Research on Structural–Mechanical Properties during the Castor Episperm Breaking Process

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental Material

2.2. Experimental Device and Facility

3. Results and Discussion

3.1. Extrusion Pressure-Time Curve and In-Situ Observation of Castor Seed Coat

3.2. Mechanical Properties of Castor Seed Coat under Different Pressure Spacing

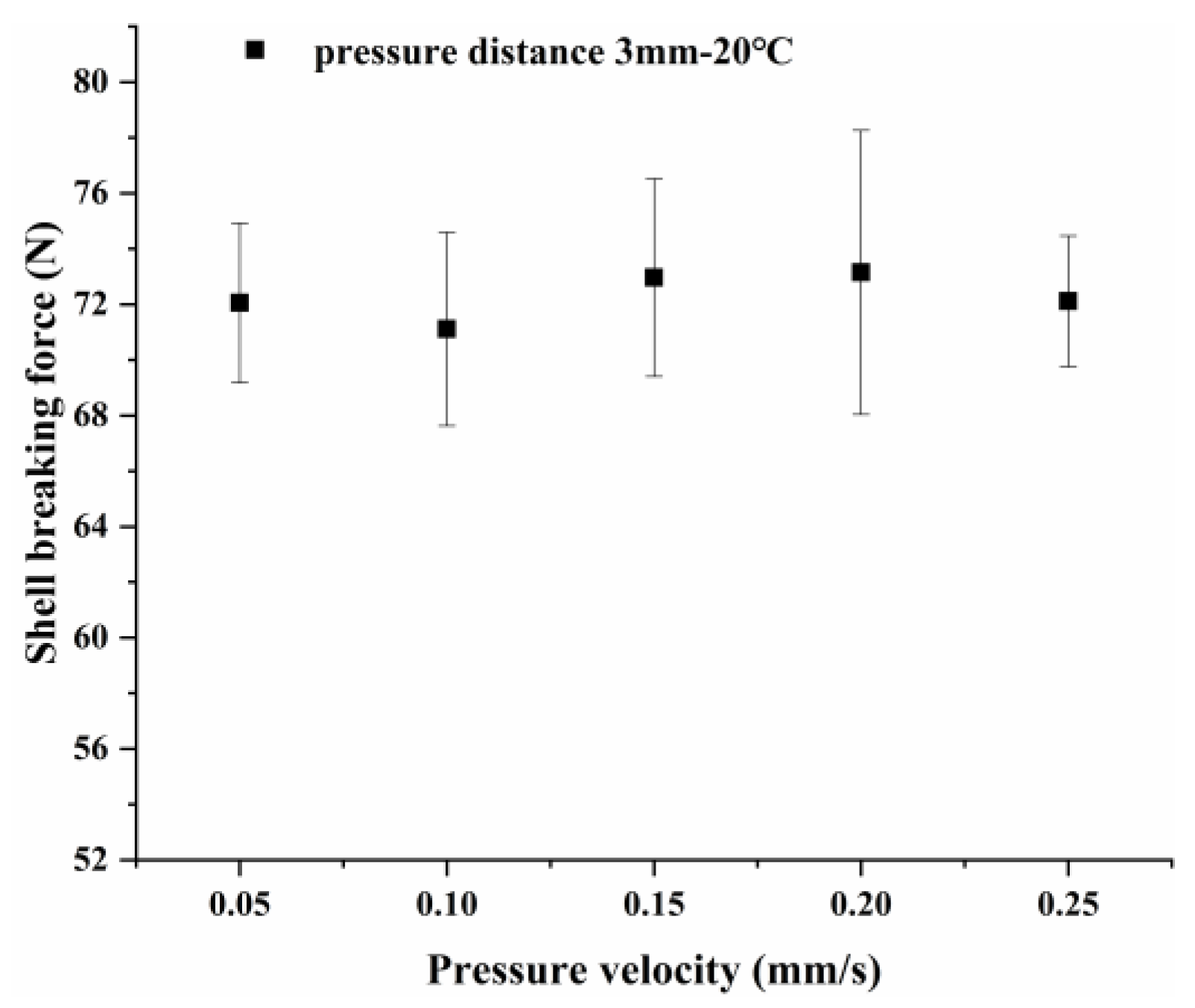

3.3. Mechanical Property of Castor Outer Seed Coat under Different Pressing Rates

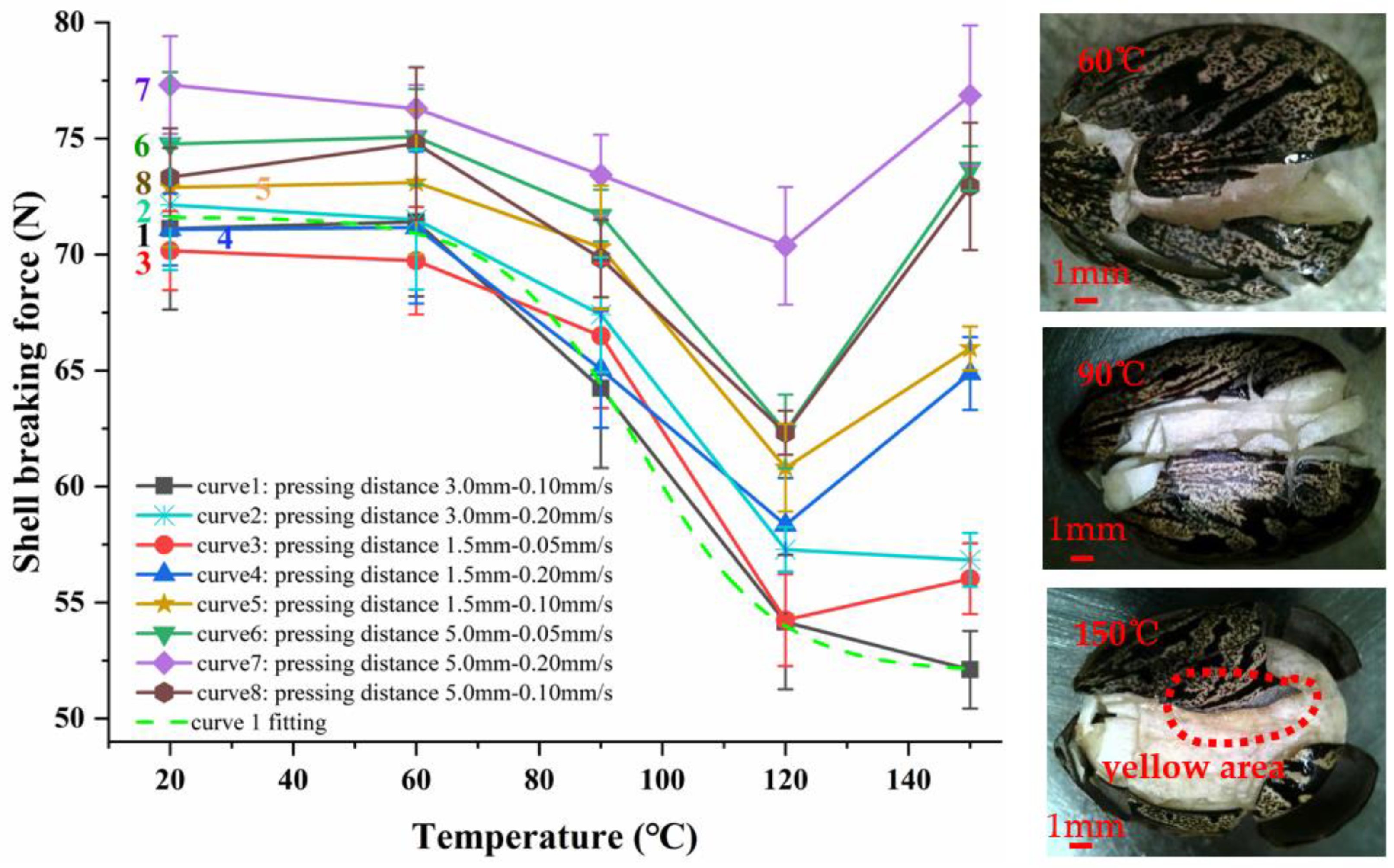

3.4. Mechanical Properties of Castor Bean Outer Seed Coat at Different Temperatures

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Das, A.; Satyanarayana, P.A.; Srinu, P.; Sridevi, V.; Ranjan, R. Qualitative Study on production of Methyl ester (Biodiesel) from Castor oil and Nannochloropsis. Mater. Today Proc. 2019, 18, 4751–4762. [Google Scholar] [CrossRef]

- Severino, L.S.; da Silva Mendes, B.S.; Saboya, R.D.C.C.; Barros, L.A.; de Farias Marinho, D.R. Nutrient content of solvent-extracted castor meal separated in granulometric fractions by dry sieving and applied as organic fertilizer. Ind. Crops Prod. 2021, 161, 113178–113185. [Google Scholar] [CrossRef]

- Pasha, Y.; Shrinivasa, U.; Swamy, D.; Ahmed, S.M. Experimental Analysis of Fuel Properties and Performance Analysis of Diesel Engine with Esterified Castor Oil Blended with Gasoline; Elsevier BV: Amsterdam, The Netherlands, 2021; Volume 46, pp. 4892–4899. [Google Scholar]

- Baskar, G.; Selvakumari, I.A.E.; Aiswarya, R. Biodiesel production from castor oil using heterogeneous Ni doped ZnO nanocatalyst. Bioresour. Technol. 2018, 250, 793–798. [Google Scholar] [CrossRef] [PubMed]

- Fu, Q.; Long, Y.; Gao, Y.; Ling, Y.; Qian, H.; Wang, F.; Zhu, X. Synthesis and properties of castor oil based plasticizers. RSC Adv. 2019, 9, 10049–10057. [Google Scholar] [CrossRef] [Green Version]

- David, H.; Abraham, K.; Satya, S. Mathematical model of mechanical behaviour of Jatropha curcas L. seeds under compression loading. Biosyst. Eng. 2013, 114, 279–288. [Google Scholar]

- Chapuis, A.; Blin, J.; Carré, P.; Lecomte, D. Separation efficiency and energy consumption of oil expression using a screw-press: The case of Jatropha curcas L. seeds. Ind. Crops Prod. 2014, 52, 752–761. [Google Scholar] [CrossRef]

- Matthäus, B. Oil technology. In Technological Innovations in Major World Oil Crops; Gupta, S.K., Ed.; Springer: New York, NY, USA, 2012; pp. 23–92. [Google Scholar]

- Yusuf, A.K.; Agunwa, U.; Ahmed, A.S.; Agunwa, U. Extraction and characterization of castor seed oil from wild Ricinus Communis Linn. Int. J. Sci. Environ. Technol. 2015, 4, 2278–3687. [Google Scholar]

- Akpan, U.G.; Jimoh, A.; Mohammed, A.D. Extraction, characterization and modification of castor seed oil. Leonardo J. Sci. 2006, 8, 43–52. [Google Scholar]

- Lorestani, A.N.; Jaliliantabar, F.; Gholami, R. Physical and mechanical properties of castor seed. Qual. Assur. Saf. Crop. Foods 2012, 4, e29–e32. [Google Scholar] [CrossRef]

- Bircan, C.; Koç, M. Determination of some mechanical properties of castor seed (Ricinus communis L.) to design and fabricate an oil extraction machine. J. Agric. Sci. Technol. 2012, 14, 1219–1227. [Google Scholar]

- Herak, D.; Gurdil, G.; Sedlacek, A.; Dajbych, O.; Simanjuntak, S. Energy demands for pressing Jatropha curcas L. seeds. Biosyst. Eng. 2010, 106, 527–534. [Google Scholar] [CrossRef]

- Braga, G.C.; Couto, S.M.; Hara, T.; Neto, J.T.A. Mechanical behaviour of macadamia nut under compression loading. J. Agric. Eng. Res. 1999, 72, 239–245. [Google Scholar] [CrossRef]

- Delprete, C.; Sesana, R. Mechanical characterization of kernel and shell of hazelnuts: Proposal of an experimental procedure. J. Food Eng. 2014, 124, 28–34. [Google Scholar] [CrossRef]

- Aviara, N.A.; Iyilade, I.J.; Oyeniyi, S.K.; Aremu, A.K. Effect of moisture content and loading orientation on mechanical properties of bush mango (Irvingia gabonensis) nut. Agric. Eng. Int. CIGR J. 2019, 20, 227–232. [Google Scholar]

- Zheng, H.-D.; Liu, L.-L.; Deng, C.-L.; Shi, Z.-F.; Ning, C.-Y. Mechanical properties of AM Ti6Al4V porous scaffolds with various cell structures. Rare Met. 2019, 38, 561–570. [Google Scholar] [CrossRef]

- Jia, Z.; Gao, Z.-X.; Ji, J.-J.; Liu, D.-X.; Guo, T.-B.; Ding, Y.-T. High-temperature deformation behavior and processing map of the as-cast Inconel 625 alloy. Rare Met. 2021, 40, 2083–2091. [Google Scholar] [CrossRef]

- Zhang, W.L.; Xiao, D.H.; Li, T.; Du, J.D.; Ding, D.Y. Microstructure and mechanical properties of two-stage aged Al–Cu–Mg–Ag–Sm alloy. Rare Met. 2019, 38, 42–51. [Google Scholar] [CrossRef]

- Yu, C.-Q.; Yu, Y.-R.; Zhao, Y.-M.; He, P.-G.; Xu, C.-S.; Fu, S.; Yang, Z.-H. Mechanical properties and in situ fracture behavior of SiO2f/phosphate geopolymer composites. Rare Met. 2019, 39, 562–569. [Google Scholar] [CrossRef]

| Variables (Level) | Pressing Distance (mm) | Pressing Velocity (mm/s) | Temperature (°C) |

|---|---|---|---|

| 1 | 1.0 | 0.05 | 20 |

| 2 | 1.5 | 0.10 | 60 |

| 3 | 2.0 | 0.15 | 90 |

| 4 | 2.5 | 0.20 | 120 |

| 5 | 3.0 | 0.25 | 150 |

| 6 | 4.0 | —— | —— |

| 7 | 5.0 | —— | —— |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, L.; Chen, H.; Xiao, J.; Fan, Y.; Song, S.; Zhang, Y.; Liu, X. Research on Structural–Mechanical Properties during the Castor Episperm Breaking Process. Processes 2021, 9, 1777. https://doi.org/10.3390/pr9101777

Yang L, Chen H, Xiao J, Fan Y, Song S, Zhang Y, Liu X. Research on Structural–Mechanical Properties during the Castor Episperm Breaking Process. Processes. 2021; 9(10):1777. https://doi.org/10.3390/pr9101777

Chicago/Turabian StyleYang, Liu, Huan Chen, Junyu Xiao, Yuchao Fan, Shaoyun Song, Yonglin Zhang, and Xiaopeng Liu. 2021. "Research on Structural–Mechanical Properties during the Castor Episperm Breaking Process" Processes 9, no. 10: 1777. https://doi.org/10.3390/pr9101777

APA StyleYang, L., Chen, H., Xiao, J., Fan, Y., Song, S., Zhang, Y., & Liu, X. (2021). Research on Structural–Mechanical Properties during the Castor Episperm Breaking Process. Processes, 9(10), 1777. https://doi.org/10.3390/pr9101777