Evaluation of Techno-Economic Studies on the bioliq® Process for Synthetic Fuels Production from Biomass

Abstract

1. Introduction

2. Methods

3. Results and Discussion

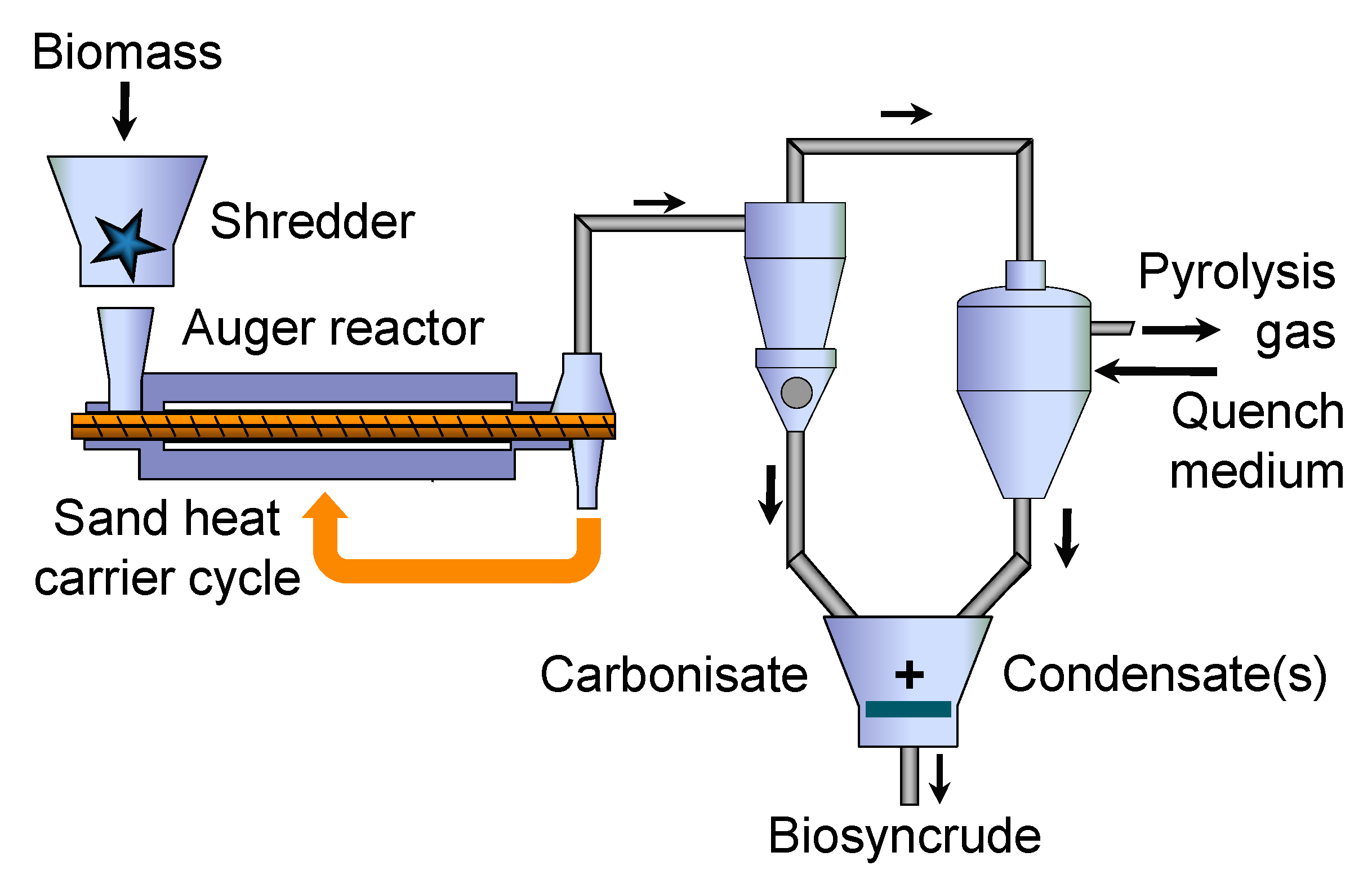

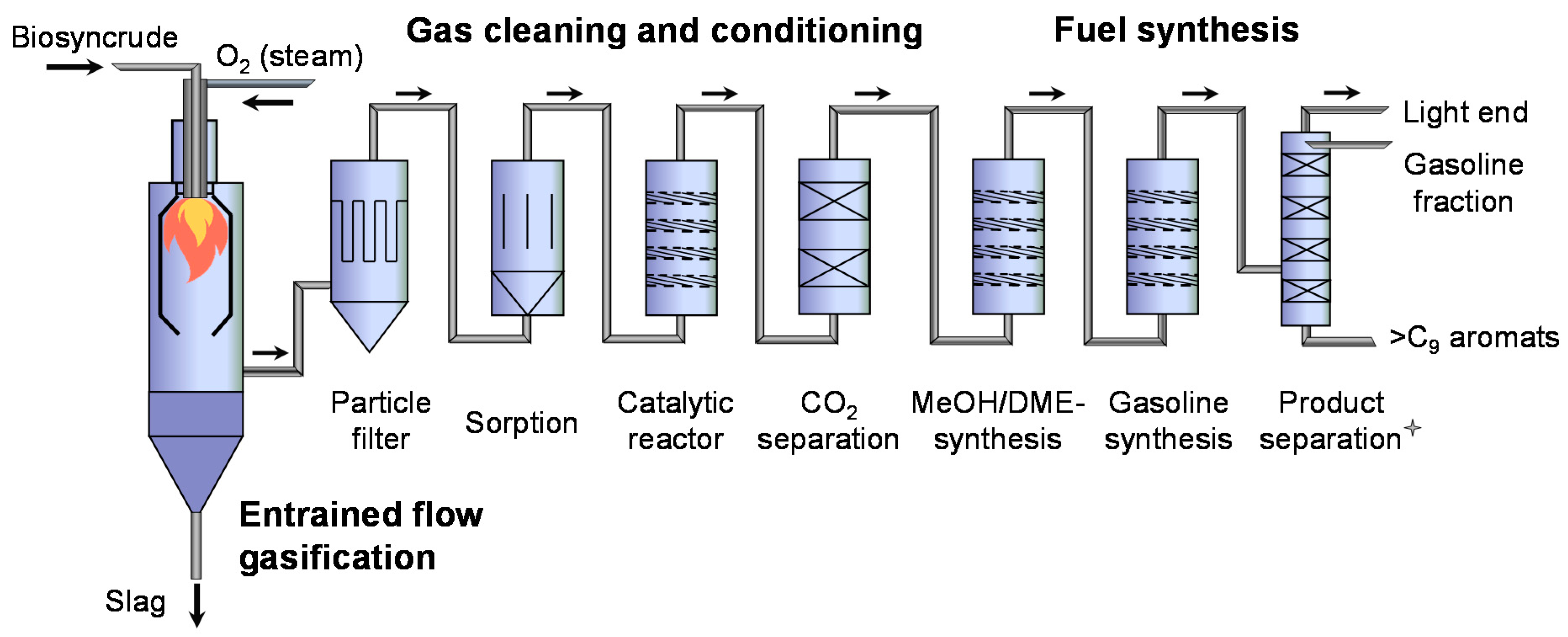

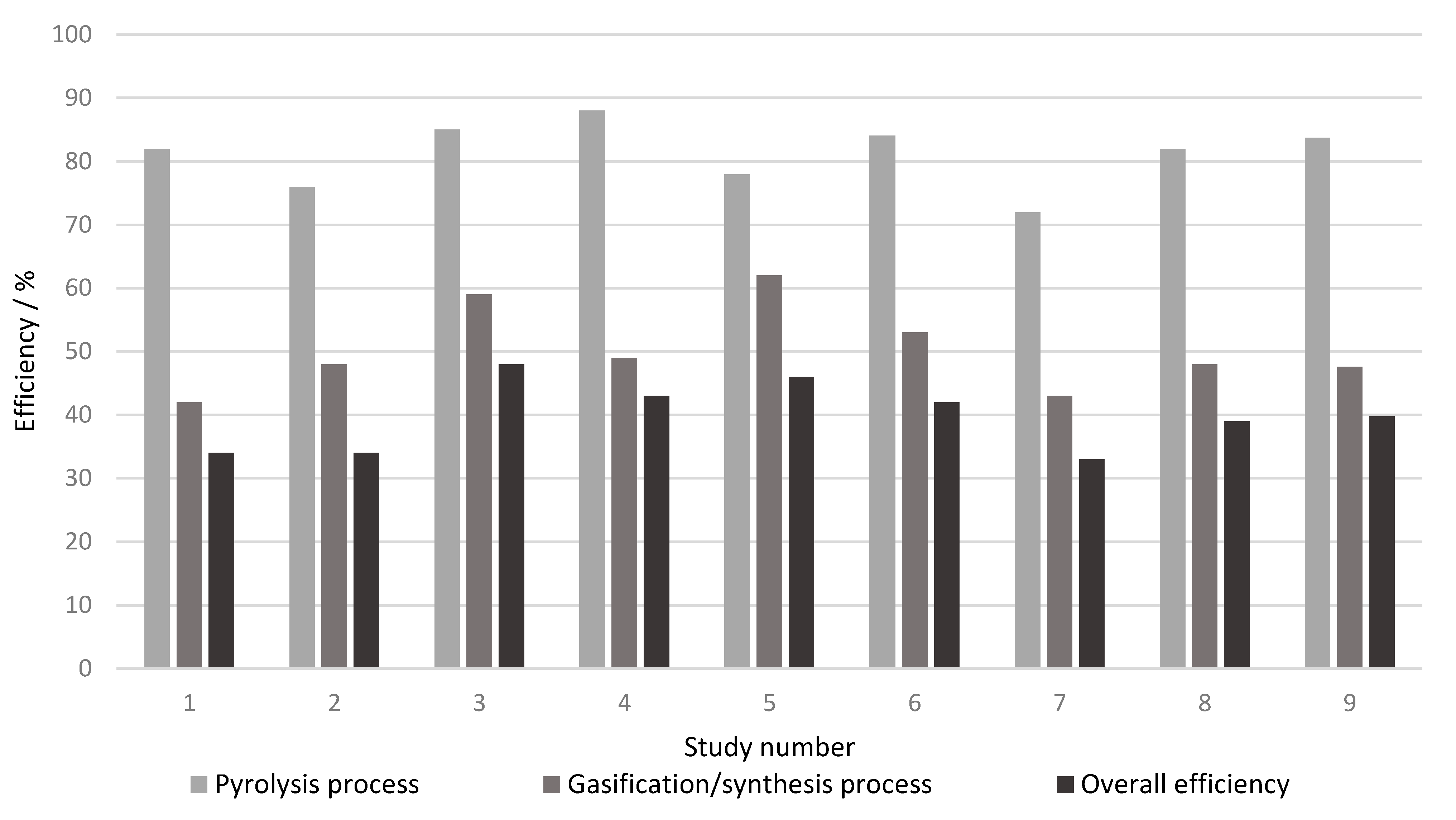

3.1. Mass and Energy Balance, Conversion Efficiency

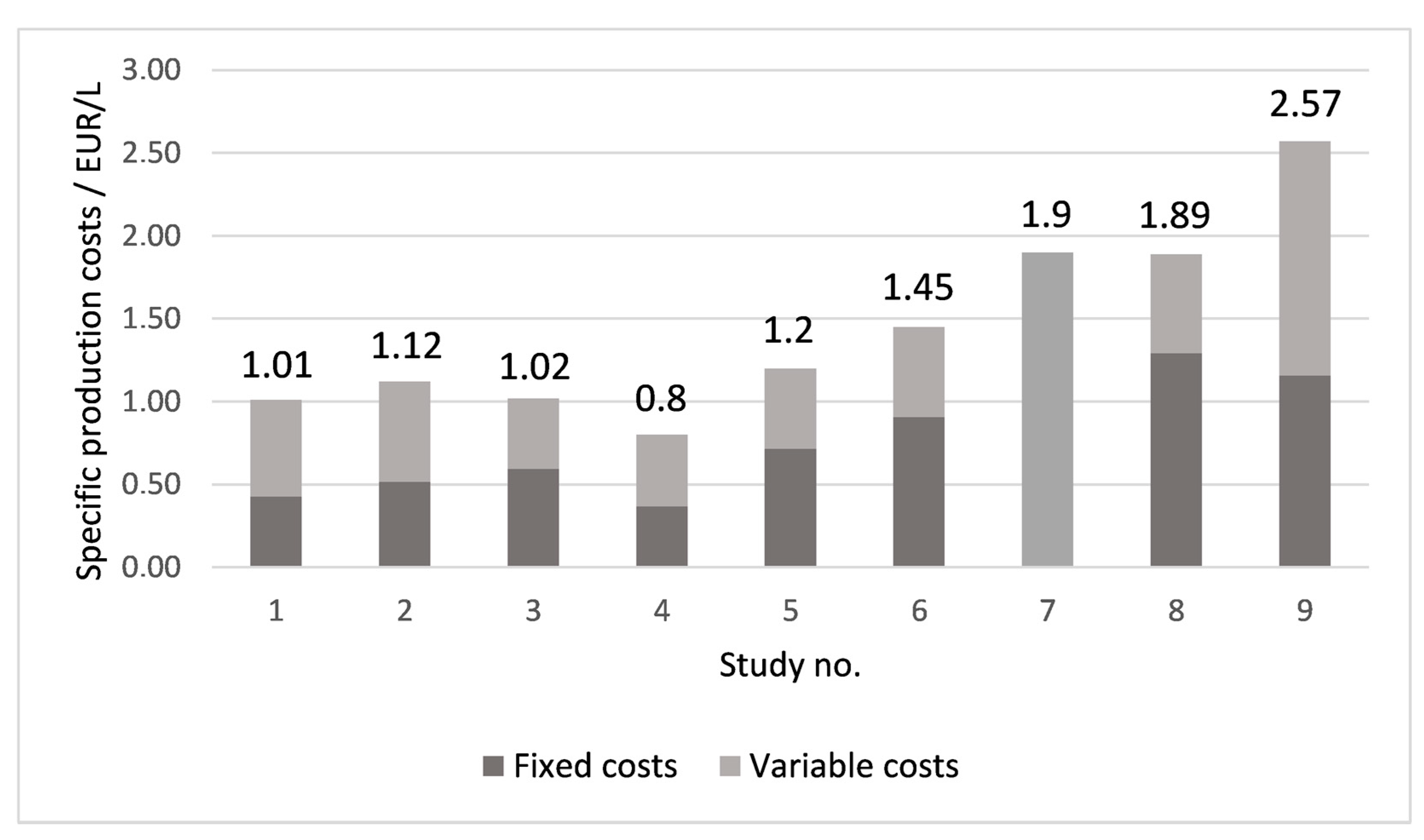

3.2. BtL Production Cost Estimation

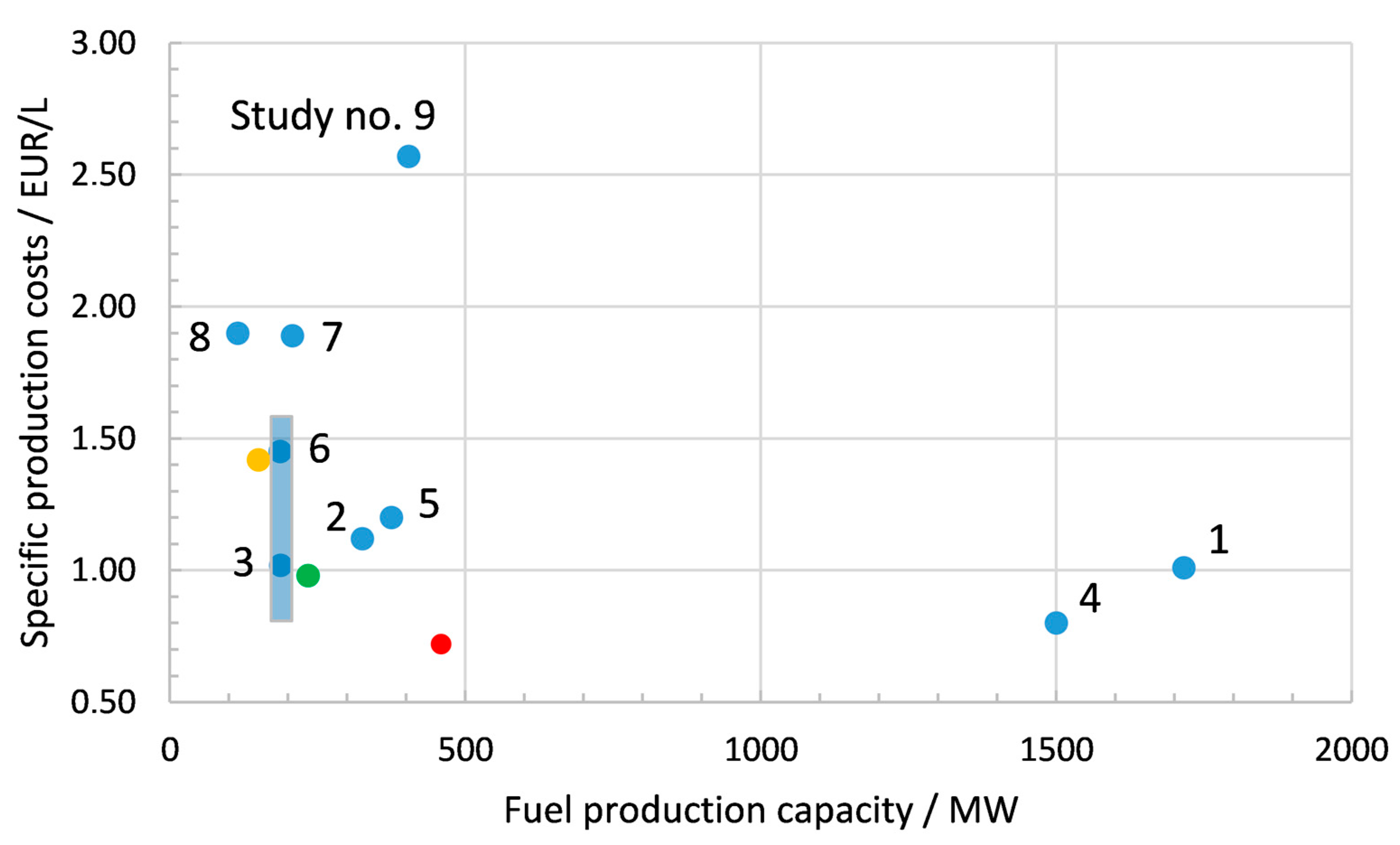

3.2.1. BtL Production Costs

3.2.2. BtL Production Cost Distribution

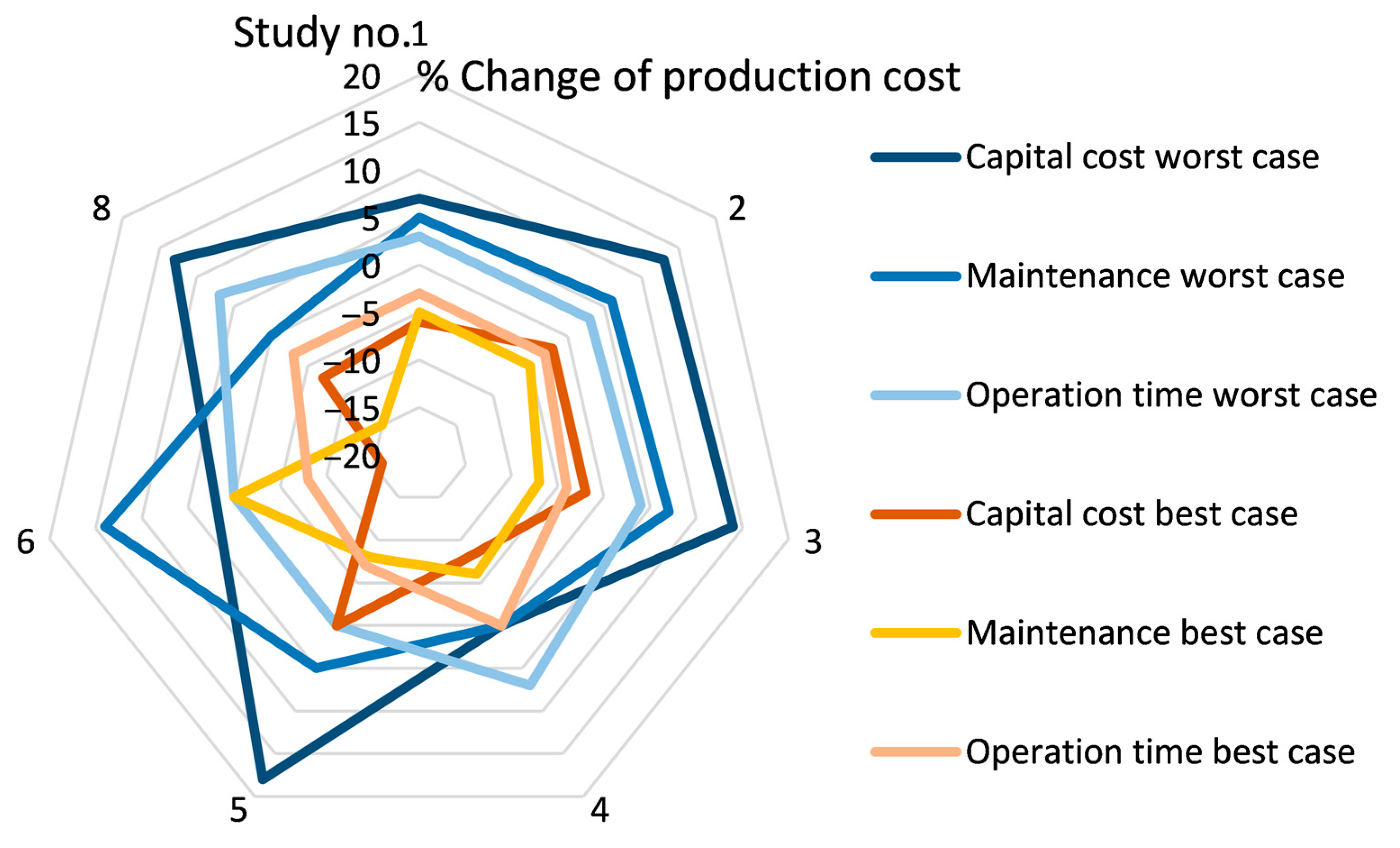

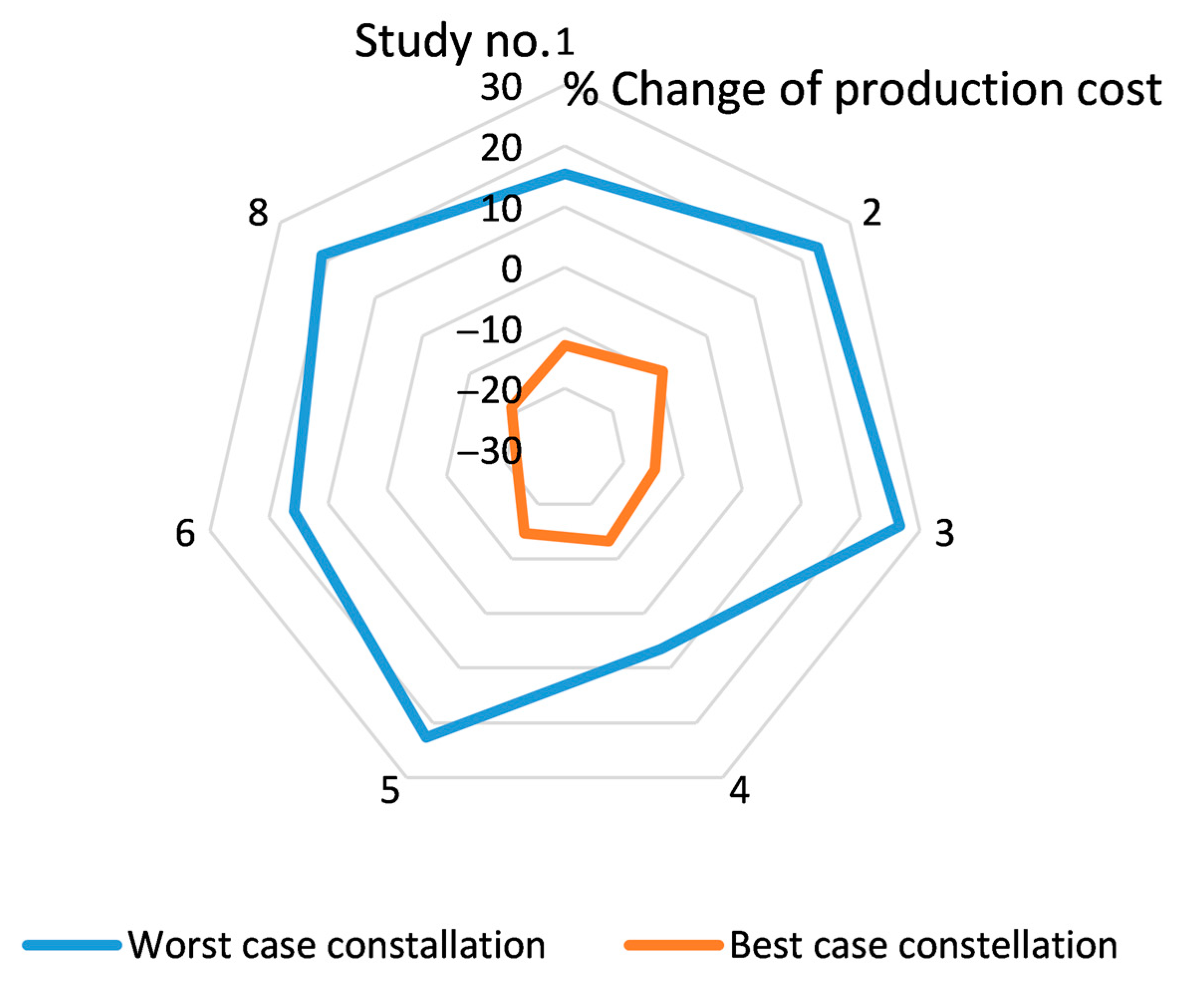

3.3. Model Variations

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Huber, G.W.; Iborra, S.; Corma, A. Synthesis of transportation fuels from biomass: Chemistry, catalysts, and engineering. Chem. Rev. 2006, 106, 4044–4098. [Google Scholar] [CrossRef]

- Grim, R.G.; To, A.T.; Farberow, C.A.; Hensley, J.E.; Ruddy, D.A.; Schaidle, J.A. Growing the Bioeconomy through Catalysis: A Review of Recent Advancements in the Production of Fuels and Chemicals from Syngas-Derived Oxygenates. ACS Catal. 2019, 9, 4145–4172. [Google Scholar] [CrossRef]

- Yarulina, I.; Chowdhury, A.D.; Meirer, F.; Weckhuysen, B.M.; Gascon, J. Recent trends and fundamental insights in the methanol-to-hydrocarbons process. Nat. Catal. 2018, 1, 398–411. [Google Scholar] [CrossRef]

- Dahmen, N.; Henrich, E.; Henrich, T. Synthesis Gas Biorefinery; Springer: Berlin/Heidelberg, Germany, 2019; Volume 166. [Google Scholar]

- Albrecht, F.G.; König, D.H.; Baucks, N.; Dietrich, R.U. A standardized methodology for the techno-economic evaluation of alternative fuels—A case study. Fuel 2017, 194, 511–526. [Google Scholar] [CrossRef]

- Snehesh, A.S.; Mukunda, H.S.; Mahapatra, S.; Dasappa, S. Fischer-Tropsch route for the conversion of biomass to liquid fuels—Technical and economic analysis. Energy 2017, 130, 182–191. [Google Scholar] [CrossRef]

- Dimitriou, I.; Goldingay, H.; Bridgwater, A.V. Techno-economic and uncertainty analysis of Biomass to Liquid (BTL) systems for transport fuel production. Renew. Sustain. Energy Rev. 2018, 88, 160–175. [Google Scholar] [CrossRef]

- Kargbo, H.; Harris, J.S.; Phan, A.N. “Drop-in” fuel production from biomass: Critical review on techno-economic feasibility and sustainability. Renew. Sustain. Energy Rev. 2021, 135, 110168. [Google Scholar] [CrossRef]

- Brown, T.R. A techno-economic review of thermochemical cellulosic biofuel pathways. Bioresour. Technol. 2015, 178, 166–176. [Google Scholar] [CrossRef] [PubMed]

- Meyer, B.; Krzack, S.; Stahlschmidt, R.; Boblenz, K. Ermittlung Spezifizierter Kosten und Ökologischer Auswirkungen der Erzeugung von BtL-Kraftstoffen und Biogas; TU Bergakademie Freiberg, Institut für Energieverfahrenstechnik und Chemieingenieurwesen: Freiberg, Germany, 2010. [Google Scholar]

- Kumar, A.; Cameron, J.B.; Flynn, P.C. Biomass Power Cost and Optimum Plant Size in Western Canada. Biomass Bioenergy 2003, 24, 445–464. [Google Scholar] [CrossRef]

- Brown, D.; Rowe, A.; Wild, P. A techno-economic analysis of using mobile distributed pyrolysis facilities to deliver a forest residue resource. Bioresour. Technol. 2013, 150, 367–376. [Google Scholar] [CrossRef]

- Maung, T.A.; Gustafson, C.R.; Saxowsky, D.M.; Nowatzki, J.; Miljkovic, T.; Ripplinger, D. The logistics of supplying single vs. multi-crop cellulosic feedstocks to a biorefinery in southeast North Dakota. Appl. Energy 2013, 109, 229–238. [Google Scholar] [CrossRef]

- Sultana, A.; Kumar, A. Optimal configuration and combination of multiple lignocellulosic biomass feedstocks delivery to a biorefinery. Bioresour. Technol. 2011, 102, 9947–9956. [Google Scholar] [CrossRef]

- Leible, L.; Kälber, S.; Kappler, G. KIT Scientific Reports 7580: Systemanalyse zur Gaserzeugung aus Biomasse; Karlsruhe Institute of Technology: Karlsruhe, Germany, 2011. [Google Scholar]

- Biomass Based Energy Intermediates Boosting Biofuel Production—Executive Summary. Available online: http://www.bioboost.eu/results/public-results.htm. (accessed on 12 April 2021).

- Gunukula, S.; Daigneault, A.; Boateng, A.A.; Mullen, C.A.; DeSisto, W.J.; Wheeler, M.C. Influence of upstream, distributed biomass-densifying technologies on the economics of biofuel production. Fuel 2019, 249, 326–333. [Google Scholar] [CrossRef]

- Brown, D.; Rowe, A.; Wild, P. Techno-economic comparisons of hydrogen and synthetic fuel production using forest residue feedstock. Int. J. Hydrogen Energy 2014, 39, 12551–12562. [Google Scholar] [CrossRef]

- Brown, T.R.; Thilakaratne, R.; Brown, R.C.; Hu, G. Techno-economic analysis of biomass to transportation fuels and electricity via fast pyrolysis and hydroprocessing. Fuel 2013, 106, 463–469. [Google Scholar] [CrossRef]

- Carrasco, J.L.; Gunukula, S.; Boateng, A.A.; Mullen, C.A.; DeSisto, W.J.; Wheeler, M.C. Pyrolysis of forest residues: An approach to techno-economics for bio-fuel production. Fuel 2017, 193, 477–484. [Google Scholar] [CrossRef]

- Brown, A.; Waldheim, L.; Landälv, I.; Saddler, J.; Ebadian, M.; McMillan, J.; Bonomi, A.; Klein, B. Advanced Biofuels-Potential for Cost Reduction; IEA Bioenergy: Paris, France, 2020. [Google Scholar]

- Zimmerlin, B.; Eberhard, M.; Lam, H.; Mai, R.; Michelfelder, B.; Niebel, A.; Otto, T.; Pfitzer, C.; Weih, N.; Willy, M.; et al. Thermochemische Konversion-Schlüsselbaustein für zukünftige Energie-und Rohstoffsysteme bioliq®-Pilotanlage zur Herstellung synthetischer Kraftstoffe-Betriebserfahrungen. In DGMK Tagungsbericht 2019-2; DGMK: Hamburg, Germany, 2019. [Google Scholar]

- Leible, L.; Kälber, S.; Kappler, G.; Lange, S.; Nieke, E.; Proplesch, P.; Wintzer, D.; Fürniss, B. Wissenschaftliche Berichte FZKA 7170: Kraftstoff, Strom und Wärme aus Stroh und Waldrestholz; Forschungszentrum: Karlsruhe, Germany, 2007. [Google Scholar]

- Lange, S. Systemanalytische Untersuchung zur Schnellpyrolyse als Prozessschritt bei der Produktion von Synthese-Kraftstoffen aus Stroh und Waldrestholz; Universität Karlsruhe (TH): Karlsruhe, Germany, 2007. [Google Scholar]

- Kerdoncuff, P. Modellierung und Bewertung von Prozessketten zur Herstellung von Biokraftstoffen der Zweiten Generation; Universität Karlsruhe (TH): Karlsruhe, Germany, 2008. [Google Scholar]

- Dahmen, N.; Henrich, E.; Dinjus, E. Cost estimate for biosynfuel production by biosyncrude gasification. Biofuels Bioprod. Biorefin. 2009, 3, 28–41. [Google Scholar]

- Trippe, F. Techno-Ökonomische Bewertung Alternativer Verfahrenskonfigurationen zur Herstellung von Biomass-to-Liquid (BtL) Kraftstoffen und Chemikalien. Ph.D. Thesis, Karlsruhe Institute of Technology, Karlsruhe, Germany, 2013. [Google Scholar]

- Trippe, F.; Fröhling, M.; Schultmann, F.; Stahl, R.; Henrich, E. Techno-economic assessment of gasification as a process step within biomass-to-liquid (BtL) fuel and chemicals production. Fuel Process. Technol. 2011, 92, 2169–2184. [Google Scholar] [CrossRef]

- Trippe, F.; Fröhling, M.; Schultmann, F.; Stahl, R.; Henrich, E. Techno-economic analysis of fast pyrolysis as a process step within biomass-to-liquid fuel production. Waste Biomass Valorization 2010, 1, 415–430. [Google Scholar] [CrossRef]

- Deutsche Energie-Agentur GmbH (dena). Biomass to Liquid-BtL Realisierungsstudie Zusammenfassung; Deutsche Energie-Agentur: Berlin, Germany, 2006. [Google Scholar]

- Stahlschmidt, F.; Boblenz, K.; Krzack, S.; Meyer, B. Ermittlung spezifizierter Kosten und ökologischer Auswirkungen der Erzeugung von BtL-Kraftstoffen. Erdöl Erdgas Kohle 2010, 126, 346–350. [Google Scholar]

- Beiermann, D. Analyse von thermochemischen Konversionsverfahren zur Herstellung von BtL-Kraftstoffen; Fortschrittberichte VDI: Karlsruhe, Germany, 2010; Volume 596. [Google Scholar]

- Mireles, I.H.; Van Horssen, A.; Van Harmelen, T.; Hagen, E. BioBoost Deliverable D6.4: Energy Carrier Chain LCA: Sustainability Assessment of Energy Carriers. Available online: www.BioBoost.eu (accessed on 12 April 2021).

- Seyfried, F. RENEW Final Report. Available online: www.renew-fuel.com (accessed on 12 April 2021).

- Landälv, I.; Waldheim, L.; Maniatis, K. (Eds.) Continuing the Work of the Sub Group on Advanced Biofuels for the RED II Market Deployment for Advanced Biofuels; ART Fuels Forum: Karlsruhe, Germany, 2018. [Google Scholar]

- Wang, B.; Gebreslassie, B.H.; You, F. Sustainable design and synthesis of hydrocarbon biorefinery via gasification pathway: Integrated life cycle assessment and technoeconomic analysis with multiobjective superstructure optimization. Comput. Chem. Eng. 2013, 52, 55–76. [Google Scholar] [CrossRef]

- Müller-Langer, F.; Vogel, A.; Brauer, S. RENEW-Renewable Fuels for Advanced Powertrains Integrated Project Sustainable energy Systems—Deliverable 5.3.8 Overall Costs. Available online: http://www.renew-fuel.com/fs_documents.html (accessed on 12 April 2021).

- Scarlat, N.; Fahl, F.; Lugato, E.; Monforti-Ferrario, F.; Dallemand, J.F. Integrated and spatially explicit assessment of sustainable crop residues potential in Europe. Biomass Bioenergy 2019, 122, 257–269. [Google Scholar] [CrossRef]

- Li, Q.; Hu, G. Techno-economic analysis of biofuel production considering logistic configurations. Bioresour. Technol. 2016, 206, 195–203. [Google Scholar] [CrossRef] [PubMed]

- Brosowski, A.; Krause, T.; Mantau, U.; Mahro, B.; Noke, A.; Richter, F.; Raussen, T.; Bischof, R.; Hering, T.; Blanke, C.; et al. How to measure the impact of biogenic residues, wastes and by-products: Development of a national resource monitoring based on the example of Germany. Biomass Bioenergy 2019, 127, 105275. [Google Scholar] [CrossRef]

- Christensen, P.; Dysert, L.R.; Bates, J.; Burton, D.; Creese, R.C.; Hollmann, J. 18R-97: Cost Estimate Classification System—As Applied in Engineering, Procurement, and Construction for the Process Industries; AACE, Inc.: Morgantown, WV, USA, 2005. [Google Scholar]

| No. | Project | Feedstock | Key Technologies | Products |

|---|---|---|---|---|

| A | LTU Green Fuels, S | Black liquor, pyrolysis oil | Chemrec process with EFG, 2 MW, 30 bar, 4 t/d production | DME, methanol |

| B | Güssing Renewable Energy Multifuel Gasification, A | Forest biomass and others | Repotec fast internally circulating fluidized bed (FICFB), 8 MW, atm. pressure | CHP, SNG (1 MW), FT plant (slip stream) |

| C | NSE Biofuels Oy, Varkaus, S | Forest biomass | CFB, 12 MW Foster Wheeler, hot filtration, catalytic tar reforming, (5 MW for synfuel application) | Heat for a lime kiln, FT-products (slip stream) |

| D | bioliq®, KIT, D | Lignocellulose bio-slurries | Fast pyrolysis 2 MW + 5 MW entrained flow gasification, hot gas cleaning, 80 bar | MeOH/DME, gasoline |

| E | Goteborg Energie AB, GoBiGas, S | Forest biomass | metso/repotec Dual bed, 20 MW (50.000 t/y SNG) | Biomethane |

| F | Total, BioTfuel demo, F | Forest biomass | Torrefaction + Uhde Prenflow EF, 15 MW, 8000 t/d FT product | FT-products |

| G | Värmlandsmetanol, S | Forest biomass | Uhde-HTW gasifier, 111 MW | Methanol |

| H | Växjö Värnamo Biomass Gasification Centre, S | Forest biomass | Foster Wheeler pressurized CFB + hot gas filtering | Heat & power, clean syngas |

| I | Woodland Biomass Research Center, LLC Thermal Reformer Synthesis West BiofuelsWoodland, CA | Forest biomass | Dual fluidized bed gasifier, 5 t/d waste wood, | FT products |

| J | Red Rock Biofuels, Oregon, US | Forest biomass | Gasification, 44.0000 t/y FT liquids | FT products |

| No. | Study | Type | Author | Institution | Year | Ref |

|---|---|---|---|---|---|---|

| 1 | Kraftstoff, Strom und Wärme aus Stroh und Waldrestholz—eine systemanalytische Untersuchung | Report | L. Leible et al. | Institut für Technikfolgenabschätzung und Systemanalyse (ITAS)—KIT | 2007 | [23] |

| 2 | Systemanalytische Untersuchung zur Schnellpyrolyse als Prozessschritt bei der Produktion von Synthesekraftstoffen aus Stroh und Waldrestholz | PhD thesis | S. Lange | Institut für Technikfolgenabschätzung und Systemanalyse (ITAS)—KIT | 2008 | [24] |

| 3 | Modellierung und Bewertung von Prozessketten zur Herstellung von Biokraftstoffen der zweiten Generation | PhD thesis | P. Kerdoncuff | Institut für Industriebetriebslehre und industrielle Produktion (IIP)—KIT | 2008 | [25] |

| 4 | Cost estimate for biosynfuel production via biosyncrude gasification | Report | E. Henrich et al. | Institut für Katalyseforschung und -technik (IKFT)—KIT | 2009 | [26] |

| 5 | Techno-ökonomische Bewertung alternativer Verfahrenskonfigurationen zur Herstellung von Biomass-to-Liquid (BtL) Kraftstoffen und Chemikalien | PhD thesis | F. Trippe | Institut für Industriebetriebslehre und industrielle Produktion (IIP)—KIT | 2013 | [27,28,29] |

| 6 | Biomass-to-Liquid“ BtL, eine Realisierungsstudie | Report | - | Deutsche Energie-Agentur GmbH | 2006 | [30] |

| 7 | Ermittlung spezifizierter Kosten und ökologischer Auswirkungen der Erzeugung von BtL Kraftstoffen und Biogas | Report | B. Meyer et al. | Institut für Energieverfahrenstechnik und Chemieingenieurwesen (IEC)—Technische Universität Freiberg | 2009 | [10,31] |

| 8 | Analyse von thermochemischen Konversionsverfahren zur Herstellung von BtL-Kraftstoffen | Report | D. Beiermann | Institut für Feuerungs- und Kraftwerkstechnik (IKF)— Universität Stuttgart | 2010 | [32] |

| 9 | Energy Carrier Chain LCA, Sustainability assessment of energy carriers | Report | Deliverable D6.4 | EU FP7 BioBoost project | 2014 | [33] |

| Study | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

|---|---|---|---|---|---|---|---|---|---|

| Biomass feedstock | Straw | Straw/wood | Straw | Straw | Straw | - | Straw | Straw | Straw |

| Water content/wt.% | 14 | 14/35 | 15 | 15 | 15 | 30 | 14 | 15 | 15 |

| Water content dry/wt.% | 7 | 7 | 15 | - | 8 | 15 | 7 | 10 | - |

| LHVBiomass/MJ/kg | 14.6 | 11.9 | 14.9 | 14.4 | 14.5 | 12.6 | 14.2 | 14.0 | 13.4 |

| Decentralized pyrolysis plants | |||||||||

| Thermal fuel capacity per plant/MW | 100 | 200 | 55 | 100 | 100 | 98 | 50 | 100 | 117 |

| Number of plants | 50 | 4 | 10 | 35 | 11 | 5 | 5 | 5 | 4 |

| Total biomass conversion capacity/kt/a | 9247 | 1785 | 1000 | 6944 | 1989 | 1000 | 413 | 1027 | 2190 |

| Total biosyncrude capacity/kt/a | 5902 | 1182 | 680 | 4618 | 1347 | 503 | 306 | 724 | 1480 |

| LHVBiosyncrude/MJ/kg | 18.7 | 16.6 | 19.9 | 19.1 | 17.6 | 22.0 | 17.3 | 17.2 | 16.9 |

| Conversion efficiency | 82% | 76% | 85% | 88% | 78% | 84% | 72% | 82% | 84% |

| Central gasification + synthesis plant | |||||||||

| Biosyncrude conversion capacity/MW | 4089 | 680 | 500 | 3056 | 941 | 439 | 200 | 425 | 999 |

| Biosyncrude conversion capacity/kt/a | 5902 | 1182 | 680 | 4618 | 1347 | 503 | 306 | 724 | 1480 |

| Hydrocarbon product capacity/MW | 1716 | 326 | 187 | 1500 | 375 | 186 | 115 | 207 | 404 |

| Product capacity/kt/a | 1069 | 201 | 115 | 1000 | 216 | 106 | 66 | 136 | 238 |

| LHVproduct/MJ/kg | 43.32 | 43.83 | 43.90 | 43.20 | 43.86 | 44.05 | 44.15 | 44.00 | 42.8 |

| Electricity export/MW | 0 | 0 | 74 | 0 | 146 | 22 | 0 | 0 | 85.5 |

| Conversion efficiency | 42% | 48% | 37 + 22% 1 | 40 + 22% 1 | 42 + 11% 1 | 43% | 43% | 48% | 39.4 + 8.2% 1 |

| Overall energetic efficiency | 34% | 34% | 34 + 14% 1 | 43% | 33 + 13% 1 | 37 + 4% 1 | 33% | 39% | 33.0 + 6.9% 1 |

| Study | 1 | 2 | 3 | 4 | 5 | 8 |

|---|---|---|---|---|---|---|

| Gas | 23.10 | 18.30 | 20.00 | 21.40 | 24.80 | 21.20 |

| Biosyncrude | 76.90 | 81.70 | 80.00 | 78.60 | 75.20 | 78.80 |

| thereof: | ||||||

| Condensates | 54.98 | 51.39 | 60.00 | 30.97 | 27.52 | 47.91 |

| Char solid | 21.92 | 23.86 | 20.00 | 29.79 | 24.97 | 21.83 |

| Water | 6.45 | 0.00 | 17.84 | 22.71 | 9.06 | |

| LHV/MJ·kg−1 | 18.7 | 16.6 | 19.9 | 19.1 | 17.6 | 17.2 |

| Study 1 | Study 2 | Study 3 | Study 4 | |

| Invest local plants | 1,177,415 kEUR | 341,598 kEUR | 130,920 kEUR | 700,000 kEUR |

| Invest central plant | 2,011,136 kEUR | 439,000 kEUR | 401,490 kEUR | 750,000 kEUR |

| Production costs | 1.01 EUR/L | 1.12 EUR/L | 1.02 EUR/L | 0.8 EUR/L |

|  |  |  | |

| Capital cost | 11.4% of TCI | 9.4% | 10.2% | 14.2% |

| Interest rate | 7% | 7% | 8% | 7% |

| Depreciation period | 18 years | 20 years | 20 years | 10 years |

| Maintenance | 4% of TCI | 5/3% 1 of TCI | 4% of TCI | 6% of TCI |

| Biomass | 72 EUR/t | 68 EUR/t | 63 EUR/t | 64 EUR/t |

| Electrical energy price | - | 61 EUR/MWh | 76 EUR/MWh | - |

| Electricity demand | - | 2.6 kW/L | 1.9 kW/L | - |

| Share of electricity costs | - | 0.06 EUR/L | 0.05 EUR/L | - |

| Personnel | 1287 | 306 | 50 | 1168 |

| Annual operation time | 7500 h | 7500/8000 h | 7502 h | 8000 h |

| Study 5 | Study 6 | Study 8 | Study 9 | |

| Invest local plants | 374,880 kEUR | 245,160 kEUR | 343,295 kEUR | 640,722 kEUR |

| Invest central plant | 693,200 kEUR | 414,440 kEUR | 691,526 kEUR | 864,734 kEUR |

| Production costs | 1.20 EUR/L | 1.45 EUR/L | 1.90 EUR/L | 2.57 EUR/L |

|  |  |  | |

| Capital cost | 8.3% of TCI | 13.6% | 10.2% | 9.3% |

| Interest rate | 5% | 8% | Not specified | 5% |

| Depreciation period | 20 years | 15 years | 20 years | 20 years |

| Maintenance | 4% of TCI | 2% of TCI | 6% of TCI | 7% of TCI |

| Biomass | 70 EUR/t | 68 EUR/t | 65 EUR/t | 60 EUR/t |

| Electrical energy price | 90 EUR/MWh | 50 EUR/MWh | 150 EUR/MWh | - |

| Electricity demand | 1.7 kW/L | 1.3 kW/L | 1.2 kW/L | - |

| Personnel | 533 | 293 | 232 | 251 |

| Annual operation time | 7008 h | 7000 h | 7008 h | 7008 h |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dahmen, N.; Sauer, J. Evaluation of Techno-Economic Studies on the bioliq® Process for Synthetic Fuels Production from Biomass. Processes 2021, 9, 684. https://doi.org/10.3390/pr9040684

Dahmen N, Sauer J. Evaluation of Techno-Economic Studies on the bioliq® Process for Synthetic Fuels Production from Biomass. Processes. 2021; 9(4):684. https://doi.org/10.3390/pr9040684

Chicago/Turabian StyleDahmen, Nicolaus, and Jörg Sauer. 2021. "Evaluation of Techno-Economic Studies on the bioliq® Process for Synthetic Fuels Production from Biomass" Processes 9, no. 4: 684. https://doi.org/10.3390/pr9040684

APA StyleDahmen, N., & Sauer, J. (2021). Evaluation of Techno-Economic Studies on the bioliq® Process for Synthetic Fuels Production from Biomass. Processes, 9(4), 684. https://doi.org/10.3390/pr9040684