Research Regarding the Energy Recovery from Municipal Solid Waste in Maramures County Using Incineration

Abstract

1. Introduction

2. Materials and Methods

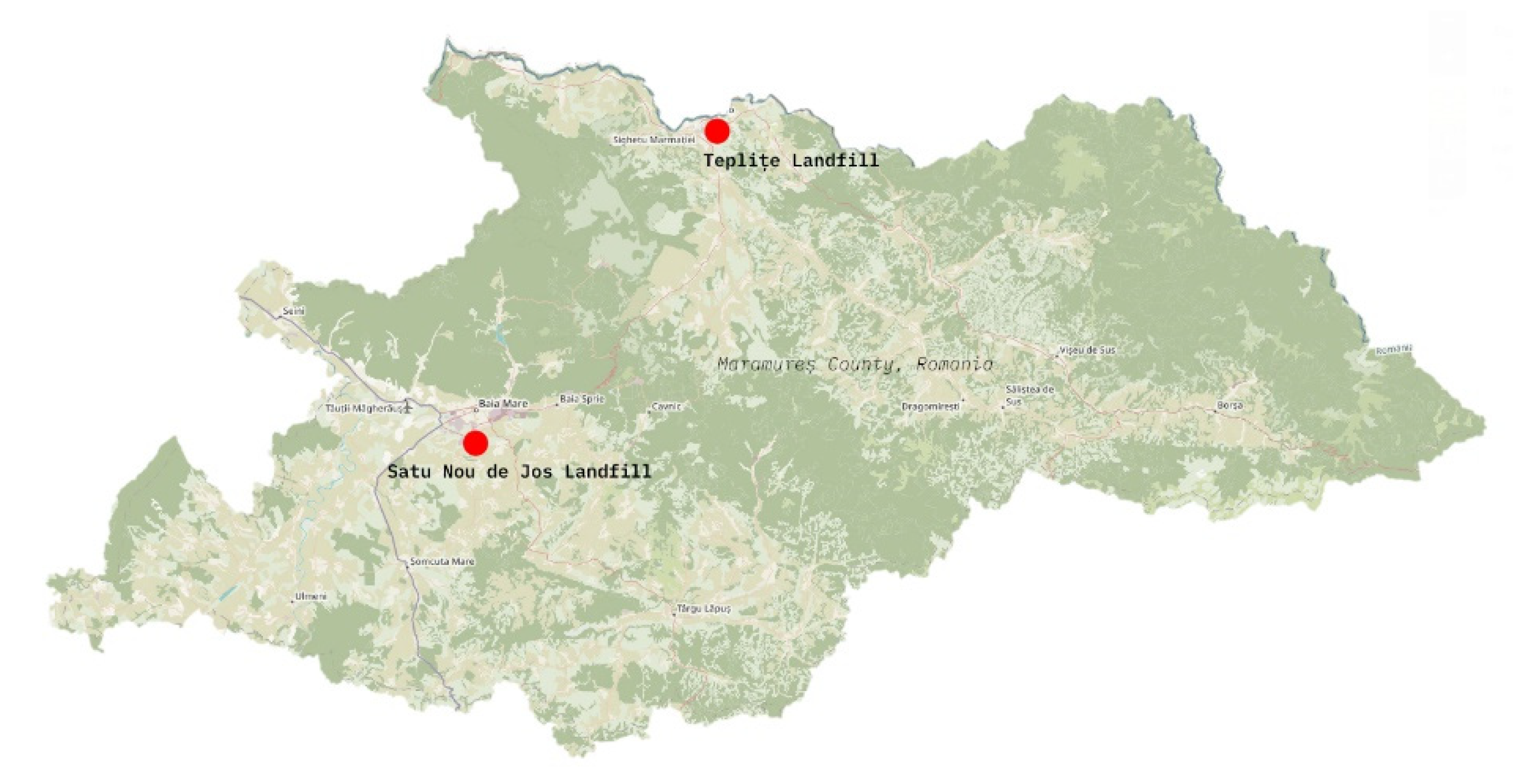

2.1. Waste Generation in Maramures County

2.2. The Estimated Municipal Solid Waste Quantity for Energy Recovery

2.3. Collection and Preparation of Samples

- Organic matter in percentage of 57.75%;

- 10.72% plastic;

- 10.66% of paper and cardboard;

- 7.5% of textile materials;

- 4.82% of wood; and

- 8.5% bulk waste.

2.4. Moisture Content of the Municipal Solid Waste

2.5. Chemical Composition of Municipal Solid Waste

3. Results

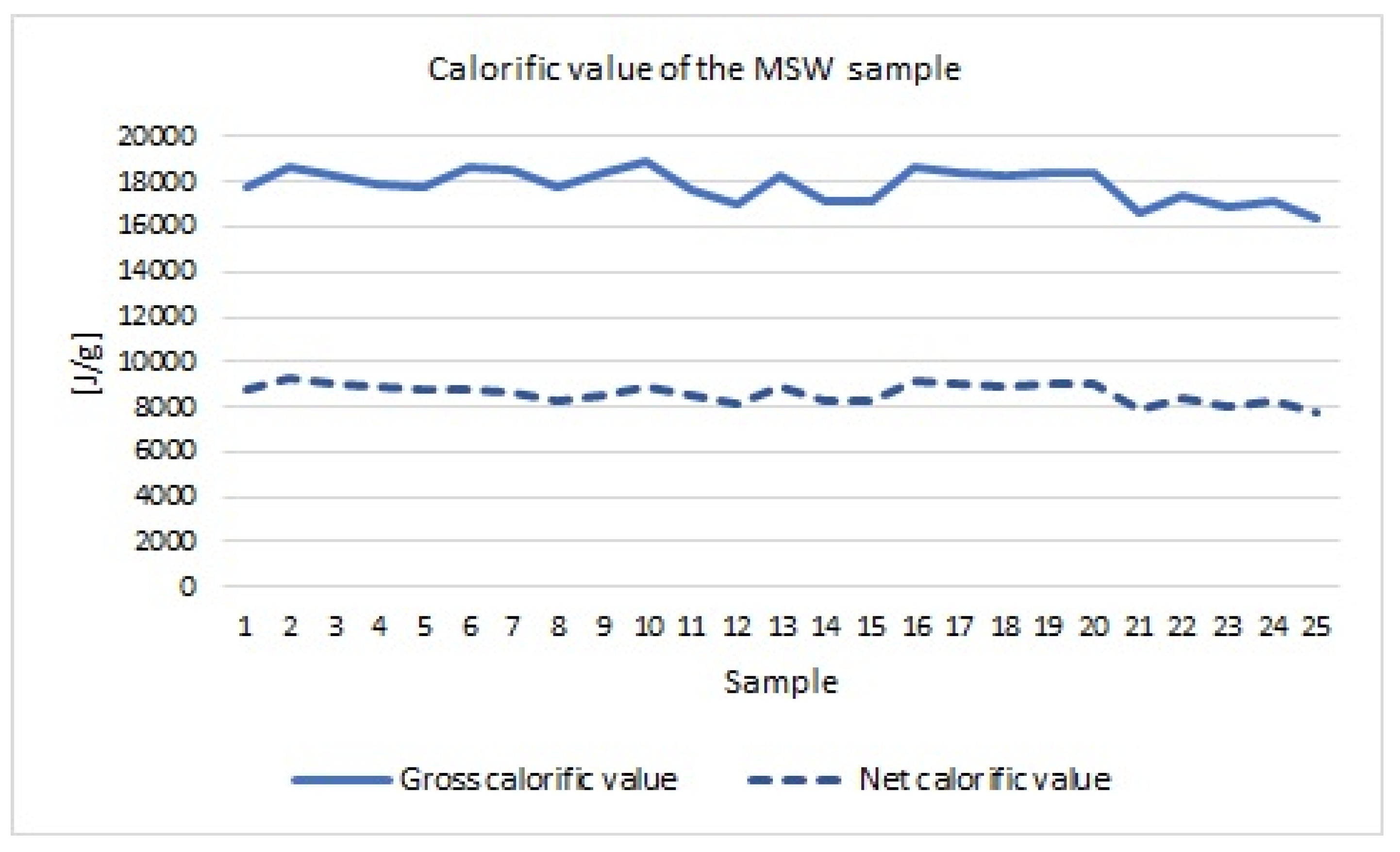

3.1. Determination of Calorific Value

- qp,net,m is the net calorific value of the fuel at constant pressure and water content;

- qV,gr,d is the gross calorific value at constant volume and free water;

- wH,d is the hydrogen content of the sample, expressed as a percent mass fraction, of the moisture-free (dry) fuel;

- wO,d is the oxygen content of the sample, expressed as a percent mass fraction, of the moisture-free fuel;

- wN,d is the nitrogen content of the sample, expressed as a percent mass fraction, of the moisture-free fuel.

- MT is the total moisture content, expressed as a percent mass fraction.

3.2. Energy Recovery Potential of Municipal Solid Waste

- EPMSW/year is the annual energy content of the treated waste, calculated on the basis of the lower net calorific value of the waste), [GJ];

- WMSW/year-total waste quantity per year, [t];

- NCV—net calorific value, [kJ/kg].

- Energy potential of the treated waste per year EPMSW = 460,168 GJ = 127,824 MWh;

- production of steam per year = 133,314.7 t; and

- energy potential of electricity and thermal energy per year, EPCMSW/year = 102,259.58 MWh.

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hussain, A.A.; Wesam, S.N.; Al-Rekabi, N.A.; Hamdan, A. Prediction of Potential Electrical Energy Generation from MSW of Basrah Government. In Proceedings of the 5th International Conference on Waste Management, Ecology and Biological Sciences (WMEBS-2017), Istanbul, Turkey, 15–18 May 2017; pp. 172–181. [Google Scholar]

- Anshar, M.; Ani, F.N.; Kader, A.S. The energy potential of municipal solid waste for power generation in Indonesia. J. Mek. 2014, 37, 42–54. [Google Scholar]

- Scarlat, N.; Fahl, F.; Dallemand, J.-F. Status and Opportunities for Energy Recovery from Municipal Solid Waste in Europe. Waste Biomass Valorization 2019, 10, 2425–2444. [Google Scholar] [CrossRef]

- Rada, E.C.; Ragazzi, M.; Torretta, V.; Castagna, G.; Adami, L.; Cioca, L.I. Circular Economy and Waste to Energy. In Conference Proceedings, May, Technologies and Materials for Renewable Energy, Environment and Sustainability. AIP Conf. Proc. 2018, 1968, 030050-1–030050-6. [Google Scholar] [CrossRef]

- Williams, T.P. Waste Treatment and Disposal, 2nd ed.; John Wiley & Sons Ltd.: Hoboken, NJ, USA, 2005; ISBN-13 978-0470849132, ISBN-10 0470849134. [Google Scholar]

- Alzate, S.; Restrepo-Cuestas, B.; Jaramillo-Duque, A. Municipal Solid Waste as a Source of Electric Power Generation in Colombia: A Techno-Economic Evaluation under Different Scenarios. Resources 2019, 8, 51. [Google Scholar] [CrossRef]

- Puna, J.F.; Santos, M.T. Thermal Conversion Technologies for Solid Wastes: A New Way to Produce Sustainable Energy. Waste Manag. 2010, 89–124. [Google Scholar] [CrossRef][Green Version]

- Grech, H.; Neubacher, F. Waste–to–Energy in Austria; Austrian Federal Ministry of Agriculture, Forestry, Environment and Water Management. Available online: https://www.iswa.org/fileadmin/galleries/Publications/White%20Book/Whitebook_20Incineration_2009%5B1%5D.pdf (accessed on 15 May 2020).

- Pecorini, I.; Rossi, E.; Iannelli, R. Mitigation of Methane, NMVOCs and Odor Emissions in Active and Passive Biofiltration Systems at Municipal Solid Waste Landfills. Sustainability 2020, 12, 3203. [Google Scholar] [CrossRef]

- Zhang, C.; Xu, T.; Feng, H.; Chen, S. Greenhouse Gas Emissions from Landfills: A Review and Bibliometric Analysis. Sustainability 2019, 11, 2282. [Google Scholar] [CrossRef]

- Vieru, D. NOMOGRAMA of a Landfill (msw)—Setting m Parameter Values. Atmos. Clim. Sci. 2017, 7, 436–454. [Google Scholar]

- Lu, J.-W.; Zhang, S.; Hai, J.; Lei, M. Status and perspectives of municipal solid waste incineration in China: A comparison with developed regions. Waste Manag. 2017, 69, 170–186. [Google Scholar] [CrossRef] [PubMed]

- Lee, U.; Han, J.; Wang, M. Evaluation of landfill gas emissions from municipal solid waste landfills for the life-cycle analysis of waste-to-energy pathways. J. Clean. Prod. 2017, 166, 335–342. [Google Scholar] [CrossRef]

- Ryu, C.; Shin, D. Combined Heat and Power from Municipal Solid Waste: Current Status and Issues in South Korea. Energies 2013, 6, 45–57. [Google Scholar] [CrossRef]

- Ministerul Industriei Şi Resurselor. Normativ Tehnic Din 10 Ianuarie 2003 Privind Incinerarea Deşeurilor; Technical Regulation of 10 January 2003 on waste incineration; Ministry of Industry and Resources: Bucharest, Romania, 2003.

- European Parliament. Directive 2008/98/EC of the European Parliament and of the Council of 19 November 2008 on Waste and Repealing Certain Directives; Directive 2008/98/EC; Council of the European Union: Brussels, Belgium, 2008. [Google Scholar]

- Zhou, Z.; Tang, Y.; Chi, Y.; Ni, M.; Buekens, A. Waste-to-energy: A review of life cycle assessment and its extension methods. Waste Manag. Res. 2018, 36, 3–16. [Google Scholar] [CrossRef] [PubMed]

- Petrişor, A.-I.; Meiţă, V. Implications of Spatial Sustainability on the Territorial Planning Framework in a Transition Country. In Proceedings of the Asian Conference on Sustainability, Energy and the Environment 2013, Official Conference Proceedings, Osaka, Japan, 6–9 June 2013; pp. 182–191. [Google Scholar]

- Ozcan, H.K.; Guvenc, S.Y.; Guvenc, L.; Demir, G. Municipal Solid Waste Characterization According to Different Income Levels: A Case Study. Sustain. J. Rec. 2016, 8, 1044. [Google Scholar] [CrossRef]

- Da Silva, L.J.D.V.B.; Dos Santos, I.F.S.; Mensah, J.H.R.; Gonçalves, A.T.T.; Barros, R.M. Incineration of municipal solid waste in Brazil: An analysis of the economically viable energy potential. Renew. Energy 2020, 149, 1386–1394. [Google Scholar] [CrossRef]

- Aryampa, S.; Maheshwari, B.; Sabiiti, E.; Bateganya, N.L.; Bukenya, B. Status of Waste Management in the East African Cities: Understanding the Drivers of Waste Generation, Collection and Disposal and Their Impacts on Kampala City’s Sustainability. Sustain. J. Rec. 2019, 11, 5523. [Google Scholar] [CrossRef]

- Maramureş County Sustainable Development Strategy for the Period 2014–2020. Available online: https://www.cjmaramures.ro/attachments/strategie/Strategia%20de%20Dezvoltare%20Durabila%20a%20Judetului%20Maramures%202014-2020.pdf (accessed on 26 March 2020).

- OpenStreetMap. Available online: https://www.openstreetmap.org (accessed on 10 March 2020).

- Maramureș Environmental Protection Agency. 2018-County Report on the State of the Environment. 2017. Available online: http://www.anpm.ro/web/apm-maramures/rapoarte-anuale1 (accessed on 27 March 2020).

- Maramureș Environmental Agency. 2019–County Report on the State of the Environment. 2018. Available online: http://www.anpm.ro/web/apm-maramures/rapoarte-anuale1 (accessed on 27 March 2020).

- Menikpura, S.N.M.; Basnayake, B.F.A.; Boyagoda, P.B.; Kularathne, I.W. Estimations and Mathematical Model Predictions of Energy Contents of Municipal Solid Waste (MSW) in Kandy. Trop. Agric. Res. 2007, 19, 389–400. [Google Scholar]

- Puiu, D.; Cruceru, L.V. Guidance tool for waste analysis in an accredited laboratory. INCD ECOIND–International Symposium–SIMI 2016 “The Environment and the Industry”. 2016, pp. 81–88. Available online: https://ibn.idsi.md/sites/default/files/imag_file/The%20Environment%20and%20the%20Industry_2017_0.pdf (accessed on 15 October 2020).

- ISO (International Organization for Standardization). Solid Mineral Fuels–Determination of Gross Calorific Value by the Bomb Calorimetric Method and Calculation of Net Calorific Value; Czech Office for Standards, Metrology and Testing: Prague, Czech Republic, 2010; ISO 1928:2009. [Google Scholar]

| Physical Composition of MSW | Quantity (t) | Percentage |

|---|---|---|

| Paper, cardboard | 5683.49 | 10.66 |

| Plastic | 5718.14 | 10.72 |

| Wood | 2571.99 | 4.82 |

| Organic matter | 30,794.78 | 57.75 |

| Textile | 3998.28 | 7.5 |

| Bulk waste | 4559.21 | 8.55 |

| Total | 53,325.87 | 100 |

| Sample Number | Relative Moisture Sample [%] | Hygroscopic Moisture [%] | Total Moisture [%] |

|---|---|---|---|

| Sample 1 | 3.69 | 40.01 | 42.22 |

| Sample 2 | 2.18 | 42.08 | 43.34 |

| Sample 3 | 3.97 | 41.21 | 43.54 |

| Sample 4 | 2.13 | 41.93 | 43.17 |

| Sample 5 | 2.78 | 40.84 | 42.48 |

| Name of Determination | Procedure |

|---|---|

| Carbon | ASTM D 5373-16PS-AGC-15 |

| Hydrogen | ASTM D 5373-16PS-AGC-15 |

| Nitrogen | ASTM D 5373-16PS-AGC-15 |

| Sulphur | PS-AGC-15 |

| Oxygen | Calculus |

| Sample No | Carbon [%] | Hydrogen [%] | Nitrogen [%] | Sulphur [%] | Oxygen [%] |

|---|---|---|---|---|---|

| Sample 1 | 7.25 ± 1.07 | 3.74 ± 0.09 | 0.46 ± 0.02 | S < LQ 1 | 17.75 |

| Sample 2 | 46.47 ± 1.33 | 6.24 ± 0.16 | 0.90 ± 0.03 | 0.50 ± 0.03 | 25.68 |

| Sample 3 | 25.86 ± 0.74 | 2.96 ± 0.07 | 0.91 ± 0.03 | 0.30 ± 0.02 | 19.78 |

| Sample 4 | 26.53 ± 0.76 | 2.98 ± 0.07 | 0.66 ± 0.02 | 0.29 ± 0.02 | 20.07 |

| Sample 5 | 36.52 ± 1.05 | 4.97 ± 0.12 | 0.34 ± 0.01 | S < LQ 1 | 15.29 |

| Sample | Gross Calorific Value (GCV) () [J/g] | Net Calorific Value (NCV) () [J/g] |

|---|---|---|

| Sample 1 | 17,822 | 8800 |

| 18,724 | 9321 | |

| 18,264 | 9055 | |

| 17,932 | 8863 | |

| 17,825 | 8801 | |

| Sample 2 | 18,633 | 8737 |

| 18,532 | 8680 | |

| 17,828 | 8281 | |

| 18,350 | 8577 | |

| 18,958 | 8921 | |

| Sample 3 | 17,636 | 8530 |

| 17,020 | 8182 | |

| 18,283 | 8895 | |

| 17,163 | 8263 | |

| 17,089 | 8221 | |

| Sample 4 | 18,643 | 9172 |

| 18,437 | 9055 | |

| 18,254 | 8935 | |

| 18,390 | 9028 | |

| 18,389 | 9027 | |

| Sample 5 | 16,676 | 7941 |

| 17,375 | 8343 | |

| 16,893 | 8066 | |

| 17,204 | 8245 | |

| 16,422 | 7795 | |

| Average | 17,869.68 | 8629.36 |

| Deviation | 711.76 | 417.37 |

| RSD (%) | 3.98 | 4.84 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ungureanu, M.; Jozsef, J.; Brezoczki, V.M.; Monka, P.; Ungureanu, N.S. Research Regarding the Energy Recovery from Municipal Solid Waste in Maramures County Using Incineration. Processes 2021, 9, 514. https://doi.org/10.3390/pr9030514

Ungureanu M, Jozsef J, Brezoczki VM, Monka P, Ungureanu NS. Research Regarding the Energy Recovery from Municipal Solid Waste in Maramures County Using Incineration. Processes. 2021; 9(3):514. https://doi.org/10.3390/pr9030514

Chicago/Turabian StyleUngureanu, Miorita, Juhasz Jozsef, Valeria Mirela Brezoczki, Peter Monka, and Nicolae Stelian Ungureanu. 2021. "Research Regarding the Energy Recovery from Municipal Solid Waste in Maramures County Using Incineration" Processes 9, no. 3: 514. https://doi.org/10.3390/pr9030514

APA StyleUngureanu, M., Jozsef, J., Brezoczki, V. M., Monka, P., & Ungureanu, N. S. (2021). Research Regarding the Energy Recovery from Municipal Solid Waste in Maramures County Using Incineration. Processes, 9(3), 514. https://doi.org/10.3390/pr9030514