Optimization of PCL Polymeric Films as Potential Matrices for the Loading of Alpha-Tocopherol by a Combination of Innovative Green Processes

Abstract

:1. Introduction

2. Materials, Equipment, and Methods

2.1. Materials

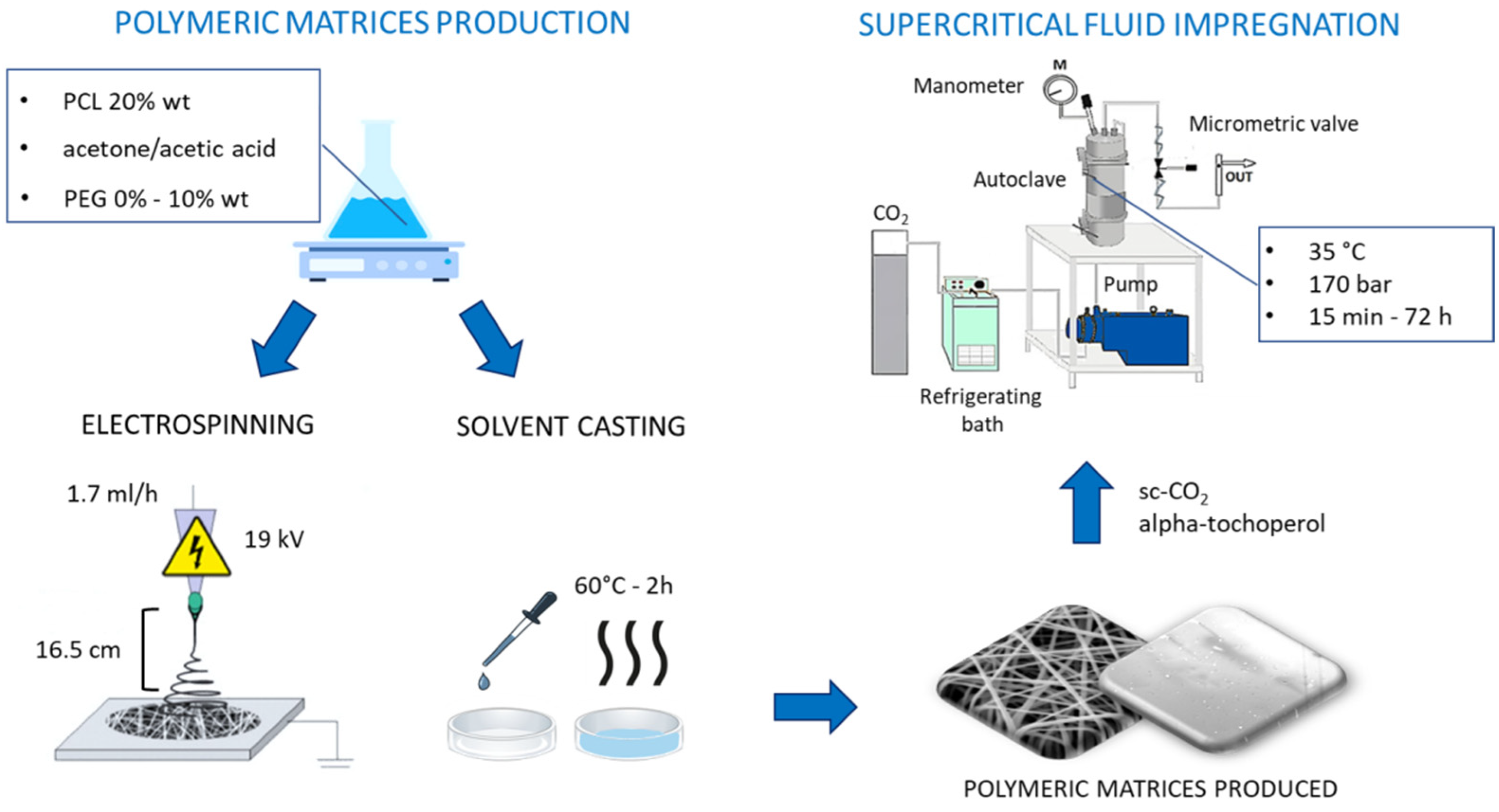

2.2. Production of PCL-Based Matrices

2.3. Supercritical Fluid Impregnation

2.4. Analytical Methods

3. Results

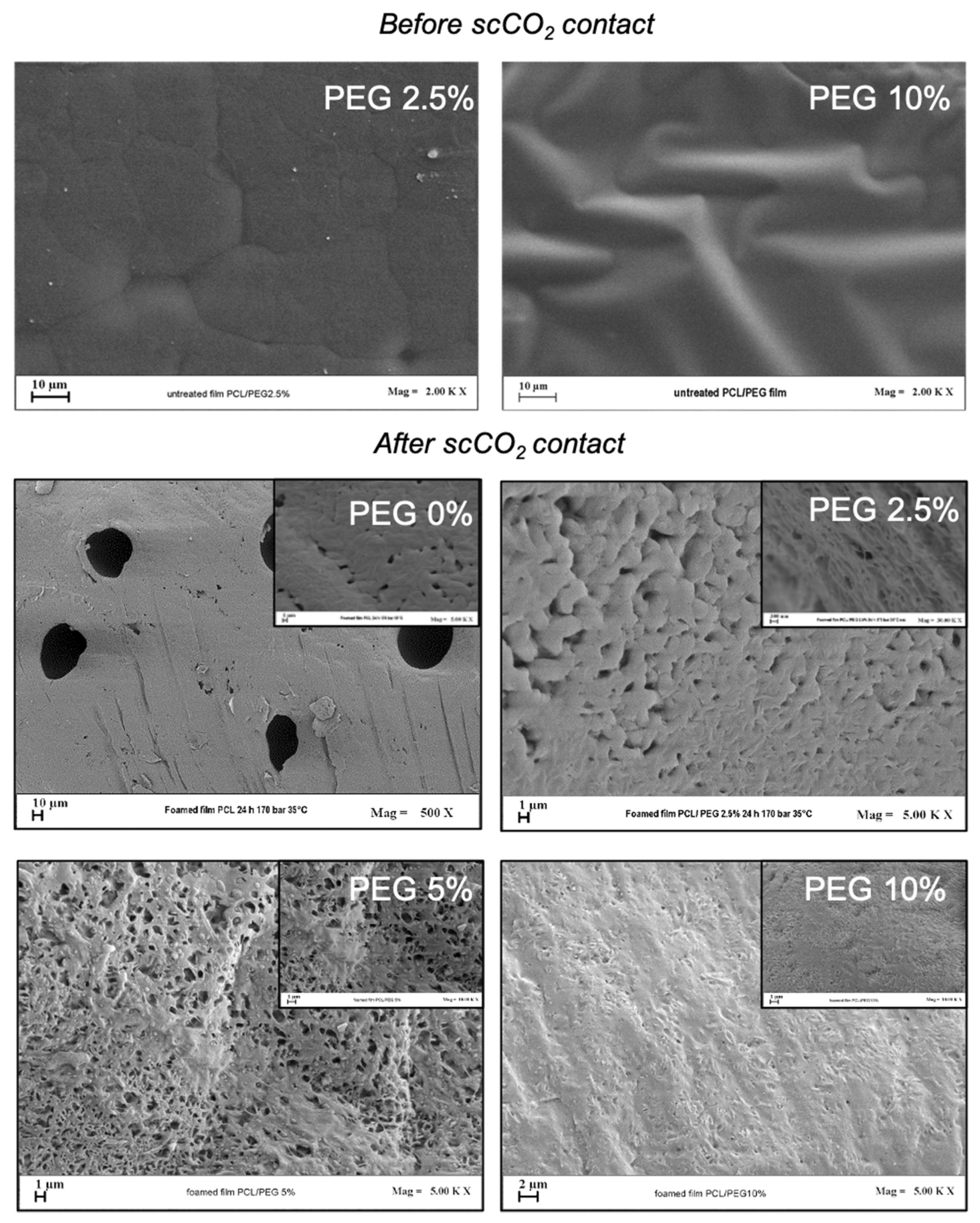

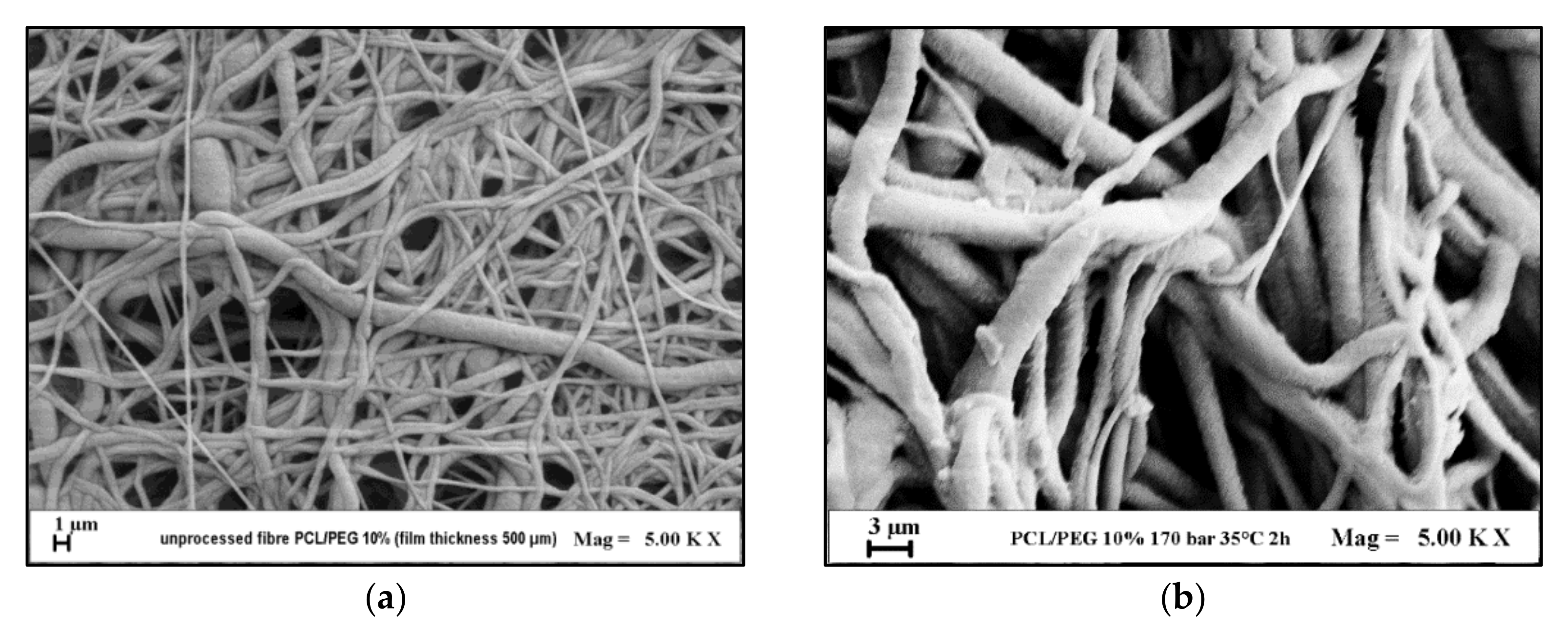

3.1. Feasibility Study of the SFI Process and PCL Supports Optimization

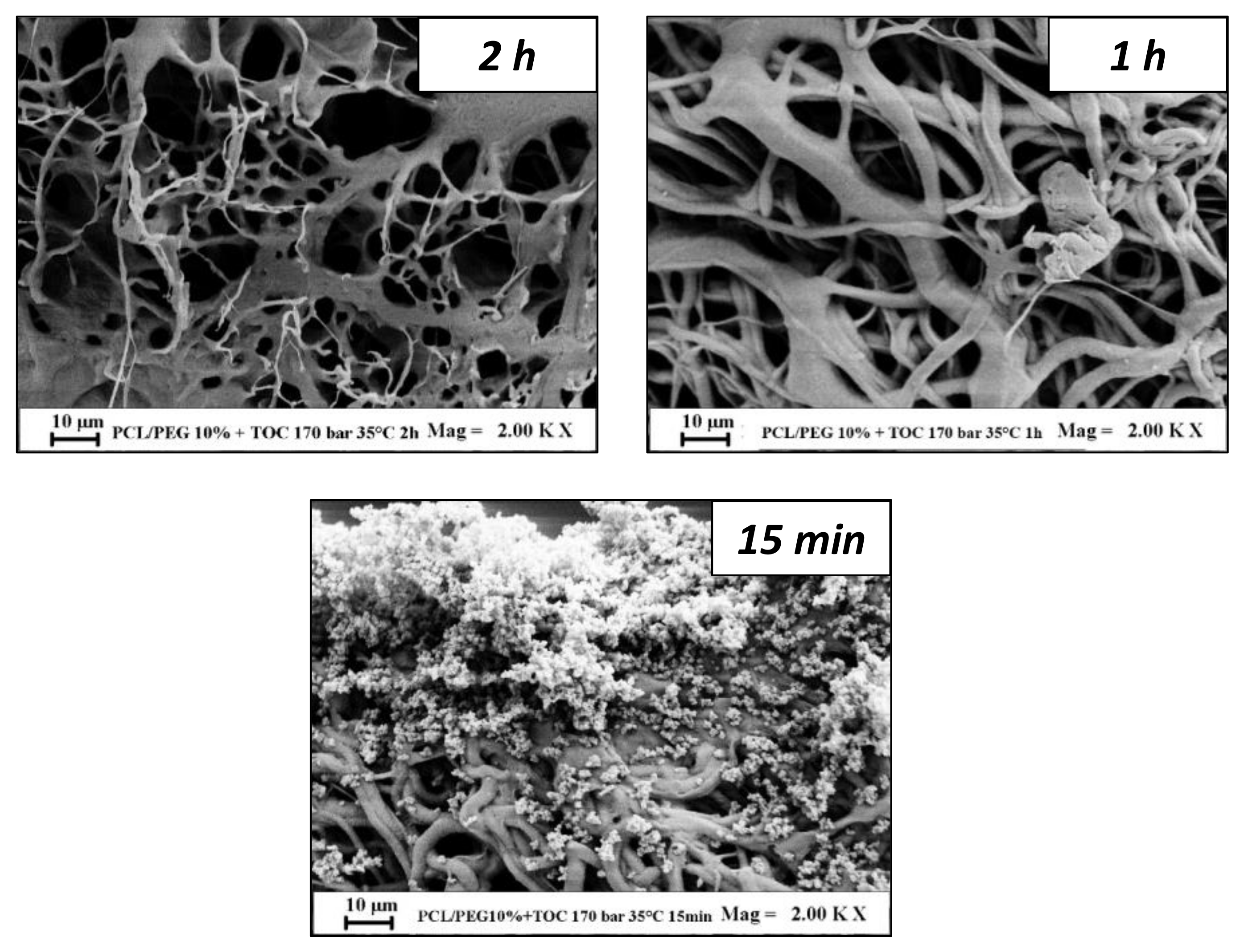

3.2. Loading of Alpha-Tocopherol and Study of the Supercritical Impregnation Kinetics Performed on the Optimized Supports

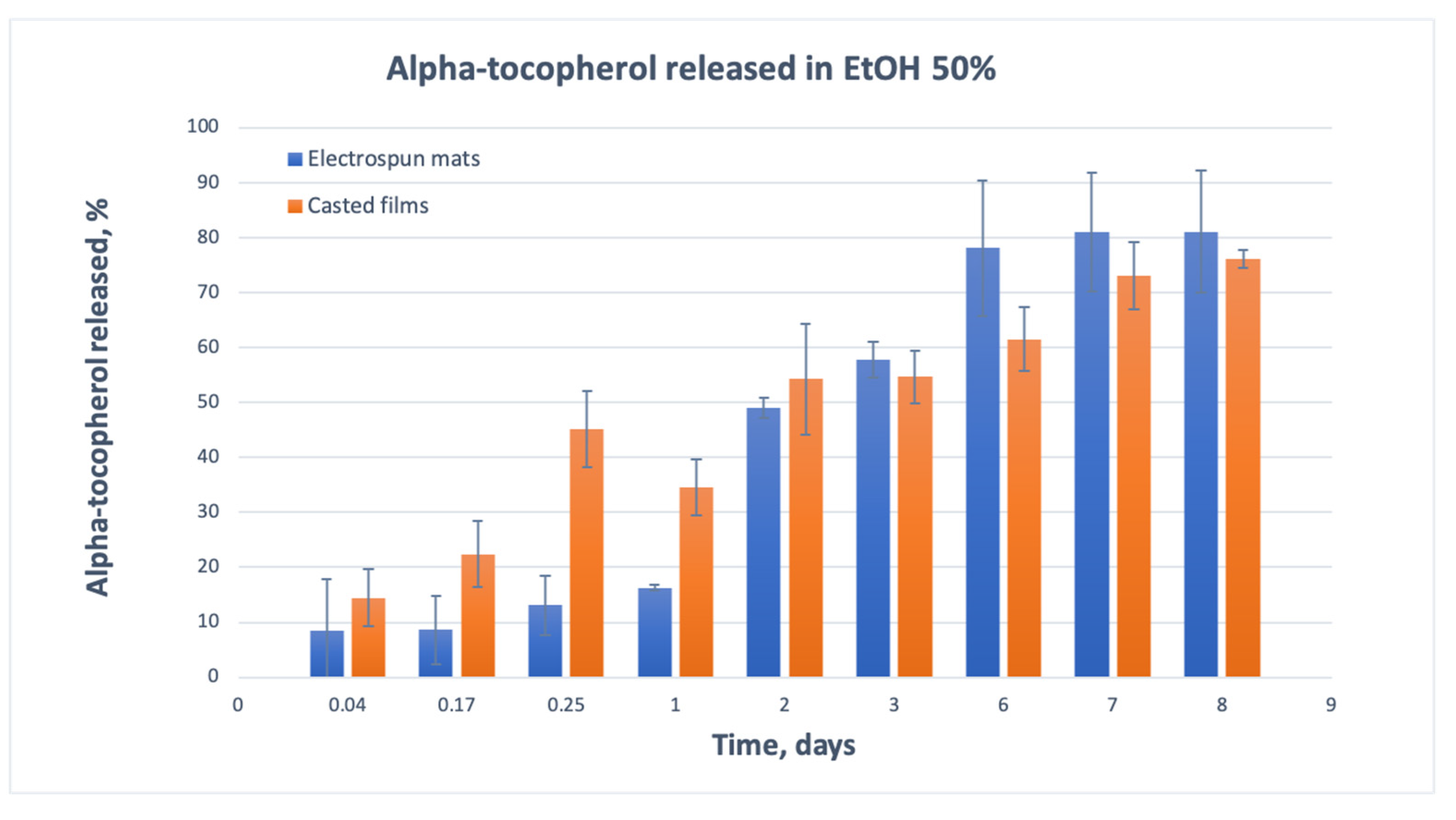

3.3. Migration Test of Alpha-Tocopherol into Fluid Simulant

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gowthaman, N.S.K.; Lim, H.N.; Sreeraj, T.R.; Amalraj, A.; Gopi, S. Advantages of biopolymers over synthetic polymers: Social, economic and environmental aspects. In Biopolymers and Their Industrial Applications; Elsevier: Amsterdam, The Netherlands, 2021; Volume 15, pp. 351–372. [Google Scholar] [CrossRef]

- Dey, A.; Dhumal, C.V.; Sengupta, P.; Kumar, A.; Pramanik, N.K.; Alam, T. Challenges and possible solutions to mitigate the problems of single-use plastics used for packaging food items: A review. J. Food Sci. Technol. 2021, 58, 3251–3269. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Awasthi, A.K.; Wei, F.; Tan, Q.; Li, J. Single-use plastics: Production, usage, disposal, and adverse impacts. Sci. Total Environ. 2021, 752, 141772. [Google Scholar] [CrossRef] [PubMed]

- George, A.; Sanjay, M.R.; Srisuk, R.; Parameswaranpillai, J.; Siengchin, S. A comprehensive review on chemical properties and applications of biopolymers and their composites. Int. J. Biol. Macromol. 2020, 154, 329–338. [Google Scholar] [CrossRef]

- Adeyeye, O.A.; Sadiku, E.R.; Reddy, A.B.; Ndamase, A.S.; Makgatho, G.; Sellamuthu, P.S.; Perumal, A.B.; Nambiar, R.B.; FasikuIdowu, V.O.; Ibrahim, I.D.; et al. The Use of Biopolymers in Food Packaging. In Green Biopolymers and Their Nanocomposites; Springer: Berlin/Heidelberg, Germany, 2019; pp. 137–158. [Google Scholar] [CrossRef]

- Porta, R.; Sabbah, M.; Di Pierro, P. Biopolymers as Food Packaging Materials. Int. J. Mol. Sci. 2020, 21, 4942. [Google Scholar] [CrossRef]

- Torres-Giner, S.; Figueroa-Lopez, K.J.; Melendez-Rodriguez, B.; Prieto, C.; Pardo-Figuerez, M.; Lagaron, J.M. Emerging Trends in Biopolymers for Food Packaging. Sustain. Food Packag. Technol. 2021, 1–33. [Google Scholar] [CrossRef]

- Lionetto, F.; Corcione, C.E. Recent Applications of Biopolymers Derived from Fish Industry Waste in Food Packaging. Polymers 2021, 13, 2337. [Google Scholar] [CrossRef]

- Calva-Estrada, S.J.; Jimènez-Fernàndez, M.; Lugo-Cervantes, E. Protein-Based Films: Advances in the Development of Biomaterials Applicable to Food Packaging. Food Eng. Rev. 2019, 11, 78–92. [Google Scholar] [CrossRef]

- Bilal, M.; Gul, I.; Basharat, A.; Qamar, S.A. Polysaccharides-based bio-nanostructures and their potential food applications. Int. J. Biol. Macromol. 2021, 176, 540–557. [Google Scholar] [CrossRef] [PubMed]

- Mantecón-Oria, M.; Diban, N.; Berciano, M.T.; Rivero, M.J.; David, O.; Lafarga, M.; Tapia, O.; Urtiaga, A. Hollow Fiber Membranes of PCL and PCL/Graphene as Scaffolds with Potential to Develop In Vitro Blood-Brain Barrier Models. Membranes 2020, 10, 161. [Google Scholar] [CrossRef]

- Fawal, G.E.; Hong, H.; Mo, X.; Wang, H. Fabrication of scaffold based on gelatin and polycaprolactone (PCL) for wound dressing application. J. Drug Deliv. Sci. Technol. 2021, 63, 102501. [Google Scholar] [CrossRef]

- Malikmammadov, E.; Tanir, T.E.; Kiziltay, A.; Hasirci, V.; Hasirci, N. PCL and PCL-based materials in biomedical applications. J. Biomater. Sci. Polym. Ed. 2018, 29, 863–893. [Google Scholar] [CrossRef]

- Dash, T.K.; Konkimalla, V.B. Polymeric Modification and Its Implication in Drug Delivery: Poly-ε-caprolactone (PCL) as a Model Polymer. Mol. Pharm. 2012, 9, 2365–2379. [Google Scholar] [CrossRef]

- Hadi, A.; Mahsa, J.O.; Ayda, S. A review on techniques utilized for design of controlled release food active packaging. Crit. Rev. Food Sci. Nutr. 2020, 1–21. [Google Scholar] [CrossRef]

- Firouz, M.S.; Mohi-Alden, K.; Omid, M. A critical review on intelligent and active packaging in the food industry: Research and development. Food Res. Int. 2021, 141, 110113. [Google Scholar] [CrossRef]

- Commission Regulation (EU). No. 10/2011 of 14 January 2011 on Plastic Materials and Articles Intended to Come into Contact with Food. Off. J. Eur. Union L 2011, 12, 1. [Google Scholar]

- Kanatt, S.R. Development of active/intelligent food packaging film containing Amaranthus leaf extract for shelf-life extension of chicken/fish during chilled storage. Food Packag. Shelf Life 2021, 24, 100506. [Google Scholar] [CrossRef]

- Moreirinha, C.; Vilela, C.; Silva, H.C.S.; Pinto, R.J.B.; Almeida, A.; Rocha, M.A.M.; Coelho, E.; Coimbra, M.A.; Silvestre, A.J.D.; Freire, C.S.R. Antioxidant and antimicrobial films based on brewers spent grain arabinoxylans, nanocellulose and feruloylated compounds for active packaging. Food Hydrocoll. 2020, 108, 105836. [Google Scholar] [CrossRef]

- Ibrahim, S.; Elsayed, H.; Hasanin, M. Biodegradable, Antimicrobial and Antioxidant Biofilm for Active Packaging Based on Extracted Gelatin and Lignocelluloses Biowastes. J. Polym. Environ. 2020, 29, 472–482. [Google Scholar] [CrossRef]

- Piri, H.; Moradi, S.; Amiri, R. The fabrication of a novel film based on polycaprolactone incorporated with chitosan and rutin: Potential as an antibacterial carrier for rainbow trout packaging. Food Sci. Biotechnol. 2021, 30, 683–690. [Google Scholar] [CrossRef] [PubMed]

- Uzunlu, S.; Niranjan, K. Laboratory antimicrobial activity of cinnamaldehyde and pomegranate-based polycaprolactone films. J. Appl. Polym. Sci. 2017, 134, 45347. [Google Scholar] [CrossRef]

- Sikora, J.; Majewski, L.; Puszka, A. Modern Biodegradable Plastics-Processing and Properties: Part I. Materials 2020, 13, 1986. [Google Scholar] [CrossRef] [PubMed]

- Bastarrachea, L.J.; Wong, D.E.; Roman, M.J.; Lin, Z.; Goddard, J.M. Active Packaging Coatings. Coatings 2015, 5, 771–791. [Google Scholar] [CrossRef]

- Zhang, C.; Li, Y.; Wang, P.; Zhang, H. Electrospinning of nanofibers: Potentials and perspectives for active food packaging. Compr. Rev. Food Sci. Food Saf. 2020, 19, 479–502. [Google Scholar] [CrossRef] [PubMed]

- Sameen, D.E.; Ahmed, S.; Lu, R.; Li, R.; Dai, J.; Qin, W.; Zhang, Q.; Li, S.; Liu, Y. Electrospun nanofibers food packaging: Trends and applications in food systems. Crit. Rev. Food Sci. Nutr. 2021, 1–14. [Google Scholar] [CrossRef] [PubMed]

- Luraghi, A.; Peri, F.; Moroni, L. Electrospinning for drug delivery applications: A review. J. Control Release 2021, 334, 463–484. [Google Scholar] [CrossRef] [PubMed]

- Pasha, H.Y.; Mohtasebi, S.S.; Tabatabaeekoloor, R.; Taherimehr, M.; Javadi, A.; Firous, M.S. Preparation and characterization of the plasticized polylactic acid films produced by the solvent-castin method for food packaging applications. J. Food Process. Preserv. 2021, e16089. [Google Scholar] [CrossRef]

- Peng, W.; Li, Y.; Zhang, C.; Que, F.; Weiss, J.; Zhang, H. Characterization and antioxidant activity of trilayer gelatin/dextran-propyl gallate/gelatin films: Electrospinning versus solvent casting. LWT 2020, 128, 109536. [Google Scholar] [CrossRef]

- Tampau, A.; Gonzalez-Martinez, C.; Chiralt, A. Polylactic acid-based materials encapsulating carvacrol obtained by solvent casting and electrospinning. J. Food Sci. 2020, 85, 1177–1185. [Google Scholar] [CrossRef] [PubMed]

- Drago, E.; Franco, P.; Campardelli, R.; De Marco, I. Zein electrospun fibers purification and vanillin impregnation in a one-step supercritical process to produce safe active packaging. Food Hydrocoll. 2022, 122, 107082. [Google Scholar] [CrossRef]

- Franco, P.; Incarnato, L.; De Marco, I. Supercritical CO2 impregnation of α-tocopherol into PET/PP films for active packaging applications. J. CO2 Util. 2019, 34, 266–273. [Google Scholar] [CrossRef]

- Mosquera, J.E.; Goñi, M.L.; Martini, R.E.; Gañàn, N.A. Mass transfer kinetics of CO2 and eugenol in the supercritical impregnation of polyamide fibers: Experimental data and modeling. J. Supercrit. Fluid. 2020, 166, 105030. [Google Scholar] [CrossRef]

- Bastante, C.C.; Silva, H.C.S.; Cardoso, L.C.; Serrano, C.M.; Martinez de la Ossa, E.J.; Freire, C.S.R.; Vilela, C. Biobased films of nanocellulose and mango leaf extract for active food packaging: Supercritical impregnation versus solvent casting. Food Hydrocoll. 2021, 117, 106709. [Google Scholar] [CrossRef]

- Champeau, M.; Thomassin, J.-M.; Tassaing, T.; Jérome, C. Drug loading of polymer implants by supercritical CO2 assisted impregnation: A review. J. Control Release 2015, 209, 248–259. [Google Scholar] [CrossRef]

- Yoganathan, R.; Mammucari, R.; Foster, N.R. Impregnation of Ibuprofen into Polycaprolactone Using Supercritical Carbon Dioxide. J. Phys. Conf. Ser. 2010, 215, 012087. [Google Scholar] [CrossRef]

- Campardelli, R.; Franco, P.; Reverchon, E.; De Marco, I. Polycaprolactone/nimesulide patches obtained by a one-step supercritical foaming + impregnation process. J. Supercrit. Fluid. 2019, 146, 47–54. [Google Scholar] [CrossRef]

- Liparoti, S.; Franco, P.; Pantani, R.; De Marco, I. Supercritical CO2 impregnation of caffeine in biopolymer films to produce anti-cellulite devices. J. Supercrit. Fluids 2022, 179, 105411. [Google Scholar] [CrossRef]

- Yañez, F.; Martikainen, L.; Braga, M.E.M.; Alvarez-Lorenzo, C.; Concheiro, A.; Duarte, C.M.M.; Gil, M.H.; De Sousa, H.C. Supercritical fluid-assisted preparation of imprinted contact lenses for drug delivery. Acta Biomater. 2011, 7, 1019–1030. [Google Scholar] [CrossRef] [PubMed]

- Shen, Z.; Huvard, G.S.; Warriner, C.; Mc Hugh, M.; Banyasz, J.L.; Mishra, M.K. CO2-assisted fiber impregnation. Polymers 2008, 49, 1579–1586. [Google Scholar] [CrossRef]

- Hussain, Y.; Grant, C.S. Ibuprofen impregnation into submicron polymeric films in supercritical carbon dioxide. J. Supercrit. Fluids 2012, 71, 127–135. [Google Scholar] [CrossRef]

- Natu, M.V.; Gil, M.H.; De Sousa, H.C. Supercritical solvent impregnation of poly(ε-caprolactone)/poly(oxyethylene-b-oxypropylene-b-oxyethylene) and poly(ε-caprolactone)/poly(ethylene-vinyl acetate) blends for controlled release applications. J. Supercrit. Fluids 2008, 47, 93–102. [Google Scholar] [CrossRef] [Green Version]

- Garcia-Casas, I.; Montes, A.; Valor, D.; Pereyra, C.; Martinez de la Ossa, E.J. Foaming of Polycaprolactone and Its Impregnation with Quercetin Using Supercritical CO2. Polymers 2019, 11, 1390. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gaikwad, K.K.; Singh, S.; Ajji, A. Moisture absorbers for food packaging applications. Environ. Chem. Lett. 2019, 17, 609–628. [Google Scholar] [CrossRef]

- Dumitriu, R.P.; Stoleru, E.; Mitchell, G.R.; Vasile, C.; Brebu, M. Bioactive Electrospun Fibers of Poly(ε-Caprolactone) Incorporating α-Tocopherol for Food Packaging Applications. Molecules 2021, 26, 5498. [Google Scholar] [CrossRef] [PubMed]

- Raza, Z.A.; Abid, S.; Azam, A.; Rehman, A. Synthesis of alpha-tocopherol encapsulated chitosan nano-assemblies and their impregnation on cellulosic fabric for potential antibacterial and antioxidant cosmetotextiles. Cellulose 2020, 27, 1717–1731. [Google Scholar] [CrossRef]

- Hwang, S.W.; Shim, J.K.; Selke, S.E.M.; Soto-Valdez, H.; Matuana, L.; Rubino, M.; Auras, R. Poly(L-lactic acid) with added α-tocopherol and resveratrol: Optical, physical, thermal and mechanical properties. Polym. Int. 2012, 61, 418–425. [Google Scholar] [CrossRef]

- Jamshidian, M.; Tehrany, E.A.; Imran, M.; Akhtar, M.J.; Cleymand, F.; Desobry, S. Structural, mechanical and barrier properties of active PLA-antioxidant films. J. Food Eng. 2012, 110, 380–389. [Google Scholar] [CrossRef]

| Thickness (µm) | % PEG | Contact Time (h) | Macroscopic Aspect | Formation of Pores |

|---|---|---|---|---|

| ELECTROSPUN SUPPORTS | ||||

| <100 | 0–2.5–5–10 | 15 min–72 h | Nonintact structure | yes |

| >100 | 0–2.5–5 | <2 h | Nonintact structure | yes |

| >100 | 5–10 | <2 h | Intact structure | yes |

| SOLVENT CASTING SUPPORTS | ||||

| <100 | 0–2.5–5–10 | 15 min–72 h | Nonintact structure | yes |

| >100 | 0 | <24 h | Nonintact structure | yes |

| >100 | 2.5–5 | <24 h | Semi-intact structure | yes |

| >100 | 10 | <24 h | Intact structure | no |

| PEG Content (%) | Pore Size (μm) | Standard Deviation (μm) |

|---|---|---|

| 0 | 1.22 | 0.28 |

| 2.5 | 0.85 | 0.22 |

| 5 | 0.46 | 0.09 |

| 10 | 0.15 | 0.04 |

| % PEG | Alpha-Tocopherol Impregnated (mgTOC/mgFILM) | Effect |

|---|---|---|

| 0 | 1.234 | Higher impregnation but a significant modification of the structure |

| 2.5 | 0.998 | Impregnation and foaming |

| 5 | 0.959 | Impregnation and foaming |

| 10 | 0.828 | Lower impregnation but preservation of the structure |

| Impregnation Time | Alpha-Tocopherol Impregnated (mgTOC/mgFILM) |

|---|---|

| PCL + PEG 10% CASTING FILMS | |

| 2 h | 0.25 |

| 6 h | 0.40 |

| 15 h | 0.67 |

| 24 h | 0.82 |

| PCL + PEG 10% ELECTROSPUN FILMS | |

| 15 min | 0.17 |

| 1 h | 0.31 |

| 2 h | 0.64 |

| Conditions | Electrospun Films | Casted Films |

|---|---|---|

| Thickness (µm) | >100 | >100 |

| PEG content % | 10 | 10 |

| Impregnation time [h] | <2 | <24 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Drago, E.; Campardelli, R.; Marco, I.D.; Perego, P. Optimization of PCL Polymeric Films as Potential Matrices for the Loading of Alpha-Tocopherol by a Combination of Innovative Green Processes. Processes 2021, 9, 2244. https://doi.org/10.3390/pr9122244

Drago E, Campardelli R, Marco ID, Perego P. Optimization of PCL Polymeric Films as Potential Matrices for the Loading of Alpha-Tocopherol by a Combination of Innovative Green Processes. Processes. 2021; 9(12):2244. https://doi.org/10.3390/pr9122244

Chicago/Turabian StyleDrago, Emanuela, Roberta Campardelli, Iolanda De Marco, and Patrizia Perego. 2021. "Optimization of PCL Polymeric Films as Potential Matrices for the Loading of Alpha-Tocopherol by a Combination of Innovative Green Processes" Processes 9, no. 12: 2244. https://doi.org/10.3390/pr9122244

APA StyleDrago, E., Campardelli, R., Marco, I. D., & Perego, P. (2021). Optimization of PCL Polymeric Films as Potential Matrices for the Loading of Alpha-Tocopherol by a Combination of Innovative Green Processes. Processes, 9(12), 2244. https://doi.org/10.3390/pr9122244