Oscillating Combustion—Primary Measure to Reduce Nitrogen Oxide in a Grate Furnace–Experiments and Simulations

Abstract

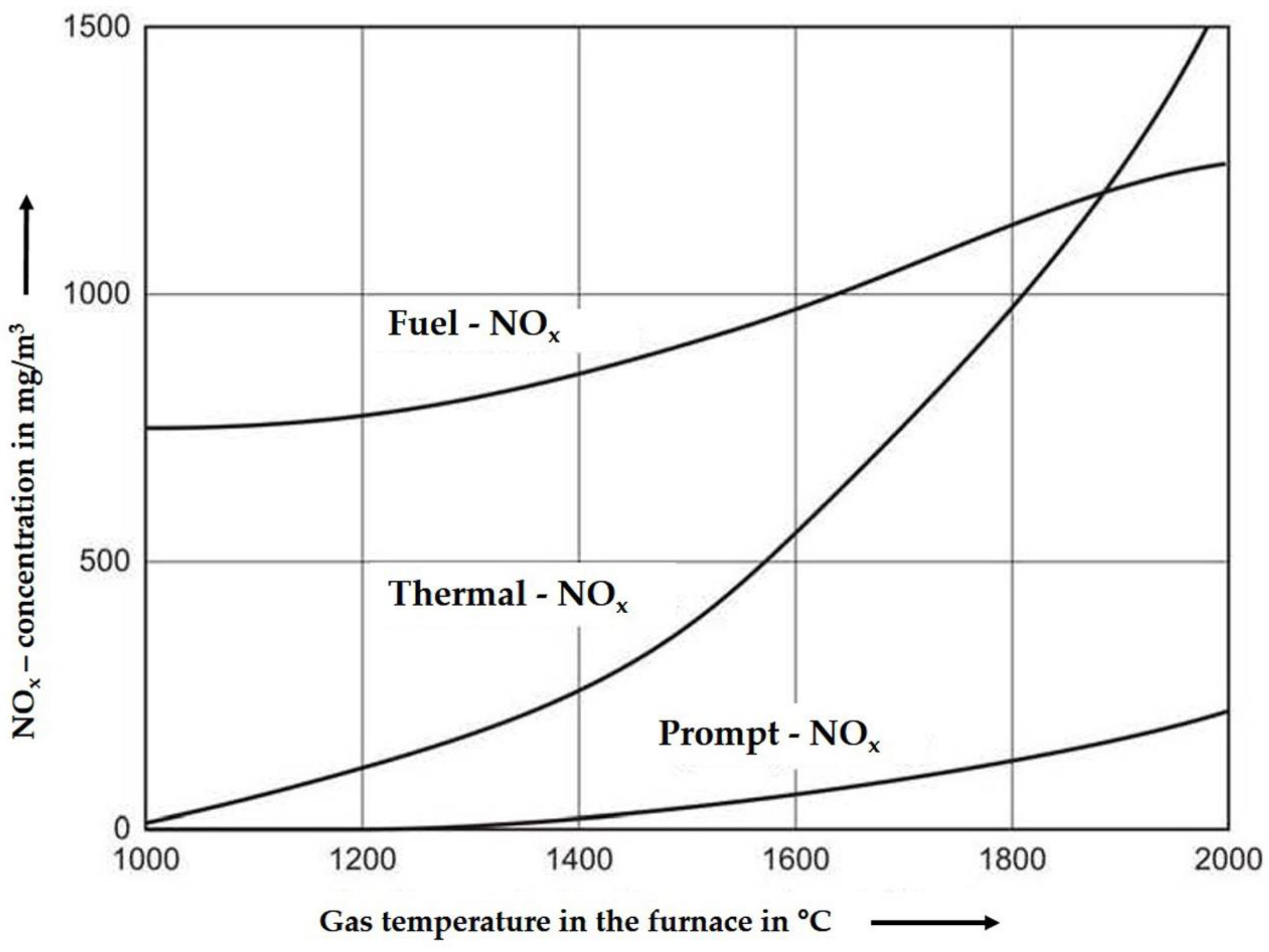

:1. Introduction

2. Oscillating Combustion

3. Materials and Methods

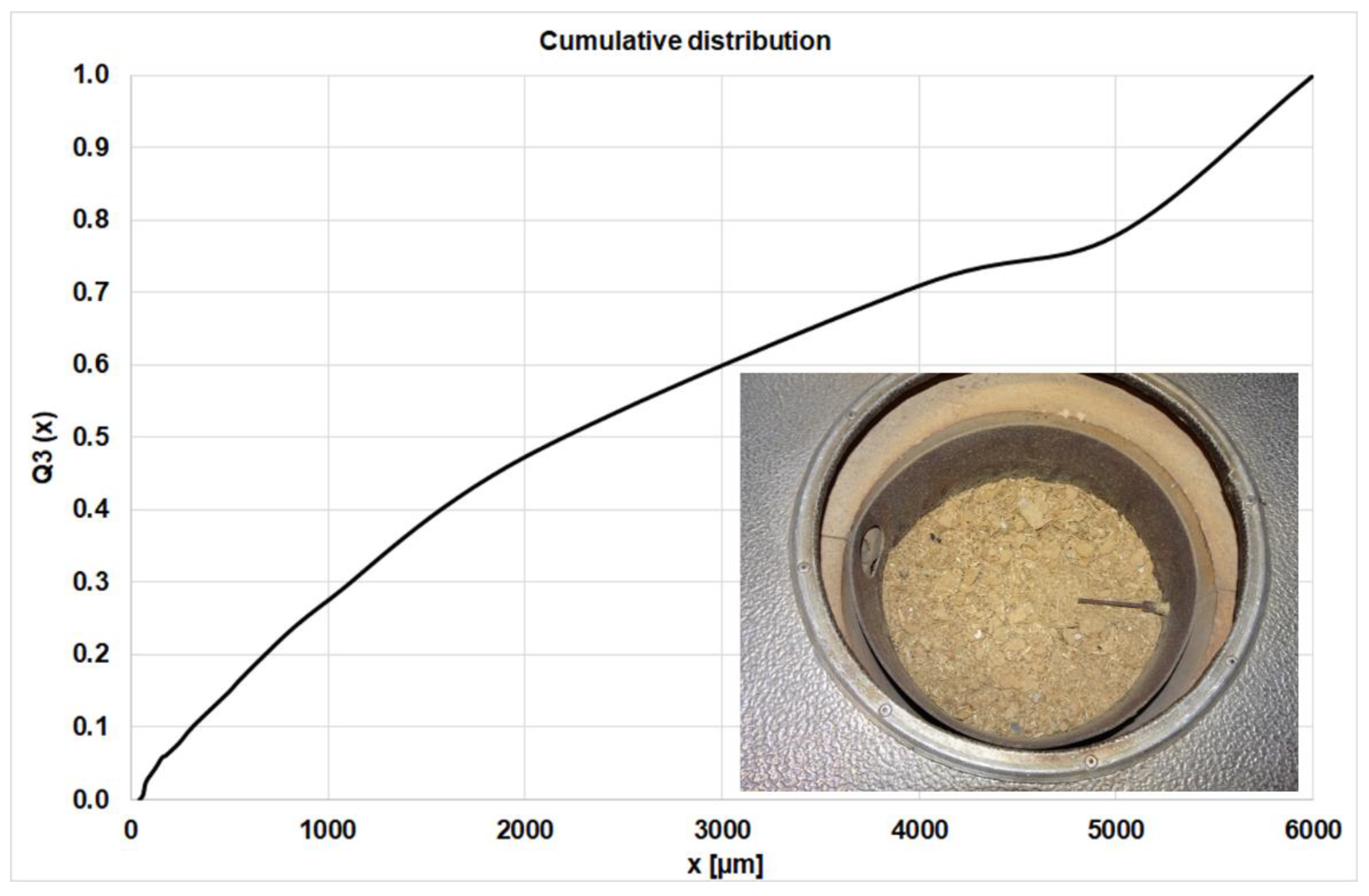

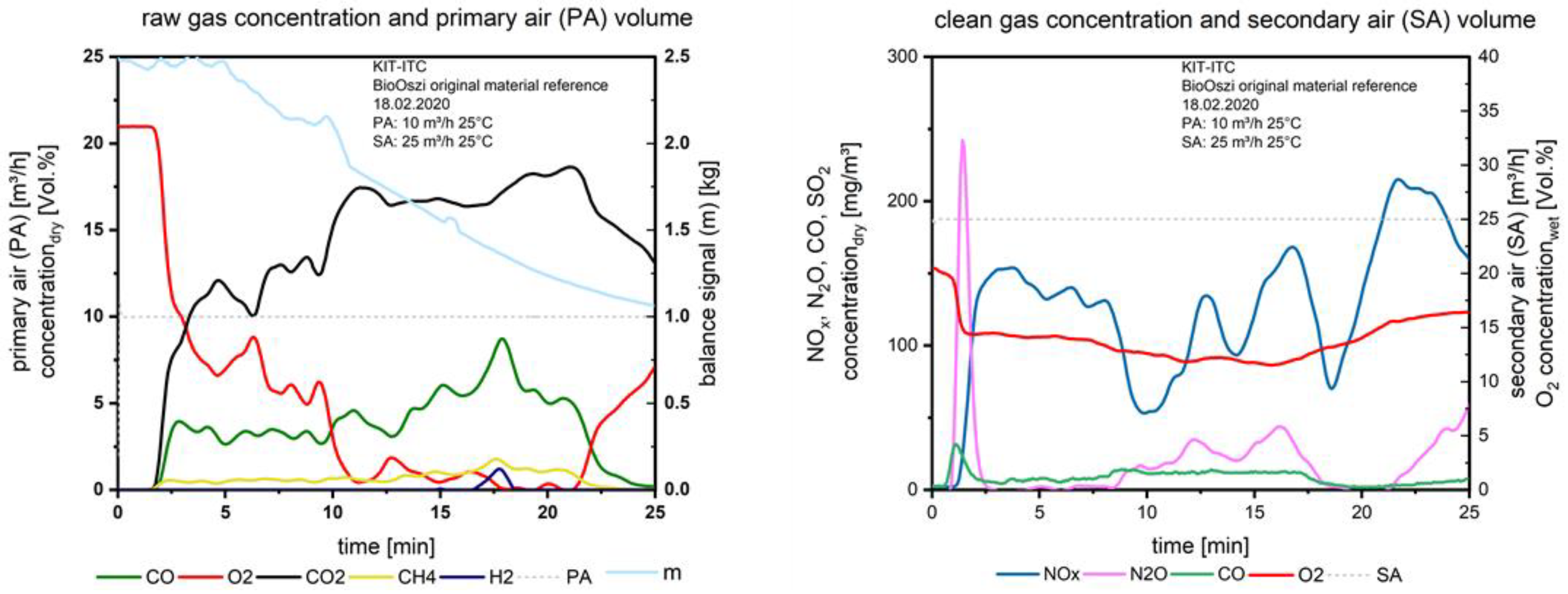

3.1. Experimental Approach

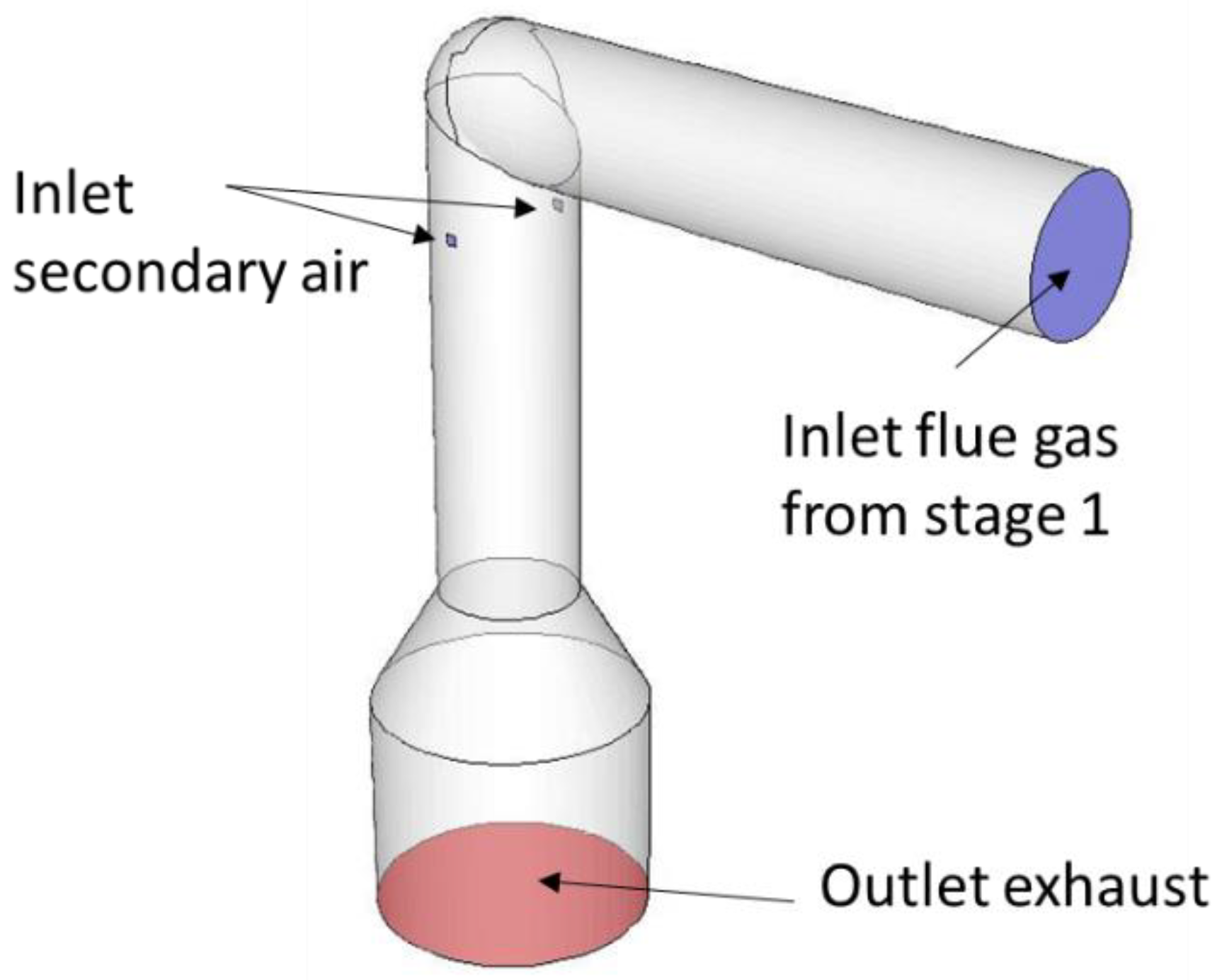

3.2. Numerical Approach

3.2.1. Numerical Mesh and Modeling Approach

3.2.2. Turbulent Flow Modeling and Solver Parameter

3.2.3. Radiation Model

3.2.4. Combustion and NOx Model

3.2.5. Boundary Conditions

3.2.6. Simulation Procedure

4. Results

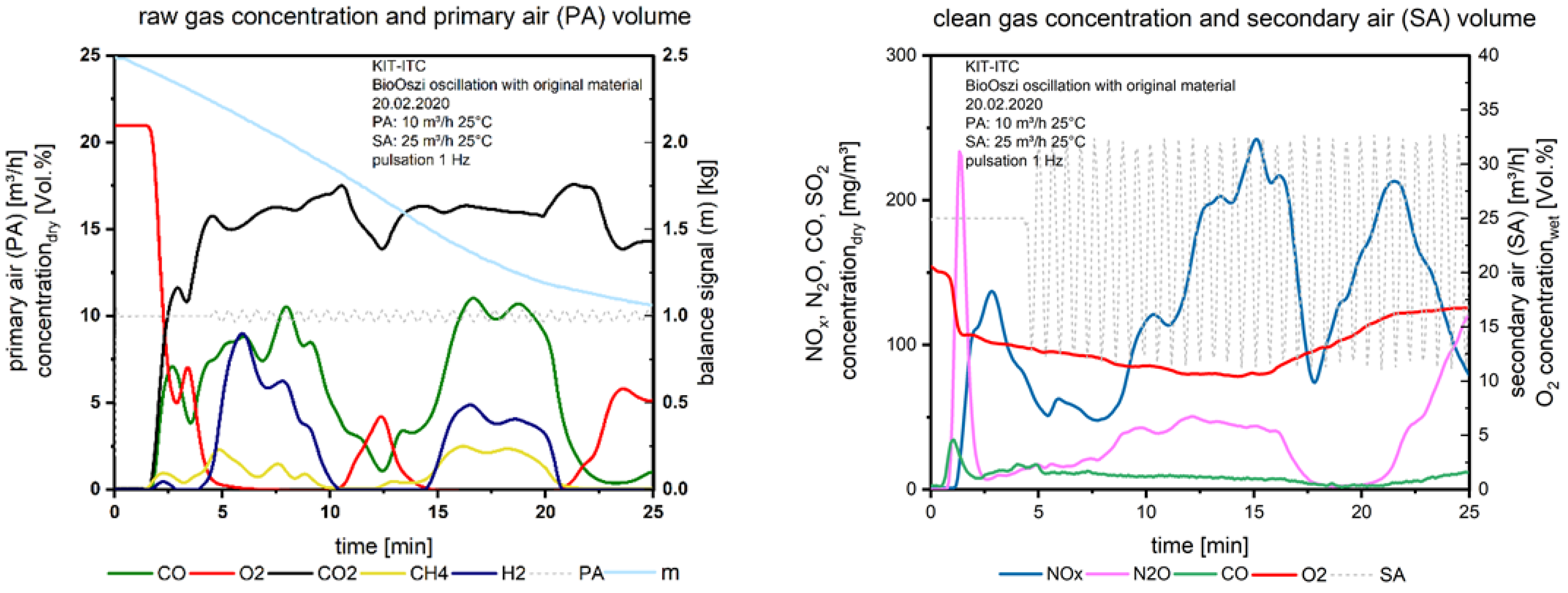

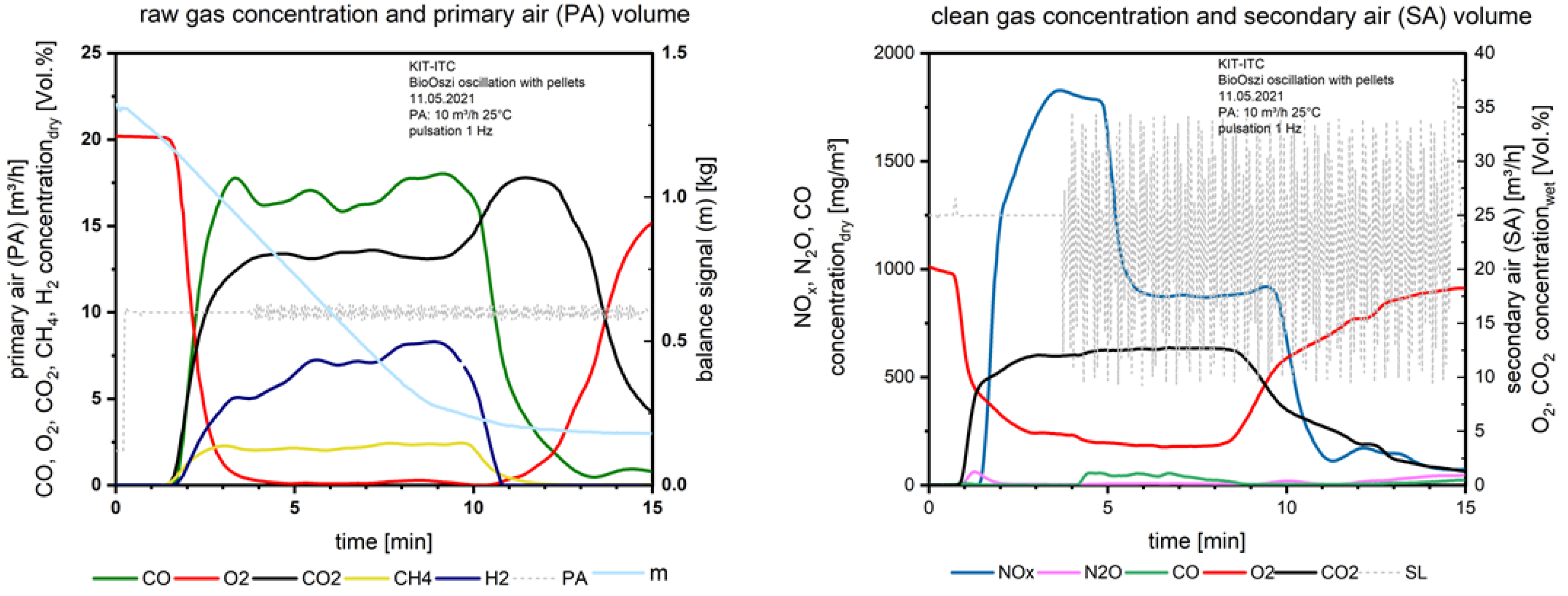

4.1. Experiments

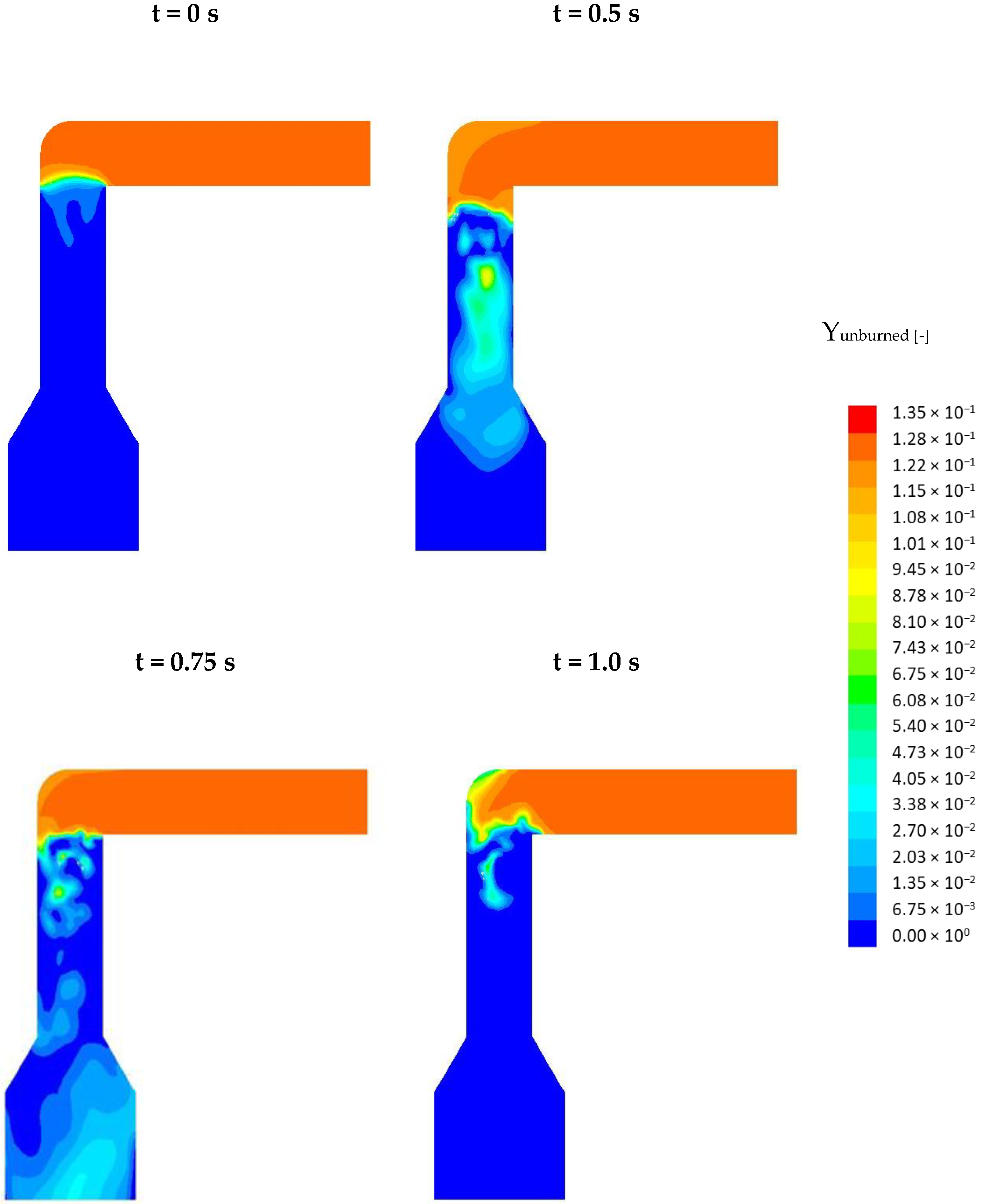

4.2. Simulations

- (a)

- the size of the reduction zone,

- (b)

- the residence time in the reduction zone and

- (c)

- the stoichiometry inside the reduction zone.

5. Conclusions

6. Discussion/Outlook

7. Patents

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Available online: https://www.delphi.com/sites/default/files/2020-04/DELPHI%20booklet%20emission%20passenger%20cars%202020%20online%20complet.pdf (accessed on 7 December 2021).

- Koger, S. Reaktionskinetische Untersuchungen zur Umwandlung stickstoffhaltiger Gaskomponenten unter Bedingungen der Abfallverbrennung; KIT Scientific Publishing: Karlsruhe, Germany, 2010. [Google Scholar]

- The Medium Combustion Plant Directive. Available online: https://ec.europa.eu/environment/industry/stationary/mcp.htm (accessed on 6 December 2021).

- Jolibois, N.; Aleksandrov, K.; Hauser, M.; Stapf, D.; Seifert, H.; Matthes, J.; Waibel, P.; Vogelbacher, M.; Keller, H.B.; Gehrmann, H.-J. Analysis of Oscillating Combustion for NOx Reduction in Pulverized Fuel Boilers. Inventions 2021, 6, 9. [Google Scholar] [CrossRef]

- Freudenmann, T.; Gehrmann, H.-J.; Aleksandrov, K.; El-Haji, M.; Stapf, D. Hybrid Models for Efficient Control, Optimization, and Monitoring of Thermo-Chemical Processes and Plants. Processes 2021, 9, 515. [Google Scholar] [CrossRef]

- Stapf, D. Experimentell basierte Weiterentwicklung von Berechnungsmodellen der NOx-Emission technischer Verbrennungssysteme. In Fortschrittsberichte VDI. 1998; VDI-Verlag: Düsseldorf, Germany, 1998. [Google Scholar]

- Miller, J.A.; Bowman, C.T. Mechanism and modeling of nitrogen chemistry in combustion. Prog. Energy Combust. Sci. 1989, 15, 287–338. [Google Scholar] [CrossRef]

- Beckmann, M. Beschreibung Unterschiedlicher Techniken und deren Entwicklungspotentiale zur Minderung von Stickstoffoxiden im Abgas von Abfallverbrennungsanlagen. und Ersatzbrennstoff-Kraftwerken Hinsichtlich Leistungsfähigkeit, Kosten und Energieverbrauch, Dessau-Roßlau, 2011. Available online: https://www.umweltbundesamt.de/publikationen/beschreibung-unterschiedlicher-techniken-deren (accessed on 6 December 2021).

- Gehrmann, H.-J.; Baris, D.; Stapf, D.; Seifert, H.; Zorbach, I. Stickoxidminderung durch oszillatorische Verbrennung bei der Rostfeuerung. Energ. Aus Abfall Bd. 2018, 15, 243–253. [Google Scholar]

- Freudenmann, T.; Gehrmann, H.-J.; El-Haji, M.; Stapf, D. Hybridmodelle zur effizienten Regelung, Optimierung und Überwachung von thermo-chemischen Prozessen und Anlagen am Beispiel der oszillierenden Verbrennung. In Proceedings of the 29 Deutscher Flammentag, 29 Deutscher Flammentag, Bochum, Germany, 17–18 September 2019. [Google Scholar]

- Cho, H.; Cho, K.W.; Kim, H.J. NOx Emission Characteristics in Radiant Tube Burner with Oscillating Combustion Technology. Trans. Korean Soc. Mech. Eng. B 2008, 32, 100–106. [Google Scholar] [CrossRef]

- Scherello, A.; Konold, U.; Flamme, M.; Kremer, H. Experimentelle Untersuchung zum Einfluss der oszillierenden Verbrennung auf die Wärmeübertragung und die Stickoxidemissionen vom Gasflammen; Final Report af an AiF-Project; Gaswärme-Institut: Essen, Germany, 2002. [Google Scholar]

- Wagner, J.C. NOx Emission Reduction by Oscillating Combustion. Final Report GTI Project No. 61111; Gas Technology Institute: Des Plaines, IL, USA, 2004. [Google Scholar]

- Mätzing, H.; Gehrmann, H.-J.; Seifert, H.; Stapf, D. Modelling grate combustion of biomass and low rank fuels with CFD application. Waste Manag. 2018, 78, 686–697. [Google Scholar] [CrossRef] [PubMed]

- Gehrmann, H.-J.; Mätzing, H.; Nowak, P.; Baris, D.; Seifert, H.; Dupont, C.; Defoort, F.; Peyrot, M.; Castagno, F. Waste wood characterization and combustion behaviour in pilot lab scale. J. Energy Inst. 2020, 93, 1634–1641. [Google Scholar] [CrossRef]

- Ansys® Fluent, Release 17.2, Ansys Fluent Theory Guide; ANSYS, Inc.: Canonsburg, PA, USA, 2016.

- Peters, N. Laminar Flamelet Concepts in Turbulent Combustion. Combust. Inst. 1986, 21, 1231–1250. [Google Scholar] [CrossRef]

- Peters, N. Laminar Diffusion Flamelet Models in Non Premixed Combustion. Prog. Energy Combust. Sci. 1984, 10, 319–339. [Google Scholar] [CrossRef]

- Bray, K.N.; Peters, N. Laminar Flamelets in Turbulent Flames. In Turbulent Reacting Flows; Libby, P.A., Williams, F.A., Eds.; Elsevier Academic Press: Amsterdam, The Netherlands, 1994; pp. 63–114. [Google Scholar]

- Magnussen, B.F. On the Structure of Turbulence and a Generalized Eddy Dissipation Concept for Chemical Reaction in Turbulent Flow. In Proceedings of the Nineteenth AIAA Meeting, St. Louise, MO, USA, 12–15 January 1981. [Google Scholar]

- Pope, S.B. Computationally efficient implementation of combustion chemistry using in-situ adaptive tabulation. Combust. Theory Model. 1997, 1, 41–63. [Google Scholar] [CrossRef]

- Buchmayr, M.; Gruber, J.; Hargassner, M.; Hochenauer, C. Performance analysis of a steady flamelet model for the use in small-scale biomass combustion under extreme air-staged conditions. J. Energy Inst. 2017, 91, 534–548. [Google Scholar] [CrossRef]

- De Soete, G.G. Overall Reaction Rates of NO and N2 Formation from Fuel Nitrogen. In Proceedings of the 15th Symp. (Int’I.) on Combustion, Tokyo, Japan, 25–31 August 1974. [Google Scholar]

- Brink, A.; Kilpinen, P. A Simplified Kinetic Rate Expression for Describing the Oxidation of Fuel-N in Biomass Combustion; Report 00-10; Process Chemistry Group: Abo Akademi, Finland, 2000. [Google Scholar]

- Mitchell, J.W.; Tarbell, J.M. A Kinetic Model of Nitric Oxide Formation During Pulverized Coal Combustion. AIChE J. 1982, 28, 302–311. [Google Scholar] [CrossRef]

- Glarborg, P.; Miller, J.A.; Ruscic, B.; Klippenstein, S.J. Modeling nitrogen chemistry in combustion. Prog. Energy Combust. Sci. 2018, 67, 31–68. [Google Scholar] [CrossRef] [Green Version]

- Kilpinen, P. Detailed Kinetic Scheme “Kilpinen 97”; Åbo Akademi University-PCG: Turku, Finland, 1997. [Google Scholar]

- Smith, G.P.; Golden, D.M.; Frenklach, M.; Moriarty, N.W.; Eiteneer, B.; Goldenberg, M.; Bowman, C.T.; Hanson, R.K.; Song, S.; Gardiner, W.C., Jr.; et al. Available online: http://combustion.berkeley.edu/gri-mech/version30/text30.html (accessed on 24 November 2021).

- Li, T.; Skreiberg, O.; Lovas, T.; Glarborg, P. Skeletal mechanisms for prediction of NOx emission in solid fuel combustion. Fuel 2019, 254, 115569. [Google Scholar] [CrossRef]

- Goodwin, D.G.; Speth, R.L.; Moffat, H.K.; Weber, B.W. Cantera: An Object-Oriented Software Toolkit for Chemical Kinetics, Thermodynamics, and Transport Processes. Version 2.4. 2021. Available online: https://www.cantera.org (accessed on 2 December 2021).

- Stubenberger, G.; Scharler, R.; Zahirovic, S.; Obernberger, I. Experimental investigation of nitrogen species release from different solid biomass fuels as a basis for release models. Fuel 2008, 87, 793–806. [Google Scholar] [CrossRef]

- Bui-Pham, M.; Seshadri, K. Comparison between experimental measurements and numerical calculations of the structure of heptane-air diffusion flames. Combust. Sci. Technol. 1991, 79, 293–310. [Google Scholar] [CrossRef]

- Pang, K.M.; Ng, H.K.; Gan, S. In-cylinder diesel spray combustion simulations using parallel computation: A performance benchmarking study. Appl. Energy 2012, 93, 466–478. [Google Scholar] [CrossRef]

- Stickoxidminderung bei der Oszillierenden Verbrennung von Ammoniak als Kohlenstofffreiem Energieträger. Available online: https://www.gwiessen.de/fileadmin/dateien/pdf/Forschung/Steckbriefe_lfd._Projekte/Jahr_2021/Projektsteckbrief_AmOszi.pdf (accessed on 6 December 2021).

- BioOszi Reduction of NOx-Emissions in Small Combustion Plants for Energetic Utilization of Biomass via Oscillating Combustion Air Supply. Available online: https://www.itc.kit.edu/downloads/BioOszi_Steckbrief_en_01022019.pdf (accessed on 6 December 2021).

| Test | Fuel | Primary Air | Secondary Air | Frequency Secondary Air [Hz] |

|---|---|---|---|---|

| test ww1 | Waste wood (ww) | 10 m3/h | 25 m3/h | 0 |

| test ww2 | 1 | |||

| pellet 1 | Pellets from waste wood (length 10 mm; Ø 6 mm) | 0 | ||

| pellet 2 | 1 |

| wt.-% | Waste Wood (ww) | Pellets from Waste Wood |

|---|---|---|

| water | 5.20 | 3.10 |

| ash | 1.10 | 1.12 |

| volatiles | 76.40 | 78.09 |

| char | 18.30 | 18.71 |

| fixed carbon Cfix | 17.20 | 17.58 |

| C | 46.90 | 47.94 |

| H | 5.78 | 5.91 |

| N | 4.00 | 4.09 |

| oxygen by diffrence Odiff | 36.83 | 37.65 |

| total—S | 0.03 | 0.03 |

| total—Cl | 0.16 | 0.17 |

| sum | 100.00 | 100.00 |

| bulk density [kg/m3] | 250 | 130 |

| lower heating value [Mj/kg] | 17.2 | 17.8 |

| Species * | Pellet1 (0 Hz) | Pellet2 (1 Hz) | Simulation (above Fuel Bed) | Simulation (Pcc Inlet) |

|---|---|---|---|---|

| CO | 14.07 | 16.87 | 14.07 | 12.20 |

| H2 | 7.90 | 6.73 | 7.89 | 6.85 |

| CH4 | 1.52 | 2.24 | 1.52 | 1.31 |

| CO2 | 14.82 | 13.31 | 14.8 | 12.84 |

| O2 | 0.01 | 0.16 | 0.01 | 8.67 × 10−3 |

| NO | Not measured | 640 | 220.84 | |

| NH3 | 6021 | 4139 | 5080 | 4255.06 |

| HCN | 66 | 247 | 157 | 145.14 |

| mFuel [kg/s] | 0.0015 | 0.0019 | 0.0015 | 0.0015 |

| Species | Unit | Simulation: Steady-State | Experimental Pellet1 (2021) |

|---|---|---|---|

| NOx | mg/m3-dry (11%-O2) | 1479.06 | 1006.23 |

| N2O | mg/m3-dry (11%-O2) | 4.33 | 9.87 |

| CO | mg/m3-dry (11%-O2) | 1.00 | 4.71 |

| O2 | vol-%-dry | 8.60 | 9.35 |

| H2O | vol-%-wet | 9.48 | 9.46 |

| CO2 | vol-%-dry | 10.67 | 9.97 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gehrmann, H.-J.; Jaeger, B.; Wirtz, S.; Scherer, V.; Aleksandrov, K.; Hauser, M.; Stapf, D.; Pollmeier, G.; Danz, P. Oscillating Combustion—Primary Measure to Reduce Nitrogen Oxide in a Grate Furnace–Experiments and Simulations. Processes 2021, 9, 2210. https://doi.org/10.3390/pr9122210

Gehrmann H-J, Jaeger B, Wirtz S, Scherer V, Aleksandrov K, Hauser M, Stapf D, Pollmeier G, Danz P. Oscillating Combustion—Primary Measure to Reduce Nitrogen Oxide in a Grate Furnace–Experiments and Simulations. Processes. 2021; 9(12):2210. https://doi.org/10.3390/pr9122210

Chicago/Turabian StyleGehrmann, Hans-Joachim, Bo Jaeger, Siegmar Wirtz, Viktor Scherer, Krasimir Aleksandrov, Manuela Hauser, Dieter Stapf, Gregor Pollmeier, and Philipp Danz. 2021. "Oscillating Combustion—Primary Measure to Reduce Nitrogen Oxide in a Grate Furnace–Experiments and Simulations" Processes 9, no. 12: 2210. https://doi.org/10.3390/pr9122210

APA StyleGehrmann, H.-J., Jaeger, B., Wirtz, S., Scherer, V., Aleksandrov, K., Hauser, M., Stapf, D., Pollmeier, G., & Danz, P. (2021). Oscillating Combustion—Primary Measure to Reduce Nitrogen Oxide in a Grate Furnace–Experiments and Simulations. Processes, 9(12), 2210. https://doi.org/10.3390/pr9122210