1. Introduction

Heat exchanger network (HEN) synthesis can effectively realize heat recovery, reduce external utility consumptions, and improve economic benefits, so it has attracted extensive attention from many academic researchers and engineering workers in the past four decades and is widely applied in various fields including chemical process and crude refining industries [

1,

2]. HEN synthesis (HENS) is the heat integration between hot and cold process streams [

3] with the aim of minimizing total annual cost (TAC) consisting of three sections i.e., utility consumption cost, fixed charge, and area cost of heat units.

Many methodologies for HENS have been developed and they can be broadly split into two categories, thermodynamic approaches and mathematical programming methods [

4]. Pinch method [

5] is a classical method used to evaluate optimal HEN using thermodynamics laws. In this method, the pinch point is first identified based on the given heat recovery approach temperature to predict maximal heat recovery, then the original HEN is decomposed according to the pinch point to predict minimal heat units. Subsequently, several methods deriving from pinch technology are proposed, including dual-temperature approach [

6] and pseudo-pinch design method [

7]. The pinch-based methods are well developed and demonstrated excellent efficiency [

8,

9,

10].

Mathematical programming methods mean the formulation and solution of mathematical models, some key developments of which should also be highlighted. In 1983, a linear programming (LP) for the minimization of utility consumptions and a mixed integer linear programming (MILP) for the minimal heat units were formulated in a transshipment model [

11] and a transportation model [

12]. In 1986, a non-linear programming (NLP) was proposed by Floudas et al. [

13] to solve the lowest heat exchanger area cost following the solution of LP and MILP problems. The solution process was substantially sequential, which was similar to pinch technology. The common shortcoming of the sequential methods are the lack of simultaneous consideration for the three-way costs, tending to get suboptimal HENs [

14]. Hence, simultaneous methods with mixed integer non-linear programming (MINLP) formulation were proposed and could achieve better HENs than sequential methods [

15], the most popular one in which was a stage-wised superstructure (SWS) model proposed by Yee and Grossmann [

16]. However, in the SWS model, the utility was only allowed to be placed at the end of streams, limiting the flexible development of structures.

The simultaneous optimization models with MINLP formulation is strongly non-linear and non-convex. The structure optimization related to integer variables is essentially a complex combinatorial problem. Even for a fixed structure, how to obtain optimal distribution of heat exchanger area is a complex non-linear problem with multiple local optimums. Furthermore, Furman and Sahinidis [

17] proved that HENS based on MINLP model was non-deterministic polynomial-time hard (NP-hard), so it is difficult to get global optimum even for small cases. Therefore, seeking for efficient global optimization methods to tackle MINLP problems has been the critical issue of HENS. Current methods can be generally classified into deterministic approaches and stochastic approaches [

18]. The deterministic approaches [

19,

20,

21] tend to get local optimums. Their computational efficiency decreased exponentially with the increase of problem size [

22], indicating an unaccepted computation effort.

Compared with deterministic approaches, stochastic approaches are flexible, efficient, and independent of the initial conditions, which can provide satisfactory results in reasonable time. The stochastic approaches have been widely investigated, including genetic algorithm (GA) [

23], simulated annealing (SA) algorithm [

24], particle swarm optimization (PSO) [

25], differential evolution (DE) algorithm [

26], etc. Luo et al. [

27] presented a GA considering areas and heat capacity flow rates as genes, so infeasible networks could be avoided. The randomized algorithms had success in uncovering new and better HENs by the random search of the cost landscape, proving that randomization technique can be applied to HEN designs effectively [

28,

29,

30]. A two-level concept [

31] consisting of nondeterministic performances has also been developed for HENS, where one level handles the network structures related to integer variables, the other one handles heat loads and spilt ratios related to continuous variables [

22,

32,

33]. Further, Lucas et al. [

34] used a two-level meta-heuristic optimization approach involving PSO and SA to optimize work and heat exchange networks. The application of two-level methods improves the HEN results to some extent, but it makes the optimization of integer and continuous variables separate, which can hardly explore the optimal HEN. Recently, GA has been greatly developed in recent years. Feyli et al. [

35] combined GA with a technique named modified quasi-linear programming. Their method can get lower TAC of HENs due to the relatively linear behavior of the proposed method. A combined GA [

36] method was also used to obtain optimal path of streams inside shell and tube HEs. Thus, the pressure drop of streams can be considered in HENs to reduce pump cost. Furthermore, the stochastic algorithms like GA, PSO, and DE require information exchanges between individuals, which may lead to a certain degree of weakening of the global optimization ability in the later stages of the optimization. To overcome this problem, a novel random walk algorithm with compulsive evolution (RWCE) was presented by Xiao and Cui [

37]. In RWCE, individuals executed random walking independently and realized the simultaneous optimization of integer and continuous variables. A simplified Metropolis acceptance rule was also designed to promote structure mutation, which was implemented by accepting imperfect solutions (AIS) with a certain probability. The Metropolis acceptance rule i.e., the AIS behavior was an effective strategy applied to HENS problems [

28,

33], which was conducive to the local minimum avoidance. However, in RWCE, the AIS may cause individuals to get trapped in long-term evolutionary stagnation with the generation of numerous ineffective random walks, which is a limitation found in substantial case studies. We named this limitation L1. Additionally, AIS may also cause the original solutions before AIS to be replaced by imperfect solutions, so the original solutions cannot be exploited completely, which is another limitation called L2. Due to the two limitations, the RWCE can hardly evolve further and consequently miss the optimum.

The AIS plays a significant role in the applications of stochastic methods to HENS problems, the limitations of which should be investigated to help design better HENs. Therefore, the motivation of this work is to explore the specific limitations of AIS in HENS problems, based on which, two novel strategies including back substitution strategy and elite optimization strategy are proposed respectively to deal with L1 and L2. Then a novel algorithm combining RWCE and the two novel strategies is formed. Moreover, a modified SWS model is also designed with a flexible utility placement strategy, to embed more possible network structures. Finally, the novel algorithm and the modified SWS model are applied for the stream-splitting HENS problems.

In the following parts of the paper, the representation of the modified SWS model and the corresponding mathematical formulation are presented in

Section 2, the novel algorithm is described in detail in

Section 3, the investigative results of three illustrative cases are presented in

Section 4 to verify the effectiveness of the proposed method, finally

Section 5 provides the conclusions.

3. Methodology

A novel algorithm combining RWCE and two strategies to solve the limitations of AIS is designed to solve the complex MSWS model with multiple optimization variables. Several points presented as follows should also be paid attention to. In RWCE, the historical optimum of an individual means the best solution obtained by the individual in the past iterations. The current solution of an individual represents the solution obtained by the individual at the current iteration. The optimal solution indicates the best one in the historical optimums of all the individuals. The optimal TAC after AIS means the best TAC obtained since the individual accepts an imperfect solution at a certain iteration.

3.1. RWCE Method for HENS with Stream Splits

In consideration of MSWS model, an individual in RWCE represents a HEN consisting of heat exchanger loads, inner utility loads, and stream split ratios. The main evolution to implement is the “random walking” of each individual as presented in Equations (30)–(34).

where

is the initial heat exchanger load,

is the heat exchanger load after walking.

is the initial load of inner cold utility,

is the load of inner cold utility after walking.

represents the initial split ratio of hot stream,

is the split ratio of hot stream after walking.

,

, and

are respectively maximal walking step sizes of heat exchanger load, inner cold and hot utilities.

and

are respectively maximal walking step sizes of split ratios of hot and cold streams.

~

are uniform random numbers distributed in the interval (0, 1). Lower bound

Qmin is set to handle integer variables to determine the generation and elimination of heat exchangers and inner utilities, which is described as Equation (35) (taking heat exchanger as an example).

is a parameter to control the existing of heat exchanger and its value is 10 kW in this paper. If

is smaller than

, the corresponding heat exchanger will be eliminated, making the effective heat exchanger load

equal to 0.

At the

iteration, the initial solution for individual

n can be expressed as

. After walking, the new effective solution

is generated. Then the TAC(

) is compared with TAC(

), and the lower one is selected. If TAC(

) is not smaller than TAC(

),

can also be accepted with a certain probability

δ. The specific operation is expressed as Equation (36), which is the mutation and selection criterion of RWCE.

3.2. Limitations of Accepting Imperfect Solutions

Two limitations of AIS are discussed in this section.

L1: The individuals may not avoid local optimums or even walk to imperfect regions by AIS in the middle or late period, which will lead to the evolution stagnation and efficiency decrease. A nine stream problem listed in

Table 1 was used to explain the L1.

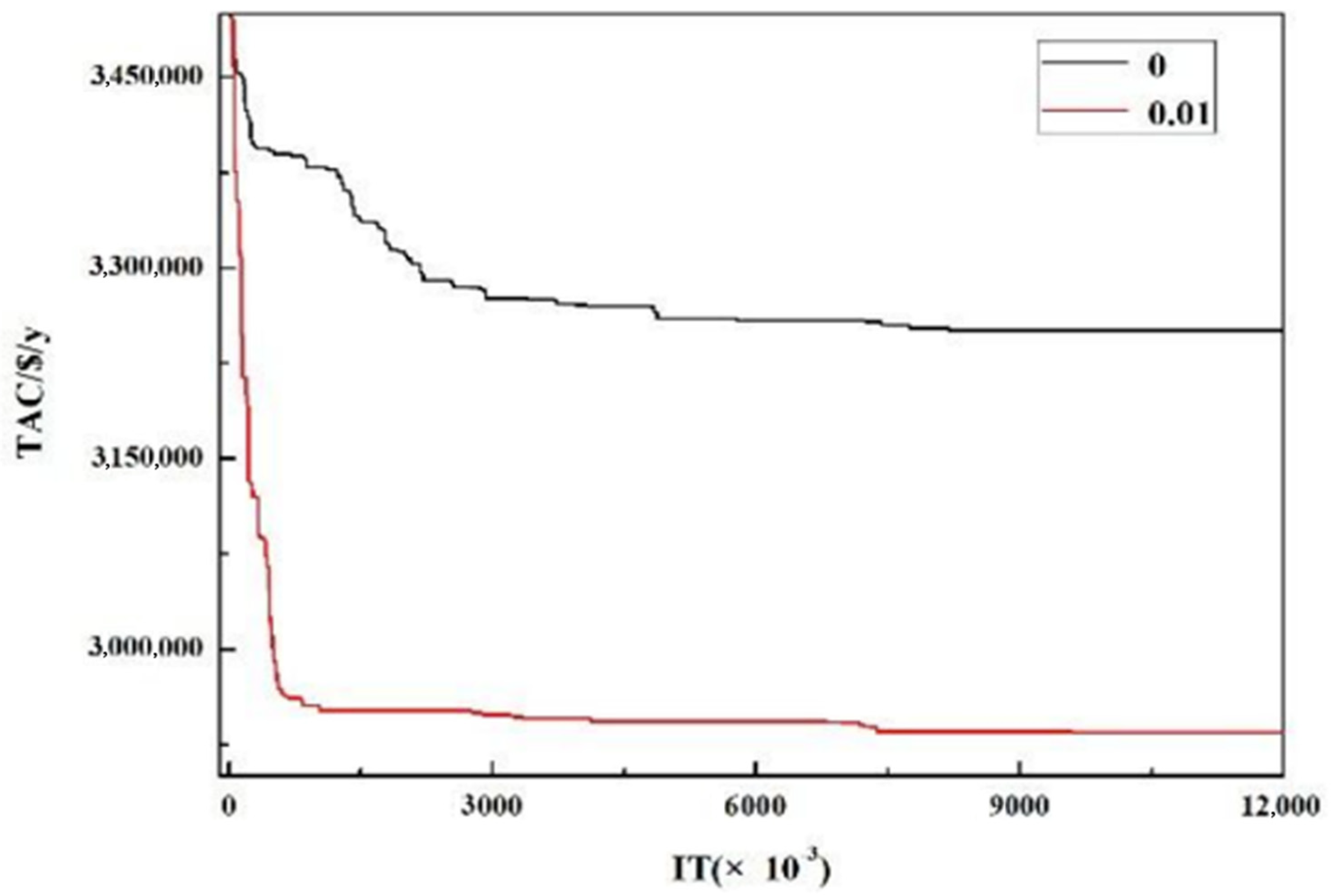

Figure 2 depicts the iteration of optimal TACs obtained by RWCE (

N = 1) with the δ respectively set to 0 and 0.01. It is pronounced that the TAC corresponding to δ = 0 declines more slowly compared to that corresponding to δ = 0.01 in the early period. The final TACs corresponding to δ = 0 and δ = 0.01 were respectively 3,250,825

$/year and 2,934,609

$/year, so the AIS could accelerate the evolution process and improve the convergence precision. However, for δ = 0.01, the individual did not evolve (the TAC didn’t decline) any more after about 9,500,000 iterations. By tracking the optimization process, the individual accepted an imperfect solution at the 9,601,186th iteration and the current TAC rose from 2,934,609

$/year to 2,939,384

$/year.

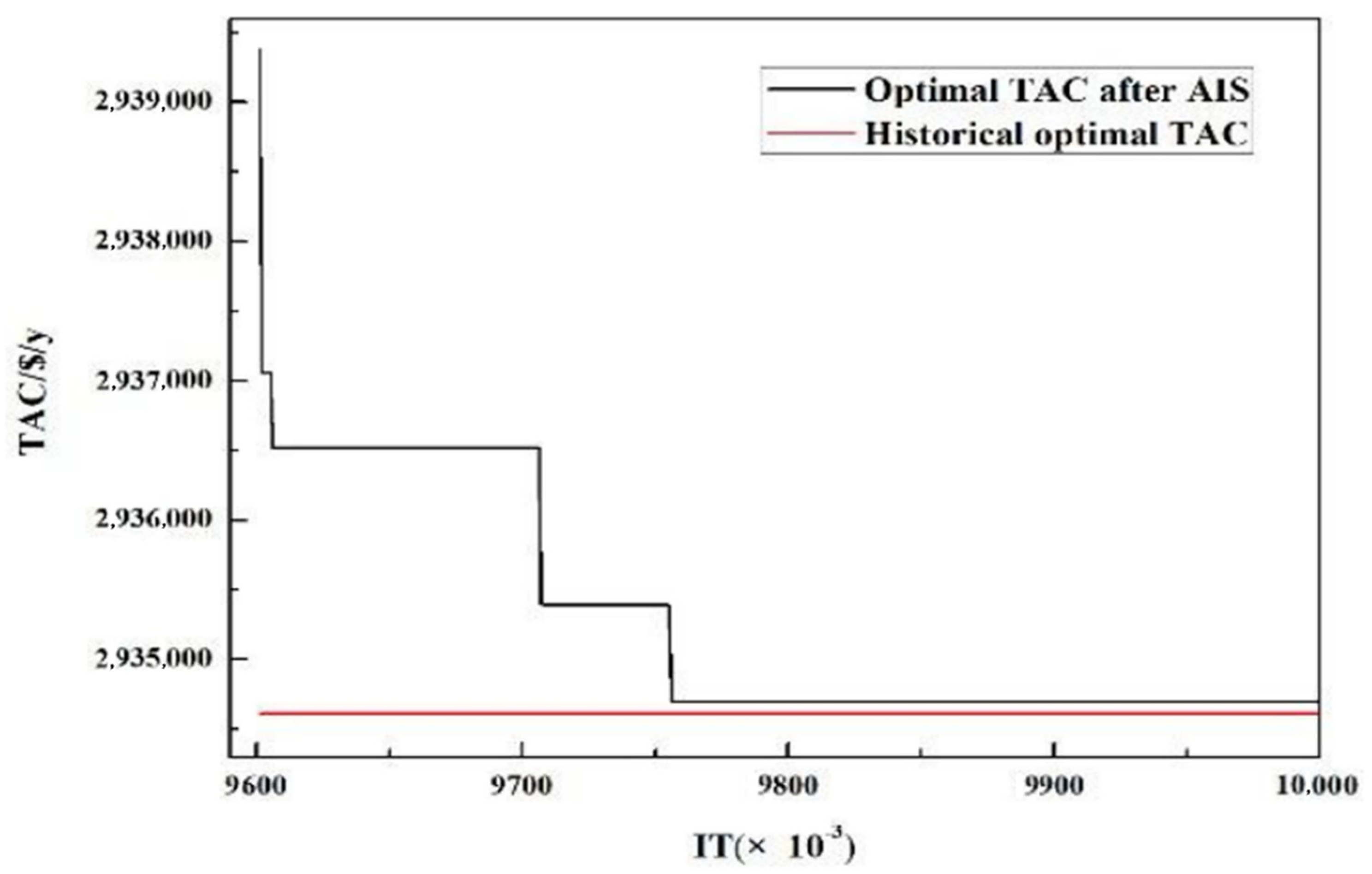

Figure 3 displays the iteration of the historical optimal TAC and the optimal TAC after AIS from the 9,601,186th to the 9,999,186th iteration (after the 9,999,186th iteration, the two TACs keep constant). After AIS, the individual could not find better solutions for a long time and stopped at a TAC of 2,934,699

$/year which was inferior to the historical optimal TAC 2,934,609

$/year.

When the individual stopped evolving, its corresponding HEN structure was recorded to compare with its historical optimal structure before AIS.

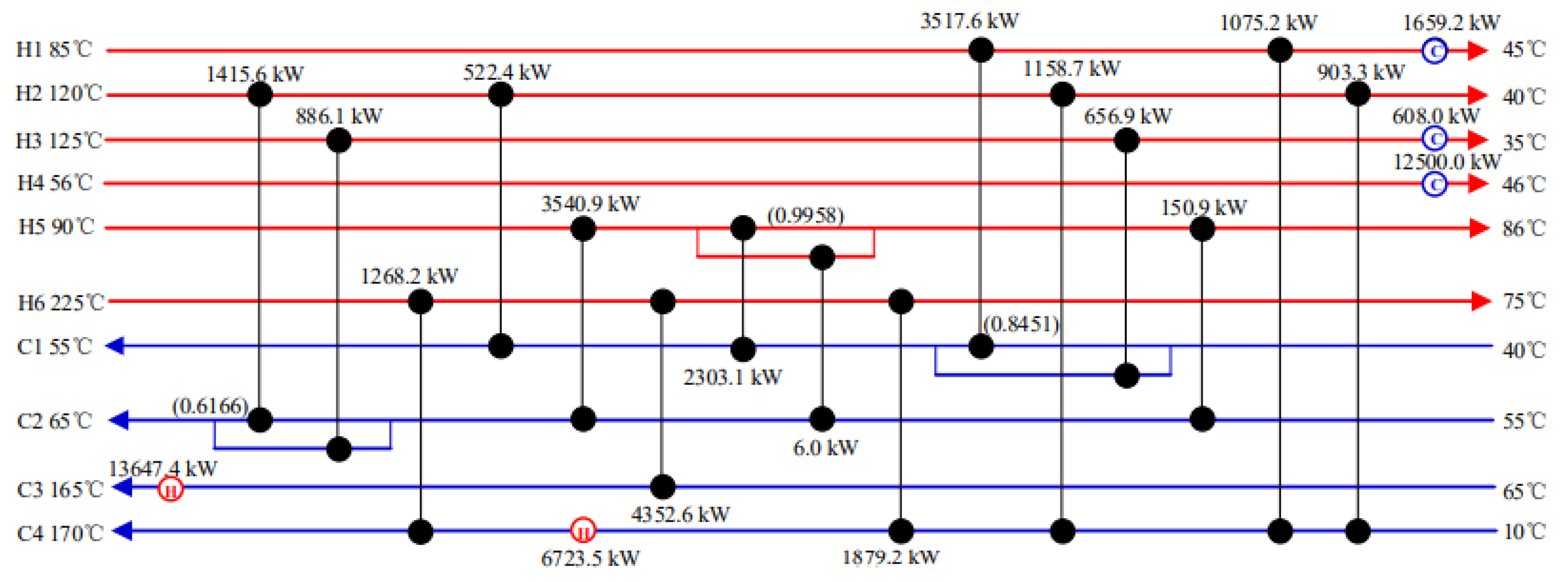

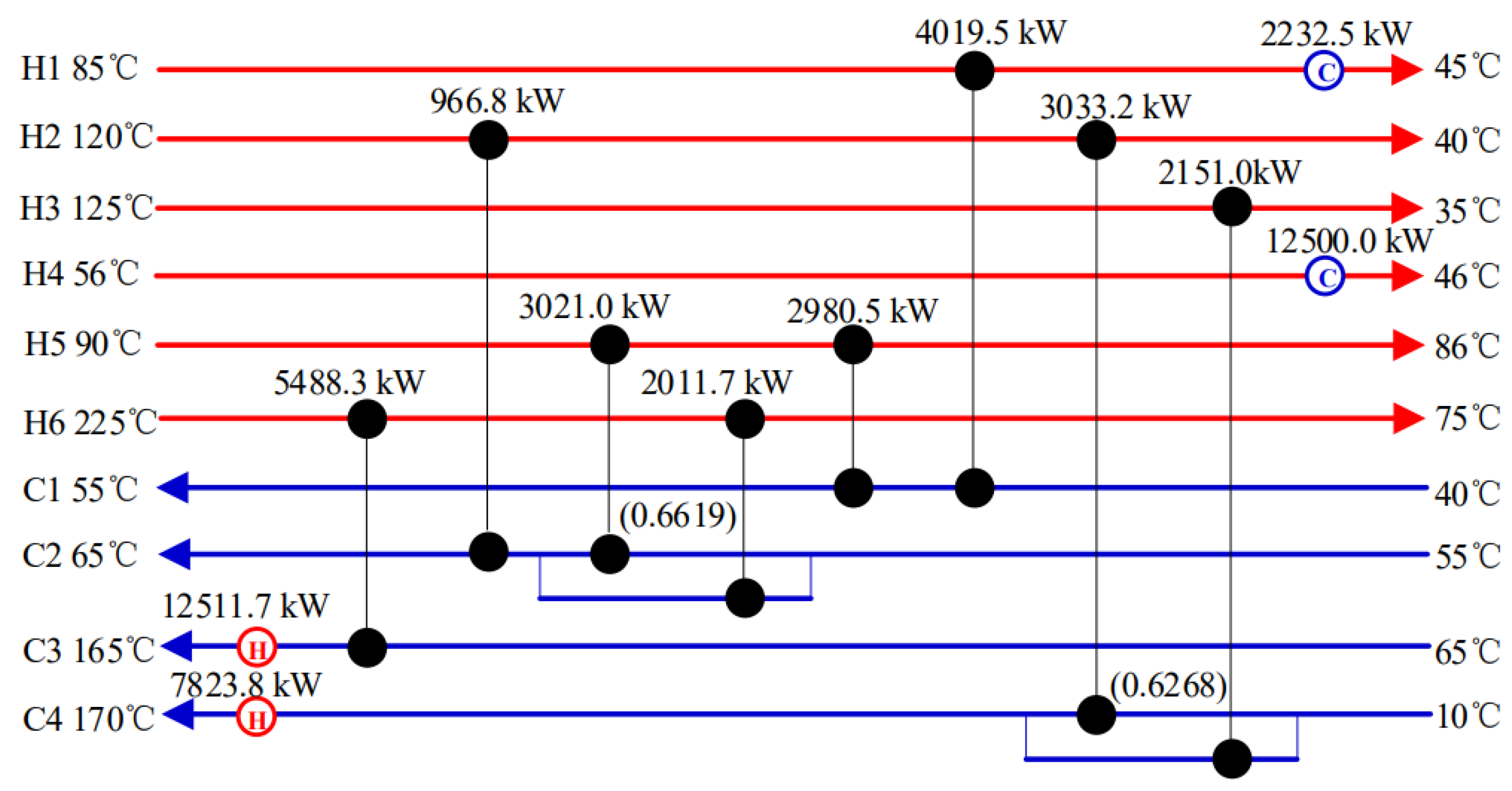

Figure 4 depicts the diagrammatic sketch of the comparison result.

Figure 4a shows the best HEN structure before AIS,

Figure 4b,c gives possible HEN structures when evolution stops after AIS. It can be found that

Figure 4b has the same structure as

Figure 4a, but their continuous variables are different. For instance, the heat loads of heat unit 1 in the two structures are respectively 100 kW and 90 kW. While

Figure 4c has a structure different from

Figure 4a, because the heat unit 2 is deleted in

Figure 4c. Therefore, both the continuous variables distribution and the structure might be destroyed after AIS, making the individuals walk ineffectively for a long time and have difficulty in returning to their own best position.

L2: The L2 has a negative effect on the convergence precision, which should also be paid attention to. After accepting an imperfect solution, the original solution before AIS is abandoned that cannot get further optimization, so the original solution is not exploited fully and then the precision declines.

3.3. Strategies

Removing the AIS behavior is obviously an ineffective approach to deal with the two limitations, because it can only keep the local optimums. Therefore, to enhance the search ability of RWCE, two novel strategies aiming at the limitations of AIS are designed in this section. The strategies are then combined with RWCE to form a novel stochastic algorithm named IRWCE.

3.3.1. Back Substitution of Optimums

To deal with the L1, a new strategy called back substitution of optimums is developed to compulsively make the individuals in long-term stagnation return to their own historical optimums to adjust their optimization direction in time.

The historical optimum of each individual is first recorded; then an individual condition monitoring mechanism is proposed, a counter is designed to count the evolution stagnation iterations of each individual after AIS. When the individual evolves, the counter resets; when the counter reaches a certain value (BSC), the corresponding individual is considered to be in a long-time stagnation; subsequently, the recorded historical optimum will be delivered to the corresponding individual to implement the back substitution. After back substitution, the count does not continue and becomes zero only if the corresponding individual evolves. If the counter reaches the value 2 × BSC, the back substitution of the recorded historical optimum to the corresponding individual will be performed again. The maximal iteration BSC between two back substitutions is called back substitution cycle. The strategy will be performed repeatedly based on the back substitution cycle if the count continues.

Limited by the relatively small walking step size i.e.,

, individuals can hardly walk with a long distance in the limited iterations. Hence, when the individual cannot evolve the structure after several operations of back substitution, a random perturbation is executed to achieve a long jump. The perturbation here is described as follows. Some heat loads

are selected randomly from the individual historical optimal HEN, which are then given perturbation as presented in Equation (37), finally the small heat units are also eliminated as Equation (35). The

is a uniform random number distributed in the interval (0, 1), k is the perturbation factor. In this study,

κ is directly set to 12. The perturbation may help realize long jumps by giving relatively big changes to the heat exchanger loads. However, this perturbation may also destroy the efficient matches of individual historical optimums, so it is executed only when several back substitutions of individual historical optimums cannot evolve the structure.

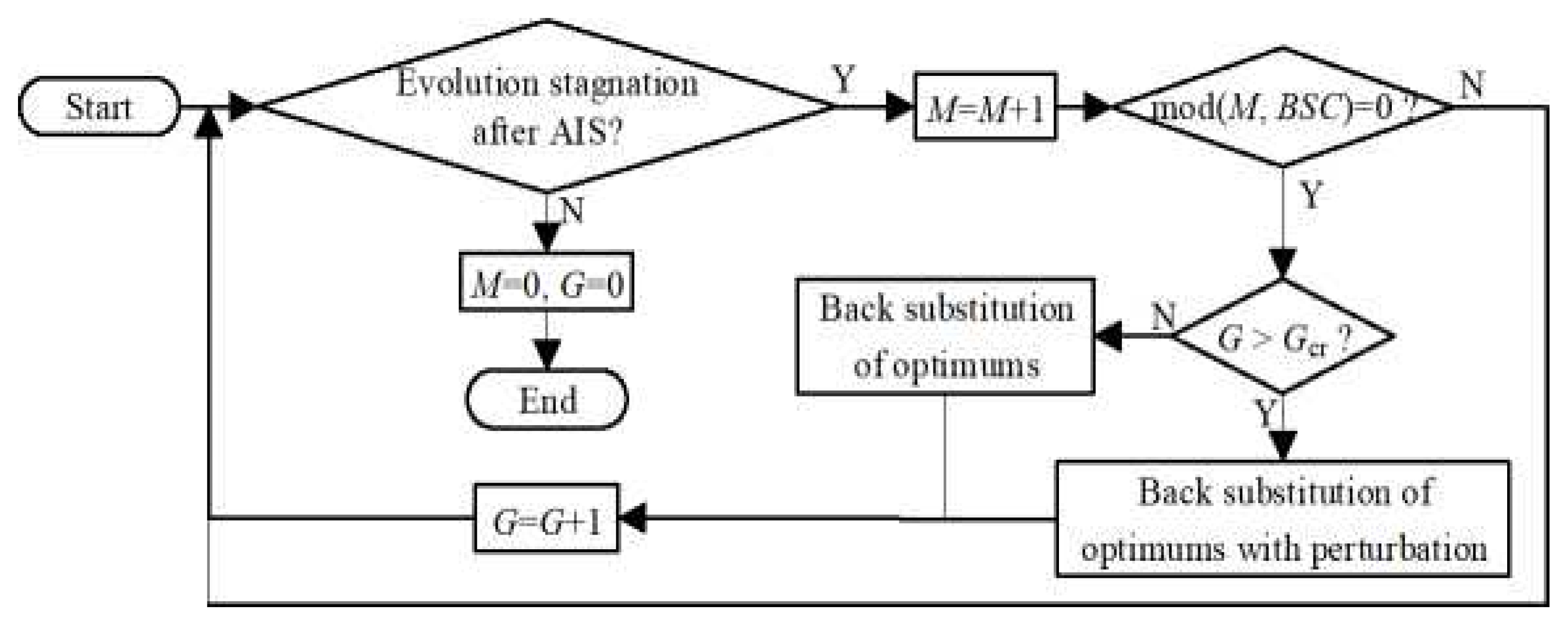

The working procedure of the back substitution strategy is depicted in

Figure 5. The

“M” represents the evolution stagnation iterations, “

G” is the number of back substitution. The “

” is set to determine whether the perturbation can be implemented or not.

3.3.2. Elite Optimization

The L2 shows that original solutions before AIS may be replaced by imperfect solutions, so it cannot get complete optimization. Hence, an elite optimization strategy is proposed here to solve L2, where the population is divided into two sections, one section includes NP (NPV0.5N) elite individuals, the other section includes N-NP basic individuals. The elite individuals protect and optimize the solutions with better potentials i.e., elite solutions from being replaced by imperfect solutions, where elite solutions are selected in the optimization process of basic individuals.

The basic individuals evolve as the original RWCE, their historical optimums are sequenced according to TAC, where the top NP historical optimums with relatively lower TACs are selected as the elite solutions and delivered to elite individuals. An elite solution corresponds to an elite individual. If a basic individual updates its historical optimum which is better than the worst elite solution, the new generated optimum will replace the worst elite solution. Thus, the elite solutions are kept without being replaced by imperfect solutions and also have the opportunity to get further optimization.

For the elite solutions, a fine-search (FS) strategy [

43] is introduced. The FS strategy can improve the precision in both the continuous and integer variables, which is described in the following. In Equation (38), three logical variables

, , and

to determine whether the continuous variables walk

( = = = 1) or not

( = = = 0) are given. A parameter

Φ is set to control the number of variables to evolve. Equations (39)–(43) present the evolution formulation of the elite individuals (the basic individuals use Equations (30)–(34)). The minimal heat load and the AIS probability for the elite individuals are set relatively small to keep the fine search.

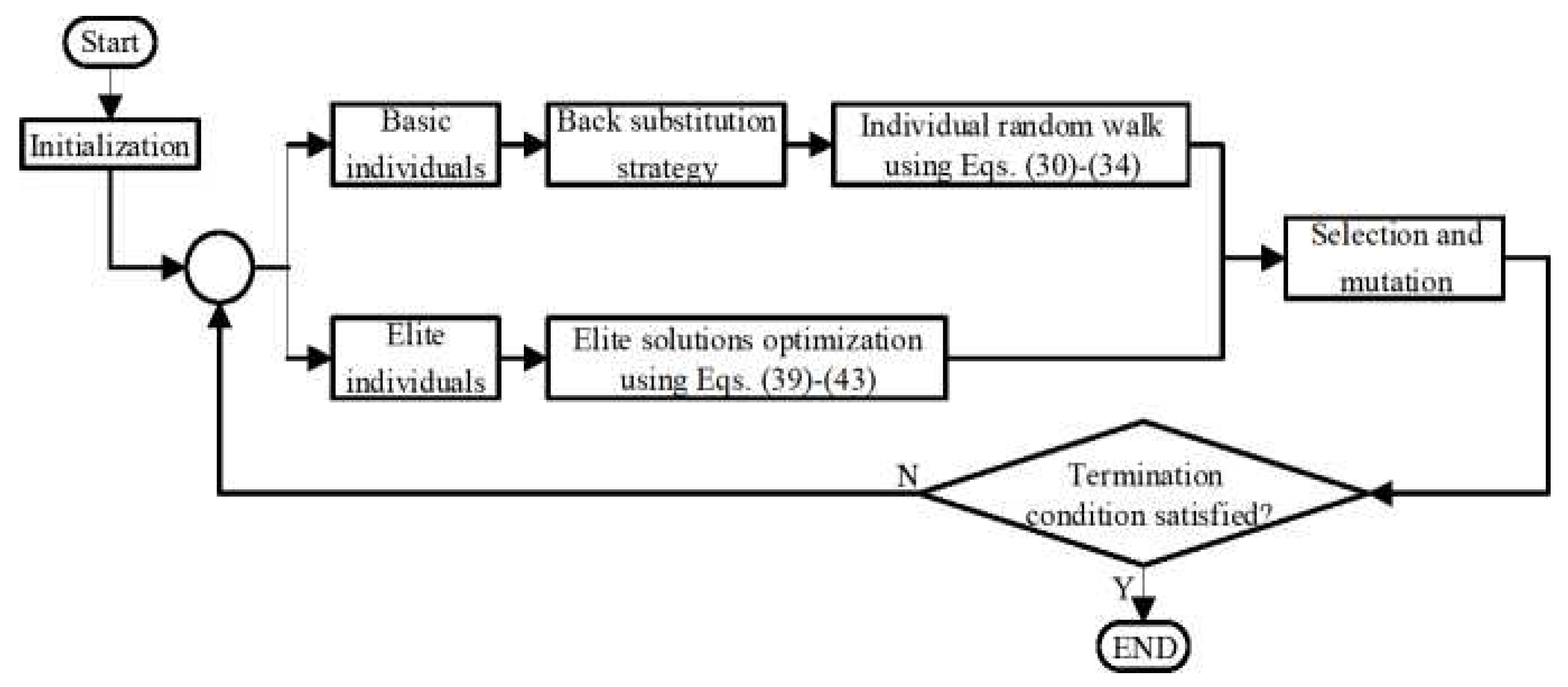

Figure 6 shows the schematic illustration of the elite optimization strategy.

3.4. Calculation Steps of the Improved RWCE

An improved RWCE (IRWCE) based on the original RWCE and the two new strategies is developed, the process of which is exhibited in

Figure 7.

(1) Initialization

The population including N-NP basic individuals and NP elite individuals is set. Each individual is initialized as Equations (44)–(48). Where

,

,

, and

respectively represents the initial heat exchanger load, inner cold, and hot utility loads, and split ratios of hot and cold streams;

,

,

,

, and

are respectively the initial maximal heat exchanger load, inner cold and hot utility loads, and split ratios of hot and cold streams, they are set as 200 kW, 0 kW, 0 kW, 10 and 10 in this work.

(2) Back substitution

The back substitution strategy is used for basic individuals. The individual condition monitoring mechanism works to count the evolution stagnation iterations after AIS. If the individuals do not satisfy the requirements of back substitution, this step will be skipped. The strategy is executed based on the back substitution cycle and ends only if the corresponding individual evolves its structure after back substitutions.

(3) Individual random walk

The basic individuals walk according to the Equations (30)–(34), while the elite individuals walk by the Equations (39)–(43). The Equation (35) is used to deal with integer variables, the minimal heat loads for the basic and elite individuals are respectively and .

(4) Selection and mutation

Equation (36) presents the specific implementation of selection and mutation. After random walking, the generated candidate solutions are compared with the initial ones, where the better ones are selected. If the candidate solution is not better than the initial one, the candidate solution will also be accepted with a certain mutation probability. The mutation probabilities for the basic and elite individuals are respectively and .

(5) Termination

If the maximal iteration is satisfied, the iteration ends; otherwise go to step (2).

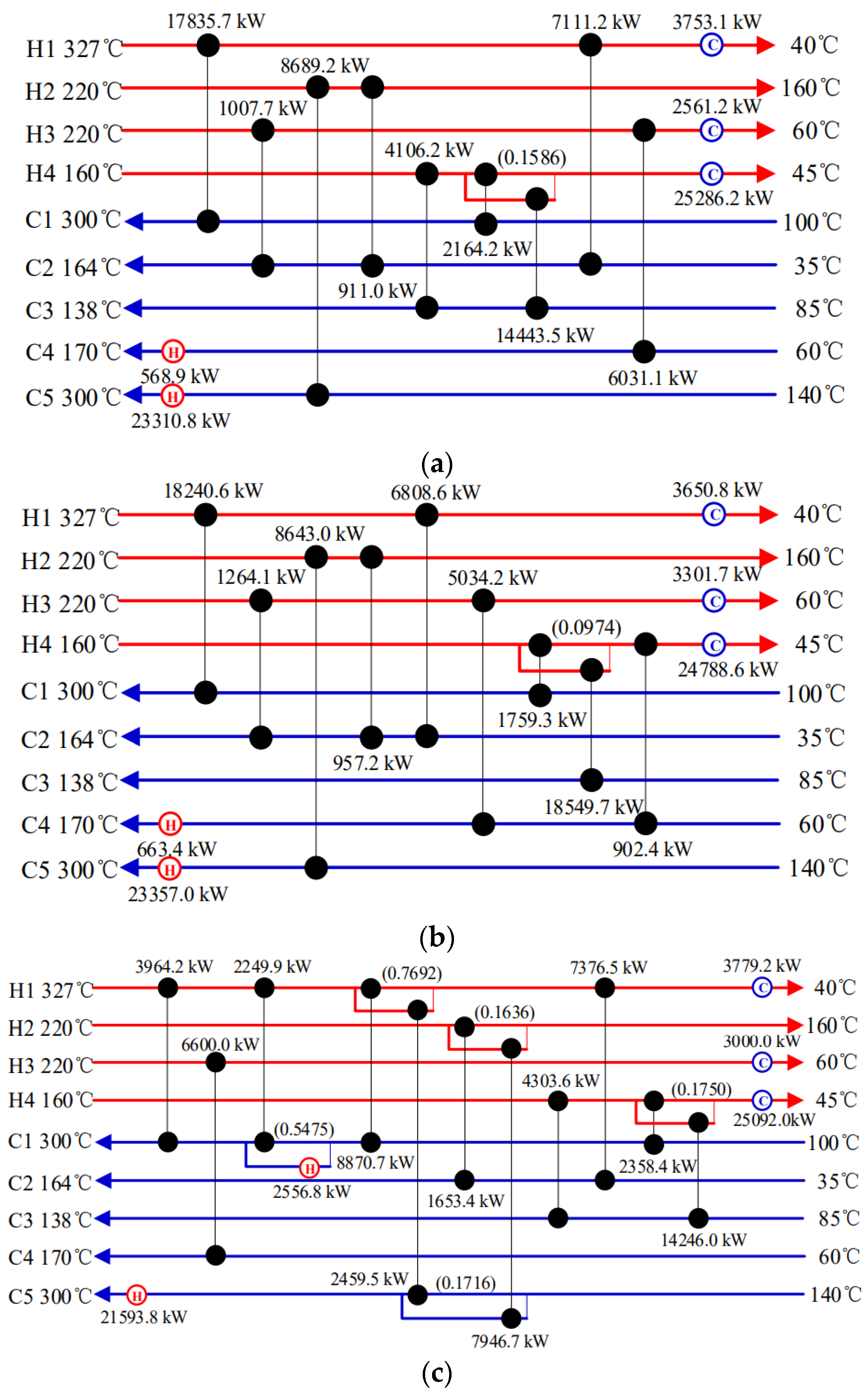

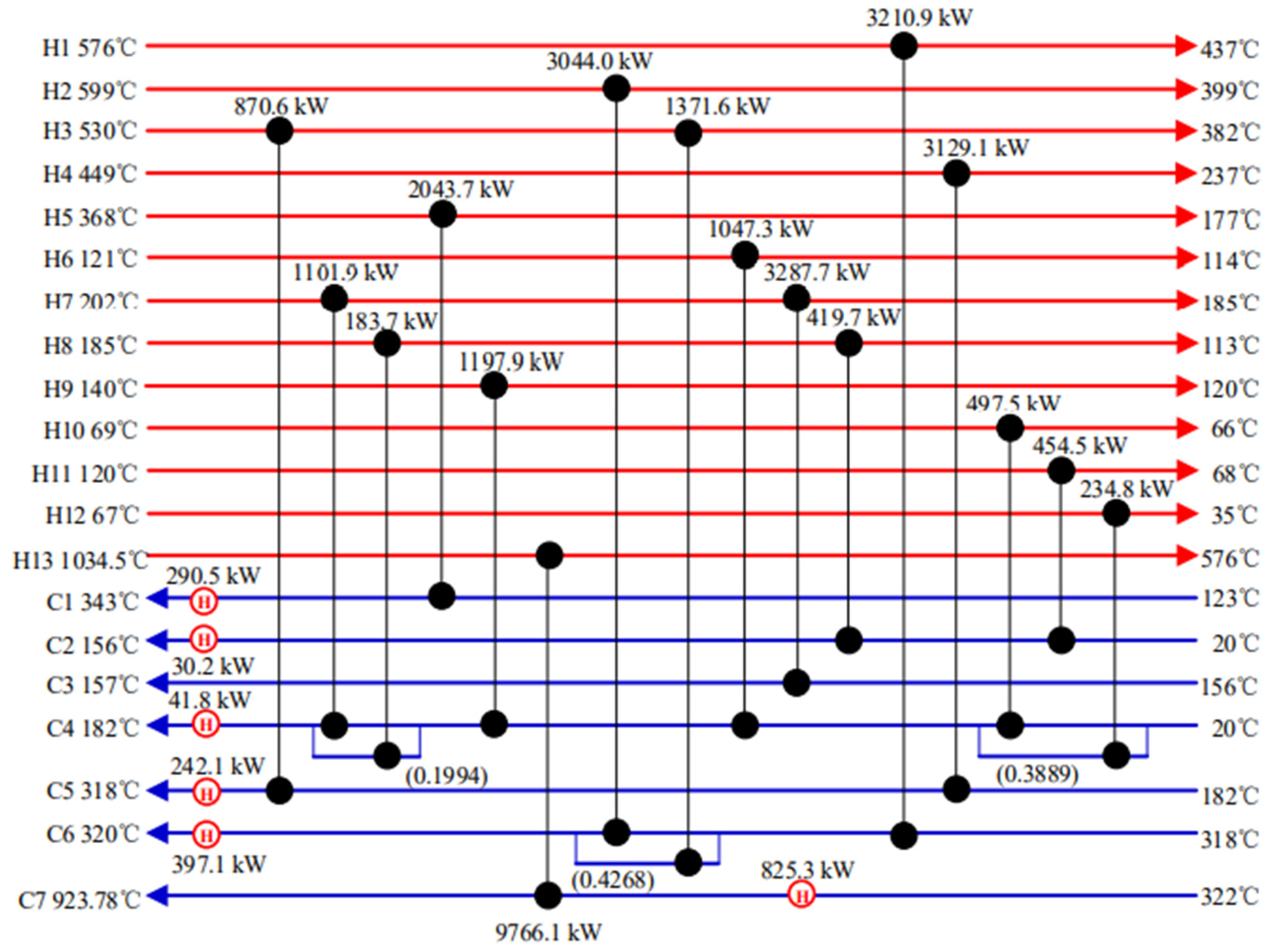

5. Conclusions

A novel stochastic method IRWCE consisting of RWCE, back substitution strategy, and elite optimization strategy is proposed to solve the HENS problems based on a modified SWS model considering inner utilities. The two novel strategies can maintain the positive effect of AIS and also solve the limitations of AIS, making the IRWCE satisfy the needs of relatively strong global and local search ability. The back substitution strategy is an effective solver of L1, which can deliver the historical optimums to the corresponding individuals in long-term stagnation condition to adjust their evolution direction in time. The elite optimization strategy can deal with L2 by performing a fine search for the selected elite solutions. It was also found that AIS might destroy the efficient structure and continuous variables, significantly influencing the optimization process. The optimal TACs of the three cases obtained by IRWCE were respectively 5,586,395 $/year (5,713,746 $/year when the fixed charge was set to 8000 $/year), 2,907,007 $/year, and 1,434,297 $/y, which saved 2219 $/year (1280 $/year), 2899 $/year, and 13,185 $/year as compared to the reported optimal ones. Some HEN structures with inner utilities were also obtained and significantly reduced the TACs, demonstrating the effectiveness of the MSWS model that enlarged the solution space. The investigative results demonstrated IRWCE and MSWS could achieve better savings in energy consumptions and design cost for HENS problems.