Abstract

Constructed wetlands (CW) is an environmentally friendly technique for removing pollutants from wastewater and has been applied to municipal wastewater, petroleum refinery wastewater, agriculture drainage, acid mine drainage, etc. The past decade has seen a remarkable number of innovations in the exponentially growing field of microbiology. This manuscript covers a critical review of key aspects of CW, such as various types of CW, the contaminants and their removal mechanisms, degradation pathways, challenges and opportunities, materials, applications, and theory with a focus on recent advances in the last three decades. In addition, an attempt has been taken to project future advances in the field of CW and facilitate these advances by framing key unsolved problems in CW. Guidelines are prepared for the fast-growing CW field through the standardization of key design aspects. This review covers the evaluation of the current state-of-the-art of CW technology and provides definitions and performance metric nomenclature in an effort to unify the fast-growing CW community. It also contains an outlook on the emerging trends in CW and proposes future research and development directions.

1. Introduction

In the last decade, environmental awareness has increased, and the treatment of environmental pollution and contamination has become the main agenda of concerned governmental bodies around the world. Usually, a suitable environmental remediation method for a certain type of waste is selected based on the effectiveness of the degradation process and the cost of the method [1,2,3]. More importantly, the environmental impact of the selected method is of special concern because in some remediation methods the daughter product of the degradation process is more toxic than the original contaminant. Scientists and researchers believe that there is no single universal remediation method suitable for all types of contaminants and all sources; instead, an effective remediation program may involve the collective implementation of two or more methods [1,2]. Wetlands are one of the effective remediation technologies that now attract the environmentalist for the treatment of wastewater contaminants [2]. Mother Nature, through natural wetlands, removes contaminants from water resources through different natural processes including biodegradation, sorption, phytostabilization, phytoextraction, and rhizofiltration [2,4,5,6,7]. Constructed wetlands are developed to mimic the natural processes in removing/degrading contaminants in wastewater [8,9]. Municipal wastewater, industrial wastewater (particularly petroleum refinery and sour-water treatment wastewater products), agriculture wastewater, stormwater, textile wastewater, landfill leachates, mining drainage, etc., are examples of contaminated wastewater that can be treated using wetlands [10,11,12]. Constructed wetlands use natural processes in degrading contamination; therefore, it is an environmentally friendly remediation method with minimum adverse environmental impact [13]. CW is designed to treat wastewater from different sources similar to common effluent treatment plants [14].

Wetlands are generally defined by the saturation of soil for a long enough period for anaerobic conditions to develop. There are various types of wetlands including natural fresh and salt-water wetlands and constructed wetlands [2]. Wetlands constructed for remediation of contaminants integrate complicated inclusive processes that involve water, substrate (soil), plants, animals, microorganisms, and the environment. Constructed wetlands implemented various remediation methods including biodegradation, phytoremediation, and natural attenuation [15]. The main processes that occur in wetlands include physical processes such as filtration and sedimentation, chemical processes such as adsorption and precipitation, and biological processes such as biodegradation and plant assimilation [16].

The vast majority of the wetlands are characterized by a high density of vascular plants. High-density vegetation results in slowing the water flow, creating microenvironments, and providing sorption sites for contaminants and attachments sites for microorganisms [5]. As the plants die and fall in the water, the parts of the plants above the water create additional sorption and exchange sites. In addition, plant debris is a suitable source of organic carbon and nutrients (nitrogen and phosphorous) for microorganism metabolism. The oxygen concentration is very low in wetlands due to soil saturation conditions. Therefore, the vegetation in wetlands is limited to species (vascular plants) that can grow at low oxygen concentrations [5].

Microorganisms play a dominant role in the contaminant degradation process and in the transformation of the contamination between the environment and the plant. Usually, a microbial consortium is involved in contaminant degradation and the transformation processes [9]. There are specific degradation pathways for each microorganism to degrade a specific contaminant. The success of the process of contaminant degradation relies on the existence of microorganisms that are required for the degradation process and suitable environmental conditions [17,18].

Constructed wetlands have been used all around the world for the treatment of wastewater. For instance, CWs have been used in Europe since the second half of the last century; the first country to use CWs in Europe was Germany [16]. Many other countries including the United Kingdom, Austria, Slovenia, Switzerland, and Denmark have CWs in operation. Some countries in Africa have been using CWs, such as South Africa, Tanzania, Kenya, and Seychelles. Some statistics show that the cost of subsurface CWs in Africa for wastewater treatment is around US $5 per person compared to mechanical wastewater treatment (i.e., activated sludge system), which costs around US $50 per person [16,17]. A recent study showed that the total cost (including operation, maintenance, and disposal of sludge) of wastewater treatment varies between €0.30 to €0.88 per m3 [19]. In China there are more than 400 CWs [20].

Constructed wetlands are characterized by very slow water flow and shallow water depth. The slow water flow results in a long retention time that facilitates the settlement of the sediment and increases the contact time between the wastewater and the components of the wetland [21]. Thus, in the design, it is critical to choose a suitable flow velocity to provide enough time for microorganisms to degrade the contaminants. The components of the constructed wetland affect the degradation processes. For instance, the number of sorption sites in the soil and the substrate control the bioavailability and degradation process [21]. There are two schools of thought concerning bioavailability; some scientists believe that bacteria can degrade contaminants without the need for the contaminants to be desorbed [21]. On the other hand, some researchers believe that the contaminants need to be desorbed first before bacteria can degrade them. Some types of bacterial strains are capable of producing biosurfactants to facilitate the desorption process [22]. Therefore, for constructed wetlands, understanding the capabilities of the available microorganism consortium is essential for a successful treatment process.

The main functions of CWs are to improve wastewater quality by degradation or sorption, control the flood by creating storage for the storm rainfall and surface runoff, and recycle nutrients [4,8,11]. However, the values of wetlands include providing recreational areas and providing suitable data for research and education. The advantages of CWs include (i) the low construction cost compared to other remediation methods, (ii) an environmentally friendly approach that is viewed with favor by the public, (iii) relatively low maintenance and operation costs, (iv) high flexibility in the landscape design to provide habitat for wildlife and organisms, and (v) wetlands facilitate the reuse of treated water. Although they have great advantages, there are some limitations of CWs that include (i) requiring large land areas compared to the other remediation methods, (ii) the inconsistency of the treatment compared to the other wastewater treatment methods, (iii) not suitable to treat if the discharge should meet specific standards, (iv) ammonia and pesticides have detrimental effects on the plants and microorganisms, and (v) low tolerance of near-complete drying conditions [9,17]. The local regulations and bylaws directly affect the selection of the type of flow in constructed wetlands. Some locations have stringent laws that prohibit surface flow, and the designers have to choose the vertical flow in these cases [23].

2. Wetland Treatment Systems

Generally, constructed wetlands can be classified according to different criteria such as hydrology (surface-flow and subsurface-flow), macrophyte types (free-floating, emergent, and submerged), and flow path (horizontal or vertical) [24]. As mentioned before, there are many types of constructed wetlands including surface flow (SF) wetlands, subsurface flow (SSF) wetlands, and hybrid systems, which encompass surface and subsurface flow wetlands [25]. The hybrid system is a multistage system in which the treatment is performed in different units that are designed for specific functions. For instance, for wastewater treatment, some units are designed to promote aerobic reactions, while other units are designed for anaerobic conditions. A wetland equipped with an air pump connected to a subsurface network of air distribution pipes is called aerated CW [26]. The air bubbles introduced by the air pump can increase the oxygen transfer rate in horizontal flow (HF) or vertical flow (VF) type wetlands and effectively creates aerobic conditions. The estimated oxygen consumption rate in CW could be 250 g of O2/m2/d with air flow rate and distribution to be ≥0.6 m3/m2/h and 30 cm × 30 cm, respectively. Mechanically aerated wetlands can provide higher oxygen transfer rates (more than 1 m3/m2/h). The aerated wetland has improved nitrification/denitrification capacity as well as better biogeochemical conditions in the wetland subsurface and the plants [26,27].

In the literature, scientists and engineers use various terms to describe wetlands. For instance, in free-surface flow (FSF) the surface of the wastewater flow is above the soil (substrate in the CWs) [2,3,4]. Alternatively, some scientists use the term SF surface flow to denote the FSF. Additionally, the term SSF is used for sub-surface flow system in which the wastewater flows horizontally or vertically such that the water level is below the ground surface. The abbreviation HSSF is used for horizontal subsurface flow or alternatively SSHF subsurface horizontal flow [2,4,5,13]. The terms VSSF and SSVF are used for the vertical subsurface flow or subsurface vertical flow, respectively. Sometimes the abbreviation of the constructed wetlands CWs is added to the above-mentioned terms. For example, CWs is added to HF to become HFCWs [1,22]. In an attempt to unify the terms used in the literature, this article will use the following abbreviations: SF for surface flow, VSSF for vertical subsurface flow, and HSSF for horizontal subsurface flow.

2.1. Surface Flow (SF)

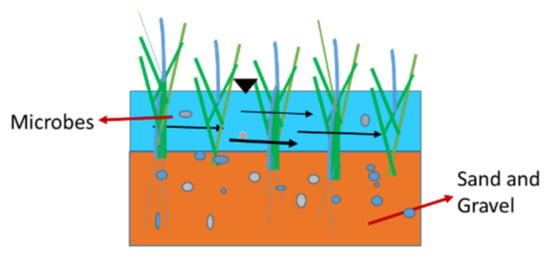

Surface flow wetlands (SF) is where the surface of the wastewater flow is above the soil (substrate) [28]. The SF is composed of a substrate (clay and sand soil) to support the roots of the plants and water control structures that maintain a shallow depth of water above the soil (see Figure 1) [4,5]. The bottom of the soil is sealed to maintain water within the system. SF wetlands can be used to treat wastewater while supporting wildlife habitats. In the SF, the concentration of oxygen varies with depth [29]. Depending on the water level, the top layers (near the water surface) have a high oxygen concentration, while the bottom layers have a very low (or zero) oxygen concentration [2]. Therefore, the top layers support aerobic processes (nitrification), and the bottom layer supports anaerobic (denitrification) processes. SF can be used to treat stormwater, agricultural runoff, and mining wastewater. SF wetlands require a large area compared with the subsurface flow wetlands. The advantages of the surface flow wetlands are that their construction and operational cost are lower than the subsurface flow wetlands, and it is simple technology compared with the subsurface flow wetlands. The disadvantages include odor problems and more area required compared to subsurface flow CWs and other remediation methods [29].

Figure 1.

Schematic layout of free surface flow.

2.2. Subsurface Flow (SSF)

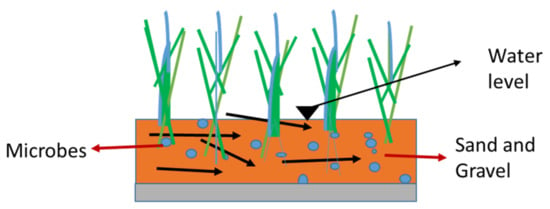

Subsurface flow (SSF) wetland substrate is composed of porous soil (rock and gravel) sealed from the bottom [9,13]. In the SSF, the water level should be below the soil level all the time (see Figure 2). The flow path in the SSF wetland is either a horizontal or vertical flow path. SSF wetlands are suitable for the treatment of wastewater, provided that the solid concentration in the wastewater is low. For high solid concentration in the wastewater, sedimentation tanks or basins are used to remove the solids from the wastewater [25,30,31]. The main advantages of SSF wetlands include tolerance of cold weather, fewer odor problems compared to SF wetlands, greater sorption and exchange sites compared to SF wetlands, and efficient use of the land compared to SF wetlands. SSF wetlands can be constructed below public parks because the water level is below the ground surface. The limitations of SSF wetlands include their higher cost compared to SF wetlands, used for small flows, and clogging of the pores [26,27].

Figure 2.

Schematic layout of horizontal subsurface flow.

The complex processes that contribute to purifying the wastewater in wetlands include sorption, filtration through the substrate, sedimentation, settlement, ion exchange, plant sorption, and microorganism oxidation [2,4,5]. Constructed wetlands with the subsurface flow have been used to treat heavy oil-produced water containing asphalt, gelatinoids, wax, polymers, surfactant, and other artificial products. The constructed wetland has been approved to be successful in treating heavy oil-produced water. There is no proper design guideline that specifies the filtration rate; as such, some studies used 0.52 m day−1 [25]. Previous research showed that the removal of COD is highly affected by DO concentration. The anaerobic conditions and high organic loading rate can reduce the efficiency of COD removal. There are two types of flows in SSF: the first is the horizontal subsurface flow (HSSF), and the second type is vertical subsurface flow (VSSF) [32].

2.2.1. Horizontal Subsurface Flow Constructed Wetland (HSSF)

The horizontal subsurface flow (HSSF) is composed of a channel located below the ground surface [9,13]. The channel is filled with selected types and sizes of gravel and sand. The channel is planted with a suitable plant. There are certain considerations that should be taken into account when designing the channel. For instance, the water flow in HSSF is designed such that the level of the water is below the ground surface. Solids should also be removed from the wastewater before entering the channel to avoid clogging [13]. A sedimentation tank or filter are usually used to remove the solid particles from the wastewater. The cross-sectional area of the HSSF plays a dominant role in the efficiency of the decontamination process. The oxygen level in the HSSF should be enough to promote the growth and metabolism of aerobic bacteria as well as plants. Many mechanisms facilitate oxygen transfer to the subsurface environment. Plant roots contribute to the increase in oxygen in the environment near the roots [5,9,13].

2.2.2. Vertical Subsurface-Flow Constructed Wetlands (VSSF)

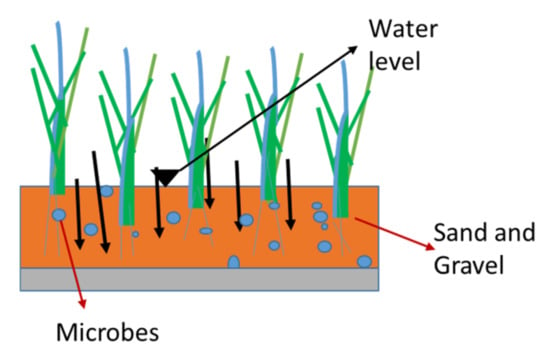

Some constructed wetlands are designed to have vertical water flow. In such a case, it is called vertical subsurface-flow constructed wetlands (VSSF) [30]. Similar to HSSF, the flow of VSSF should be passed through filter beds before entering the CW channels (See Figure 3). The flow in VSSF is either by gravity or by pumps. Certain considerations should be taken into account in the design of VSSF. The time required for the wastewater to percolate through the vertical channels should be calculated. In most cases, the flow in VSSF is controlled such that there is a time interval between the loading events, and intermittence loading is adopted [33]. The plant roots transfer some oxygen to the subsurface, and dryness periods allow oxygen diffusion to subsurface. Thus, the oxygen level in VSSF is high, which promotes the growth of aerobic bacteria. Therefore, VSSF enhances aerobic degradation and is found to be suitable for nitrification and is more aerobic than HSSF. Previous studies found that VSSF promotes a wide range of degradation and decontaminations processes including, biodegradation, adsorption, precipitation, and filtration [34]. It was also found that the VSSF is successful in removing the organic matter and suspended solids. The VSSF capital cost is less than the HSSF capital cost because the VSSF needs a smaller area size compared to HSSF [24].

Figure 3.

Schematic layout of vertical subsurface flow constructed wetlands.

2.3. Constructed Wetlands Design, Construction, Operation and Maintenance

2.3.1. Design

- (a)

- General design criteria

The design of wetlands contains many components that influence the performance of wetlands. The performance of CW depends on the location, climate, weather, type of wastewater, type of runoff, and expected variations during the year [9,32,34]. In general, constructed wetlands are designed to simulate the natural wetlands with special attention to the system that leads to the enhancement of the wastewater quality. Researchers, engineers, and scientists recommended that the design of CWs should be simple. It is highly recommended to use native and available media as well as environmentally friendly technologies [9]. The CWs should be designed in such a way that results in low maintenance and minimizes the use of pumps. The CW design guidelines include the detention time, size, length, width, depth, etc. More space and a greener environment are required to build CWs than other technologies [32]. The CWs can be designed on a small scale to serve a single family or can be designed on a large scale to serve a community [32]. Special consideration should be given to design parameters such as geometry of the CW, influent quality, media type, microorganisms and plant species, water depth, and hydraulic retention time. The geometry is basically dependent on the type of the CW. For instance, for surface flow CW, the basin slope should be between 3:1 and 5:1. Impervious media should be used at the bottom of the CW. The hydraulic retention time should be between 2 and 3 days. The quality of the influent includes the biological oxygen demand (BOD) and total suspended solids (TSS). For the BOD and TSS, loading could be between 20 and 30 mg/L or 45 and 50 kg/ha per day. On the other hand, for subsurface flow, the BOD and TSS should be around 7–16 g/m2 per day and 20 g/m2 per day, respectively. The recommended minimum length is 15 m, and the maximum width is 61 m. The hydraulic conductivity varies in the longitudinal and transversal directions. A previous study showed that the hydraulic conductivity subsurface flow of CW varies between 1400 and 2800 m/day, and another study recommended 1000 m/day for the first 30% of the length. However, for ageing systems, clogging of the soil pores is expected, which can result in reduced porosity of the system. Pervious studies show, for ageing systems, that the hydraulic conductivity is between 30 and 107 m/d in the outlet zone [35,36,37,38].

For a single family, the general consideration that should be taken in the design of CWs includes removal of trees and grass, construction of a fence around the selected area to stop compaction, and use of inorganic fine-grained soil for backfilling. The size of CWs should be 1 m2 for 30 L (1 m2/30 L) influent or the detention time of 5 days. Provision should be taken that the length should be double the width. The wastewater can be estimated at 210 L/capita/day, and the number of people can be estimated as two persons per bedroom. Therefore, for a two-bedroom household, the area of CWs should be 28 m2 with dimensions of 7.5 m × 3.75 m [32]. In a previous study, a vertical flow CW of surface area of 24.4 m2 and depth of 1.3 m was divided into two equal sizes (3.5 × 3.5 × 1.5 m) and used to treat wastewater from two-family residence of eight persons. The system includes two settling tanks, a vault tank, zeolite tank, effluent collection tank, and pump to feed the CW with 150 L wastewater every 3 h. The system was designed to treat 150 L/capita/day. Coarse gravel (20–40 mm diameter) and fine gravel (2–10 mm diameter) were used as the porous media. The zeolite tank was used to remove ammonia and phosphorus. Removal efficiencies were 96.4% for BOD, 94.4% for COD, 90.8% for TKN, 92.8% for ammonia, 61.6% for OP, and 69.8% for TP [39]. A previous study used HSSF CW for a single family of four people. The system consisted of two settling tanks (each 1.3 × 1.3 × 1.2 m, width × length × depth), CW (10 × 2.5 × 0.5 m), and a zeolite tank (1.6 × 1.3 m). The mean BOD loading was about 120–150 mg/L, the hydraulic residence time was 7 days, and the flow rate was 0.6 m3/d. The mean BOD effluent concentration was about 30 mg/L indicating 87% removal [40].

A septic tank is required to filter the solid or scum before the CWs. It is recommended to load the CWs by gravity (gravity inflow); however, pumping can be used to load the CWs but avoids large doses [5]. The water depth in the cells should be 600 mm or less to ensure enough oxygen concentration in CWs to support microorganism metabolism. Polyvinylchloride (PVC), high-density polyethylene (HDPE), or polypropylene (PPE) of 1.0 mm may be used to prevent leakage from the CWs [5,24,32]. The liner should be free from pinholes and damage, and provision should be taken during the insulation to prevent punctures of the lining. The CWs should be filled with gravel of different sizes. Generally, the CWs can be divided into three sections that should be filled with gravel, including the inlet and outlet (the far edges), the middle bottom layer, and the middle top layer. Large gravel size of 38 to 76 mm should be placed near the inlet and outlet (the edges), medium gravel size of 12.7 to 25.4 mm should be placed at a depth of 18 inches in the middle bottom layer, and a small size of 9.5 to 12.7 mm should be placed to form the top middle layer. The design of inflow and outflow is crucial for efficient CWs [5,24,32]. The following equation can be used to calculate the amount of water in the system:

where Qin = influent wastewater flow (m3/s); Qout = effluent wastewater flow (m3/s); P= precipitation (m3/s); ET= evapotranspiration (m3/s); V= volume of water (m3); t = time.

Qin − Qout + P − ET = dv/dt

- (b)

- Vertical flow (VF): the inflow in VF is required to be passed through a filtration system to prevent clogging of the subsurface flow system [13]. Materials with high sorption sites, such as charcoal and clay, may be used in the filtration system, which can support the growth of pathogens [30]. Therefore, the selection of suitable materials, such as gravel and slag, that reduces the growth of microorganisms can contribute positively to the quality of the effluent and can control the infection. On the other hand, temperature has a significant effect on the biological treatment of wastewater. Therefore, the temperature is a very important parameter in the design of CWs. Low temperature can result in slowing down the degradation process, and as a result, the retention time should be increased in the design. For example, for an influent of 112 kg/ha, a detention time of 11 days is required for a temperature around 5 °C, and a detention time of 5 days is required in the summer at higher temperatures [30]. The detention time is controlled by changing the number of cells in operation and/or by changing the water depth.

- (c)

- Horizontal flow (HF): the flow in HF can be modelled using Darcy’s Law as follows

q = k. i. A

The HF CW system should rely on gravity flow; reduce the amount of filling and cutting, and consider the time required for the system to be fully functional [41]. In addition, the design should be performed based on the hydraulic and organic design criteria; however, other parameters should be measured such as nutrient removal and pathogen reduction. In HF, the water flow should be designed to maintain water flow levels above the surface of the bed depending on the type of CW [24,42,43]. In the HF the degradation in the top surface layer should be designed to support aerobic degradation, while the deep layers should be designed to support anaerobic degradation [41].

2.3.2. Construction

Wetlands should be constructed to meet regulations and high standards of reliability and safety. Special consideration and attention should be paid to the compaction and elevations [41]. Proper compaction is required because compaction controls the infiltration process, especially in the case of SSF. The elevation is equally important to maintain gravity flow. Specifications should be prepared based on site conditions and include regulatory body requirements [32]. In SSF, a sedimentation or filtration tank with suitable retention time is needed for the removal of solid waste to avoid clogging of the subsurface hydraulic system. Usually, the sedimentation tank is placed to receive the influent. The loading of the system should also be adequate. Table 1 contains information about the design of different types of CWs.

Table 1.

Design, operation, and maintenance of CWs.

2.3.3. Operation

After construction, the wetland should be tested for the water level. The channeling and erosion, if any, should be fixed in the trial period [44]. It is preferred to allow a full growing season before introducing the wastewater that needs to be treated. The water level should be maintained as per the design because if the wetland were to dry, remobilization of contaminants may occur. Table 1 contains information about the operation of different types of CWs [44,45].

2.3.4. Maintenance

A plan and schedule for regular maintenance should be prepared and followed strictly to ensure that the wetland performance is up to the required level [45,46]. It is very important to ensure that there is enough contact time between the waste to be treated and the components of the wetlands (microorganism, soil, and plant). A suitable environment for microorganisms and plant growth should be maintained all the time to achieve optimum degradation of contaminants [24,45,46]. Table 1 contains information about the maintenance of different types of CWs.

3. Types of Contaminants Treated in CW

Over the last two decades, the bioremediation technology of CWs has been shown to be an efficient natural process method for wastewater treatment. CWs have been proved to be effective in the treatment of domestic, municipal, agricultural, and industrial wastewaters [29]. CWs, a promising green technology, are also very effective in treating organic-rich wastewater [47], toxic metal contaminated water (e.g., Cr (VI), Se) [48], pharmaceuticals and personal care products (PPCPs) [23], oil refinery wastewater, diesel [41], and agricultural drainage water. In the following subsections of the paper, the use of constructed wetlands in removal of different contaminants is discussed.

3.1. Domestic and Municipal Wastewater Contaminants

Expansion of urban populations has resulted in an increase in the footprint of domestic water supply and sewerage, giving a rise to greater quantities of wastewater. Properly managed municipal wastewater treatment would result in reducing surface water contamination problems [4,5,24]. The process of wastewater treatment not only conserves valuable water resources, but it also takes advantage of the nutrients contained in sewage to grow crops. Wastewater is increasingly viewed as an additional source that can provide a new source of good quality water. However, in many parts of the world, especially in under-developed countries, the operation cost of the wastewater treatment plant is an issue [5]. On the other hand, the applications of CWs for the treatment of domestic and municipal wastewater have been rapidly increasing throughout the world because of their unique advantages of lower operational and maintenance costs. Different types of contaminants (such as nitrogen, phosphorus, organics, solids, metals, and coliforms) can be removed from wastewater by CW treatment methods. This method includes a complex inter-connected system of plants, media, bulk water, and biomass population. The removal of biological oxygen demand (BOD), chemical oxygen demand (COD), total suspended solids (TSS), nitrogen and phosphorous pollutants, heavy metals, and different organic matter (e.g., amino acids, fatty acids, proteins, carbohydrates, lipids) by CW systems have gained substantial attention in recent years [25,49]. In subsurface flow wetlands, the removal of contaminants depends on a diverse range of co-existing physical, chemical, and biological routes depending on numerous environmental and operational factors.

Nitrogen, one of the principal pollutants in wastewater, exists in wastewater in both organic and inorganic forms. The removal of nitrogen through nitrification and denitrification can be achieved using constructed wetlands. The design should carefully consider the parameters that affect the processes such as pH, temperature, dissolved oxygen concentration, and ammonia concentration. Other factors that affect the nitrification and denitrification processes include the plant species and the wetland type [50].

Organic nitrogen presents in amino acids (a form of peptide chain that makes proteins), urea (dispose of ammonia by mammals when amino acids are used for energy production), uric acids (produced by birds and insects), and purine and pyrimidines (involved in DNA making) [25]. The inorganic forms (e.g., ammonium (NH4+), nitrite (NO2−), nitrate (NO3− nitrous oxide (N2O), and dissolved elemental nitrogen or nitrogen gas (N2) as well as free ammonia (NH3)) can be removed in subsurface flow wetland systems, and the removal processes includes biological (i.e., ammonification, nitrification, denitrification, plant uptake, biomass assimilation, dissimilatory nitrate reduction) and physicochemical routes (e.g., ammonia volatilization, and adsorption) [25,51,52]. The organic compounds can be reduced aerobically and anaerobically. The common interactions are as follows:

Aerobic organic degradation:

C6H12O6 + 6O2→6CO2 + 6H2O

Anaerobic organic degradation:

C6H12O6→2CH3CHOHCOOH (Lactic acid)

C6H12O6→2CH3CH2OH (Ethanol) + 2CO2

The removal routes of nitrogen and organics in CW systems are critically dependent on different environmental parameters, such as pH, temperature, oxygen and operational strategies, i.e., presence of organic carbon, hydraulic load, feeding mode, retention time, pollutant loading, recirculation, and plant harvesting [31,53,54].

Phosphorus removal in the CW systems involves the immobilization/removal of phosphorus through chemical precipitation, bacterial action, plant uptake and related physico-chemical pathways, and the adsorptive capacity of the gravel layer. Some studies reported removal of BOD, COD, NH4-N and Total Nitrogen (TN) to be as 77%, 78%, 99%, and 100%, respectively [55]. Different substrate media (such as rice husk, organic wood-mulch, zeolite, aggregates, alum sludge, slag, peat, maert, compost, and shale) were employed to increase the performance of contaminant removal from wastewater by different CW methods. In addition, the common media substrates, such as sand, fine to coarse gravel, limestone, zeolite, calcite, native soil, basic oxygen furnace slag, activated carbon, lightweight aggregates, etc., are used in VF, FWS (free water surface), and HF constructed wetland systems to remove TSS, TN, TP, SO42−, COD, BOD, and organic matters from domestic and municipal wastewater [56]. Moreover, free-floating, submerged, emergent plants, and also microalgae can treat P (>90% of removal) in CWs. Plant species, hydraulic retention time, temperature, type of CWs, effluent concentration, and seasonal changes can influence the removal efficiency of P in CWS [57].

3.2. Toxic Metals/Metaloids Contaminated Water

Treating industrial wastewater, particularly metal-containing wastewater in wetlands, has received increased attention [58]. Wetland soils characterized by their reduced condition and high organic matter content could accumulate heavy metals. Soil and its overlying water, and vegetation, play a major role to remove the metals within wetlands. Dissolved or particulate forms of metals are introduced into wetland systems through the wastewater. The free metal ions are the most biologically available fraction, and sediments in the wetland systems can serve as sinks and reservoirs for metals [59].

Heavy metals are one of the major pollutants in industrial wastewater and gain special concern to treat in easiest and less expensive methods [58,59]. Nowadays, the removal of heavy metals using CWs shows promising results and high efficiency. The heavy metal removal performance of the wetland treatment system depends on the inflow water quality and the metal removal mechanisms. Metal mass removal ranges from 27% to 99% within the wetland. It has been reported that an average of 7.6 kg/ha/year, or 54% of influent metals loadings, could be sequestered within the internal wetland compartments [60,61].

Table 2 presents the heavy metal removal efficiency from different types of wastewaters using different types of plants. Previous studies have assessed the removal of some heavy metals including Cu and Ni from constructed wetlands [49]. For example, the heavy metal removal performance by a laboratory-scale wetland system treating storm runoff has been studied. It was found that the heavy metal removal efficiency in CW ranged from 81.7% to 91.8% with the rates of 36.6–372.7 mg/m2/day for Cu, 75.8–95.3% and 30.8–387 mg/m2 /day for Pb, and 82.8–90.4% and 33.6–362.1 mg/m2/day for Zn, respectively [49,60,61,62,63,64]. Heavy metals such as Cu, Cd, Zn, Pb, Ni, and Co could be readily removed by constructed wetland systems, and the metal uptake seems to be influenced by the types of media used and the types of wastewaters to be treated. The extent of different removal mechanisms might vary depending on the speciation of inflow metals and physicochemical water parameters (e.g., redox, pH, and types of wetland systems).

Table 2.

Heavy metals removal by CW treatment.

3.3. Industrial Wastewater

The discharge of industrial wastewater into the aquatic environment has been one of the primary threats to the ecosystem. Industrial wastewater management faces high technical challenges to achieve its effective treatment for the delivery of a high-quality treated effluent [66]. CWs, especially in developing countries, have been proposed to offer a low-cost and low maintenance treatment alternative for industrial effluent. The feasibility of treating industrial wastewater within a pilot-scale wetland in Argentina was studied. It was found that the average metal removal efficiencies were 83%, 82%, 69%, and 55% for Fe, Cr, Ni, and Zn, respectively [49,61,62,63,64,65].

Previous study reported significant removal of chemical and microbial parameters such as COD (68%), BOD (71%), ammoniacal nitrogen (66%), total phosphorus (21.5%), and total nitrogen (68.5%), and fecal coliforms (47.2%) were achieved in Duckweed-microalgae constructed wetland (DM-CW) [47]. Constructed wetlands (CWs) using S. grossus plat could be used to remove diesel from wastewater [41]. The removal of total suspended solids and chemical oxygen demand (COD) from a 0.1% diesel concentration of wastewater were 100 and 75.4%, respectively.

3.4. Oilfield Produced Wastewater

The treatment and production processes used in the oil and gas industry have a significant impact on the environment and contribute to the contamination of natural ecosystems including surface water [67]. The oil exploration and production processes result in a substantial amount of highly contaminated water. The wastewater from oilfields can contain toxic organic and inorganic pollutants. The wastewater from oilfields is usually stored in large ponds in remote areas. The wastewater from the oilfield can contain various components, including groundwater, water, and chemical compounds used in the extraction process. Previous studies showed that the quality of oilfield wastewater can be improved using a suitable type of CW [68]. Many plants, characterized by high tolerance to saltwater, can be used to decontaminate oilfields wastewater, including acacia nilotica, cotton, Brassica napus, and ricinus communis [29].

A recent study showed that CW can be used to decontaminate/treat oilfield wastewater. The results showed that the contaminant concentration was reduced from 500 mg/L to 30 mg/L [69]. In addition, the results showed that a substantial amount between 30 and 50% of water was lost in the process due to the evapotranspiration process. It has been proved that CWs can completely remove nitrogen and phosphorous from petroleum-contaminated wastewater. The decontamination of petroleum wastewater is known to be a companied with a 10–12% increase in the pH of the water flow.

Petroleum refinery or oilfield produced wastewater can be treated in vertical surface flow constructed wetland (VSFCW) systems vegetated with Eichhornia crassipes (water hyacinth) to meet the compliance permissible limit set by Federal Environmental Protection Agency (FEPA) and WHO for discharge into surface waters [28]. Bio-treatment of petroleum wastewater in vertical surface flow constructed wetland resulted in the removal efficiencies of 91.5% turbidity, 94.6% BOD5, 80.2% COD, 92.6% TPH, 9 mg 0.4% oil and grease, 94% cadmium, 92.5% lead, 93% chromium, 94.8% iron, 92.2% nickel, and 57.7% chloride [28].

3.5. Oil Refinery Wastewater

Large volumes of wastewater during extraction processes are produced as a result of production, storage, distribution, and processing of petroleum [70]. Oil refinery wastewater is also generated by accidents due to spills from water/fuel mixtures and leaks from underground storage or water [70]. Oil exploration and exploitation activities generate a variety of toxic wastewater consisting of different organic compounds and inorganic and heavy metals, thus leading to pollution of the terrestrial and aquatic ecosystems [71]. Organic contaminants produced by oil refinery industrial activity include BTEX (benzene, toluene, ethylbenzene, and xylene), PAH, linear alkylbenzene sulfonates chlorinated hydrocarbons, benzene and methyl tert-butyl ether (MTBE), aliphatic and aromatic petroleum hydrocarbons consisting of methyl-tetrabutyl ether, phenol, 2,3,5,6-tetramethylphenol, naphthalene, xylene, tetradecane, 4-chloro-3-methylphenol, and 3-tert-butylphenol at different concentrations [72]. Table 3 shows the plants that can be used in CW for oil refinery wastewater.

Table 3.

Major contaminant removal from oil refinery wastewater in different wetland systems.

A previous study reported that refined wastewater has higher toxicity than crude oil due to the addition of metals and their speciation during the refining processes [28]. Many heavy metals such as Fe, Cr, Cd, Pb, Hg, Ag, Mo, Cu, Zn, and As from oil exploration and exploitation activities can be found in petroleum wastewater [71]. Petroleum refinery secondary wastewater can be treated by vertical surface flow constructed wetland (VSF-CW) vegetated with Eichhornia crassipes [28]. The wastewater having relatively elevated levels of turbidity (18.30 NTU), BOD (20.40 mg/L), COD (86 mg/L), TPH (16.6 mg/L), oil and grease (18.4 mg/L), heavy metals (cadmium (0.034 mg/L), lead (0.12 mg/L), chromium (0.47 mg/L), iron (1.54 mg/L), nickel (0.09 mg/L)), and chloride (1412 mg/L) can be treated with the 90% to 95% of removal efficiency by vertical surface flow constructed wetland (VSF-CW). Plants, with the natural ability to uptake metals, can remove heavy metals in CWs by microbiota uptake [76], plant uptake, as well as adsorption onto media and sediments in the system [77]. In CWs, additional processes such as biosorption, bioaccumulation, redox transformation, dissimilatory sulphate reduction, and precipitation as insoluble salts can remove heavy metals from wastewater [48,49,51]. A previous study showed that Cu can be removed using the calcined sludge; therefore, treating different waste at CW can enhance removal efficiency [78].

3.6. Pharmaceuticals and Personal Care Products (PPCPs)

Over the last few decades, the production of a wide array of pharmaceuticals and personal care products (PPCPs) has been seen in the world due to unprecedented advancements in the medicine and cosmetics industry that revolutionized healthcare and beautification facilities [79]. Biotechnology, a cost-effective and environmentally sound approach, has gained great interest that uses aquatic macrophytes and microalgae for wastewater treatment [23,34,80]. Phytoremediation in CW is a well-established and efficient method for decontamination of PPCPs from the environment. Scientists and engineers from several countries have paid attention to the potential of aquatic macrophytes to treat and recycle pollutants from municipal and industrial wastewater.

The phytoremediation process in CW, one of the methods used to remove PPCPs, can act as a primary, secondary, or tertiary treatment step [80]. A previous study reported that caffeine (>99.9%), acetaminophen (99.98%), IBU (99.6%), naproxen (99.4%), and triclosan (98%) were up-taken in CW treatment [23]. Another study showed more than 95% removal efficiencies for caffeine, carboxy-ibuprofen, hydrocinnamic acid, hydroxy-ibuprofen, methyl dihydrojasmonate, oxybenzone, salicylic acid, and IBU, while 70–90% of naproxen, diclofenac, galaxolide, and tonalide. Treatment of water contaminated with PPCPs such diclofenac, IBU, naproxen, tonalide, and bisphenol using as HSSF planted with P. australis is promising, and the removal was around 90% [43]. The removal can be attributed to biodegradation as well as biosorption. Various studies show evidence that plant species including Berulaerecta, Irispseudacorus, Juncus effusus, P. ustralis, and Typha latiflolia can be used to remove/degrade 90% of IBU and iohexol from wastewater. On the other hand, it was proven that CWs planted with Scirpus validus can reduce 74% of carbamazepine and 98% of naproxen from wastewater in hydroponic conditions [81,82]. Different types of plants such as Phragmites australis, Typha Angustifolia, P. australis, Spathiphyllum, Oryza sativa, Capsicum annuum, Scirpus validus, Populus nigra, Typha angustifolia, P. australis, Cucumis sativus, etc., were used in HSSF, VF, and SSF type CWs to remove PPCPs (e.g., Caffeine, Ibuprofen, Naproxen, Chlortetracycline, Diclofenac, Carbamazepine, Tonalide and Ketoprofen etc.). The removal of these PPCPs was found to be in the range of 70% to 95% [20,51,52].

In a recent study, five endocrine disrupting chemicals (EDCs), such as Bisphenol A (BPA), Nonylphenol (NP), Nonylphenol monoethoxylate (NP1EO), Nonylphenol diethoxylate (NP2EO), and Triclosan (TCS), were treated in HSF and VF CWs system. The removal range was found to be 48% to 99%. The removal mechanisms of these EDCs were biodegradation under aerobic or/and anaerobic conditions as well as adsorption onto the organic matter present in the CW substrate. Compared to the VF CW system, HF CW demonstrated low efficiency in removing BPA. On the other hand, higher removal efficiencies were achieved for NP1EO and NP2EO in the HF CW system [83].

All PPCPs can be considered as persistent organic pollutants (POPs). In addition to PPCPs, other chemicals such as aldrin, chlordane, dieldrin, endrin, heptachlor, mirex, toxaphene, hexachlorobenzene (HCB), polychlorinated biphenyls (PCB) DDT, and polycyclic aromatic hydrocarbons (PAHs) such as polychlorinated dibenzo-p-dioxins/dibenzofurans were treated with subsurface flow systems (SSF) and free surface flow types constructed wetland [84,85]. Phytoremediation process in CW can remove most POPs, and nearly 100% efficiency in removing organic compounds from wastewater may be achieved in such systems. The plants used in CW to treat different POPs were Acorus calamus L., Carex rostrate Stokes, Phragmites australis, Schoenoplectus lacustris (L.) Palla, and Typha latifolia L., Nymphaea alba L., Nuphar lutea Myriophyllum spicatum Lemna minor L., Spirodela polyrhiza L., and Eichhornia crassipes [85]. The removal capacity by phytoremediation process in CW were found to be 66% to 100% when free water surface systems (FWS), subsurface flow systems (SSF), or vertical subsurface flow (VFS) constructed wetlands were used [85].

3.7. Agricultural Wastewater

Wastewater discharge into natural systems, rivers, lakes, and groundwater can cause a detrimental impact on the future use or function of these natural aquatic systems. Rainfalls, floods, and overflow can carry wastewater from livestock and spread contamination [86]. The wastewater from livestock processes needs to be treated to reduce the nutrients concentration, organic matters, and suspended solids [86]. The SF constructed wetlands support wildlife habitats. On the other hand, the SSF prevents the spread of mosquitoes in CWs, reduces the bad odor associated with CWs, and results in avoiding human contacts [87].

It has been proven that CW can be used to treat the BOD, TSS, and facial coliforms from dairy parlour wastewater. CW planted with different macrophytes show 75% to 85% removal of TSS from agricultural wastewater. The retention time is directly proportional to the efficiency of the removal process of dissolved humic substance. Results showed that 7-d retention time resulted in 47% to 75% removal of nitrogen, 37% to 74% removal of phosphorous, and 99% fecal coliform removal. The selection of suitable plant species is crucial in the degradation process. For instance, CWs planted with Juncus, Scirpus Typha and mixed spices resulted in 90%, 92%, 94%, 91%, and 99% removal of BOD5, TTS, NH3-N, TKN, and facial coliforms, respectively [88].

Some other operational challenges include the removal of pesticides. Constructed wetlands can be used to remove fungicides, insecticides, and herbicides from wastewater mixed with agriculture wastewater. Recent research concluded that the deposit load has an important effect on the removal of pesticides from the wastewater [89].

A recent study discussed the removal efficiency of boscalid from rinsing water produced during cleaning of pesticide spraying equipment using two pilot-scale horizontal subsurface flow (HSSF) constructed wetlands (CWs) [90]. The CWs were planted with common reeds (Phragnites australis) in fine gravel (code name FG-R) and the other cobbles (CO-R). The results showed that the removal in both systems ranged from 49% to 100%, indicating the efficiency of HSSF systems in treating boscalid-polluted agricultural equipment rinsing water in the agricultural area.

Another study investigated the removal of pesticides using horizontal subsurface flow (HSSF) CW systems that were operated continuously for a long period of time (one year). The CWs (containing either Phragmites australis or Typha latifolia) were able to remove up to 73.7% and 58.4% of pesticides in the system, respectively. High concentrations of terbuthylazine were detected in roots, leaves, and shoots of both plants of the CWs [91]. In another study, three horizontal subsurface flow (HSSF) constructed wetlands (CWs) planted with Phragmites australis in fine gravel layers were used to treat fluopyram from rinsing water produced during the cleaning of pesticide spraying equipment. Higher fluopyram removal efficiency (>96%) was achieved in the HSSF system. The fluopyram removal mechanisms were achieved through microbial biodegradation, adsorption on porous media, and bioaccumulation processes [92].

3.8. Compost and Landfill Leachates

The leachate from landfill facilities can be harmful and can be a real threat to the environment. CWs can be used as one of the alternatives to treat landfill leachate. For instance, HSSF CW planted with Vetiver was used to treat leachate from composting facility in Isfahan, Iran [42]. The study period was five months, during which the results of leachate treated with CWs were compared to leachate that was not treated. The loading rate used for the HSSF CW was 24 L/d. The results showed that 75% of the BOD5 was removed. Although the removal of COD was around 53%, it was considered as an improvement compared to the removal without the CWs, which was around 26%. The removal of NH3-N, NO3-N, and TN was around 70%, 74%, and 74% respectively. This study showed that a sub-surface horizontal flow constructed wetland planted with Vetiver has the potential to be used as a leachate pre-treatment or treatment method to treat highly contaminated composting leachate [42].

3.9. Mine Drainage

Mining activities use a considerable amount of water in extracting valuable parts from ores. The process resulted in a highly toxic solution of acid mine drainage (AMD). The AMD is carcinogenic and has a detrimental effect on the environment. Nevertheless, CW can be used to treat AMD and reduce the toxicity in the effluent. CW is an environmentally friendly process that encompasses various processes including biological, chemical, biogeochemical, geochemical, and physical processes to reduce contamination in the wastewater. Heavy metal compounds are the main component of AMD, which is characterized by low pH [93]. The mechanisms that are responsible for heavy metal removal from AMD include sedimentation, sorption, accumulation in the plant, and precipitation. Heavy metals accumulation in the plant represents part of the removal, but not a high percentage. It has been proven that a significant amount of heavy metals is removed from AMD in CW by sedimentation [93].

3.10. Storm Water Runoff

Storm runoff is a highly variable and intermittent feedstock that can be treated by constructed wetlands. There has been increasing interest in the use of constructed wetlands to remediate storm runoff, which often contains high levels of metals, mainly including Cu, Cd, Zn, and Pb [24,58,59]. Previous work investigated the heavy metal removal performance by a laboratory-scale wetland system treating storm runoff. The removal efficiencies and rates for metals monitored ranged from 81.7% to 91.8% and 36.6–372.7 mg/m2/day for Cu, 75.8–95.3% and 30.8–387 mg/m2/day for Pb, and 82.8–90.4% and 33.6–362.1 mg/m2/day for Zn, respectively. Stormwater runoff where systems receive low hydraulic and constituent loads can be treated by constructed wetland systems (CWs). The CWs remove contaminants, nutrients, and solids from runoff water [49,74].

3.11. Microplastic on CWs

Synthetic organic polymer plastics have been heavily used in different purposes such as household and personal care products, medical applications, clothing, agricultural (e.g., mulching,) engineering materials, infrastructure, and land use practices media [94,95]. The micro and nano plastics are invisible, and humans are exposed to these products through the use of personal care products containing microplastics [96,97]. The extensive use of plastics products (which are very slow biodegradable materials) in human everyday life has resulted in posing a risk to humans and the ecosystem. The distribution and transport of microplastics (MPs) in CWs depend on morphological features and the apertures of the substrate, soil texture, and vegetation coverage [98]. Moreover, macroinvertebrates were used in horizontal subsurface flow constructed wetlands (as tertiary treatment) to investigate the distribution of MPs in CW and found the potential role of macroinvertebrates in MPs distribution and removal [99]. Recent study showed that wetland plants, substrate composition, hydraulic loading rate, hydraulic retention time (HRT), and biofilm in CWs can influence the migration, transformation, and removal behaviors of MPs [100,101,102]. Multi-stage constructed wetlands (CWs) played a crucial role in treating the MPs (>89% of removal) in water. Plant species such as P. australis, Lolium perenne (garden cress), Sphagnum palustre (peat moss), Vigna radiata (mung bean), Spirodela polyrhiza (great duckweed), and Allium cepa (garden onion) were used in CWs to reduce MPs or control MPs migration [103]. The transformation of toxic MP compounds into nontoxic or less toxic forms through accumulation by roots or immobilization within plants species is one of the mechanisms to control MPs migration and distribution in water [20,103]. Previous studies showed that mangroves can uptake considerable amounts of microplastics [93,97,98,99]. The retention of microplastic in the mangrove depends on the paling pattern and density, roots of the mangrove, as well as the dead plant debris and branches [94]. Another study showed that the uptake of microplastics by plants depends on particle characteristics such as size and charge, as well as plant features [103,104]. It was found that microplastic particles are attracted to the soil organic carbon resulting in an increased stability of microplastic in the soil sediments [105,106]. A recent study presented evidence of the accumulation and retention of microplastic particles in freshwater reeds [107]. The average concentration of microplastics on reeds samples was found be around 4.9 items/individual [107]. Very few studies are available in this area in the current literature; therefore, the numbers here are not confirmed by other studies [107]. A recent study showed that microplastic fibers contributed positively on the growth of plant community, and this was attributed to the reduction in soil bulk density and increase in aeration due to the existence of the microfibers [108]. Another study showed plastic particles can contribute to an increase in plant biomass [103]. Some studies reported negative toxic effects of microplastics on plant germination and root elongation [103,109]. On the other hand, contradicting results have been reported on the effect of the plastic particles on plant photosynthesis [103].

4. Microorganisms Used in the Wetland

The design of wetland components includes the substrate (the soil matrix), the hydrology (water flow and water control structures), and the plants. However, important components of wetlands such as communities of microbes and invertebrates are developed naturally [51,110]. Bacteria play a dominant role in contaminant degradation and in the transformation of contaminants between the environment and the plant. Different types of heterotrophic and autotrophic bacteria contribute to contaminant degradation. Heterotrophic bacteria utilize organic carbon for their metabolism; therefore, they are active in the degradation of organic pollutants such as petroleum hydrocarbon. On the other hand, autotrophic bacteria use carbon dioxide for cell growth [111].

In aerobic digestion, the organic pollutant serves as electron donor and oxygen serves as electron acceptor. In this process, the pollutant is decomposed to CO2 through a certain pathway, which involves the production of daughter products of the original contaminant [23,73,112]. It is very important to mention that in some cases some daughter products of these processes are more toxic than the original pollutant. Therefore, it is very important to ensure that degradation happens at the end of the processes (i.e., produce CO2 and H2O). The shallow surface of the surface flow constructed wetlands and the top layers of the subsurface flow constructed wetlands provide a suitable environment (i.e., oxygen concentration) for aerobic degradation of contaminants [23].

In anaerobic digestion, the organic pollutant serves as electron donor and CO2 serves as electron acceptor. Some other chemical compounds serve as electron acceptors including nitrate, nitrite, sulphate, and carbonate. In denitrification, nitrate and nitrite serve as electron acceptors, and the organic pollutant serves as the electron donor [13,23]. Table 4 shows various types of bacteria that contribute to nitrification and denitrification processes

Table 4.

Bacterial strains involved in nitrification and denitrification in constructed wetlands.

The metabolism of each type of bacteria is optimum under specific environmental conditions including pH, temperature, oxygen concentration, and sunlight. In general, pH around 6–7 is suitable for most types of bacteria. A temperature around 28–30 is suitable for most types of bacteria. However, thermophilic bacterial strains survive under very high temperatures, such as Sulfolobus Solfataricus, Bacillus licheniformis, and Thermomonas hydrothermalis [110].

Temperature has an effect on the microbial activity in the wetlands; therefore, the temperature can directly affect the success of the treatment process. Low temperatures slow down the microbial activities, while very high temperatures have detrimental effects on the microorganisms. Sorption and sedimentation processes are also affected by the temperature. Temperature directly affects the concentration of dissolved oxygen in the water and the oxidation-reduction potential. High temperatures cause low dissolved oxygen environments. Temperatures between 20 and 30 °C are suitable for the growth of plants as well as bacterial growth [11,23].

There are several aspects concerning microorganisms in enhancing the outcome of constructed wetlands through prolonging the survival of the microorganisms or improving bacterial viability and persistence in the wastewater environment. This can be divided into two main factors: the wetland environment and the characteristics of microorganisms. Survival and persistence of bacteria in the wetlands are affected by changes in soil pH, nutrients, electron acceptors, osmotic stress, temperature (cold or hot weather), UV exposure, and chemicals [117]. In addition to the wetland environment, the characteristics of the microorganisms play a significant role in their existence; for example, some bacteria form biofilms that protect themselves from external stresses. Another mechanism for bacteria to survive is to produce spores [118]. In the event of severe weather and nutrient deprivation, bacteria will die, eventually producing endospores which have a very hard shell and protect them [119]. Typically, under extremely poor living conditions, endospores are in a state of dormancy (sleeping condition); once the environmental conditions improve, the spore will germinate and outgrow [1].

Alga contributes to removal of contaminants in constructed wetlands. For instance, Chlorella vulgaris and Scenedesmus obliquus strains can remove selenium from river water when treated with a wetlands system by volatilization and accumulation [48]. Plants and microorganisms can contribute to the volatilization of selenium. The volatilization of selenium has been approved to be dependent on nutrients (N and P). Previous studies showed that the volatilization of selenium is more sensitive to increase in P than the increase in N [120].

5. Phytoremediation and Bacteria Interaction

Phytoremediation in constructed wetlands includes phytoextraction, phytovolatilization, phytodegradation, rhizodegradation, and phytostabilization [15]. Different plants, as well as phytoplankton, are used in wetlands [121]. The most common plants used in constructed wetlands are P. australis (35.29%), T. latifolia (17.65%), J. effusus (8.82%), P. arundinacea (7.84%), and Z. latifolia (5.88%). Other plants also are used in the wetlands [1,79,81]. Cattails (Typha latifolua) and reed (Phragmites australis) are common on most wetlands. Some of these plants are vascular and some are non-vascular plants. The main role of the plants in the wetlands is to provide sorption sites and exchange mediums for microorganisms and the pollutant [121]. The plants provide an organic carbon source for microorganisms and slow down the flow of water, therefore enhancing the sedimentation and pollutant settlement. Moreover, plants provide means for soil stabilization, and the roots increase the soil permeability. The plants are important elements in the aesthetic value of the wetland. Not all plants can tolerate high concentrations of wastewater or pollutants [122]. The selection is made based on which plant can grow better. For instance, Acorus calamus tolerates an acidic environment, Iris versicolor can tolerate high nutrient concentrations, Scripus validus is effective in contaminant removal, and Scirpus pungens can remove heavy metals [123].

The contaminant concentration in the wetlands can affect the growth of the plants. In some cases, the above-water parts of the plants are not affected by the contaminant, but the length of the roots is affected [4,5,24]. This can be attributed to the fact that the roots are in direct contact with the contaminated water. Depending on plant tolerance to the specific contaminant, the stem height, as well as the root length, can be affected with physiological toxicity at certain contaminant concentrations [73,121].

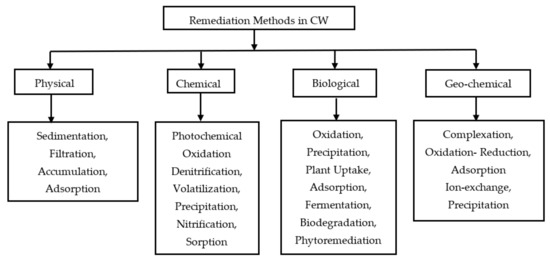

5.1. Conventional Contaminant Removal Mechanisms

The conventional processes in the constructed wetlands include physical, chemical, geochemical, and biological processes. Figure 4 shows the removal mechanisms of different wastewaters in CW. The biodegradation processes are initiated as the contaminated water flows through various components of the wetlands including substrate (gravel and/or sand), plants, and microorganisms [4,5,24]. The pollutants are removed/degraded by different mechanisms such as filtration and sedimentation of suspended particles [124]. Other mechanisms also contribute to the removal of pollutants such as sorption, photolysis, precipitation, volatilization, and plant uptake [124,125,126]. The mechanisms by which plants can degrade contaminants include metabolic and hydraulic processes. The plants grow rapidly and transfer the contaminant from the environment around the roots to the leaves. The indigenous microorganisms in the vicinity of the roots play a dominant role in the removal process. Microorganisms facilitate the following processes: phytotransformation, rhizosphere bioremediation, phytostabilization, phytoextraction, or rizofiltration [122].

Figure 4.

Remediation mechanisms in CW for different wastewaters.

Various plants show not only high potential in removing organic contaminants from wastewater but also transforming the contaminant into harmless by-products [122]. The pollutants are degraded due to the process of releasing certain enzymes, roots exudates, and also the accumulation of organic carbon in the soil. For example, rizofiltration is the process through which the dissolved heavy metals are removed from the water to the roots and the to the plant leaves [82]. On the other hand, organic matters are degraded/ removed from wastewaters through various mechanisms that contribute positively to decreasing the concentration of pollutants. Volatilization, photochemical oxidation, sedimentation, sorption, microbial degradation, fermentation, and aerobic and anaerobic respiration are mechanisms that are involved in the degradation of organic pollutants [76,82]. Nitrification denitrification, plant uptake, volatilization, and adsorption are the mechanisms through which the concentrations of various types of nitrogen, organic and inorganic, are reduced [112]. Phosphorous, a major component of the storm runoff and agriculture wastewater, is removed from wastewater through adsorption, precipitation, and plant uptake [112].

5.2. Kinetics of Biotreatment in CW

Researchers have investigated the use of various kinetics modeling approaches including first-order kinetics, the constant stirred tank reactor (CSTR), Monod kinetics, and Monod-CSTR kinetics to describe the degradation process in the CW. For instance, a previous study investigated the removal rates of BOD5, COD, TPH, and NO3-N from wastewater using CW planted with Eichhornia crassipes [29]. The results showed that the removal constant rates R2 were around 0.89 to 0.99 for BOD5, COD, NO3-N, and TPH [127]. For BOD5 removal, in vegetated VSF-CW, the estimated area-based first-order (K-C) and the first-order (K-C *) removal rate constants of BOD5 (kA) were 0.12 and 0.16 md−1, respectively [29,52]. The area-based first-order (K-C)-CSTR removal rate constant is 0.57 m day−1 while the Monod-CSTR kinetics maximum removal rate (Kmax) and multiple Monod-CSTR kinetics (Kmax) were 3.27 and 3.47 gm−2 d−1, respectively, in the vegetated VSF-CW. For the COD removal in the vegetated VSF-CW, the kA (first-order K-C) and kA (first-order K-C *) for COD were 0.07 and 0.11 mday−1, respectively, while the kA (first-order CSTR flow), Kmax (Monod-CSTR), and Kmax (multiple Monod-CSTR) were 0.21 m day−1, 4.12 gm−2 day−1, and 4.35 gm−2 day−1, respectively. Previous studies showed that the first-order CSTR model is not precise enough to describe the BOD5 and NO3-N removal. On the other hand, Monod CSTR model showed high match between the model and the test results [52].

The contaminant removal can be described by the mathematical model (). The rate (k) is dependent on area of wetland, volume of flow, and temperature. The rate coefficient represents the contaminant degradation speed [52]. The relation between the degradation and constructed wetland inflow and out flow is described by the second equation in Table 5. The water flow in the constructed wetland cannot be described by Plug Flow (PF) nor Continuous Stirred Tank Reactor (CSTR). The best model found to describe the constructed wet lands is the Tank-in-Series (TIS) model, which it takes into consideration background concentration and the time effect on the process [127]. A single equation can be formed using a combination of non-ideal flow and background concentration to describe the contaminant removal in the wetlands [52]. This equation can be denoted by P-k-C*, where P is the pollutant weathering, k is the first-order kinetic, and C* is the non-zero background concentration [127]. Monod kinetics can be combined with CSTR to form a model describing the relation between the inlet and outlet concentrations through the half saturation constant of the limiting substrate and maximum pollutant rates. Multiple Monod kinetics, which assumes more than one substrate that limits the rate of contaminant degradation, can be used to express the reactions in the constructed wetlands. Table 5 below contains kinetics equations that can be used in the design of constructed wetlands [127].

Table 5.

Kinetics equations that are used in CWs.

6. Economical Evaluation and Challenges in the Field

In general, there are variations in the construction cost of SSF CW compared to the construction cost of SF CW [2,4]. However, there are common items that should be considered in the calculation of the cost of both approaches. The cost can be divided into two stages: the acquisition and design stage and the construction and commissioning stage [5,19]. The first stage includes land acquisition, geotechnical investigation, and system design. The construction and commissioning stage includes site mobilization (site office, fence and access road), construction activities (plastic liners, filtration, media, vegetation, flow system, hydraulic structures), supervision fees, and commissioning (trial period) [24]. Special consideration should be taken in the cost regarding the availability of water and additional area if required.

The cost of CW is mainly dependent on the specification and the design components, which vary from one system to another. The costs of media, plant species (vegetation), hydraulic structures, pumps, and filtration systems are considered as the main design components that contribute to the majority of the total cost [19]. The selection of suitable components for the wastewater to be treated is crucial for the maintenance and operating costs. Economical CW systems should have low maintenance and operation cost. In most cases, the selection of remediation method is made based on the efficiency of the method (output/cost) [128]. The operation and maintenance costs include the personnel need to run the facility, the energy cost, facility infrastructure maintenance, plant replacement and disposal, cleaning, pumps and tools replacement, and maintenance quality control (sampling and analysis cost) [24].

The challenges facing constructed wetlands include methane production. It has been observed that an increase in the concentration of CH4 in the air is associated with constructed wetlands used to treat sewer wastewater [126]. Methane is considered one of the important contributors (greenhouse gases) to ozone destruction. There are specific types of plants that when used in constructed wetlands produce high CH4, for instance, Z. latifolia, J. effusus, and P. australis. On the other hand, some plants including P. arundinacea, C. papyrus, and T. latifolia produce less CH4 in the air compared to the aforementioned types. Not only the types of plants affect the production of CH4 but also the intensity and the combination of the plants have a significant effect on the emission of CH4 [44]. Potential for development and challenges in biogas (e.g., CH4) as an energy resource is one of the alternative options to reduce greenhouse gas emissions from the constructed wetland [129]. Wetland biomass as a cooking fuel can offset some of the demand for unsustainable and unhealthy solid fuels (such as charcoals). The potential to employ proven small-scale biogas technologies in CW can be utilized as an energy source in the community. Depending on the plant type selected, wetland biomass can yield energy for a 200-person community ranging from about 12–150 GJ/year [129]. Thus, biomass replacing wood can reduce stress on ecosystems. Moreover, biomass can also replace manure as a fuel source; this organic matter can be used as fertilizer in agricultural activities, thus offsetting some of the needs for artificial fertilizers [129].

7. Conclusions, Innovations, and New Directions

CWs have unique characteristics, as they are not only a simple and environmentally friendly treatment method but also continuously evolving to contribute to the global ecosystem. CWs are a home for native and migratory wildlife and create a balance between the land development and the need for green cover [130]. The new innovations and directions in the CW are as follows:

- (I)

- Potential use of wetlands to sustain food source

Recent discussion in the scientific community and in engineering societies landed on some potential uses for CWs in the near future. CWs can be utilized in agriculture schemes. CWs can result in increasing fertility of the soil, creating a belt to protect the agriculture schemes from storm runoff, and providing shade from wind. It is highly recommended for the stakeholder representing governments to increase the uses of CWs.

The agricultural schemes use fertilizers (phosphate), and an excess amount of these fertilizers is usually flashed with storm runoff and contaminates the nearby water bodies. High phosphorus concentration promotes the growth of algae. Thus, covering the surface of water bodies results in low oxygen concentration and decreases the quality of water. The watershed conservation authorities in many parts of the world are responsible for management of the storm runoff, which in many cases is associated with agriculture wastewater. These governmental bodies strive to develop regulations to protect the public interest in water bodies. However, the framers are usually in conflict with these government bodies regarding the regulation and operation of the agricultural schemes. The runoff from agriculture schemes contributes negatively to the quality of the receiving water bodies. The negative effect in the receiving waters can occur as change in salinity or excess nutrients. Constructed wetlands can be used as a receiving water body that contributes to reducing the nutrients in the runoff and decreases the erosion effect. CWs can provide a shade for the agricultural schemes and minimize the adverse effect of the foods. Nevertheless, CWs host birds and can be used as a source of timber and wood.

- (II)

- Wetlands as mitigation and adaptation to the climate change

In the last decade, the greenhouse gas effect in climate change has gained increasing interest in the scientific community. Constructed wetlands and natural wetlands can play a dominant role in reducing the adverse effect of the greenhouse gases. The plants can contribute and utilize the carbon, which is a major components of greenhouse gases. On the other hand, recent studies showed that certain microorganisms can be used in carbon fixation. CWs, as a part of the global ecosystem, can also be affected by the phenomena resulting from greenhouse gases such as sea level rise and the groundwater level. It has been recognized that the CWs can store large amount of carbon; however, CWs can release CO2, CH4, and NO when subjected to disturbance. Therefore, it is essential for a sustainable environment to keep the CWs running and increase the area covered with the CWs.

- (III)

- Wetland Wildlife Considerations

The CWs support a diversity of microorganisms, birds, and plants. The environment in CWs is suitable for other wildlife species. Microorganisms can be introduced to the CWs or can form colonies naturally. The vegetation in the CWs plus the microorganism colonies form a suitable habitat for a wide range of species. Various types of plants and animals have the capability to grow in contaminated water, including air-breathing invertebrates such as water beetles, bugs, water snails, etc. These species can contribute to the ecological cycles.

- (IV)

- Biomass and Renewable Energy Source

Constructed wetlands (CWs) are a biological technology, require optimum maintenance, and are effective in treating wastewater under the ambient environment. Biomass, as a source of renewable energy, harvested from CW can be used as a renewable energy source. The CW-treated effluent can also be used in the agricultural field. For example, plants such as Phragmites spp., Typha spp., A. donax, and C. papyrus used in CW can yield about 1500 g to 6000 g/m2 of dry mass per square meter (g/m2) [129]. Methane yields vary from about 170 to 360 L of methane per kilogram of dry mass (LN/kg). They further reported that an average of 110 MJ through direct combustion or 1660 L of methane from biogas can be generated from 1 m2 of CW planted with A. donax. Thus, bioenergy production from CW can reduce reliance on fossil fuels and has the potential to offset energy and irrigation needs in different regions. The microbial fuel cell (MFC), which is used to generate energy from wastewater, is characterized by anaerobic conditions at the anode and aerobic environment at the vicinity of the anode. Similar conditions naturally exist in CW, where a high concentration of oxygen presents at the water surface and anoxic conditions at the bottom of the CW. Therefore, MFC can be integrated into CW to promote the use of CW as powerful tool for treatment of wastewater and generation of energy [131,132]. The basic concept of the MCF is the use of anerobic digestion of high-strength wastewater to produce biogas. The fact that CWs require low energy for operation and low maintenance costs, plus the integration of MFC, could make the CW the best choice for the authorities and policy makers [132,133]. From the current state, it is obvious that the technology has the potential to provide sustainable wastewater management as well as a bioenergy source without creating any burden on water resources.

- (V)

- The removal of POPs and microplastics on CW

The current knowledge is limited about the accumulation and retention of microplastics in plant. There is a potential to advance the understanding of the interactions between micro- and nanoplastics on plants and macrophytes. The is a gap in knowledge that needs to be addressed including the discussion about plant exposure conditions, the uptake mechanisms, and the toxic effect of the microplastic on the plants. It was reported that 83–89% of MPs are removed using integrated vertical flow CW systems, and 27–60% are removed by surface flow constructed wetlands; however, more studies are required to address the gap of knowledge [100].

POPs such as polychlorinated biphenyls (PCBs) and polycyclic aromatic hydrocarbons (PAHs) can be removed in CW systems. The removal capacity by phytoremediation processes in CW were found to be between 66 to 100%. A recent study showed that five endocrine disrupting chemicals (EDCs) were removed with different percentages of 48% to 99% in HSF and VF CW systems [83]. The removal mechanisms include plant uptake, adsorption to the bottom sediments (in the SF system) or substrate of the beds (in the SSF systems), as well as adsorption to suspended solids, followed by sedimentation. Although POPs can be removed in CW, there are some limitations that need to be addressed including the effect of changes of temperature from season to season, and the uptake pathways need to be investigated to determine the contribution of each uptake mechanism.

Author Contributions

Conceptualization, I.H. and S.R.C.; methodology, I.H. and P.K.P.; formal analysis, S.A.R. and I.H.; investigation, I.H. and S.R.C.; resources, S.A.R.; data curation, I.H. and S.R.C.; writing—original draft preparation, I.H. and S.R.C.; writing—review and editing, I.H., S.R.C., P.K.P. and S.A.R.; visualization, P.K.P. and S.A.R.; supervision, S.A.R.; funding acquisition, S.A.R. All authors have read and agreed to the published version of the manuscript.

Funding

The support received from Interdisciplinary Research Center for Membranes and Water Security, King Fahd University of Petroleum & Minerals, Dhahran, Saudi Arabia, with funding grant and financial support for this work through project No. INMW2105.

Data Availability Statement

The data presented in this study are available in all tables and figures of this article.

Acknowledgments