Bispacer Multi-Stage Direct Contact Membrane Distillation System: Analytical and Experimental Study

Abstract

1. Introduction

2. Analytical Approach

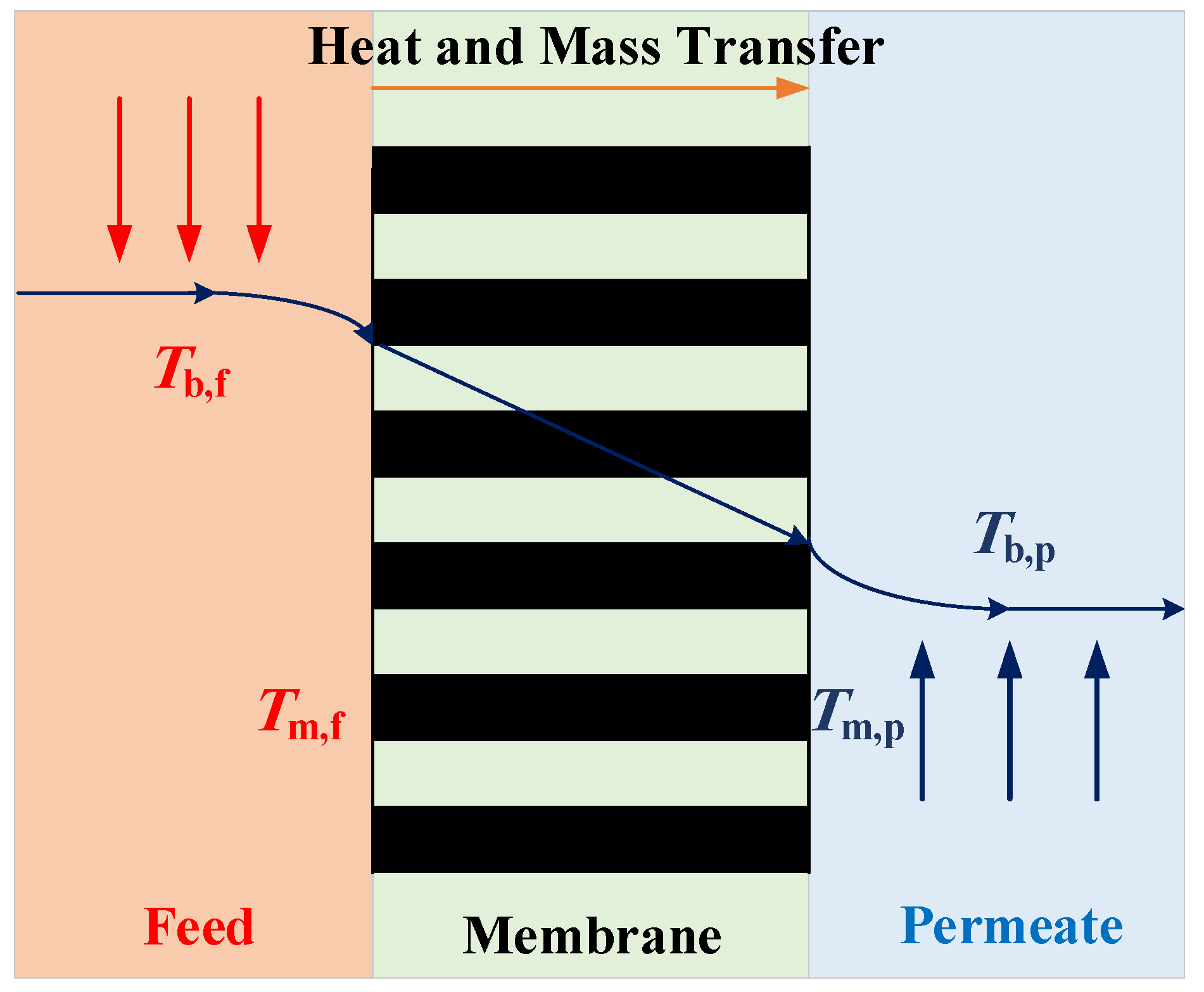

2.1. Heat Transfer Model

2.1.1. Heat Transfer: The Feed Stream to the Membrane Boundary Layer

2.1.2. Heat Transfer: Through the Membrane

2.1.3. Heat Transfer: The Membrane Surface to the Permeate Stream

2.1.4. Conservation Energy

2.2. Mass Transfer Model

2.3. MDCMD Module Efficiency

2.3.1. Thermal Efficiency

2.3.2. Gained Output Ratio (GOR)

2.3.3. Temperature Polarization Coefficient (TPC)

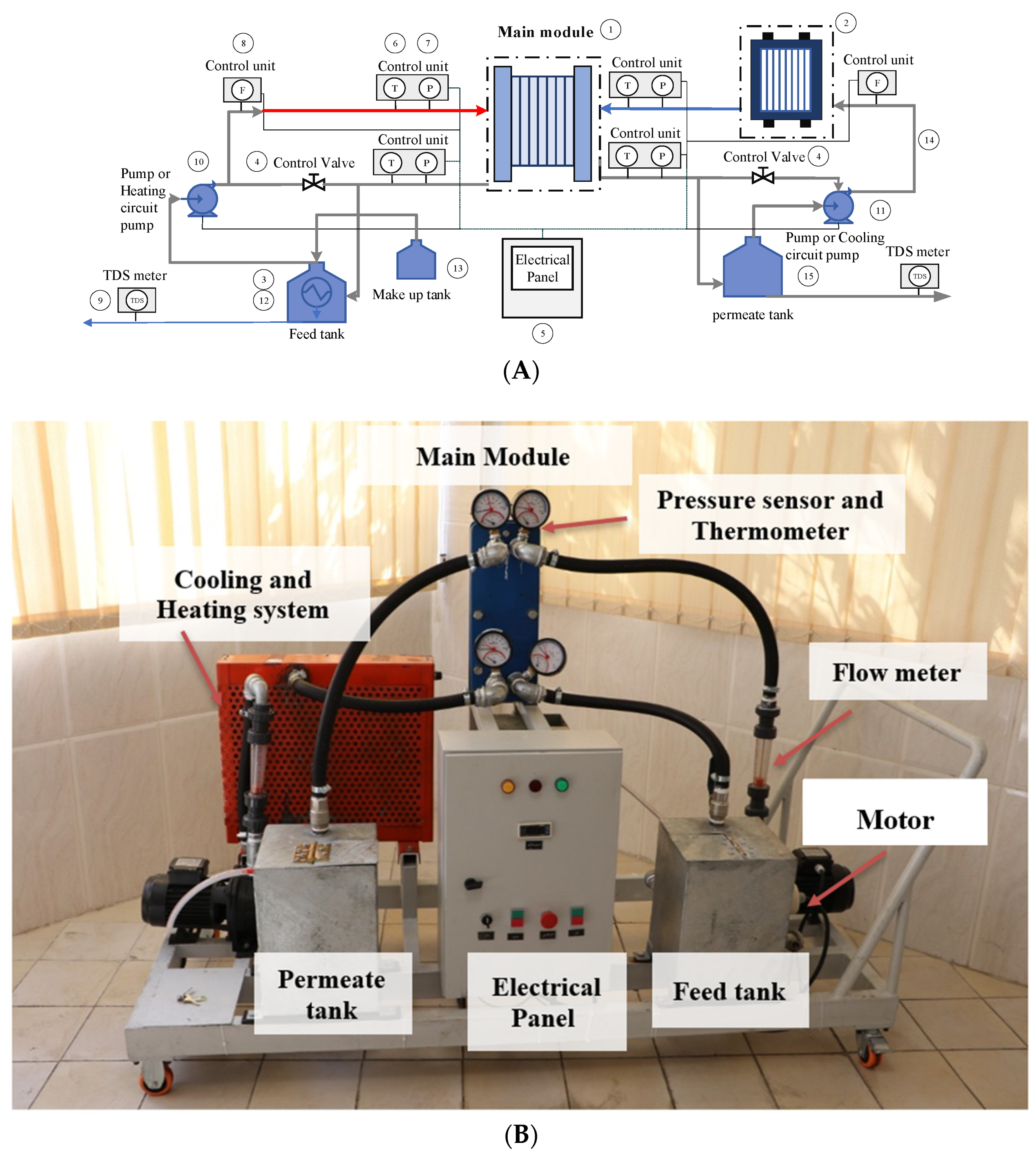

3. Materials and Methods

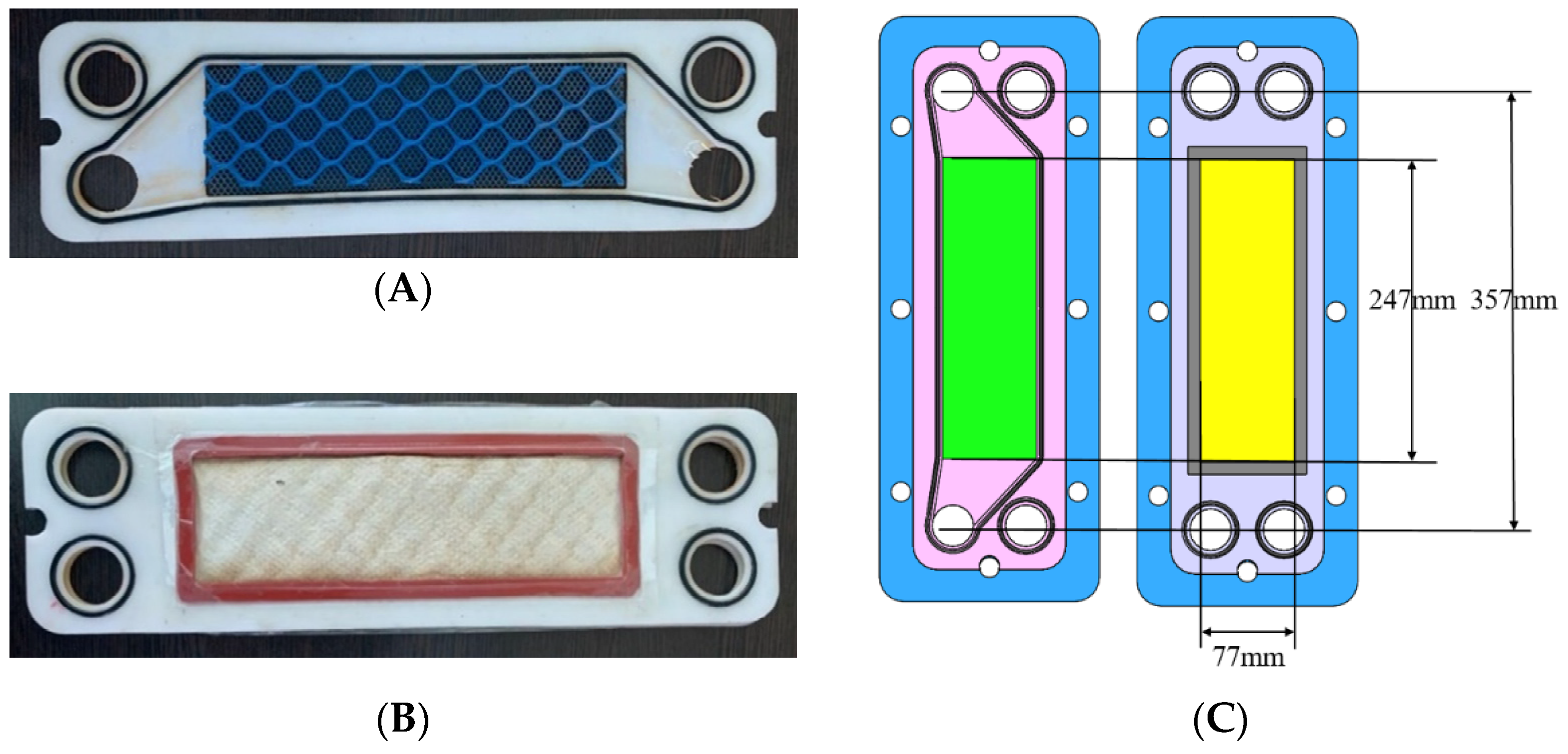

3.1. Membrane and Membrane Module

3.2. Experimental Procedure and Set Up

4. Results and Discussion

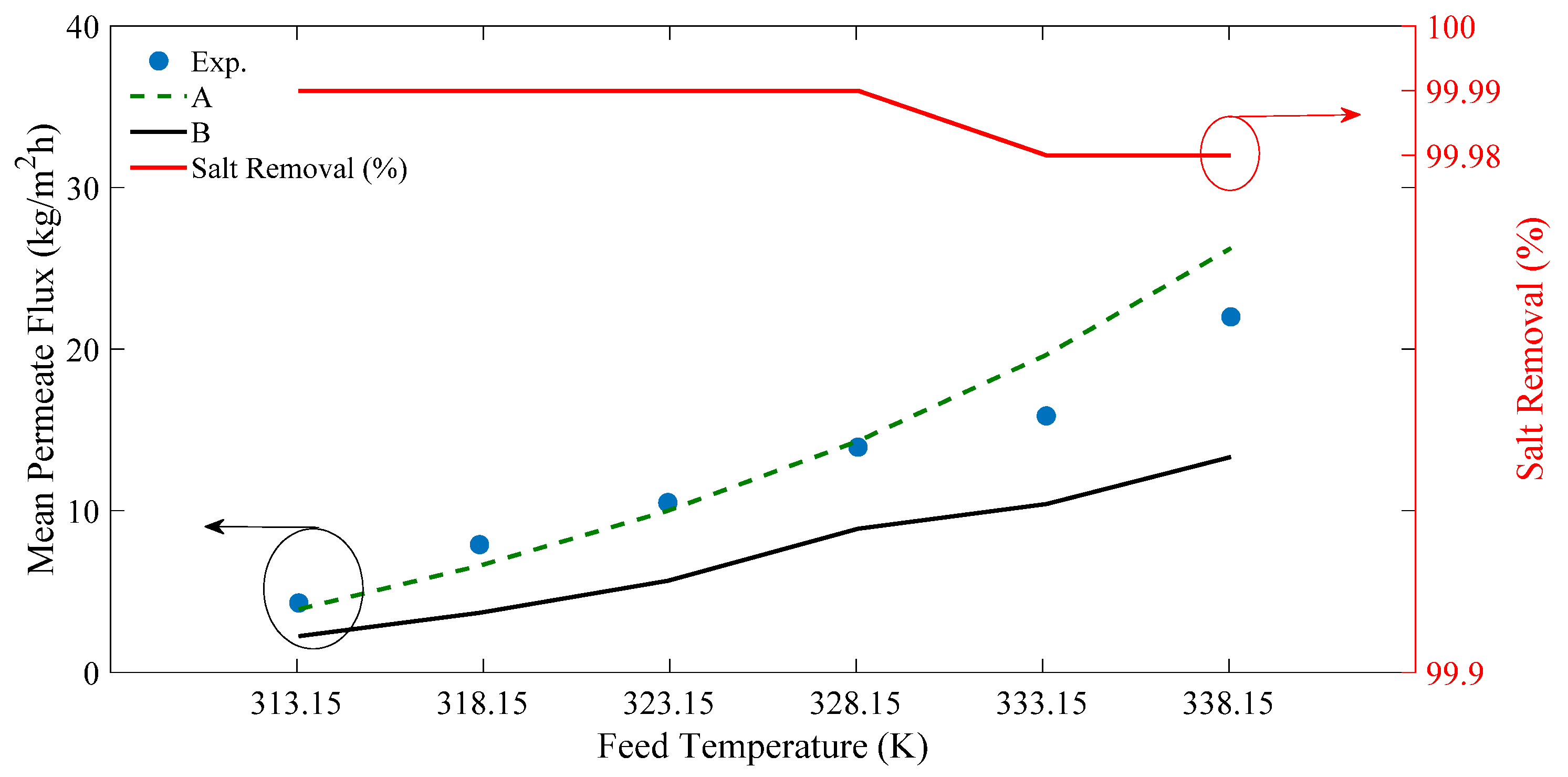

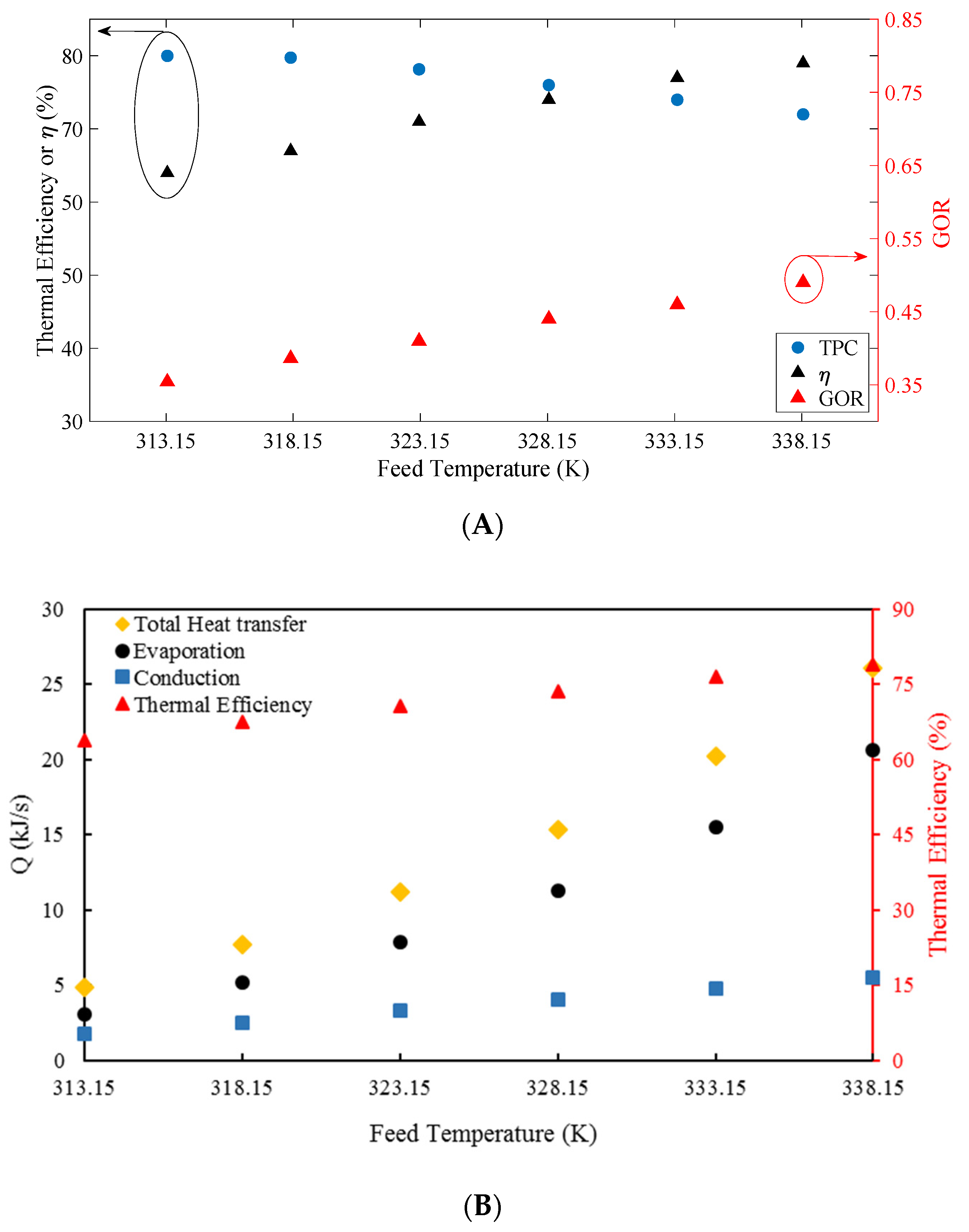

4.1. Effect of Feed Temperature

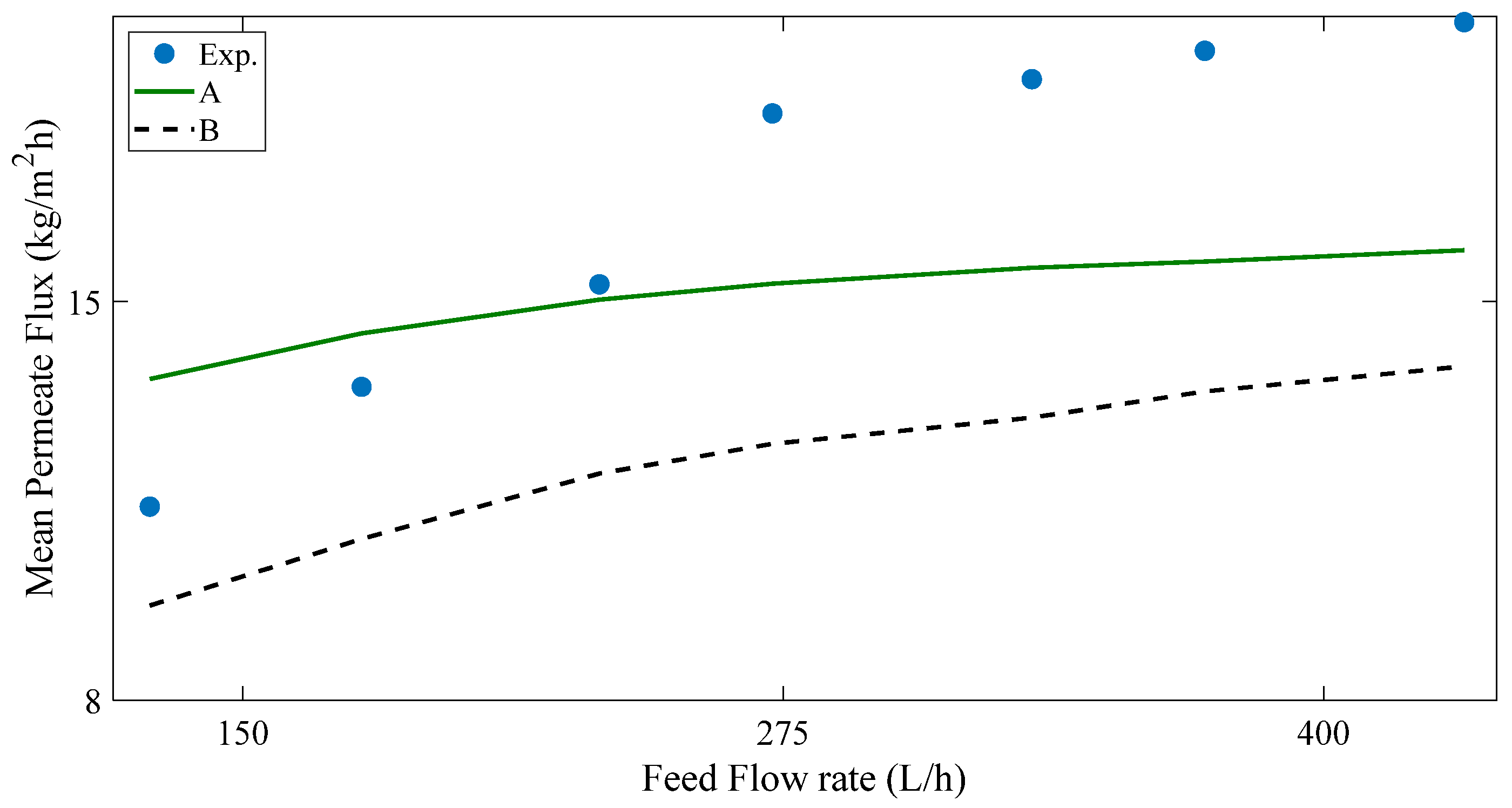

4.2. Effect of Feed Flow Rate

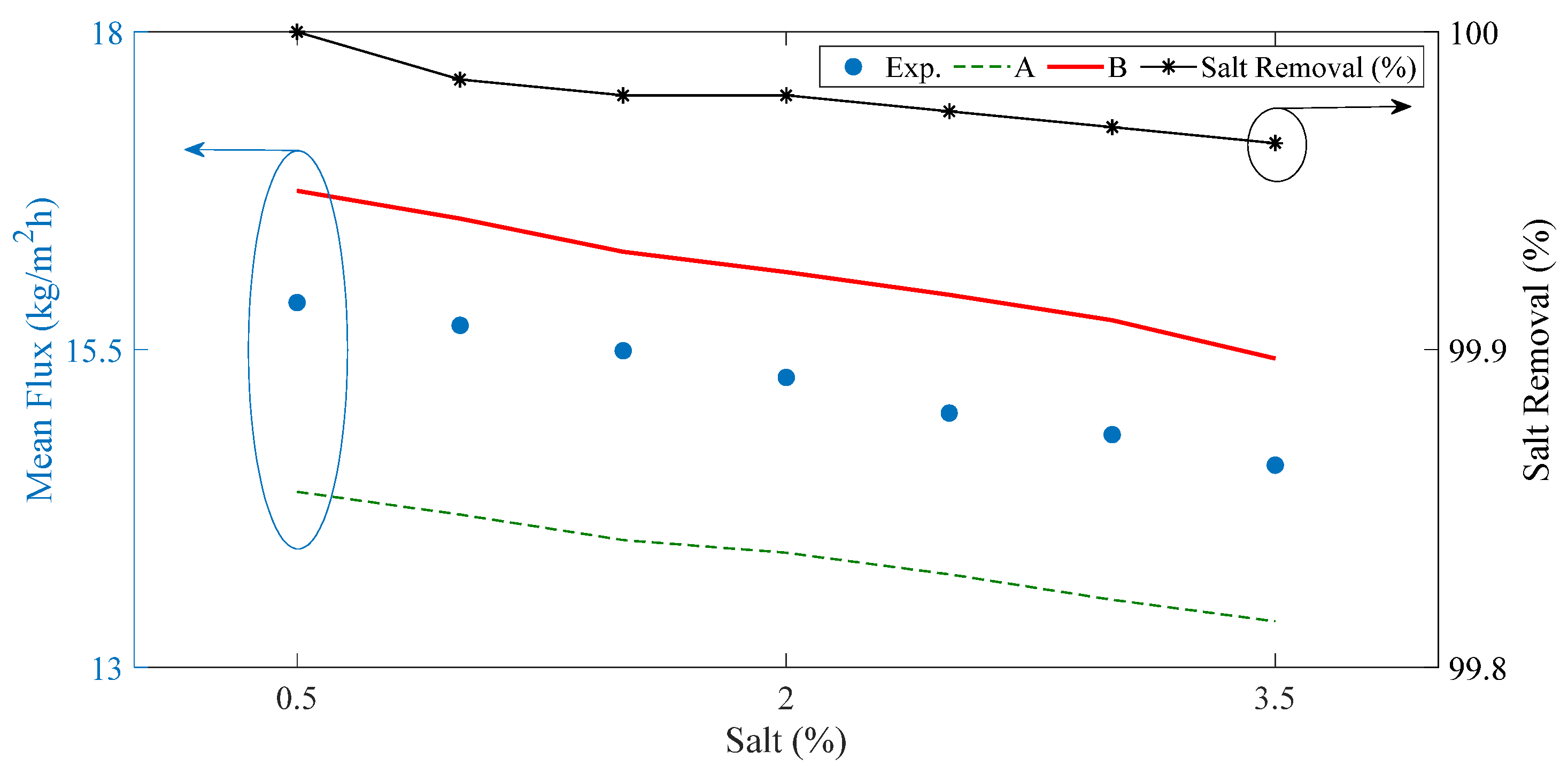

4.3. Effect of Feed Salinity

4.4. Effect of Number of Stages

4.5. The Efficiency

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Parameter | Definition | Unit |

| P | Mean vapor pressure of the membrane | Pa |

| Pa | Entrapped air pressure | Pa |

| P0 | Vapor pressure of pure water | Pa |

| P1 | Vapor pressure at feed membrane surface | Pa |

| P2 | Vapor pressure at permeates membrane surface | Pa |

| Pr | Prandtl number | - |

| Q | Heat flux | W/m2 |

| R | Gas constant | J/kg·K |

| Re | Reynolds number | - |

| S | Mean free path of the transferred gas molecule | m |

| Tb,f | Bulk feed side temperature | K |

| Tb,p | Bulk permeate side temperature | K |

| Tp,f | Temperature at the hot membrane surface | K |

| Tm,p | Temperature at cold membrane surface | K |

| U | The overall heat transfer through the membrane | W/m2·K |

| Χw | Weight fraction of water | - |

| XNaCl | Weight fraction of NaCl | - |

| δ | Membrane thickness | m |

| ε | Membrane porosity | % |

| μ | Kinematic viscosity | Pa·s |

| ν | Dynamic viscosity | Pa·s |

| τ | Membrane tortuosity | - |

| γ | Coefficient of activity | - |

| ρ | Density | Kg/m3 |

| TPC | Thermal polarization coefficient | - |

| qSTEC | Specific thermal energy consumption | J·s/m3 |

| η | Thermal efficiency | - |

| aw | Activity of water | - |

| Cm | Membrane mass flux coefficient | kg/m2·Pa·h |

| cp | Specific heat coefficient | J/kg·K |

| D | Diffusion coefficient | - |

| de | Collision diameter of the water vapor and air | m |

| dh | Hydraulic diameter in empty channel | m |

| dhs | Hydraulic diameter in spacer-filled channel | m |

| dp | Membrane pore diameter | m |

| GOR | Gained output ratio | - |

| hf | Heat transfer coefficient at feed side | W/m2·K |

| hm | Heat transfer coefficient of the membrane | W/m2·K |

| hp | Heat transfer coefficient at permeate side | W/m2·K |

| Hv | Vaporization enthalpy of water at the mean temperature | kJ/kg |

| J | Total mass flux of the membrane | kg/m2·h |

| k | Thermal conductivity of fluid | W/m·k |

| kB | Boltzmann constant | J/K |

| kg | Vapor–air heat transfer coefficient | W/m·k |

| km | Membrane heat transfer coefficient | W/m·k |

| kn | Knudsen number | |

| ks | PTFE heat transfer coefficient | W/m·k |

| L | Channel length | m |

| lm | Mesh size | m |

| LMTD | Log mean temperature coefficient | K |

| M | Molecular weight | kg/mole |

| Nu | Nusselt number | - |

| Tb,f,in | Inlet hot feed temperatures | K |

| Tb,f,out | Outlet hot feed temperatures | K |

Appendix A

Appendix B

| Run | Feed Temperature (K) | FluxExp. (kg/m2 h) | FluxTh. (kg/m2 h) | Error % | ||

|---|---|---|---|---|---|---|

| A | B | A | B | |||

| 1 | 313.15 | 4.3 | 3.9 | 2.13 | 9.3 | 50.46 |

| 2 | 318.15 | 7.9 | 6.62 | 3.67 | 16.2 | 53.54 |

| 3 | 323.15 | 10.5 | 9.63 | 5.51 | 8.28 | 47.52 |

| 4 | 328.15 | 13.93 | 13.82 | 8.67 | 0.79 | 37.76 |

| 5 | 333.15 | 15.87 | 19.19 | 10.22 | 20.92 | 35.6 |

| 6 | 338.15 | 22 | 25.88 | 12.79 | 17.64 | 41.86 |

| Run | Feed Flow Rate (L/h) | FluxExp. (kg/m2 h) | FluxThe. (kg/m2 h) | Error % | ||

|---|---|---|---|---|---|---|

| A | B | A | B | |||

| 1 | 125 | 11.4 | 13.64 | 9.66 | 19.64 | 15.26 |

| 2 | 175 | 13.5 | 14.44 | 10.83 | 6.9 | 19.77 |

| 3 | 235 | 15.3 | 15.03 | 11.98 | 1.7 | 21.7 |

| 4 | 275 | 17.2 | 15.31 | 12.5 | 10.99 | 27.32 |

| 5 | 325 | 18.9 | 15.59 | 12.96 | 17.51 | 31.42 |

| 6 | 375 | 19.4 | 15.7 | 13.42 | 19.07 | 30.82 |

| 7 | 435 | 19.9 | 15.9 | 13.86 | 20.1 | 30.35 |

| Salt (%) | FluxExp. (kg/m2 h) | FluxTh. | Error % | ||

|---|---|---|---|---|---|

| A | B | A | B | ||

| 0.5 | 15.87 | 14.57 | 7.98 | 8.19 | 49.71 |

| 1 | 15.69 | 14.4 | 7.89 | 8.22 | 49.71 |

| 1.5 | 15.49 | 14.22 | 7.79 | 8.19 | 49.71 |

| 2 | 15.28 | 14.04 | 7.69 | 8.11 | 49.67 |

| 2.5 | 15.00 | 13.83 | 7.58 | 7.8 | 49.46 |

| 3 | 14.83 | 13.63 | 7.46 | 8.09 | 49.69 |

References

- Negewo, B.D. Renewable Energy Desalination: An Emerging Solution to Close the Water Gap in the Middle East and North Africa; World Bank Publications: Washington, DC, USA, 2012. [Google Scholar]

- Ali, A.; Macedonio, F.; Drioli, E.; Aljlil, S.; Alharbi, O. Experimental and theoretical evaluation of temperature polarization phenomenon in direct contact membrane distillation. Chem. Eng. Res. Design 2013, 91, 1966–1977. [Google Scholar] [CrossRef]

- Mahmoudi, F.; Goodarzi, G.M.; Dehghani, S.; Akbarzadeh, A. Experimental and theoretical study of a lab scale permeate gap membrane distillation setup for desalination. Desalination 2017, 419, 197–210. [Google Scholar] [CrossRef]

- Tomaszewska, M. Membrane distillation-examples of applications in technology and environmental protection. Pol. J. Environ. Stud. 2000, 9, 27–36. [Google Scholar]

- García-Payo, M.; Izquierdo-Gil, M.A.; Fernández-Pineda, C. Air gap membrane distillation of aqueous alcohol solutions. J. Membr. Sci. 2000, 169, 61–80. [Google Scholar] [CrossRef]

- Ali, E.; Orfi, J.; Najib, A. Assessing the thermal efficiency of brackish water desalination by membrane distillation using exergy analysis. Arab. J. Sci. Eng. 2018, 43, 2413–2424. [Google Scholar] [CrossRef]

- Zhao, K.; Heinzl, W.; Wenzel, M.; Büttner, S.; Bollen, F.; Lange, G.; Heinzl, S.; Sarda, N. Experimental study of the memsys vacuum-multi-effect-membrane-distillation (V-MEMD) module. Desalination 2013, 323, 150–160. [Google Scholar] [CrossRef]

- Andrés-Mañas, J.; Ruiz-Aguirre, A.; Acién, F.; Zaragoza, G. Performance increase of membrane distillation pilot scale modules operating in vacuum-enhanced air-gap configuration. Desalination 2020, 475, 114202. [Google Scholar] [CrossRef]

- Alkhudhiri, A.; Darwish, N.; Hilal, N. Membrane distillation: A comprehensive review. Desalination 2012, 287, 2–18. [Google Scholar] [CrossRef]

- Khayet, M. Membranes and theoretical modeling of membrane distillation: A review. Adv. Colloid Interface Sci. 2011, 164, 56–88. [Google Scholar] [CrossRef]

- Manawi, Y.M.; Khraisheh, M.; Fard, A.K.; Benyahia, F.; Adham, S. Effect of operational parameters on distillate flux in direct contact membrane distillation (DCMD): Comparison between experimental and model predicted performance. Desalination 2014, 336, 110–120. [Google Scholar] [CrossRef]

- Khalifa, A.; Ahmad, H.; Antar, M.; Laoui, T.; Khayet, M. Experimental and theoretical investigations on water desalination using direct contact membrane distillation. Desalination 2017, 404, 22–34. [Google Scholar] [CrossRef]

- Zhang, J.; Gray, S. Modelling heat and mass transfers in DCMD using compressible membranes. J. Membr. Sci. 2012, 387, 7–16. [Google Scholar] [CrossRef]

- Ve, Q.L.; Rahaoui, K.; Bawahab, M.; Faqeha, H.; Date, A.; Akbarzadeh, A.; Do, M.C.; Nguyen, Q.L. Experimental investigation of heat transfer correlation for direct contact membrane distillation. J. Heat Transf. 2020, 142, 012001. [Google Scholar] [CrossRef]

- Ve, Q.L.; Koirala, R.; Bawahab, M.; Faqeha, H.; Do, M.C.; Nguyen, Q.L.; Date, A.; Akbarzadeh, A. Experimental investigation of the effect of the spacer and operating conditions on mass transfer in direct contact membrane distillation. Desalination 2020, 114839. [Google Scholar] [CrossRef]

- Alsaadi, A.S.; Ghaffour, N.; Li, J.-D.; Gray, S.; Francis, L.; Maab, H.; Amy, G.L. Modeling of air-gap membrane distillation process: A theoretical and experimental study. J. Membr. Sci. 2013, 445, 53–65. [Google Scholar] [CrossRef]

- Ameen, N.A.M.; Ibrahim, S.S.; Alsalhy, Q.F.; Figoli, A. Highly Saline Water Desalination Using Direct Contact Membrane Distillation (DCMD): Experimental and Simulation Study. Water 2020, 12, 1575. [Google Scholar] [CrossRef]

- Wang, P.; Chung, T.-S. Recent advances in membrane distillation processes: Membrane development, configuration design and application exploring. J. Membr. Sci. 2015, 474, 39–56. [Google Scholar] [CrossRef]

- Ibrahim, S.S.; Alsalhy, Q.F. Modeling and simulation for direct contact membrane distillation in hollow fiber modules. AIChE J. 2013, 59, 589–603. [Google Scholar] [CrossRef]

- Janajreh, I.; Suwwan, D.; Hashaikeh, R. Assessment of direct contact membrane distillation under different configurations, velocities and membrane properties. Appl. Energy 2017, 185, 2058–2073. [Google Scholar] [CrossRef]

- Lawal, D.U.; Khalifa, A.E. Flux prediction in direct contact membrane distillation. Int. J. Mater. Mech. Manuf. 2014, 2, 302–308. [Google Scholar] [CrossRef][Green Version]

- Sanmartino, J.A.; Khayet, M.; García-Payo, M.; Hankins, N.; Singh, R. Desalination by Membrane Distillation; Elsevier: Amsterdam, The Netherlands, 2016. [Google Scholar]

- Das, S.K. General dusty gas model for porous media with a specified pore size distribution. Chem. Eng. Sci. 2019, 203, 293–301. [Google Scholar] [CrossRef]

- El-Bourawi, M.; Ding, Z.; Ma, R.; Khayet, M. A framework for better understanding membrane distillation separation process. J. Membr. Sci. 2006, 285, 4–29. [Google Scholar] [CrossRef]

- Essalhi, M.; Khayet, M. Self-sustained webs of polyvinylidene fluoride electrospun nanofibers at different electrospinning times: 2. Theoretical analysis, polarization effects and thermal efficiency. J. Membr. Sci. 2013, 433, 180–191. [Google Scholar] [CrossRef]

- Lawson, K.W.; Lloyd, D.R. Membrane distillation. J. Membr. Sci. 1997, 124, 1–25. [Google Scholar] [CrossRef]

- Chen, T.-C.; Ho, C.-D.; Yeh, H.-M. Theoretical modeling and experimental analysis of direct contact membrane distillation. J. Membr. Sci. 2009, 330, 279–287. [Google Scholar] [CrossRef]

- Duong, H.C.; Cooper, P.; Nelemans, B.; Cath, T.Y.; Nghiem, L.D. Optimising thermal efficiency of direct contact membrane distillation by brine recycling for small-scale seawater desalination. Desalination 2015, 374, 1–9. [Google Scholar] [CrossRef]

- Criscuoli, A. Improvement of the Membrane Distillation performance through the integration of different configurations. Chem. Eng. Res. Des. 2016, 111, 316–322. [Google Scholar] [CrossRef]

- Burhan, M.; Shahzad, M.W.; Ybyraiymkul, D.; Oh, S.J.; Ghaffour, N.; Ng, K.C. Performance investigation of MEMSYS vacuum membrane distillation system in single effect and multi-effect mode. Sustain. Energy Technol. Assess. 2019, 34, 9–15. [Google Scholar] [CrossRef]

- Dutta, N.; Singh, B.; Subbiah, S.; Muthukumar, P. Performance analysis of a single and multi-staged direct contact membrane distillation module integrated with heat recovery units. Chem. Eng. J. Adv. 2020, 4, 100055. [Google Scholar] [CrossRef]

- Da Costa, A.R. Fluid Flow and Mass Transfer in Spacer-Filled Channels for Ultrafiltration; University of New South Wales: Kensington, Australia, 1993. [Google Scholar]

- Nakoa, K.; Rahaoui, K.; Date, A.; Akbarzadeh, A. An experimental review on coupling of solar pond with membrane distillation. Sol. Energy 2015, 119, 319–331. [Google Scholar] [CrossRef]

| Spacer Condition | With Spacer [14] | Without Spacer [19] | |

|---|---|---|---|

| Re | All domain | Re < 2100 | Re > 2500 |

| Nusselt number | |||

| Condition | Type of Flow Mechanism |

|---|---|

| kn < 0.01 | Molecular diffusion |

| 0.01 < kn < 1 | Knudsen-molecular diffusion |

| kn > 1 | Knudsen diffusion |

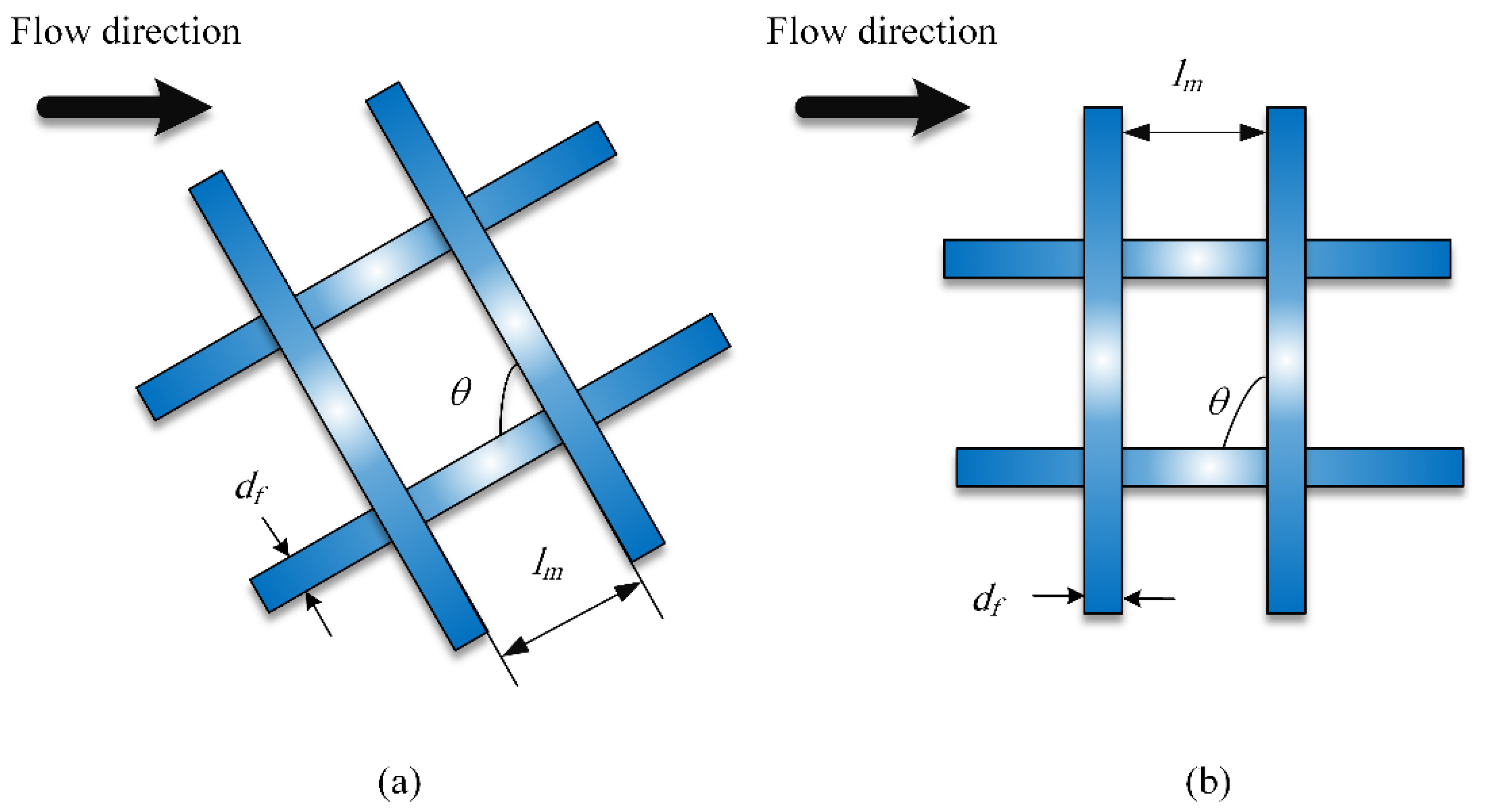

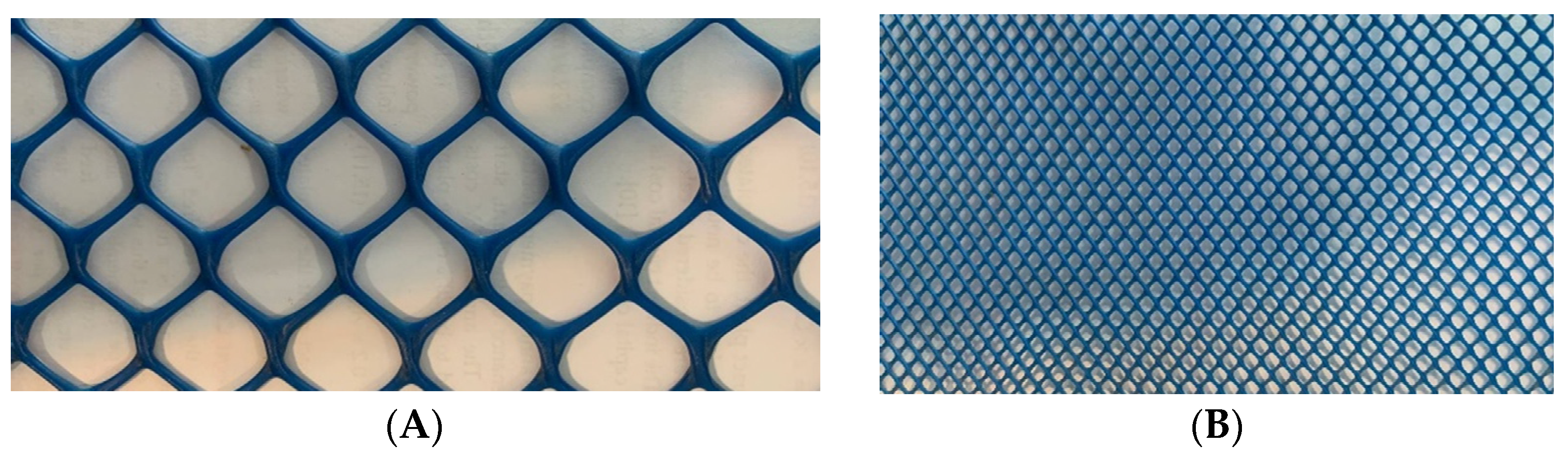

| Types of Spacer→ Properties↓ | 1 | 2 | Types of Spacer→ Properties↓ | 1 | 2 |

|---|---|---|---|---|---|

| Material | PP | PP | Angle between filaments (θ) (deg) | 90 | 90 |

| Thickness (ts) (mm) | 1.8 | 1.25 | Mesh size (lm) (mm) | 17.8 | 2.5 |

| Diameter of filament (df) (mm) | 1.8 | 0.625 |

| Number | Equipment | Number | Equipment |

|---|---|---|---|

| (1) | Main module | (9) | TDS meter |

| (2) | Air chiller | (10) | Heating pump |

| (3) | Element heater | (11) | Cooling pump |

| (4) | Control valve | (12) | Feed tank |

| (5) | Electrical panel | (13) | Make up tank |

| (6) | Thermometer | (14) | Piping |

| (7) | Pressure sensor | (15) | Permeate tank |

| (8) | Flow meter |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aliabadi, M.; Ghorashi, H.; Shokri Motlagh, S.; Nabavi, S.F.; Pakzad, S.A.; Farshidianfar, M.H.; Farshidianfar, A.; Mahmoudi, F.; Akbarzadeh, A. Bispacer Multi-Stage Direct Contact Membrane Distillation System: Analytical and Experimental Study. Processes 2021, 9, 1297. https://doi.org/10.3390/pr9081297

Aliabadi M, Ghorashi H, Shokri Motlagh S, Nabavi SF, Pakzad SA, Farshidianfar MH, Farshidianfar A, Mahmoudi F, Akbarzadeh A. Bispacer Multi-Stage Direct Contact Membrane Distillation System: Analytical and Experimental Study. Processes. 2021; 9(8):1297. https://doi.org/10.3390/pr9081297

Chicago/Turabian StyleAliabadi, Morteza, Hassan Ghorashi, Shamim Shokri Motlagh, Seyedeh Fatemeh Nabavi, Seyed Arash Pakzad, Mohamad Hossein Farshidianfar, Anooshiravan Farshidianfar, Farzaneh Mahmoudi, and Aliakbar Akbarzadeh. 2021. "Bispacer Multi-Stage Direct Contact Membrane Distillation System: Analytical and Experimental Study" Processes 9, no. 8: 1297. https://doi.org/10.3390/pr9081297

APA StyleAliabadi, M., Ghorashi, H., Shokri Motlagh, S., Nabavi, S. F., Pakzad, S. A., Farshidianfar, M. H., Farshidianfar, A., Mahmoudi, F., & Akbarzadeh, A. (2021). Bispacer Multi-Stage Direct Contact Membrane Distillation System: Analytical and Experimental Study. Processes, 9(8), 1297. https://doi.org/10.3390/pr9081297