Insights into the Supercritical CO2 Extraction of Perilla Oil and Its Theoretical Solubility

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials and Reagents

2.2. Supercritical Carbon Dioxide (SCCO2) Extraction

2.3. Essential Oil Extraction by Hydrodistillation (HD)

2.4. Gas Chromatographic (GC) Analysis

2.5. Statistical Analysis

3. Results and Discussion

3.1. Essential Oils Obtained by HD

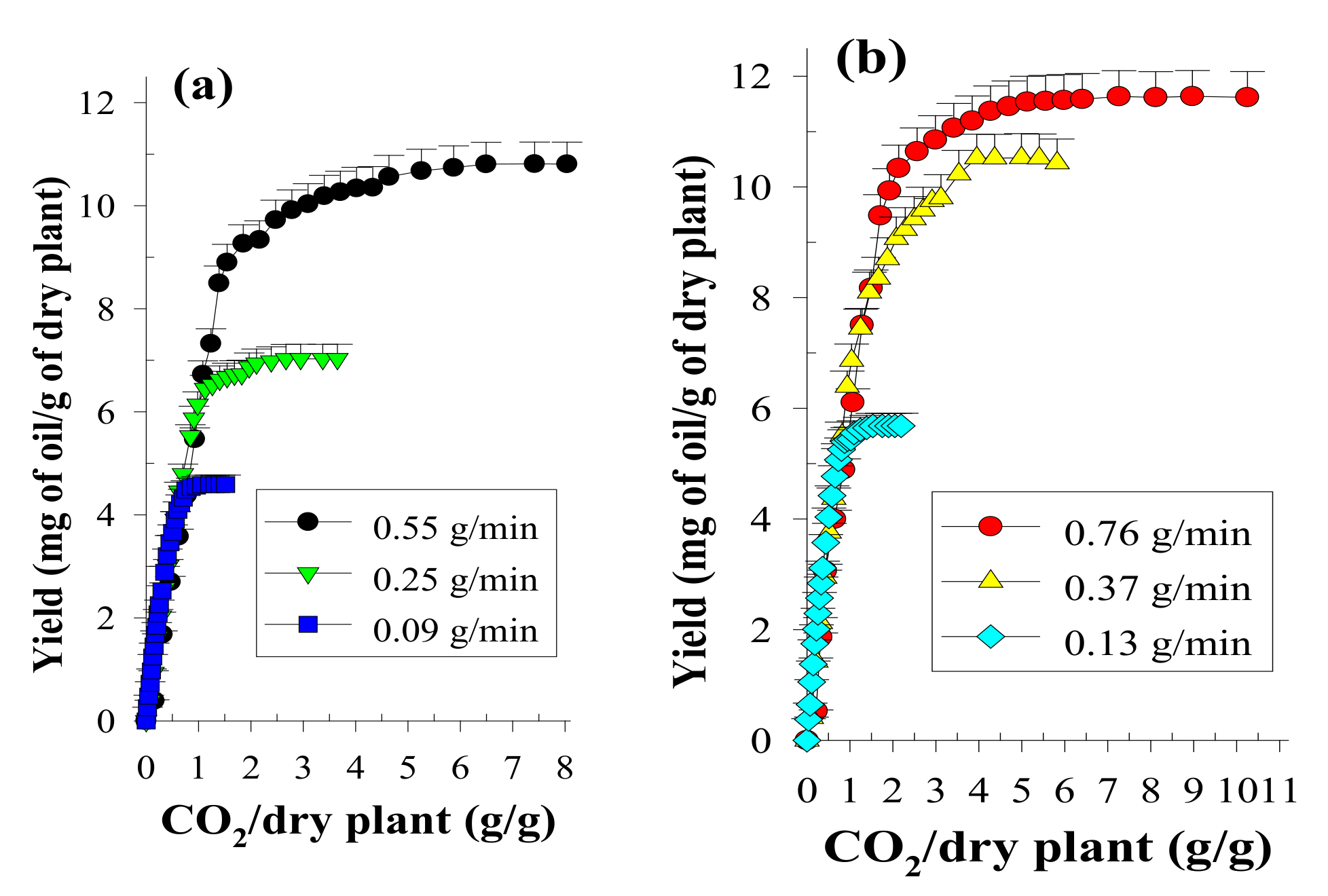

3.2. Influence of the CO2 Flow Rate

3.3. Influences of Temperature and Pressure

3.4. Characterization of Oils Obtained by SCCO2 Extraction and HD

3.5. Theoretical Solubility of Volatile Oils and Models

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Tabanca, N.; Demirci, B.; Ali, A.; Ali, Z.; Blythe, E.K.; Khan, I.A. Essential oils of green and red Perilla frutescens as potential sources of compounds for mosquito management. Ind. Crops Prod. 2015, 65, 36–44. [Google Scholar] [CrossRef]

- Torri, L.; Bondioli, P.; Folegatti, L.; Rovellini, P.; Piochi, M.; Morini, G. Development of perilla seed oil and extra virgin olive oil blends for nutritional, oxidative stability and consumer acceptance improvements. Food Chem. 2019, 286, 584–591. [Google Scholar] [CrossRef] [PubMed]

- Tian, J.; Zeng, X.B.; Zhang, S.; Wang, Y.Z.; Zhang, P.; Lu, A.J.; Peng, X. Regional variation in components and antioxidant and antifungal activities of Perilla frutescens essential oils in China. Ind. Crops Prod. 2014, 59, 69–79. [Google Scholar] [CrossRef]

- Park, S.H.; Paek, J.H.; Shin, D.; Lee, J.Y.; Lim, S.S.; Kang, Y.H. Purple perilla extracts with α-asarone enhance cholesterol efflux from oxidized LDL-exposed macrophages. Int. J. Mol. Med. 2015, 35, 957–965. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.C.; Wang, C.S.; Wei, M.C. Development and validation of an ultrasound-assisted supercritical carbondioxide procedure for the production of essential oils from Perilla frutescens. LWT Food Sci. Technol. 2020, 128, 109503. [Google Scholar] [CrossRef]

- Chang, X.L.; Zhao, Z.L.; Li, X.L.; Xu, H.; Sun, Y.; Wang, W.H. Extraction and advanced adsorbents for the separation of perillaldehyde from Perilla frutescens (L.) Britton var. crispa f. viridis leaves. Food Sci. Technol. Res. 2014, 20, 189–199. [Google Scholar] [CrossRef][Green Version]

- You, C.X.; Wang, Y.; Zhang, W.J.; Yang, K.; Wu, Y.; Geng, Z.F.; Chen, H.P.; Jiang, H.Y.; Du, S.S.; Deng, Z.W.; et al. Chemical constituents and biological activities of the purple Perilla essential oil against Lasioderma serricorne. Ind. Crops Prod. 2014, 61, 331–337. [Google Scholar] [CrossRef]

- Ahmed, H.M.; Tavaszi-Sarosi, S. Identification and quantification of essential oil content and composition, total polyphenols and antioxidant capacity of Perilla frutescens (L.) Britt. Food Chem. 2019, 275, 730–738. [Google Scholar] [CrossRef]

- Chen, F.; Liu, S.; Zhao, Z.; Gao, W.; Ma, Y.; Wang, X.; Yan, S.; Luo, D. Ultrasound pre-treatment combined with microwave-assisted hydrodistillation of essential oils from Perilla frutescens (L.) Britt. leaves and its chemical composition and biological activity. Ind. Crops Prod. 2020, 143, 111908. [Google Scholar] [CrossRef]

- Yang, Y.C.; Wang, C.S.; Wei, M.C. Insights into the major phenolic acids in Perilla frutescens obtained by a sustainable procedure. J. Ind. Eng. Chem. 2021. In Press. [Google Scholar] [CrossRef]

- Szydłowska-Czerniak, A.; Tułodziecka, A.; Karlovits, G.; Szłyk, E. Optimisation of ultrasound-assisted extraction of natural antioxidants from mustard seed cultivars. J. Sci. Food Agric. 2015, 95, 1445–1453. [Google Scholar] [CrossRef] [PubMed]

- El Marsni, Z.; Torres, A.; Varela, R.M.; Molinillo, J.M.; Casas, L.; Mantell, C.; Martinez de la Ossa, E.J.; Macias, F. Isolation of bioactive compounds from sunflower leaves (Helianthus annuus L.) extracted with supercritical carbon dioxide. J. Agric. Food Chem. 2015, 63, 6410–6421. [Google Scholar] [CrossRef] [PubMed]

- Sanjaya, R.E.; Tedjo, Y.Y.; Kurniawan, A.; Ju, Y.H.; Ayucitra, A.; Ismadj, S. Investigation on supercritical CO2 extraction of phenolic-phytochemicals from an epiphytic plant tuber (Myrmecodia pendans). J. CO2 Util. 2014, 6, 26–33. [Google Scholar] [CrossRef]

- Yousefi, M.; Rahimi-Nasrabadi, M.; Pourmortazavi, S.M.; Wysokowski, M.; Jesionowski, T.; Ehrlich, H.; Mirsadeghi, S. Supercritical fluid extraction of essential oils. Trends Anal. Chem. 2019, 118, 182–193. [Google Scholar] [CrossRef]

- Yang, Y.C.; Wei, M.C.; Lian, F.Y.; Huang, T.C. Simultaneous extraction and quantitation of oleanolic acid and ursolic acid from Scutellaria barbata D. Don by ultrasound-assisted extraction and high-performance liquid chromatography. Chem. Eng. Comm. 2014, 201, 482–500. [Google Scholar] [CrossRef]

- Yang, Y.C.; Wei, M.C.; Hong, S.J. Ultrasound-assisted extraction and quantitation of oils from Syzygium aromaticum flower bud (clove) with supercritical carbon dioxide. J. Chromatogr. A 2014, 1323, 18–27. [Google Scholar] [CrossRef]

- Yang, Y.C.; Wang, C.S.; Wei, M.C. Kinetics and mass transfer considerations for an ultrasound-assisted supercritical CO2 procedure to produce extracts enriched in flavonoids from Scutellaria barbata. J. CO2 Util. 2019, 32, 219–231. [Google Scholar] [CrossRef]

- Yang, Y.C.; Wei, M.C. A combined procedure of ultrasound-assisted and supercritical carbon dioxide for extraction and quantitation oleanolic and ursolic acids from Hedyotis corymbosa. Ind. Crops Prod. 2016, 79, 7–17. [Google Scholar] [CrossRef]

- Huang, B.K.; Lei, Y.L.; Tang, Y.H.; Zhang, J.C.; Qin, L.P.; Liu, J.A. Comparison of HS-SPME with hydrodistillation and SFE for the analysis of the volatile compounds of Zisu and Baisu, two varietal species of Perilla frutescens of Chinese origin. Food Chem. 2011, 125, 268–275. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, H.; Zhang, J. Comparison of MAHD with UAE and hydrodistillation for the analysis of volatile oil from four parts of Perilla frutescens cultivated in southern China. Anal. Lett. 2012, 45, 1894–1909. [Google Scholar] [CrossRef]

- Wei, M.C.; Xiao, J.; Yang, Y.C. Extraction of α-humulene-enriched oil from clove by ultrasound-assisted supercritical carbon dioxide extraction and studies of its fictitious solubility. Food Chem. 2016, 210, 172–181. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.C.; Wang, C.S.; Wei, M.C. Separation and quantification of bioactive flavonoids from Scutellaria barbata using a green procedure. Food Bioprod. Process. 2019, 118, 77–90. [Google Scholar] [CrossRef]

- Wei, M.C.; Yang, Y.C. Kinetic studies for ultrasound-assisted supercritical carbon dioxide extraction of triterpenic acids from healthy tea ingredient Hedyotis diffusa and Hedyotis corymbosa. Sep. Purif. Technol. 2015, 142, 316–325. [Google Scholar] [CrossRef]

- Yang, Y.C.; Wang, C.S.; Wei, M.C. A green approach for the extraction and characterization of oridonin and ursolic and oleanolic acids from Rabdosia rubescens and its kinetics behavior. Food Chem. 2020, 319, 126582. [Google Scholar] [CrossRef]

- Ferreira, S.R.S.; Meireles, M.A.A. Modeling the supercritical fluid extraction of black pepper (Piper nigrum L.) essential oil. J. Food Eng. 2002, 54, 263–269. [Google Scholar] [CrossRef]

- Santana, Á.L.; Queirós, L.D.; Martínez, J.; Macedo, G.A. Pressurized liquid- and supercritical fluid extraction of crude and waste seeds of guarana (Paullinia cupana): Obtaining of bioactive compounds and mathematical modeling. Food Bioprod. Process. 2019, 117, 194–202. [Google Scholar] [CrossRef]

- Wei, M.C.; Hong, S.J.; Yang, Y.C. Isolation of triterpenic acid-rich extracts from Hedyotis corymbosa using ultrasound-assisted supercritical carbon dioxide extraction and determination of their fictitious solubilities. J. Ind. Eng. Chem. 2017, 48, 202–211. [Google Scholar] [CrossRef]

- Yang, Y.C.; Wei, M.C. Development and characterization of a green procedure for apigenin extraction from Scutellaria barbata D. Don. Food Chem. 2018, 252, 381–389. [Google Scholar] [CrossRef]

- Said, P.P.; Pradhan, R.C.; Rai, B.N. A green separation of Lagenaria siceraria seed oil. Ind. Crops Prod. 2014, 52, 796–800. [Google Scholar] [CrossRef]

- Wei, M.C.; Yang, Y.C.; Hong, S.J. Determination of oleanolic and ursolic acids in Hedyotis diffusa using hyphenated ultrasound-assisted supercritical carbon dioxide extraction and chromatography. Evid. Based Complement. Alternat. Med. 2015, 2015, 450547. [Google Scholar] [CrossRef]

- Tomita, K.; Machmudah, S.; Fukuzato, R.; Kanda, H.; Quitain, A.T.; Sasaki, M.; Goto, M. Extraction of rice bran oil by supercritical carbon dioxide and solubility consideration. Sep. Purif. Technol. 2014, 12, 5319–5325. [Google Scholar] [CrossRef]

- Rudyk, S.; Spirov, P.; Tyrovolas, A. Effect of temperature on crude oil extraction by SC-CO2 at 40–70 °C and 40–60 MPa. J. CO2 Util. 2018, 24, 471–478. [Google Scholar] [CrossRef]

- Couto, R.; Seifried, B.; Moquin, P.; Temellia, F. Coenzyme Q10 solubility in supercritical CO2 using a dynamic system. J. CO2 Util. 2018, 24, 315–320. [Google Scholar] [CrossRef]

- Yang, Y.C.; Wei, M.C. Ethanol solution-modified supercritical carbon dioxide extraction of triterpenic acids from Hedyotis corymbosa with ultrasound assistance and determination of their solubilities. Sep. Purif. Technol. 2015, 150, 204–214. [Google Scholar] [CrossRef]

- Wei, M.C.; Lin, P.H.; Hong, S.J.; Chen, J.M.; Yang, Y.C. Development of a green alternative procedure for simultaneous separation and quantification of clove oil and its major bioactive constituents. ACS Sustain. Chem. Eng. 2016, 4, 6491–6499. [Google Scholar] [CrossRef]

- Chrastil, J. Solubility of solids and liquids in supercritical gases. J. Phys. Chem. 1982, 86, 3016–3021. [Google Scholar] [CrossRef]

- Bartle, K.D.; Clifford, A.; Jafar, S.A.; Shilton, G.F. Solubilities of solids and liquids of low volatility in supercritical carbon dioxide. J. Phys. Chem. Ref. Data 1991, 20, 713–756. [Google Scholar] [CrossRef]

- Kumar, S.K.; Johnston, K.P. Modeling the solubility of solids in supercritical fluids with density as the independent variable. J. Supercrit. Fluids 1988, 1, 15–22. [Google Scholar] [CrossRef]

- Yang, Y.C.; Lin, P.H.; Wei, M.C. Production of oridonin-rich extracts from Rabdosia rubescens using hyphenated ultrasound-assisted supercritical carbon dioxide extraction. J. Sci. Food Agric. 2017, 97, 3323–3332. [Google Scholar] [CrossRef]

| HD | SCCO2 Extraction | |

|---|---|---|

| Sample of P. frutescens leaves | P1 | P1 |

| Mean particle size (mm) | 0.36 | 0.36 |

| Plant weight (g) | 100 | 20 |

| Static extraction time (min) | — | 30 |

| Dynamic time (min) | — | 170 |

| Extraction time (min) | 240 | 200 |

| Extraction temperature (°C) | 100 | 55 |

| Extraction pressure (MPa) | — | 33.0 |

| CO2 flow rate (g/min) | — | 0.37 |

| Yields | ||

| oil (%, w/w) 1 | 1.02 ± 0.02 | 1.33 ± 0.04 |

| limonene (%, w/w) 2 | 10.59 ± 0.50 | 11.81 ± 0.45 |

| perillaldehyde (%, w/w) 2 | 39.07 ± 1.62 | 40.52 ± 1.50 |

| β-caryophyllene (%, w/w) 2 | 9.14 ± 0.33 | 9.57 ± 0.36 |

| (Z,E)-α-farnesene (%, w/w) 2 | 4.95 ± 0.21 | 5.30 ± 0.20 |

- 1

- Values are written as the mean ± SD (g of oil/g of dry plant weight) of the extracted oils.

- 2

- Values are written as the mean ± SD (g of constituent/g of oil) of four replications.

| T (°C) | P (MPa) | ρ (kg/m3) 1 | Y*oil × 103 (g oil/g CO2) 2 |

|---|---|---|---|

| 32 | 10.5 | 760.051 | 3.787 ± 0.152 |

| 18.5 | 867.666 | 5.199 ± 0.20 | |

| 23.5 | 904.672 | 5.835 ± 0.234 | |

| 28.5 | 933.114 | 6.625 ± 0.265 | |

| 33.0 | 953.445 | 6.898 ± 0.276 | |

| 38 | 10.5 | 667.094 | 3.105 ± 0.124 |

| 18.5 | 834.302 | 5.783 ± 0.232 | |

| 23.5 | 877.501 | 6.496 ± 0.260 | |

| 28.5 | 909.376 | 7.308 ± 0.292 | |

| 33.0 | 931.632 | 8.065 ± 0.321 | |

| 43 | 10.5 | 578.482 | 2.496 ± 0.101 |

| 18.5 | 804.654 | 6.389 ± 0.256 | |

| 23.5 | 854.039 | 7.145 ± 0.287 | |

| 28.5 | 889.141 | 7.904 ± 0.319 | |

| 33.0 | 913.159 | 8.506 ± 0.343 | |

| 49 | 10.5 | 441.899 | 1.818 ± 0.073 |

| 18.5 | 766.348 | 6.742 ± 0.269 | |

| 23.5 | 824.725 | 7.409 ± 0.296 | |

| 28.5 | 864.279 | 8.227 ± 0.334 | |

| 33.0 | 890.625 | 8.853 ± 0.355 | |

| 55 | 10.5 | 361.884 | 1.385 ± 0.055 |

| 18.5 | 725.117 | 7.358 ± 0.296 | |

| 23.5 | 794.638 | 7.970 ± 0.321 | |

| 28.5 | 838.944 | 8.759 ± 0.352 | |

| 33.0 | 867.733 | 8.971 ± 0.367 |

- 1

- ρ: density of the scCO2.

- 2

- Y*oil: the theoretical solubility of volatile oil in scCO2.

| Model | n4 | Parameters | AARD(%) 5 | Thermodynamic Parameters | ||

|---|---|---|---|---|---|---|

| a0: | a1: | a2: | ∆HT,C (kJ/mol) 6 | |||

| 1 1 | 25 | –13.29 | 2.52 | –2750.33 | 1.39 | 22.87 |

| b0: | 103b1: | b2: | ∆HT,K-J (kJ/mol) 7 | |||

| 2 2 | 25 | 1.58 | 3.56 | –3033.85 | 1.53 | 25.23 |

| c0: | 103c1: | c2: | ∆Hvap(kJ/mol) 8 | |||

| 3 3 | 25 | 14.19 | 6.97 | –4701.20 | 3.25 | 39.08 |

| ∆Hsolv (kJ/mol) 9 | ||||||

| –15.03 | ||||||

- 1

- Chrastil model: ,

- 2

- K-J model: ,

- 3

- Bartle model: , where y* is the theoretical solubility; P is the pressure (MPa); Pref is 0.1 MPa; ρ is the density of the scCO2 (kg/m3); ρref is a reference density (700 kg/m3); T is the temperature (K); a0, a1, a2, b0, b1, b2, c0, c1, and c2 are the fitted parameters.

- 4

- Number of data points used in the correlation.

- 5

- Average absolute relative deviation. ,

- 6

- Total heat of solution obtained from the Chrastil model, ∆HT, C = −a2 × 8.314 J/mol-K.

- 7

- Total heat of solution obtained from the K-J model, ∆HT, K-J = −b2 × 8.314 J/mol-K.

- 8

- Heat of vaporization obtained from the Bartle model, ∆Hvap = −c2 × 8.314 J/mol-K.

- 9

- Heat of solvation, .

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wei, M.-C.; Wang, C.-S.; Wei, D.-H.; Yang, Y.-C. Insights into the Supercritical CO2 Extraction of Perilla Oil and Its Theoretical Solubility. Processes 2021, 9, 239. https://doi.org/10.3390/pr9020239

Wei M-C, Wang C-S, Wei D-H, Yang Y-C. Insights into the Supercritical CO2 Extraction of Perilla Oil and Its Theoretical Solubility. Processes. 2021; 9(2):239. https://doi.org/10.3390/pr9020239

Chicago/Turabian StyleWei, Ming-Chi, Chia-Sui Wang, Da-Hsiang Wei, and Yu-Chiao Yang. 2021. "Insights into the Supercritical CO2 Extraction of Perilla Oil and Its Theoretical Solubility" Processes 9, no. 2: 239. https://doi.org/10.3390/pr9020239

APA StyleWei, M.-C., Wang, C.-S., Wei, D.-H., & Yang, Y.-C. (2021). Insights into the Supercritical CO2 Extraction of Perilla Oil and Its Theoretical Solubility. Processes, 9(2), 239. https://doi.org/10.3390/pr9020239