Temperature Stress Analysis of Super-Long Frame Structures Accounting for Differences in the Linear Expansion Coefficients of Steel and Concrete

Abstract

:1. Introduction

2. Analysis Methods and Calculation Cases

2.1. Brief Introduction of the Adopted Degenerated Three-Dimensional Solid Virtual Laminated Element and Analysis Methods

2.2. Calculation Case Analysis and Test Verification

3. Super-Long Frame Structure Analysis Model

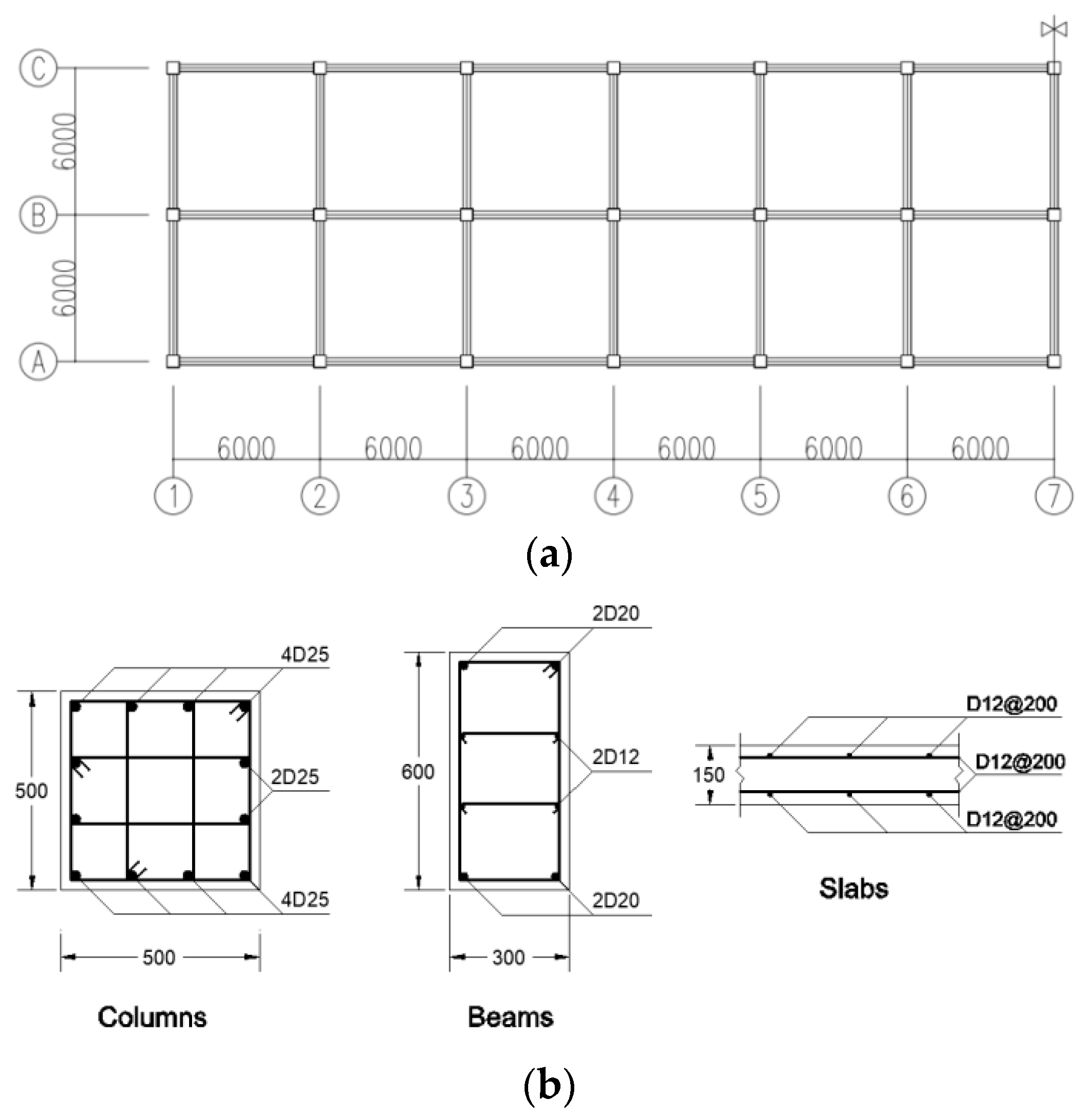

3.1. Structural Model Design

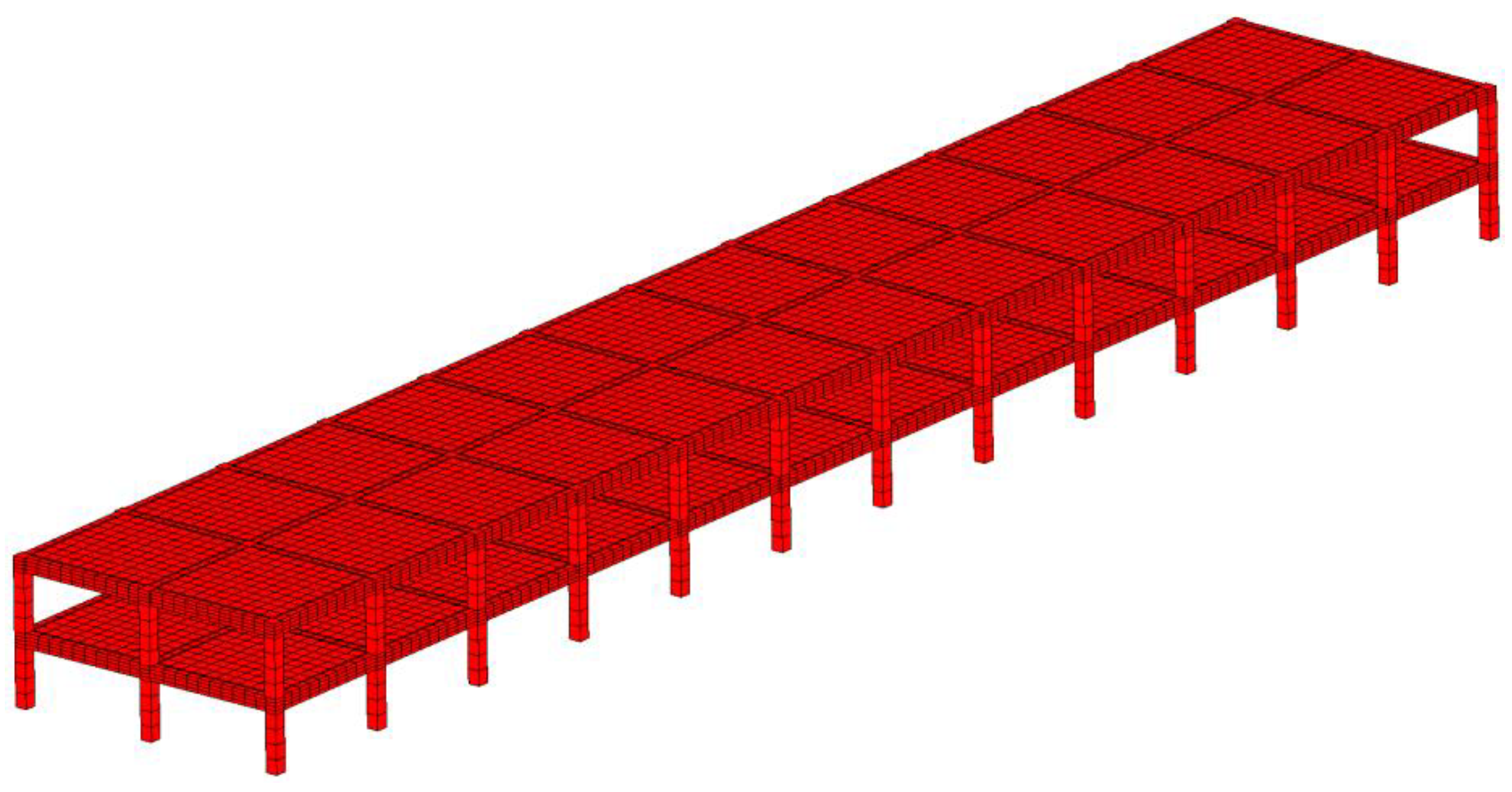

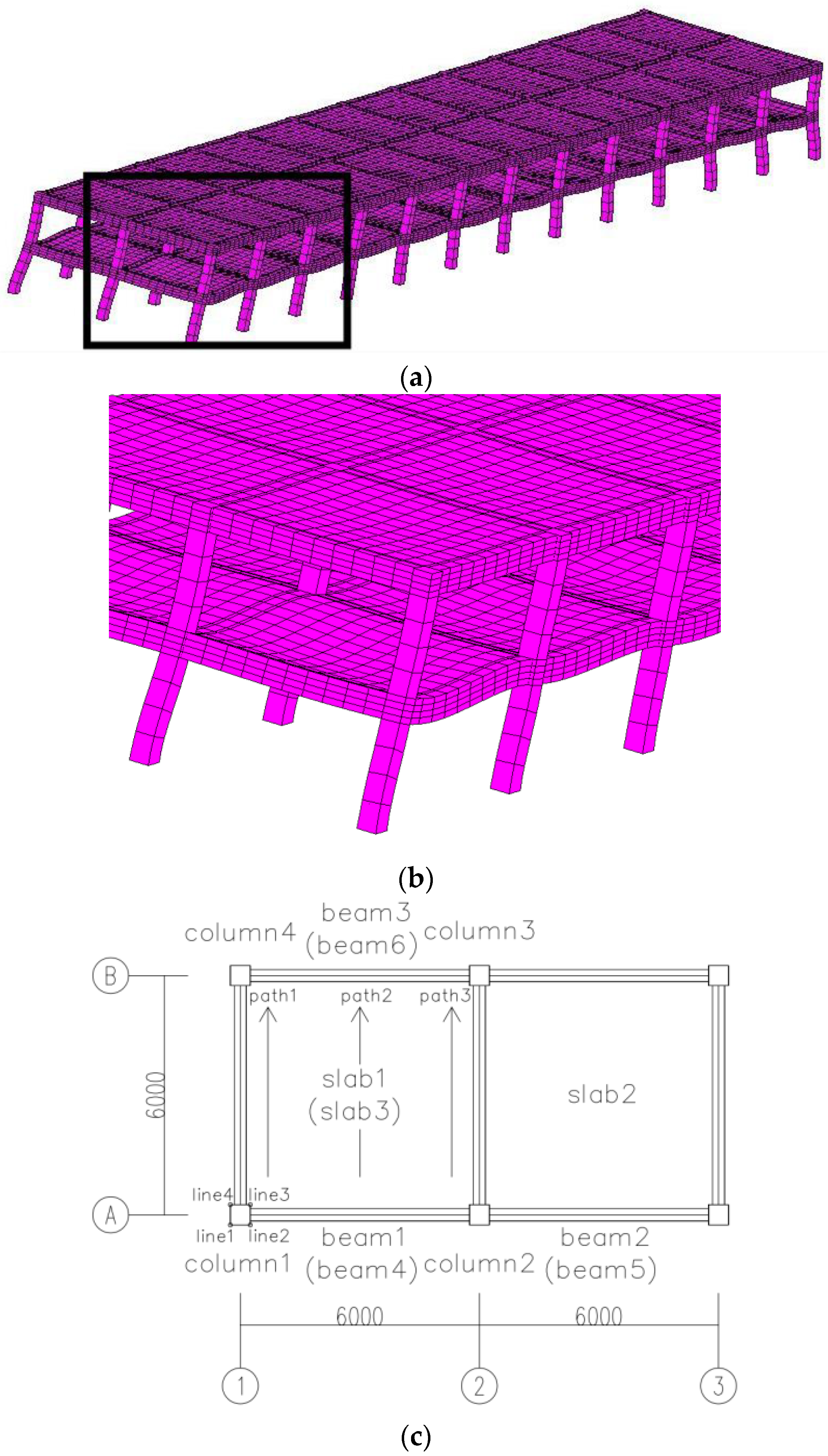

3.2. Modeling and Simulated Analysis

4. Calculation Results and Analysis

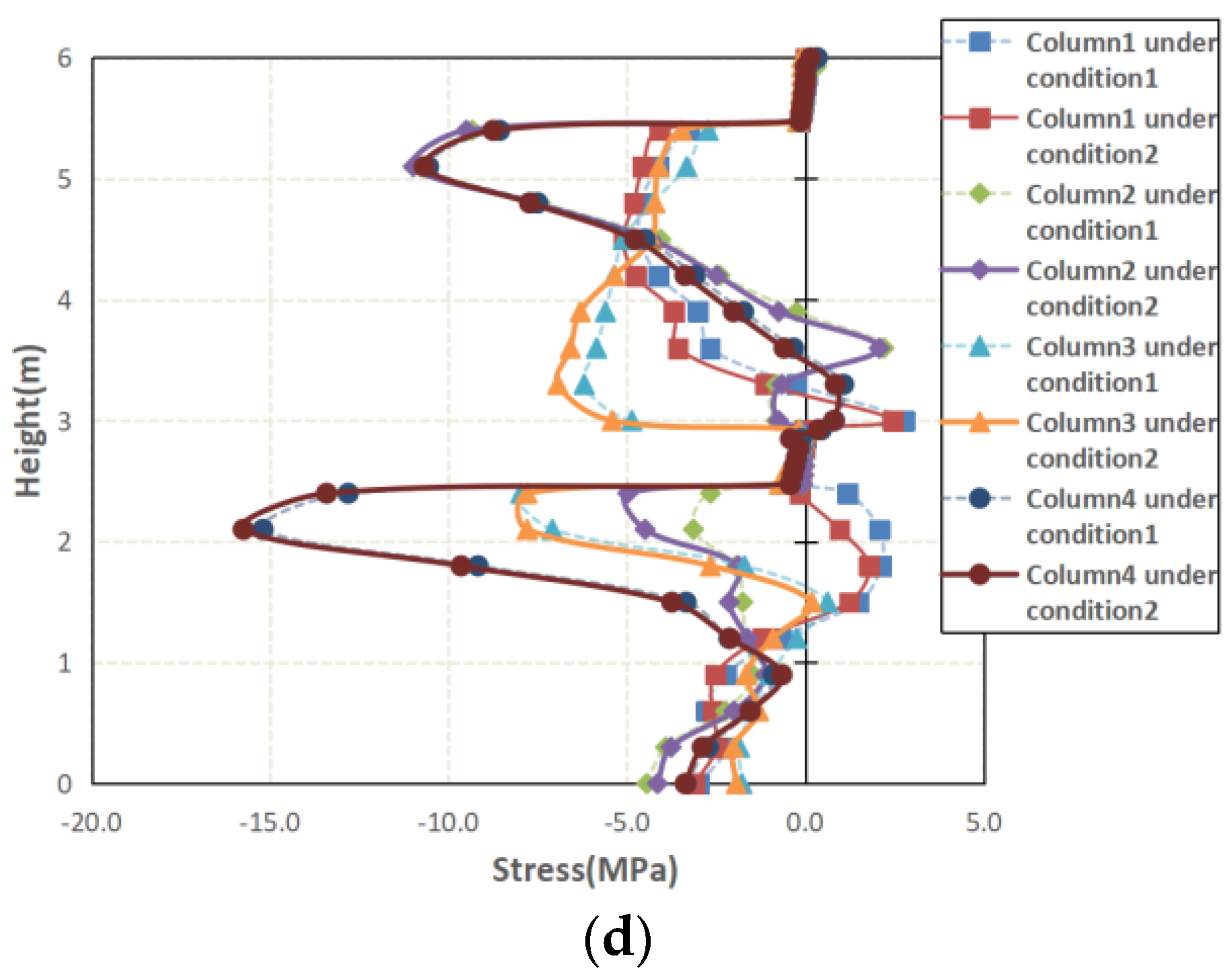

4.1. Temperature Stress Analysis of Columns

4.2. Temperature Stress Analysis of Beams

4.3. Temperature Stress Analysis of Slabs

5. Conclusions

- (1)

- In the temperature stress analysis of the super-long frame structure under uniform cooling at 30 °C, the difference in linear expansion coefficients of steel and concrete can lead to variable stress differences in the analysis of members and due to their position in the structure.

- (2)

- Under influence of the difference in the linear expansion coefficients of steel and concrete, a larger tensile stress difference appears in the columns and beams of the second layer compared to those the first layer, due to the weakening of constraints, and this adversely affects attempts to avoid concrete cracking.

- (3)

- Compared to the columns and beams, the slabs are more affected by the difference in linear expansion coefficients of steel and concrete, which can increase the tensile stress and even turn the stress from compressive to tensile in the corners of the slabs, such that the corners of the slabs are more likely to crack than the center and the edge.

- (4)

- The difference in linear expansion coefficients of steel and concrete can cause internal restraint in the super-long frame structure and variation in the temperature stress difference for members in the structure with different constraints, which adversely affects attempts to avoid structure cracking. Therefore, the difference in linear expansion coefficients of steel and concrete should be seriously considered during the analysis and design of super-long frame structures.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Saetta, A.; Scotta, R.; Vitaliani, R. Stress Analysis of Concrete Structures Subjected to Variable Thermal Loads. J. Struct. Eng. 1995, 121, 446–457. [Google Scholar] [CrossRef]

- Zeng, D.M. Finite element analysis and design study of temperature effect on super-long structure of a cold storage building. Build. Struct. 2020, 50, 224–229. [Google Scholar]

- Fan, Z.; Chen, W.; Li, X.; Chai, L.N.; Ge, H.B.; Huang, J.F. Study on temperature effect of super long frame structures. J. Build. Struct. 2018, 39, 136–145. [Google Scholar]

- Zhao, N.; Ma, K. Temperature Stress Analysis and Control Practice on a Long Span Concrete Structure. Struct. Eng. 2013, 29, 14–18. [Google Scholar]

- Hua, D.; Wu, J.; Gan, G. Analysis and engineering practice of temperature stress on super-long concrete structures. Build. Struct. 2012, 42, 56–59. [Google Scholar]

- Lei, J.S.; Yang, D.S.; Ying, S.C.; Zou, Y.S. Influence of Temperature on the Cracking of Reinforced Concrete Frame. Key Eng. Mater. 2008, 400, 963–968. [Google Scholar] [CrossRef]

- Yu, D.; Liu, Y.K. Deformation analysis of overlong isolated buildings due to temperature and shrinkage effects. Build. Struct. 2013, 13, 42–45. [Google Scholar]

- Shi, N.N.; Zhang, R.X.; Huang, D.H. Research on Temperature Stress of Annular Super-Long Frame Structure by Finite Element Method. Adv. Mater. Res. 2013, 639, 1200–1205. [Google Scholar]

- Yang, Z.Y.; Zhao, L.; Zhang, P.; Xing, Y.X. Thermal stress analyses and reinforcement design of massive RC structures. Eur. J. Environ. Civ. Eng. 2015, 19, 901–916. [Google Scholar]

- Fojtík, R.; Cajka, R. Thermal changes of the environment and their influence on reinforced concrete structures. IOP Conf. Ser. Earth Environ. Sci. 2018, 143, 012007. [Google Scholar] [CrossRef]

- Zhang, Y.M.; Zhao, Y.F.; Song, Y.P. Stress analysis of reinforced concrete’s axial tension component under action of thermal difference. Concrete 2004, 8, 19–21. [Google Scholar]

- Wang, T.M. Crack Control of Buildings; Shanghai Science Press: Shanghai, China, 1987. [Google Scholar]

- Long, B.H.; Li, S.J.; Peng, S.M. Measurement of thermal stress of concrete member with difference in thermal coefficients between steel and concrete. J. Test Meas. Tech. 1998, 12, 417–422. [Google Scholar]

- Long, B.H.; Li, S.J.; Sun, Y.; Peng, S.M. Experimental Research on Thermal Stress of RC Members with Difference in Linear Expansion Coefficients between Steel and Concrete. J. Build. Struct. 1999, 20, 54–58. [Google Scholar]

- Wu, S.X.; Ni, J.; Kang, Q.L.; Zhou, D. Experimental Study and Nonlinear Analysis of RC Frame Structure Subjected to Thermal Action. J. Ho Hai Univ. 1997, 25, 37–42. [Google Scholar]

- Gong, C.S.; Li, G.Z. Temperature Stresses in Reinforced Concrete Hydraulic Structure due to Differential Linear Expansion Coefficients. Des. Hydroelectr. Power Stn. 2004, 20, 58–62. [Google Scholar]

- GB 50010. Code for Design of Concrete Structures; China Architecture & Building Press: Beijing, China, 2010. [Google Scholar]

- Xu, X.; Guo, Y.M.; Shen, Y.X. Nonlinear Finite Element and Program Design; Zhejiang University Press: Hangzhou, China, 1993. [Google Scholar]

- Wang, X.C.; Shao, M. Fundamental Principles and Numerical Methods of Finite Element Method; Tsinghua University Press: Beijing, China, 1995. [Google Scholar]

- Chen, H.F.; Sarip, A.F. Constitutive Equation of Concrete and Soil; Yu, T., Wang, X., Liu, X., Eds.; China Building Industry Press: Beijing, China, 2004. [Google Scholar]

- Gan, G.; Li, Z.L.; Tang, J.C. Nonlinear research on temperature stress of over-long frame structure. J. Eng. Des. 2004, 11, 37–42. [Google Scholar]

- Chen, J.Y.; Zou, D.Q.; Gan, G. Analysis on temperature stress of super-long frame structure with temperature lag taken into account. Ind. Constr. 2007, 13, 39–43, 84. [Google Scholar]

| Reinforcement Ratio (%) | Elongation per Unit (10−4) | Reinforcement Stress (Mpa) | |||||

|---|---|---|---|---|---|---|---|

| 20 °C | 40 °C | 60 °C | 20 °C | 40 °C | 60 °C | ||

| Test data | 2.18 | 2.0352 | 4.1300 | 6.2550 | −6.8323 | −13.6646 | −20.4968 |

| 1.4 | 2.0260 | 4.0630 | 6.2220 | −7.2088 | −14.4175 | −21.6263 | |

| FEM | 2.18 | 2.0827 | 4.1657 | 6.2519 | −6.4341 | −12.8680 | −19.2710 |

| 1.4 | 2.0582 | 4.1165 | 6.1752 | −6.9189 | −13.8380 | −20.7570 | |

| Ratio(%) | 2.18 | 2.34 | 0.86 | −0.05 | −5.83 | −5.83 | −5.98 |

| 1.4 | 1.59 | 1.32 | −0.75 | −4.02 | −4.02 | −4.02 | |

| Concrete (C35) | |

| Density (ρc) | 2600 kg·m−3 |

| Poisson’s ratio (νc) | 0.2 |

| Yong’s modulus (Ec) | 31.5 GPa |

| Aver. comp. strength (fck) | 23.4 MPa |

| Aver. tensile strength (fctk) | 2.2 MPa |

| Linear expansion coefficient (αc) | 0.00001 °C−1 |

| Steel (HRB400) | |

| Density (ρs) | 7800 kg·m−3 |

| Poisson’s ratio (νs) | 0.3 |

| Yong’s modulus (Es) | 200 GPa |

| Aver. yield strength (fsyk) | 400 MPa |

| Linear expansion coefficient (αs) | 0.000012 °C−1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jia, Y.; Lu, L.; Wu, G.; Zhang, B.; Wang, H. Temperature Stress Analysis of Super-Long Frame Structures Accounting for Differences in the Linear Expansion Coefficients of Steel and Concrete. Processes 2021, 9, 1519. https://doi.org/10.3390/pr9091519

Jia Y, Lu L, Wu G, Zhang B, Wang H. Temperature Stress Analysis of Super-Long Frame Structures Accounting for Differences in the Linear Expansion Coefficients of Steel and Concrete. Processes. 2021; 9(9):1519. https://doi.org/10.3390/pr9091519

Chicago/Turabian StyleJia, Yigang, Liangjian Lu, Guangyu Wu, Bo Zhang, and Huibin Wang. 2021. "Temperature Stress Analysis of Super-Long Frame Structures Accounting for Differences in the Linear Expansion Coefficients of Steel and Concrete" Processes 9, no. 9: 1519. https://doi.org/10.3390/pr9091519

APA StyleJia, Y., Lu, L., Wu, G., Zhang, B., & Wang, H. (2021). Temperature Stress Analysis of Super-Long Frame Structures Accounting for Differences in the Linear Expansion Coefficients of Steel and Concrete. Processes, 9(9), 1519. https://doi.org/10.3390/pr9091519