Microstructure and Mechanical Performance of Resistance Spot Welded Martensitic Advanced High Strength Steel

Abstract

:1. Introduction

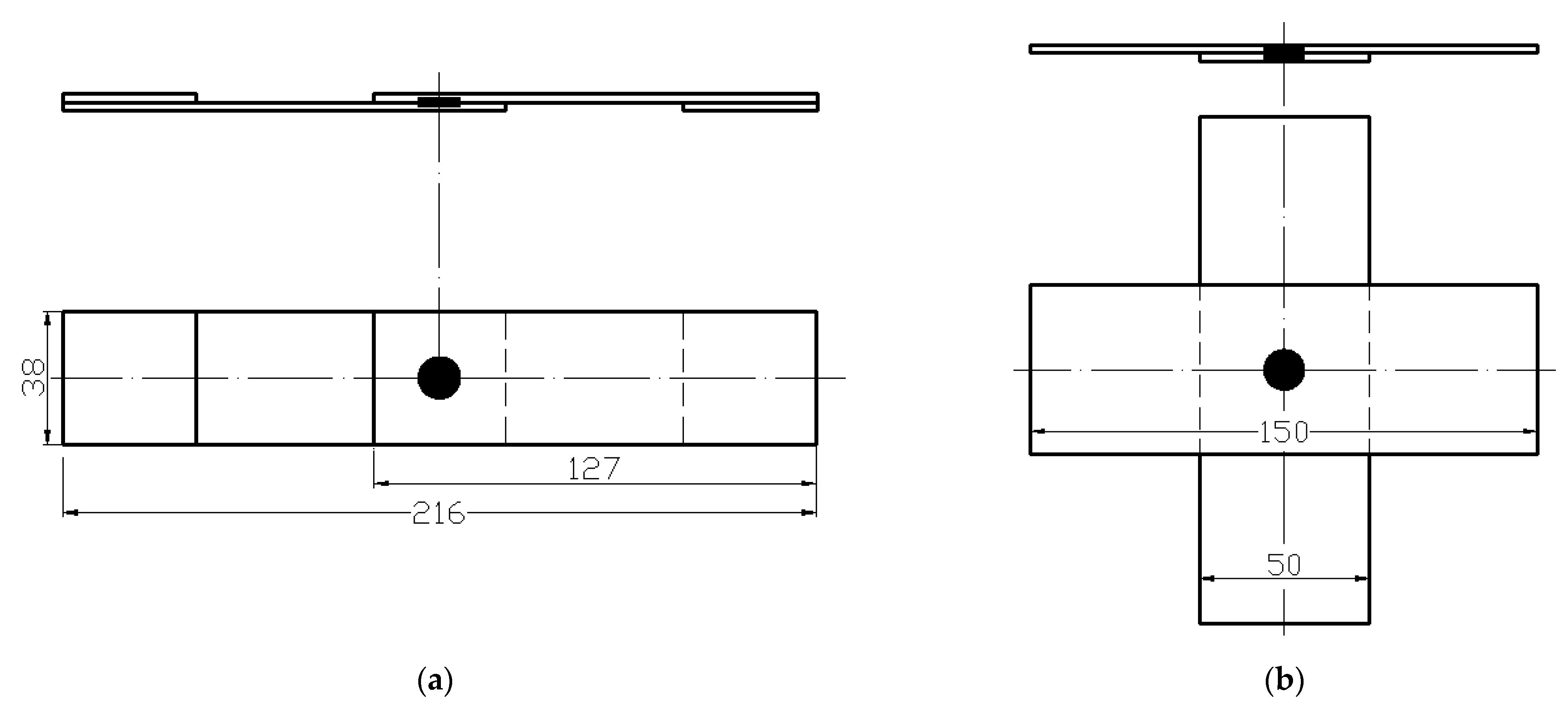

2. Materials and Methods

3. Results and Discussion

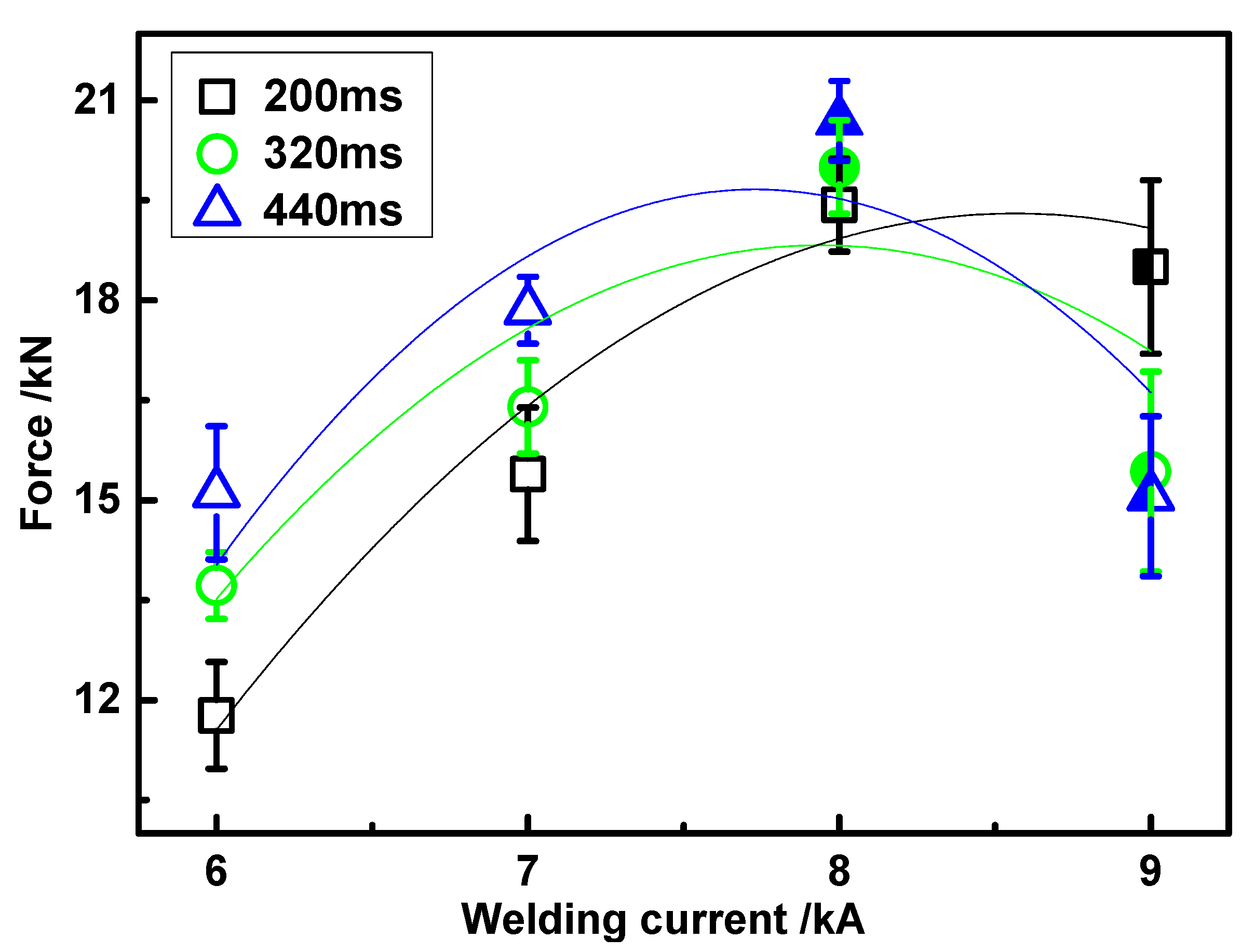

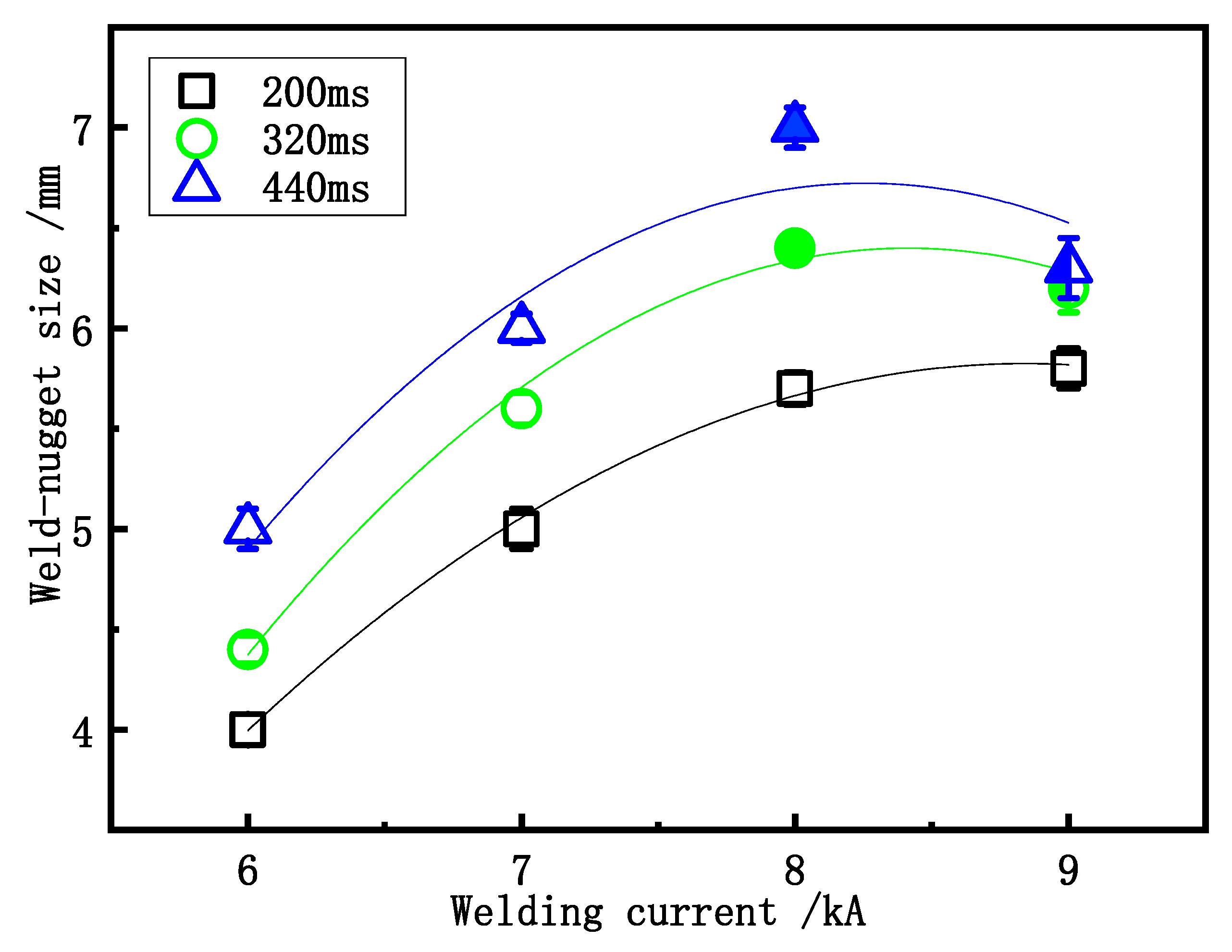

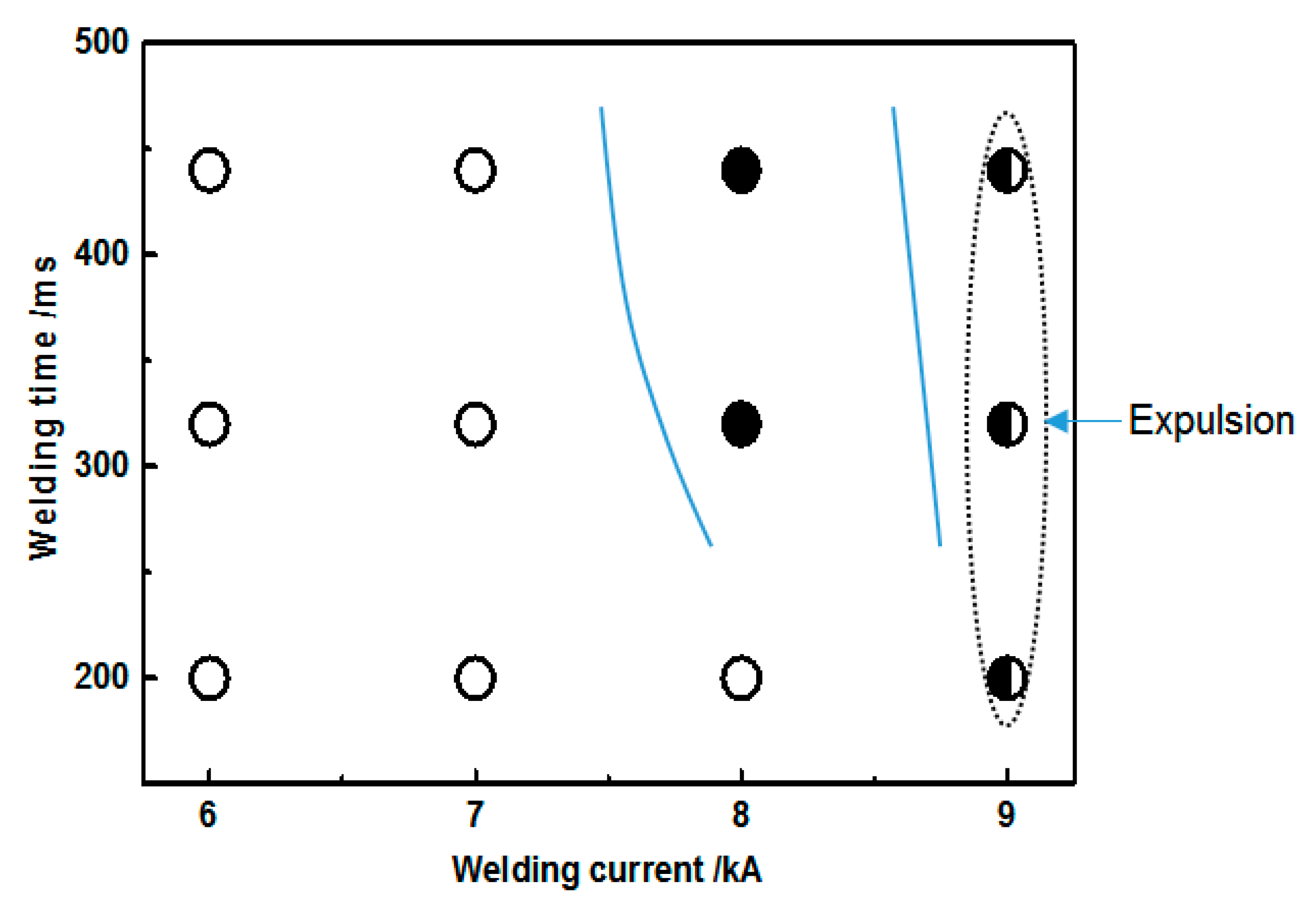

3.1. Effect of Welding Parameters on Mechanical Properties of Welded MS1400

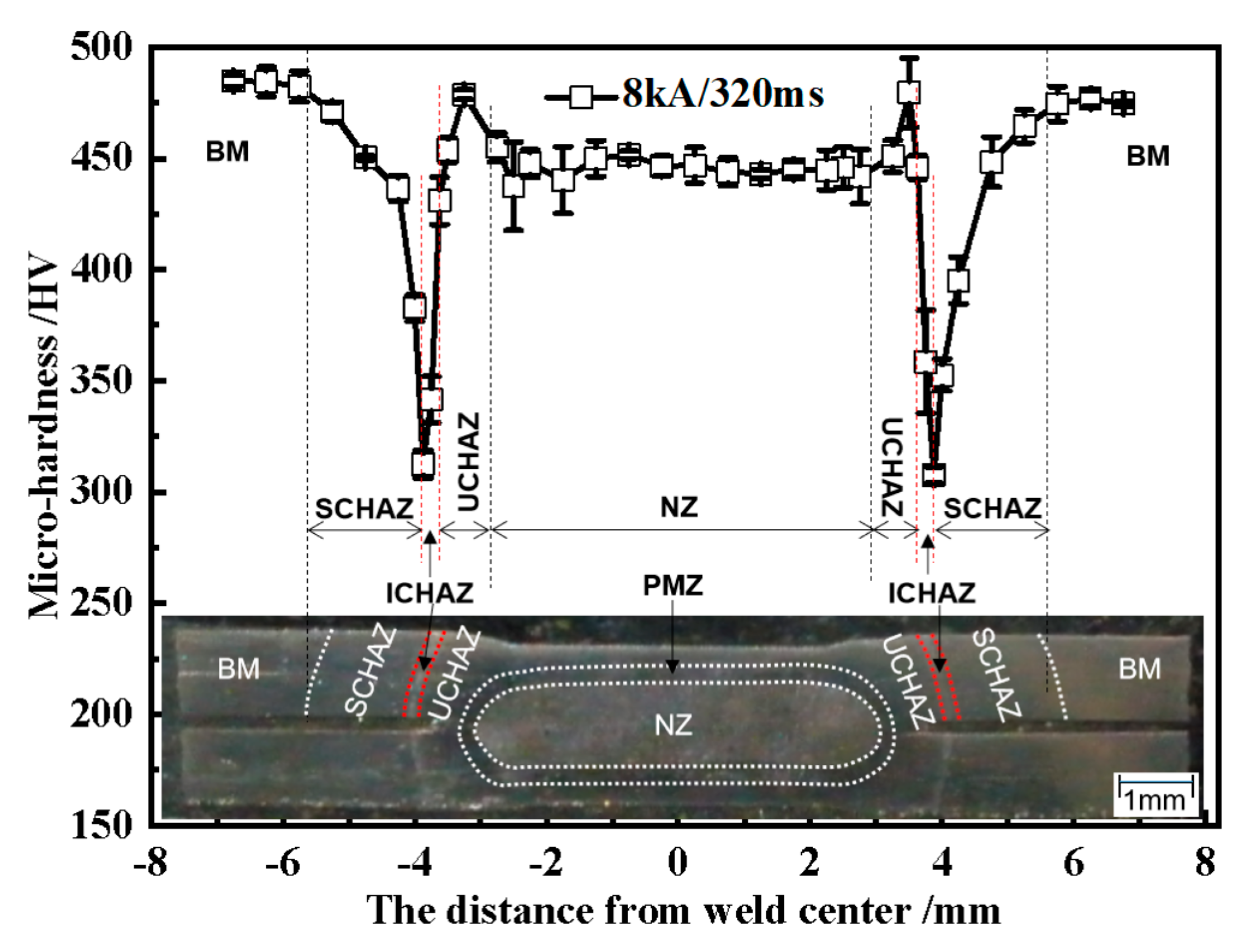

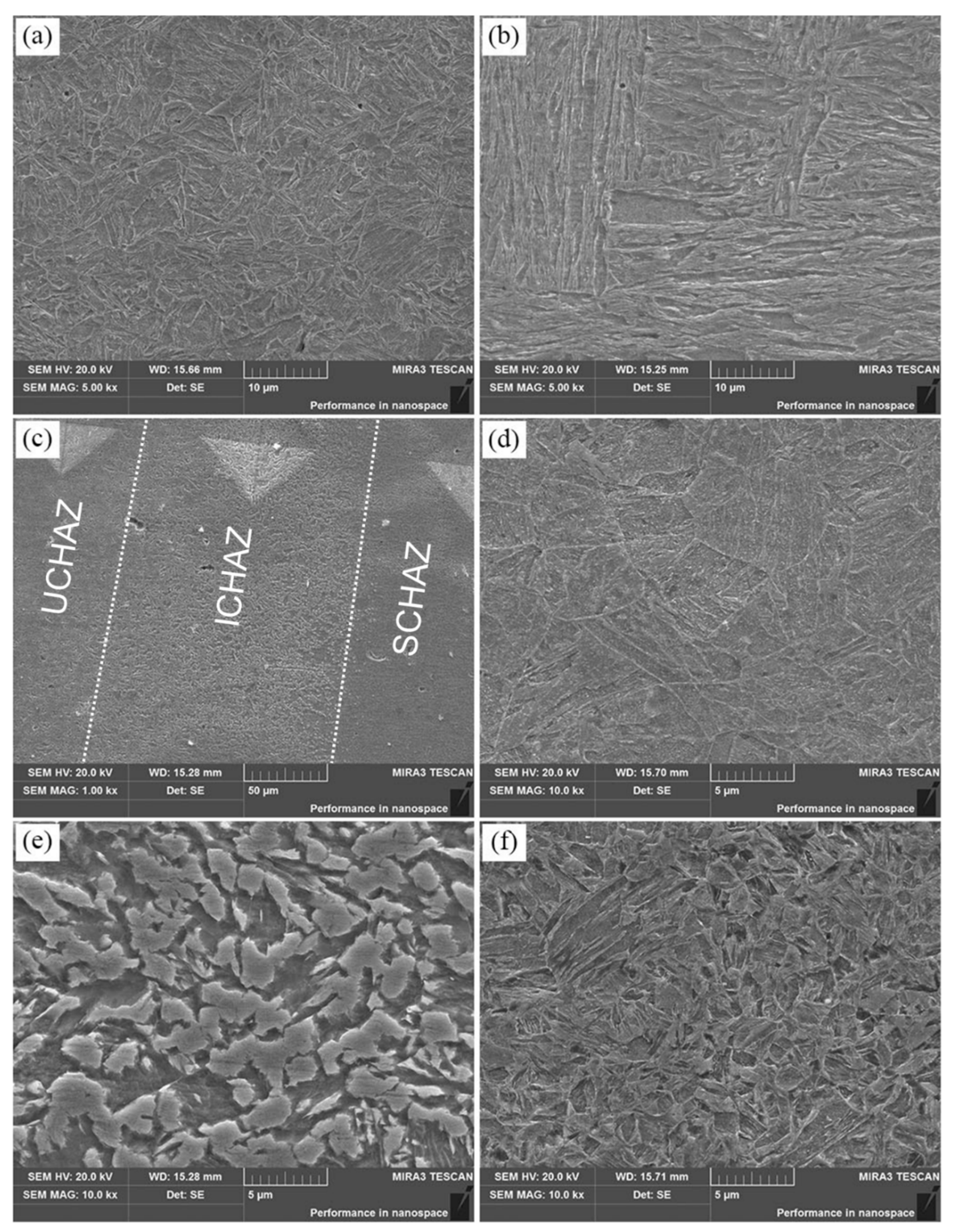

3.2. Microstructure of Welded MS1400

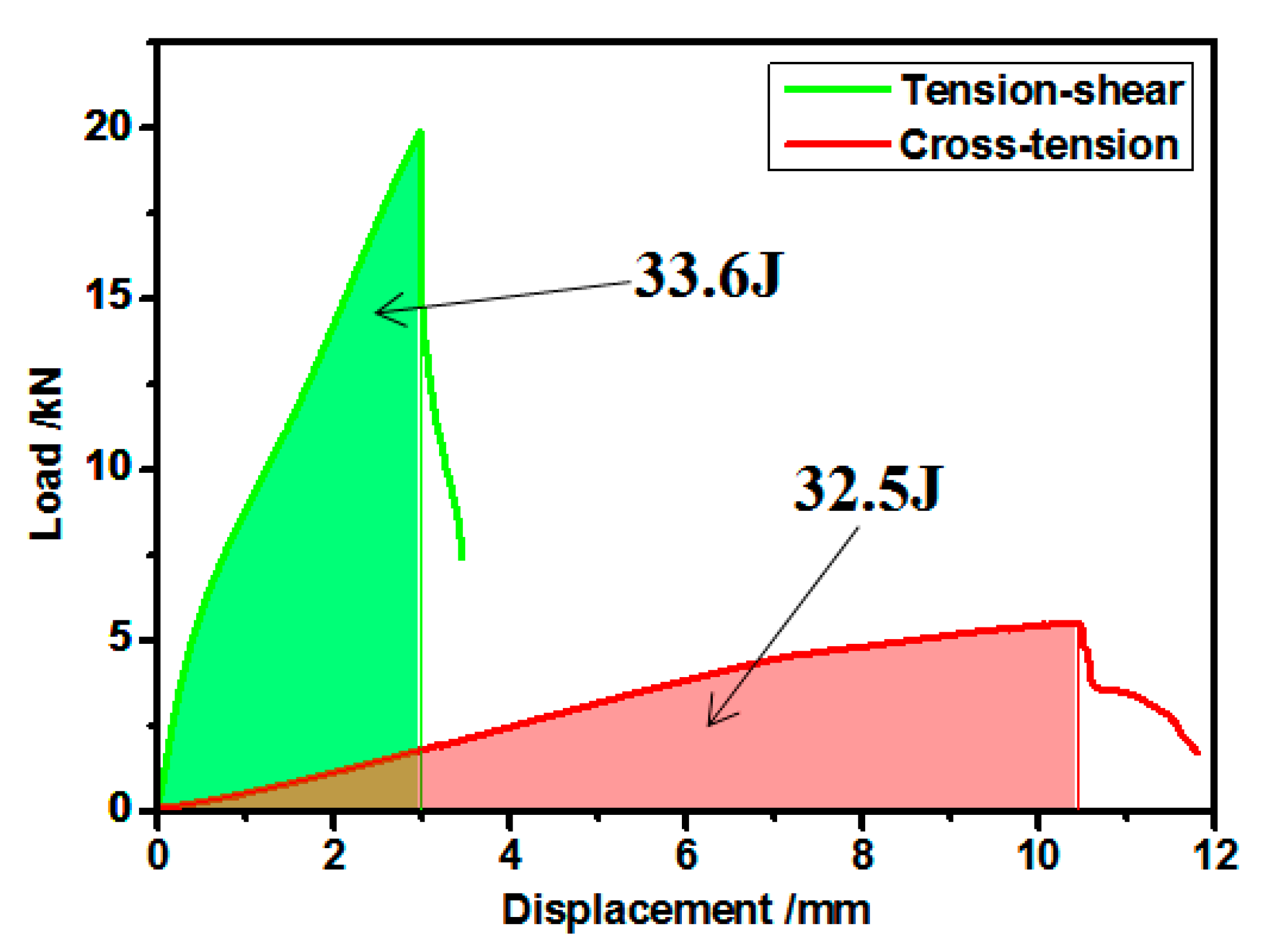

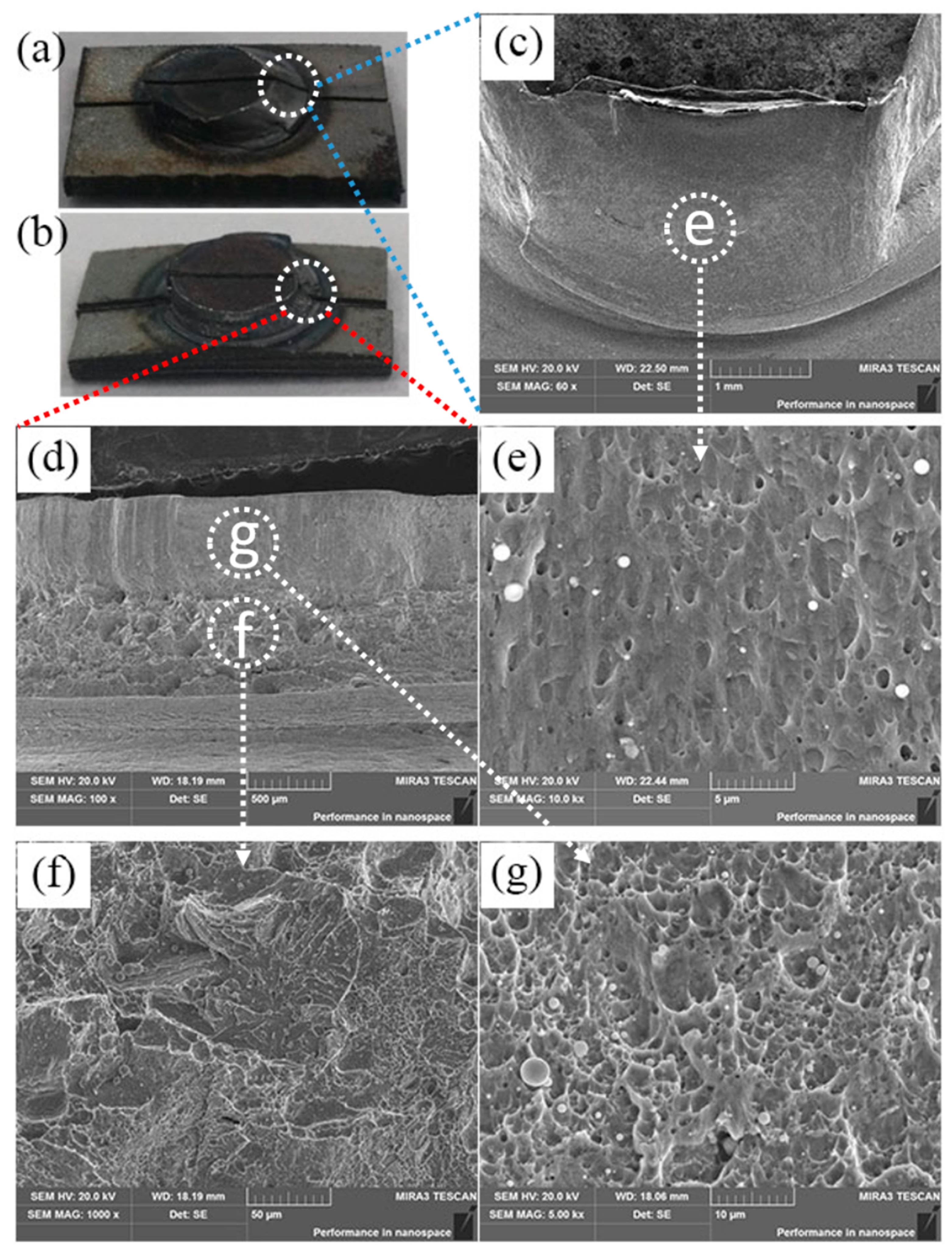

3.3. Absorb Energies and Fracture Behavior under Cross-Tension and Tension-Shear Test

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Keeler, S.; Kimchi, M.; Mooney, P.J. Advanced High-Strength Steels Application Guidelines Version 6.0; World Auto Steel: Brussels, Belgium, 2017. [Google Scholar]

- Roy, T.K.; Bhattacharya, B.; Ghosh, C.; Ajmani, S. Advanced High Strength Steel; Springer: Berlin/Heidelberg, Germany, 2018. [Google Scholar]

- Bernert, W.; Bzdok, M.; Davis, J.; Fekete, J.; Fitzgerald, K.; Noel, J.; Saez, M.; Schmid, K.; Telleck, G.; Velentine, M. Advanced High-Strength Steel Applications Design and Stamping Process Guidelines; Auto/Steel Partnership: Southfield, MI, USA, 2010. [Google Scholar]

- Maatz, D. Advanced High Strength Steel (AHSS) Weld Performance Study for Autobody Structural Components. Mater. Sci. Technol. Assoc. Iron Steel Technol. 2007, 5, 3114. [Google Scholar]

- Auto/Steel Partnership. An Investigation of Resistance Welding Performance of Advanced High Strength Steels; Auto/Steel Partnership: Southfield, MI, USA, 2017. [Google Scholar]

- Demeri, M.Y. Advanced-High Strength Steels: Science, Technology, and Applications; ASM International: Materials Park, OH, USA, 2013. [Google Scholar]

- Shome, M.; Tumuluru, M. Welding and Joining of Advanced High Strength Steels (AHSS); Woodhead Publishing: Cambridge, UK, 2015. [Google Scholar]

- Ahiale, G.K.; Oh, Y.J. Microstructure and fatigue performance of butt-welded joints in advanced high-strength steels. Mater. Sci. Eng. A 2014, 597, 342. [Google Scholar] [CrossRef]

- Nemecek, S.; Muzik, T.; Misek, M. Differences between laser and arc welding of HSS steel. Phys. Procedia 2012, 39, 67. [Google Scholar] [CrossRef] [Green Version]

- Maa, J.; Konga, F.; Carlsonb, B.; Kovacevica, R. Two-pass laser welding of galvanized high-strength dual-phase steel for a zero-gap lap joint configuration. J. Mater. Process. Technol. 2013, 213, 495. [Google Scholar] [CrossRef]

- Saha, D.C. Kinetics of Carbide Precipitation during Laser Beam Welding of Dual-Phase and Martensitic Steels; University of Waterloo: Waterloo, ON, Canada, 2016. [Google Scholar]

- Pouranvari, M.; Sobhani, S.; Goodarzi, F. Resistance spot welding of MS1200 martensitic advanced high strength steel: Microstructure-properties relationship. J. Manuf. Process. 2018, 31, 867–874. [Google Scholar] [CrossRef]

- Ramazani, A.; Mukherjee, K.; Abdurakhmanov, A.; Abbasi, M.; Prahl, U. Characterization of microstructure and mechanical properties of resistance spot welded DP600 steel. Metals 2015, 5, 1704–1716. [Google Scholar] [CrossRef] [Green Version]

- Spena, P.R.; de Maddis, M.; D’Antonio, G.; Lombardi, F. Weldability and Monitoring of Resistance Spot Welding of Q&P and TRIP Steels. Metals 2016, 6, 270. [Google Scholar]

- Nikoosohbat, F.; Kheirandish, S.; Goodarzi, M.; Pouranvari, M.; Marashi, S. Microstructure and failure behaviour of resistance spot welded DP980 dual phase steel. Mater. Sci. Technol. 2010, 26, 738–744. [Google Scholar] [CrossRef]

- Goodarzi, M.; Marashi, S.; Pouranvari, M. Dependence of overload performance on weld attributes for resistance spot welded galvanized low carbon steel. J. Mater. Process. Technol. 2009, 209, 4379–4384. [Google Scholar] [CrossRef]

- Ma, C.; Chen, D.L.; Bhole, S.D.; Boudreau, G.; Lee, A.; Biro, E. Microstructure and fracture characteristics of spot-welded DP600 steel. Mater. Sci. Eng. A 2008, 485, 334–346. [Google Scholar] [CrossRef]

- Eshraghi, M.; Tschopp, M.A.; Zaeem, M.A.; Felicelli, S.D. Effect of resistance spot welding parameters on weld pool properties in a DP600 dual-phase steel: A parametric study using thermomechanically-coupled finite element analysis. Mater. Des. 2014, 56, 387–397. [Google Scholar] [CrossRef]

- Sun, X.; Stephens, E.V.; Khaleel, M.A. Effects of fusion zone size and failure mode on peak load and energy absorption of advanced high-strength steel spot welds. Weld. J. N. Y. 2007, 86, 18. [Google Scholar]

- Sun, X.; Stephens, E.V.; Khaleel, M.A. Effects of fusion zone size and failure mode on peak load and energy absorption of advanced high strength steel spot welds under lap shear loading conditions. Eng. Fail. Anal. 2008, 15, 356–367. [Google Scholar] [CrossRef]

- Tamizi, M.; Pouranvari, M.; Movahedi, M. Welding metallurgy of martensitic advanced high strength steels during resistance spot welding. Sci. Technol. Weld. Join. 2017, 22, 327–335. [Google Scholar] [CrossRef]

- Tamizi, M.; Pouranvari, M.; Movahed, M. The role of HAZ softening on cross-tension mechanical performance of martensitic advanced high strength steel resistance spot welds. Metall. Mater. Trans. A 2021, 52, 655–667. [Google Scholar] [CrossRef]

- Rezayat, H.; Ghassemi-Armaki, H.; Sriram, S.; Babu, S.S. Correlation of local constitutive properties to global mechanical performance of advanced high-strength steel spot welds. Metall. Mater. Trans. A 2020, 51, 1–13. [Google Scholar] [CrossRef]

- ANSI/AWS/SAE/D8.9–2012 “Test Method for Evaluating the Resistance Spot Welding Behavior of Automotive Sheet Steel Materials”; American Welding Society: Miami, FL, USA, 2012.

- Scotchmer, N. Widening the Welding Lobe of Advanced High Strength Steels in the Resistance Spot Welding Process; Huys Industries Limited: North York, ON, Canada, 2007. [Google Scholar]

- Zhang, X.; Chen, G.; Zhang, Y.; Lai, X. Improvement of resistance spot weldability for dual-phase (DP600) steels using servo gun. J. Mater. Process. Technol. 2009, 209, 2671–2675. [Google Scholar] [CrossRef]

- Japanese Industrial Standards Committee. Method of Inspection for Spotwelds; JIS Z 3140; Japanese Industrial Standards Committee: Tokyo, Japan, 1989.

- German Industrial Standards Committee. Resistance Spot Welding; DVS 2923; Deutsches Institut für Normung: Berlin, Germany, 1986. [Google Scholar]

- Pouranvari, M.; Asgari, H.; Mosavizadch, S.; Marashi, P.; Goodarzi, M. Effect of weld nugget size on overload failure mode of resistance spot welds. Sci. Technol. Weld. Join. 2007, 12, 217–225. [Google Scholar] [CrossRef]

- Dancette, S.; Fabrègue, D.; Massardier, V.; Merlin, J.; Dupuy, T.; Bouzekri, M. Experimental and modeling investigation of the failure resistance of advanced high strength steels spot welds. Eng. Fract. Mech. 2011, 78, 2259–2272. [Google Scholar] [CrossRef]

| Chemical Composition (wt. %) | Mechanical Properties | |||||||

|---|---|---|---|---|---|---|---|---|

| C | Si | Mn | P | S | Al | Yield Strength (MPa) | Tensile Strength (MPa) | Elongation (%) |

| 0.17 | 0.42 | 1.66 | 0.009 | 0.002 | 0.03 | 1338 | 15,184 | 4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Tang, H.; Lai, R. Microstructure and Mechanical Performance of Resistance Spot Welded Martensitic Advanced High Strength Steel. Processes 2021, 9, 1021. https://doi.org/10.3390/pr9061021

Li Y, Tang H, Lai R. Microstructure and Mechanical Performance of Resistance Spot Welded Martensitic Advanced High Strength Steel. Processes. 2021; 9(6):1021. https://doi.org/10.3390/pr9061021

Chicago/Turabian StyleLi, Yunzhao, Huaping Tang, and Ruilin Lai. 2021. "Microstructure and Mechanical Performance of Resistance Spot Welded Martensitic Advanced High Strength Steel" Processes 9, no. 6: 1021. https://doi.org/10.3390/pr9061021

APA StyleLi, Y., Tang, H., & Lai, R. (2021). Microstructure and Mechanical Performance of Resistance Spot Welded Martensitic Advanced High Strength Steel. Processes, 9(6), 1021. https://doi.org/10.3390/pr9061021