Abstract

Suspended sludge deammonification technologies are frequently applied for sidestream ammonia removal from dewatering liquors resulting from a thermal hydrolysis anaerobic digestion (THP/AD) process. This study aimed at optimizing the operation, evaluate the performance and stability of a full-scale suspended sludge continuous stirred tank reactor (S-CSTR) with a hydrocyclone for anaerobic ammonia oxidizing bacteria (AMX) biomass separation. The S-CSTR operated at a range of nitrogen loading rates of 0.08–0.39 kg N m−3 d−1 displaying nitrogen removal efficiencies of 75–89%. The hydrocyclone was responsible for retaining 56–83% of the AMX biomass and the washout of ammonia oxidizing bacteria (AOB) and nitrite-oxidizing bacteria (NOB) was two times greater than AMX. The solid retention time (SRT) impacted on NOB washout, that ranged from 0.02–0.07 d−1. Additionally, it was demonstrated that an SRT of 11–13 d was adequate to wash-out NOB. Microbiome analysis revealed a higher AMX abundance (Candidatus scalindua) in the reactor through the action of the hydrocyclone. Overall, this study established the optimal operational envelope for deammonification from THP/AD dewatering liquors and the role of the hydrocyclone towards maintaining AMX in the S-CSTR and hence obtain process stability.

1. Introduction

Deammonification is an ammonia removal process widely used to remove ammonia from sludge dewatering liquors after anaerobic digestion (AD). Recently, much AD in wastewater treatments plants (WWTPs) has been upgraded to achieve greater biogas production and higher sludge dewaterability. One of the widespread advanced AD technologies includes a pre-treatment step with the thermal hydrolysis process (THP). In THP, steam (160–180 °C) is applied to the sludge, changing the sludge rheology, breaking down complex macromolecules and promoting hydrolysis [1]. This enables the loading rate to the AD to be increased, which subsequently increases the biogas production [1]. Nevertheless, the enhanced hydrolysis results in ammonia concentrations in sludge dewatering liquors of >1000 mg N L−1 [1,2]. These liquors can be treated by a follow on deammonification process for ammonia removal. Ammonia oxidizing bacteria (AOB) convert part of the ammonia into nitrite in the partial nitritation process [3]. Then ammonia and nitrite are converted to nitrogen gas by anaerobic ammonia oxidizing bacteria (AMX) [4].

Only a handful of studies have reported on the ability of deammonification to remove ammonia from THP/AD dewatering liquors, with some considering them as challenging due to proclaimed inhibition [5,6]. The inhibition of THP/AD dewatering liquors has been associated with parts of the particulate and colloidal chemical oxygen demand (COD) that decreased AOB and AMX activity [6]. However, some recent studies found that deammonification technologies removed ammonia from THP/AD dewatering liquors efficiently, according to their design load and removal without displaying inhibition [7,8]. Many full-scale suspended sludge deammonification technologies operate at nitrogen loading rates (NLR) of 0.3–0.8 kg N m−3 d−1 with conventional AD dewatering liquors while displaying of 85–90% [9]. But tighter consents and population growth in urban areas requires sidestream technologies to produce higher effluent quality and to reduce the returned ammonia load to the mainstream wastewater treatment process. One of the limitations of higher effluent quality is the alkalinity concentration of influent dewatering liquors which is the ideal ratio for partial nitritation of 1.98 mol HCO3− mol−1 NH4+ [10,11]. Thus, ammonia conversion that exceeds this ratio will require alkalinity supplementation [10,11]. An indirect way to supplement alkalinity to the wastewater is by dosing sodium hydroxide, that in turn buffers pH, stabilizes any present acids resulting in a higher HCO3− in solution [11,12]. A further key difficulty in deammonification is to balance the bacterial populations to promote partial nitritation and anammox reactions, whilst avoiding full nitrification. Anaerobic ammonia oxidizing bacteria are slow-growing organisms compared to AOB and nitrite oxidizing bacteria (NOB) with doubling times of 0.1–0.2 d−1 [3,13]. Therefore, different solids retention time (SRT) control strategies have been utilized to retain AMX in the biological reactor. The simplest approach for AMX retention is in a biofilm either attached to plastic media in moving bed biofilm reactors or as granules (>300 µm) [14,15]. The biofilm technologies allow nitrogen loading rates (NLR) of 0.3–2.0 kg N m−3 d−1 [9]. However, the most popular deammonification technologies rely on suspended sludge in sequencing batch reactors (SBRs) and can operate at NLR of 0.30 kg N m−3 d−1 [9,16]. Biomass separation strategies such as hydrocyclones or screens allow for process intensification and higher NLR of 0.5–1.0 kg N m−3 d−1 [17]. Anaerobic ammonia-oxidizing bacteria retention can be achieved by various separation strategies that rely on the density difference of bacterial flocs [18]. It is known that AMX aggregate in dense granules of 100–300 µm while AOB and NOB tend to form flocs >100 µm with lower density [19]. Three different separation processes can be utilized to selectively part microbial flocs by density/size difference: the settling stage in an SBR, hydrocyclones and screens [16,20]. Only a handful of peer-reviewed studies discuss these processes in detail, their sludge separation ability and impact on deammonification efficiency, while their depiction and claims are taken for granted. The benefits of the biomass separation processes in the deammonification processes have been described as 75–95% biomass AMX retention [17,20,21], increased activity [20], overall resulting in enhanced nitrogen removal efficiency (NRE) up to 90% [18,20]. In a modelling study, Van Winckel (2019) [18] evaluated the impact of different SRTs on the biomass type (AOB, AMX, and NOB) and identified that greater AMX retention of 88–91% could lead to the enhanced nitrogen removal rate of 1.04–1.16 kg N m−3 d−1. However, AMX washout from a hydrocyclone has also been observed [22]. Past studies that evaluated hydrocyclones are limited and relied on different ex-situ activity measurement methods with sample sizes of <5. The actual effectiveness and impact of the hydrocyclone remain unclear since AMX washout has been reported and previous studies rely on assumption-based process models or have small sample sizes (<5) with ex-situ activity tests as the main parameter.

This study aimed at optimizing the operation, evaluating the performance and stability of a full-scale suspended sludge continuous stirred tank reactor (S-CSTR) with a hydrocyclone for AMX biomass separation. A solids mass balance coupled with the microbiome and biological activity tests enabled the understanding of separation of different groups of microorganisms in the hydrocyclone of the S-CSTR treating dewatering liquors resulting from a THP/AD process.

2. Materials and Methods

2.1. Influent Characteristics

The dewatering liquors investigated in this study originated from a UK WWTP serving 250,000 people equivalent. The secondary wastewater treatment process was composed of an activated sludge process with chemical phosphorous precipitation. Primary and secondary sludge were collected in a balancing tank and first gravity thickened and then dewatered in belt presses. Then the sludge was fed to the THP at a temperature of 160 °C before being digested. The AD was fed with a 1:0.5 sludge mixture from THP and recirculated digestate, as reported by site operators. The sludge was then dewatered in belt presses. The final sludge cake dry-solid content (DS) was 35% DS. The filtrate from the belt presses was diluted (1:1 and 1:0.5) with final effluent added as wash-water and collected in a 6 m3 balancing tank. The ammonia concentration in the dewatering liquors ranged from 881–1186 mg N L−1 (Table 1). The nitrite and nitrate concentrations were 1.5 mg N L−1 and 9.6 mg N L−1, respectively. The average COD, soluble COD, and biochemical oxygen demand BOD concentration were 2139 mg L−1, 1018 mg L−1 and 216 mg L−1, respectively. The alkalinity and the pH in the dewatering liquors were in average 3365 mg CaCO3 L−1 and 8.3, respectively (Table 1).

Table 1.

Influent and operational characteristics of the full-scale suspended sludge deammonification continuous stirred deammonification process.

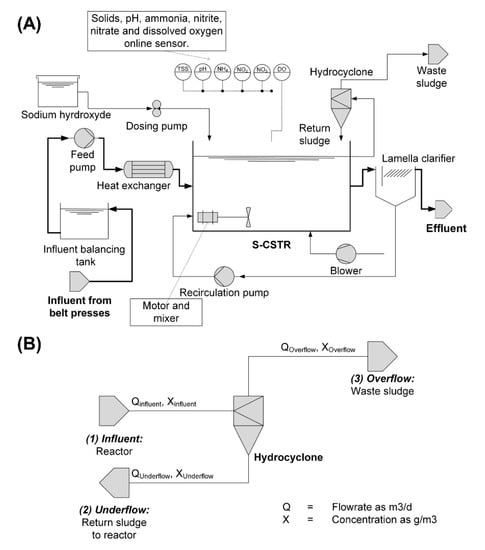

2.2. Reactor Configurations

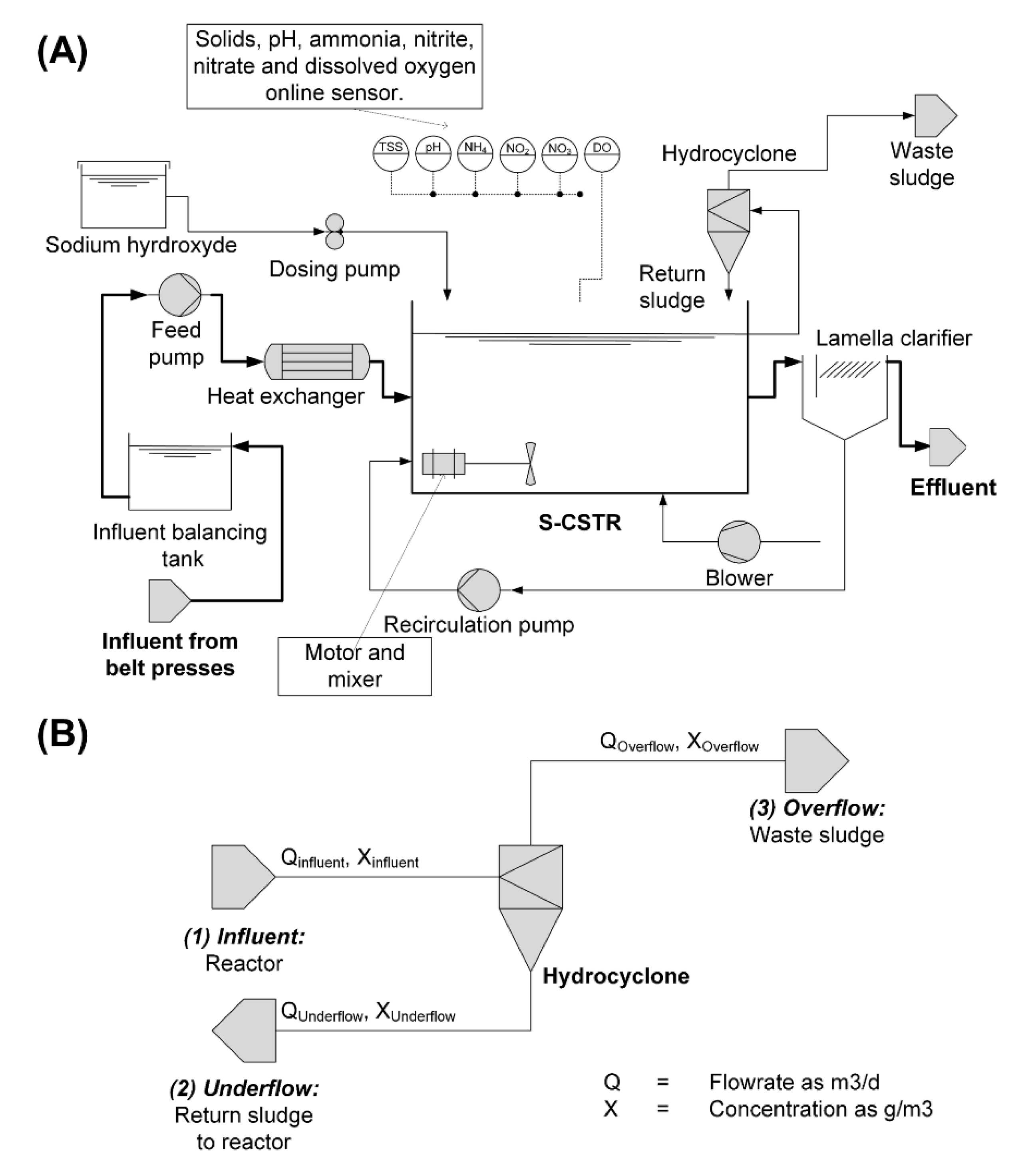

The full-scale deammonification technology used in this study was a suspended sludge continuous stirred tank reactor (S-CSTR) (Figure 1A). The reactor had a volume of 1640 m3 and it was fed with an NLR of 0.08–0.39 kg N m−3 d−1. The S-CSTR was controlled by pH and ammonia measurements in the biological reactor, that actuated on the feed flowrate and aeration. The applied flowrate was on average 505 m3 d−1. The design ammonia loading rate was 0.5 kg N m−3 d−1 and the pH setpoint was 6.8–7.0. The reactor was aerated intermittently with dissolved oxygen (DO) with a set-point of 0.3 mg L−1. During the anoxic periods, the biomass was kept in suspension by two submersible mixers. Additionally, the S-CSTR was monitored by online total suspended solids (TSS), nitrite (NO2− N), and nitrate (NO3− N) sensors (Figure 1). The temperature was kept at 33 °C using a tube heat exchanger in the influent. The sludge from the reactor was passed by hydrocyclone, which aimed at retaining denser particles (e.g., AMX flocs) and recycling the AMX flocs back to the reactor whilst the less dense flocs (e.g., NOB and AOB) were washed-out, and this was verified by a mass balance (Figure 1). The S-CSTR was fitted with a lamella clarifier to prevent washout of the biomass from the biological reactor, and the sludge was recirculated back into the biological reactor (Figure 1). Sodium hydroxide (27% v v−1) was dosed at 917 L d−1 to buffer the pH in the S-CSTR and stabilize alkalinity during a period of the operation (Table 1).

Figure 1.

(A) Flowchart of the suspended sludge continuous stirred tank reactor (S-CSTR) and (B) schematic representation of the mass-balance to the hydrocyclone.

2.3. Reactor Operation and Process Evaluation

The S-CSTR was evaluated based on nitrogen loading rates and effluent quality. The S-CSTR operation was separated into five different periods (Table 1). Period 1 was the start-up, that was defined as the time required until the reactor reached stable NRE of 85%, as per the process design. During Period 1, the SRT and NLR were 61.3 d and 0.08 kg N m−3 d−1, respectively. During Period 2, the reactor was operated without hydrocyclone, an SRT of 28.1 d and NLR of 0.22 kg N m−3 d−1, respectively. In Period 3, the SRT was controlled via hydrocyclone and sodium hydroxide (NaOH, Aquachem Ltd., Wrexham, UK) dosing started. The SRT and NLR were 17.7 and 0.30 kg N m−3 d−1, respectively. Period 4 refers to the operation with SRT control via hydrocyclone and an SRT of 11.8 d and NLR of 0.34 kg N m−3 d−1. Period 5 refers to the operation at high NLR and SRT control via hydrocyclone at an SRT of 13.4 d and an NLR 0.39 kg N m−3 d−1 (Table 1).

In order to evaluate the sludge/biomass separation in the hydrocyclone, the periods were examined for similar NLR, according to the statistical analysis described below. Three periods had similar NLR, as identified using statistical analysis: Period 2 and Period 3, Period 3 and Period 4, and Period 4 and Period 5. The periods displaying similar NLR were compared for their nitrogen removal, effluent quality, and deammonification stability using the nitrate produced to ammonia removed ratio (0.08) [23].

To evaluate the hydrocyclone for its ability to retain the slow-growing AMX a mass balance and microbiome analysis were completed (Figure 1B). The biomass retention of AMX, AOB, and NOB (i.e., ηorganism) was calculated in Equation (1) [18], where r describes the volumetric activity rate in underflow and overflow as kg N m−3 d−1.

The washout per organism was calculated using the SRT for the biological reactor well as the retention by the organism (AOB, NOB, and AMX) according to Equation (2) [18].

2.4. Sample Collection and Analysis

Influent and effluent 24-h composite samples were collected with autosamplers (Hach Lange AS9000, Loveland, CO, USA). The samples were analyzed for ammonia, nitrite, nitrate, total COD, soluble COD, BOD, alkalinity, and TSS using standard methods [24] and measured using Hach Cuvette test kits with a spectrophotometer (Hach Lange DR3900, Loveland, CO, USA). Once a week, solids samples were collected from the biological reactor, the underflow, and the overflow of the hydrocyclone (Figure 1). The samples were analyzed for TSS and volatile suspended solids (VSS) using standard methods [24]. Additionally, the biomass was used in ex-situ bacterial activity test to determine the maximum AOB, NOB, and AMX activity. Ammonia oxidizing bacteria activity tests were completed using the manometric methods [25]. Ammonia oxidizing bacteria and NOB activity tests were completed using the chemical method [26]. The activity rates were calculated for AOB, NOB, and AMX and normalized by the VSS concentration of the sample, described as mg N mg VSS−1 h−1. Ammonia oxidizing bacteria inhibition tests were conducted with THP/AD dewatering liquors and a synthetic solution for the control group. The tests were executed following the activity measurements described above. The control group was fed with a synthetic solution made up from final effluent with NaNO2 and NH4Cl. The feed volume was based on the mass balance with the appropriate NLR of 0.5 kg N m−3 d−1. All tests were executed in duplicates.

Samples for 16S RNA analysis were collected from each operational period and were centrifuged (Eppendorf centrifuge 5804 R, Hamburg, Germany) and then preserved in a 1:1 dilution of 99.9% ethanol stored in a freezer at −10 °C.

The collected biomass samples were subjected to DNA extraction using the Power Soil DNA Isolation Kit (MO BIO Laboratories Inc, Carlsbad, CA, USA) as per the manufacturer’s instructions. The microbiome was investigated by targeting the V3-V4 region of the 16S rRNA gene using 341F/806R primers [27]. Sequencing was performed using the Illumina HiSeq2000 platform (Illumina, San Diego, CA, USA), and sequence reads were processed using Mothur (version 1.35.0) [28]. Chimeras were removed using UCHIME [29]. Remaining sequences were clustered into operational taxonomic units (OTUs) at 97% similarity. Representative sequences were aligned against the SILVA database (release 132) [30] for taxonomy assignment. Sequences assigned to five anammox genera, Kuenenia, Brocadia, Anammoxoglobus, Jettenia, and Scalindua, were analyzed in this study. Microbiome results from the 16S analysis were analyzed in R using the Ampvis2 toolkit [31]. The data was analyzed and compared in R (base R, tidyverse, and psych libraries) using ANOVA test, t-test, and post-hoc tests via Tukey honest significance difference (HSD).

3. Results and Discussion

3.1. Reactor Performance

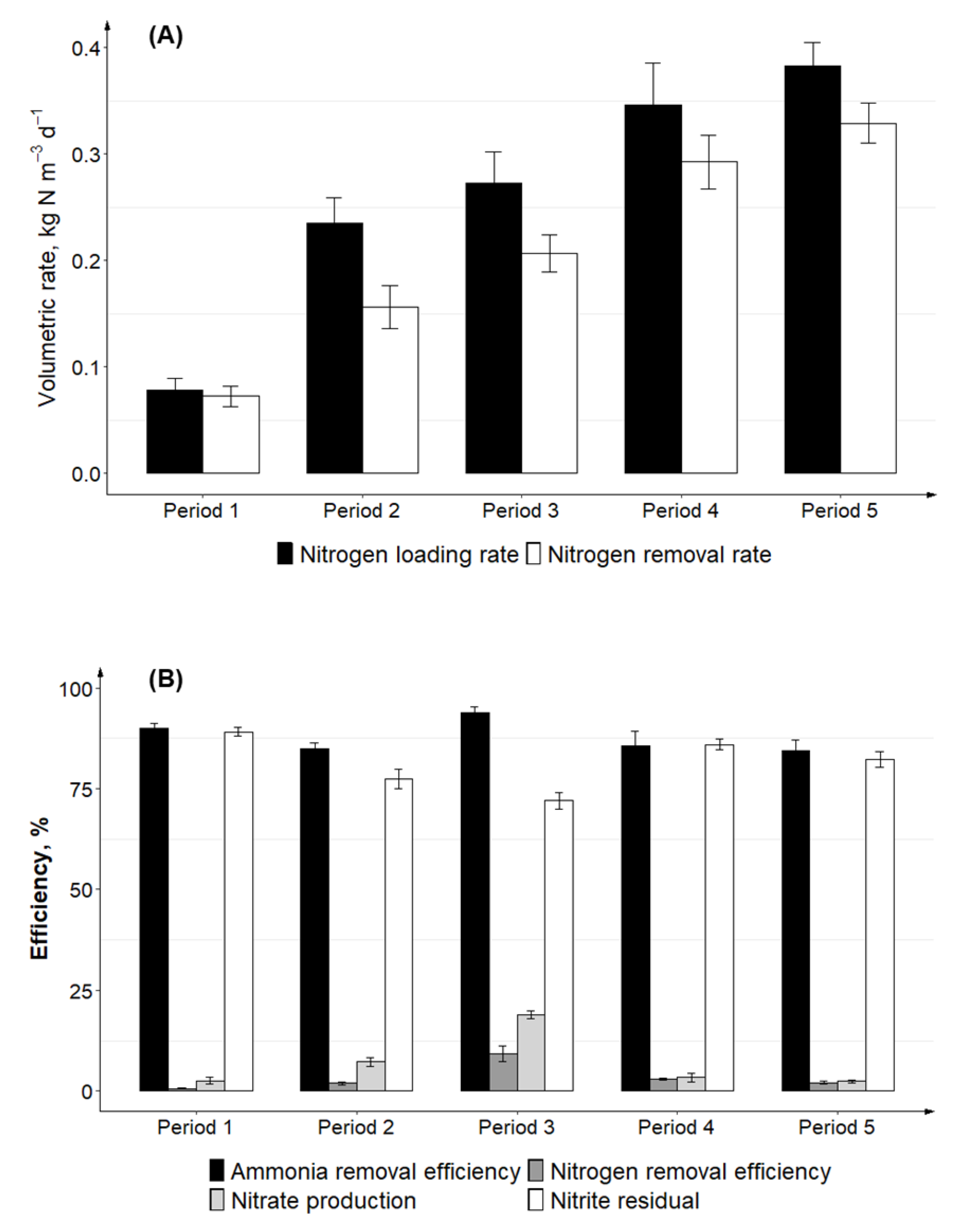

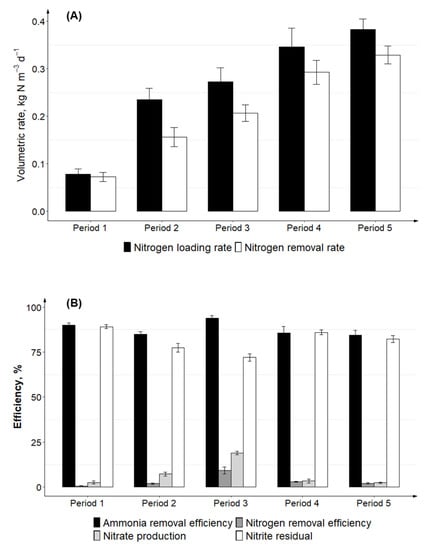

The full-scale S-CSTR was able to remove ammonia from sludge dewatering liquors from THP/AD with NRL of 0.08–0.39 kg N m−3 d−1 (Figure 2). Overall, the NRR of the S-CSTR of this study was slightly lower when compared with other studies. Suspended sludge deammonification technologies operating in similar configuration achieved NRR of 0.20–0.50 kg N m m−3 d−1 with dewatering liquors from conventional AD [16,32] and achieved NRR of 0.13–0.52 kg N m−3 d−1 with THP/AD dewatering liquors [5,6].

Figure 2.

(A) Nitrogen loading and removal rates (B) and efficiencies with ammonia removal efficiency, nitrogen removal efficiency, nitrate production, and nitrite residual for Period 1 to Period 5 (B).

The first part of the analysis focused on the ammonia removal and process stability of the S-CSTR. During Period 2 and Period 3, similar NRR were observed, 0.17–0.22 kg N m−3 d−1 (Figure 2). However, the effluent ammonia concentration decreased from 114.2 mg N L−1 to 45.9 mg N L−1 from Period 2 to Period 3 (Table 2). The lower ammonia in Period 3 was associated with the NaOH dosing leading to higher nitrite production by AOB. This was confirmed by an increase in nitrite from 2.6 mg N L−1 to 4.2 mg N L−1 and a decrease in alkalinity from 427.8 to 344.7 mg CaCO3 L−1 from Period 2 to Period 3 (Table 2).

Table 2.

Effluent characteristics and performance of the suspended sludge continuous stirred tank reactor for Period 1 to Period 5.

Furthermore, the nitrate production to ammonia removed ratio (NO3/NH4) was 0.06 to 0.20 from Period 2 to Period 3, respectively (Table 2). The ideal stoichiometric ratio of NO3/NH4 is 0.08 [23], and a value above this is commonly associated with an overgrowth of NOB and indicates that full nitrification is taking place [9]. This is of particular concern for Period 3 (0.20 ratio NO3/NH4 ratio) with NaOH dosing. Furthermore, a >0.08 NO3/NH4 ratio and subsequent NOB activity could lead to nitrite shortage for AMX metabolism. The full-scale S-CSTR instrumentation and control strategy was based on online ammonia and pH measurements were unable to pick up on the overgrowth of NOB. The overgrowth of NOB related to a combined effect of higher reactor nitrite, lower reactor ammonia, and increase in pH due to NaOH dosing that led to a decrease in FA concentration in the reactor to 1.9 mg N L−1 (Table 2). This was below the FA inhibition threshold for NOB of 3.4 mg N L−1 as reported from past studies [33,34].

Nitrate accumulation in deammonification technologies has been reported to be a common issue [9,35]. Previous studies even suggest that FA concentrations of 5–20 mg N L−1 are needed to suppress NOB growth [33,36]. The operation of deammonification technologies at ammonia levels of <50 mg N L−1 has been reported in various full-scale technologies [9]. However, more stringent instrumentation and control based on a combination of ammonia and pH and measurements in reactors would be more adequate to identify imbalances and actuate on feed flowrates. Furthermore, the addition of a nitrate sensor would be of value. The measurements of nitrate could actuate on the hydrocyclone flowrate to provide an increased wash-out of NOB from the biological reactor with increasing nitrate concentration.

Overall, it was highlighted that NaOH dosing to enhance ammonia conversion was troublesome and led to the undesired NOB overgrowth reflected in nitrate accumulation.

In Period 3 and Period 4, the NRR achieved was similar, at 0.30–0.34 kg N m−3 d−1, (Figure 2A) with NRE of 75–85% (Figure 2B). After the NOB overgrowth in Period 3, the NO3/NH4 ratio decreased to 0.2 (Figure 2B) which indicated that NOB were successfully washed-out in Period 4. As the dosing of NaOH was stopped in Period 4, this led to a reduction in ammonia conversion, as the concentration in the reactor increased to 10 mg N L−1 (Table 2). This caused an increase in the FA in the biological reactor from 1.1 mg N L−1 to 5.0 mg N L−1. The higher FA concentration of 5.0 mg N L−1 in Period 4 is likely to have inhibited NOB limiting their activity and thus the nitrate production. Nitrite oxidizing bacteria washout was finally achieved during Period 4 and Period 5 by maintaining SRTs of 13.4 and 11.8 d (Table 2). This aligns with reports from previous studies where SRTs of 4–9 d led to NOB washout [17,37].

Period 4 and Period 5 displayed similar NRR, between 0.34–0.39 kg N m−3 d−1 (Figure 2A), removal and conversion rates (Figure 2B). However, the ammonia effluent concentration increased from 103.9 mg N L−1 (Period 4) to 144.7 mg N L−1 (Period 5) (Table 2). The SRT was 11.8 d in Period 4 and 13.4 d in Period 5. At the same, a reduction in the NO2/NH4 ratio was observed from 0.04 to 0.02 (Table 2). Furthermore, the alkalinity in the S-CSTR increased to 546.6 mg L−1 in Period 5 (Table 2). This could imply that short SRTs during Period 4 and Period 5 of the S-CSTR induced an unwanted washout of AOB which led to a reduced nitrite conversion in Period 5. Contrary to the previous studies that focused on hydrocyclone, this highlights the sensitivity of AOB wash-out at SRTs of 11–13 d in a suspended reactor.

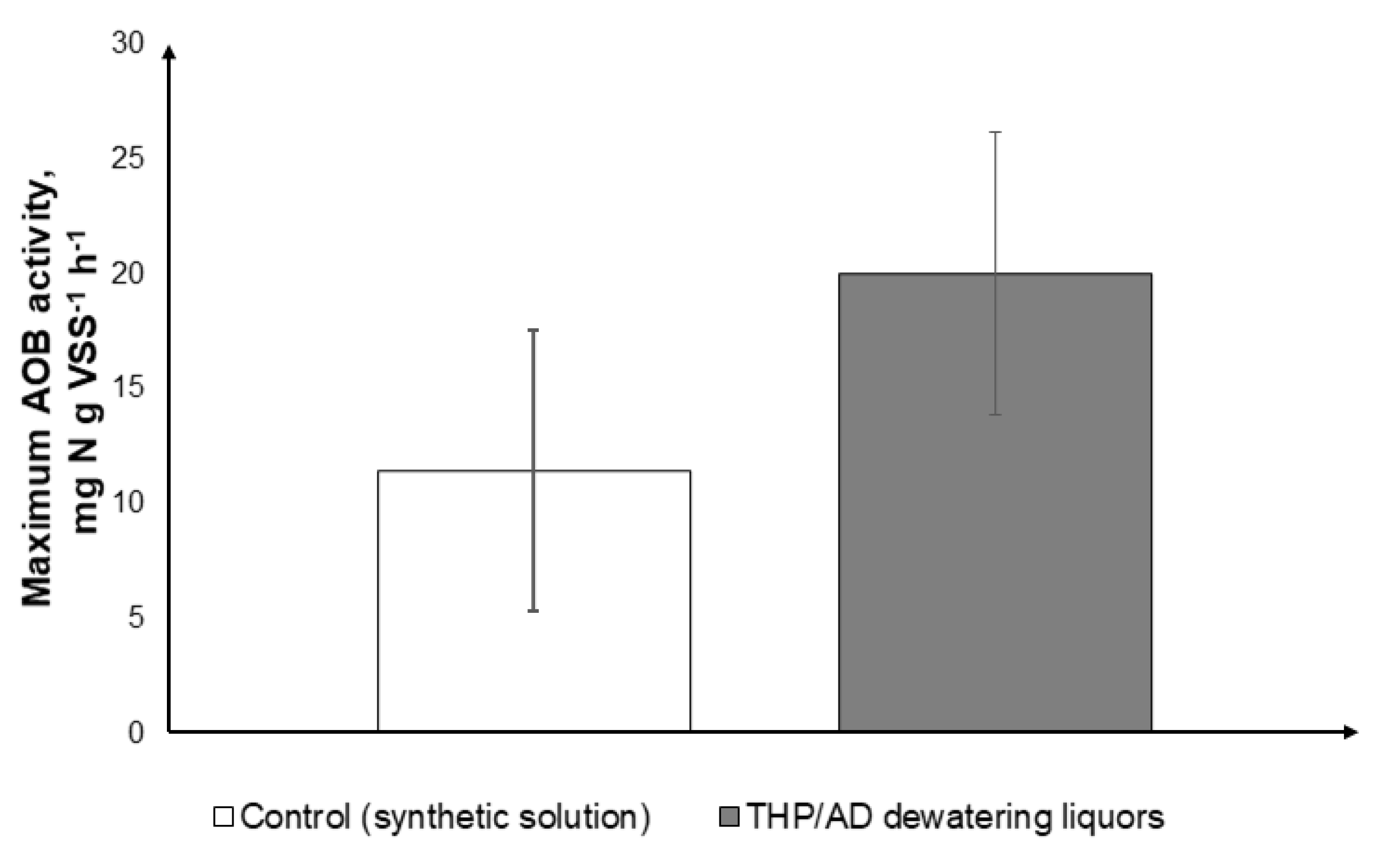

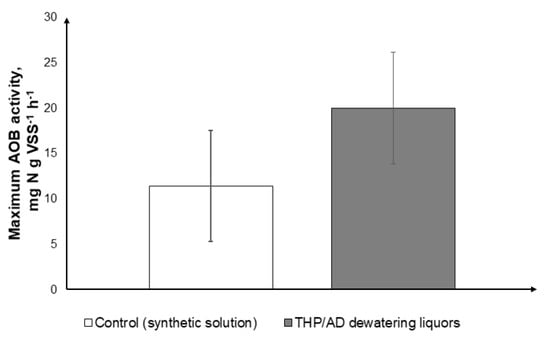

Previous studies reported inhibition and operational difficulties with THP/AD dewatering liquors [5,6]. This was not observed in this study; as Figure 2 clearly shows, the ammonia removal efficiency was always 75% and it was not impacted by increasing loading rates. Additionally, the maximum AOB activity measured was 20.0 mg N g VSS−1 h−1 for THP/AD dewatering liquors and 11.4 mg N g VSS−1 h−1 (Figure 3). No inhibition was observed in the ex-situ batch experiment activity tests either, in both control (synthetic solutions) and THP/AD. Previous studies reported a reduction of AOB activity by 40–60% AOB in THP/AD [5,6], but the same was not observed in this study. Our results align with the reports by Driessen et al. (2020) [7] who demonstrated successful nitrogen removal with a granular sludge deammonification process from THP/AD dewatering liquors (NRR 1.0–2.0 kg N m−3 d−1). Hence, this study provides additional evidence that deammonification can be used as a nitrogen removal process for ammonia from THP/AD dewatering liquors and concerns about inhibition must be further investigated on a case-by-case basis.

Figure 3.

Maximum ammonia oxidizing bacteria (AOB) activity with thermal hydrolysis dewatering anaerobic digestion liquors and synthetic feed solution for control.

3.2. Biomass Retention

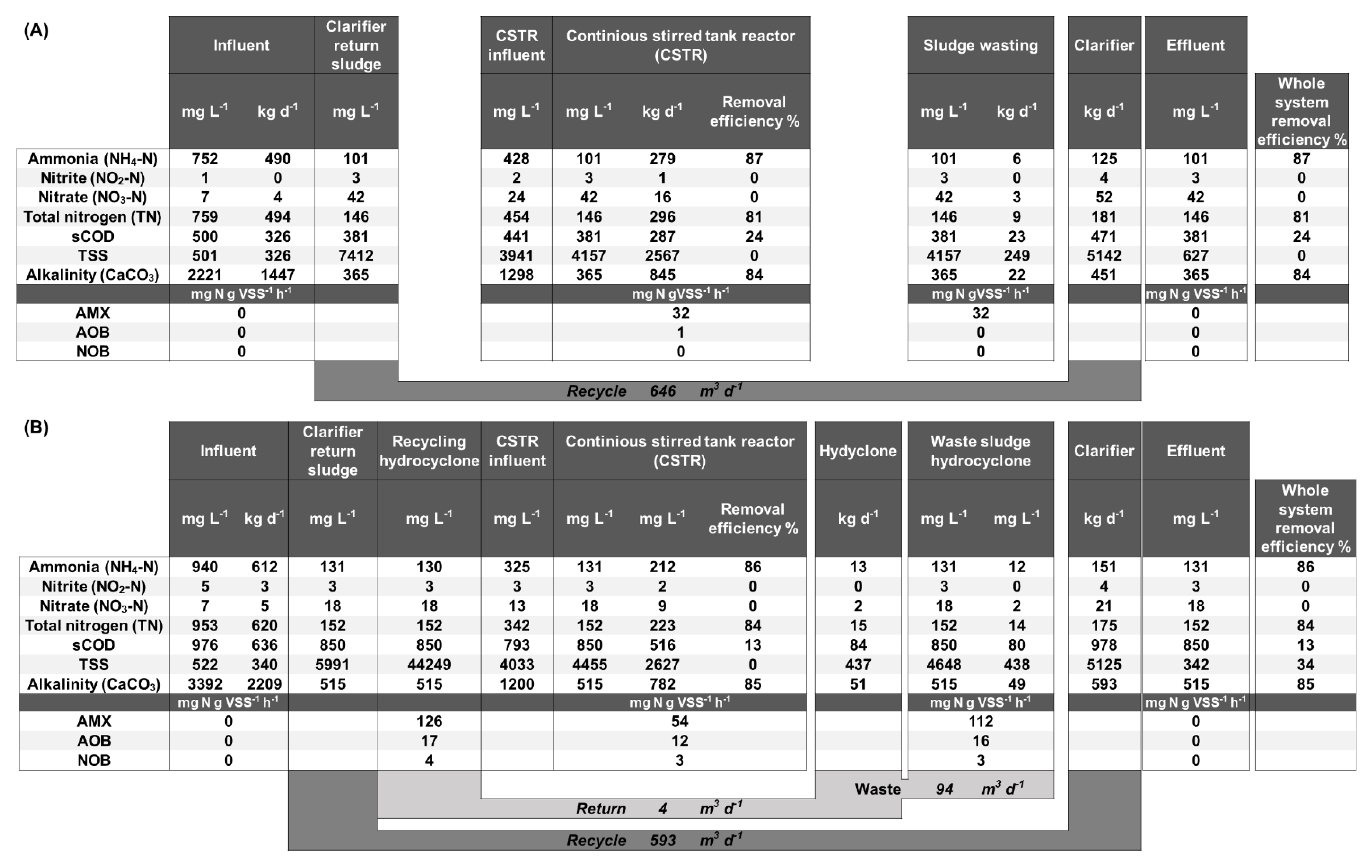

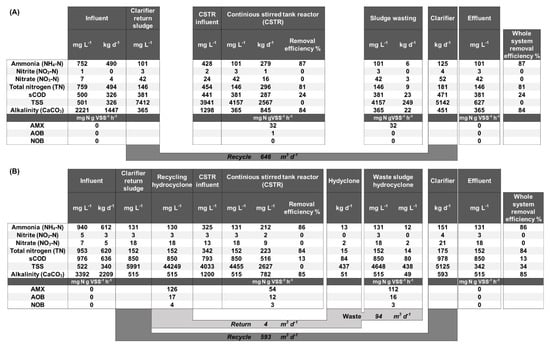

The S-CSTR mass balance, with and without hydrocyclone, is presented in Figure 4. The MLSS and the TSS wasted in the reactor were 4157 mg MLSS L−1 and 249 kg TSS d−1 without hydrocyclone, and 4450 mg MLSS L−1 and 438 kg TSS d−1 with hydrocyclone. The hydrocyclone allowed a solids retention of 65% on average (Figure 4B). The AMX activity increased to 54.3 mg N g VSS−1 h−1 (Figure 4B) when hydrocyclone was operated compared with only 31.8 mg N g VSS−1 h−1 without it. The highest AMX activity measured in the hydrocyclone underflow was 111.5 mg N g VSS−1 h−1 (Figure 4B). Based on the mass balance, the AMX retention with the hydrocyclone was estimated at 70%, while the AOB and NOB retention efficiency was 46% and 58%, respectively. This data very clearly indicates that slow-growing AMX was successfully retained in the S-CSTR with the hydrocyclone. Previous studies based on modelling or only a few data points reported solids separation in hydrocyclones to be between 60–90% [17,18]. The authors suggested that the superior biomass separation via a screen of 91% lead to an additional improvement of 10–12% in nitrogen removal ability [18]. However, this data was not validated by field data. Others also observed higher AMX activity in the underflow of the hydrocyclone compared to the biological reactor of 2.0–15.0 mg NO2− N g TSS−1 h−1 [20]. However, comparisons of this study with Wett (2010) [20] are limited due to differences in the activity test methodology. When treating manure digestate dewatering liquors, Kwon (2019) [22] measured up to 90% of AMX retention in a system with an hydrocyclone, however there was also instability with periods of excessive AMX washout.

Figure 4.

Mass-balance of the S-CSTR and anaerobic ammonia oxidizing bacteria (AMX), ammonia oxidizing bacteria (AOB), and nitrite oxidizing bacteria (NOB) activities in the sludge lines and main reactor for Period 2 (A), operation without solids retention time control (A) and for Period 4, operation with solid retention time control (B).

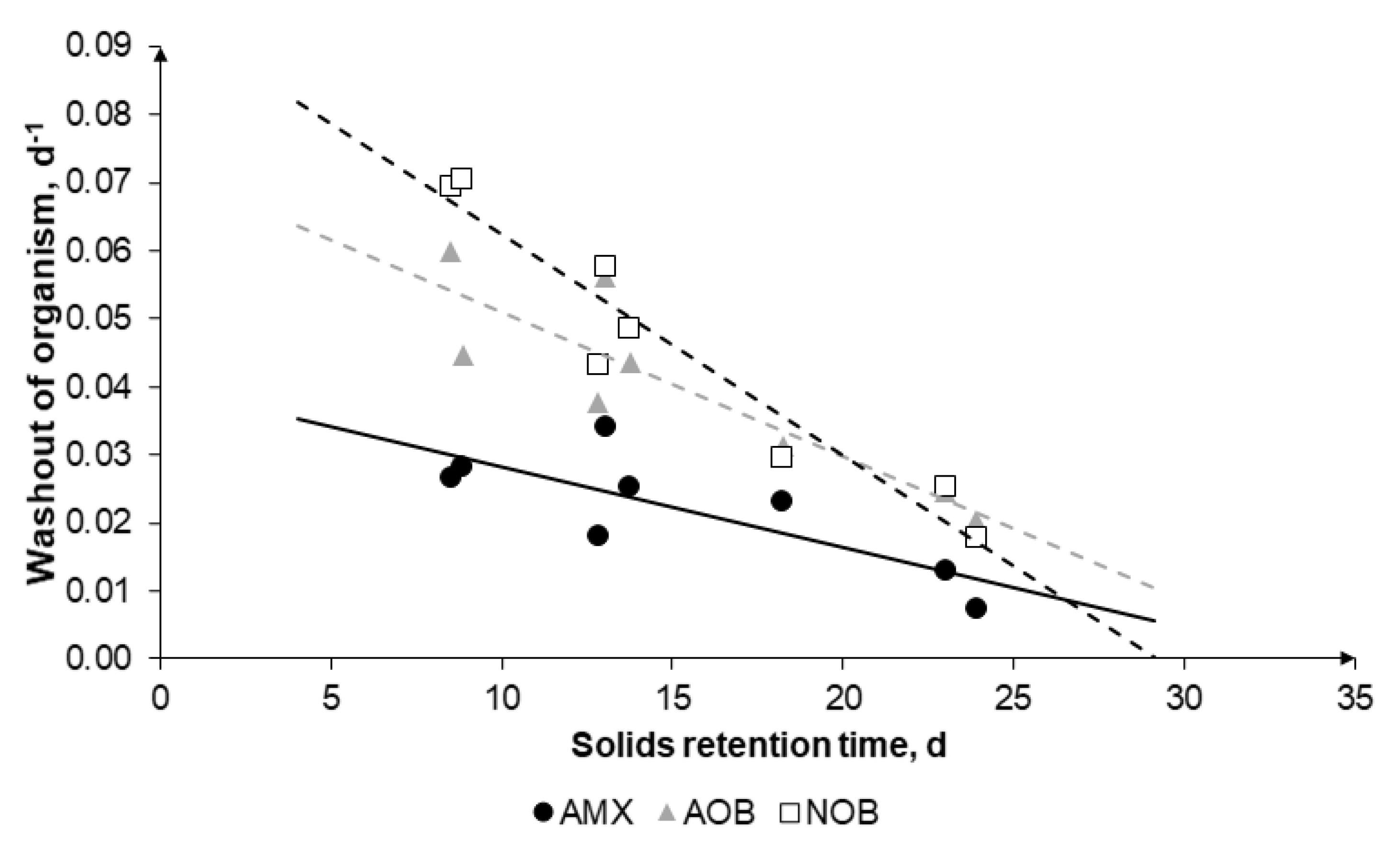

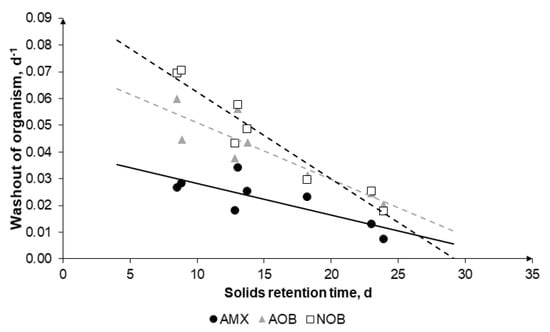

The biomass washout for the different biomass types (e.g., AMX, AOB, and NOB) and Period 4 and Period 5 are presented in Figure 5. Anaerobic ammonia oxidizing bacteria were retained more effectively compared to AOB and NOB in the S-CSTR. In particular, AMX had a lower wash-out rate of 0.01–0.03 d−1 compared to AOB and NOB with 0.03–0.07 d−1 (Figure 5). Additionally, the washout of both AOB and NOB was similar, between 0.03–0.07 d−1 which confirms the prior observation that SRTs of 11–13 d led to the washout of both AOB and NOB. Additionally, Figure 5 indicates that the NOB had a slightly higher wash-out rate in relation to SRT than the AOB.

Figure 5.

Dilution rate by anammox (AMX) (black circles with black trendline), ammonia-oxidizing bacteria (AOB) (grey triangle with grey line), nitrite-oxidizing bacteria (NOB) (white cubes with black dashed line), versus solids retention time of the suspended sludge continuous stirred tank reactor with hydrocyclone. The R-square was 0.6, 0.8, and 0.9 for AMX, AOB, and NOB, respectively.

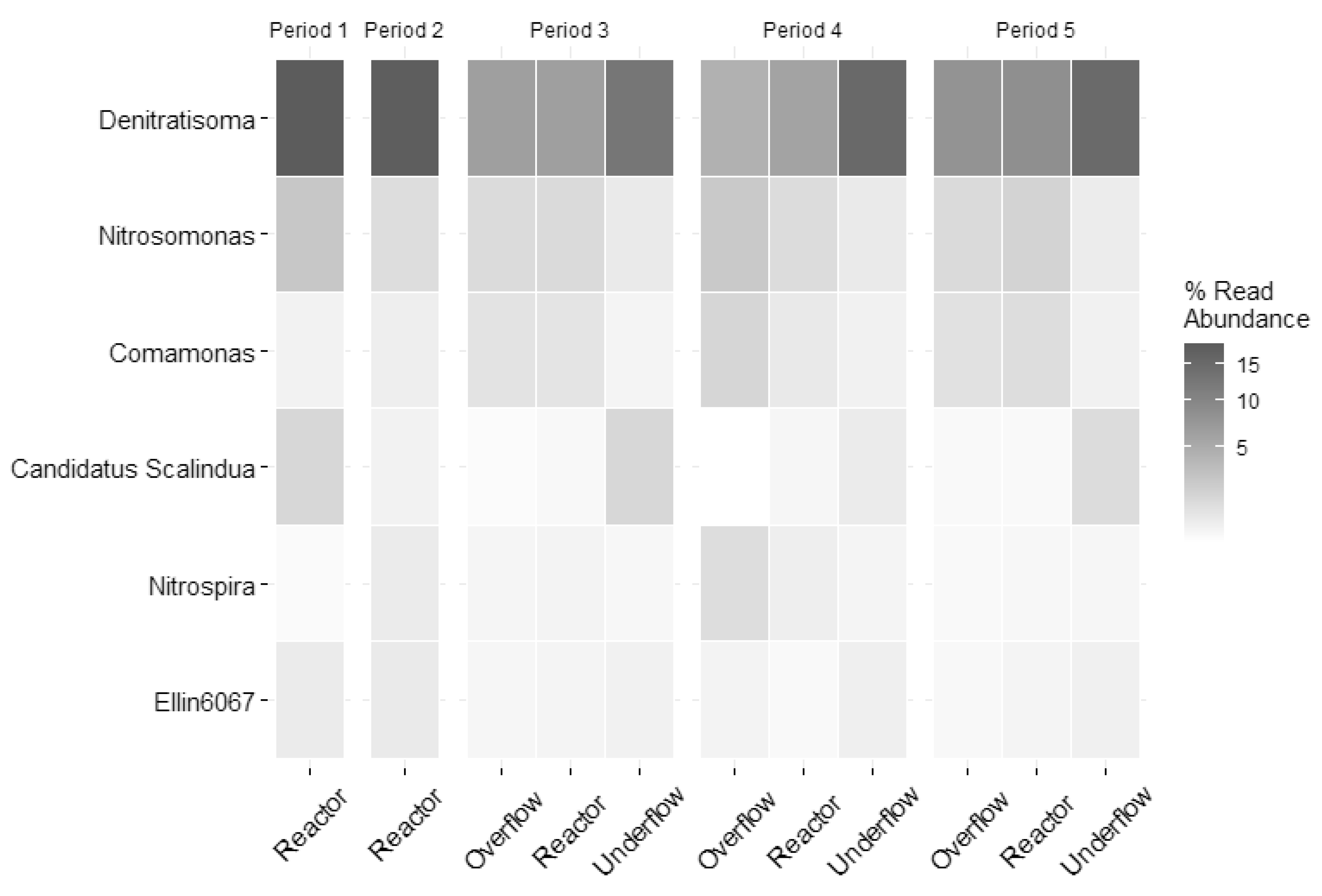

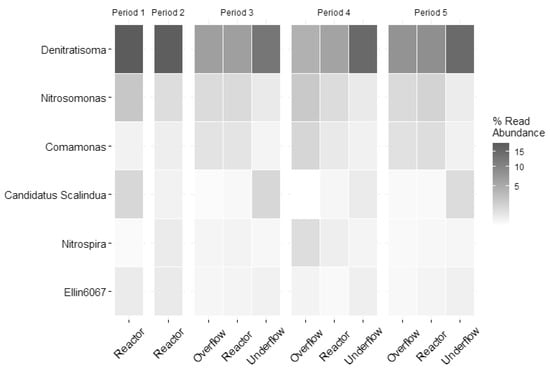

The microbiome analysis was key to identifying Denitratisoma as the dominant group in the reactor. Denitratisoma is known for its ability to use nitrate as electron acceptor [38] and is reported, in high abundance, in deammonification technologies treating conventional AD dewatering liquors [39]. Candidatus Scalindua was identified as the dominant AMX genus in the S-CSTR (Figure 6). Candidatus Scalindua has been previously described in non-engineered ecosystems or saltwater deammonification systems [40]. Dewatering liquors from conventional AD and THP/AD have a high salt of content 5000–6000 µS cm−1 [41,42]. Further to this, a recent study shows the relevance of Candidatus Scalindua in freshwater environments too, demonstrating the versatility and potential underestimation of this genus in deammonification systems [43]. The abundance of Candidatus Scalindua was around 0.2–0.5% in the biological reactor, 1.2% in the underflow of the hydrocyclone, and 0.1% in the hydrocyclone overflow (Figure 6). This also clearly corroborated that indeed AMX was successfully retained with the hydrocyclone. Kwon (2019) [22] also identified a higher abundance of 8.3% in the underflow of the hydrocyclone compared to 7.1% in the biological reactor. Previous studies reported an archaeal fraction of 1.4–3.8% in suspended sludge deammonification technologies [44] and AMX abundances of 0.3–9.3% [22,45]. The microbiome results from this study can also be used as an indicator due to the limited sample size.

Figure 6.

The relative abundance of main genus types for AMX (Candidatus Scalindua), denitrification (Denitratisoma), partial nitritation (Nitrosomas), and nitratation (Nitrospira) for hydrocyclone overflow underflow as well as a reactor for Period 1 to Period 5.

4. Conclusions

In this study, a full-scale suspended sludge continuous stirred tank reactor (S-CSTR) deammonification technology with a hydrocyclone treating THP/AD dewatering liquors was optimized and its performance and stability analyzed. This study demonstrated that:

- The S-CSTR achieved successful ammonia removal from THP/AD dewatering liquors with efficiencies >85%. Ex-situ AOB activity tests indicated that THP/AD dewatering liquors did not impact the ammonia conversion.

- Sodium hydroxide dosing enabled the greater ammonia removal efficiencies of 95% but led to the undesired NOB overgrowth, and nitrate accumulation.

- The hydrocyclone was key to retain 56–83% AMX biomass. Additionally, the AMX washout of the hydrocyclone based on mass-balance was 0.01–0.03 d−1 while the washout of AOB and NOB was 0.3–0.7 d−1.

- SRTs of shorter than 13 days lead to NOB washout, but below 11 days AOB will also be wash-out.

Author Contributions

P.O. is the first author having completed all the experiments, devised the methodology, data curation, and analysis, and prepared the manuscript including conceptualization; B.D.M. advised on the manuscript data collection, supervision, project administration, funding acquisition, and provided minor comments on the manuscript; E.G. advised on the manuscript data collection, supervision, and funding acquisition; Z.W. completed the microbiome analysis and data processing; P.-H.L. provided support and data curation on the microbiome analysis; M.v.L. acted as advisor on the project and provided comments on the manuscript. T.S. acted as an advisor on the project and provided minor comments on the manuscript; A.S. is the principal investigator, having provided significant input on the methodology, data collection interpretation, conceptualization, validation, funding acquisition, project administration, and completed all the revisions on the manuscript. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Thames Water and EPSRC Centre for Doctoral Training in Engineering for the Water Sector (STREAM IDC), grant number EP/L015412/1.

Data Availability Statement

Data from this study can be made available upon request.

Acknowledgments

We would like to express our thanks to the Laboratory of Thames Water Utilities Ltd. for analyzing the composite samples.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Barber, W.P.F. Thermal hydrolysis for sewage treatment: A critical review. Water Res. 2016, 104, 53–71. [Google Scholar] [CrossRef]

- Winter, P.; Ng, B.; Smith, S.R.; Strange, G.; Jarvis, S.; Macedo, F.; Shen, X. Impact of Sludge Liquors on the Hydraulic, Nutrient and Solids Load of Wastewater Treatment. In Proceedings of the IWA Specialist Conference on Sludge Management 17; IWA Publishing: London, UK, 2017; pp. 1–17. [Google Scholar]

- Strous, M.; Heijnen, J.; Kuenen, J.; Jetten, M. The sequencing batch reactor as a powerful tool for the study of slowly growing anaerobic ammonium-oxidizing microorganisms. Appl. Microbiol. Biotechnol. 1998, 50, 589–596. [Google Scholar] [CrossRef]

- Jetten, M.S.M.; Strous, M.; Fuerst, J.A.; Kramer, E.H.M.; Logemann, S.; Muyzer, G.; van de Pas-Schoonen, K.T.; Webb, R.; Kuenen, J.G.; Jhon, A.F.; et al. Missing lithotroph identified as new planctomycete. Nature 1999, 400, 446–449. [Google Scholar] [CrossRef]

- Figdore, B.; Wett, B.; Hell, M.; Murthy, S. Deammonification of Dewatering Sidestream from Thermal Hydrolysis-Mesophilic Anaerobic Digestion Process. Proc. Water Environ. Fed. 2011, 2011, 1037–1052. [Google Scholar] [CrossRef][Green Version]

- Zhang, Q.; de Clippeleir, H.; Su, C.; Omari, A.A.; Wett, B.; Vlaeminck, S.E.; Murthy, S.; Figdore, B.; Wett, B.; Hell, M.; et al. Deammonification for digester supernatant pretreated with thermal hydrolysis: Overcoming inhibition through process optimization. Appl. Microbiol. Biotechnol. 2016, 100, 5595–5606. [Google Scholar] [CrossRef]

- Driessen, W.; van Veldhoven, J.T.A.; Janssen, M.; van Loosdrecht, M.C.M. Treatment of sidestream dewatering liquors from thermally hydrolised and anaerobically digested biosolids. Water Pract. Technol. 2020, 15, 142–150. [Google Scholar] [CrossRef]

- Ochs, P.; Martin, B.D.; Germain, E.; Stephenson, T.; van Loosdrecht, M.; Soares, A. Ammonia removal from thermal hydrolysis dewatering liquors via three different deammonification technologies. Sci. Total Environ. 2021, 755, 142684. [Google Scholar] [CrossRef]

- Lackner, S.; Gilbert, E.M.; Vlaeminck, S.E.; Joss, A.; Horn, H.; van Loosdrecht, M.C.M. Full-scale partial nitritation/anammox experiences—An application survey. Water Res. 2014, 55, 292–303. [Google Scholar] [CrossRef]

- Daigger, G.T.; Sanjines, P.; Pallansch, K.; Sizemore, J.; Wett, B. Implementation of a full-scale anammox-based facility to treat an anaerobic digestion sidestream at the alexandria sanitation authority water resource facility. Water Pract. Technol. 2011, 6. [Google Scholar] [CrossRef]

- Tchobanoglous, G.; Burton, F.L.; Tsuchihashi, R.; Stensel, H.D. Wastewater Engineering: Treatment and Resource Recovery, 5th ed.; Abu-Orf, M., Bowden, G., Pfrang, W., Tchobanoglous, G., Stensel, D.H., Tsuchihashi, R.B.F., Eds.; McGraw-Hill: New York, NY, USA, 2014; ISBN 0073401188. [Google Scholar]

- Mehrdad, M.; Park, H.; Ramalingam, K.; Fillos, J.; Beckmann, K.; Deur, A.; Chandran, K. Anammox moving bed biofilmreactor pilot at the 26th Ward wastewater treatment plants in Brooklyn, New York: Start-up, biofilm population diversity and performance optimization. Water Sci. Technol. 2014, 70, 1448–1455. [Google Scholar] [CrossRef]

- Lotti, T.; Kleerebezem, R.; Hu, Z.; Kartal, B.; Jetten, M.S.M.; van Loosdrecht, M.C.M. Simultaneous partial nitritation and anammox at low temperature with granular sludge. Water Res. 2014, 66, 111–121. [Google Scholar] [CrossRef]

- Fux, C.; Siegrist, H. Nitrogen removal from sludge digester liquids by nitrification/denitrification or partial nitritation/anammox: Environmental and economical considerations. Water Sci. Technol. 2004, 50, 19–26. [Google Scholar] [CrossRef]

- van der Star, W.R.L.; Abma, W.R.; Blommers, D.; Mulder, J.W.; Tokutomi, T.; Strous, M.; Picioreanu, C.; van Loosdrecht, M.C.M. Startup of reactors for anoxic ammonium oxidation: Experiences from the first full-scale anammox reactor in Rotterdam. Water Res. 2007, 41, 4149–4163. [Google Scholar] [CrossRef] [PubMed]

- Wett, B. Development and implementation of a robust deammonification process. Water Sci. Technol. 2007, 56, 81–88. [Google Scholar] [CrossRef] [PubMed]

- Wett, B.; Hell, M.; Nyhuis, G.; Puempel, T.; Takacs, I.; Murthy, S. Syntrophy of aerobic and anaerobic ammonia oxidisers. Water Sci. Technol. 2010, 61, 1915–1922. [Google Scholar] [CrossRef] [PubMed]

- van Winckel, T.; Vlaeminck, S.E.; Omari, A.A.; Bachmann, B.; Sturm, B.; Wett, B.; Takács, I.; Bott, C.; Murthy, S.N.; de Clippeleir, H. Screen versus cyclone for improved capacity and robustness for sidestream and mainstream deammonification. Environ. Sci. Water Res. Technol. 2019, 5, 1769–1781. [Google Scholar] [CrossRef]

- Shi, Y.; Wells, G.; Morgenroth, E. Microbial activity balance in size fractionated suspended growth biomass from full-scale sidestream combined nitritation-anammox reactors. Bioresour. Technol. 2016, 218, 38–45. [Google Scholar] [CrossRef]

- Wett, B.; Nyhuis, G.; Takács, I.; Murthy, S. Development of Enhanced Deammonification Selector. Proc. Water Environ. Fed. 2010, 2010, 5917–5926. [Google Scholar] [CrossRef]

- Han, M.; Vlaeminck, S.E.; Omari, A.A.; Wett, B.; Bott, C.; Murthy, S.; De Clippeleir, H. Uncoupling the solids retention times of flocs and granules in mainstream deammonification: A screen as effective out-selection tool for nitrite oxidizing bacteria. Bioresour. Technol. 2016, 221, 195–204. [Google Scholar] [CrossRef]

- Kwon, K.; Kim, H.; Kim, W.; Lee, J. Efficient nitrogen removal of reject water generated from anaerobic digester treating sewage sludge and livestock manure by combining anammox and autotrophic Sulfur denitrification processes. Water (Switzerland) 2019, 11, 204. [Google Scholar] [CrossRef]

- Lotti, T.; Kleerebezem, R.; Lubello, C.; van Loosdrecht, M.C.M. Physiological and kinetic characterization of a suspended cell anammox culture. Water Res. 2014, 60, 1–14. [Google Scholar] [CrossRef] [PubMed]

- APHA. Standard Methods for the Examination of Water and Wastewater, 23rd ed.; American Public Health Association, American Water Works Association, and Water Environment Federation: Washington, WA, USA, 2017; ISBN 9780875532875. [Google Scholar]

- Lotti, T.; van der Star, W.R.L.; Kleerebezem, R.; Lubello, C.; van Loosdrecht, M.C.M.; Van der Star, W.; Kleerebezem, R.; Research, C.L.-W. The effect of nitrite inhibition on the anammox process. Water Res. 2012, 46, 2559–2569. [Google Scholar] [CrossRef]

- van Loosdrecht, M.C.M.; Nielsen, P.H.; Vazquez, C.M.L.; Brdjanovic, D. Experimental Methods in Wastewater Treamtent, 1st ed.; IWA Publishing: London, UK, 2016; ISBN 9781780404745. [Google Scholar]

- Klindworth, A.; Pruesse, E.; Schweer, T.; Peplies, J.; Quast, C.; Horn, M.; Glöckner, F.O. Evaluation of general 16S ribosomal RNA gene PCR primers for classical and next-generation sequencing-based diversity studies. Nucleic Acids Res. 2013, 41, e1. [Google Scholar] [CrossRef]

- Schloss, P.D.; Westcott, S.L.; Ryabin, T.; Hall, J.R.; Hartmann, M.; Hollister, E.B.; Lesniewski, R.A.; Oakley, B.B.; Parks, D.H.; Robinson, C.J.; et al. Introducing mothur: Open-source, platform-independent, community-supported software for describing and comparing microbial communities. Appl. Environ. Microbiol. 2009, 75, 7537–7541. [Google Scholar] [CrossRef] [PubMed]

- Edgar, R.C.; Haas, B.J.; Clemente, J.C.; Quince, C.; Knight, R. UCHIME improves sensitivity and speed of chimera detection. Bioinformatics 2011, 27, 2194–2200. [Google Scholar] [CrossRef] [PubMed]

- Pruesse, E.; Quast, C.; Knittel, K.; Fuchs, B.M.; Ludwig, W.; Peplies, J.; Glöckner, F.O. SILVA: A comprehensive online resource for quality checked and aligned ribosomal RNA sequence data compatible with ARB. Nucleic Acids Res. 2007, 35, 7188–7196. [Google Scholar] [CrossRef] [PubMed]

- Albertsen, M.; Karst, S.M.; Ziegler, A.S.; Kirkegaard, R.H.; Nielsen, P.H. Back to basics—The influence of DNA extraction and primer choice on phylogenetic analysis of activated sludge communities. PLoS ONE 2015, 10, e0132783. [Google Scholar] [CrossRef] [PubMed]

- Nifong, A.; Nelson, A.; Johnson, C.; Bott, C.B. Performance of a Full-Scale Sidestream DEMON Deammonification Installation. Proc. Water Environ. Fed. 2013, 2013, 3686–3709. [Google Scholar] [CrossRef][Green Version]

- Vlaeminck, S.E.; van der Linden, D.; Boon, N.; Verstraete, W.; Carballa, M.; Terada, A.; Smets, B.F. Nitrogen removal from digested black water by one-stage partial nitritation and anammox. Environ. Sci. Technol. 2009, 43, 5035–5041. [Google Scholar] [CrossRef]

- Anthonisen, A.C.; Srinath, E.G.; Loehr, R.C.; Prakasam, T.B.S. Inhibition of nitrification and nitrous acid compounds. J. Water Pollut. Control Fed. 1976, 48, 835–852. [Google Scholar] [CrossRef]

- Feng, Y.; Lu, X.; Hazmi, H.A.; Mąkinia, J. An overview of the strategies for the deammonification process start-up and recovery after accidental operational failures. Rev. Environ. Sci. Biotechnol. 2017, 16, 541–568. [Google Scholar] [CrossRef]

- Chung, J.; Shim, H.; Park, S.J.; Kim, S.J.; Bae, W. Optimization of free ammonia concentration for nitrite accumulation in shortcut biological nitrogen removal process. Bioprocess Biosyst. Eng. 2006, 28, 275–282. [Google Scholar] [CrossRef] [PubMed]

- Regmi, P.; Miller, M.W.; Holgate, B.; Bunce, R.; Park, H.; Chandran, K.; Wett, B.; Murthy, S.; Bott, C.B. Control of aeration, aerobic SRT and COD input for mainstream nitritation/denitritation. Water Res. 2014, 57, 162–171. [Google Scholar] [CrossRef] [PubMed]

- Fahrbach, M.; Kuever, J.; Meinke, R.; Kämpfer, P.; Hollender, J. Denitratisoma oestradiolicum gen. nov., sp. nov., a 17 β-oestradiol-degrading, denitrifying betaproteobacterium. Int. J. Syst. Evol. Microbiol. 2006, 56, 1547–1552. [Google Scholar] [CrossRef] [PubMed]

- Wang, G.; Xu, X.; Zhou, L.; Wang, C.; Yang, F. A pilot-scale study on the start-up of partial nitrification-anammox process for anaerobic sludge digester liquor treatment. Bioresour. Technol. 2017, 241, 181–189. [Google Scholar] [CrossRef] [PubMed]

- Wu, Z.; Meng, H.; Huang, X.; Wang, Q.; Chen, W.H.; Gu, J.D.; Lee, P.H. Salinity-driven heterogeneity toward anammox distribution and growth kinetics. Appl. Microbiol. Biotechnol. 2019, 103, 1953–1960. [Google Scholar] [CrossRef]

- Daims, H.; Purkhold, U.; Bjerrum, L.; Arnold, E.; Wilderer, P.A.; Wagner, M. Nitrification in sequencing biofilm batch reactors: Lessons from molecular approaches. Water Sci. Technol. 2001, 43, 9–18. [Google Scholar] [CrossRef]

- Simoes, F.; Colston, R.; Rosa-Fernandes, C.; Vale, P.; Stephenson, T.; Soares, A. Predicting the potential of sludge dewatering liquors to recover nutrients as struvite biominerals. Environ. Sci. Ecotechnol. 2020, 3, 100052. [Google Scholar] [CrossRef]

- Zhang, L.; Okabe, S. Ecological niche differentiation among anammox bacteria. Water Res. 2020, 171, 115468. [Google Scholar] [CrossRef]

- Martinez, A.G.; Morillo, J.A.; Ruiz, M.J.G.; Lopez, J.G.; Osorio, F.; Toledo, M.V.M.; van Loosdrecht, M.C.M. Archaeal populations in full-scale autotrophic nitrogen removal bioreactors operated with different technologies: CANON, DEMON and partial nitritation/anammox. Chem. Eng. J. 2015, 277, 194–201. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, L.; Cheng, J.; Zhang, S.; Li, X.; Peng, Y. Microbial community evolution in partial nitritation/anammox process: From sidestream to mainstream. Bioresour. Technol. 2018, 251, 327–333. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).