Research on Local Heating Regeneration Method for Air-Conditioning Systems

Abstract

1. Introduction

2. Material and Method

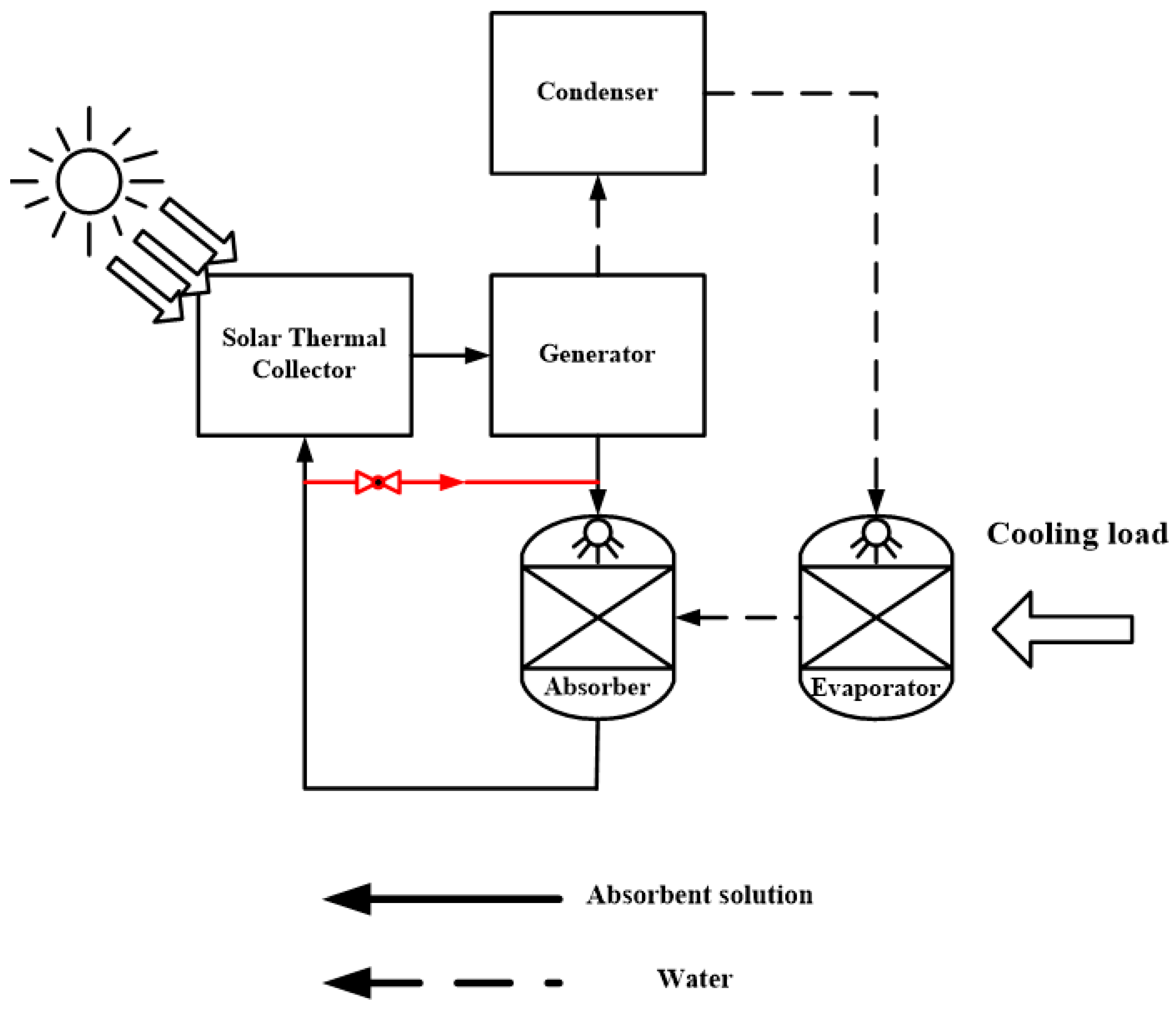

2.1. Regeneration of Smaller Solution Body for Absorption System

2.2. Solar Steam Mode

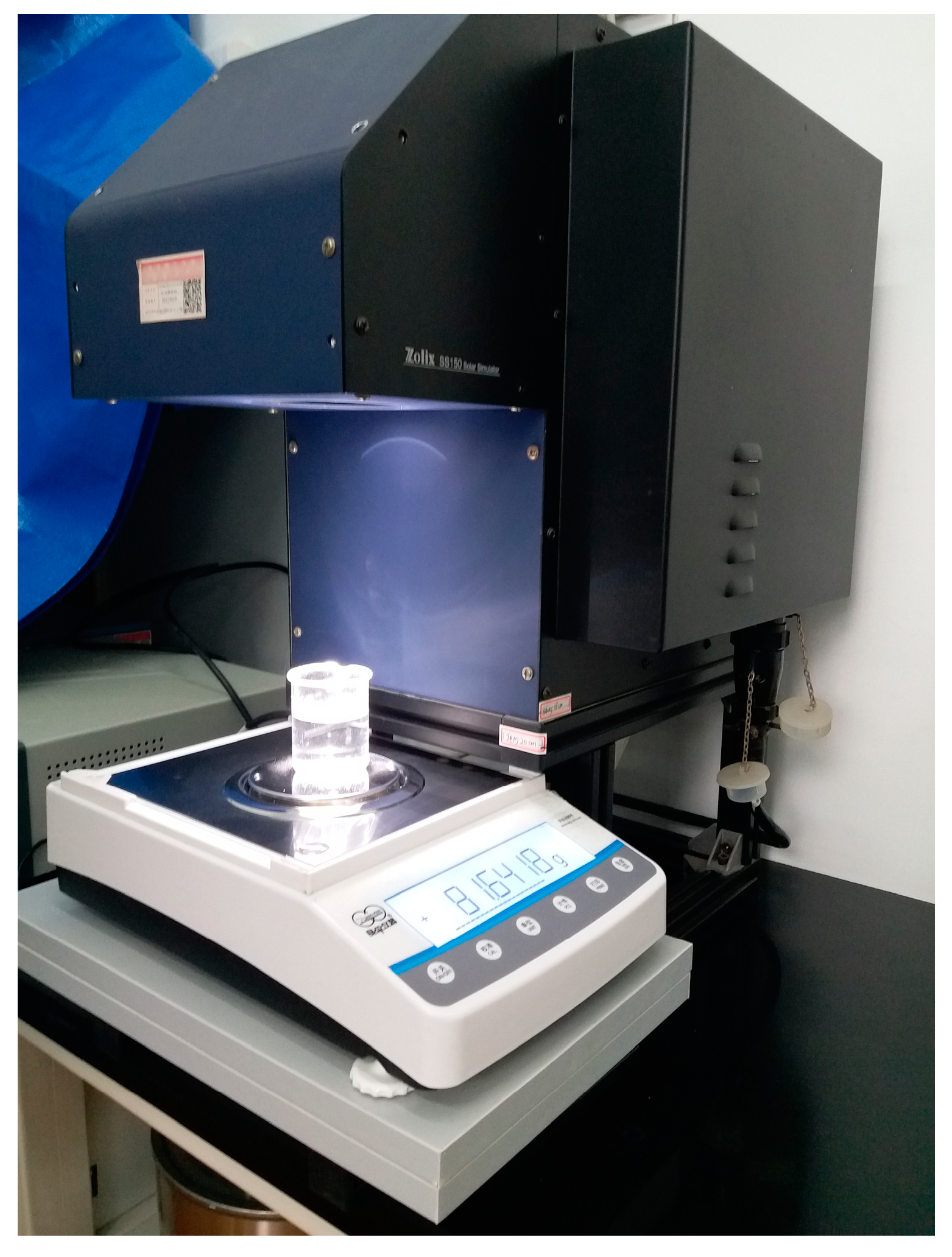

2.3. Experimental System

2.4. Theoretical Analysis of the Performance with the Local Heating Method

3. Results and Discussion

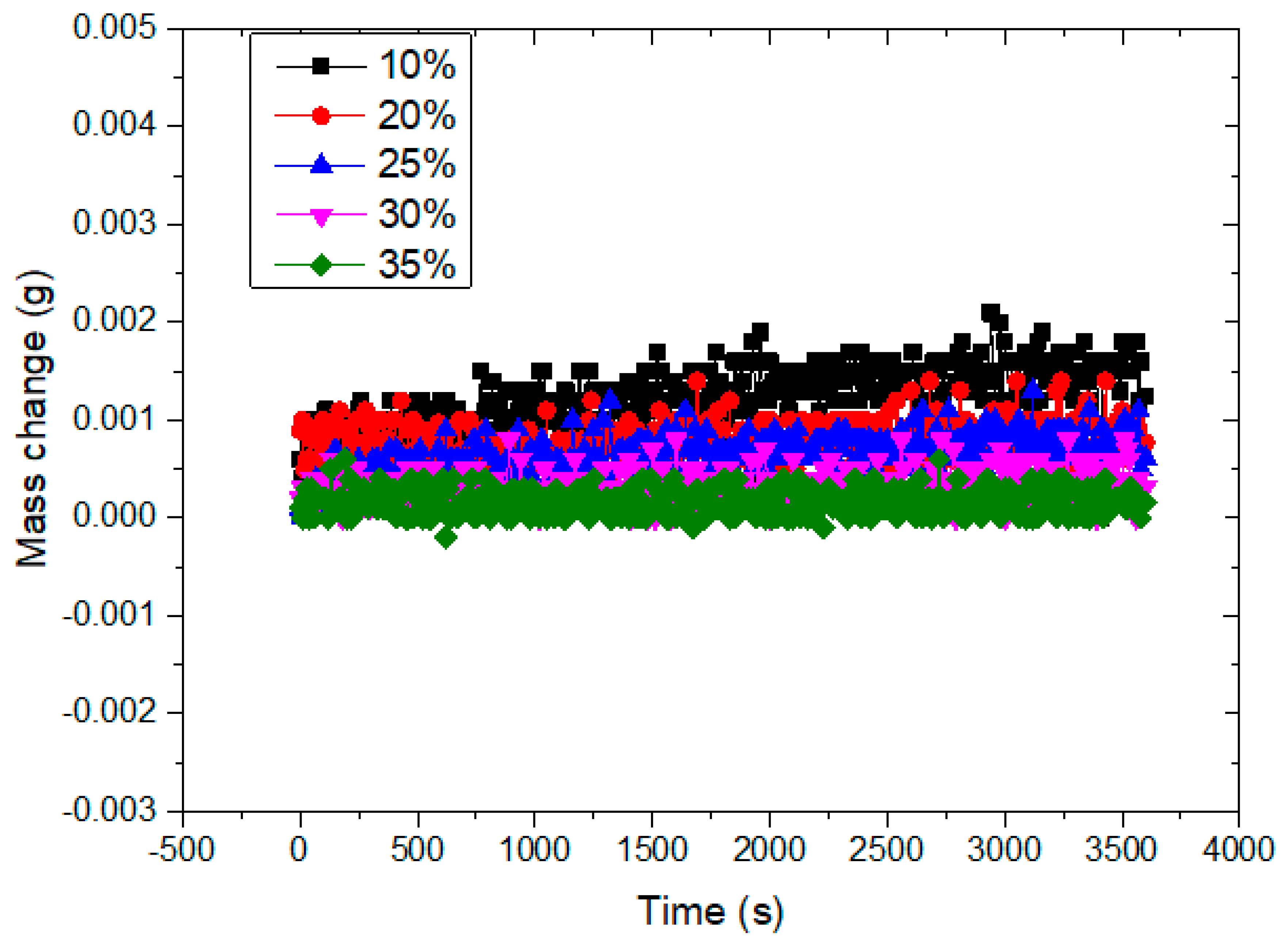

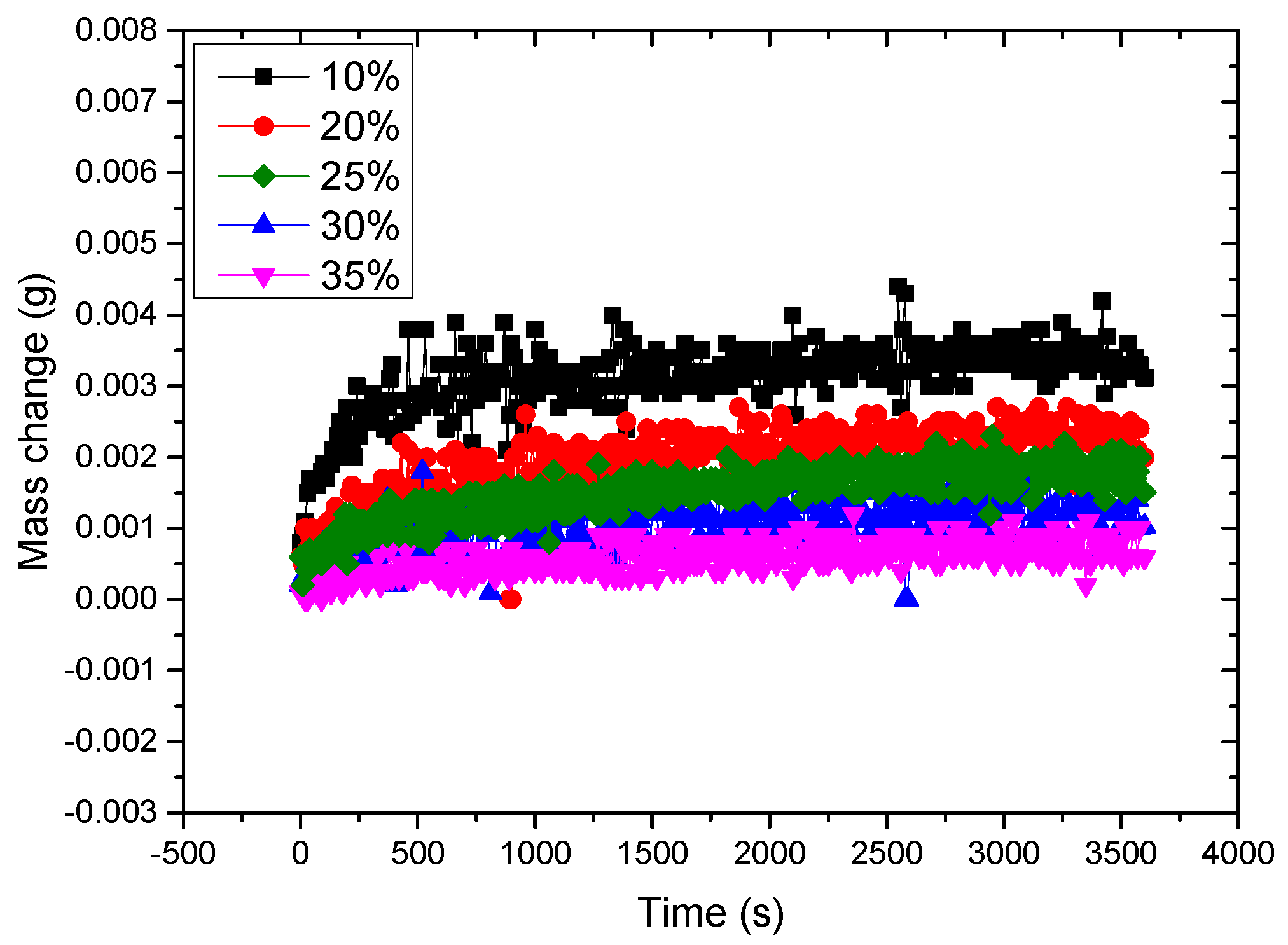

3.1. Experimental Results of the Heating Localization Idea (Not in the Solar Steam Mode)

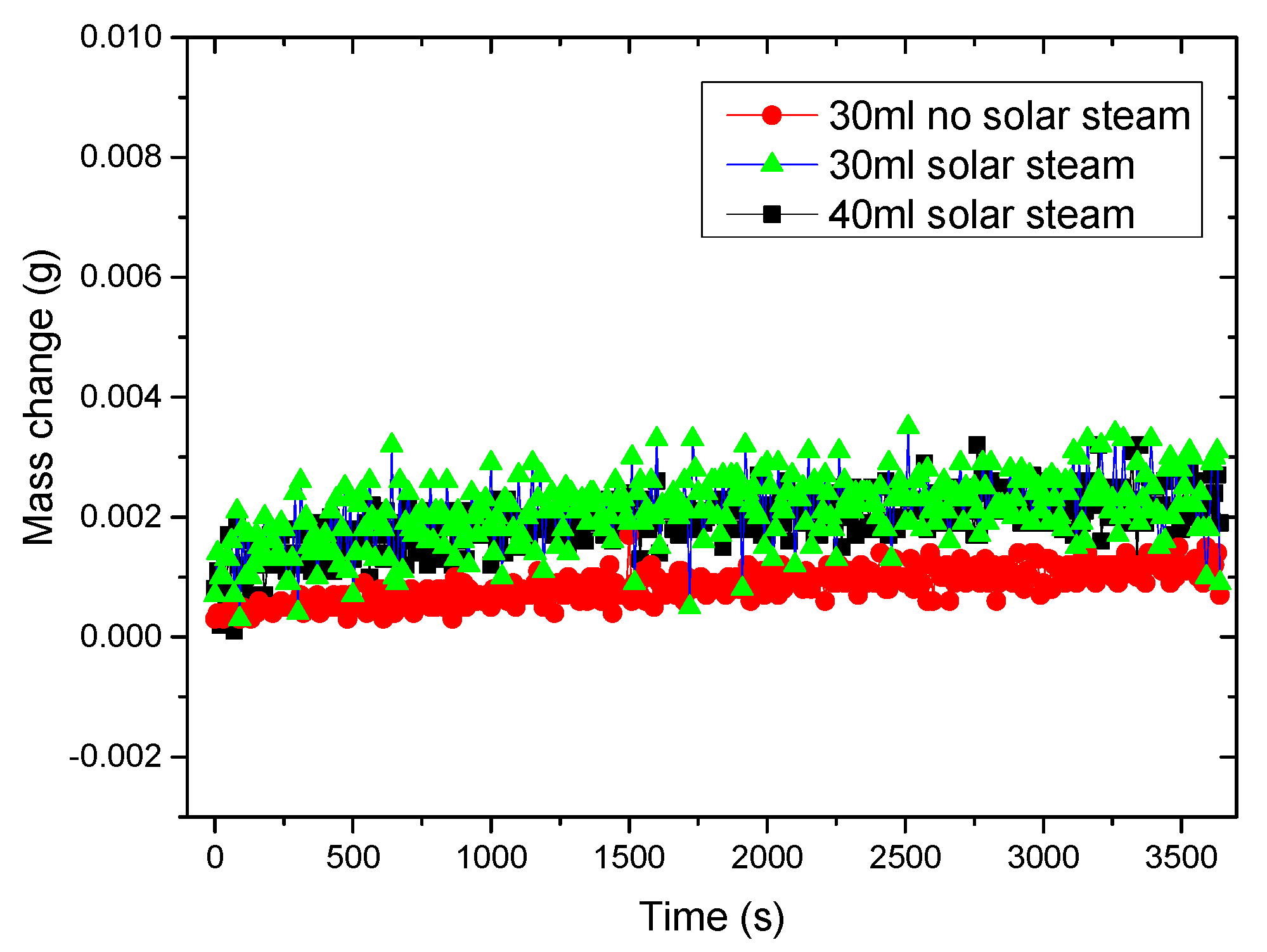

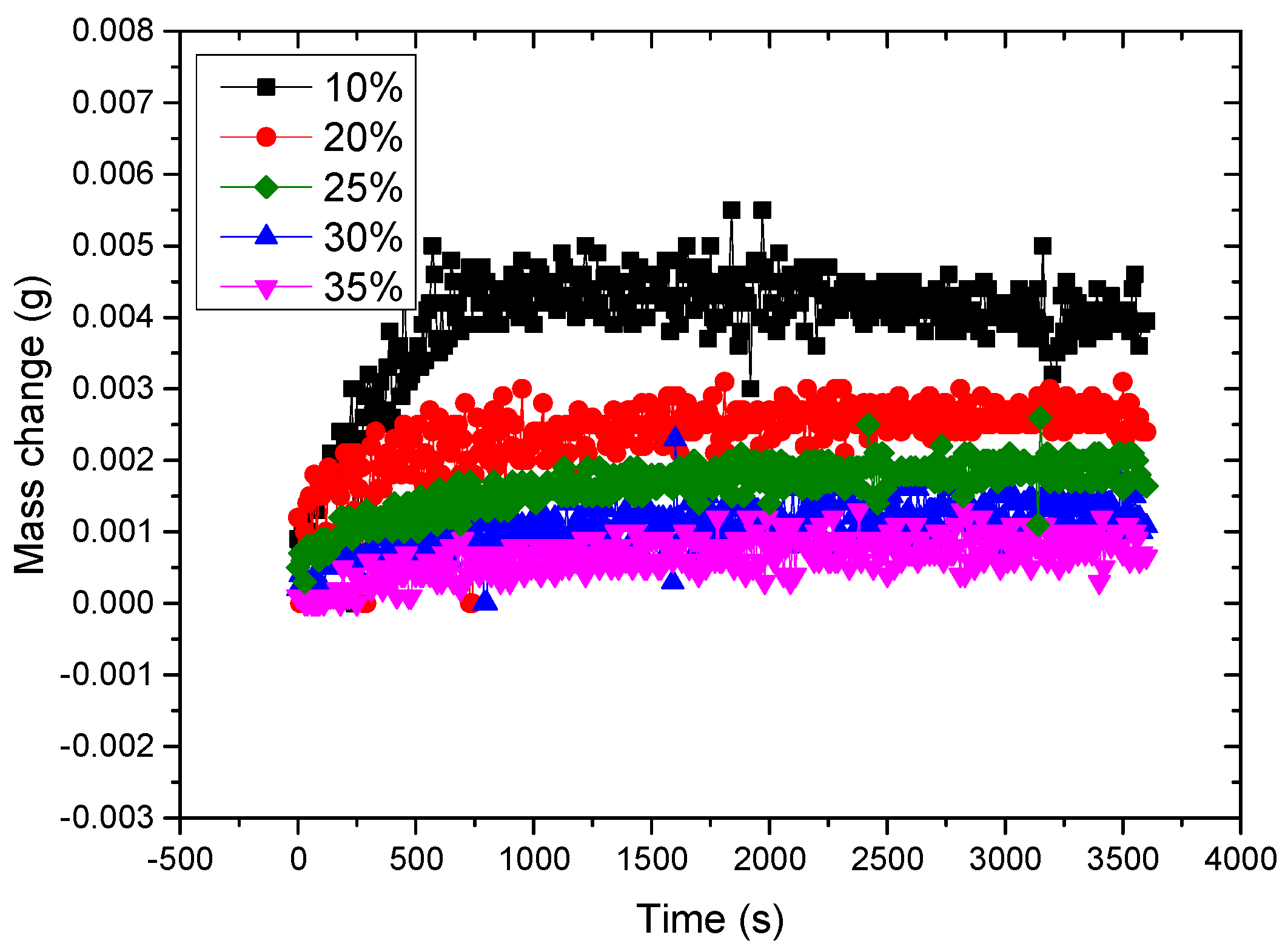

3.2. Experimental Results of the Localization Heating (in the Solar Steam Mode)

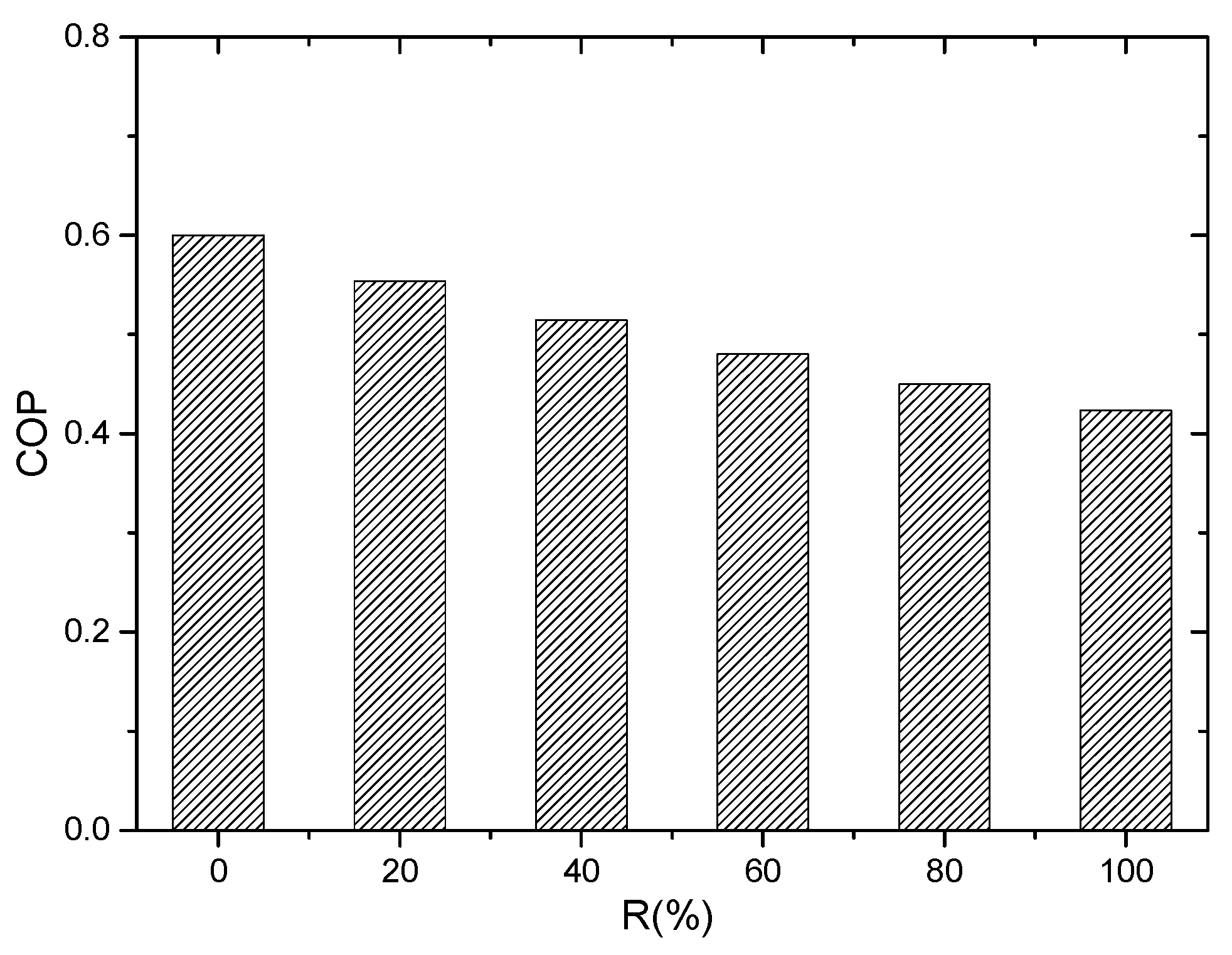

3.3. COP Evaluation for the Absorption System with the Local Heating Idea

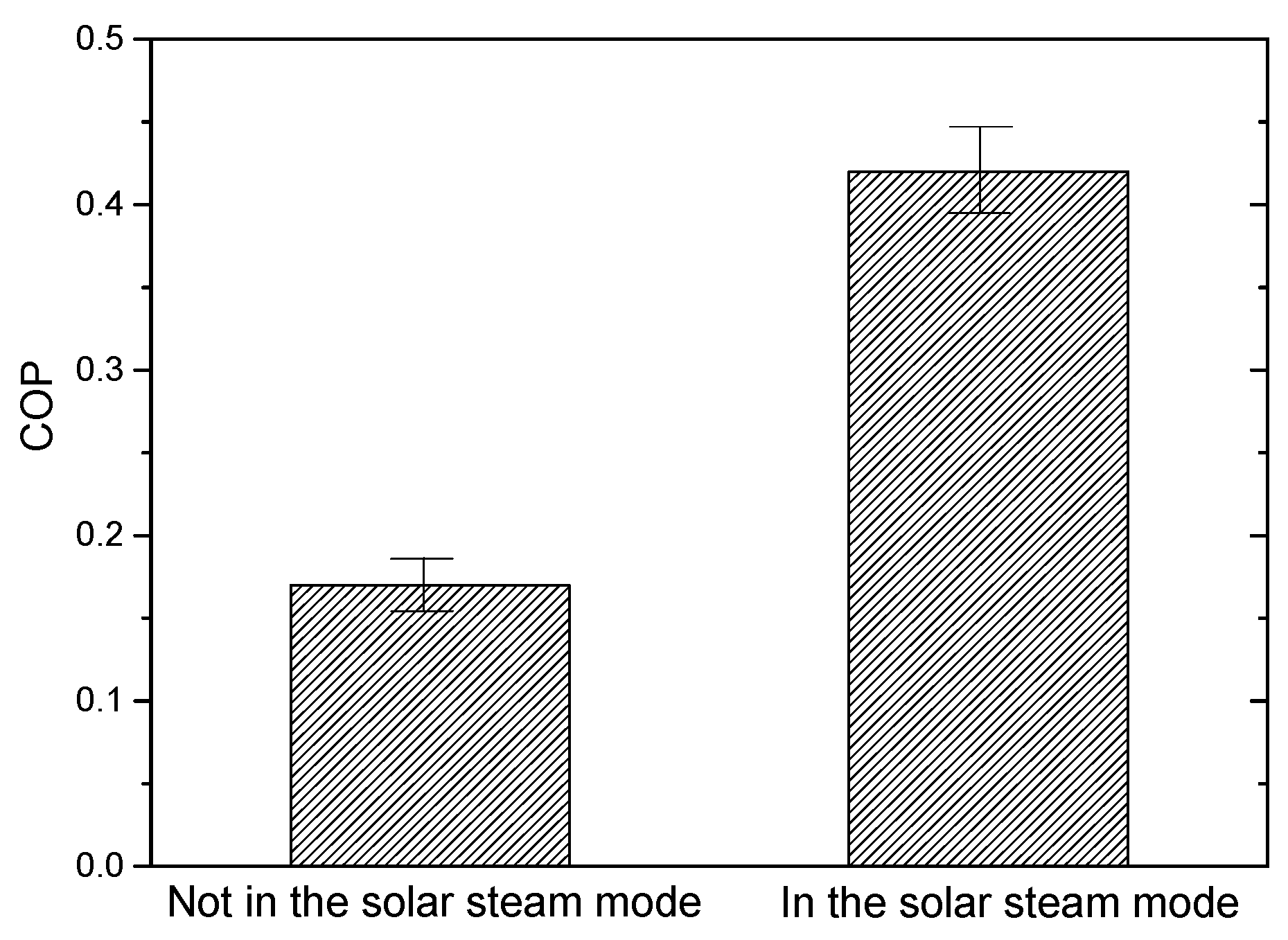

3.4. COP Evaluation for the System in the Solar Steam Mode

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Con | mass concentration (%) |

| cps | specific heat of the solution (kJ kg−1 K−1) |

| cpw | specific heat of the water vapor (kJ kg−1 K−1) |

| COP | coefficient of performance (dimensionless) |

| G | energy input (kJ) |

| H | enthalpy (kJ) |

| l | latent heat of water vaporization (kJ kg−1) |

| mw | amount of evaporated water vapor (kg) |

| ms | solution mass (kg) |

| P | power input (kW) |

| Qi | input energy (kJ) |

| Ql | energy loss (kJ) |

| Q0 | cooling capacity (kJ) |

| S | area (m2) |

| t | temperature (°C) |

| Greek letters | |

| ζ | solar thermal conversion efficiency (%) |

| Subscripts | |

| 1 | before regeneration |

| 2 | after regeneration |

| i | in |

| o | out |

| r | regenerator |

| s | solution |

| w | water |

References

- Yang, J.; Mohan Kumar, D.I.; Pyrgou, A.; Chong, A.; Santamouris, M.; Kolokotsa, D.; Lee, S.E. Green and cool roofs’ urban heat island mitigation potential in tropical climate. Sol. Energy 2018, 173, 597–609. [Google Scholar] [CrossRef]

- Solangi, Y.A.; Cheng, L.; Shah, S.A.A.; Alsanad, A.; Ahmad, M.; Akbar, M.A.; Gumaei, A.; Ali, S. Analyzing renewable energy sources of a developing country for sustainable development: an integrated fuzzy based-decision methodology. Processes 2020, 8, 825. [Google Scholar] [CrossRef]

- Liu, X.; Paritosh, P.; Awalgaonkar, N.M.; Bilionis, I.; Karava, P. Model predictive control under forecast uncertainty for optimal operation of buildings with integrated solar systems. Sol. Energy 2018, 171, 953–970. [Google Scholar] [CrossRef]

- Al-Nimr, M.A.; Qananba, K.S. A solar hybrid system for power generation and water distillation. Sol. Energy 2018, 171, 92–105. [Google Scholar] [CrossRef]

- Nader, N.; Al-Kouz, W.; Al-Dahidi, S. Assessment of existing photovoltaic system with cooling and cleaning system: Case study at Al-Khobar City. Processes 2020, 8, 9. [Google Scholar] [CrossRef]

- Meyers, S.; Schmitt, B.; Vajen, K. The future of low carbon industrial process heat: A comparison between solar thermal and heat pumps. Sol. Energy 2018, 173, 893–904. [Google Scholar] [CrossRef]

- Hamrahi, S.E.; Goudarzi, K.; Yaghoubi, M. Experimental study of the performance of a continues solar adsorption chiller using Nano-activated carbon/methanol as working pair. Sol. Energy 2018, 173, 920–927. [Google Scholar] [CrossRef]

- Afanasyeva, S.; Bogdanov, D.; Breyer, C. Relevance of PV with single-axis tracking for energy scenarios. Sol. Energy 2018, 173, 173–191. [Google Scholar] [CrossRef]

- Awad, H.; Gül, M. Load-match-driven design of solar PV systems at high latitudes in the Northern hemisphere and its impact on the grid. Sol. Energy 2018, 173, 377–397. [Google Scholar] [CrossRef]

- Eidan, A.A.; AlSahlani, A.; Ahmed, A.Q.; Al-fahham, M.; Jalil, J.M. Improving the performance of heat pipe-evacuated tube solar collector experimentally by using Al2O3 and CuO/acetone nanofluids. Sol. Energy 2018, 173, 780–788. [Google Scholar] [CrossRef]

- Jain, V.; Sachdeva, G.; Kachhwaha, S.S. Comparative performance study and advanced exergy analysis of novel vapor compression-absorption integrated refrigeration system. Energy Convers. Manag. 2018, 172, 81–97. [Google Scholar] [CrossRef]

- Shirazi, A.; Taylor, R.A.; Morrison, G.L.; White, S.D. Solar-powered absorption chillers: A comprehensive and critical review. Energy Convers. Manag. 2018, 171, 59–81. [Google Scholar] [CrossRef]

- Mahmoudi, S.M.S.; Kordlar, M.A. A new flexible geothermal based cogeneration system producing power and refrigeration. Renew. Energy 2018, 123, 499–512. [Google Scholar] [CrossRef]

- Wang, Y.; Li, M.; Du, W.; Yu, Q.; Ji, X.; Ma, X. Performance comparative study of a solar-powered adsorption refrigerator with a CPC collector/adsorbent bed. Energy Convers. Manag. 2018, 173, 499–507. [Google Scholar] [CrossRef]

- Wang, Y.; Li, M.; Yu, Q.; Li, G.; Ma, X. Experimental study of the effect of enhanced mass transfer on the performance improvement of a solar-driven adsorption refrigeration system. Appl. Energy 2018, 224, 417–425. [Google Scholar] [CrossRef]

- Dai, E.; Lin, M.; Xia, J.; Dai, Y. Experimental investigation on a GAX based absorption heat pump driven by hybrid liquefied petroleum gas and solar energy. Sol. Energy 2018, 169, 167–178. [Google Scholar] [CrossRef]

- Patel, B.; Desai, N.B.; Kachhwaha, S.S. Thermo-economic analysis of solar-biomass organic Rankine cycle powered cascaded vapor compression-absorption system. Sol. Energy 2017, 157, 920–933. [Google Scholar] [CrossRef]

- Ezzat, M.F.; Dincer, I. Energy and exergy analyses of a new geothermal–solar energy based system. Sol. Energy 2016, 134, 95–106. [Google Scholar] [CrossRef]

- Fan, Z.; Ferreira, C.A.I.; Mosaffa, A.H. Numerical modelling of high temperature latent heat thermal storage for solar application combining with double-effect H2O/LiBr absorption refrigeration system. Sol. Energy 2014, 110, 398–409. [Google Scholar] [CrossRef]

- El-Shaarawi, M.A.I.; Said, S.A.M.; Siddiqui, F.R. Unsteady thermodynamic analysis for a solar driven dual storage absorption refrigeration cycle in Saudi Arabia. Sol. Energy 2014, 110, 286–302. [Google Scholar] [CrossRef]

- Siavashi, M.; Ghasemi, K.; Yousofvand, R.; Derakhshan, S. Computational analysis of SWCNH nanofluid-based direct absorption solar collector with a metal sheet. Sol. Energy 2018, 170, 252–262. [Google Scholar] [CrossRef]

- Kumar, R.; Chand, P. Performance prediction of extended surface absorber solar air collector with twisted tape inserts. Sol. Energy 2018, 169, 40–48. [Google Scholar] [CrossRef]

- Rodríguez-Sánchez, M.R.; Marugán-Cruz, C.; Acosta-Iborra, A.; Santana, D. Thermo-mechanical modelling of solar central receivers: Effect of incident solar flux resolution. Sol. Energy 2017, 165, 43–54. [Google Scholar] [CrossRef]

- Ghasemi, H.; Ni, G.; Marconnet, A.M.; Loomis, J.; Yerci, S.; Miljkovic, N.; Chen, G. Solar steam generation by heat localization. Nat. Commun. 2014, 5449, 1–7. [Google Scholar] [CrossRef]

- Kaur, M.; Ishii, S.; Shinde, S.L.; Nagao, T. All-ceramic microfibrous solar steam generator: TiN plasmonic nanoparticle-loaded transparent microfibers. ACS Sustain. Chem. Eng. 2017, 5, 8523–8528. [Google Scholar] [CrossRef]

- Yang, J.; Pang, Y.; Huang, W.; Shaw, S.K.; Schiffbauer, J.; Pillers, M.A.; Mu, X.; Luo, S.; Zhang, T.; Huang, Y.; et al. Functionalized graphene enables highly efficient solar thermal steam generation. ACS Nano 2017, 11, 5510–5518. [Google Scholar] [CrossRef] [PubMed]

- Yin, Z.; Wang, H.; Jian, M.; Li, Y.; Xia, K.; Zhang, M.; Wang, C.; Wang, Q.; Ma, M.; Zheng, Q.; et al. Extremely black vertically aligned carbon nanotube arrays for solar steam generation. ACS Appl. Mater. Interfaces 2017, 9, 28596–28603. [Google Scholar] [CrossRef]

- Jia, C.; Li, Y.; Yang, Z.; Chen, G.; Yao, Y.; Jiang, F.; Kuang, Y.; Pastel, G.; Xie, H.; Yang, B.; et al. Rich mesostructures derived from natural woods for solar steam generation. Joule 2017, 1, 588–599. [Google Scholar] [CrossRef]

- Xue, G.; Liu, K.; Chen, Q.; Yang, P.; Li, J.; Ding, T.; Duan, J.; Qi, B.; Zhou, J. Robust and low-cost flame-treated wood for high-performance solar steam generation. ACS Appl. Mater. Interfaces 2017, 9, 15052–15057. [Google Scholar] [CrossRef] [PubMed]

- Conde, M.R. Properties of aqueous solutions of lithium and calcium chlorides: Formulations for use in air conditioning equipment design. Int. J. Therm. Sci. 2004, 43, 367–382. [Google Scholar] [CrossRef]

- Zeidan, E.B.; Aly, A.A.; Hamed, A.M. Modeling and simulation of solar-powered liquid desiccant regenerator for open absorption cooling cycle. Sol. Energy 2011, 85, 2977–2986. [Google Scholar] [CrossRef]

- Xiao, C.H.; Liang, W.D.; Hasi, Q.M.; Wang, F.; Chen, L.; He, J.; Liu, F.; Sun, H.; Zhu, Z.; Li, A. Efficient solar steam generation of carbon black incorporated hyper-cross-linked polymer composites. ACS Appl. Energy Mater. 2020, 3, 11350–11358. [Google Scholar] [CrossRef]

- Chen, T.J.; Xie, H.; Qiao, X.; Hao, S.; Wu, Z.; Sun, D.; Lui, Z.; Cao, F.; Wu, B.; Fang, X. Highly anisotropic corncob as an efficient solar steam-generation device with heat localization and rapid water transportation. SACS Appl. Mater. Interfaces 2020, 12, 50397–50405. [Google Scholar] [CrossRef] [PubMed]

- Behera, S.; Kim, C.W.; Kim, K.S. Solar steam generation and desalination using ultra-broadband absorption in plasmonic alumina nanowire haze structure–graphene oxide–gold nanoparticle composite. Langmuir 2020, 36, 12494–12503. [Google Scholar] [CrossRef] [PubMed]

- Yang, J.; Chen, Y.; Jia, X.H.; Li, Y.; Wang, S.; Song, H. Wood-based solar interface evaporation device with self-desalting and high antibacterial activity for efficient solar steam generation. ACS Appl. Mater. Interfaces 2020, 12, 47029–47037. [Google Scholar] [CrossRef]

- Zhang, X.F.; Wu, G.; Yang, X.C. MoS2 Nanosheet–carbon foam composites for solar steam generation. ACS Appl. Nano Mater. 2020, 3, 9706–9714. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cheng, F.; Wu, Y.; Li, X. Research on Local Heating Regeneration Method for Air-Conditioning Systems. Processes 2021, 9, 444. https://doi.org/10.3390/pr9030444

Cheng F, Wu Y, Li X. Research on Local Heating Regeneration Method for Air-Conditioning Systems. Processes. 2021; 9(3):444. https://doi.org/10.3390/pr9030444

Chicago/Turabian StyleCheng, Feng, Yunlei Wu, and Xiuwei Li. 2021. "Research on Local Heating Regeneration Method for Air-Conditioning Systems" Processes 9, no. 3: 444. https://doi.org/10.3390/pr9030444

APA StyleCheng, F., Wu, Y., & Li, X. (2021). Research on Local Heating Regeneration Method for Air-Conditioning Systems. Processes, 9(3), 444. https://doi.org/10.3390/pr9030444