Improvements of Micro-CHP SOFC System Operation by Efficient Dynamic Simulation Methods

Abstract

:1. Introduction

- Stationary grid-connected CHP systems in regions where space heating/cooling or domestic hot water production is required, especially introduced in European, Asian (Japanese), United States markets (heat-regulated mode);

- Stationary off-grid battery hybrid systems for power or combined heat and power generation in places without reliable access to electricity (electricity-regulated mode);

- Stationary grid-connected systems for power supply in the higher kW-class for industries or other (electricity-regulated mode);

- Mobile off-grid power generator for power supply and uninterrupted power supply (UPS).

2. Literature Review

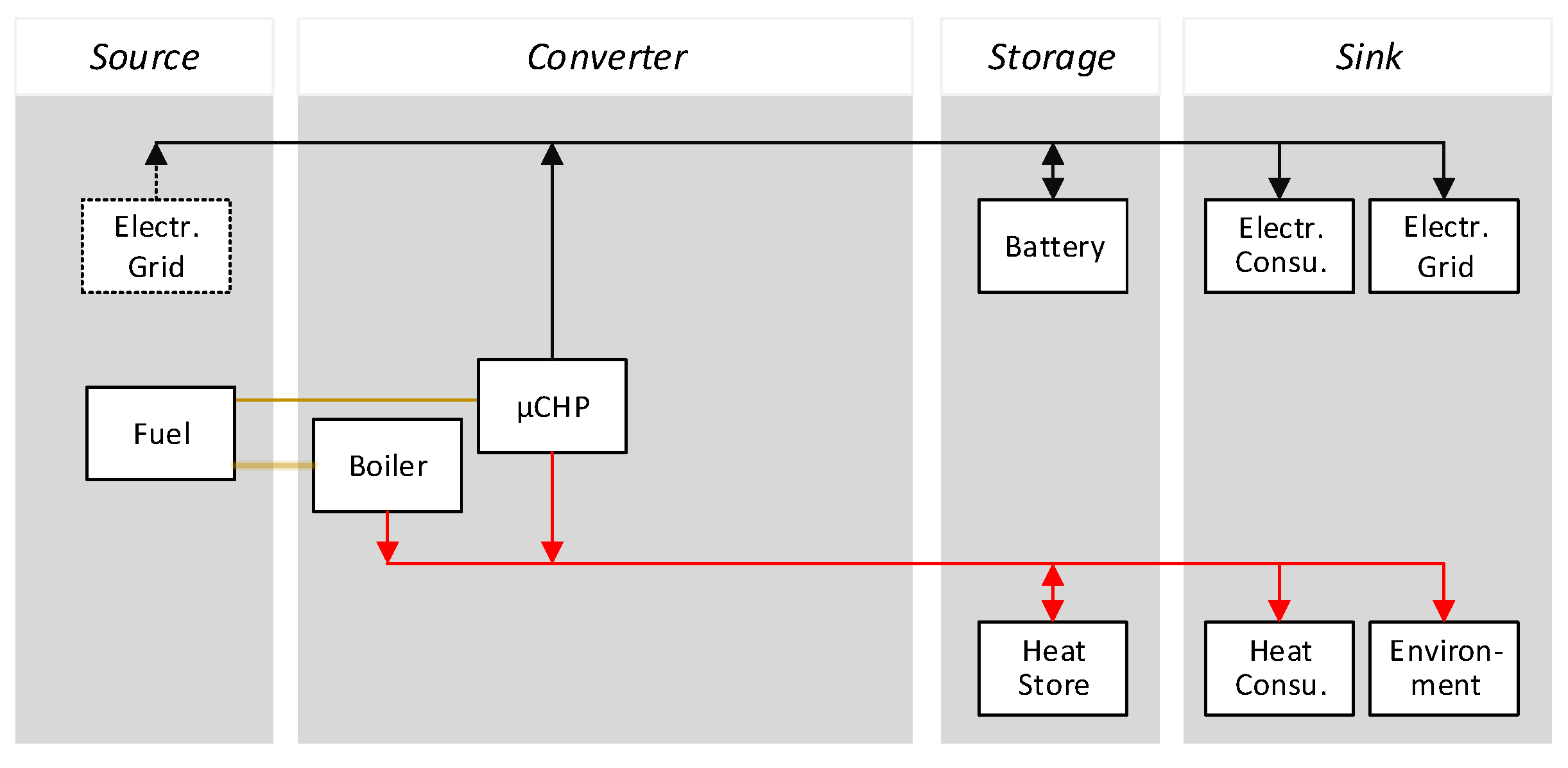

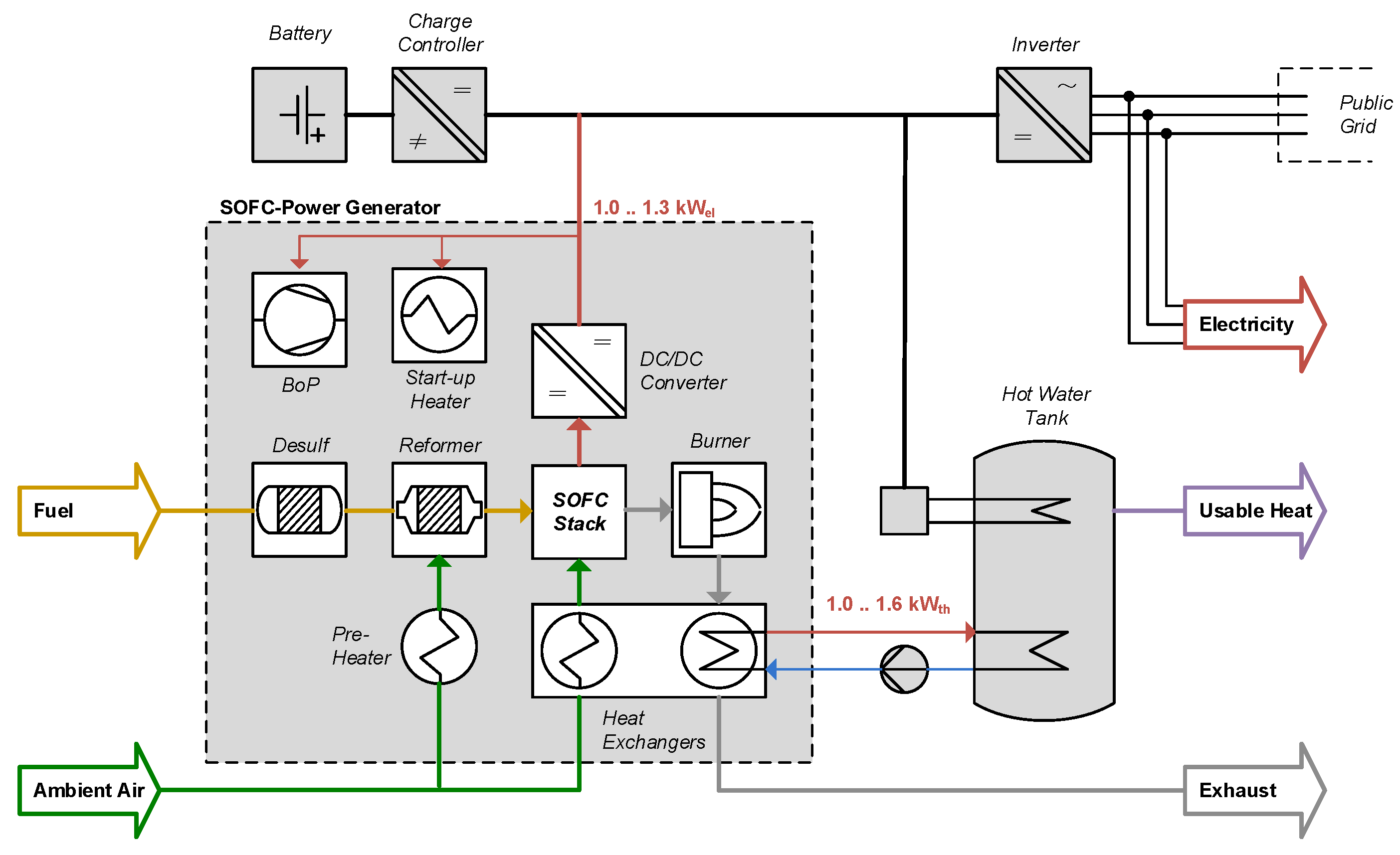

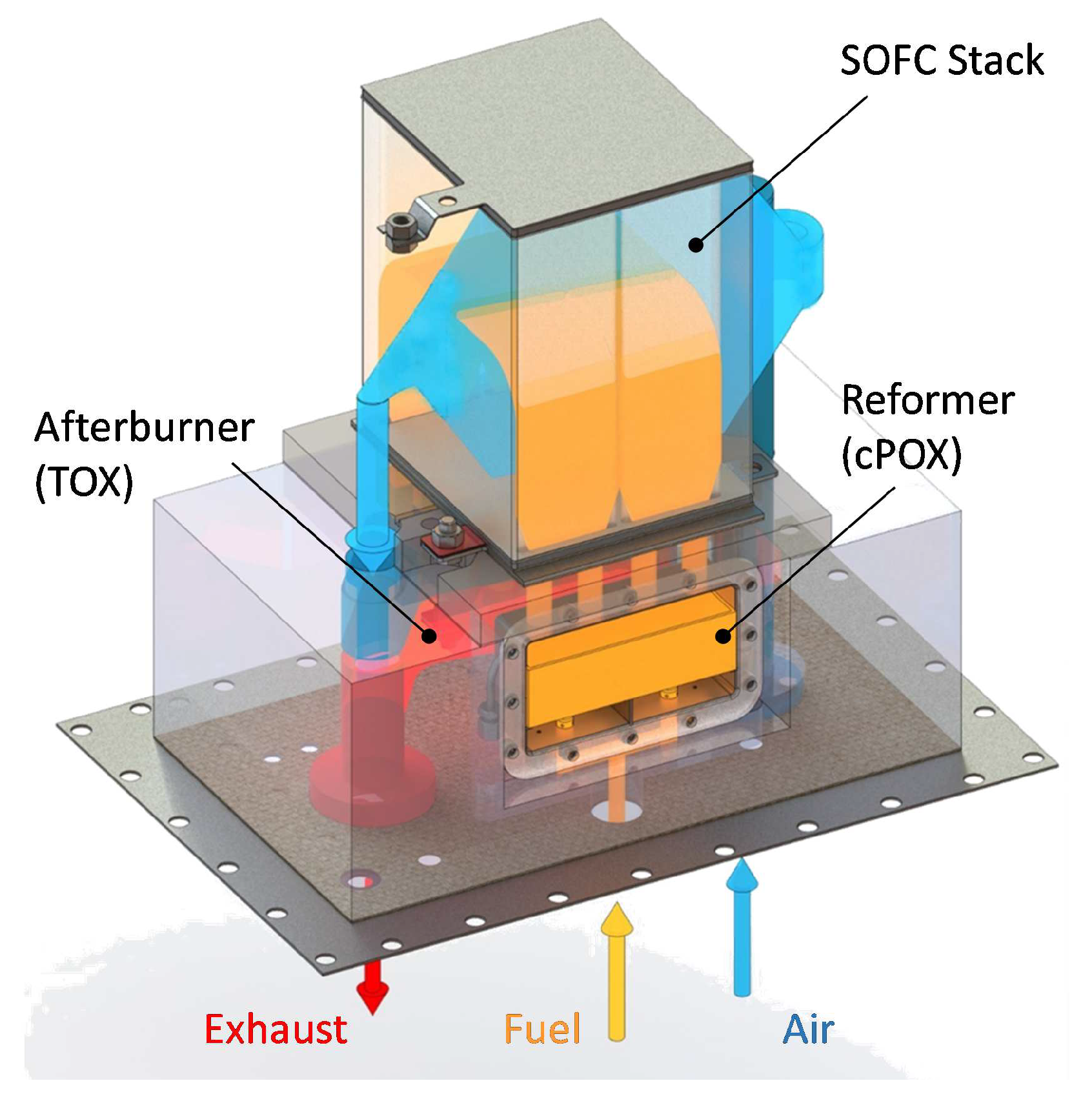

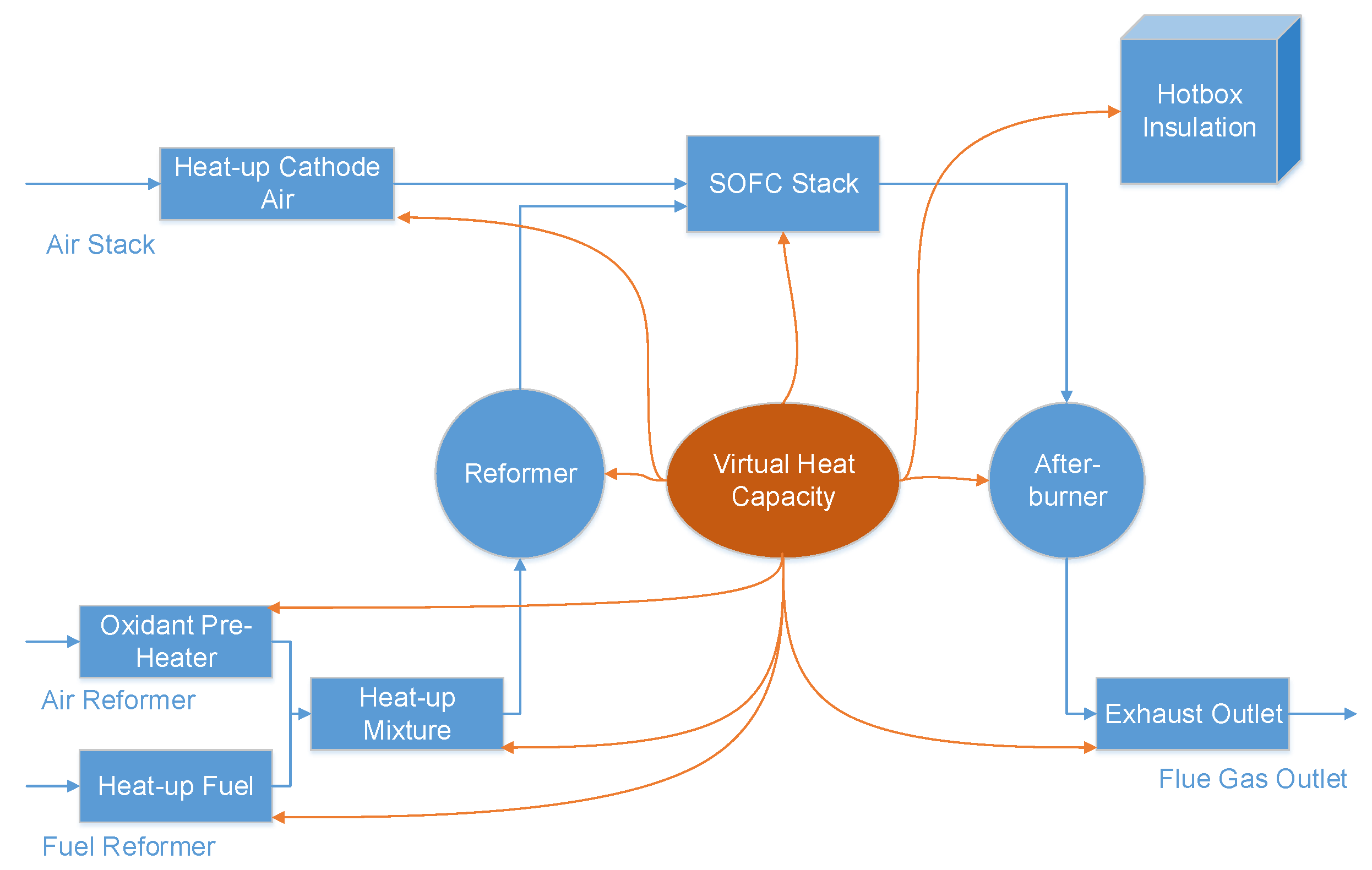

3. SOFC Hybrid System

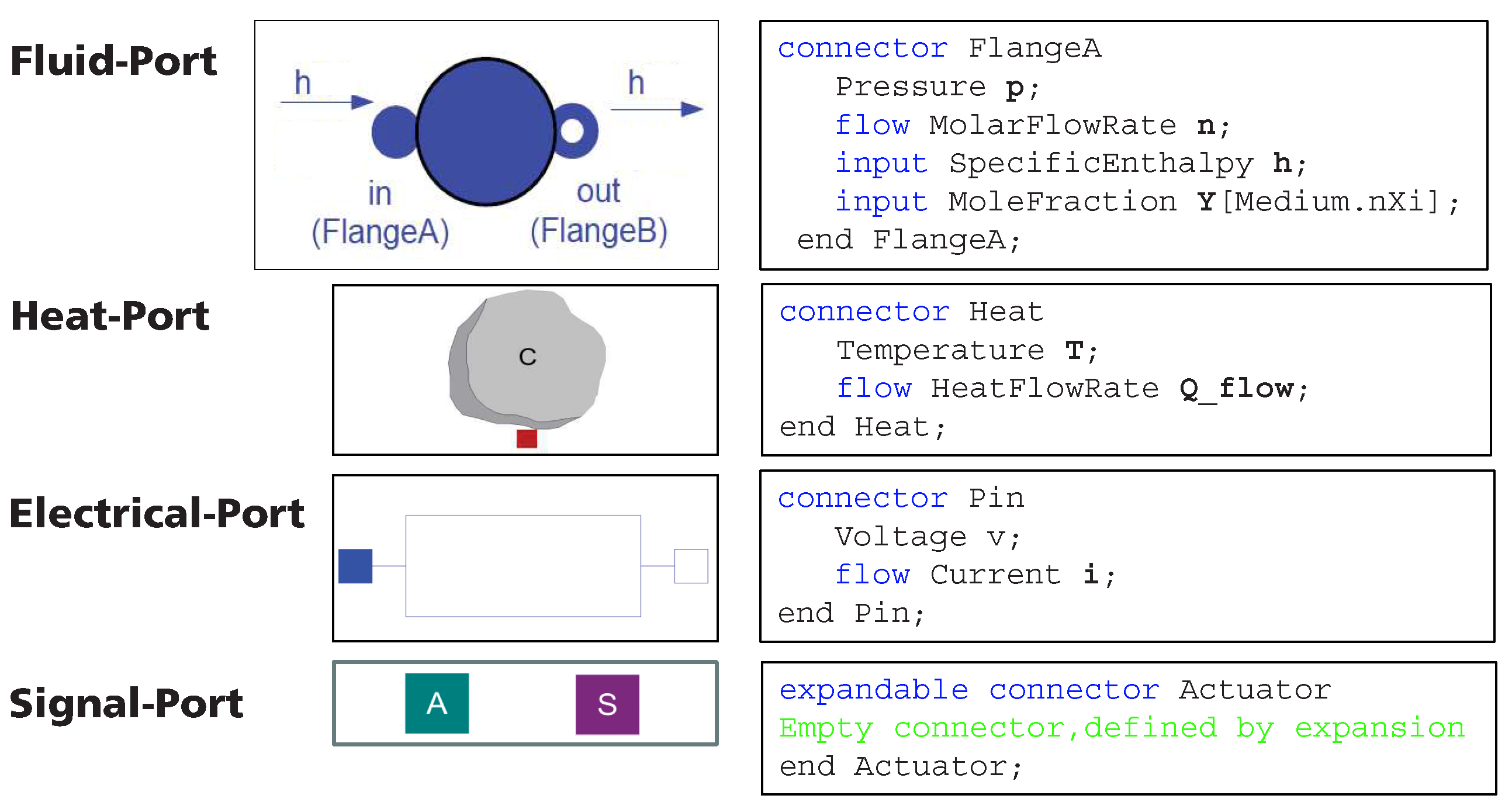

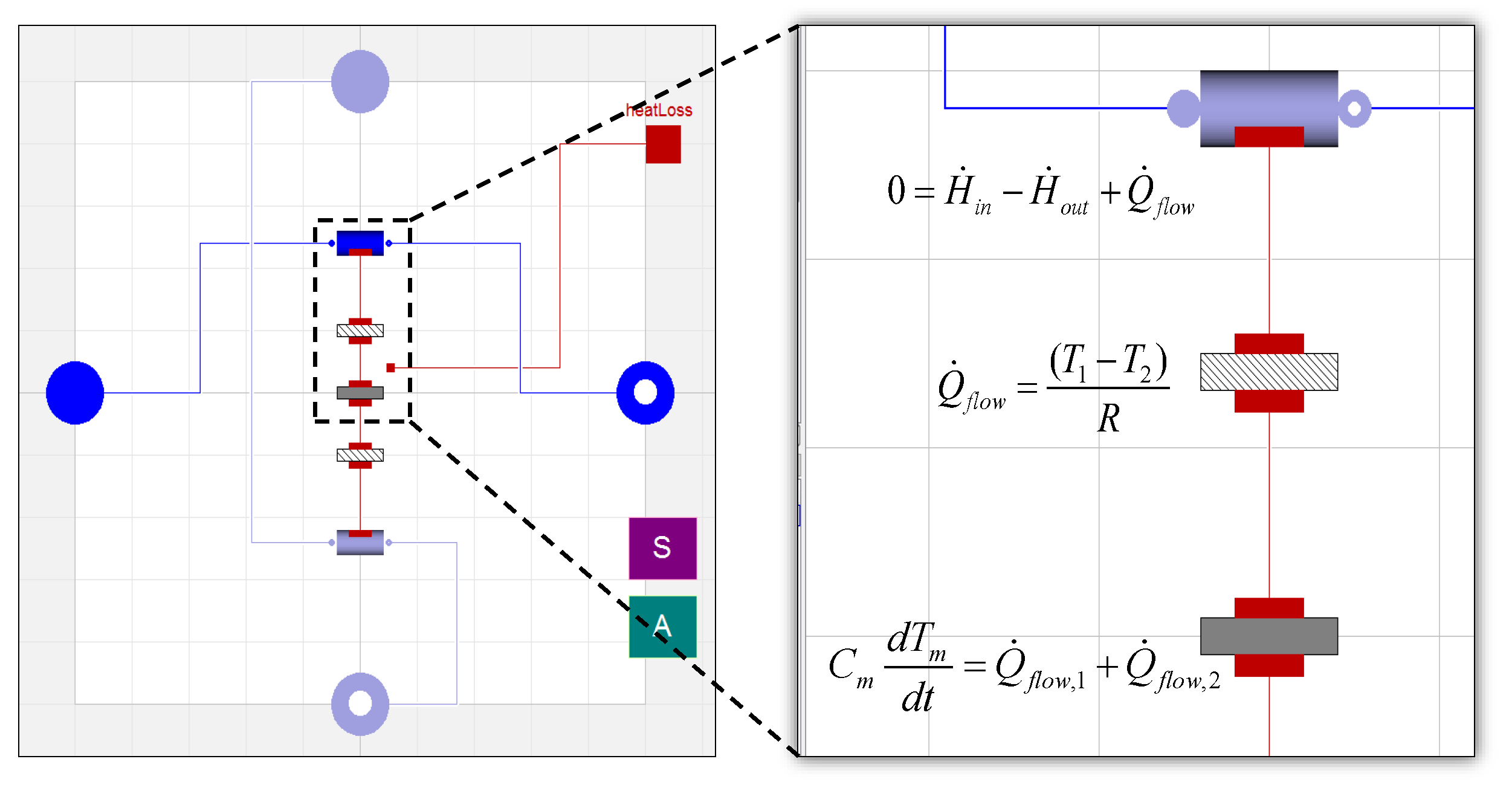

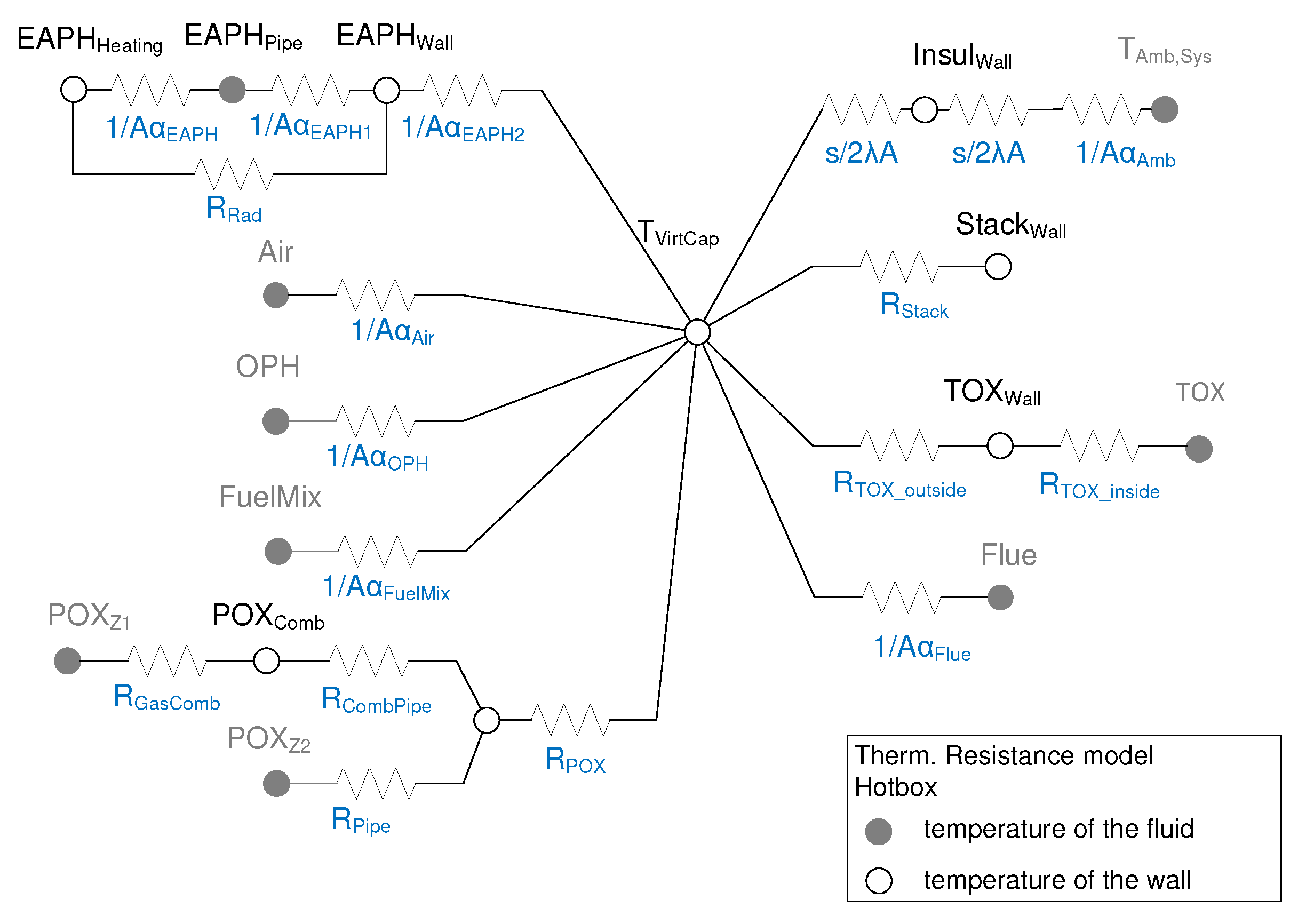

4. System Modeling Methods

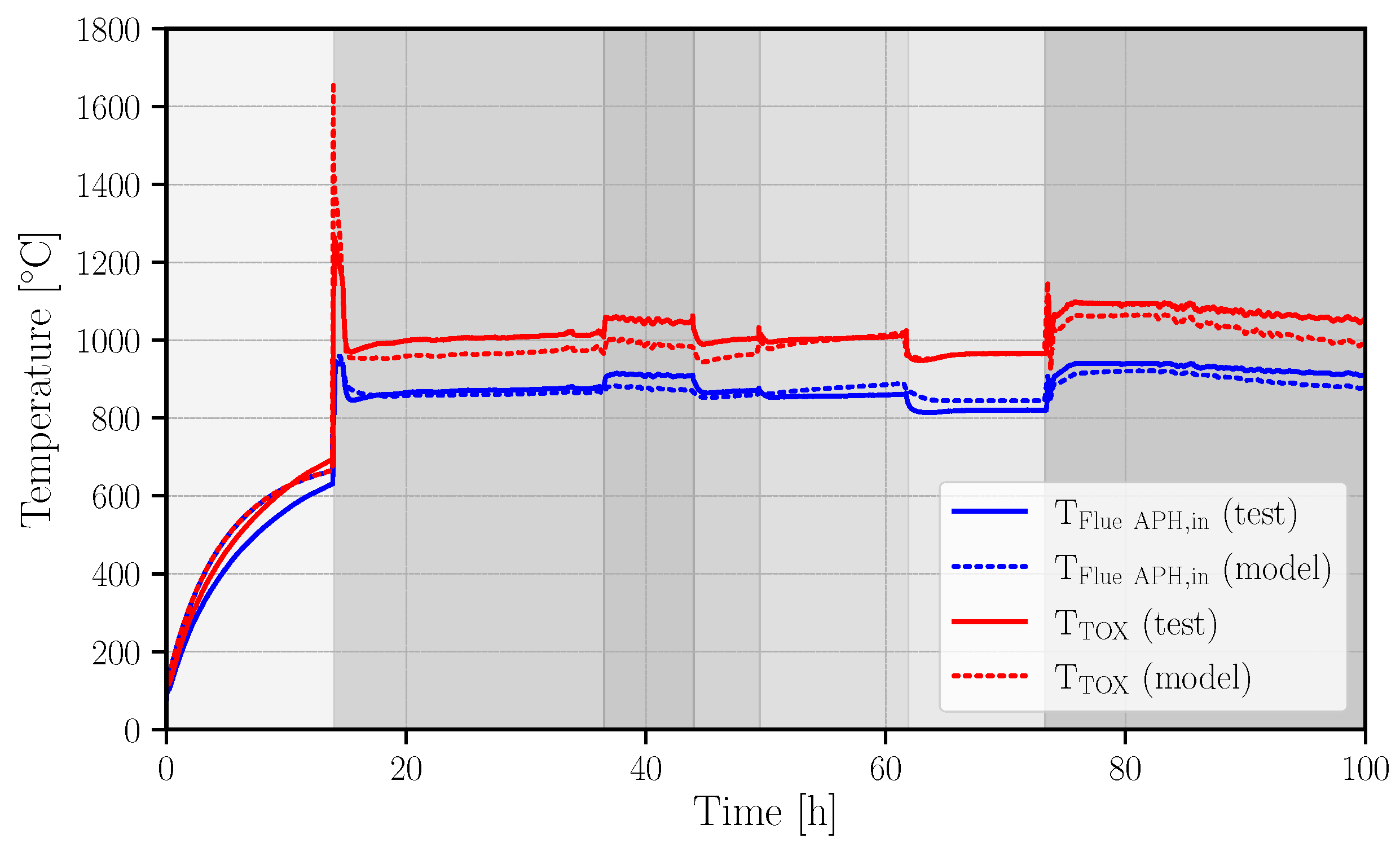

5. Results

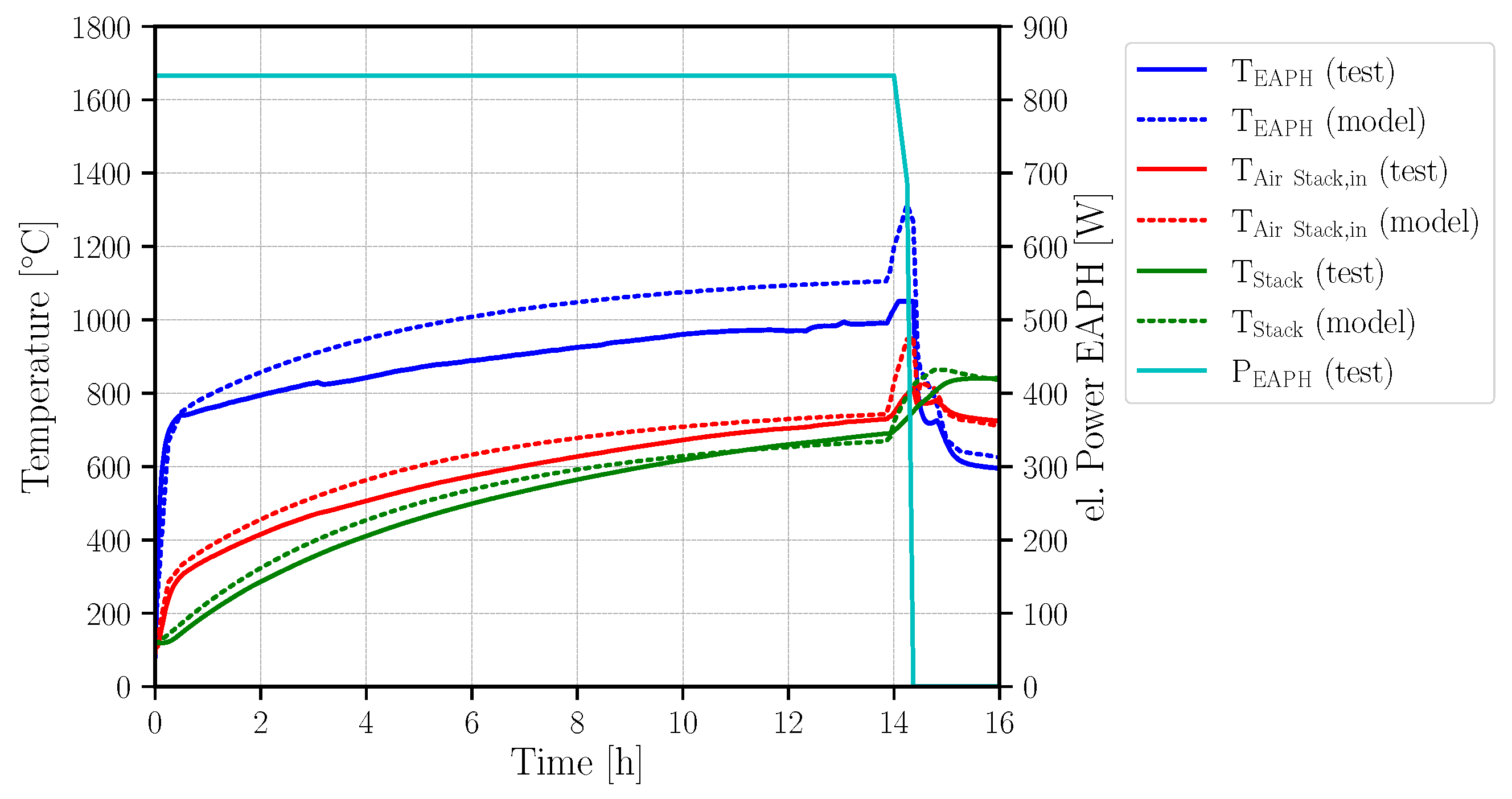

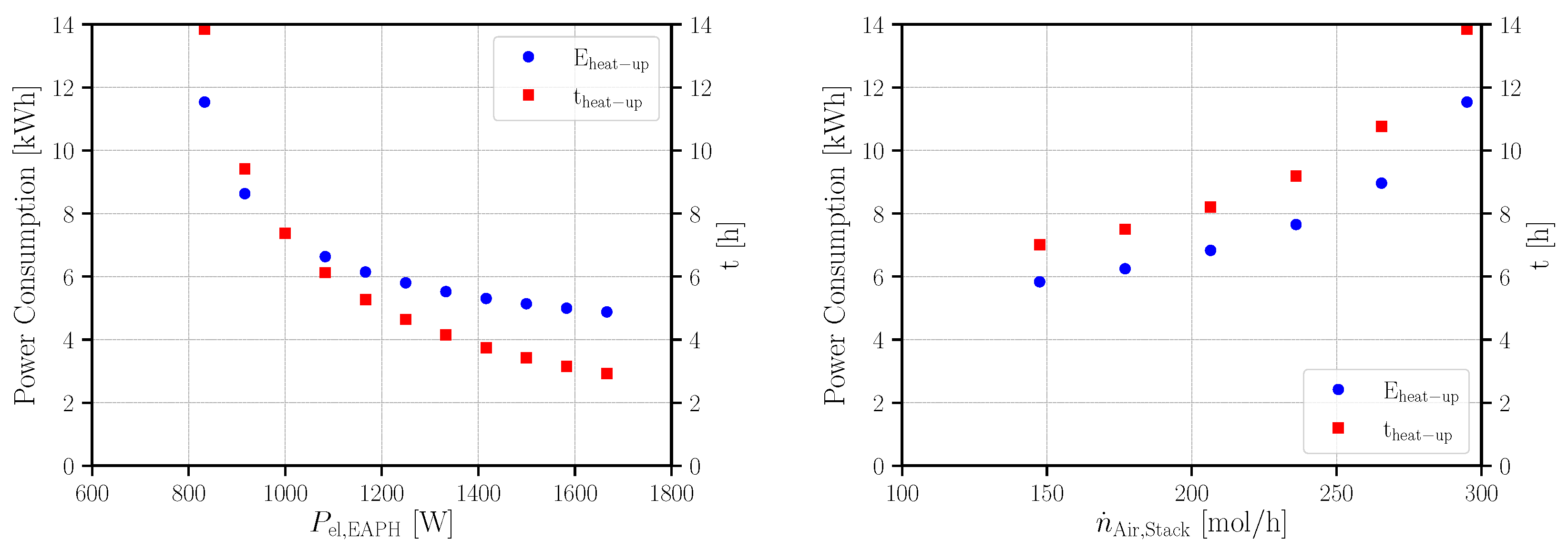

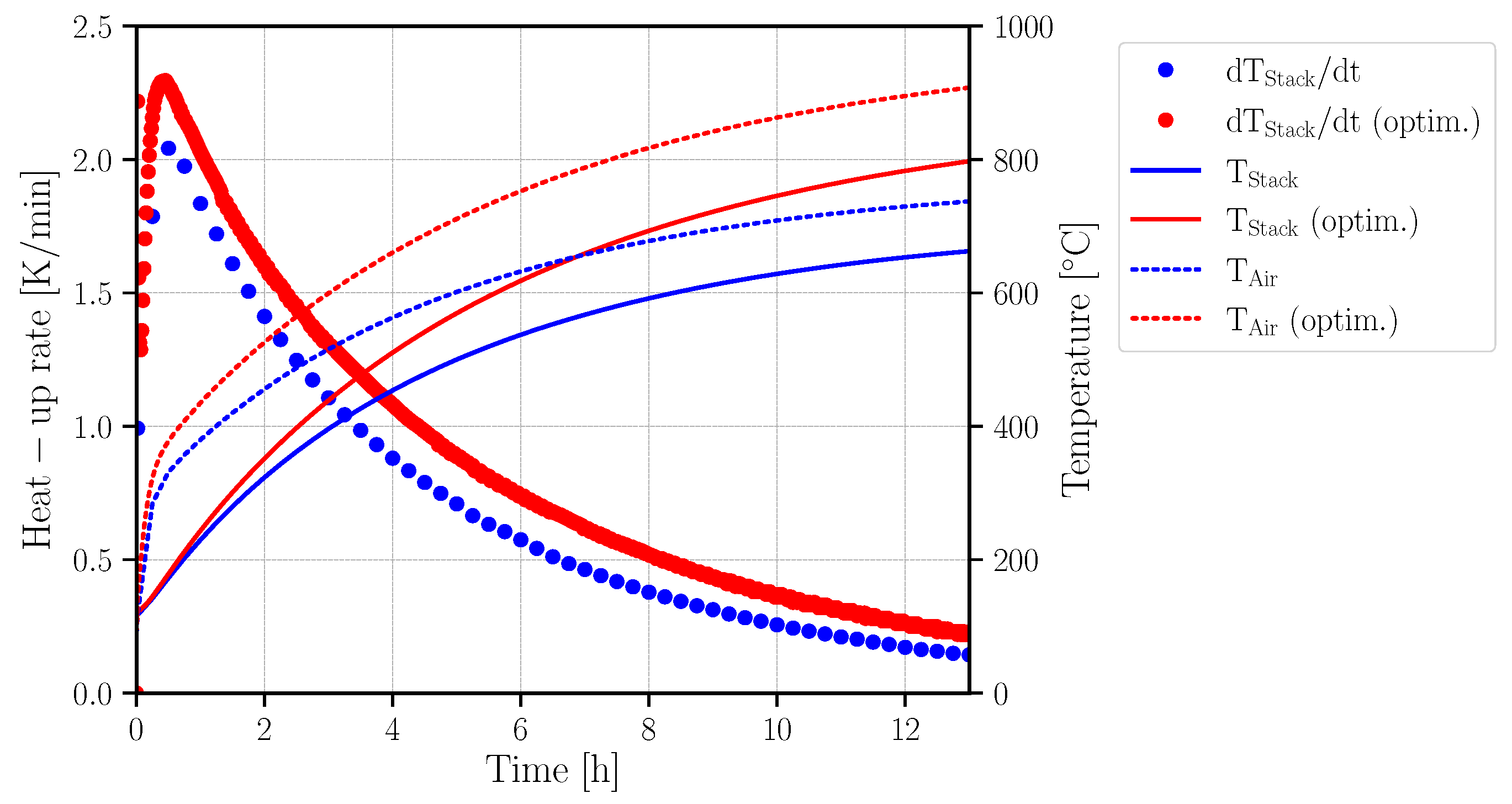

5.1. Improvement of the System Heat-Up

- Increase of electrical power input to the EAPH by 10% (883 W to 916 W) and

- Reduction of cathode air input by 20% (295 mol/h to 236 mol/h),

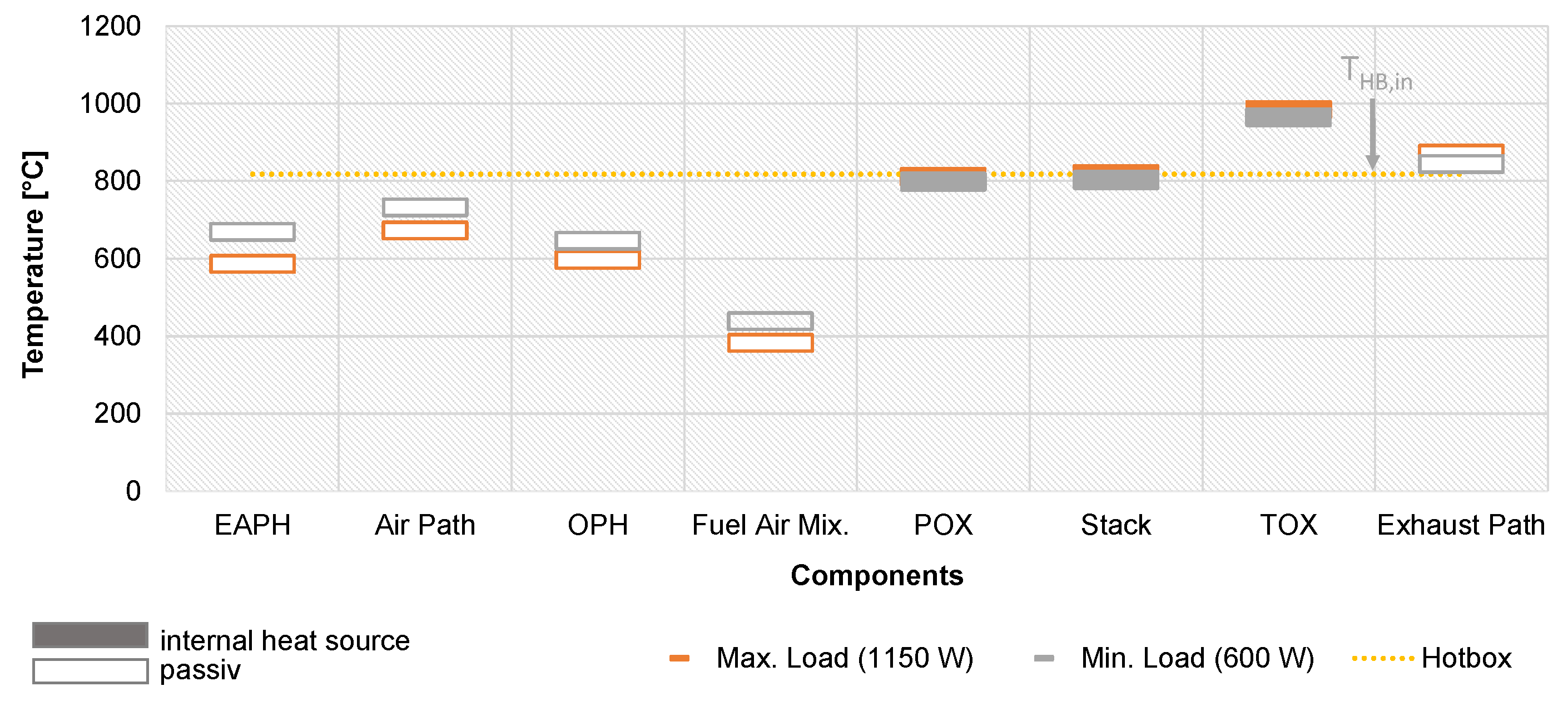

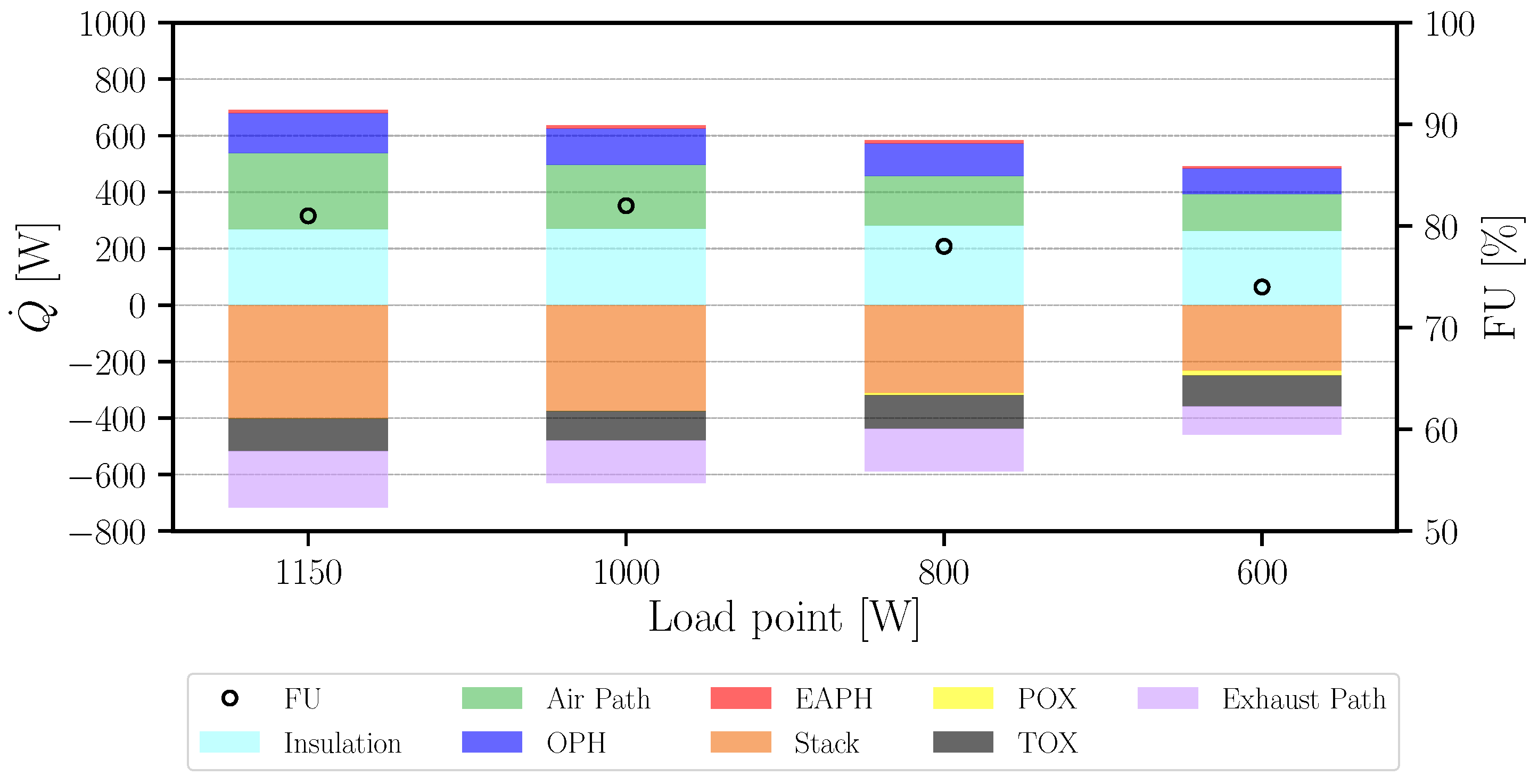

5.2. Partial Load Behavior

- Improvement of the arrangement of the hotbox components to:

- –

- Enable a better heat transfer from the hot to the cold hotbox components,

- –

- Achieve a smaller size of the hotbox for heat loss reduction.

- Improvement the of hotbox materials with:

- –

- Higher heat transfer between components,

- –

- Lower heat capacity to reduce the thermal inertia of the system,

- –

- Improved insulation with less heat loss, e.g., using evacuated cabinets.

- Improvement of the TOX by:

- –

- Application of high-temperature stable materials to realize higher combustion temperature and further stack FU reduction,

- –

- Redesign the TOX to homogenize and reduce the combustion temperatures, e.g., with a porous burner or adding of cooling air.

- Deploying another heat source within the hotbox by:

- Considering a slightly lower stack and hotbox temperature during lower load points

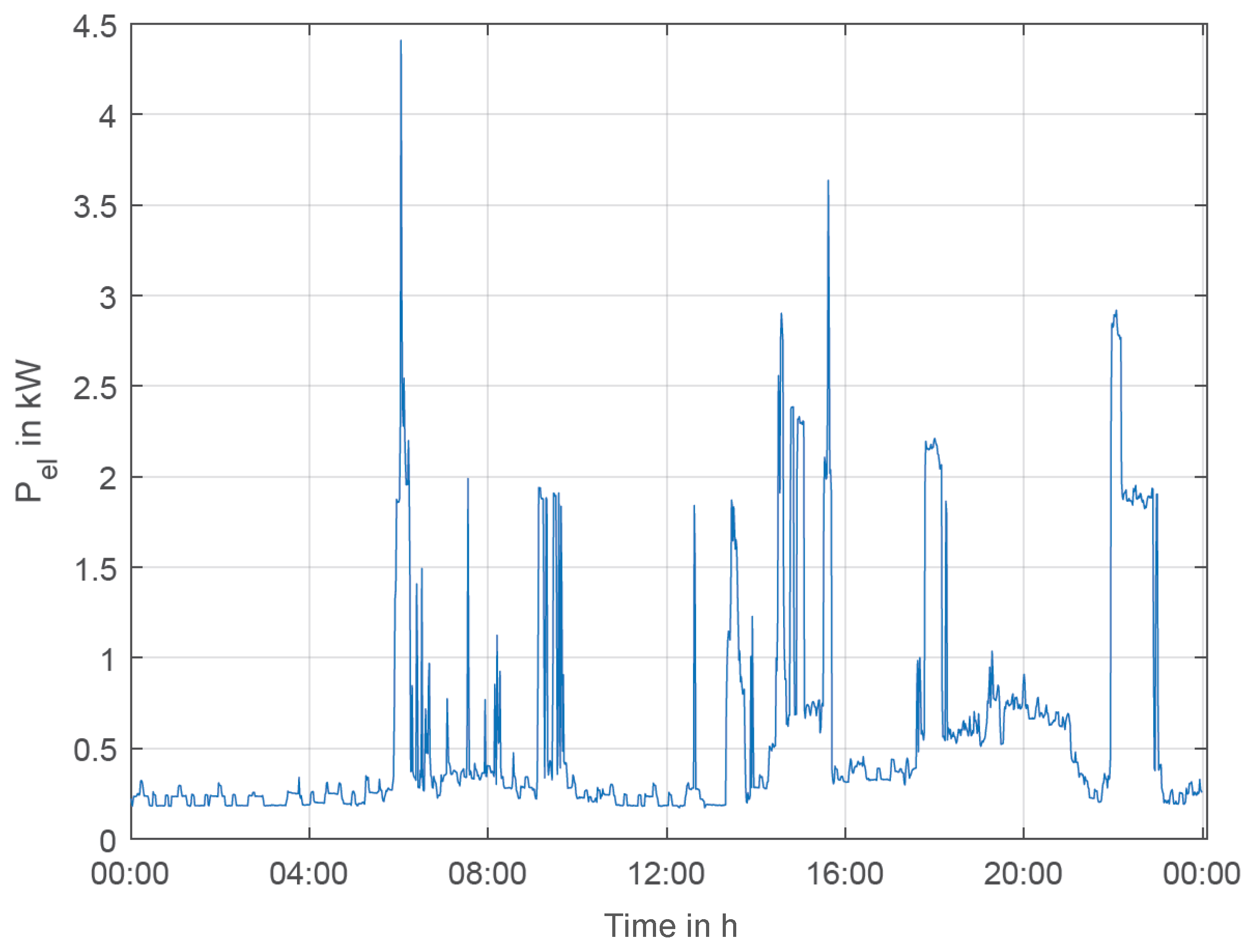

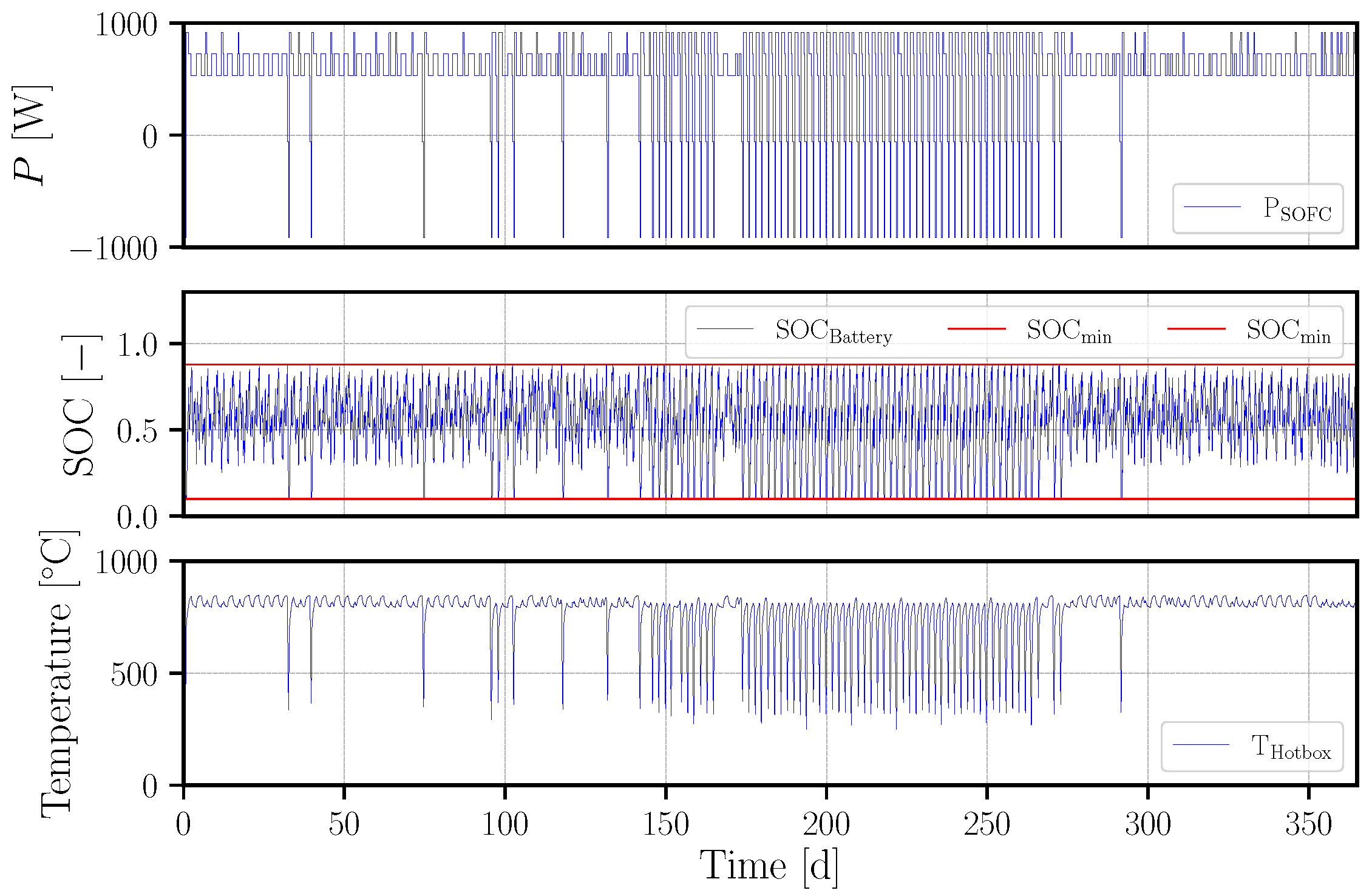

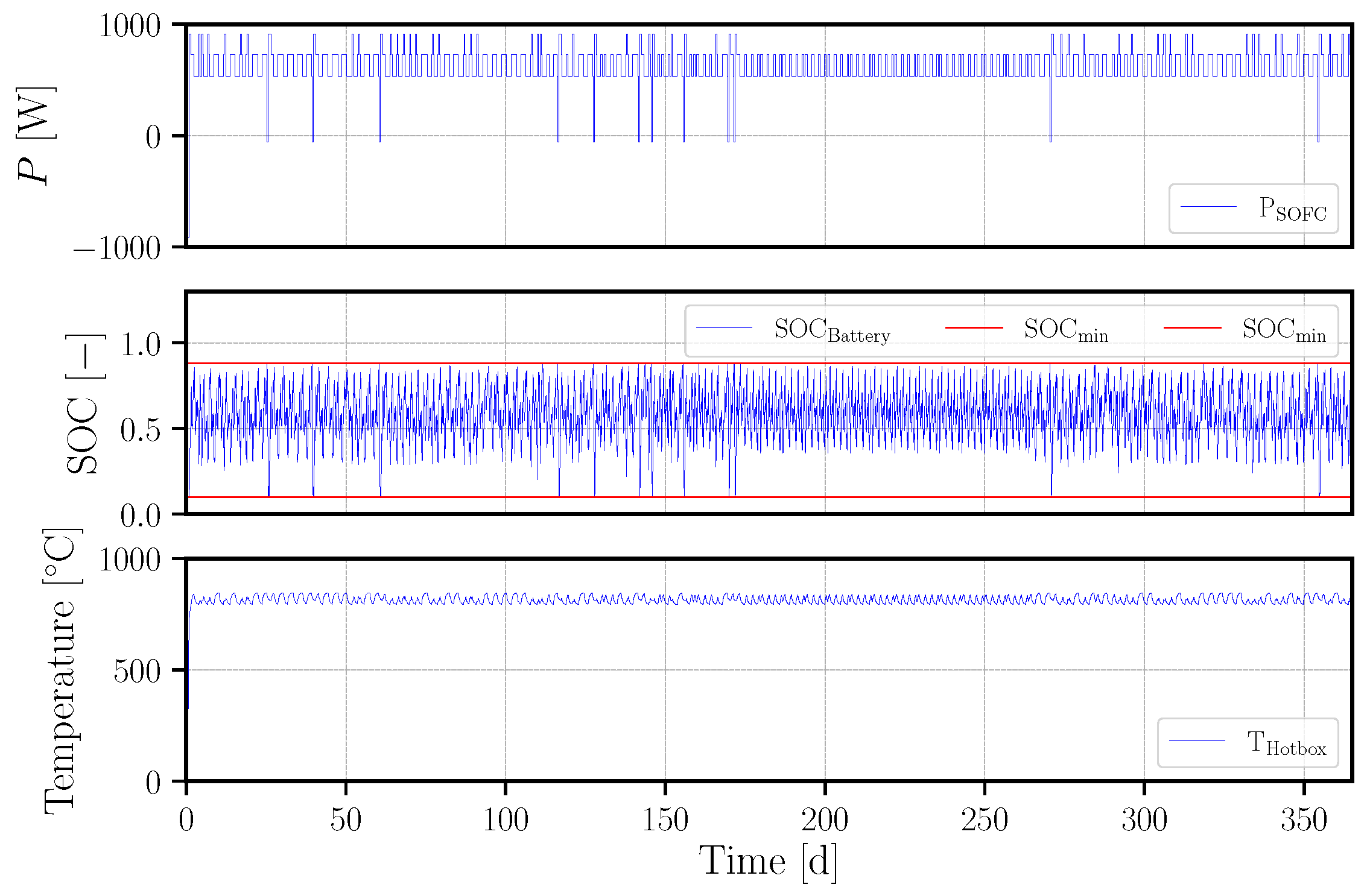

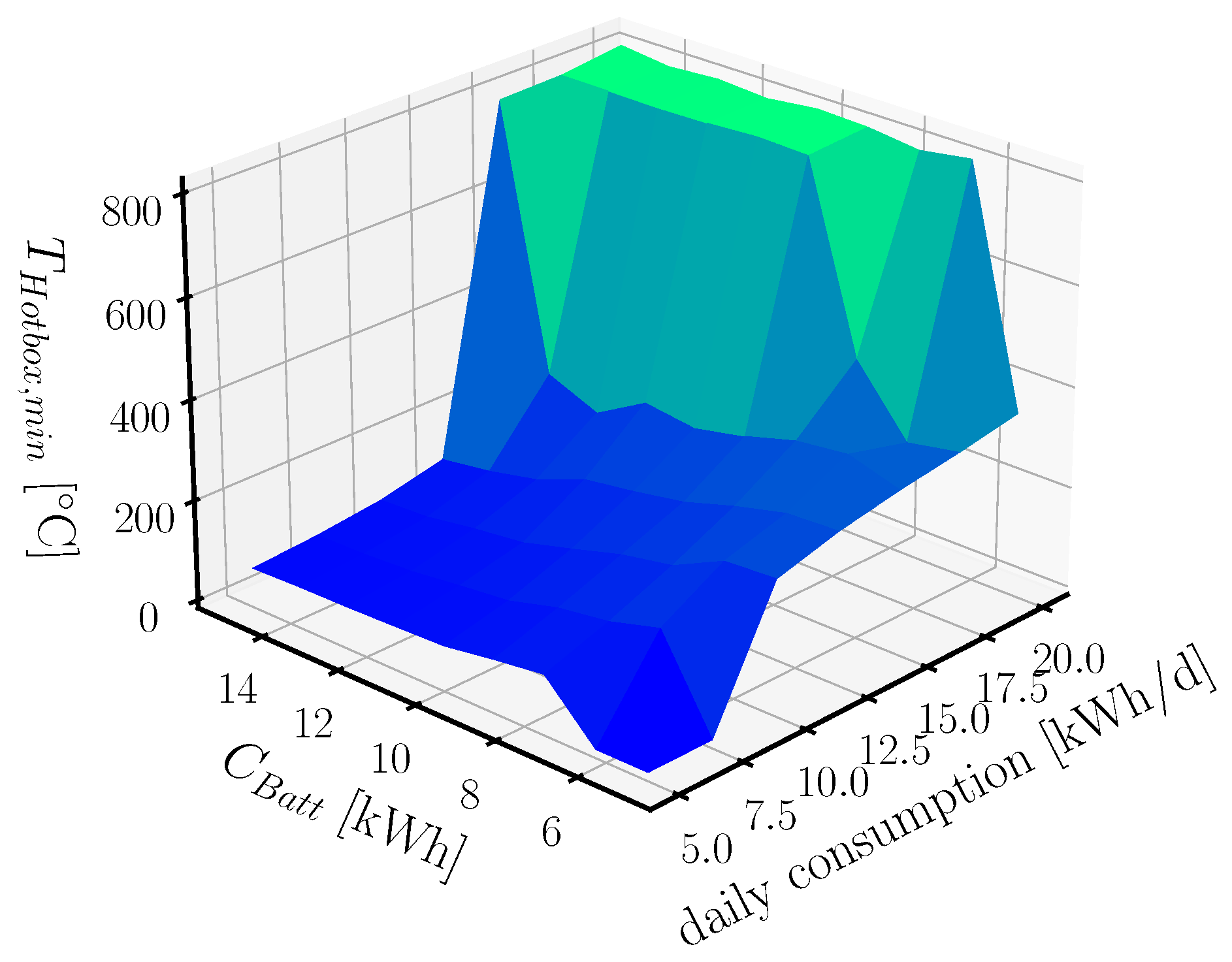

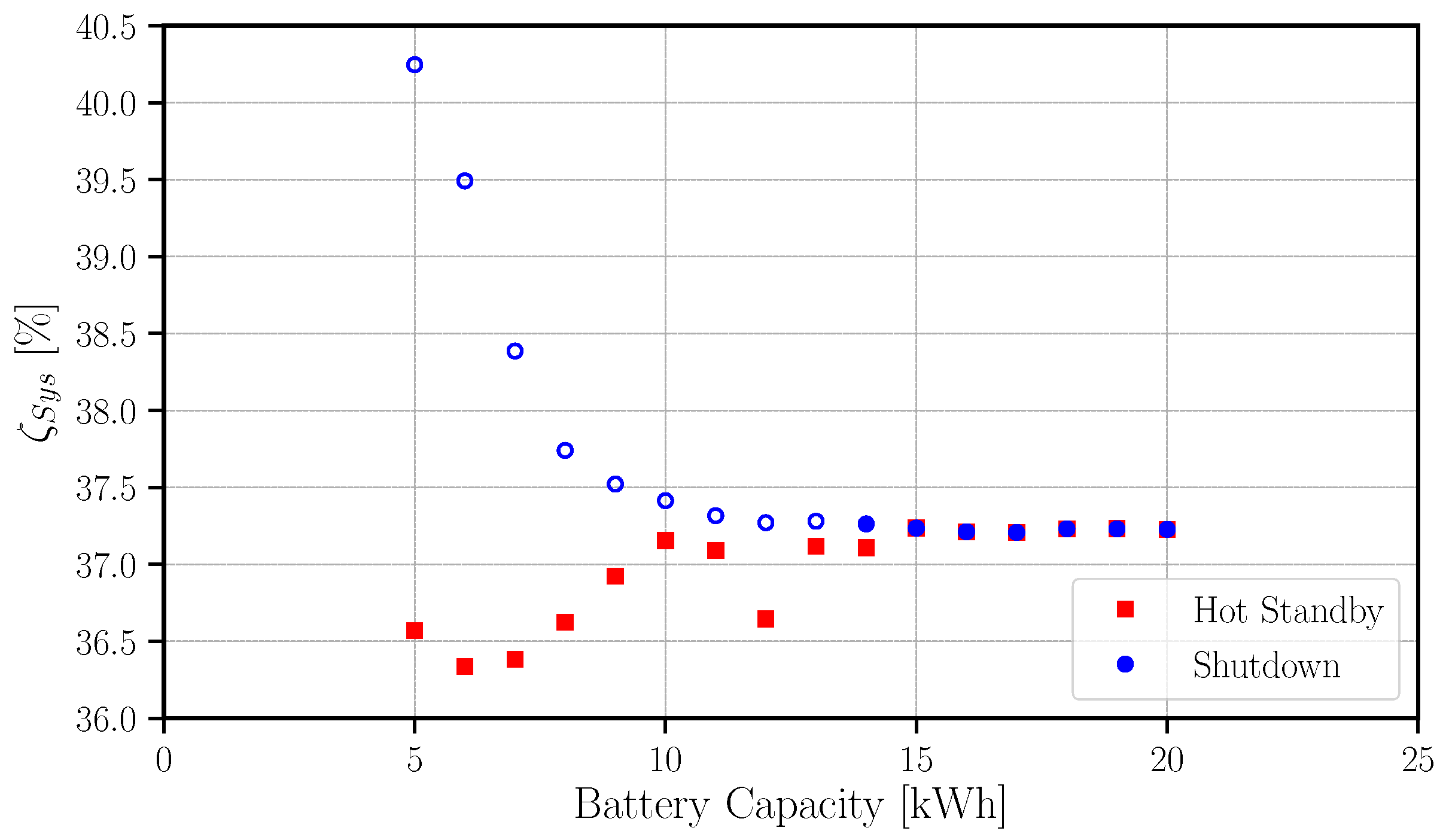

5.3. Simulation of the Hybrid System in a Residential Application Scenario

6. Discussion

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| A | Area in m2 |

| Heat transfer coefficient in W/(m2 K) | |

| c | Concentration in mol/m3 |

| Effective heat capacity in J/K | |

| E | Energy in kWh/a |

| Enthalpy flow in J/s | |

| k | Thermal transmittance in W/(m2 K) |

| K | Equilibrium constant |

| Thermal conductivity in W/(m K) | |

| P | Power in W |

| R | Thermal resistance in K/W |

| s | Thickness in m |

| T | Temperature in K |

| t | Time in s |

| Heat flow in W |

Abbreviations

| APH | Air Preheater |

| Desulf | Desulfurizer |

| CAD | Computer-aided Design |

| CHP | Combined Heat and Power |

| EAPH | Electric Air Preheater |

| FU | Fuel Utilization |

| OPH | Oxidant Preheater |

| PEM | Polymer-electrolyte membrane |

| cPOX/POX | Partial Oxidation |

| SOC | State of Charge |

| SOFC | Solid Oxide Fuel Cell |

| TOX | Tail gas Oxidizer |

| UPS | Uninterrupted power supply |

References

- Schulz, D.; Jahn, M.; Pfeifer, T. Grid Integration of Photovoltaics and Fuel Cells. In Power Electronics in Smart Electrical Energy Networks; Strzelecki, R.M., Benysek, G., Eds.; Power Systems; Springer: London, UK, 2008. [Google Scholar]

- Baldinelli, A.; Barelli, L.; Bidini, G.; Cinti, G. Micro-cogeneration based on solid oxide fuel cells: Market opportunities in the agriculture/livestock sector. Int. J. Hydrogen Energy 2020. [Google Scholar] [CrossRef]

- Gandiglio, M.; Lanzini, A.; Santarelli, M.; Acri, M.; Hakala, T.; Rautanen, M. Results from an industrial size biogas-fed SOFC plant (the DEMOSOFC project). Int. J. Hydrogen Energy 2020, 45, 5449–5464. [Google Scholar] [CrossRef]

- Cavalli, A.; Fernandes, A.; Aravind, P.V. Thermodynamic analysis of an improved integrated biomass gasifier solid oxide fuel cell micro combined heat and power system. Energy 2021, 231, 120945. [Google Scholar] [CrossRef]

- Costa, P.; Pinto, F.; André, R.N.; Marques, P. Integration of Gasification and Solid Oxide Fuel Cells (SOFCs) for Combined Heat and Power (CHP). Processes 2021, 9, 254. [Google Scholar] [CrossRef]

- Cinti, G.; Discepoli, G.; Sisani, E.; Desideri, U. SOFC operating with ammonia: Stack test and system analysis. Int. J. Hydrogen Energy 2016, 41, 13583–13590. [Google Scholar] [CrossRef]

- Ding, X.; Sun, W.; Harrison, G.P.; Lv, X.; Weng, Y. Multi-objective optimization for an integrated renewable, power-to-gas and solid oxide fuel cell/gas turbine hybrid system in microgrid. Energy 2020, 213, 118804. [Google Scholar] [CrossRef]

- Loy-Benitez, J.; Safder, U.; Nguyen, H.; Li, Q.; Woo, T.; Yoo, C. Techno-economic assessment and smart management of an integrated fuel cell-based energy system with absorption chiller for power, hydrogen, heating, and cooling in an electrified railway network. Energy 2021, 233, 121099. [Google Scholar] [CrossRef]

- Vialetto, G.; Noro, M.; Colbertaldo, P.; Rokni, M. Enhancement of energy generation efficiency in industrial facilities by SOFC–SOEC systems with additional hydrogen production. Int. J. Hydrogen Energy 2019, 44, 9608–9620. [Google Scholar] [CrossRef]

- Srikanth, S.; Heddrich, M.P.; Gupta, S.; Friedrich, K.A. Transient reversible solid oxide cell reactor operation–Experimentally validated modeling and analysis. Appl. Energy 2018, 232, 473–488. [Google Scholar] [CrossRef]

- Hauth, M.; Rechberger, J.; Megel, S.; Kusnezoff, M. Operating Results of the SOFC20 Stationary SOFC CHP System Using a CFY-Stack Platform: A1205. In Proceedings of the 11th European SOFC & SOE Forum 2014, Lucerne, Switzerland, 1–7 July 2014. [Google Scholar]

- Megel, S.; Dosch, C.; Rothe, S.; Kusnezoff, M.; Trofimenko, N.; Sauchuk, V.; Michaelis, A.; Bienert, C.; Brandner, M.; Venskutonis, A.; et al. CFY-Stacks for Use in Stationary SOFC and SOEC Applications. ECS Trans. 2013, 57, 89–98. [Google Scholar] [CrossRef]

- Kusnezoff, M.; Megel, S.; Rix, C.; Adam, P.; Reichelt, E.; Herz, G.; Jahn, M.; Trofimenko, N.; Michaelis, A. Co-Electrolysis CFY-Stack Operation and Integration for Carbon Capture and Utilization. ECS Trans. 2019, 91, 2579–2587. [Google Scholar] [CrossRef]

- Herz, G.; Müller, N.; Adam, P.; Megel, S.; Reichelt, E.; Jahn, M. High Temperature Co–Electrolysis as a Key Technology for CO2 Emission Mitigation–A Model–Based Assessment of CDA and CCU. Chem. Ing. Tech. 2020, 92, 1044–1058. [Google Scholar] [CrossRef]

- Heddrich, M.P.; Jahn, M.; Michaelis, A.; Näke, R.; Weder, A. SOFC System Design Using Ideal Efficiency Modeling–Model and Experimental Implementation. Fuel Cells 2013. [Google Scholar] [CrossRef]

- Pfeifer, T.; Nousch, L.; Lieftink, D.; Modena, S. System design and process layout for a SOFC micro-CHP unit with reduced operating temperatures. Int. J. Hydrogen Energy 2013, 38, 431–439. [Google Scholar] [CrossRef]

- Poenicke, A.; Reuber, S.; Dosch, C.; Megel, S.; Kusnezoff, M.; Wunderlich, C.; Michaelis, A. Efficient Planar SOFC Technology for a Portable Power Generator. In Advances in Solid Oxide Fuel Cells VIII; Singh, P., Bansal, N.P., Halbig, M., Mathur, S., Eds.; Ceramic Engineering and Science Proceedings; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2012; pp. 125–136. [Google Scholar]

- Reuber, S.; Ponicke, A.; Wunderlich, C.; Michaelis, A. Eneramic Power Generator—A Reliable and Cycleable 100W SOFC-System. ECS Trans. 2013, 57, 161–169. [Google Scholar] [CrossRef]

- Rao, T.P.; Turaga, U.T. Opportunities and challenges for fuel cells in India: Symposium on Fuel Cell Systems and Fuel Processing for Fuel Cell Applications. J. Am. Chem. Soc. 2003, 48, 795–796. [Google Scholar]

- Dalvi, S.N.; Jadhav, M.V. A Review: Research Opportunities And Challenges In Fuel Cell For India. Indian Streams Res. J. 2012, 2. [Google Scholar]

- Brunaccini, G.; Sergi, F.; Aloisio, D.; Ferraro, M.; Blesznowski, M.; Kupecki, J.; Motylinski, K.; Antonucci, V. Modeling of a SOFC-HT battery hybrid system for optimal design of off-grid base transceiver station. Int. J. Hydrogen Energy 2017, 42, 27962–27978. [Google Scholar] [CrossRef]

- Gallo, M.; Marra, D.; Sorrentino, M.; Pianese, C.; Au, S.F. A versatile computational tool for model-based design, control and diagnosis of a generic Solid Oxide Fuel Cell Integrated Stack Module. Energy Convers. Manag. 2018, 171, 1514–1528. [Google Scholar] [CrossRef]

- Bove, R.; Ubertini, S. (Eds.) Modeling Solid Oxide Fuel Cells: Methods, Procedures and Techniques, reprinted ed.; Fuel Cells and Hydrogen Energy; Springer: New York, NY, USA, 2008; Volume 1. [Google Scholar]

- Secanell, M.; Wishart, J.; Dobson, P. Computational design and optimization of fuel cells and fuel cell systems: A review. J. Power Sources 2011, 196, 3690–3704. [Google Scholar] [CrossRef]

- Leucht, F. Der Festoxidbrennstoffzellengenerator im Hybridkraftwerk: Untersuchung von Betriebsweisen und ihrer Wirtschaftlichkeit; Shaker: Stuttgart, Germany, 2013. [Google Scholar]

- Barelli, L.; Cinti, G.; Desideri, U.; Ottaviano, A. SOFC Thermal Transients: Modeling by Application of Experimental System Identification Techniques. Fuel Cells 2014, 14, 107–122. [Google Scholar] [CrossRef]

- Fardadi, M.; McLarty, D.F.; Jabbari, F. Actuator Limitations in Spatial Temperature Control of SOFC. J. Fuel Cell Sci. Technol. 2013, 10, 031005–1–031005–10. [Google Scholar] [CrossRef]

- Salogni, A.; Colonna, P. Modeling of solid oxide fuel cells for dynamic simulations of integrated systems. Appl. Therm. Eng. 2010, 30, 464–477. [Google Scholar] [CrossRef] [Green Version]

- Padullés, J.; Ault, G.W.; McDonald, J.R. An integrated SOFC plant dynamic model for power systems simulation. J. Power Sources 2000, 86, 495–500. [Google Scholar] [CrossRef]

- Li, Y.H.; Choi, S.S.; Rajakaruna, S. An Analysis of the Control and Operation of a Solid Oxide Fuel-Cell Power Plant in an Isolated System. IEEE Trans. Energy Convers. 2005, 20, 381–387. [Google Scholar] [CrossRef]

- Komatsu, Y.; Kimijima, S.; Szmyd, J.S. Numerical analysis on dynamic behavior of solid oxide fuel cell with power output control scheme. J. Power Sources 2013, 223, 232–245. [Google Scholar] [CrossRef]

- Mueller, F.; Jabbari, F.; Brouwer, J. On the intrinsic transient capability and limitations of solid oxide fuel cell systems. J. Power Sources 2009, 187, 452–460. [Google Scholar] [CrossRef] [Green Version]

- Zhang, L.; Li, X.; Jiang, J.; Li, S.; Yang, J.; Li, J. Dynamic modeling and analysis of a 5-kW solid oxide fuel cell system from the perspectives of cooperative control of thermal safety and high efficiency. Int. J. Hydrogen Energy 2015, 40, 456–476. [Google Scholar] [CrossRef]

- Pohjoranta, A.; Halinen, M.; Pennanen, J.; Kiviaho, J. Model predictive control of the solid oxide fuel cell stack temperature with models based on experimental data. J. Power Sources 2015, 277, 239–250. [Google Scholar] [CrossRef]

- Leone, P.; Lanzini, A. Experimental Modeling of Transients in Large SOFC Systems. J. Fuel Cell Sci. Technol. 2013, 10, 011004–011011. [Google Scholar] [CrossRef]

- Sorrentino, M.; Pianese, C. Model-based development of low-level control strategies for transient operation of solid oxide fuel cell systems. Fuel Cells Sci. Technol. 2010 2011, 196, 9036–9045. [Google Scholar] [CrossRef]

- Andersson, D.; Aberg, E.; Eborn, J.; Yuan, J.; Sundén, B. Dynamic modeling of a solid oxide fuel cell system in Modelica. In Proceedings of the 8th Modelica Conference, Brooklyn, New York, USA, 14–16 June 2010; Modelica Association: Linköping, Sweden, 2011. [Google Scholar]

- Barelli, L.; Bidini, G.; Ottaviano, A. Part load operation of a SOFC/GT hybrid system: Dynamic analysis. Appl. Energy 2013, 110, 173–189. [Google Scholar] [CrossRef]

- Barelli, L.; Bidini, G.; Gallorini, F.; Ottaviano, P.A. Design optimization of a SOFC-based CHP system through dynamic analysis. Int. J. Hydrogen Energy 2013, 38, 354–369. [Google Scholar] [CrossRef]

- Borello, D.; Evangelisti, S.; Tortora, E. Modelling of a CHP SOFC system fed with biogas from anaerobic digestion of municipal waste integrated with solar collectors and storage unit. Int. J. Thermodyn. 2013, 16, 28–35. [Google Scholar] [CrossRef] [Green Version]

- Chatterjee, K.; Shankar, R.; Kumar, A. Fuzzy Logic Based Controller for a Grid-Connected Solid Oxide Fuel Cell Power Plant. J. Fuel Cell Sci. Technol. 2014, 11, 051005–1–051005–9. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chen, S. Simulation eines SOFC-Brennstoffzellensystems mit Anodenabgasrückführung, 1st ed.; Schriftenreihe des Energie-Forschungszentrums Niedersachsen (EFZN); Cuvillier: Braunschweig, Germany, 2014; Volume 19. [Google Scholar]

- D’Andrea, G.; Gandiglio, M.; Lanzini, A.; Santarelli, M. Dynamic model with experimental validation of a biogas-fed SOFC plant. Energy Convers. Manag. 2017, 135, 21–34. [Google Scholar] [CrossRef]

- Hong, S.K.; Dong, S.K.; Yang, J.B. Experimental and simulated investigation of 1 kW solid oxide fuel cell balance of power system. J. Power Sources 2012, 214, 28–32. [Google Scholar] [CrossRef]

- Kandepu, R.; Imsland, L.; Foss, B.A.; Stiller, C.; Thorud, B.; Bolland, O. Modeling and control of a SOFC-GT-based autonomous power system. Energy 2007, 32, 406–417. [Google Scholar] [CrossRef]

- Leucht, F.; Bessler, W.G.; Kallo, J.; Friedrich, A.K.; Müller-Steinhagen, H. Fuel cell system modeling for solid oxide fuel cell/gas turbine hybrid power plants, Part I: Modeling and simulation framework. J. Power Sources 2011, 196, 1205–1215. [Google Scholar] [CrossRef]

- Martinez, A.S.; Brouwer, J.; Samuelsen, G.S. Feasibility study for SOFC-GT hybrid locomotive power: Part I. Development of a dynamic 3.5 MW SOFC-GT FORTRAN model. J. Power Sources 2012, 213, 203–217. [Google Scholar] [CrossRef] [Green Version]

- McLarty, D.; Brouwer, J.; Samuelsen, S. Hybrid Fuel Cell Gas Turbine System Design and Optimization. J. Fuel Cell Sci. Technol. 2013, 10, 041005–1–041005–11. [Google Scholar] [CrossRef] [Green Version]

- Mueller, F.; Gaynor, R.; Auld, A.E.; Brouwer, J.; Jabbari, F.; Samuelsen, G.S. Synergistic integration of a gas turbine and solid oxide fuel cell for improved transient capability. J. Power Sources 2008, 176, 229–239. [Google Scholar] [CrossRef] [Green Version]

- Nanaeda, K.; Mueller, F.; Brouwer, J.; Samuelsen, S. Dynamic modeling and evaluation of solid oxide fuel cell–combined heat and power system operating strategies. J. Power Sources 2010, 195, 3176–3185. [Google Scholar] [CrossRef] [Green Version]

- Tchonla, E.F. SOFC-Brennstoffzellen-Kraftwerke für die Dezentrale Elektrische Energieversorgung. Ph.D. Thesis, Universität Erlangen-Nürnberg, Erlangen, Germany, 2012. [Google Scholar]

- Wahl, S. Verfahrenstechnische Optimierung und Leistungsskalierung Eines Festoxid-Brennstoffzellensystems mit Hilfe Multiphysikalischer Modellierung und Experimenteller Daten. Ph.D. Thesis, Universität Stuttgart, Stuttgart, Germany, 2015. [Google Scholar]

- Windeknecht, M.; Tzscheutschler, P. Simulation der Abwärmenutzung eines Hochtemperatur-Brennstoffzellen-Systems in einem Einfamilienhaus. In Human-Centred Building(s), Proceedings of the 5th German-Austrian IBPSA Conference, Aachen, Germany, 22–24 September 2014; Treeck, C., Müller, D., Eds.; 2014; pp. 555–561. Available online: http://www.ibpsa.org/proceedings/bausimPapers/2014/p1204_final.pdf (accessed on 26 June 2021).

- Yang, C.; Shu, C.; Miao, H.; Wang, Z.; Wu, Y.; Wang, J.; Zhao, J.; Wang, F.; Ye, W.; Yuan, J. Dynamic modelling and performance analysis of reversible solid oxide fuel cell with syngas. Int. J. Hydrogen Energy 2019, 44, 6192–6211. [Google Scholar] [CrossRef]

- Liso, V.; Zhao, Y.; Brandon, N.; Nielsen, M.P.; Kær, S.K. Analysis of the impact of heat-to-power ratio for a SOFC-based mCHP system for residential application under different climate regions in Europe. Int. J. Hydrogen Energy 2011, 36, 13715–13726. [Google Scholar] [CrossRef]

- Adam, A.; Fraga, E.S.; Brett, D.J.L. Modelling and Optimisation in Terms of CO2 Emissions of a Solid Oxide Fuel Cell based Micro-CHP System in a Four Bedroom House in London. Energy Procedia 2013, 42, 201–209. [Google Scholar] [CrossRef] [Green Version]

- Tofighi, A.; Kalantar, M. Power management of PV/battery hybrid power source via passivity-based control. Renew. Energy 2011, 36, 2440–2450. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, H.; Yan, P.; Jermsittiparsert, K. Multi-objective optimization for efficient modeling and improvement of the high temperature PEM fuel cell based Micro-CHP system. Int. J. Hydrogen Energy 2020, 45, 6970–6981. [Google Scholar] [CrossRef]

- Vasallo, M.J.; Bravo, J.M.; Andújar, J.M. Optimal sizing for UPS systems based on batteries and/or fuel cell. Appl. Energy 2013, 105, 170–181. [Google Scholar] [CrossRef]

- Zhan, Y.; Guo, Y.; Zhu, J.; Wang, H. Intelligent uninterruptible power supply system with back-up fuel cell/battery hybrid power source. J. Power Sources 2008, 179, 745–753. [Google Scholar] [CrossRef] [Green Version]

- Brett, D.J.L.; Aguiar, P.; Brandon, N.P.; Bull, R.N.; Galloway, R.C.; Hayes, G.W.; Lillie, K.; Mellors, C.; Smith, C.; Tilley, A.R. Concept and system design for a ZEBRA battery–intermediate temperature solid oxide fuel cell hybrid vehicle. J. Power Sources 2006, 157, 782–798. [Google Scholar] [CrossRef]

- Brett, D.J.L.; Aguiar, P.; Brandon, N.P. System modelling and integration of an intermediate temperature solid oxide fuel cell and ZEBRA battery for automotive applications. J. Power Sources 2006, 163, 514–522. [Google Scholar] [CrossRef]

- Baldi, F.; Wang, L.; Pérez-Fortes, M.; Maréchal, F. A Cogeneration System Based on Solid Oxide and Proton Exchange Membrane Fuel Cells With Hybrid Storage for Off-Grid Applications. Front. Energy Res. 2019, 6, 139. [Google Scholar] [CrossRef]

- Pfeifer, T.; Barthel, M.; Dosch, C.; Megel, S.; Scholz, M.; Wunderlich, C. Development of a SOFC/Battery-Hybrid System for Distributed Power Generation in India. In Proceedings of the 11th European SOFC & SOE Forum 2014, Lucerne, Switzerland, 1–7 July 2014; Volume Session A12, pp. 79–87. [Google Scholar]

- Pfeifer, T.; Chakradeo, A.; Ahire, N.; Baade, J.; Barthel, M.; Dosch, C.; Näke, R.; Hartmann, M. Development of a SOFC Power Generator for the Indian Market. Fuel Cells 2017, 17, 550–561. [Google Scholar] [CrossRef] [Green Version]

- Davarpanah, A.; Zarei, M.; Valizadeh, K.; Mirshekari, B. CFD design and simulation of ethylene dichloride (EDC) thermal cracking reactor. Energy Sources Part A Recover. Util. Environ. Eff. 2019, 41, 1573–1587. [Google Scholar] [CrossRef]

- Peksen, M. 3D transient multiphysics modelling of a complete high temperature fuel cell system using coupled CFD and FEM. Int. J. Hydrogen Energy 2014, 39, 5137–5147. [Google Scholar] [CrossRef]

- Freundt, P. Systemnahe thermische Charakterisierung eines oxidkeramischen Brennstoffzellen-Stacks für die mobile Anwendung. Ph.D. Thesis, Universität Stuttgart, Stuttgart, Germany, 2015. [Google Scholar]

- Luyben, W.L. Process Modeling, Simulation, and Control for Chemical Engineers, 2nd ed.; Schaum’s Outline Series in Civil Engineering; McGraw-Hill: New York, NY, USA; Hamburg, Germany, 2009. [Google Scholar]

- Thorud, B. Dynamic Modelling and Characterisation of a Solid Oxide Fuel Cell Integrated in a Gas Turbine Cycle. Ph.D. Thesis, Norwegian University of Science and Technology Trondheim, Trondheim, Norway, 2005. [Google Scholar]

- Winkler, W. Brennstoffzellenanlagen; Engineering online library; Springer: Berlin/Heidelberg, Germany, 2002. [Google Scholar]

- Colpan, O.; Dincer, I.; Hamdullahpur, F. A review on macro–level modeling of planar solid oxide fuel cells. Int. J. Energy Res. 2008, 32, 336–355. [Google Scholar] [CrossRef]

- Starke, E.; Marschner, U.; Pfeifer, G.; Fischer, W.-J.; Flatau, A. Combining network models and FE-models for the simulation of electromechanical systems. In Active and Passive Smart Structures and Integrated Systems 2011; Ghasemi-Nejhad, M.N., Ed.; SPIE: Bellingham, DC, USA, 2011. [Google Scholar]

- Janschek, K. Systementwurf Mechatronischer Systeme: Methoden, Modelle, Konzepte; Springer: Berlin/Heidelberg, Germany, 2010. [Google Scholar] [CrossRef]

- Casella, F.; Leva, A. Object-Oriented Modelling & Simulation of Power Plants with Modelica. In Proceedings of the 44th IEEE Conference on Decision and Control, and the European Control Conference 2005, Seville, Spain, 12–15 December 2005; pp. 7597–7602. [Google Scholar]

- Jahn, M.; Reichelt, E.; Heddrich, M.P.; Weder, A.; Klemm, E.; Sauer, J. Synthesegaserzeugung aus Biogas–Reaktordesign und Integration in ein Festoxidbrennstoffzellensystem: Production of Synthesis Gas from Biogas –Reactor Design and Integration into a Solid Oxide Fuel Cell System. Chem. Ing. Tech. 2014, 86. [Google Scholar] [CrossRef]

- Kattke, K.J.; Braun, R.J. Implementing Thermal Management Modeling Into SOFC System Level Design. J. Fuel Cell Sci. Technol. 2011, 8, 021009–021012. [Google Scholar] [CrossRef] [Green Version]

- Baehr, H.D.; Stephan, K. (Eds.) Wärme- und Stoffübertragung, 6th ed.; Springer: Berlin/Heidelberg, Germany, 2008. [Google Scholar] [CrossRef]

- Nytsch-Geusen, C.; Huber, J.; Ljubijankic, M.; Rädler, J. Modelica BuildingSystems-eine Modellbibliothek zur Simulation komplexer energietechnischer Gebäudesysteme. In Proceedings of the BS2012: Fourth German-Austrian IBPSA Conference, Berlin, Germany, 19–21 September 2012. [Google Scholar]

- VDI-Gesellschaft Energie und Umwelt. VDI-Richtlinien: Reference load profiles of residential buildings for power, heat and domestic hot water as well as reference generation profiles for photovoltaic plants. In VDI Manual Energy Technology; VDI-Gesellschaft Energie und Umwelt (The Association of German Engineers): Berlin, Germany, 2019. [Google Scholar]

- Antonucci, V.; Branchini, L.; Brunaccini, G.; de Pascale, A.; Ferraro, M.; Melino, F.; Orlandini, V.; Sergi, F. Thermal integration of a SOFC power generator and a Na–NiCl2 battery for CHP domestic application. Appl. Energy 2017, 185, 1256–1267. [Google Scholar] [CrossRef]

- Dokiya, M. SOFC system and technology. Solid State Ionics 2002, 152–153, 383–392. [Google Scholar] [CrossRef]

- Hanasaki, M.; Uryu, C.; Daio, T.; Kawabata, T.; Tachikawa, Y.; Lyth, S.M.; Shiratori, Y.; Taniguchi, S.; Sasaki, K. SOFC Durability against Standby and Shutdown Cycling. J. Electrochem. Soc. 2014, 161, F850–F860. [Google Scholar] [CrossRef]

- Wu, X.-L.; Xu, Y.; Xue, T.; Zhao, D.; Jiang, J.; Deng, Z.; Fu, X.; Li, X. Standby and Shutdown Cycles Modeling of SOFC Lifetime Prediction. Energy Procedia 2019, 158, 1573–1578. [Google Scholar] [CrossRef]

| Author | Year | Approach | Tool | Utilization | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| PHY | BB | Mod. | Matl. | Other | S | O | C | V | ||

| Andersson [37] | 2011 | x | x | x | ||||||

| Barelli [38] | 2013 | x | x | x | ||||||

| Barelli [39] | 2012 | x | x | x | ||||||

| Borello [40] | 2013 | x | x | x | ||||||

| Chatterjee [41] | 2014 | x | x | x | ||||||

| Chen [42] | 2014 | x | x | x | (x) | (x) | ||||

| D’Andrea [43] | 2017 | x | x | x | x | |||||

| Fardadi [27] | 2013 | x | x | x | ||||||

| Gallo [22] | 2018 | x | x | x | x | |||||

| Hong [44] | 2012 | x | x | x | ||||||

| Kandepu [45] | 2007 | x | x | x | ||||||

| Leone [35] | 2013 | x | x | x | x | |||||

| Leucht [46] | 2011 | x | x | x | x | |||||

| Martinez [47] | 2012 | x | x | x | ||||||

| McLarty [48] | 2013 | x | x | x | ||||||

| Mueller [49] | 2008 | x | x | x | ||||||

| Nanaeda [50] | 2010 | x | x | x | ||||||

| Sorrentino [36] | 2011 | x | x | x | x | |||||

| Tchonla [51] | 2012 | x | x | x | ||||||

| Wahl [52] | 2015 | x | x | x | x | (x) | ||||

| Windeknecht [53] | 2014 | x | x | x | ||||||

| Yang [54] | 2019 | x | x | x | ||||||

| Zhang [33] | 2015 | x | x | x | x | (x) | ||||

| Presented Paper | 2021 | x | x | x | (x) | x | x | |||

| Component | Dim. | Energy Balance | Chem. Conversion | Heat Transfer |

|---|---|---|---|---|

| SOFC stack | 0D | dynamic | chemical equil. | convection, conduction |

| POX reformer | 1D | dynamic | chemical equil. | convection, conduction |

| TOX | 0/1D | dynamic | complete combustion | convection, conduction |

| Heat exchanger | 0D/1D | dynamic | - | convection, conduction |

| Hotbox | 0D | dynamic | - | convection, conduction |

| Outer insulation | 1D | dynamic | - | convection, conduction |

| Electrical heater | 1D | dynamic | - | convection, heat radiation |

| Aspect | Improvement | Limitations |

|---|---|---|

| Fast, energy-saving system heat-up | Power input (electrical or chemical) during the heat-up and the cathode air input should be controlled in a way that the max. heat rate at the stack is reached. | Adaption of actuators and component design with respect to max. allowable temperature gradients between stack and cathode air |

| Operating low partial load points (<58%) and the hot standby | Decreasing the stack heat losses might be possible by adaption of design or well-directed lowering of the stack temperature (max. 200 K), hot standbys operation saves installed battery capacity for hybrid systems. | Danger of stack cooling, decrease of the system degree of efficiency during hot standby |

| Hotbox design | Favorable for SOFC systems, due to lower heat losses and temperature balancing between the hotbox components. | High thermal inertia for the system with complex control |

| TOX design | Robust, high-temperature stable burner supports the load flexibility during partial load and end of life stack operation. | Ignition and combustion behavior and long-term stability need to be considered |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nousch, L.; Hartmann, M.; Michaelis, A. Improvements of Micro-CHP SOFC System Operation by Efficient Dynamic Simulation Methods. Processes 2021, 9, 1113. https://doi.org/10.3390/pr9071113

Nousch L, Hartmann M, Michaelis A. Improvements of Micro-CHP SOFC System Operation by Efficient Dynamic Simulation Methods. Processes. 2021; 9(7):1113. https://doi.org/10.3390/pr9071113

Chicago/Turabian StyleNousch, Laura, Mathias Hartmann, and Alexander Michaelis. 2021. "Improvements of Micro-CHP SOFC System Operation by Efficient Dynamic Simulation Methods" Processes 9, no. 7: 1113. https://doi.org/10.3390/pr9071113

APA StyleNousch, L., Hartmann, M., & Michaelis, A. (2021). Improvements of Micro-CHP SOFC System Operation by Efficient Dynamic Simulation Methods. Processes, 9(7), 1113. https://doi.org/10.3390/pr9071113