Development of a New Sensor Module for an Enhanced Fuel Flexible Operation of Biomass Boilers

Abstract

1. Introduction

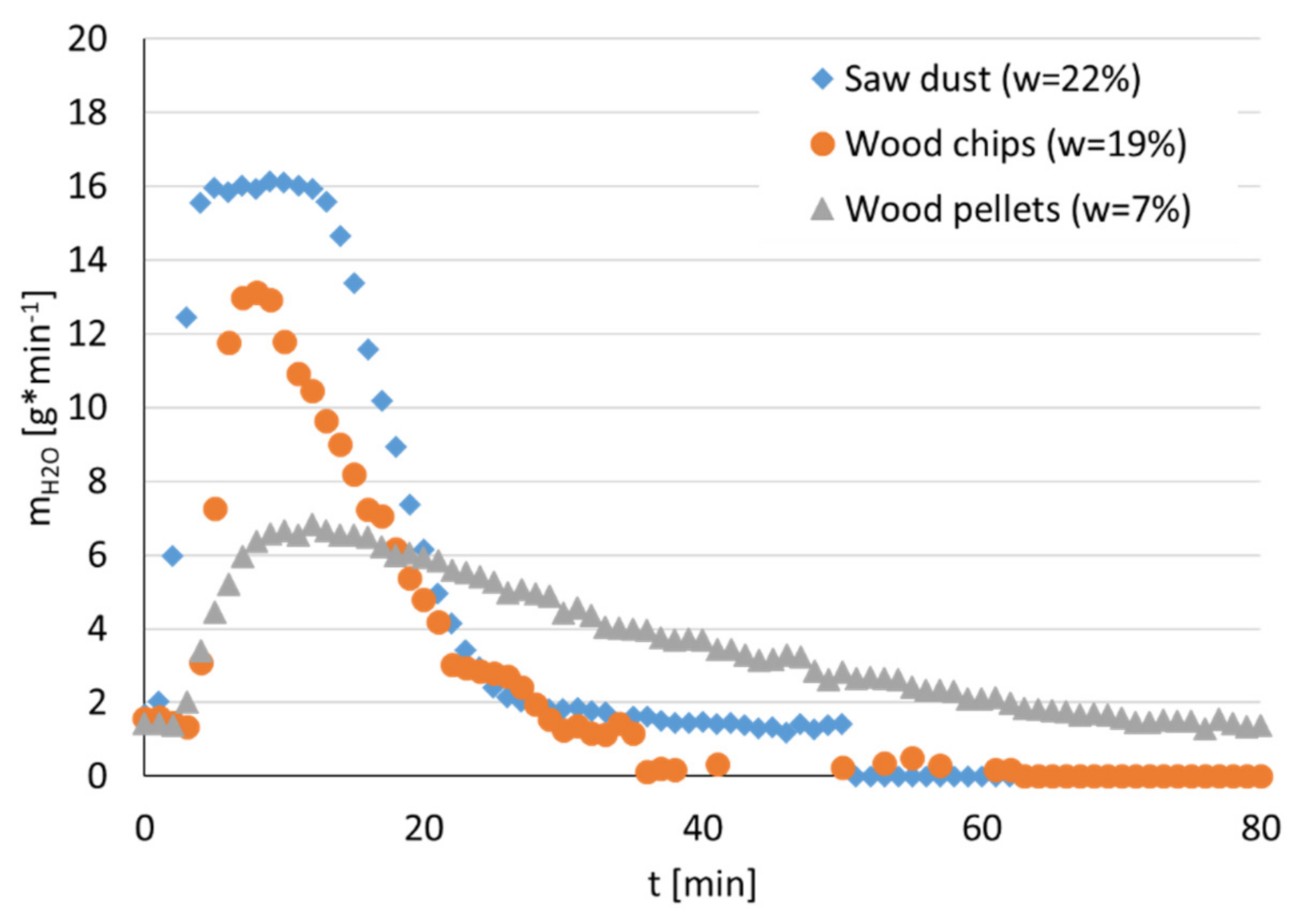

2. Materials and Methods

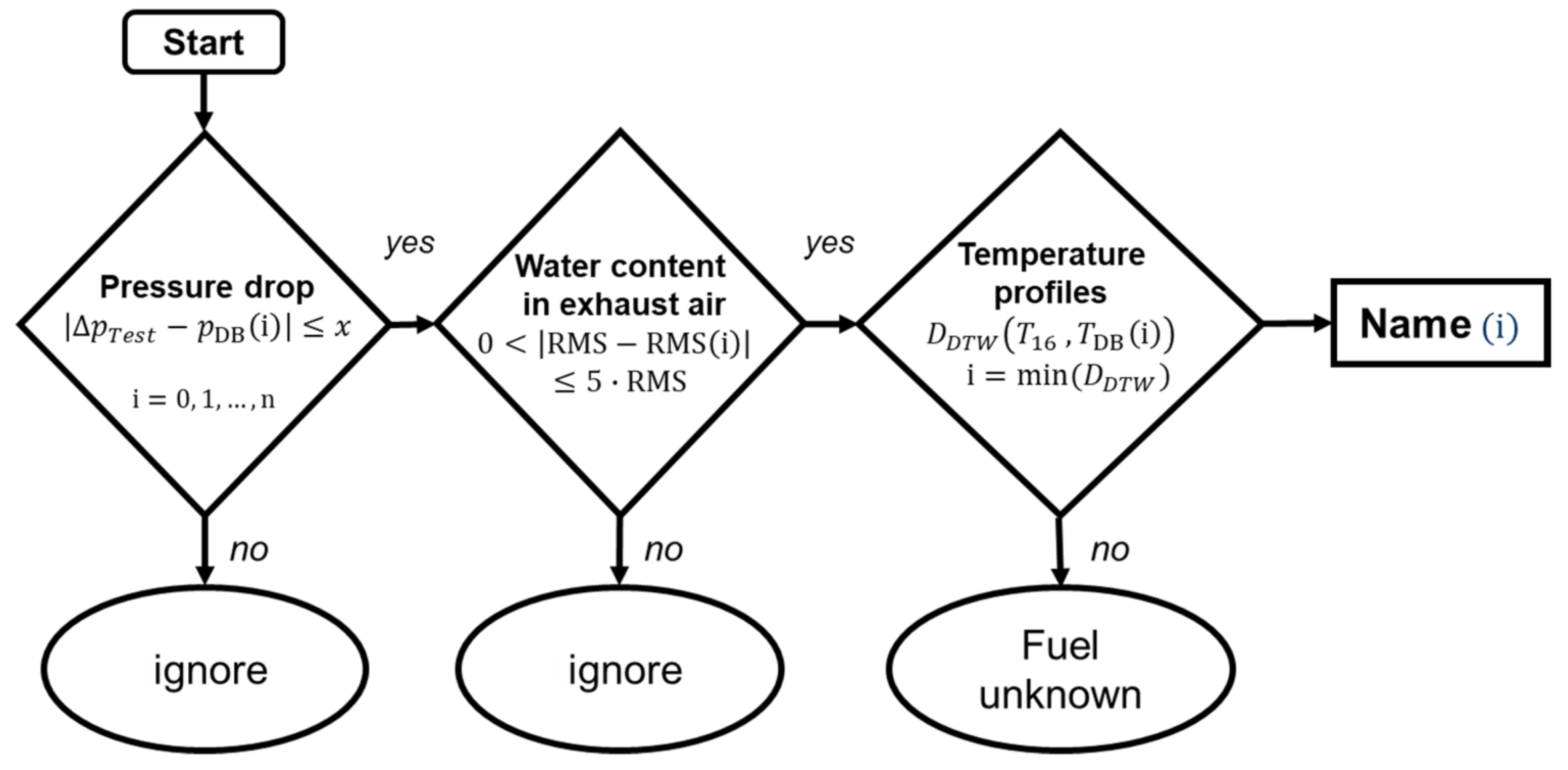

2.1. Lab Scale Test Rig

2.2. Test Procedure

2.3. Feedstock

3. Results

3.1. Screening of Biogenic Residues

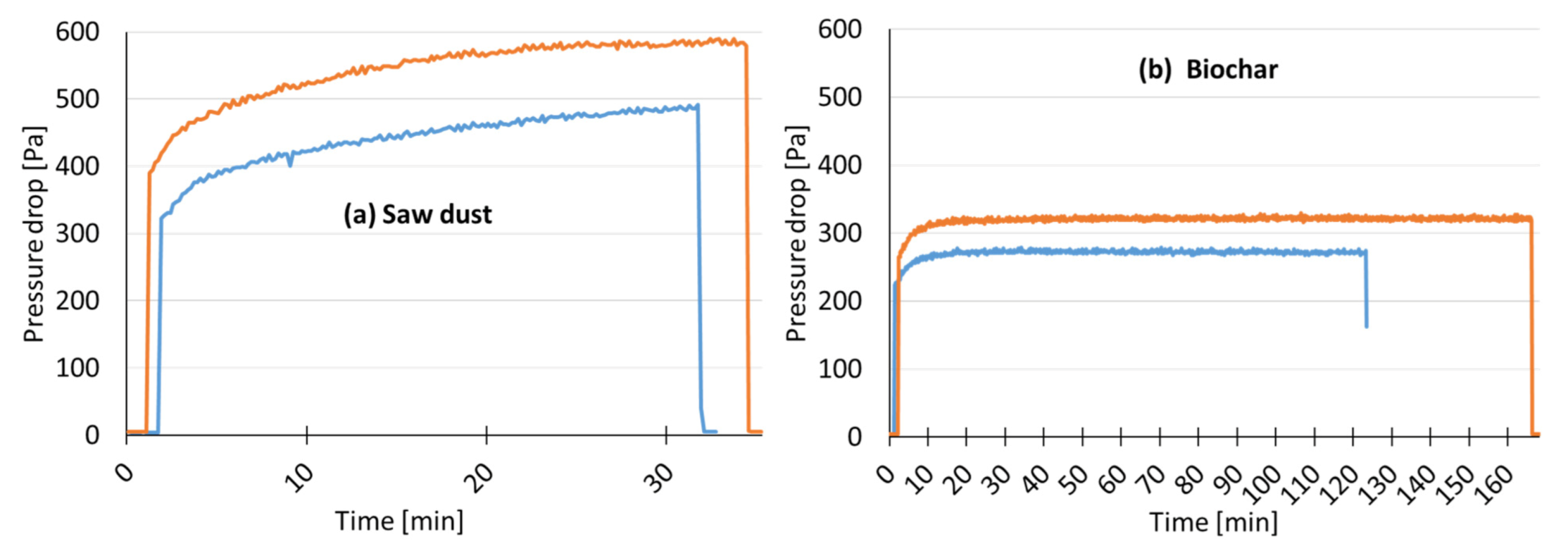

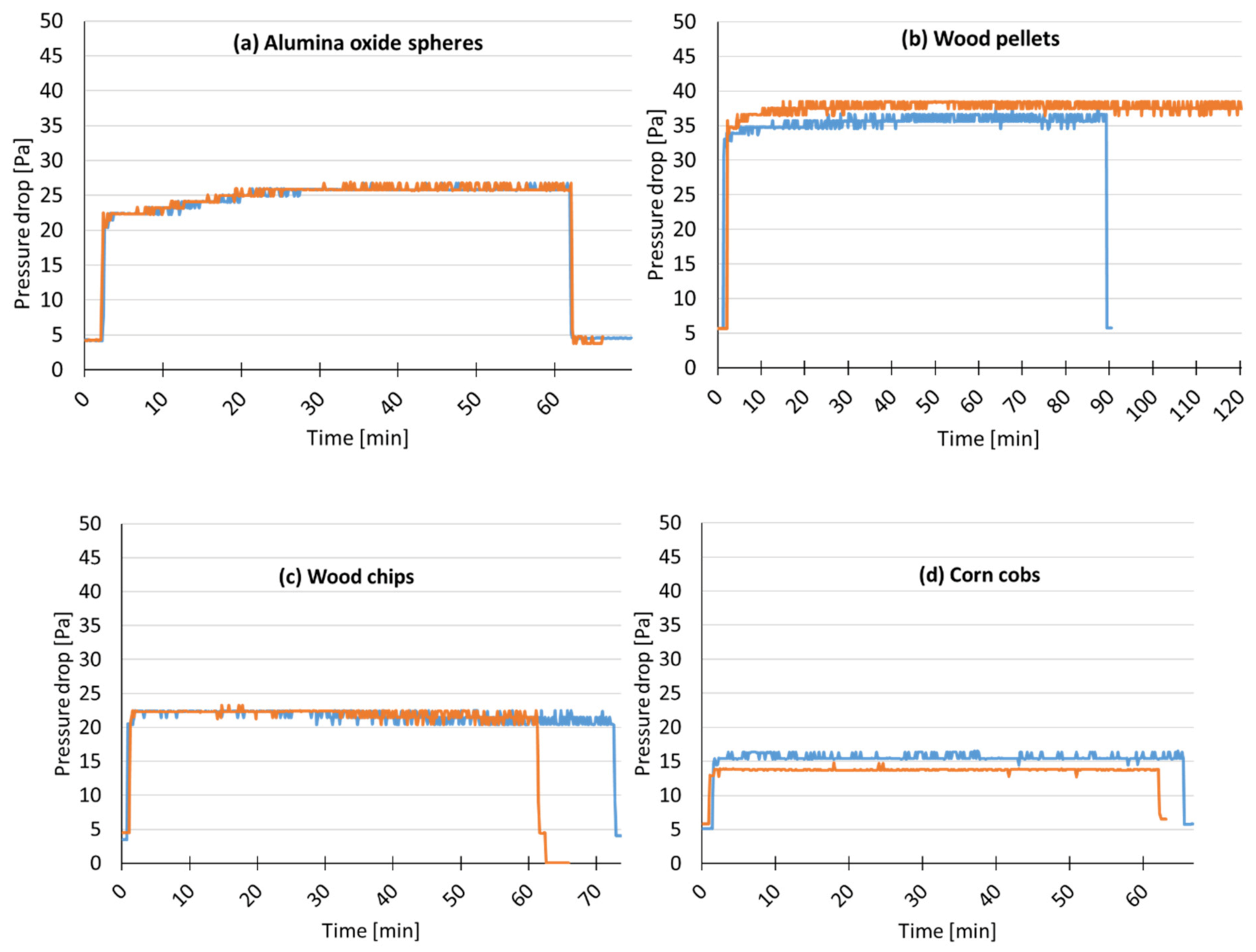

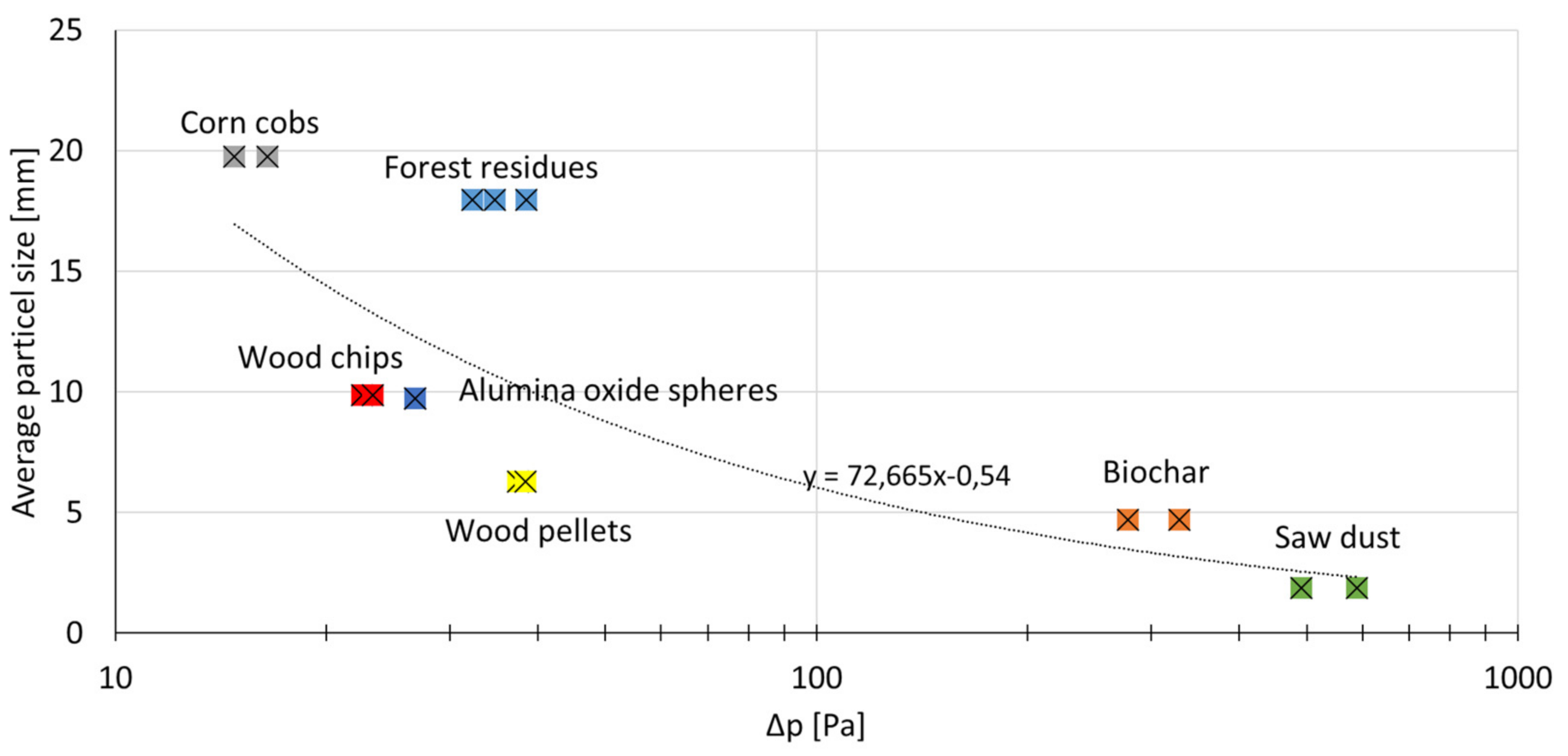

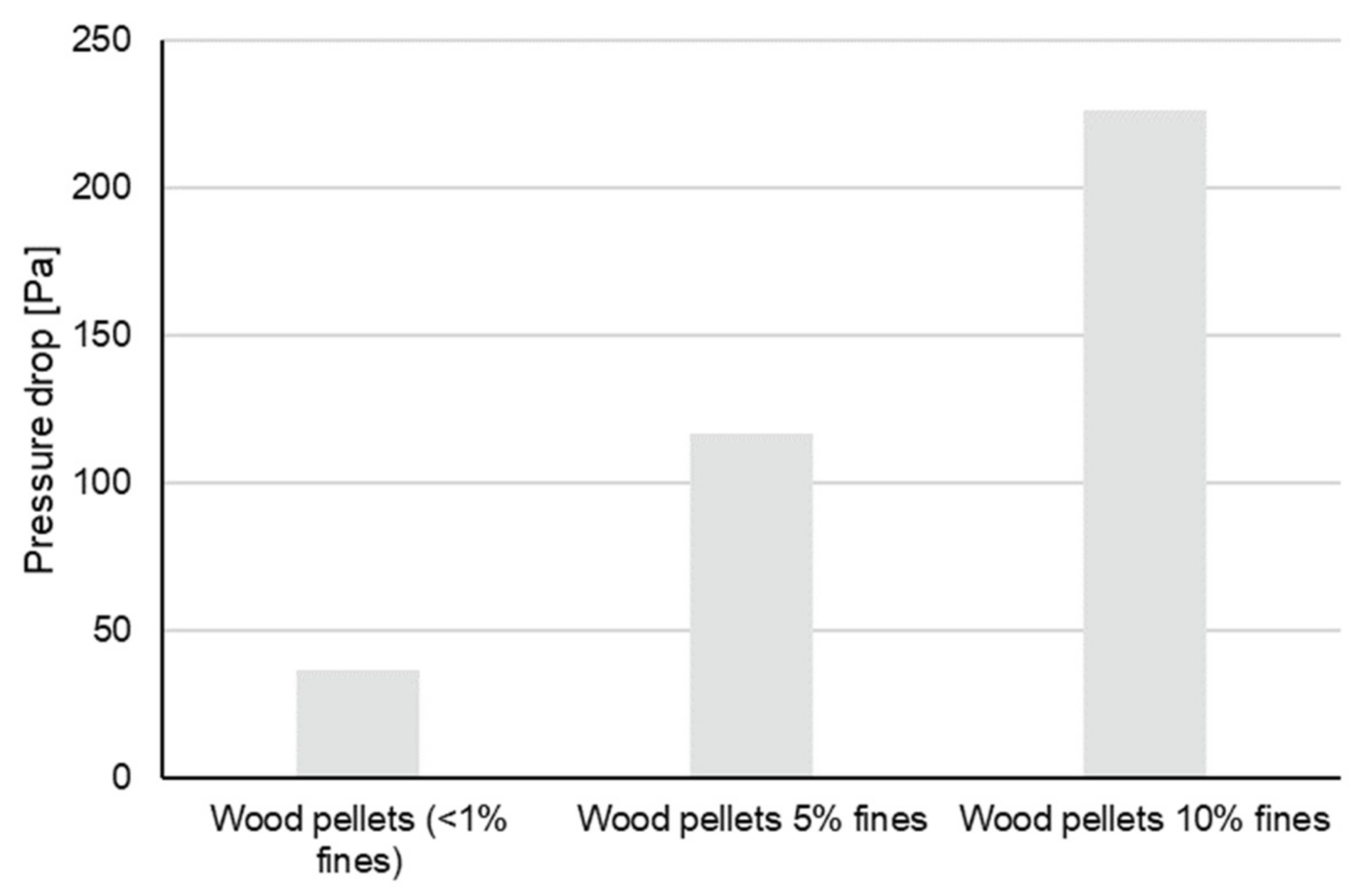

3.1.1. Pressure Drop

3.1.2. Temperature

3.2. Specific Variation of Fuel Parameters

3.3. Energy and Mass Balance as a Basis for Data Evaluation

4. Discussion

5. Conclusions

6. Patents

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Abbreviations | |

| a | Ash content (%) |

| DTW | Dynamic Time Warping |

| LHV | Lower Heating Value (MJ·kg−1) |

| NIR | Near infrared (spectroscopy) |

| p | Pressure (Pa) |

| PIR | Pressure Indicator and Recorder |

| QIR | Quantity Indicator and Recorder |

| RDF | Refuse Derived Fuel |

| RMS | Root Mean Square |

| TIR | Temperature Indicator and Recorder |

| w | Water content (%) |

| Subscripts | |

| A | Air |

| d | dry |

| dA | dry Air |

| dm | dry matter |

| in | Input |

| out | Output |

| V | Vapour |

| w | Water |

References

- Jenkins, B.M.; Baxter, L.L.; Miles, T.R. Combustion properties of biomass. Fuel Process. Technol. 1998, 54, 17–46. [Google Scholar] [CrossRef]

- Kuptz, D.; Schreiber, K.; Schulmeyer, F.; Lesche, S.; Zeng, T.; Ahrens, F.; Zelinski, V.; Schön, C.; Pollex, A.; Borchert, H. Evaluation of combined screening and drying steps for the improvement of the fuel quality of forest residue wood chips—results from six case studies. Biomass Convers. Bioref. 2019, 9, 83–98. [Google Scholar] [CrossRef]

- TFZ Bayern. Handbuch zum Qualitätsmanagement von Holzhackschnitzeln. Available online: https://www.tfz.bayern.de/mam/cms08/festbrennstoffe/dateien/fo_projekt_brennstoff-qualifizierung_und_qualit%C3%A4tsmanagement_in_der_hackschnitzelproduktion.pdf (accessed on 11 March 2021).

- DIN EN ISO 17225-4 Solid Biofuels—Fuel Specifications and Classes—Part 4: Graded Wood Chips (ISO 17225-4:2014); German Version EN ISO 17225-4:2014 STANDARD by DIN-Adopted European-Adopted ISO Standard. Available online: https://www.iso.org/obp/ui/#iso:std:iso:17225:-4:ed-1:v1:en (accessed on 2 March 2021).

- Nurek, T.; Gendek, A.; Roman, K.; Dombrowska, M. The effect of temperature and moisture on the chosen parameters of briquettes made of shredded logging residues. Biomass Bioenergy 2019, 130. [Google Scholar] [CrossRef]

- Nurek, T.; Gendek, A.; Roman, K.; Dombrowska, M. The Impact of Fractional Composition on the Mechanical Properties of Agglomerated Logging Residues. Sustainability 2020, 12, 6120. [Google Scholar] [CrossRef]

- Gaderer, M.H. Thermische Nutzung von Biomasse und Reststoffen in Deutschland. Chem. Ing. Tech. 2011, 83, 1897–1911. [Google Scholar] [CrossRef]

- Di Sarli, V.; Cammarota, F.; Salzano, E. Explosion parameters of wood chip-derived syngas in air. J. Loss Prev. Process Ind. 2014, 32, 399–403. [Google Scholar] [CrossRef]

- Puttkamer, T. Charakterisierung Biogener Festbrennstoffe. Ph.D. Thesis, Universität Stuttgart, Stuttgart, Germany, 2015. [Google Scholar]

- Widder, T.; Beckmann, M. Identifizierung Problematischer Brennstoffkomponenten Mittels Feuerungsmodell mit Nichtlinearer Optimierung; Deutschen Flammentag: Bochum, Deutschland, 2019. [Google Scholar]

- Widder, T.; Pohl, M.; Wen, T.; Woite, M.; Vogeler, M.; Beckmann, M. Modellbasierte Betriebsdatenanalyse für das Anlagenmonitoring im Biomasse-HKW Ilmenau. Kraftwerkstechnik 2019-Power Plant Technology; SAXONIA Standortentwicklungs-und-verwaltungsgesellschaft mbH: Freiberg, Germany, 2019. [Google Scholar]

- Striūgas, N.; Vorotinskienė, L.; Paulauskas, R.; Navakas, R.; Džiugys, A.; Narbutas, L. Estimating the fuel moisture content to control the reciprocating grate furnace firing wet woody biomass. Energy Convers. Manag. 2017, 149, 937–949. [Google Scholar] [CrossRef]

- Lange, F. Online-Identifikation von Brennstoffen und Ihren Kalorischen Eigenschaften Beim Betrieb Einer Stationären Wirbelschichtfeuerungsanlage. Ph.D. Thesis, Universität Rostock, Rostock, Germany, 2007. [Google Scholar]

- Zwiellehner, M.; Warnecke, R.; Weghaus, M.; Müller, V. Kopplung Einer Modernen Feuerungsregelung Mit Einem Modellbasierten System. Available online: https://www.combustioncontrol.biz/publikationen/publi_VDI-WF-Korr-08-FLR%20und%20CombAte.pdf (accessed on 26 February 2021).

- Warnecke, R.; Weghaus, M.; Zwiellehner, M.; Dannerbeck, F. Einsatz eines Feuerungsmodells zum Klimaschutz durch Effizienzsteigerung und Emissionsminderung in Rostanlagen mit heterogenen Brennstoffen, EU 22776, Final Report. Available online: https://www.gks-sw.de/images/forschungsberichte/efre-schlussbericht/EFRE-Feuerungsregelung-Schlussbericht-130531-Final.pdf (accessed on 11 March 2021).

- Madlsperger, W. 2009, DE102007055168A1. Available online: https://depatisnet.dpma.de/DepatisNet/depatisnet?action=bibdat&docid=DE102007055168A1 (accessed on 2 March 2021).

- Fabinski, W. 1997, DE 19547258 A1. Available online: https://depatisnet.dpma.de/DepatisNet/depatisnet?action=bibdat&docid=DE000019547258A1 (accessed on 2 March 2021).

- Dübenhofer, P. 1999, DE 199 17 572 A1/EP000001046861A1. Available online: https://depatisnet.dpma.de/DepatisNet/depatisnet?action=bibdat&docid=DE000019917572A1 (accessed on 2 March 2021).

- Brem, G. 2000, WO002000075569A1/WO002002046661A1. Available online: https://depatisnet.dpma.de/DepatisNet/depatisnet?action=bibdat&docid=WO002000075569A1 (accessed on 2 March 2021).

- Baier, G.; Gasch, A.; Vogel, A. 1994, DE 4446022A1. Available online: https://depatisnet.dpma.de/DepatisNet/depatisnet?action=bibdat&docid=DE000004446022A1 (accessed on 2 March 2021).

- Maggale, A. 2017, AT000000015458U1. Available online: https://depatisnet.dpma.de/DepatisNet/depatisnet?action=bibdat&docid=AT000000015458U1 (accessed on 2 March 2021).

- Barker, R. 2007, WO002008079319A2. Available online: https://depatisnet.dpma.de/DepatisNet/depatisnet?action=bibdat&docid=WO002008079319A2 (accessed on 2 March 2021).

- Krämer, P.; Flamme, S.; Gehrmann, H.-J.; Glorius, T. Entwicklungen zur Echtzeitanalytik von Ersatzbrennstoffen. In Energie aus Abfall, Band 13; TK Verlag Karl Thomé-Kozmiensky: Neuruppin, Germany, 2016; Available online: https://www.vivis.de/wp-content/uploads/EaA13/2016_EaA_439-458_Kraemer (accessed on 9 March 2021).

- Lestander, A.; Rhen, C. Multivariate NIR spectroscopy models for moisture, ash and calorific content in biofuels using bi-orthogonal partial least squares. Analyst 2005. [Google Scholar] [CrossRef] [PubMed]

- Nyström, J.; Dahlquist, E. Methods for determination of moisture content in woodchips for power plants—A review. Fuel 2004, 83, 773–779. [Google Scholar] [CrossRef]

- Sensortech Systems Inc. Available online: http://sensortech.com/instruments/nir-6000/ (accessed on 23 July 2018).

- APOS GmbH. Available online: https://www.apos.biz/de/produkte/wood-reception/receivingopt-ba/ (accessed on 9 April 2021).

- APOS GmbH. Available online: https://www.apos.biz/de/produkte/process-application/apos-boilercontrol/ (accessed on 9 April 2021).

- Ropp, J.; Stäger, T.; Röthlisberger, R. XyloChips—Continuous Measurement of Woodchips Energy Content; Holzenergie-Symposium Netzintegration; Vorschriften und Feuerungstechnik: Zürich, Switzerland, 2018. [Google Scholar]

| Sample | w [%] 1 | a [%] 2 | LHV [MJ·kg−1] 3 | C [%] 4 | H [%] 4 | N [%] 4 | S [%] 4 | O [%] 4 |

|---|---|---|---|---|---|---|---|---|

| Wood pellets | 7.2 | 0.27 | 16.951 | 47.27 | 6.62 | 0.05 | 0.06 | 45.73 |

| Saw dust | 7.43 | 0.39 | 16.212 | 46.29 | 6.48 | 0.7 | 0.06 | 46.08 |

| Wood chips | 10.54 | 0.62 | 15.894 | 45.18 | 6.12 | 0.18 | 0.03 | 47.87 |

| Forestry residues | 44.4 | 2.08 | 10.989 | 42.01 | 5.69 | 0.35 | 0.06 | 49.81 |

| Corn cobs | 6.87 | 2.25 | 15.181 | 45.02 | 6.37 | 0.64 | 0.11 | 45.61 |

| Biochar | 0.93 | 41.44 | 17.542 | 48.46 | 1.86 | 1.78 | 0.29 | 6.17 |

| Particle Size 1 and Bulk Density 2 | Ø [mm] | Particles <3.15 mm [%] | Particles >45 mm [%] | Bulk Density 2 [kg·m−3] |

|---|---|---|---|---|

| Wood pellets | 6.26 | 0.2 | 0 | 648.07 |

| Saw dust | 1.84 | 81.74 | 0 | 150.15 |

| Wood chips | 9.84 | 11.13 | 0 | 173.5 |

| Forestry residues | 17.94 | 10.98 | 10.58 | 210.96 |

| Corn cobs | 19.74 | 8.48 | 3.37 | 122.34 |

| Biochar | 4.67 | 17 | 0 | 631.48 |

| Alumina oxide spheres | 9.7 | 0 | 0 | 2032.26 |

| Sample | Δpmax [Pa] |

|---|---|

| Wood pellets | 36.6 |

| Wood pellets 5% fines | 116.3 |

| Wood pellets 10% fines | 226.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Meiller, M.; Oischinger, J.; Daschner, R.; Hornung, A. Development of a New Sensor Module for an Enhanced Fuel Flexible Operation of Biomass Boilers. Processes 2021, 9, 661. https://doi.org/10.3390/pr9040661

Meiller M, Oischinger J, Daschner R, Hornung A. Development of a New Sensor Module for an Enhanced Fuel Flexible Operation of Biomass Boilers. Processes. 2021; 9(4):661. https://doi.org/10.3390/pr9040661

Chicago/Turabian StyleMeiller, Martin, Jürgen Oischinger, Robert Daschner, and Andreas Hornung. 2021. "Development of a New Sensor Module for an Enhanced Fuel Flexible Operation of Biomass Boilers" Processes 9, no. 4: 661. https://doi.org/10.3390/pr9040661

APA StyleMeiller, M., Oischinger, J., Daschner, R., & Hornung, A. (2021). Development of a New Sensor Module for an Enhanced Fuel Flexible Operation of Biomass Boilers. Processes, 9(4), 661. https://doi.org/10.3390/pr9040661