Understanding the Evolution and Applications of Intelligent Systems via a Tri-X Intelligence (TI) Model

Abstract

:1. Introduction

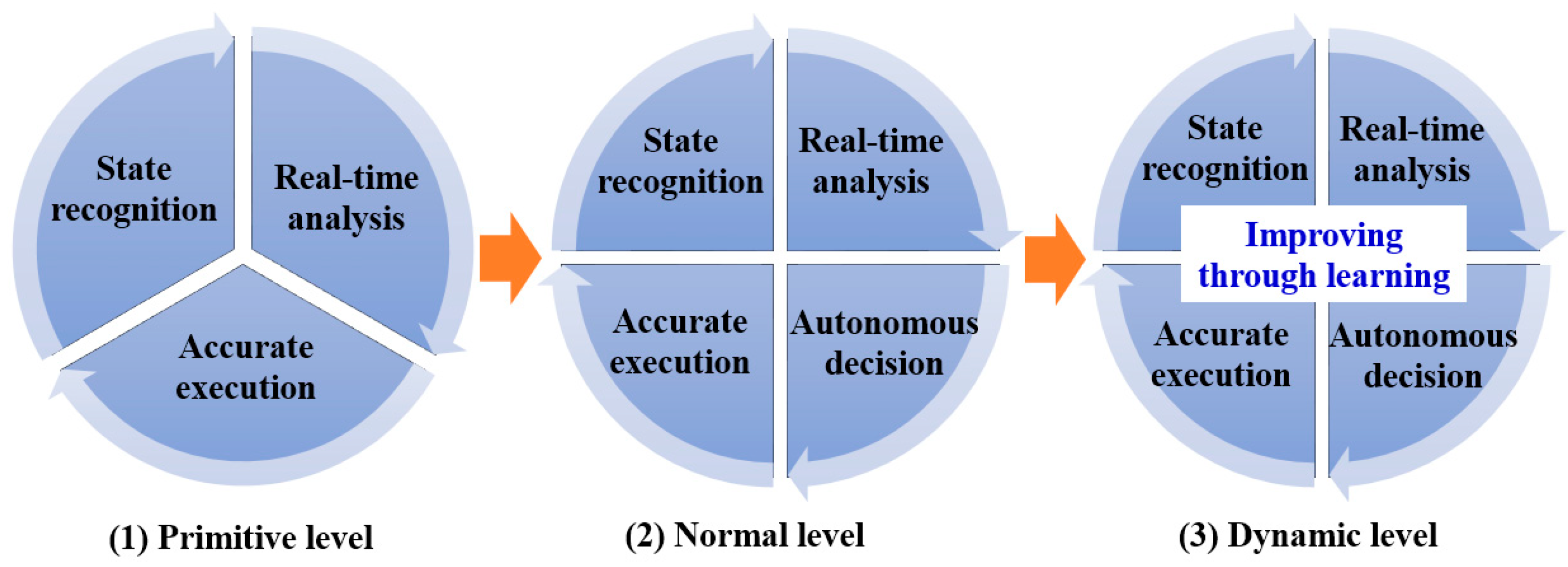

2. Elemental Intelligence Based on Scientific Effects

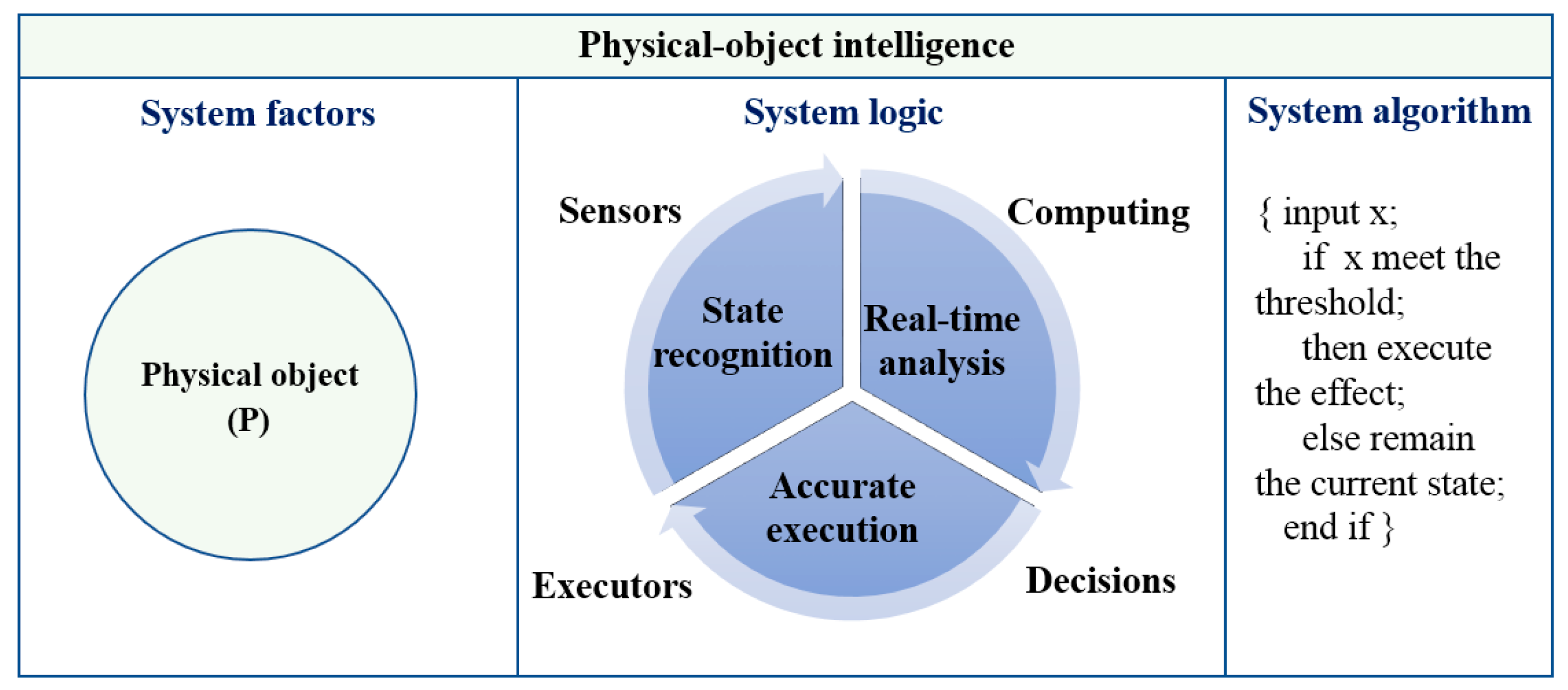

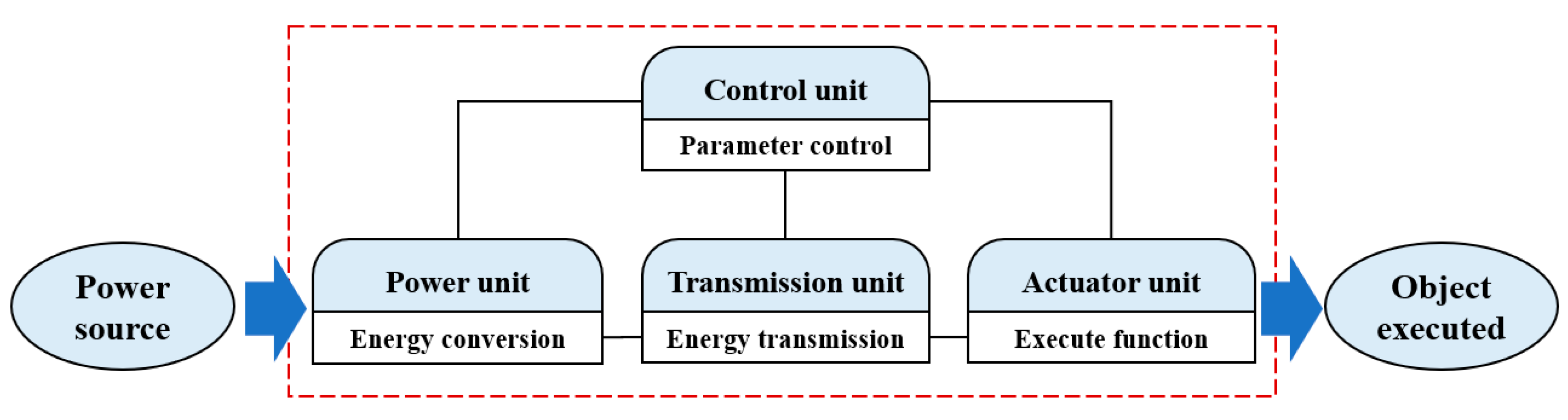

2.1. Physical Object

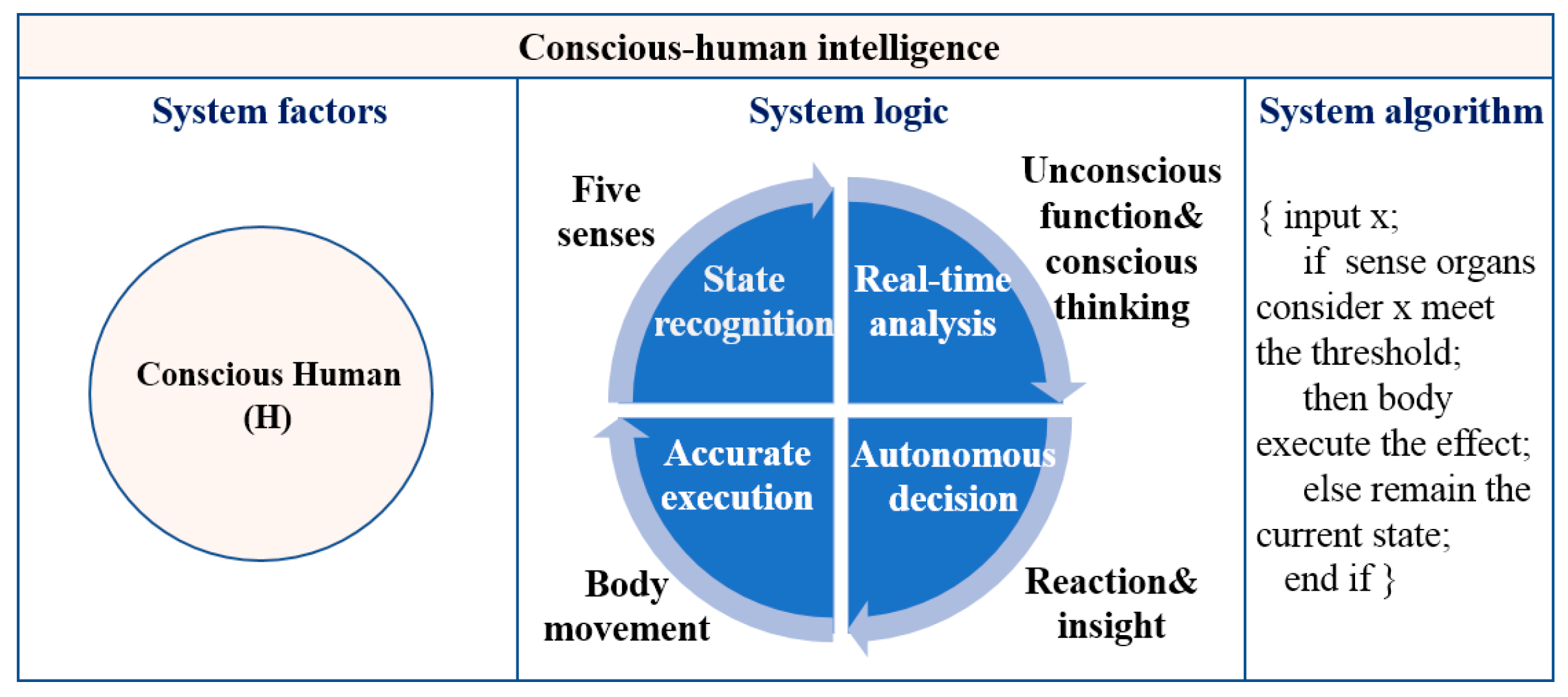

2.2. Conscious Humans

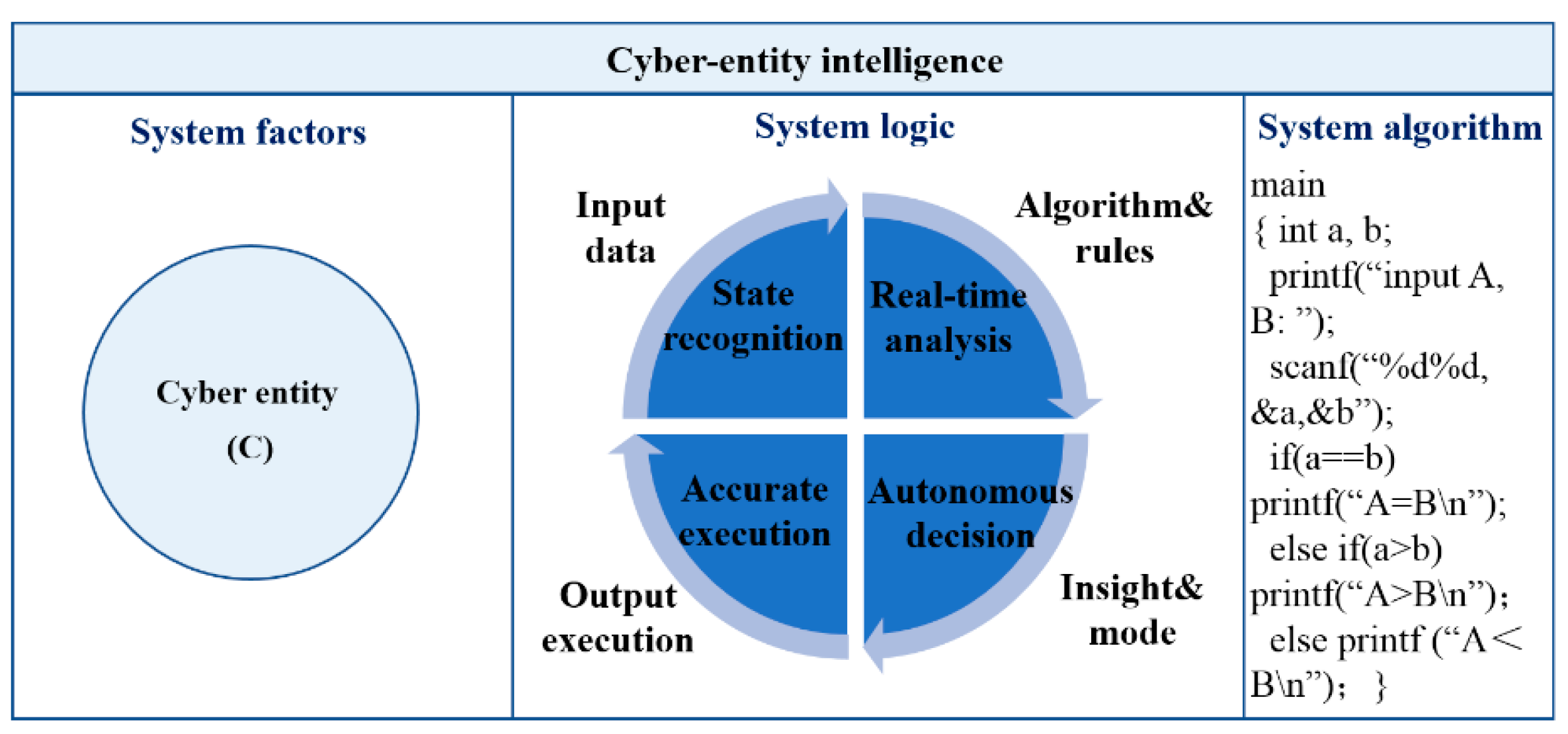

2.3. Cyber Entity

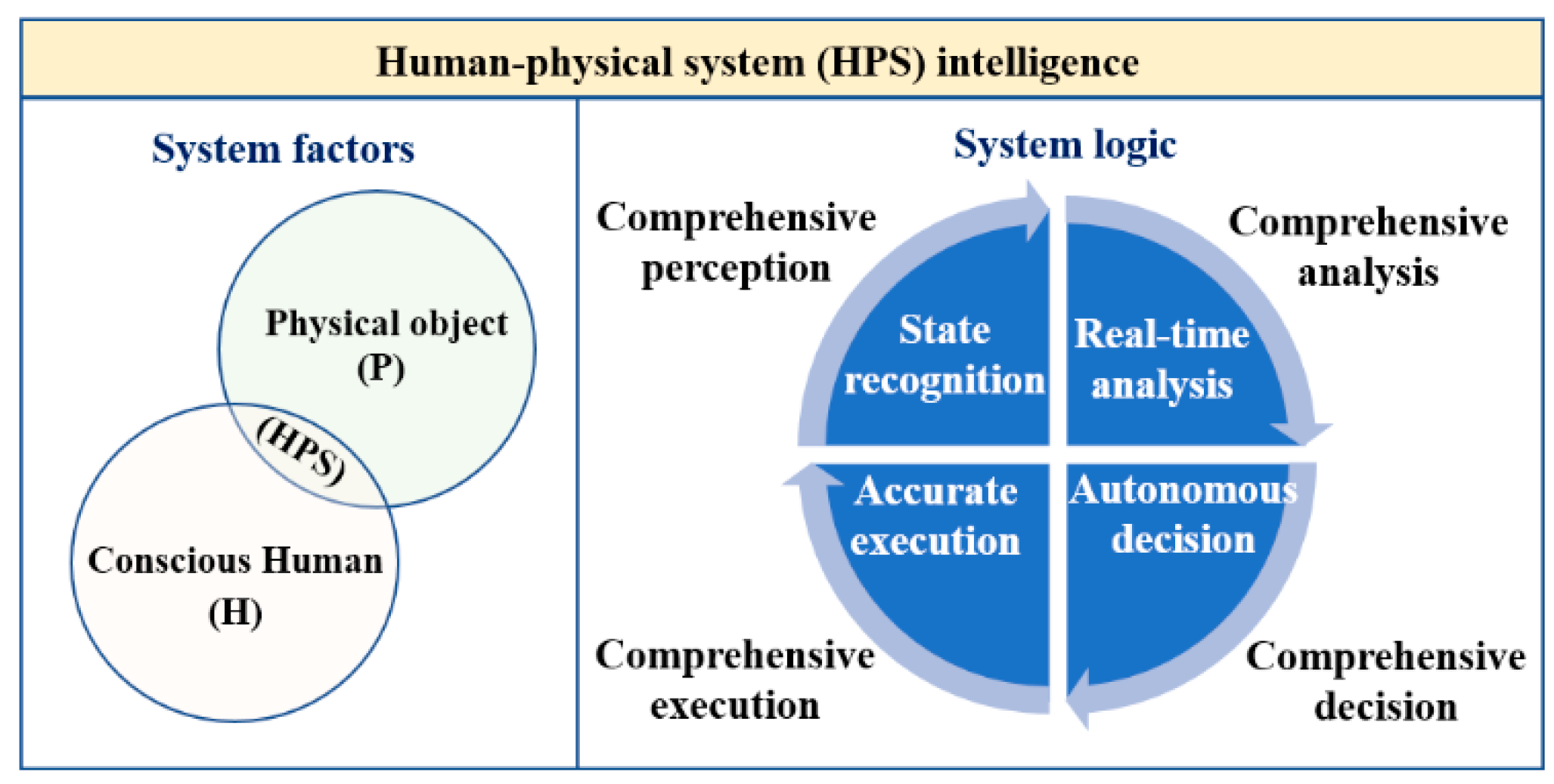

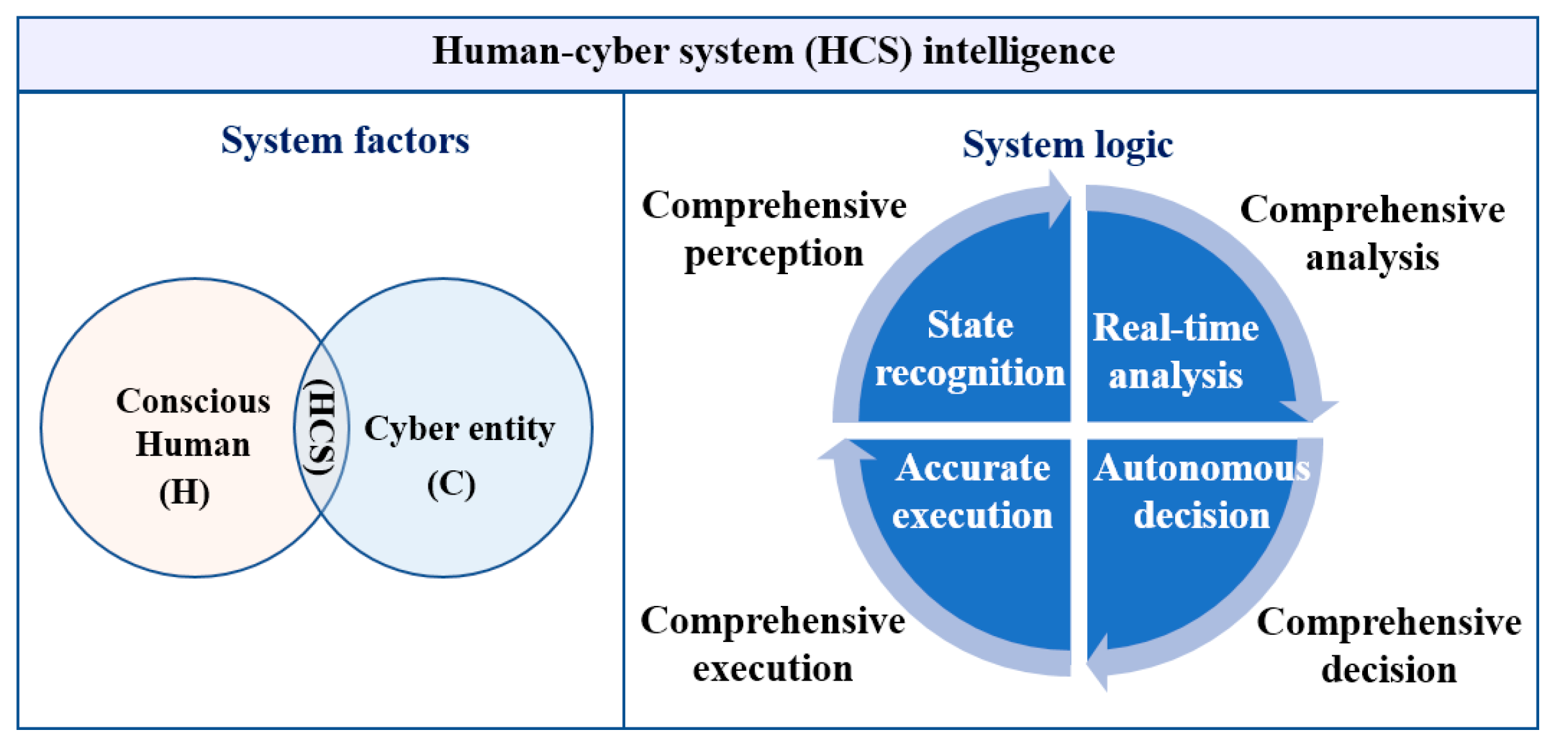

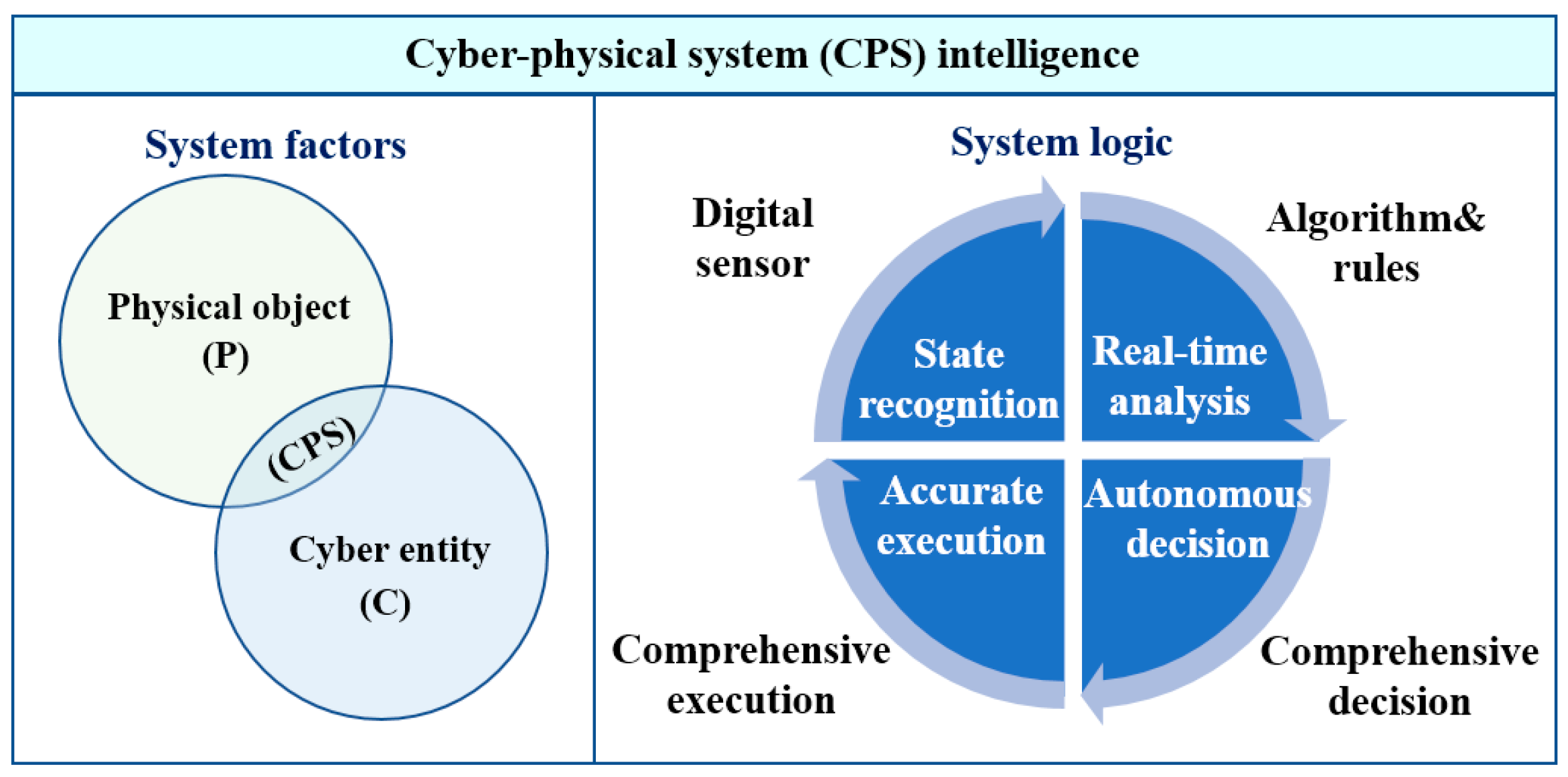

3. Integrated Intelligence Formed by Two-Elements Integration

3.1. Human-Physical System (HPS) Intelligence

3.2. Human-Cyber System (HCS) Intelligence

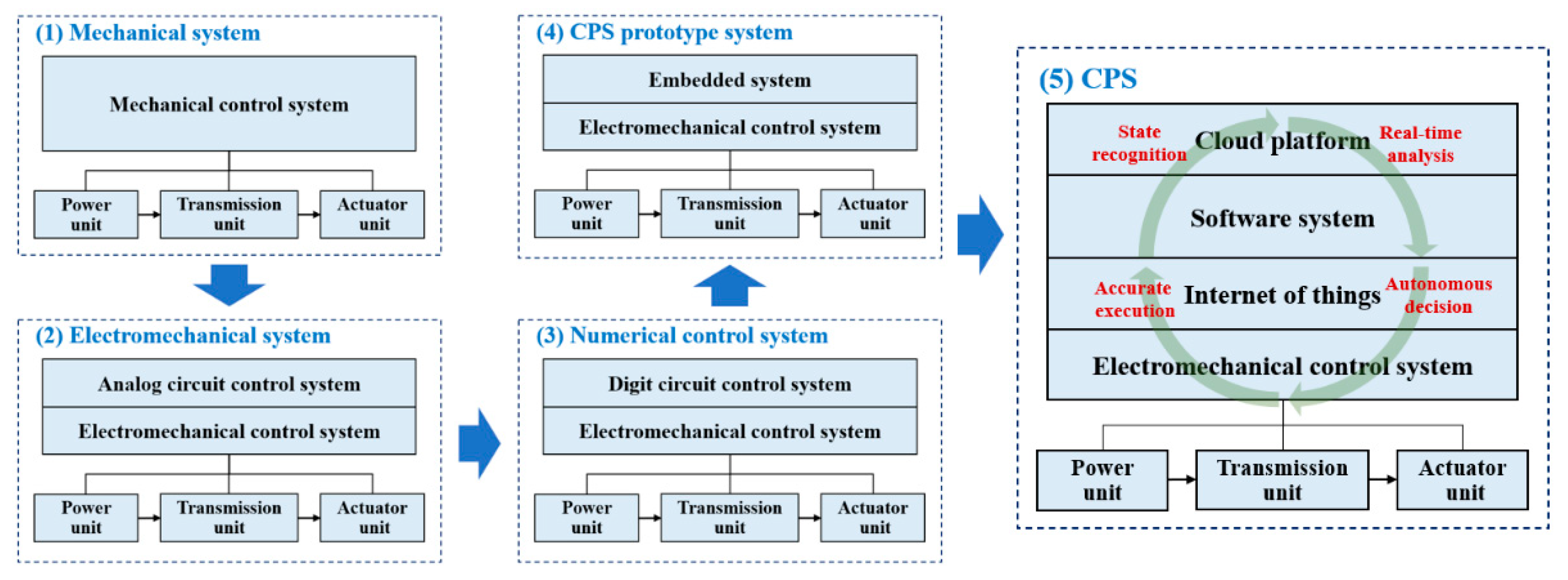

3.3. Cyber-Physical System (CPS) Intelligence

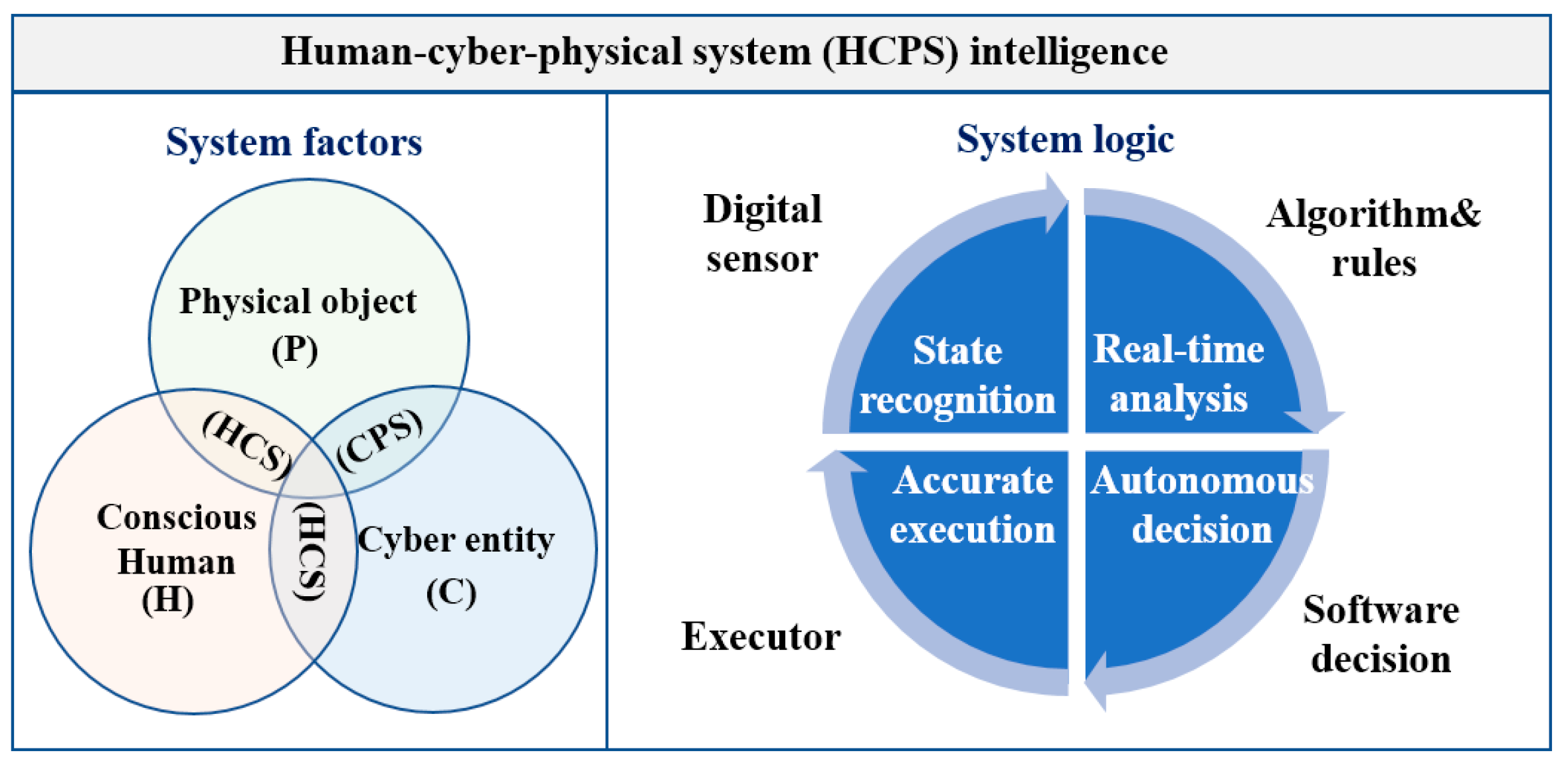

4. Complex Intelligence Formed by Ternary-Interaction

5. Implementation and Applications of Intelligent Systems

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, L. From Intelligence Science to Intelligent Manufacturing. Engineering 2019, 5, 615–618. [Google Scholar] [CrossRef]

- Albus, J.S. A Reference Model Architecture for Intelligent Systems Design; The National Institute of Standards and Technology: Gaithersburg, MD, USA, 1993; pp. 27–56. [Google Scholar]

- Albus, J.S. Outline for a theory of intelligence. IEEE Trans. Syst. Man Cybern. 1991, 214, 73–509. [Google Scholar] [CrossRef] [Green Version]

- Zhou, J.; Li, P.; Zhou, Y.; Wang, B.; Zang, J.; Meng, L. Toward New-Generation Intelligent Manufacturing. Engineering 2018, 4, 11–20. [Google Scholar] [CrossRef]

- Wiener, N. Cybernetics or Control and Communication in the Animal and the Machine; MIT Press: Boston, MA, USA, 1961. [Google Scholar]

- Zhou, J.; Zhou, Y.; Wang, B.; Zang, J. Human–Cyber–Physical Systems (HCPSs) in the Context of New-Generation Intelligent Manufacturing. Engineering 2019, 4, 624–636. [Google Scholar] [CrossRef]

- Wang, B.; Zang, J.; Qu, X.; Dong, J.; Zhou, Y. Research on New-Generation Intelligent Manufacturing based on Human-Cyber-Physical Systems. Strateg. Study Chin. Acad. Eng. 2018, 20, 29–34. [Google Scholar]

- Hu, H.; Zhao, M.; Ning, Z. Three-Body Intelligence Revolution; China Machine Press: Beijing, China, 2016. [Google Scholar]

- Li, W.; Wu, W.J.; Wang, H.M.; Cheng, X.Q.; Chen, H.J.; Zhou, Z.H.; Ding, R. Crowd intelligence in AI 2.0 era. Front. Inform. Technol. Elect. Eng. 2017, 18, 15–43. [Google Scholar] [CrossRef]

- Wright, P.K.; Bourne, D.A. Manufacturing Intelligence; Addison-Wesley Longman Publishing Co., Inc.: Boston, MA, USA, 1988. [Google Scholar]

- Wang, B.; Tao, F.; Fang, X.; Liu, C.; Liu, Y.; Freiheit, T. Smart Manufacturing and Intelligent Manufacturing: A Comparative Review. Engineering 2020. in Press. [Google Scholar] [CrossRef]

- Dickinson, H.W. A Short History of the Steam Engine; Cambridge University Press: Cambridge, UK, 2011. [Google Scholar]

- Bedeloglu, A.; Demir, A.; Bozkurt, Y.; Sariciftci, N.S. A photovoltaic fiber design for smart textiles. Text. Res. J. 2010, 80, 1065–1074. [Google Scholar] [CrossRef]

- Tan, T.Y.; Zhang, L.; Neoh, S.C.; Lim, C.P. Intelligent skin cancer detection using enhanced particle swarm optimization. Knowl. Based Syst. 2018, 158, 118–135. [Google Scholar] [CrossRef]

- Zhou, Y.; Chuah, K. Human intelligence: The key factor for successful intelligent manufacturing. Integr. Manuf. Syst. 2000, 11, 30–41. [Google Scholar] [CrossRef]

- Sanders, N.R.; Wood, J.D. The Humachine: Humankind, Machines, and the Future of Enterprise; Routledge: New York, NY, USA, 2019. [Google Scholar]

- Elmaraghy, W.H.; Nada, O.A.; ElMaraghy, H.A. Quality prediction for reconfigurable manufacturing systems via human error modelling. Int. J. Comput. Integr. Manuf. 2008, 21, 584–598. [Google Scholar] [CrossRef]

- Emmanouilidis, C.; Pistofidis, P.; Bertoncelj, L.; Katsouros, V.; Fournaris, A.; Koulamas, C.; Ruiz-Carcel, C. Enabling the human in the loop: Linked data and knowledge in industrial cyber-physical systems. Annu. Rev. Control 2019, 47, 249–265. [Google Scholar] [CrossRef]

- Zhuang, Y.; Wu, F.; Chen, C.; Pan, Y. Challenges and opportunities: From big data to knowledge in AI 2.0. Front. Inform. Technol. Elect. Eng. 2017, 18, 3–14. [Google Scholar] [CrossRef]

- Jardim-Goncalves, R.; Sarraipa, J.; Agostinho, C.; Panetto, H. Knowledge framework for intelligent manufacturing systems. J. Intell. Manuf. 2011, 22, 725–735. [Google Scholar] [CrossRef]

- Pan, Y. Heading toward artificial intelligence 2.0. Engineering 2016, 2, 409–413. [Google Scholar] [CrossRef]

- Li, B.H.; Hou, B.C.; Yu, W.T.; Lu, X.B.; Yang, C.W. Applications of artificial intelligence in intelligent manufacturing: A review. Front. Inf. Technol. Electron. Eng. 2017, 18, 86–96. [Google Scholar] [CrossRef]

- Zhang, D.; Han, X.; Deng, C. Review on the research and practice of deep learning and reinforcement learning in smart grids. CSEE J. Power Energy Syst. 2018, 4, 362–370. [Google Scholar] [CrossRef]

- Zheng, N.N.; Liu, Z.Y.; Ren, P.J.; Ma, Y.Q.; Chen, S.T.; Yu, S.Y.; Xue, J.R.; Chen, B.D.; Wang, F.Y. Hybrid-augmented intelligence: Collaboration and cognition. Front. Inf. Technol. Electron. Eng. 2017, 18, 153–179. [Google Scholar] [CrossRef]

- Peng, Y.X.; Zhu, W.W.; Zhao, Y.; Xu, C.S.; Huang, Q.M.; Lu, H.Q.; Zheng, Q.H.; Huang, T.J.; Gao, W. Cross-media analysis and reasoning: Advances and directions. Front. Inf. Technol. Electron. Eng. 2017, 18, 44–57. [Google Scholar] [CrossRef]

- Zhang, T.; Li, Q.; Zhang, C.S.; Liang, H.W.; Li, P.; Wang, T.M.; Li, S.; Zhu, Y.L.; Wu, C. Current trends in the development of intelligent unmanned autonomous systems. Front. Inf. Technol. Electron. Eng. 2017, 18, 68–85. [Google Scholar] [CrossRef] [Green Version]

- Chantem, T.; Guan, N.; Liu, D. Sustainable embedded software and systems. Sustain. Comput. Infor. 2019, 22, 152–154. [Google Scholar] [CrossRef]

- Feng, S.; Tang, M.; Quivira, F.; Dyson, T.; Cuckov, F.; Schirner, G. EEGu2: An Embedded Device for Brain/Body Signal Acquisition and Processing. In Proceedings of the 2016 27th International Symposium on Rapid System Prototyping, Pittsburg, PA, USA, 6–7 October 2016; IEEE: New York, NY, USA, 2016; pp. 19–25. [Google Scholar] [CrossRef]

- Vassanelli, S.; Mahmud, M.; Girardi, S.; Maschietto, M. On the way to large-scale and high-resolution brain-chip interfacing. Cogn. Comput. 2012, 4, 71–81. [Google Scholar] [CrossRef] [Green Version]

- Poppe, R. A survey on vision-based human action recognition. Image Vis. Comput. 2010, 28, 976–990. [Google Scholar] [CrossRef]

- Nunes, D.S.; Zhang, P.; Silva, J.S. A Survey on Human-in-the-Loop Applications towards an Internet of All. IEEE Commun. Surv. Tutor. 2015, 17, 944–965. [Google Scholar] [CrossRef]

- Lu, H.; Li, Y.; Chen, M.; Kim, H.; Serikawa, S. Brain intelligence: Go beyond artificial intelligence. Mob. Netw. Appl. 2018, 23, 368–375. [Google Scholar] [CrossRef] [Green Version]

- Gill, H.; National Science Foundation, Alexandria, VA, USA. Cyber-Physical Systems: Beyond ES, SNs, SCADA. Personal Communication, 2010. [Google Scholar]

- Gill, H.; National Science Foundation, Alexandria, VA, USA. NSF Perspective and Status on Cyber-Physical Systems. Personal Communication, 2006. [Google Scholar]

- Xu, L.D.; Xu, E.L.; Li, L. Industry 4.0: State of the art and future trends. Int. J. Prod. Res. 2018, 56, 2941–2962. [Google Scholar] [CrossRef] [Green Version]

- Yao, X.; Zhou, J.; Lin, Y.; Li, Y.; Yu, H.; Liu, Y. Smart manufacturing based on cyber-physical systems and beyond. J. Intell. Manuf. 2019, 30, 2805–2817. [Google Scholar] [CrossRef] [Green Version]

- Hankel, M.; Rexroth, B. The reference architectural model industrie 4.0 (rami 4.0). ZVEI 2015, 2, 4. [Google Scholar]

- Tao, F.; Zhang, H.; Liu, A.; Nee, A.Y.C. Digital twin in industry: State-of-the-art. IEEE Trans. Ind. Inform. 2018, 15, 2405–2415. [Google Scholar] [CrossRef]

- Qi, Q.; Tao, F. Digital twin and big data towards smart manufacturing and industry 4.0: 360 degree comparison. IEEE Access 2018, 6, 3585–3593. [Google Scholar] [CrossRef]

- Tao, F.; Cheng, J.; Qi, Q.; Zhang, M.; Zhang, H.; Sui, F. Digital twin-driven product design, manufacturing and service with big data. Int. J. Adv. Manuf. Technol. 2018, 94, 3563–3576. [Google Scholar] [CrossRef]

- Litman, T. Autonomous Vehicle Implementation Predictions; Victoria Transport Policy Institute: Victoria, BC, Canada, 2017. [Google Scholar]

- Fawkes, A.J. Developments in Artificial Intelligence: Opportunities and Challenges for Military Modeling and Simulation. In Proceedings of the 2017 NATO M&S Symposium, Lisbon, Portugal, 14–16 May 2017; pp. 11.11–11.14. [Google Scholar]

- Liu, H.; Wang, L. Gesture recognition for human-robot collaboration: A review. Int. J. Ind. Ergon. 2018, 68, 355–367. [Google Scholar] [CrossRef]

- Wang, X.V.; Wang, L. Augmented Reality Enabled Human–Robot Collaboration. In Advanced Human-Robot Collaboration in Manufacturing; Wang, L., Wang, X.V., Váncza, J., Kemény, Z., Eds.; Springer: Cham, Switzerland, 2021. [Google Scholar] [CrossRef]

- Zhu, J.; Huang, T.; Chen, W.; Gao, W. The future of artificial intelligence in China. Commun. ACM 2018, 61, 44–45. [Google Scholar] [CrossRef]

- Kusiak, A. Smart manufacturing must embrace big data. Nature 2017, 544, 23–25. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, M.; Ning, Z.; Wang, B.; Peng, C.; Li, X.; Huang, S. Understanding the Evolution and Applications of Intelligent Systems via a Tri-X Intelligence (TI) Model. Processes 2021, 9, 1080. https://doi.org/10.3390/pr9061080

Zhao M, Ning Z, Wang B, Peng C, Li X, Huang S. Understanding the Evolution and Applications of Intelligent Systems via a Tri-X Intelligence (TI) Model. Processes. 2021; 9(6):1080. https://doi.org/10.3390/pr9061080

Chicago/Turabian StyleZhao, Min, Zhenbo Ning, Baicun Wang, Chen Peng, Xingyu Li, and Sihan Huang. 2021. "Understanding the Evolution and Applications of Intelligent Systems via a Tri-X Intelligence (TI) Model" Processes 9, no. 6: 1080. https://doi.org/10.3390/pr9061080

APA StyleZhao, M., Ning, Z., Wang, B., Peng, C., Li, X., & Huang, S. (2021). Understanding the Evolution and Applications of Intelligent Systems via a Tri-X Intelligence (TI) Model. Processes, 9(6), 1080. https://doi.org/10.3390/pr9061080