Performance Studies and Energy-Saving Analysis of a Solar Water-Heating System

Abstract

:1. Introduction

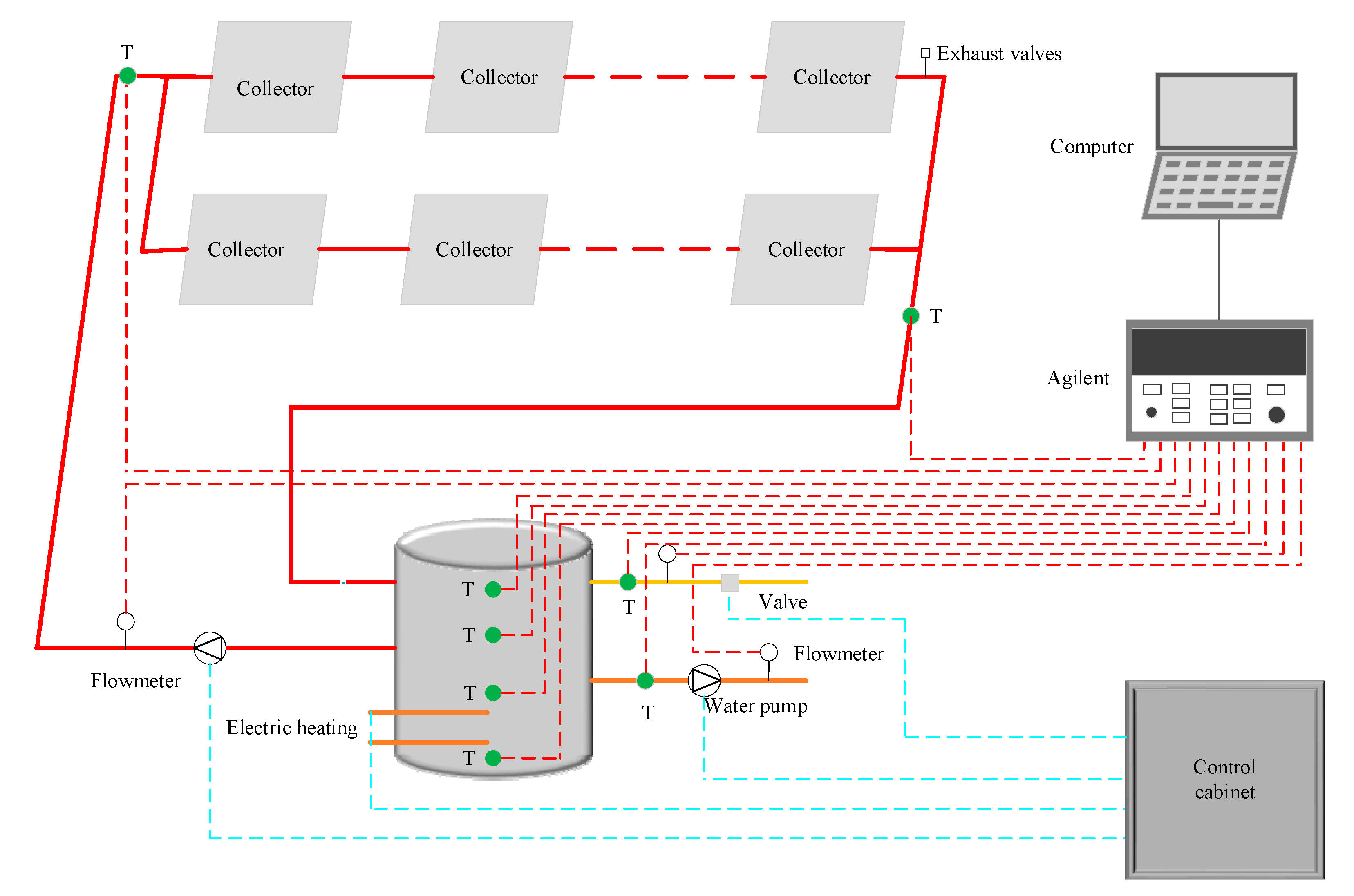

2. Solar Hot-Water System

3. System Test and Evaluation Index

4. Results and Discussion

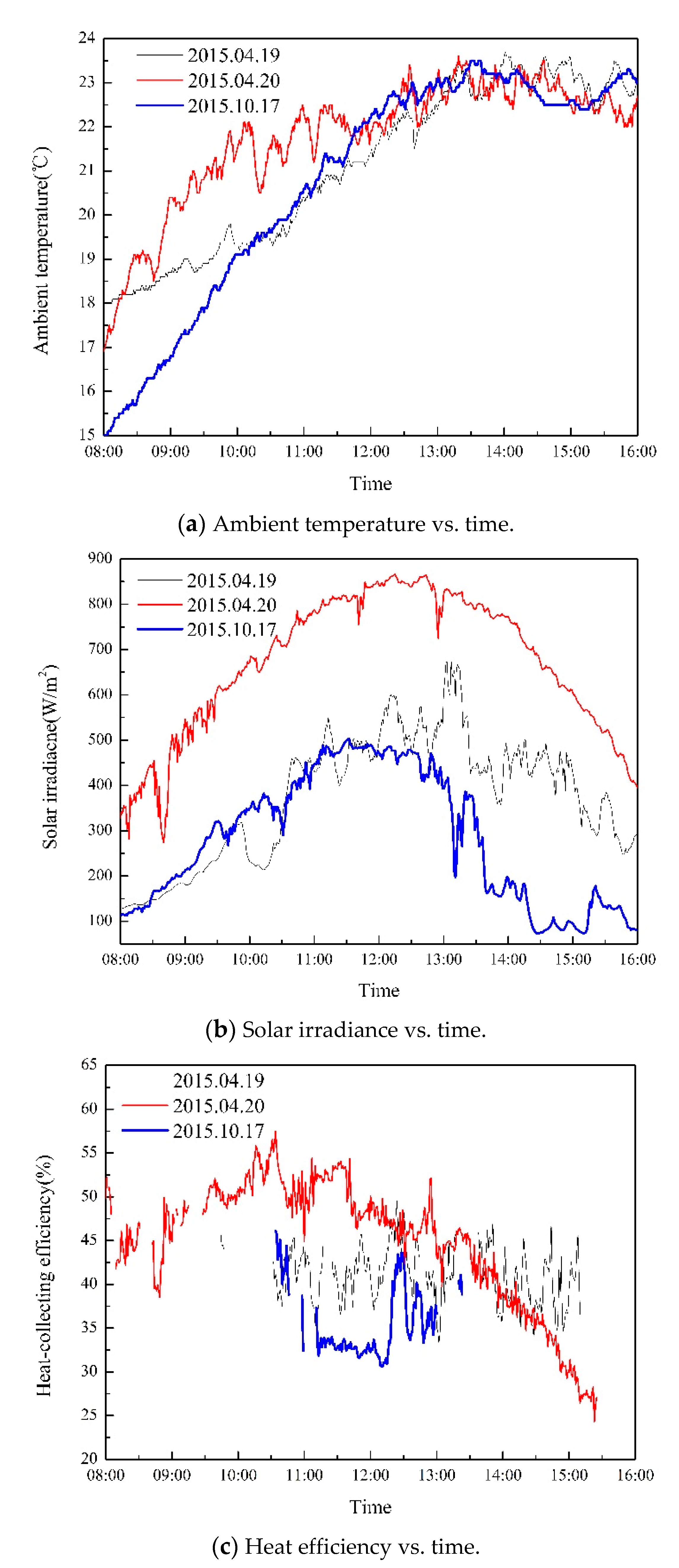

4.1. Influence of Ambient Temperature on the Performance of the Collector

4.2. Influence of Irradiance on Collector Performance

4.3. Analysis of Daily Operation Performance of the Hot-Water System

4.4. Annual Performance Analysis of the Hot-Water System

4.5. Analysis of Energy and Emission Reduction of the Hot-Water System

4.6. Performance Analysis of the Solar Hot-Water System

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Dan, N.N.; Smyth, M. Performance analysis and comparison of concentrated evacuated tube heat pipe solar collectors. Appl. Energy 2012, 98, 22–32. [Google Scholar]

- Yunfei, Y.; Zhien, Z.; Li, Z.; Changlin, D. Application and utilization technology of solar energy. Acta Energ. Sol. Sin. 2012, 33, 47–56. [Google Scholar]

- Kim, Y.D.; Thu, K.; Bhatia, H.K.; Bhatia, C.S.; Ng, K.C. Thermal analysis and performance optimization of a solar hot water plant with economic evaluation. Sol. Energy 2012, 86, 1378–1395. [Google Scholar] [CrossRef]

- Manoram, R.B.; Sathiya, M.R. Experimental investigation on energy and exergy analysis of solar water heating system using cobalt oxide based nanofluid. Heat Mass Transf. 2021, 1–16. [Google Scholar] [CrossRef]

- Naidoo, A. The socio-economic impacts of solar water heaters compared across two communities: A case study of Cato Manor. Renew. Sustain. Energy Rev. 2020, 119, 109525. [Google Scholar] [CrossRef]

- Zambolin, E.; Col, D.D. Experimental analysis of thermal performance of flat plate and evacuated tube solar collectors in stationary standard and daily conditions. Sol. Energy 2010, 84, 1382–1396. [Google Scholar] [CrossRef]

- Xiong, D.; Yang, X.; Wang, P. Design and Experimental study of air-water hybrid solar collector. Acta Energ. Sol. Sin. 2017, 38, 1117–1122. [Google Scholar]

- Jie, J.; Zhi, Y.; Wei, S.; Haifei, C.; Jingyong, C. Study of multiple solar technologies integrated with building. Acta Energ. Sol. Sin. 2016, 37, 489–493. [Google Scholar]

- Dasaien, A.V.; Elumalai, N. Performance enhancement studies in a thermosyphon flat plate solar water heater with CuO nanofluid. Therm. Sci. 2017, 21, 2757–2768. [Google Scholar] [CrossRef]

- Kalbande, V.P.; Walke, P.V.; Rambhad, K.; Nandanwar, Y.; Mohan, M. Performance evaluation of energy storage system coupled with flat plate solar collector using hybrid nanofluid of CuO+AlO/water. J. Phys. Conf. Ser. 2021, 1913, 012067. [Google Scholar] [CrossRef]

- Xu, R.J.; Zhao, Y.Q.; Chen, H.; Wu, Q.P.; Yang, L.W.; Wang, H.S. Numerical and experimental investigation of a compound parabolic concentrator-capillary tube solar collector. Energy Convers. Manag. 2020, 204, 112218. [Google Scholar] [CrossRef]

- Ayompe, L.M.; Duffy, A. Analysis of the thermal performance of a solar water heating system with flat plate collectors in a temperate climate. Appl. Therm. Eng. 2013, 58, 447–454. [Google Scholar] [CrossRef] [Green Version]

- Zhang, L.; Pei, G.; Zhang, T.; Ji, J. A new photovoltaic solar-assisted loop heat pipe/heat-pump system. J. Chem. Ind. Eng. 2014, 65, 3228–3236. [Google Scholar]

- Zou, X.; Zhou, J.; Deng, X.; Zhang, G. Research on optimal matching of solar-assisted ground-coupled heat pump domestic hot water system. Acta Energ. Sol. Sin. 2017, 38, 1281–1290. [Google Scholar]

- Wang, G.; Zhao, Y.; Quan, Z.; Tong, J. Application of a multi-function solar-heat pump system in residential buildings. Appl. Therm. Eng. 2018, 130, 922–937. [Google Scholar] [CrossRef]

- Prodanuks, T.; Veidenbergs, I.; Kirsanovs, V.; Kamenders, A.; Blumberga, D. Analysis of Energy Supply Solutions of Dwelling Buildings. Environ. Clim. Technol. 2019, 23, 182–189. [Google Scholar] [CrossRef] [Green Version]

- Zheng, R. Technical Guidebook for Solar Water Heating System of Civil Buildings; Chemical Industrial Press: Beijing, China, 2011. [Google Scholar]

| Date | Ta/°C | H/W·m2 | Q/MJ | Qp/MJ | Qr/MJ | Vf/m3 | VW/m3 | η/% |

|---|---|---|---|---|---|---|---|---|

| 9 January 2015 | 6.30 | 607.00 | 22.88 | 464.4 | 222.62 | 1.56 | 1.95 | 22.03 |

| 27 January 2015 | 0.10 | 662.60 | 39.91 | 320.04 | 129.60 | 1.15 | 1.10 | 20.66 |

| 31 January 2015 | 2.50 | 648.70 | 78.38 | 66.52 | 34.75 | 0.29 | 0.43 | 20.76 |

| 3 February 2015 | 5.70 | 425.00 | 106.10 | 0 | 18.73 | 0 | 0.31 | 24.33 |

| 5 February 2015 | 5.80 | 634.90 | 160.08 | 0 | 4.59 | 0.56 | 0.044 | 24.69 |

| 21 March 2015 | 17.20 | 756.90 | 329.78 | 0 | 219.93 | 2.17 | 2.83 | 34.40 |

| 24 March 2015 | 13.60 | 689.30 | 257.57 | 63.84 | 65.59 | 0.62 | 0.50 | 30.99 |

| 25 March 2015 | 14.90 | 545.10 | 205.37 | 0 | 139.52 | 1.02 | 1.11 | 33.16 |

| 7 April 2015 | 12.20 | 776.80 | 386.28 | 0 | 136.41 | 1.18 | 1.10 | 37.15 |

| 14 April 2015 | 22.70 | 710.70 | 473.56 | 0 | 125.21 | 2.35 | 0.93 | 46.01 |

| 25 April 2015 | 28.80 | 636.30 | 439.74 | 0 | 58.96 | 1.09 | 0.50 | 49.95 |

| 20 May 2015 | 29.00 | 688.00 | 425.59 | 0 | 133.62 | 0.84 | 0.87 | 44.95 |

| 25 May 2015 | 31.30 | 577.30 | 374.36 | 0 | 183.66 | 1.35 | 1.25 | 46.06 |

| 14 June 2015 | 32.50 | 641.50 | 190.49 | 0 | 0 | 0 | 0 | 56.63 |

| 15 June 2015 | 29.50 | 384.20 | 261.64 | 0 | 158.94 | 1.31 | 1.14 | 47.53 |

| 16 June 2015 | 31.50 | 472.60 | 349.43 | 0 | 43.99 | 0.33 | 0.39 | 48.33 |

| 6 July 2015 | 29.90 | 534.00 | 308.68 | 0 | 97.03 | 0.86 | 0.64 | 49.87 |

| 13 July 2015 | 38.50 | 618.90 | 271.03 | 0 | 85.53 | 0.57 | 0.51 | 50.83 |

| 5 August 2015 | 31.50 | 457.20 | 287.92 | 0 | 23.16 | 0.34 | 0.20 | 42.12 |

| 9 August 2015 | 33.10 | 548.40 | 258.01 | 0 | 0 | 0.11 | 0 | 42.20 |

| 2 September 2015 | 30.70 | 682.20 | 428.31 | 0 | 54.04 | 3.17 | 0.69 | 46.15 |

| 8 September 2015 | 26.90 | 433.30 | 227.46 | 0 | 57.25 | 0.64 | 0.49 | 42.56 |

| 20 September 2015 | 25.10 | 439.10 | 179.18 | 0 | 0 | 0 | 0 | 35.41 |

| 2 October 2015 | 25.00 | 718.50 | 325.17 | 0 | 9.37 | 0.32 | 0.10 | 35.27 |

| 18 October 2015 | 18.50 | 413.60 | 125.87 | 79.74 | 22.84 | 0.59 | 0.26 | 30.81 |

| 4 December 2015 | 5.80 | 584.90 | 75.91 | 375.48 | 299.45 | 2.27 | 2.67 | 23.19 |

| 11 December 2015 | 5.90 | 515.40 | 68.72 | 255.36 | 212.10 | 1.59 | 1.69 | 26.33 |

| 28 December 2015 | 1.50 | 473.60 | 29.91 | 434.19 | 179.26 | 0.86 | 1.27 | 23.12 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, X.; Li, C.; Ma, H. Performance Studies and Energy-Saving Analysis of a Solar Water-Heating System. Processes 2021, 9, 1536. https://doi.org/10.3390/pr9091536

Han X, Li C, Ma H. Performance Studies and Energy-Saving Analysis of a Solar Water-Heating System. Processes. 2021; 9(9):1536. https://doi.org/10.3390/pr9091536

Chicago/Turabian StyleHan, Xilian, Chao Li, and Hongqiang Ma. 2021. "Performance Studies and Energy-Saving Analysis of a Solar Water-Heating System" Processes 9, no. 9: 1536. https://doi.org/10.3390/pr9091536

APA StyleHan, X., Li, C., & Ma, H. (2021). Performance Studies and Energy-Saving Analysis of a Solar Water-Heating System. Processes, 9(9), 1536. https://doi.org/10.3390/pr9091536