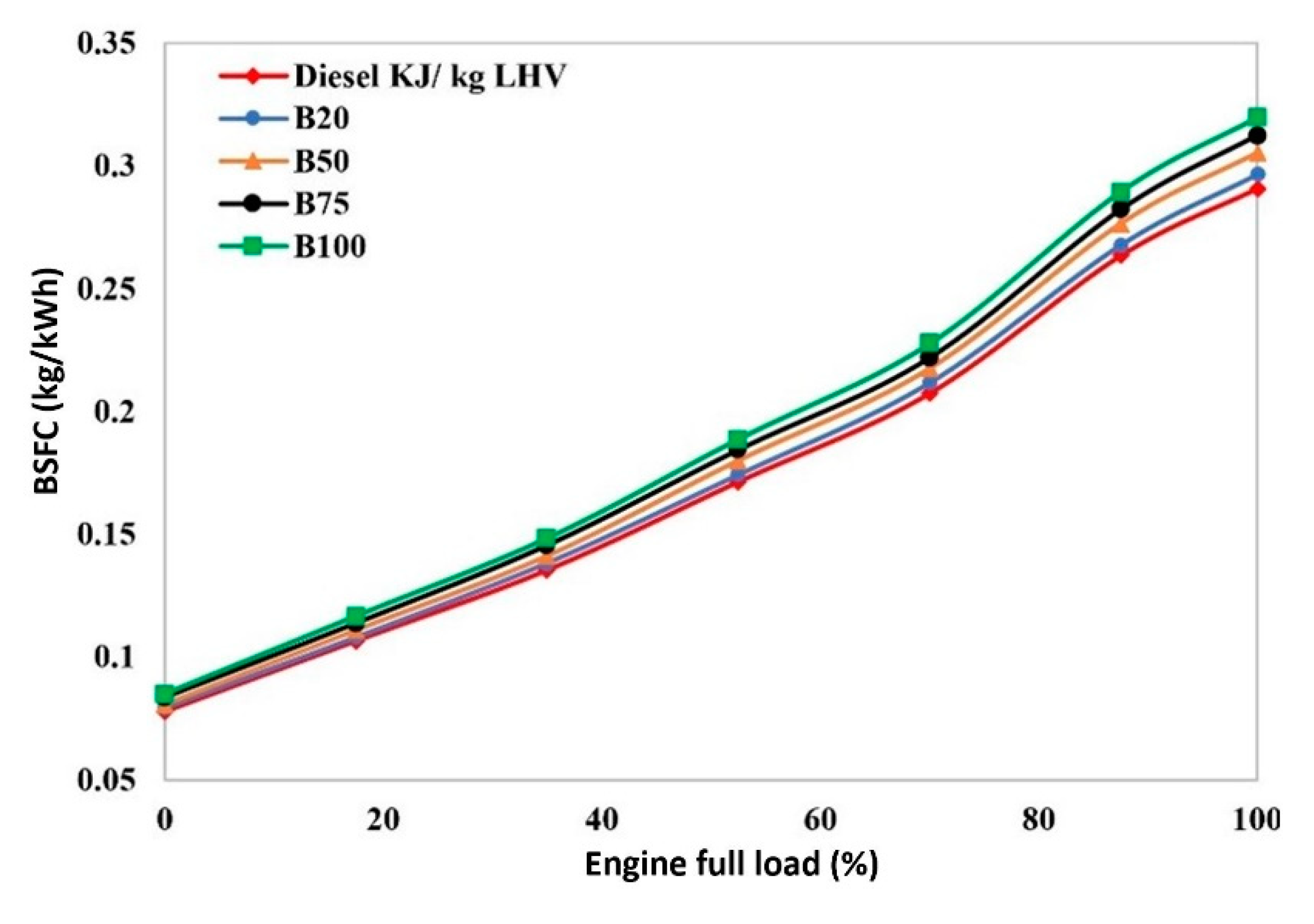

3.3. Engine Performance

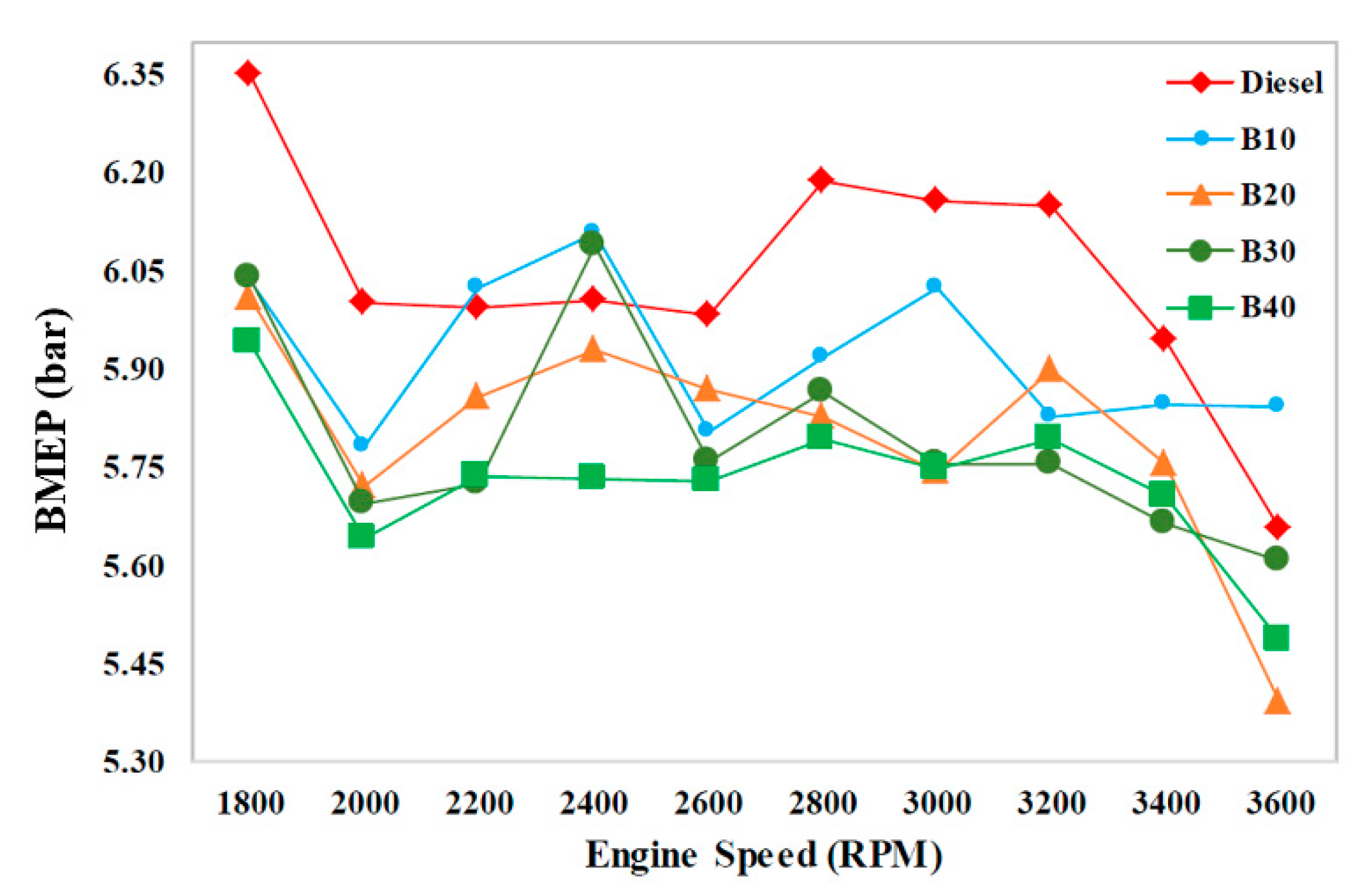

Brake Mean Effective Pressure (BMEP)

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| B100 | Pure Biodiesel |

| B20 | Diesel + Biodiesel (80:20) |

| B50 | Diesel + Biodiesel (50:50) |

| B75 | Diesel + Biodiesel (25:75) |

| BSFC | Brake-Specific Fuel Consumption |

| BTE | Brake Thermal Efficiency |

| BMEP | Brake Mean Effective Pressure |

| CO | Carbon Monoxide |

| CO2 | Carbon Dioxide |

| TCEG | Temperature of Cooled Exhaust Gases |

| FAAE | Fatty Acid Alkyl Esters |

| FFA | Free Fatty Acide |

| GHG | Greenhouse Gas |

| KOH | Potassium Hydroxide |

| LHV | Lower Heating Value |

| NO | Nitric Oxide |

| NO2 | Nitrogen Dioxide |

| NOx | Nitrogen Oxides |

| O2 | Oxygen |

| PKO | Palm Kernel Oil |

| PV | Photovoltaic |

| Ppr | Power Pulses per Revolution |

| SCE | Supercritical Ethanol |

| SFA | Saturated Fats |

| SO2 | Sulfur Dioxide |

| SPS | Solar Photovoltaic System |

References

- Rey, J.M.M. Biofuels and food security. Cuad. Estrateg. 2013, 161, 196–224. [Google Scholar]

- Bankovic-Ilic, I.B.; Stojkovic, I.J.; Stamenkovic, O.S.; Veljkovic, V.B.; Hung, Y.T. Waste animal fats as feedstocks for biodiesel production. Renew. Sustain. Energy Rev. 2014, 32, 238–254. [Google Scholar] [CrossRef] [Green Version]

- Abbas, A.S.; Othman, T.S. Production and Evaluation of Biodiesel from Sheep Fats Waste. Iraqi J. Chem. Pet. Eng. 2012, 13, 11–18. [Google Scholar]

- Solé, J.; García-Olivares, A.; Turiel, A.; Ballabrera-Poy, J. Renewable transitions and the net energy from oil liquids: A scenarios study. Renew. Energy 2018, 116, 258–271. [Google Scholar] [CrossRef]

- Milkov, A.V.; Etiope, G. Revised genetic diagrams for natural gases based on a global dataset of >20,000 samples. Org. Geochem. 2018, 125, 109–120. [Google Scholar] [CrossRef]

- Budzianowski, W.M. A review of potential innovations for production, conditioning and utilization of biogas with multiple-criteria assessment. Renew. Sustain. Energy Rev. 2016, 54, 1148–1171. [Google Scholar] [CrossRef]

- Khan, S.A.R.; Zhang, Y.; Kumar, A.; Zavadskas, E.; Streimikiene, D. Measuring the impact of renewable energy, public health expenditure, logistics, and environmental performance on sustainable economic growth. Sustain. Dev. 2020, 28, 833–843. [Google Scholar]

- Balat, M.; Balat, H. Progress in biodiesel processing. Appl. Energy 2010, 87, 1815–1835. [Google Scholar]

- Janaun, J.; Ellis, N. Perspectives on biodiesel as a sustainable fuel. Renew. Sustain. Energy Rev. 2010, 14, 1312–1320. [Google Scholar]

- Ogunkunle, O.; Ahmed, N.A. A review of global current scenario of biodiesel adoption and combustion in vehicular diesel engines. Energy Rep. 2019, 5, 1560–1579. [Google Scholar] [CrossRef]

- Ritchie, H.; Roser, M. CO2 and Greenhouse Gas Emissions; Our World in Data: Oxford, UK, 2020. [Google Scholar]

- Puricelli, S.; Cardellini, G.; Casadei, S.; Faedo, D.; Van den Oever, A.E.M.; Grosso, M. A review on biofuels for light-duty vehicles in Europe. Renew. Sustain. Energy Rev. 2020, 110398. [Google Scholar] [CrossRef]

- Popp, J.; Lakner, Z.; Harangi-Rákos, M.; Fári, M. The effect of bioenergy expansion: Food, energy, and environment. Renew. Sustain. Energy Rev. 2014, 32, 559–578. [Google Scholar] [CrossRef] [Green Version]

- Al-Nassar, W.K.; Neelamani, S.; Al-Salem, K.A.; Al-Dashti, H.A. Feasibility of offshore wind energy as an alternative source for the state of Kuwait. Energy 2019, 169, 783–796. [Google Scholar] [CrossRef]

- Alotaibi, S. Energy consumption in Kuwait: Prospects and future approaches. Energy Policy 2011, 39, 637–643. [Google Scholar] [CrossRef]

- Focus: Kuwait fails to deal with energy problems. Oil Energy Trends 2013, 38, 3–6. [CrossRef]

- Barrios, C.C.; Domínguez-sáez, A.; Martín, C.; Álvarez, P. Effects of animal fat-based biodiesel on a TDI diesel engine performance, combustion characteristics and particle number and size distribution emissions. Fuel 2014, 117, 618–623. [Google Scholar] [CrossRef]

- Hasan, M.A.; Janius, R.B.; Rashid, U.; Taufiq-yap, Y.H.; Yunus, R.; akaria, R.; Mariah, N. Performance and exhaust emission characteristics of directinjection diesel engine fueled with enriched biodiesel. Energy Convers. Manag. 2015, 106, 365–372. [Google Scholar]

- Öztürk, E. Performance, emissions, combustion and injection characteristics of a diesel engine fuelled with canola oil-hazelnut soapstock biodiesel mixture. Fuel Process. Technol. 2015, 129, 183–191. [Google Scholar] [CrossRef]

- Ilkilic, C.; Cilgin, E.; Aydin, H. Terebinth oil for biodiesel production and its diesel engine application. J. Energy Inst. Inst. 2015, 88, 292–303. [Google Scholar] [CrossRef]

- Yilmaz, N.; Vigil, F.M.; Benalil, K.; Davis, S.M.; Calva, A. Effect of biodiesel–butanol fuel blends on emissions and performance characteristics of a diesel engine. Fuel 2014, 135, 46–50. [Google Scholar] [CrossRef]

- Behçet, R.; Oktay, H.; Çakmak, A.; Aydin, H. Comparison of exhaust emissions of biodiesel-diesel fuel blends produced from animal fats. Renew. Sustain. Energy Rev. 2015, 46, 157–165. [Google Scholar] [CrossRef]

- Sanjid, A.; Masjuki, H.H.; Kalam, M.A.; Rahman, S.M.A.; Abedin, M.J.; Palash, S.M. Production of palm and jatropha based biodiesel and investigation of palm-jatropha combined blend properties, performance, exhaust emission and noise in an unmodified diesel engine. J. Clean. Prod. 2014, 65, 295–303. [Google Scholar] [CrossRef]

- Kalam, M.A.; Masjuki, H.H. Emissions and deposit characteristics of a small diesel engine when operated on preheated crude palm oil. Biomass Bioenergy 2004, 27, 289–297. [Google Scholar] [CrossRef]

- Calder, J.; Roy, M.M.; Wang, W. Performance and emissions of a diesel engine fueled by biodiesel-diesel blends with recycled expanded polystyrene and fuel stabilizing additive. Energy 2018, 149, 204–212. [Google Scholar] [CrossRef]

- Alptekin, E.; Canakci, M.; Necati, A.; Turkcan, A.; Sanli, H. Using waste animal fat-based biodiesels-bioethanol-diesel fuel blends in a DI diesel engine. Fuel 2015, 157, 245–254. [Google Scholar] [CrossRef]

- Di, Y.; Cheung, C.S.; Huang, Z. Comparison of the effect of biodieseldiesel and ethanol-diesel on the gaseous emission of a direct-injection diesel engine. Atmos. Environ. 2009, 43, 2721–2730. [Google Scholar] [CrossRef]

- Nada, T. Performance characterization of different configurations of gas diesel engines. Propuls. Power Res. 2014, 3, 121–132. [Google Scholar] [CrossRef] [Green Version]

- Palash, S.M.; Masjuki, H.H.; Kalam, M.A.; Atabani, A.E.; Fattah, I.M.R.; Sanjid, A. Biodiesel production, characterization, diesel engine performance, and emission characteristics of methyl esters from Aphanamixis polystachya oil of Bangladesh. Energy Convers. Manag. 2015, 91, 149–157. [Google Scholar] [CrossRef] [Green Version]

- Venkanna, B.K.; Venkataramana Reddy, C. Performance, emission and combustion characteristics of direct injection diesel engine running on calophyllum nophyllum linn oil (honne oil). Int. J. Agric. Biol. Eng. 2011, 4, 1–19. [Google Scholar]

| Individual Loads | Qty | Volts | AC Amps | Watt AC | Use h/d | Use d/w | /7 days | W.h.AC |

|---|---|---|---|---|---|---|---|---|

| Agitator | 1 | 220 | 0.45 | 80 | 4 | 7 | 7 | 320 |

| Solenoid valve | 3 | 220 | 0.25 | 150 | 3 | 7 | 7 | 450 |

| Pump | 1 | 220 | 0.4 | 70 | 5 | 7 | 7 | 280 |

| Heater | 1 | 220 | 3 | 1500 | 0.5 | 7 | 7 | 750 |

| AC Total Connected Watts | 1800 | AC Average Daily Loads | 1800 | |||||

| Temp Measurement | |

|---|---|

| Flue Temp Range | 20–2400 °F/−29–1315 °C |

| Inlet Temp (robe-T2) | 20–2400 °F/−29–1315 °C |

| Inlet Temp Range (Ambient) | 2–112 °F/0–50 °C |

| Net Temp (NET) | 20–2400 °F/−29–1315 °C |

| Resolution | 0.1 °F/°C |

| Flue (T1, Inlet T2, NET) Accuracy | ±[0.3% rdg +3.6°F(2 °C)] |

| Flue (T1, Inlet T2, NET) Accuracy | ±[0.3% rdg +3.6°F(2 °C)] |

| Inlet Temp Accuracy | ±[0.3% rdg +1.8°F(1 °C)] |

| Gas Measurement | |

| Oxygen | 0–21% |

| O2 Resolution/Accuracy | 0.1%/±0.3% |

| Carbon Monoxide | 0–2000 ppm (4000 max 15 min) |

| CO Resolution/Accuracy | 1 ppm/±10 ppm <100 ppm, ±5% rdg >100 ppm |

| Carbon Dioxide | 0–20% |

| CO2 Resolution/Accuracy | 1.0%/±0.2% |

| Efficiency | 0–99.9% |

| Efficiency Resolution/Accuracy | 0.1%/±3% |

| Excess Air | 0–250% |

| Excess Air Resolution/Accuracy | 0.1%/±3% reading |

| CO/CO2 ratio | 0–0.999 |

| CO/CO2 resolution/accuracy | 0.001/± 5% rdg (reading) |

| Pressure | |

| Range: | Accuracy |

| ±0.08” wc (±0.2 mBar) | 2 ± 0.002” wc (±0.005 mBar) |

| ±0.4” wc (±1 mBar) | ±0.01” wc (±0.03 mBar) |

| ±32” wc (±80 mBar) | ±3% rdg |

| Resolution | 0.001” wc < 9.999” wc |

| 0.01” wc > 10.00” wc | |

| 0.001 mBar < 24.999 mBar | |

| 0.01 mBar > 25 mBar | |

| Pre-Programmed Fuels: Natural Gas, Propane, Heavy Oil, Light Oil, Bio Fuel, Wood | |

| Properties | Standards | Units | Diesel | B20 Diesel + Biodiesel 80:20 | B50 Diesel + Biodiesel 50:50 | B75 Diesel + Biodiesel 25:75 | B100 Biodiesel |

|---|---|---|---|---|---|---|---|

| Kinematic viscosity @ 40 °C | ASTM D445 | cSt | 3.5819 | 3.7333 | 3.9604 | 4.1497 | 4.3390 |

| Density @ 25 °C | ASTM D4052 | g/cm3 °C | 0.8339 | 0.8401 | 0.8494 | 0.8572 | 0.8649 |

| Cloud point | ASTM D5773 | °C | −20 | −6.9 | −3.5 | 7.8 | 11.2 |

| Pour point | ASTM D5949 | °C | −43 | −25 | −12 | 2 | 15 |

| Flash point | ASTM D93 | °C | 90 | N/A | 89 | 87 | 97 |

| Total acid number | ASTM D664 | mgKOH/gm | 0.0110 | 0.0295 | 0.0572 | 0.0804 | 0.1035 |

| Sulfur content | ASTM D5453 | mg/L | 600.17 | 467.94 | 303.61 | 151.83 | 9.06 |

| Water content | ASTM D6304 | ppm | 83.28 | 186.66 | 436.74 | 603.47 | 790.20 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alajmi, F.; Alajmi, A.; Alrashidi, A.; Alrashidi, N.; Adam, N.M.; Hairuddin, A.A. Development of Solar Powered Biodiesel Reactor for Kuwait Sheep Tallow. Processes 2021, 9, 1623. https://doi.org/10.3390/pr9091623

Alajmi F, Alajmi A, Alrashidi A, Alrashidi N, Adam NM, Hairuddin AA. Development of Solar Powered Biodiesel Reactor for Kuwait Sheep Tallow. Processes. 2021; 9(9):1623. https://doi.org/10.3390/pr9091623

Chicago/Turabian StyleAlajmi, Fnyees, Amer Alajmi, Ahmed Alrashidi, Naser Alrashidi, Nor Mariah Adam, and Abdul Aziz Hairuddin. 2021. "Development of Solar Powered Biodiesel Reactor for Kuwait Sheep Tallow" Processes 9, no. 9: 1623. https://doi.org/10.3390/pr9091623

APA StyleAlajmi, F., Alajmi, A., Alrashidi, A., Alrashidi, N., Adam, N. M., & Hairuddin, A. A. (2021). Development of Solar Powered Biodiesel Reactor for Kuwait Sheep Tallow. Processes, 9(9), 1623. https://doi.org/10.3390/pr9091623