Abstract

Industrial wastewater contains high concentrations of inorganic salts and organic matter. This experiment studied a system for treating wastewater containing high concentrations of inorganic salts and organic matter. The setup consists of a closed-cycle humidification and dehumidification system and a filter press. Chemical wastewater was used as the treatment solution, and the treatment performance of the system was tested and analyzed. The system effectively reduced the chemical oxygen demand (COD), electric conductivity (EC), total nitrogen (TN), and ammonia nitrogen (NH4-N) in the wastewater and, at the same time, dehydrated sludge was obtained through a filter press. The system maintains a stable removal rate of each index (COD, EC, TN, and NH4-N) in wastewater and can remove inorganic salts and organic matter from wastewater. The system can successfully treat industrial wastewater containing high concentrations of inorganic salts and organic matter.

Keywords:

industrial wastewater; COD; EC; TN; NH4-N; humidification and dehumidification; removal efficiency 1. Introduction

With the development of society and industrial progress, a large amount of industrial wastewater is produced, which creates significant challenges for the environment and greatly deteriorates environmental quality [1]. The chemical industry consumes a lot of water, and if the wastewater produced is not effectively treated, it causes serious harm to the environment. [1] Wastewater cannot be directly released into the environment and needs to be treated first [2].

Industrial wastewater containing high concentrations of inorganic salts and organic substances cannot directly enter the urban wastewater pipe network or be reused for production, so certain pre-treatments are required.

Current wastewater treatment methods include reverse osmosis (RO) [3], nanofiltration (NF) [4], electrodialysis [5], microbial treatment [6], multi-effect evaporation [7], and mechanical vapor recompression (MVR) [8]. Ye et al. [9] combined desalination and photocatalytic circulation technology to treat wastewater. Salmerón et al. [10] researched the feasibility of a solar electro-oxidation process to treat high-salinity wastewater. Tim et al. [11] studied the treatment of saline wastewater by purple phototrophic bacteria. The results show that purple phototrophic bacteria can treat wastewater containing high concentrations of NaCl. These methods have certain advantages but also have disadvantages and limitations. Reverse osmosis (RO), nanofiltration (NF), and electrodialysis have specific requirements for the concentration of wastewater [12], and the treatment of wastewater containing high concentrations of inorganic salts and organic substances poses particular challenges [13].

MVR has been applied to the treatment of shale gas flowback [14,15,16]. MVR has also been applied to the separation and purification of substances in wastewater [17], such as the separation of dimethylformamide/water [18]. Multi-effect evaporation [19] and MVR can treat wastewater containing high concentrations of inorganic salts and organic substances, but steam needs be used during the treatment process [2]. The equipment environment involves high temperature and high pressure [20]. The high-temperature and high-pressure environment may cause the decomposition of organic matter, which escapes and enters the treated wastewater. Humidification and dehumidification (HDH) is a well-known process that has been used in the field of desalination [21,22,23,24,25]. It is a simple process, has a low maintenance cost, is not sensitive to the influent water quality, and uses renewable and low-grade heat [26]. These advantages allow it to be used successfully in high-salt wastewater treatment [27].

More research has been conducted on humidification and dehumidification systems for seawater desalination [28,29,30], but there has been less research on the treatment of wastewater containing high concentrations of inorganic salts and organic matter.

Thiel et al. [31] studied the impact of high-salinity brine on the energy consumption and performance of recirculating HDH systems. The results showed that the evaporation system’s energy consumption is often less sensitive to salinity changes than reverse osmosis, but the energy required for separation changes significantly with salinity. Minier-Matar et al. [32] combined membrane distillation (MD) and HDH and injected water with a total dissolved solid content of 6.3% into the MD device. The MD unit brine, with a total dissolved solid (TDS) content of 10.20%, was sent to the HDH system to recover more water.

In this study, a new industrial wastewater treatment system is tested and analyzed for the treatment of wastewater containing high concentrations of inorganic salts and organic matter. A closed-cycle humidification and dehumidification device is attached to the system. The system does not need to consume steam, only electricity. The air in the system circulates in a closed environment, effectively preventing volatile substance pollution to the outside air and preventing secondary pollution. The operating temperature of the system is less than 70 °C and can be used to treat wastewater containing high-temperature volatile substances. The system does not operate under high temperature and high pressure, which can ensure safety and prevent certain organic substances from decomposing at high temperature. The air in the system circulates in a closed space, which can effectively prevent secondary pollution caused by gas volatilization; the system can treat high-concentration wastewater and is not sensitive to concentration. The system uses heat pumps to recover heat and improves resource utilization.

Our previous research used seawater to test the performance of the closed-cycle humidification and dehumidification system and studied the setting parameters under the best working conditions [33].

The performance of the system in this study is tested to verify whether it can effectively treat wastewater containing high concentrations of inorganic salts and organic substances. The removal efficiency of the pollution indicators of the system is analyzed, including the chemical oxygen demand (COD), electric conductivity (EC), total nitrogen (TN), and ammonia nitrogen (NH4-N). The wastewater treatment efficiency of the system and the characteristics of the treated wastewater are also analyzed. The system can effectively remove inorganic salts and organic matter from wastewater, reducing the harm to the environment. It provides a better method for relevant companies to treat wastewater.

2. Experiments

2.1. Experimental Setup

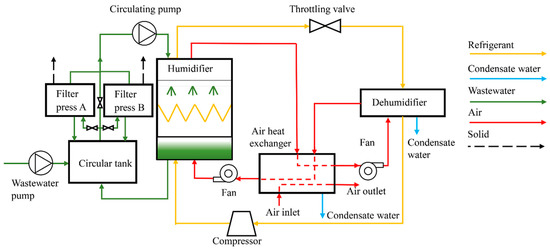

The new wastewater treatment system studied in this paper includes humidifiers, air heat exchangers, heat pumps, dehumidifiers, plate and frame filter presses, etc. Figure 1 shows the system’s schematic diagram. Figure S1 shows the humidification and dehumidification device, and Figure S2 shows the equipment operating route.

Figure 1.

System schematic diagram.

The entire system is closed, and wastewater and air circulate in the system. The system contains three outlets: two condensate water outlets and a dehydrated sludge outlet. It also contains a heat dissipation channel.

The best working conditions of the system were taken from our previous research [32].

The system operation includes three circuits and four heat exchanges.

The three circuits are as follows:

- Wastewater circulates in the circulation tank, plate and frame filter press, and humidifier.

- The air circulates in the humidifier, dehumidifier, and air heat exchanger.

- The refrigerant circulates in the humidifier and compressor unit.

The four heat exchanges are as follows:

- In the humidifier, wastewater and the refrigerant exchange heat, and the wastewater absorbs heat from the refrigerant.

- In the humidifier, air and the refrigerant exchange heat, and the air absorbs heat from the refrigerant.

- In the dehumidifier, air and the refrigerant exchange heat, and the refrigerant absorbs heat from the air.

- In the air heat exchanger, the air in different directions exchanges heat.

The wastewater treatment process is as follows: Wastewater enters the circulation tank through the wastewater pump. The wastewater enters plate and frame filter press A through the circulating pump, enters the humidifier, and is sprayed onto a titanium pipe. The wastewater is heated and evaporated, and the remaining wastewater enters the circulation tank to participate in the next cycle. Plate and frame filter press A has a filtering function. When the pressure of plate and frame filter press A reaches saturation, its water inlet valve is closed and the water inlet valve of plate and frame filter press B is opened. Plate and frame filter press A performs pressure filtration to obtain dehydrated sludge. The squeezed filtrate enters the circulation tank. The condensed water is discharged from the dehumidifier and air heat exchanger.

2.2. Wastewater Characteristics

The wastewater was taken from a pesticide company’s wastewater storage tank in Hefei (China). The wastewater produced in different production workshops is stored in a wastewater pond. At present, this wastewater is processed through MVR.

The company’s main products are quizalofop-ethyl and nicosulfuron, and the wastewater produced contains high concentrations of inorganic salts and organic matter. The values of the COD, EC, TN, and NH4-N in the wastewater can reach 140,000 mg/L, 250,000 μS/cm, 6000 mg/L, and 2700 mg/L, respectively. These values are far above the emission limits. COD, EC, TN, and NH4-N concentrations were measured according to a standard method [34].

2.3. Input Parameters

According to our previous research, the best working conditions of the system are as follows: wastewater temperature = 52 °C, air flow rate = 12,000 m3/h, and wastewater flow rate = 32 m3/h.

2.4. Experimental Procedure

- Discharge wastewater (10 m3) into the circulation tank and sample the wastewater in the circulation tank.

- Start the system. When the system is stable, continue to run it for 5 h.

- During operation, sample the condensate every half an hour.

To ensure stability and accuracy, three experiments were carried out.

2.5. Evaluation Index

2.5.1. Removal Efficiency (RE)

The removal efficiency is a crucial indicator for evaluating the effect of reducing the concentration of pollutant primers in wastewater. The removal efficiency (RE, %) is calculated as follows:

where C0 is the wastewater concentration before treatment and C1 is the concentration of the condensed water.

2.5.2. Treatment Efficiency

The production rate of condensed water is used to express the treatment efficiency. The productivity of the condensate water of the system is an essential indicator for evaluating the treatment efficiency. An ultrasonic flowmeter is introduced to measure the rate of condensate generation, and its accuracy is 0.1 m3/h.

2.5.3. Dehydrated Sludge

The production of dehydrated sludge per unit time is an important indicator of whether the system can operate stably. When the system processes wastewater normally, the production of dehydrated sludge is stable. A scale was introduced to weigh the dehydrated sludge.

3. Results and Discussion

3.1. Removal Efficiency

The wastewater before treatment was tested. The values of the COD, EC, TN, and NH4-N of the wastewater are shown in Table 1. During the 5 h continuous treatment, the discharged condensate was sampled every half an hour, and its various indicators were tested.

Table 1.

Wastewater characteristics.

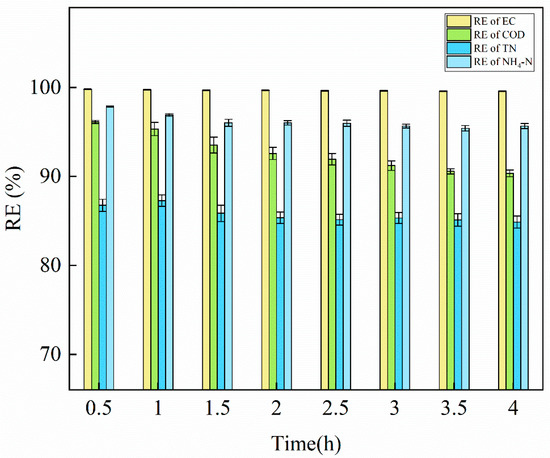

The removal efficiency of each index (COD, EC, TN, and NH4-N) was analyzed using statistical methods. Figure 2 shows the analysis results of the removal efficiency of each index. The highest removal efficiency of the COD, EC, TN, and NH4-N could reach 99.4%, 98.2%, 98.5%, and 98.7%, respectively. The removal efficiency of the COD, EC, TN, and NH4-N was maintained above 90%, 99%, 85%, and 96%, respectively.

Figure 2.

The RE (removal efficiency) of the EC, COD, TN, and NH4-N.

Figure 2 shows that the COD of wastewater significantly was reduced to below 10,000 mg/L. In the presented research, the removal efficiency of the COD showed a downward trend, from 96% to 90%. This is caused by the increasing concentration of inorganic salts and organic matter in the wastewater. The EC of wastewater was significantly reduced, with the lowest EC being reduced to 323 mg/L. In the presented research, the removal efficiency of EC was unchanged, staying above 99%. The TN in wastewater was effectively removed, and reduced from about 6000 to below 1000 mg/L. The removal efficiency of TN was maintained at 85%. This is because some volatile substances are discharged together with the condensed water. The NH4-N in the wastewater was effectively removed, and reduced from about 6000 to below 1000 mg/L. The removal efficiency of NH4-N remained above 95%. The results show that the system could operate relatively stably in the presented research, effectively removing impurities from wastewater.

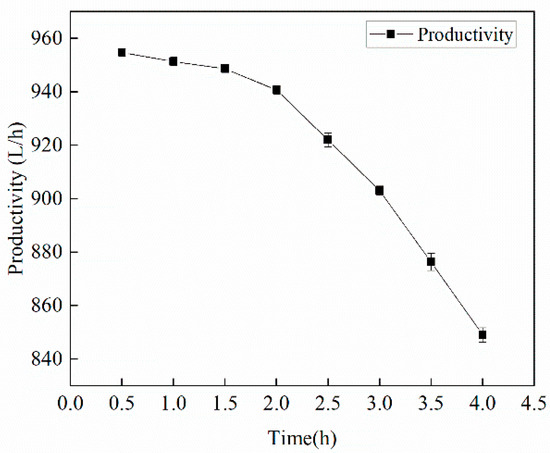

3.2. Treatment Efficiency

It can be seen from Figure 3 that, with the continuous discharge of condensed water, the processing efficiency of the system shows a downward trend. During the operation of the system, since the wastewater in the circulation tank is not replenished, when the condensate is continuously discharged, the concentration of inorganic salts and organic matter in the wastewater in the circulation tank increases continuously. When the treatment efficiency drops to 900 L/h, sludge is generated in the plate and frame filter press. The fluidity of wastewater worsens, and the flow of wastewater decreases. The increase in the concentration of inorganic salts and organic matter in the wastewater reduces the circulating pump’s working efficiency and reduces the circulating pump flow, resulting in a decrease in the wastewater flow in the humidifier. This is the reason for the decrease in the system’s processing efficiency. When no sludge is produced in the plate and frame filter press, the treatment efficiency can be stabilized above 900 L/h. When the sludge is generated in the plate and frame filter press, the processing efficiency of the system begins to decline.

Figure 3.

Treatment efficiency changes over time.

3.3. Dehydrated Sludge

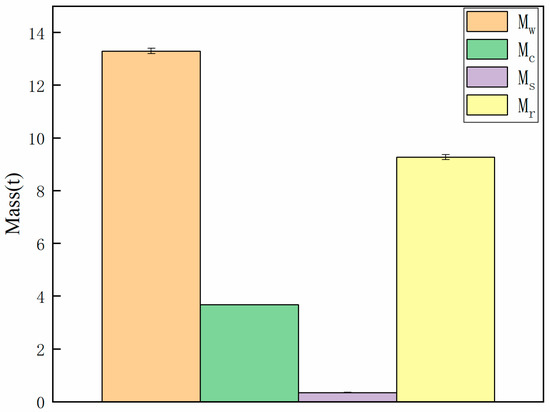

The plate and frame filter press discharges dehydrated sludge every two hours. The dehydrated sludge discharged in the first two hours was about 170 kg, and that discharged in the next two hours was about 180 kg.

Figure 4 shows the total mass of wastewater before the start of the experiments, the total mass of condensate after the experiments, the mass of dehydrated sludge, and the mass of the remaining wastewater in the system. (In Figure 4, Mw is the total mass of wastewater before the start of the experiments, Mc is the total mass of condensate after the experiments, Ms is the mass of dehydrated sludge, and Mr is the mass of the remaining wastewater in the system.) In the presented research, the mass of condensed water is about one-third of the mass of wastewater entering the system. Figure 5 shows the dehydrated sludge.

Figure 4.

Wastewater mass balance.

Figure 5.

Dehydrated sludge produced by the plate and frame filter press.

The system can collect impurities in the wastewater through a filter press and effectively remove them.

4. Conclusions

A new type of industrial wastewater treatment system was experimented on and studied to treat wastewater containing high concentrations of inorganic salts and organic substances. The system includes a closed-cycle humidification and dehumidification device. The performance of the system was analyzed with specific chemical wastewater as the treatment solution. The rate of removal of the COD, EC, TN, and NH4-N by this system was studied, and the treatment efficiency of the system was analyzed.

Our conclusions are as follows: The air in the system circulates in a closed environment, which can effectively prevent volatile substance pollution to the outside air and prevent secondary pollution.

The removal efficiency of the COD, EC, TN, and NH4-N is maintained above 90%, 99%, 85%, and 96%, respectively. The system can effectively treat wastewater containing high concentrations of inorganic salts and organic matter.

When no sludge is produced in the plate and frame filter press, the treatment efficiency can be stabilized above 900 L/h. When the sludge is generated in the plate and frame filter press, the treatment efficiency of the system begins to decline.

The system can collect the impurities in the wastewater through a filter press and effectively remove them.

The system can effectively remove inorganic salts and organic matter in industrial wastewater, reducing the harm to the environment, thereby providing a better method for relevant companies to treat wastewater.

Supplementary Materials

The following are available online at https://www.mdpi.com/article/10.3390/pr9040671/s1, Figure S1: Image of the humidification and dehumidification device, Figure S2: System operation roadmap.

Author Contributions

Conceptualization, J.W. and Y.S.; methodology, J.L. and K.H.; software, S.Y.; validation, J.L. and Y.S.; formal analysis, J.L. and K.H.; investigation, J.L.; resources, Y.S.; data curation, J.L.; writing—original draft preparation, J.L. and K.H.; writing—review and editing, J.W.; visualization, J.W.; supervision, J.W.; project administration, J.W. and Y.S.; funding acquisition, J.W. and Y.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

The authors acknowledge the support and funds received from Anhui Tongsu Environment Protection Technology Co., Ltd.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Mazhar, S.; Ditta, A.; Bulgariu, L.; Ahmad, I.; Ahmed, M.; Nadiri, A.A. Sequential Treatment of Paper and Pulp Industrial Wastewater: Prediction of Water Quality Parameters by Mamdani Fuzzy Logic Model and Phytotoxicity Assessment. Chemosphere 2019, 227, 256–268. [Google Scholar] [CrossRef]

- Liang, L.; Han, D.; Ma, R. Treatment of high-concentration wastewater using double-effect mechanical vapor recompression. Desalination 2013, 314, 139–146. [Google Scholar] [CrossRef]

- Avlonitis, S.A.; Kouroumbas, K.; Vlachakis, N. Energy consumption and membrane replacement cost for seawater RO desalination plants. Desalination 2003, 157, 151–158. [Google Scholar] [CrossRef]

- Zhou, D.; Zhu, L.; Fu, Y. Development of lower cost seawater desalination processes using nanofiltration technologies—A review. Desalination 2015, 376, 109–116. [Google Scholar] [CrossRef]

- Tado, K.; Sakai, F.; Sano, Y. An analysis on ion transport process in electrodialysis desalination. Desalination 2016, 378, 60–66. [Google Scholar] [CrossRef]

- Guo, Y.; Niu, Q.; Sugano, T. Biodegradable organic matter-containing ammonium wastewater treatment through simultaneous partial nitritation, anammox, denitrification and COD oxidization process. Sci. Total Environ. 2020, 714, 136740. [Google Scholar] [CrossRef] [PubMed]

- Raluy, G.; Serra, L.; Uche, J. Life cycle assessment of MSF, MED and RO desalination technologies. Energy 2006, 31, 2361–2372. [Google Scholar] [CrossRef]

- Dahmardeh, H.; Amiri, H.A.A.; Nowee, S.M. Evaluation of mechanical vapor recompression crystallization process for treatment of high salinity wastewater. Chem. Eng. Process. Process Intensif. 2019, 145, 107682. [Google Scholar] [CrossRef]

- Ye, G.; Yu, Z.; Li, Y. Efficient treatment of brine wastewater through a flow-through technology integrating desalination and photocatalysis. Water Res. 2019. [Google Scholar] [CrossRef]

- Salmeron, I.; Oiler, I.; Malato, S. Electro-oxidation process assisted by solar energy for the treatment of wastewater with high salinity. Sci. Total Environ. 2020, 705, 135831. [Google Scholar] [CrossRef] [PubMed]

- Hülsen, T.; Hsieh, K.; Batstone, D.J. Saline wastewater treatment with purple phototrophic bacteria. Water Res. 2019, 160. [Google Scholar] [CrossRef] [PubMed]

- Chen, P.; Wang, L.; Song, P. Recovering olaquindox and decreasing COD and salt concentrations in antibiotic wastewater by multiple freeze-thaw processes and crystallization. J. Clean. Prod. 2019, 225, 248–255. [Google Scholar] [CrossRef]

- Ghofrani, I.; Moosavi, A. Energy, exergoeconomics, and exergoenvironmental assessment of three brine recycle humidification-dehumidification desalination systems applicable for industrial wastewater treatment. Energy Convers. Manag. 2020, 205, 112349. [Google Scholar] [CrossRef]

- Hayes, T.D.; Halldorson, B.; Horner, P.H. Mechanical vapor recompression for the treatment of shale-gas flowback water. Oil Gas Facil. 2014, 3, 54–62. [Google Scholar] [CrossRef]

- Horner, P.; Halldorson, B.; Slutz, J.A. Shale Gas Water Treatment Value Chain—A Review of Technologies, Including Case Studies. In Proceedings of the Society of Petroleum Engineers SPE Annual Technical Conference and Exhibition, Denver, CO, USA, 30 October–2 November 2011. [Google Scholar]

- Heins, W.F.; Mcneill, R.; Albion, S. World’s First SAGD Facility Using Evaporators, Drum Boilers, and Zero Discharge Crystallizers to Treat Produced Water. J. Can. Pet. Technol. 2006, 45, 861–877. [Google Scholar] [CrossRef]

- Gao, X.; Chen, J.; Tan, J. Application of mechanical vapor recompression heat pump to double-effect distillation for separating N, N-dimethylacetamide/water mixture. Ind. Eng. Chem. Res. 2015, 54, 3200–3204. [Google Scholar] [CrossRef]

- Gao, X.; Ma, Z.; Ma, J. Application of Three-Vapor Recompression Heat-Pump Concepts to a Dimethylformamide–Water Distillation Column for Energy Savings. Energy Technol. 2014, 2, 250–256. [Google Scholar] [CrossRef]

- Jiang, H.; Zhang, Z.; Gong, W. Design and evaluation of a parallel-connected double-effect mechanical vapor recompression evaporation crystallization system. Appl. Therm. Eng. 2020, 179, 115646. [Google Scholar] [CrossRef]

- Onishi, V.C.; Carrero-Parreño, A.; Reyes-Labarta, J.A. Shale gas flowback water desalination: Single vs. multiple-effect evaporation with vapor recompression cycle and thermal integration. Desalination 2017, 404, 230–248. [Google Scholar] [CrossRef]

- Giwa, A.; Akther, N.; Al Housani, A. Recent advances in humidification dehumidification (HDH) desalination processes: Improved designs and productivity. Renew. Sustain. Energy Rev. 2016, 57, 929–944. [Google Scholar] [CrossRef]

- Srithar, K.; Rajaseenivasan, T.; Arulmani, M. Energy recovery from a vapour compression refrigeration system using humidification dehumidification desalination. Desalination 2018, 439, 155–161. [Google Scholar] [CrossRef]

- Lawal, D.; Antar, M.; Khalifa, A. Humidification-dehumidification desalination system operated by a heat pump, published online in Energy Conversion and Management. Energy Convers. Manag. 2018, 161, 128–140. [Google Scholar] [CrossRef]

- Mohamed, A.; Ahmed, M.S.; Shahdy, A.G. Theoretical and experimental study of a seawater desalination system based on humidification-dehumidification technique. Renew. Energy 2020, 152, 823–834. [Google Scholar] [CrossRef]

- Faegh, M.; Shafii, M.B. Performance evaluation of a novel compact humidification-dehumidification desalination system coupled with a heat pump for design and off-design conditions. Energy Convers. Manag. 2019, 194, 160–172. [Google Scholar] [CrossRef]

- Jamil, M.A.; Elmutasim, S.M.; Zubair, S.M. Exergo-economic analysis of a hybrid humidification dehumidification reverse osmosis (HDH-RO) system operating under different retrofits. Energy Convers. Manag. 2018, 158, 286–297. [Google Scholar] [CrossRef]

- Sharqawy, M.H.; Antar, M.A.; Zubair, S.M. Optimum thermal design of humidification dehumidification desalination systems. Desalination 2014, 349, 10–21. [Google Scholar] [CrossRef]

- Chiranjeevi, C.; Srinivas, T. Augmented desalination with cooling integration. Int. J. Refrig. 2017, 80, 106–119. [Google Scholar] [CrossRef]

- Shehata, A.I.; Kabeel, A.E.; Dawood, M. Achievement of humidification and dehumidification desalination system by utilizing a hot water sprayer and ultrasound waves techniques. Energy Convers. Manag. 2019, 201, 112142. [Google Scholar] [CrossRef]

- Santosh, R.; Kumaresan, G.; Kumar, G.K. Experimental parametric investigation of waste heat powered humidification dehumidification system for production of freshwater from wastewater. Desalination 2020, 484, 114422. [Google Scholar] [CrossRef]

- Thiel, G.P.; Tow, E.W.; Banchik, L.D. Energy consumption in desalinating produced water from shale oil and gas extraction. Desalination 2015, 366, 94–112. [Google Scholar] [CrossRef]

- Minier-Matar, J.; Sharma, R.; Hussain, A. Field evaluation of membrane distillation followed by humidification/dehumidification crystallizer for inland desalination of saline groundwater. Desalination 2016, 398, 12–21. [Google Scholar] [CrossRef]

- Liu, J.; Sun, Y.; Yv, S. Design and Experimental Study on a New Closed-Cycle Desalination System Based on Ambient Temperature. Processes 2020, 8, 1131. [Google Scholar] [CrossRef]

- Baton, D.; Glescer, L.; Greenberg, A.S. Standard Method for Examination of Water and Wastewater; APHA Publication: Washington, DC, USA, 2012. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).