Thermal Control Processes by Deterministic and Network-Based Models for Energy Use and Control Accuracy in a Building Space

Abstract

1. Introduction

1.1. Building Control Systems

1.2. Thermal Control Methods

1.3. Thermal Comfort Index

1.4. Problem Statement

2. Methodology

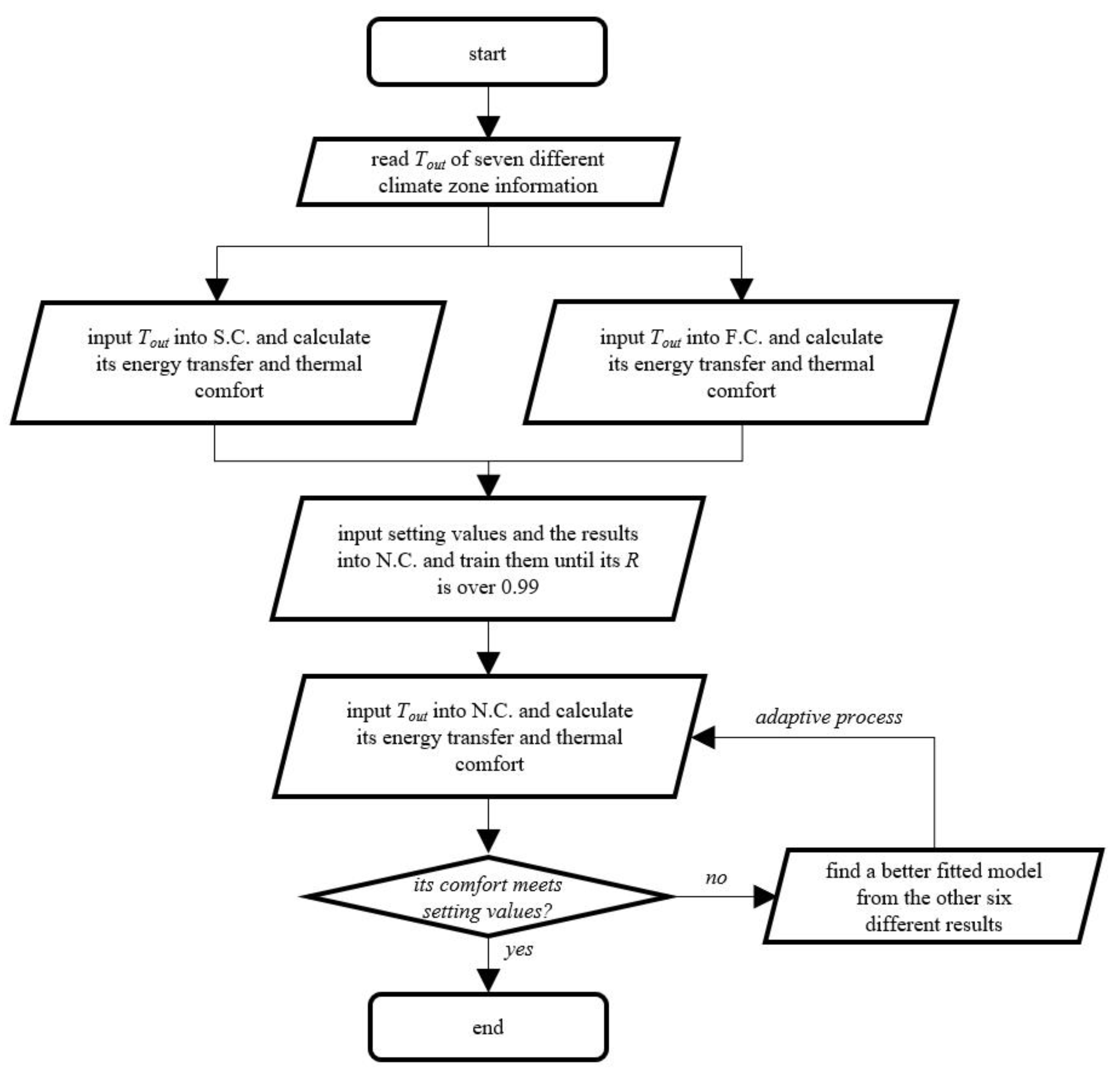

2.1. Simulation Process

2.2. Thermal and Comfort Models

2.3. Simulation Block Model

- (1)

- Create simulation modules of building, thermal, PMV, SC, and FC.

- (2)

- Using weather data from seven different climatic zones, the energy use and the comfort levels of the SC and FC modules are simulated.

- (3)

- With the results, the ANN module is learned and the NC module is built.

- (4)

- Different weather condition is inputted into the entire simulation model including the SC, FC, and NC modules.

- (5)

- With the results, their performances of energy use and thermal comfort are compared.

3. Results and Discussions

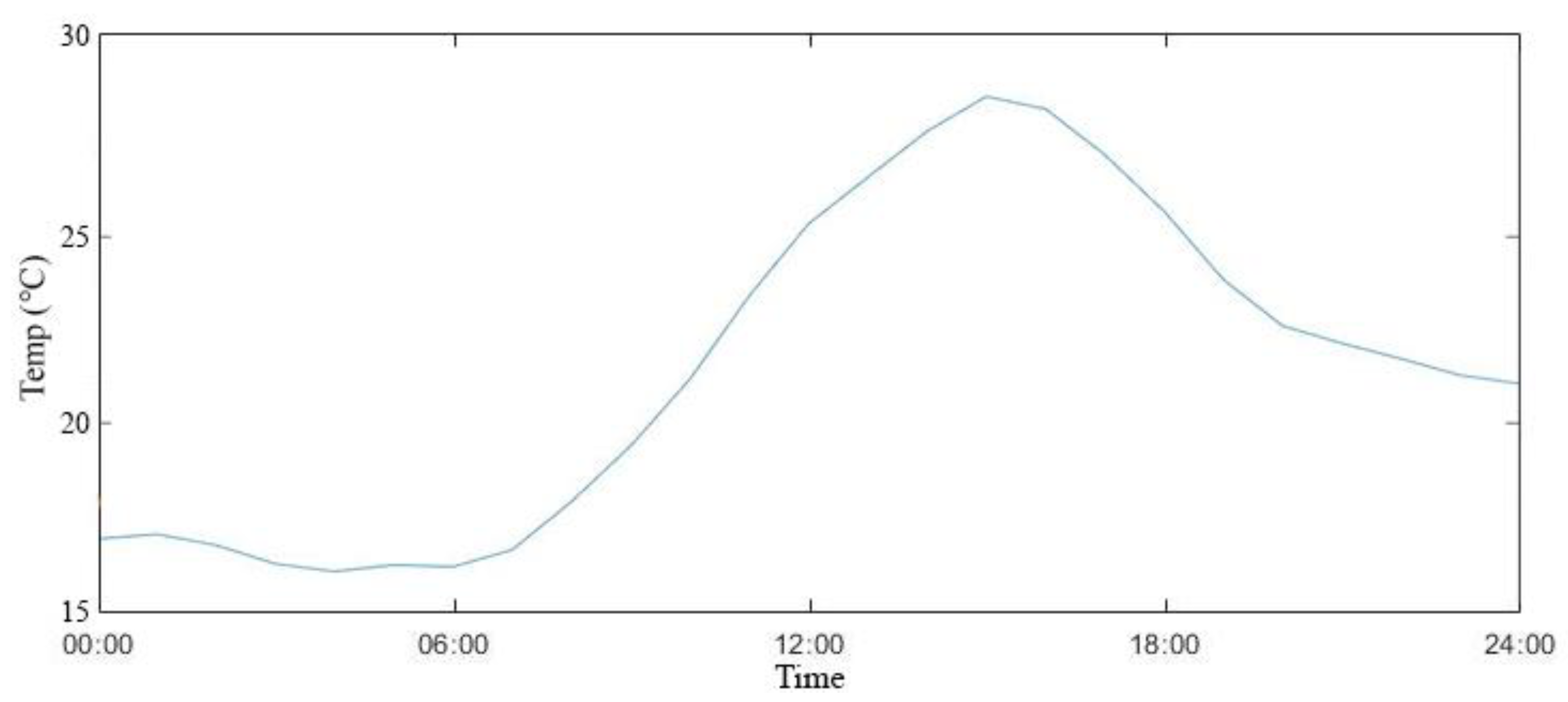

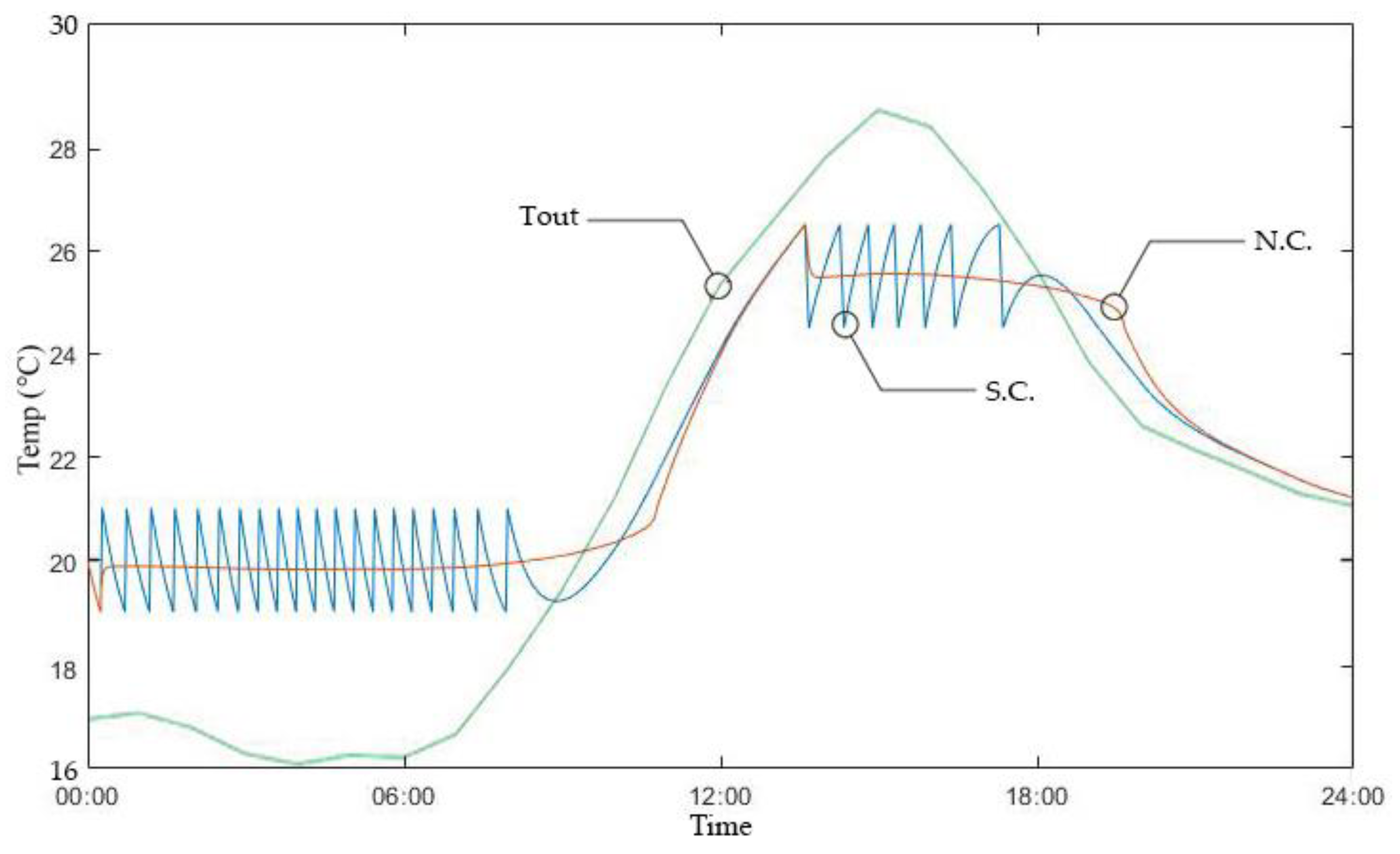

3.1. Temperature and Thermal Comfort

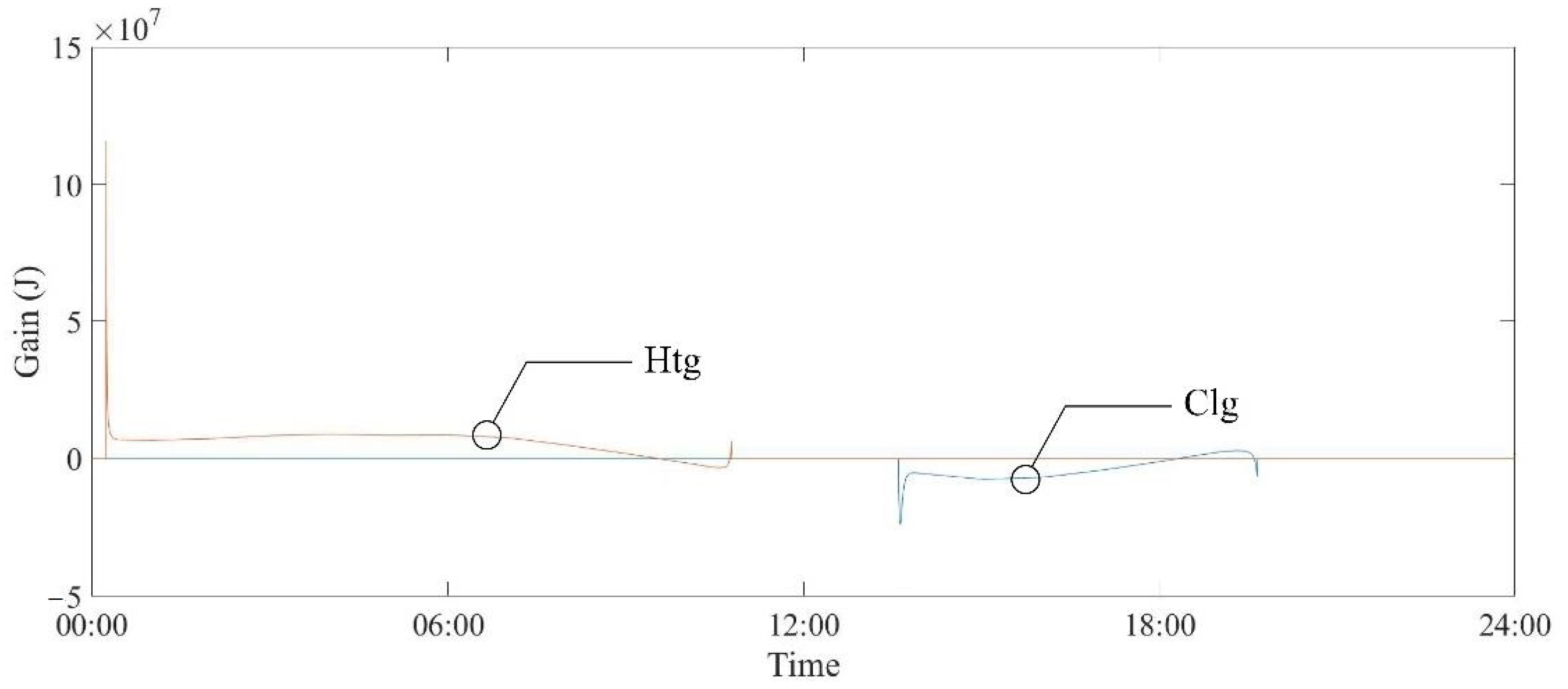

3.2. Energy Transfer

3.3. Numerical Comparison

4. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| A | area of material(s) (m2) | ṁout | mass flow-rate outside room (kg/h) |

| Clg | cooling | mroom∙air | mass flow-rate in room air (kg) |

| Cv | specific heat capacity at constant volume (J/kg·K) | Qloss | heat loss by convection and transmission (J) |

| Cp | specific heat capacity at constant pressure (J/kg·K) | Qgain | heat gain by convection and transmission (J) |

| D | thickness of material(s) (m) | R | thermal resistance (K/W) |

| fcl | ratio of clothed surface area to DuBois surface area | Tcl | average surface temperature of clothed body (°C) |

| Htg | heating | Tht | air temperature from heater (°C) |

| hin, hout | convection heat transfer coefficient inside, outside (W/m2·K) | Tout | outdoor temperature (°C) |

| IAE | integral of absolute errors | Tr | mean radiant temperature (°C) |

| k | thermal conductivity (W/m·K) | Troom | room temperature (°C) |

| L | thermal load | Tset | set-point temperature (°C) |

| M | metabolic rate | U | internal energy (J) |

| ṁht | mass flow-rate from system (kg/h) | W | work (J) |

| ṁin | mass flow-rate inside room (kg/h) | Wa, Wsh | humidity ratio of air, at the skin temperature |

References

- Rossiter, J.; Kouvaritakis, B.; Dunnett, R. Application of generalised predictive control to a boiler-turbine unit for electricity gener-ation. In Proceedings of the IEE (Control Theory and Applications), Leeds, UK, 1–4 September 2008; Volume 138, pp. 59–67. [Google Scholar] [CrossRef]

- Maffezzoni, C. Boiler-turbine dynamics in power-plant control. Control. Eng. Pract. 1997, 5, 301–312. [Google Scholar] [CrossRef]

- Tan, W.; Liu, J.; Fang, F.; Chen, Y. Tuning of PID controllers for boiler-turbine units. ISA Trans. 2004, 43, 571–583. [Google Scholar] [CrossRef]

- Braun, J.E.; Montgomery, K.W.; Chaturvedi, N. Evaluating the Performance of Building Thermal Mass Control Strategies. HVAC&R Res. 2001, 7, 403–428. [Google Scholar] [CrossRef]

- Al-Saeed, Y.W.; Ahmed, A. Evaluating Design Strategies for Nearly Zero Energy Buildings in the Middle East and North Africa Regions. Designs 2018, 2, 35. [Google Scholar] [CrossRef]

- Busamante, S.; Castro, P.; Laso, A.; Manana, M.; Arroyo, A. Smart Thermostat: An. Experimental Facility to Test. Their Capabilities and Savings Potential. Sustainability 2017, 9, 1462. [Google Scholar] [CrossRef]

- Nippon GT Corporation. What is the thermostat? Available online: https://www.ngt.co.jp (accessed on 31 January 2021).

- Ahn, J.; Cho, S. Dead-band vs. machine-learning control systems: Analysis of control benefits and energy efficiency. J. Build. Eng. 2017, 12, 17–25. [Google Scholar] [CrossRef]

- Ahn, J.; Cho, S.; Chung, D.H. Analysis of energy and control efficiencies of fuzzy logic and artificial neural network technologies in the heating energy supply system responding to the changes of user demands. Appl. Energy 2017, 190, 222–231. [Google Scholar] [CrossRef]

- Ji, Y.; Xu, P.; Duan, P.; Lu, X. Estimating hourly cooling load in commercial buildings using a thermal network model and electricity submetering data. Appl. Energy 2016, 169, 309–323. [Google Scholar] [CrossRef]

- Jang, J.; Lee, J.; Son, E.; Park, K.; Kim, G.; Lee, J.H.; Leigh, S.-B. Development of an Improved Model to Predict Building Thermal Energy Consumption by Utilizing Feature Selection. Energies 2019, 12, 4187. [Google Scholar] [CrossRef]

- Ahn, J. Performance Analyses of Temperature Controls by a Network-Based Learning Controller for an Indoor Space in a Cold Area. Sustainability 2020, 12, 8515. [Google Scholar] [CrossRef]

- Bourdeau, M.; Zhai, X.Q.; Nefzaoui, E.; Guo, X.; Chatellier, P. Modeling and forecasting building energy consumption: A review of data-driven techniques. Sustain. Cities Soc. 2019, 48, 11533. [Google Scholar] [CrossRef]

- Yoon, S.H.; Ahn, J. Comparative Analysis of Energy Use and Human Comfort by an Intelligent Control Model at the Change of Season. Energies 2020, 13, 6023. [Google Scholar] [CrossRef]

- Soyguder, S.; Alli, H. Predicting of fan speed for energy saving in HVAC system based on adaptive network based fuzzy inference system. Expert Syst. Appl. 2009, 36, 8631–8638. [Google Scholar] [CrossRef]

- Ahn, J. Improvement of the Performance Balance between Thermal Comfort and Energy Use for a Building Space in the Mid-Spring Season. Sustainability 2020, 12, 9667. [Google Scholar] [CrossRef]

- Huizenga, C.; Abbaszadeh, S.; Zagreus, L.; Arens, E.A. Air Quality and Thermal Comfort in Office Buildings: Results of a Large Indoor Environmental Quality Survey. In Proceedings of the Healthy Buildings, Lisbon, Portugal, 4–8 June 2006; Volume III, pp. 393–397. [Google Scholar]

- Nematchoua, M.K.; Tchinda, R.; Orosa, J.A. Thermal comfort and energy consumption in modern versus traditional buildings in Cameroon: A questionnaire-based statistical study. Appl. Energy 2014, 114, 687–699. [Google Scholar] [CrossRef]

- Youssef, A.; Caballero, N.; Aerts, J. Model-Based Monitoring of Occupant’s Thermal State for Adaptive HVAC Predictive Controlling. Processes 2019, 7, 720. [Google Scholar] [CrossRef]

- Sung, Y.; Ahn, J. Comparative Analyses of Energy Efficiency between on-Demand and Predictive Controls for Buildings’ Indoor Thermal Environment. Energies 2020, 13, 1089. [Google Scholar] [CrossRef]

- Dounis, A.; Santamouris, M.; Lefas, C.; Argiriou, A. Design of a fuzzy set environment comfort system. Energy Build. 1995, 22, 81–87. [Google Scholar] [CrossRef]

- Ahn, J. Abatement of the Increases in Cooling Energy Use during a Period of Intense Heat by a Network-Based Adaptive Controller. Sustainability 2021, 13, 1353. [Google Scholar] [CrossRef]

- Palladio, D.; Nardi, I.; Burati, C. Artificial Neural Network for the Thermal Comfort Index Prediction: Development of a New Simplified Algorithm. Energies 2020, 13, 4500. [Google Scholar] [CrossRef]

- Park, S.-Y.; Cho, S.; Ahn, J. Improving the quality of building spaces that are planned mainly on loads rather than residents: Human comfort and energy savings for warehouses. Energy Build. 2018, 178, 38–48. [Google Scholar] [CrossRef]

- Chen, X.; Wang, Q.; Srebric, J. Occupant feedback based model predictive control for thermal comfort and energy optimization: A chamber experimental evaluation. Appl. Energy 2016, 164, 341–351. [Google Scholar] [CrossRef]

- Ahn, J.; Cho, S. Anti-logic or common sense that can hinder machine’s energy performance: Energy and comfort control models based on artificial intelligence responding to abnormal indoor environments. Appl. Energy 2017, 204, 117–130. [Google Scholar] [CrossRef]

- Moon, J.W.; Ahn, J. Improving sustainability of ever-changing building spaces affected by users’ fickle taste: A focus on human comfort and energy use. Energy Build. 2020, 208, 109662. [Google Scholar] [CrossRef]

- Ahn, J.; Chung, D.H.; Cho, S. Network-based energy supply optimal system in the condition where both heating and cooling are required simultaneously in a swing season. Intell. Build. Int. 2017, 10, 42–57. [Google Scholar] [CrossRef]

- The Engineering ToolBox Resources Home Page. Available online: http://www.engineeringtoolbox.com (accessed on 20 February 2020).

- U.S. Department of Energy. Weather Data. EnergyPlus. Available online: https://energyplus.net/weather (accessed on 23 October 2019).

- National Institute of Building Science. Space Types. Whole Building Design Guide. Available online: https://www.wbdg.org/space-types/ (accessed on 8 May 2020).

- Kim, S.-C.; Shin, H.-I.; Ahn, J. Energy performance analysis of airport terminal buildings by use of architectural, operational information and benchmark metrics. J. Air Transp. Manag. 2020, 83, 101762. [Google Scholar] [CrossRef]

- Gilani, S.I.U.H.; Khan, M.H.; Pao, W. Thermal Comfort Analysis of PMV Model Prediction in Air Conditioned and Naturally Ventilated Buildings. Energy Procedia 2015, 75, 1373–1379. [Google Scholar] [CrossRef]

- Cheung, T.; Schiavon, S.; Parkinson, T.; Li, P.; Brager, G. Analysis of the accuracy on PMV‑PPD model using the ASHRAE Global Thermal Comfort Database II. Build. Environ. 2019, 153, 205–217. [Google Scholar] [CrossRef]

- Petković, D.; Ćojbašić, Ž.; Nikolić, V.; Shamshirband, S.; Kiah, M.L.M.; Anuar, N.B.; Wahab, A.W.A. Adaptive neuro-fuzzy maximal power extraction of wind turbine with continuously variable transmission. Energy 2014, 64, 868–874. [Google Scholar] [CrossRef]

- Beinarts, I. Fuzzy logic control method of HVAC equipment for optimization of passengers’ thermal comfort in public electric transport vehicles. In Proceedings of the Eurocon 2013, Zagreb, Croatia, 1–4 July 2013; pp. 1180–1186. [Google Scholar]

- Ahn, J.; Chung, D.H.; Cho, S. Performance analysis of space heating smart control models for energy and control effectiveness in five different climate zones. Build. Environ. 2017, 115, 316–331. [Google Scholar] [CrossRef]

- Vamsi, R. What’s a neural network? Available online: https://medium.com (accessed on 23 October 2020).

| No. | Design Parameter | Template or Value |

|---|---|---|

| 1 | Building type | Small office building |

| 2 | Building geometry | 19.5 m 19.5 m 4 m |

| 3 | Wall depth | 0.15 m |

| 4 | Thermal resistance of wall | 5.76 10−3 K/W |

| 5 | Number of windows | 6 |

| 6 | Window geometry | 1 m 1 m |

| 7 | Window depth | 0.02 m |

| 8 | Thermal resistance of window | 2.14 10−3 K/W |

| 9 | Tset for Clg (cooling) | 25.5 °C |

| 10 | Tset for Htg (heating) | 20.0 °C |

| 11 | Mass flow rate into room | 3600 kg hour−1 |

| 12 | Weather condition | 28th April, Shanghai in China (IWEC data) |

| No. | Index | SC | FC | NC |

|---|---|---|---|---|

| 1 | IAE for heating | 59.97 | 58.56 | 56.21 |

| 2 | IAE for cooling | 81.89 | 81.65 | 79.32 |

| 3 | RMSE of PPD | 23.73 | 24.61 | 22.29 |

| No. | Index | SC | FC | NC |

|---|---|---|---|---|

| 1 | Heating gain (MJ) | 231,389.4 | 435,638.1 | 229,680.8 |

| 2 | Cooling gain (MJ) | 86,029.3 | 79,248.5 | 82,068.5 |

| 3 | Energy use intensity (kWh/m2·yr) | 108.5 | 176.0 | 106.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahn, J. Thermal Control Processes by Deterministic and Network-Based Models for Energy Use and Control Accuracy in a Building Space. Processes 2021, 9, 385. https://doi.org/10.3390/pr9020385

Ahn J. Thermal Control Processes by Deterministic and Network-Based Models for Energy Use and Control Accuracy in a Building Space. Processes. 2021; 9(2):385. https://doi.org/10.3390/pr9020385

Chicago/Turabian StyleAhn, Jonghoon. 2021. "Thermal Control Processes by Deterministic and Network-Based Models for Energy Use and Control Accuracy in a Building Space" Processes 9, no. 2: 385. https://doi.org/10.3390/pr9020385

APA StyleAhn, J. (2021). Thermal Control Processes by Deterministic and Network-Based Models for Energy Use and Control Accuracy in a Building Space. Processes, 9(2), 385. https://doi.org/10.3390/pr9020385