Deep Ultraviolet AlGaN-Based Light-Emitting Diodes with p-AlGaN/AlGaN Superlattice Hole Injection Structures

Abstract

1. Introduction

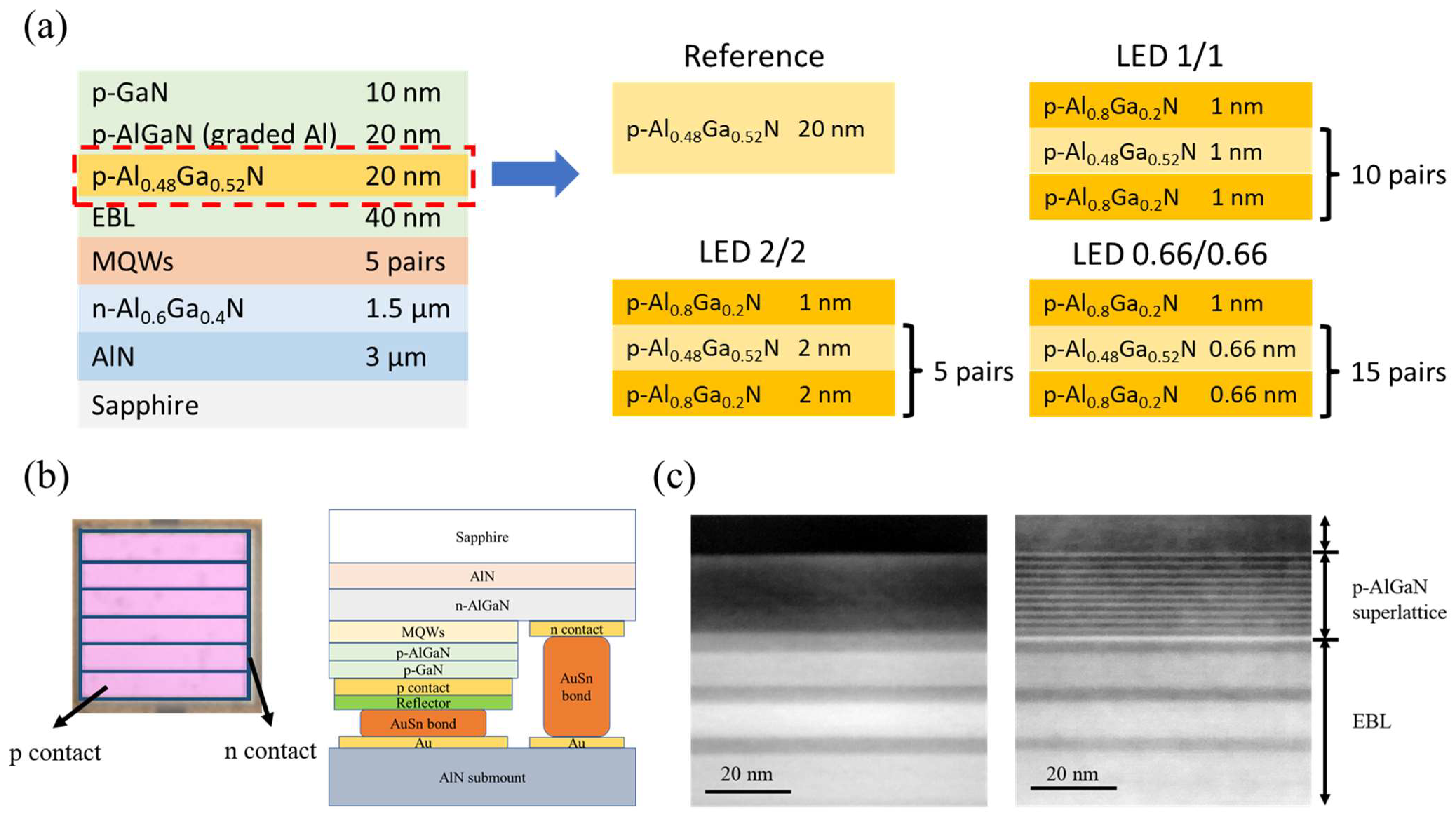

2. Materials and Methods

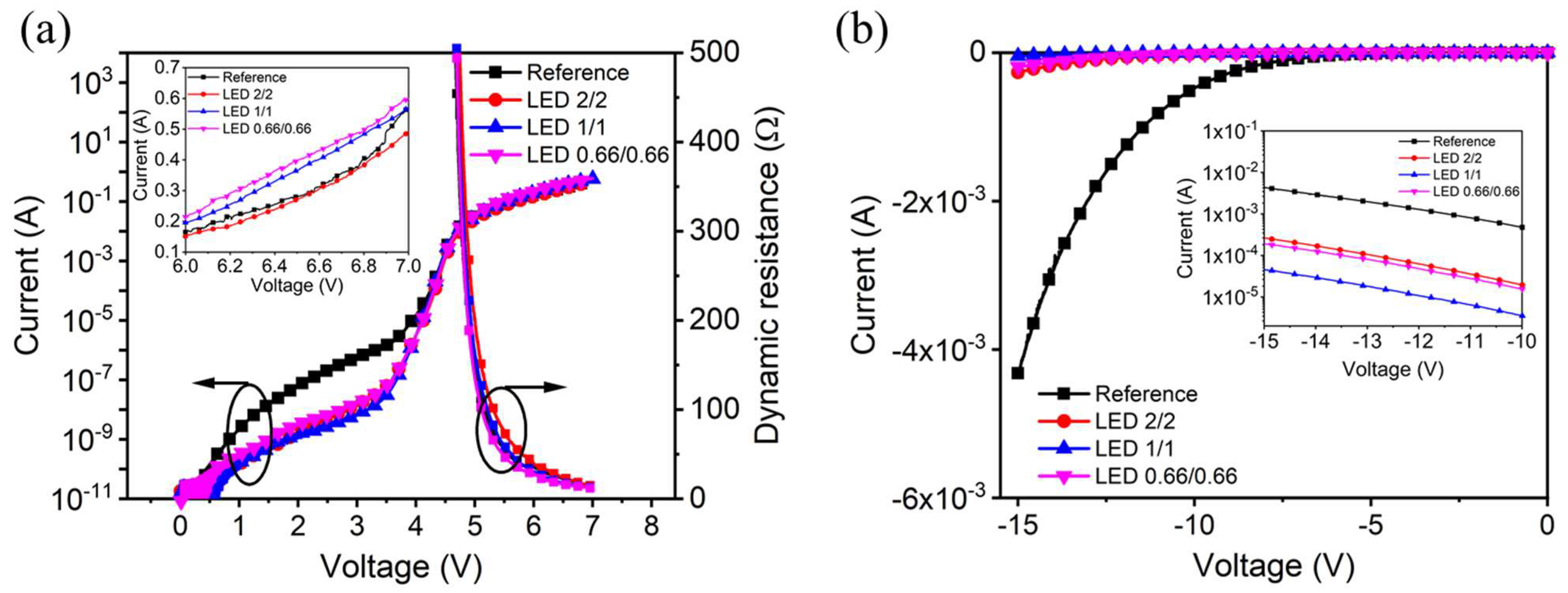

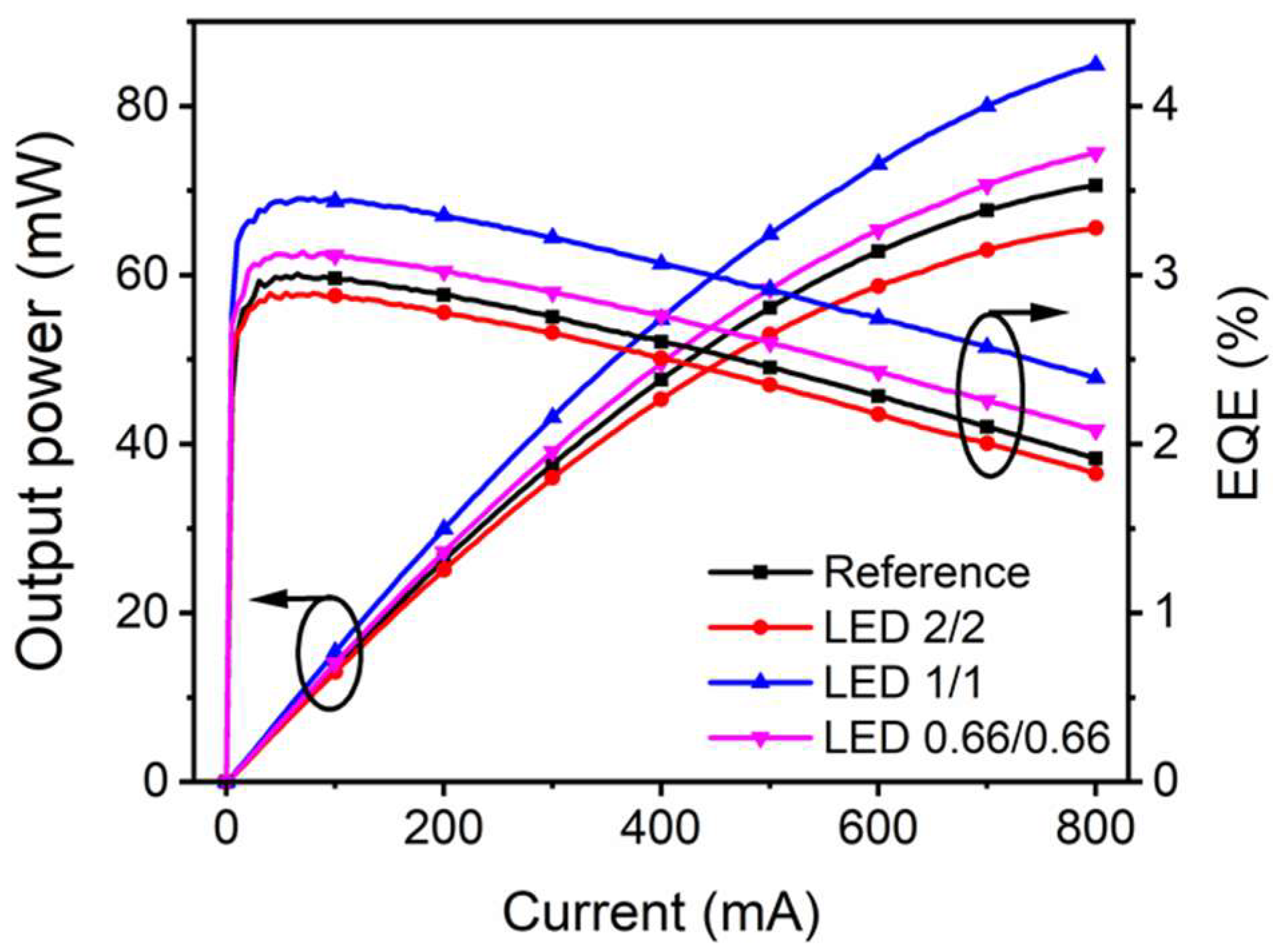

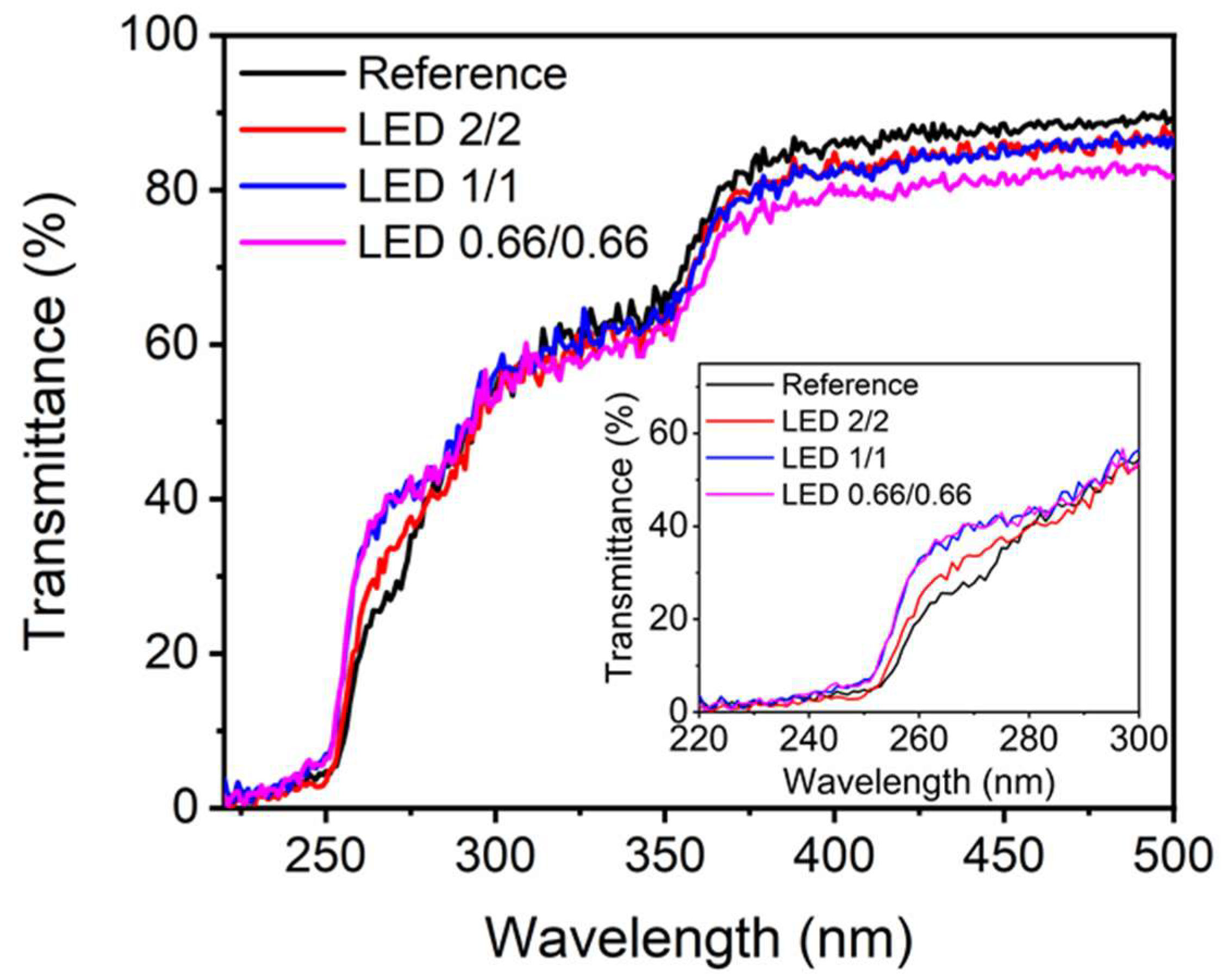

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Morison, W.L. Phototherapy and Photochemotherapy for Skin Disease; CRC Press: Boca Raton, FL, USA, 2005. [Google Scholar]

- Kneissl, M.; Rass, J. (Eds.) III-Nitride Ultraviolet Emitters: Technology and Applications; Springer: Cham, Switzerland, 2016; ISBN 9783319240985. [Google Scholar]

- Hirayama, H.; Yatabe, T.; Noguchi, N.; Kamata, N. Development of 230–270 nm AlGaN-Based Deep-UV LEDs. Electron. Commun. Jpn. 2010, 93, 24–33. [Google Scholar] [CrossRef]

- Mehnke, F.; Guttmann, M.; Enslin, J.; Kuhn, C.; Reich, C.; Jordan, J.; Kapanke, S.; Knauer, A.; Lapeyrade, M.; Zeimer, U.; et al. Gas Sensing of Nitrogen Oxide Utilizing Spectrally Pure Deep UV LEDs. IEEE J. Sel. Top. Quantum Electron. 2017, 23, 29–36. [Google Scholar] [CrossRef]

- Grandusky, J.R.; Gibb, S.R.; Mendrick, M.C.; Moe, C.; Wraback, M.; Schowalter, L.J. High Output Power from 260 nm Pseudomorphic Ultraviolet Light-Emitting Diodes with Improved Thermal Performance. Appl. Phys. Express 2011, 4, 082101. [Google Scholar] [CrossRef]

- Islam, S.M.; Protasenko, V.; Lee, K.; Rouvimov, S.; Verma, J.; Xing, H.; Jena, D. Deep-UV Emission at 219 nm from Ultrathin MBE GaN/AlN Quantum Heterostructures. Appl. Phys. Lett. 2017, 111, 091104. [Google Scholar] [CrossRef]

- Takano, T.; Mino, T.; Sakai, J.; Noguchi, N.; Tsubaki, K.; Hirayama, H. Deep-Ultraviolet Light-Emitting Diodes with External Quantum Efficiency Higher than 20% at 275 nm Achieved by Improving Light-Extraction Efficiency. Appl. Phys. Express 2017, 10, 031002. [Google Scholar] [CrossRef]

- Pernot, C.; Fukahori, S.; Inazu, T.; Fujita, T.; Kim, M.; Nagasawa, Y.; Hirano, A.; Ippommatsu, M.; Iwaya, M.; Kamiyama, S.; et al. Development of High Efficiency 255--355 nm AlGaN-Based Light-Emitting Diodes. Phys. Status Solidi 2011, 208, 1594–1596. [Google Scholar] [CrossRef]

- Shatalov, M.; Sun, W.; Jain, R.; Lunev, A.; Hu, X.; Dobrinsky, A.; Bilenko, Y.; Yang, J.; Garrett, G.A.; Rodak, L.E.; et al. High Power AlGaN Ultraviolet Light Emitters. Semicond. Sci. Technol. 2014, 29, 084007. [Google Scholar] [CrossRef]

- Liao, Y.; Thomidis, C.; Kao, C.-K.; Moustakas, T.D. AlGaN Based Deep Ultraviolet Light Emitting Diodes with High Internal Quantum Efficiency Grown by Molecular Beam Epitaxy. Appl. Phys. Lett. 2011, 98, 081110. [Google Scholar] [CrossRef]

- Mondal, R.K.; Chatterjee, V.; Pal, S. AlInGaN-Based Superlattice P-Region for Improvement of Performance of Deep UV LEDs. Opt. Mater. 2020, 104, 109846. [Google Scholar] [CrossRef]

- Yang, X.; Sun, H.; Fan, X.; Zhang, Z.; Sun, J.; Yi, X.; Guo, Z. Optimization on the Luminous Efficiency in AlGaN-Based Ultraviolet Light-Emitting Diodes by Amendment of a Superlattice Hole Reservoir Layer. Superlattices Microstruct. 2017, 101, 293–298. [Google Scholar] [CrossRef]

- Martens, M.; Mehnke, F.; Kuhn, C.; Reich, C.; Kueller, V.; Knauer, A.; Netzel, C.; Hartmann, C.; Wollweber, J.; Rass, J.; et al. Performance Characteristics of UV-C AlGaN-Based Lasers Grown on Sapphire and Bulk AlN Substrates. IEEE Photon. Technol. Lett. 2014, 26, 342–345. [Google Scholar] [CrossRef]

- Kim, M.-H.; Schubert, M.F.; Dai, Q.; Kim, J.K.; Schubert, E.F.; Piprek, J.; Park, Y. Origin of Efficiency Droop in GaN-Based Light-Emitting Diodes. Appl. Phys. Lett. 2007, 91, 183507. [Google Scholar] [CrossRef]

- Schubert, M.F.; Xu, J.; Kim, J.K.; Schubert, E.F.; Kim, M.H.; Yoon, S.; Lee, S.M.; Sone, C.; Sakong, T.; Park, Y. Polarization-Matched GaInN/AlGaInN Multi-Quantum-Well Light-Emitting Diodes with Reduced Efficiency Droop. Appl. Phys. Lett. 2008, 93, 041102. [Google Scholar] [CrossRef]

- Kuo, Y.-K.; Chang, J.-Y.; Tsai, M.-C.; Yen, S.-H. Advantages of Blue InGaN Multiple-Quantum Well Light-Emitting Diodes with InGaN Barriers. Appl. Phys. Lett. 2009, 95, 011116. [Google Scholar] [CrossRef]

- Chang, J.-Y.; Tsai, M.-C.; Kuo, Y.-K. Advantages of Blue InGaN Light-Emitting Diodes with AlGaN Barriers. Opt. Lett. 2010, 35, 1368–1370. [Google Scholar] [CrossRef]

- Wang, C.H.; Ke, C.C.; Lee, C.Y.; Chang, S.P.; Chang, W.T.; Li, J.C.; Li, Z.Y.; Yang, H.C.; Kuo, H.C.; Lu, T.C.; et al. Hole Injection and Efficiency Droop Improvement in InGaN/GaN Light-Emitting Diodes by Band-Engineered Electron Blocking Layer. Appl. Phys. Lett. 2010, 97, 261103. [Google Scholar] [CrossRef]

- Han, S.-H.; Cho, C.-Y.; Lee, S.-J.; Park, T.-Y.; Kim, T.-H.; Park, S.H.; Won Kang, S.; Won Kim, J.; Kim, Y.C.; Park, S.-J. Effect of Mg Doping in the Barrier of InGaN/GaN Multiple Quantum Well on Optical Power of Light-Emitting Diodes. Appl. Phys. Lett. 2010, 96, 051113. [Google Scholar] [CrossRef]

- Schubert, E.F.; Grieshaber, W.; Goepfert, I.D. Enhancement of Deep Acceptor Activation in Semiconductors by Superlattice Doping. Appl. Phys. Lett. 1996, 69, 3737–3739. [Google Scholar] [CrossRef]

- Hsu, L.; Walukiewicz, W. Theoretical Transport Studies of p-Type GaN/AlGaN Modulation-Doped Heterostructures. Appl. Phys. Lett. 1999, 74, 2405–2407. [Google Scholar] [CrossRef]

- Saxler, A.; Mitchel, W.C.; Kung, P.; Razeghi, M. Aluminum Gallium Nitride Short-Period Superlattices Doped with Magnesium. Appl. Phys. Lett. 1999, 74, 2023–2025. [Google Scholar] [CrossRef]

- Kozodoy, P.; Hansen, M.; DenBaars, S.P.; Mishra, U.K. Enhanced Mg Doping Efficiency in Al0.2Ga0.8N/GaN Superlattices. Appl. Phys. Lett. 1999, 74, 3681–3683. [Google Scholar] [CrossRef]

- Kozodoy, P.; Smorchkova, Y.P.; Hansen, M.; Xing, H.; DenBaars, S.P.; Mishra, U.K.; Saxler, A.W.; Perrin, R.; Mitchel, W.C. Polarization-Enhanced Mg Doping of AlGaN/GaN Superlattices. Appl. Phys. Lett. 1999, 75, 2444–2446. [Google Scholar] [CrossRef]

- Kauser, M.Z.; Osinsky, A.; Dabiran, A.M.; Chow, P.P. Enhanced Vertical Transport in p-Type AlGaN/GaN Superlattices. Appl. Phys. Lett. 2004, 85, 5275–5277. [Google Scholar] [CrossRef]

- Goepfert, I.D.; Schubert, E.F.; Osinsky, A.; Norris, P.E.; Faleev, N.N. Experimental and Theoretical Study of Acceptor Activation and Transport Properties in p-Type AlxGa1−xN/GaN Superlattices. J. Appl. Phys. 2000, 88, 2030–2038. [Google Scholar] [CrossRef]

- Hertkorn, J.; Thapa, S.B.; Wunderer, T.; Scholz, F.; Wu, Z.H.; Wei, Q.Y.; Ponce, F.A.; Moram, M.A.; Humphreys, C.J.; Vierheilig, C.; et al. Highly Conductive Modulation Doped Composition Graded P-AlGaN/(AlN)/GaN Multiheterostructures Grown by Metalorganic Vapor Phase Epitaxy. J. Appl. Phys. 2009, 106, 013720. [Google Scholar] [CrossRef]

- Duboz, J.-Y. GaN/AlGaN Superlattices for P Contacts in LEDs. Semicond. Sci. Technol. 2014, 29, 035017. [Google Scholar] [CrossRef]

- Ju, Z.G.; Liu, W.; Zhang, Z.-H.; Tan, S.T.; Ji, Y.; Kyaw, Z.; Zhang, X.L.; Lu, S.P.; Zhang, Y.P.; Zhu, B.B.; et al. Advantages of the Blue InGaN/GaN Light-Emitting Diodes with an AlGaN/GaN/AlGaN Quantum Well Structured Electron Blocking Layer. ACS Photon. 2014, 1, 377–381. [Google Scholar] [CrossRef][Green Version]

- Xia, C.S.; Li, Z.M.S.; Lu, W.; Zhang, Z.H.; Sheng, Y.; Hu, W.D.; Cheng, L.W. Efficiency Enhancement of Blue InGaN/GaN Light-Emitting Diodes with an AlGaN-GaN-AlGaN Electron Blocking Layer. J. Appl. Phys. 2012, 111, 094503. [Google Scholar] [CrossRef]

- Yan Zhang, Y.; An Yin, Y. Performance Enhancement of Blue Light-Emitting Diodes with a Special Designed AlGaN/GaN Superlattice Electron-Blocking Layer. Appl. Phys. Lett. 2011, 99, 221103. [Google Scholar] [CrossRef]

- Kang, J.; Li, H.; Li, Z.; Liu, Z.; Ma, P.; Yi, X.; Wang, G. Enhancing the Performance of Green GaN-Based Light-Emitting Diodes with Graded Superlattice AlGaN/GaN Inserting Layer. Appl. Phys. Lett. 2013, 103, 102104. [Google Scholar] [CrossRef]

- Lin, B.-C.; Chen, K.-J.; Han, H.-V.; Lan, Y.-P.; Chiu, C.-H.; Lin, C.-C.; Shih, M.-H.; Lee, P.-T.; Kuo, H.-C. Advantages of Blue LEDs With Graded-Composition AlGaN/GaN Superlattice EBL. IEEE Photon. Technol. Lett. 2013, 25, 2062–2065. [Google Scholar] [CrossRef]

- Zhang, Y.-Y.; Zhu, X.-L.; Yin, Y.-A.; Ma, J. Performance Enhancement of Near-UV Light-Emitting Diodes with an InAlN/GaN Superlattice Electron-Blocking Layer. IEEE Electron. Device Lett. 2012, 33, 994–996. [Google Scholar] [CrossRef]

- Muhin, A.; Guttmann, M.; Kuhn, C.; Mickein, E.; Aparici, J.R.; Ziffer, E.; Susilo, N.; Sulmoni, L.; Wernicke, T.; Kneissl, M. Vertical Conductivity and Poole–Frenkel-Ionization of Mg Acceptors in AlGaN Short-Period Superlattices with High Al Mole Fraction. Appl. Phys. Lett. 2020, 117, 252101. [Google Scholar] [CrossRef]

- Guttmann, M.; Susilo, A.; Sulmoni, L.; Susilo, N.; Ziffer, E.; Wernicke, T.; Kneissl, M. Light Extraction Efficiency and Internal Quantum Efficiency of Fully UVC-Transparent AlGaN Based LEDs. J. Phys. D Appl. Phys. 2021, 54, 335101. [Google Scholar] [CrossRef]

- Wang, T.-Y.; Lai, W.-C.; Sie, S.-Y.; Chang, S.-P.; Wu, Y.-R.; Chiou, Y.-Z.; Kuo, C.-H.; Sheu, J.-K. AlGaN-Based Deep Ultraviolet Light Emitting Diodes with Magnesium Delta-Doped AlGaN Last Barrier. Appl. Phys. Lett. 2020, 117, 251101. [Google Scholar] [CrossRef]

- Sun, W.H.; Zhang, J.P.; Yang, J.W.; Maruska, H.P.; Khan, M.A.; Liu, R.; Ponce, F.A. Fine Structure of AlN/AlGaN Superlattice Grown by Pulsed Atomic-Layer Epitaxy for Dislocation Filtering. Appl. Phys. Lett. 2005, 87, 211915. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, T.-Y.; Lai, W.-C.; Sie, S.-Y.; Chang, S.-P.; Kuo, C.-H.; Sheu, J.-K. Deep Ultraviolet AlGaN-Based Light-Emitting Diodes with p-AlGaN/AlGaN Superlattice Hole Injection Structures. Processes 2021, 9, 1727. https://doi.org/10.3390/pr9101727

Wang T-Y, Lai W-C, Sie S-Y, Chang S-P, Kuo C-H, Sheu J-K. Deep Ultraviolet AlGaN-Based Light-Emitting Diodes with p-AlGaN/AlGaN Superlattice Hole Injection Structures. Processes. 2021; 9(10):1727. https://doi.org/10.3390/pr9101727

Chicago/Turabian StyleWang, Tien-Yu, Wei-Chih Lai, Syuan-Yu Sie, Sheng-Po Chang, Cheng-Huang Kuo, and Jinn-Kong Sheu. 2021. "Deep Ultraviolet AlGaN-Based Light-Emitting Diodes with p-AlGaN/AlGaN Superlattice Hole Injection Structures" Processes 9, no. 10: 1727. https://doi.org/10.3390/pr9101727

APA StyleWang, T.-Y., Lai, W.-C., Sie, S.-Y., Chang, S.-P., Kuo, C.-H., & Sheu, J.-K. (2021). Deep Ultraviolet AlGaN-Based Light-Emitting Diodes with p-AlGaN/AlGaN Superlattice Hole Injection Structures. Processes, 9(10), 1727. https://doi.org/10.3390/pr9101727