Calibration of DEM for Cohesive Particles in the SLS Powder Spreading Process

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental Materials, Apparatuses and Procedures

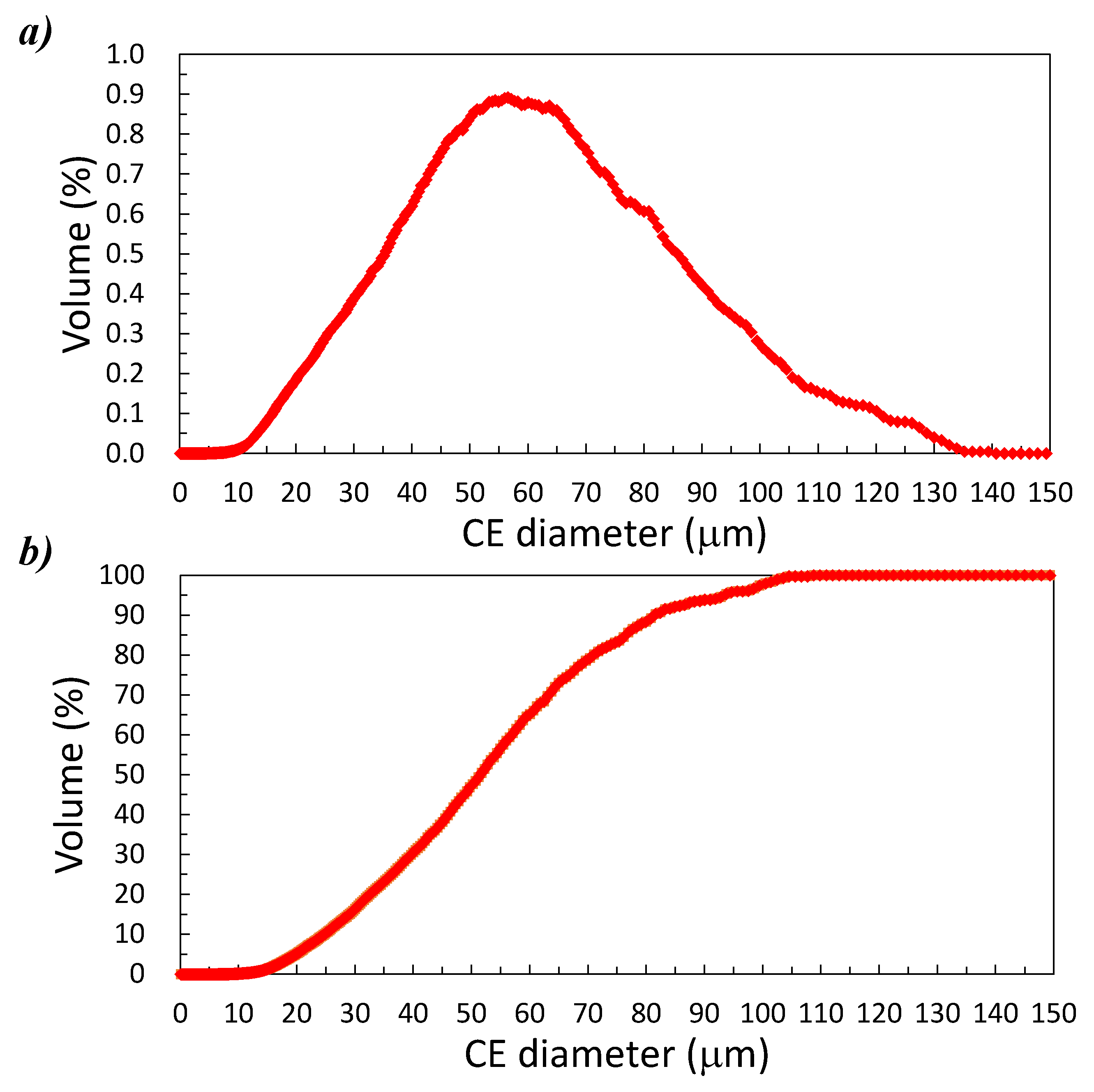

2.1.1. Materials

2.1.2. Direct Measurement of Particle Properties to Be Used in DEM

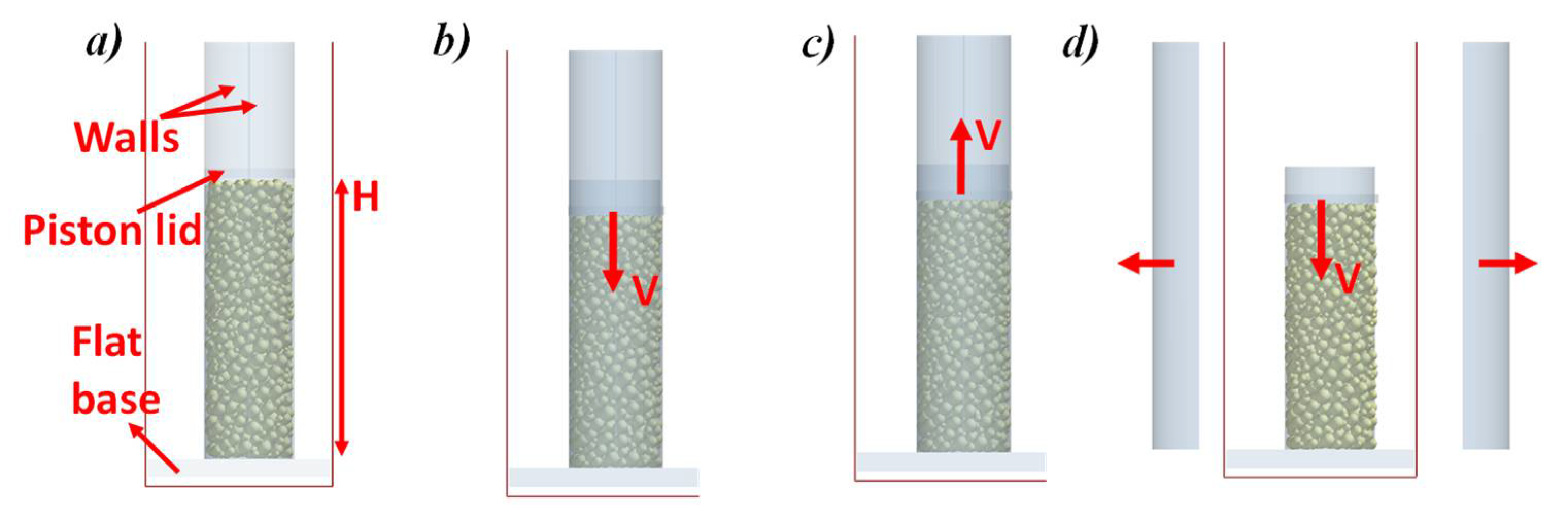

2.1.3. Experimental Setup Used for the Unconfined Yield Strength Calibration Method

2.2. Modelling Approach

2.2.1. DEM

2.2.2. Model Tuning for SLS Applications and Calibration Procedures

2.2.3. DEM Calibration Methods

DEM Calibration Using the Static Angle of Repose

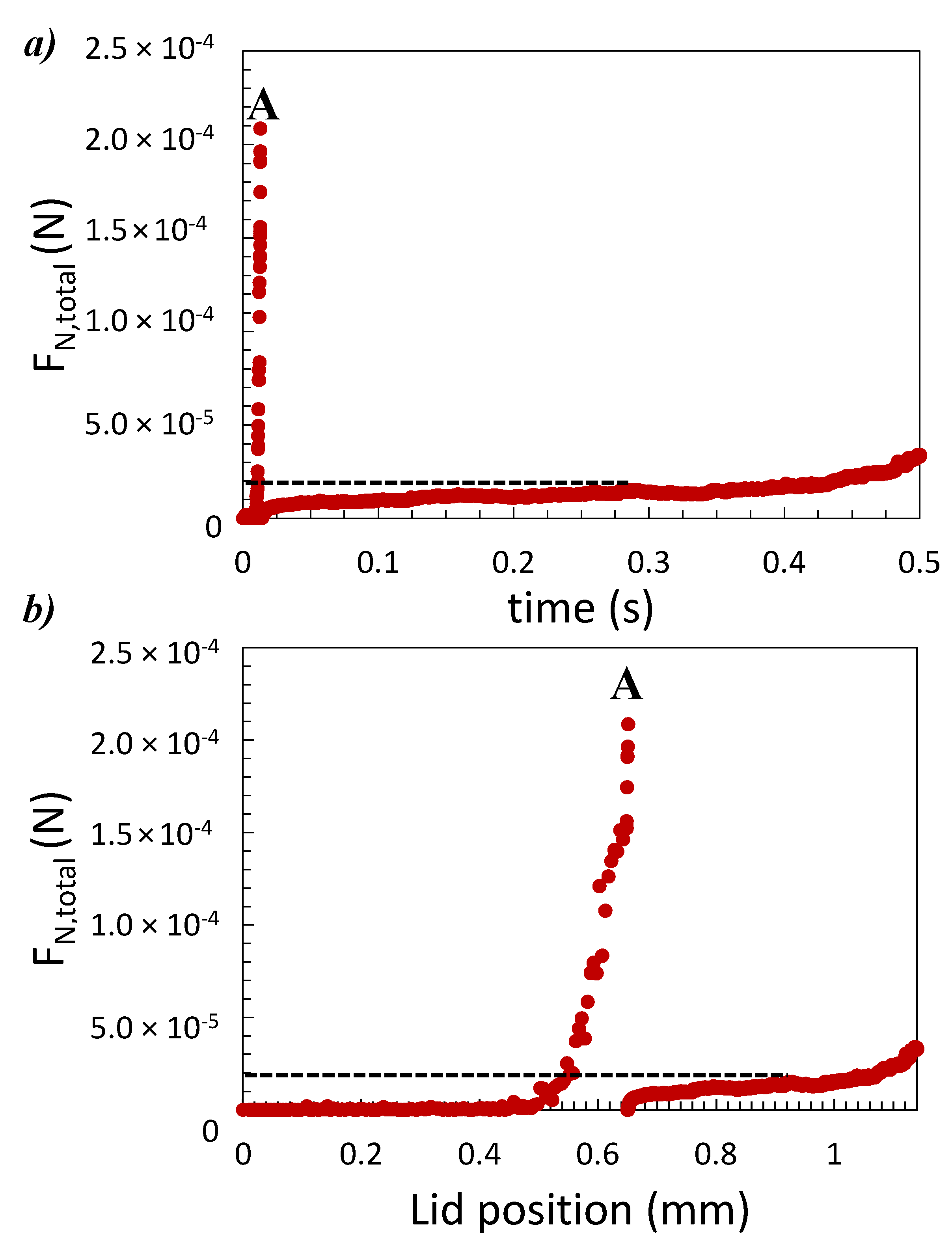

DEM Calibration Using the Unconfined Yield Strength

3. Results and Discussion

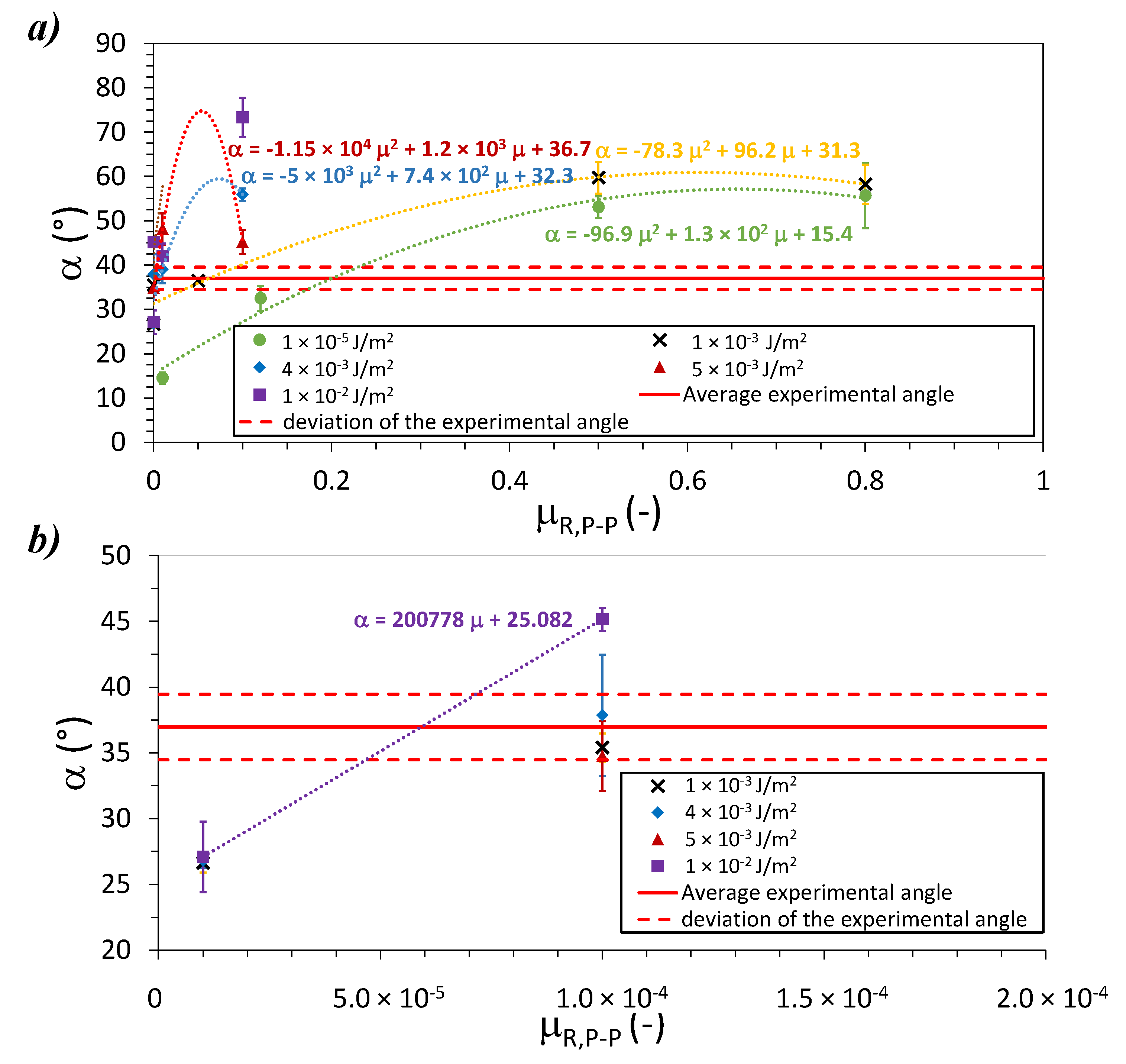

3.1. Calibration According to the Static Angle of Repose

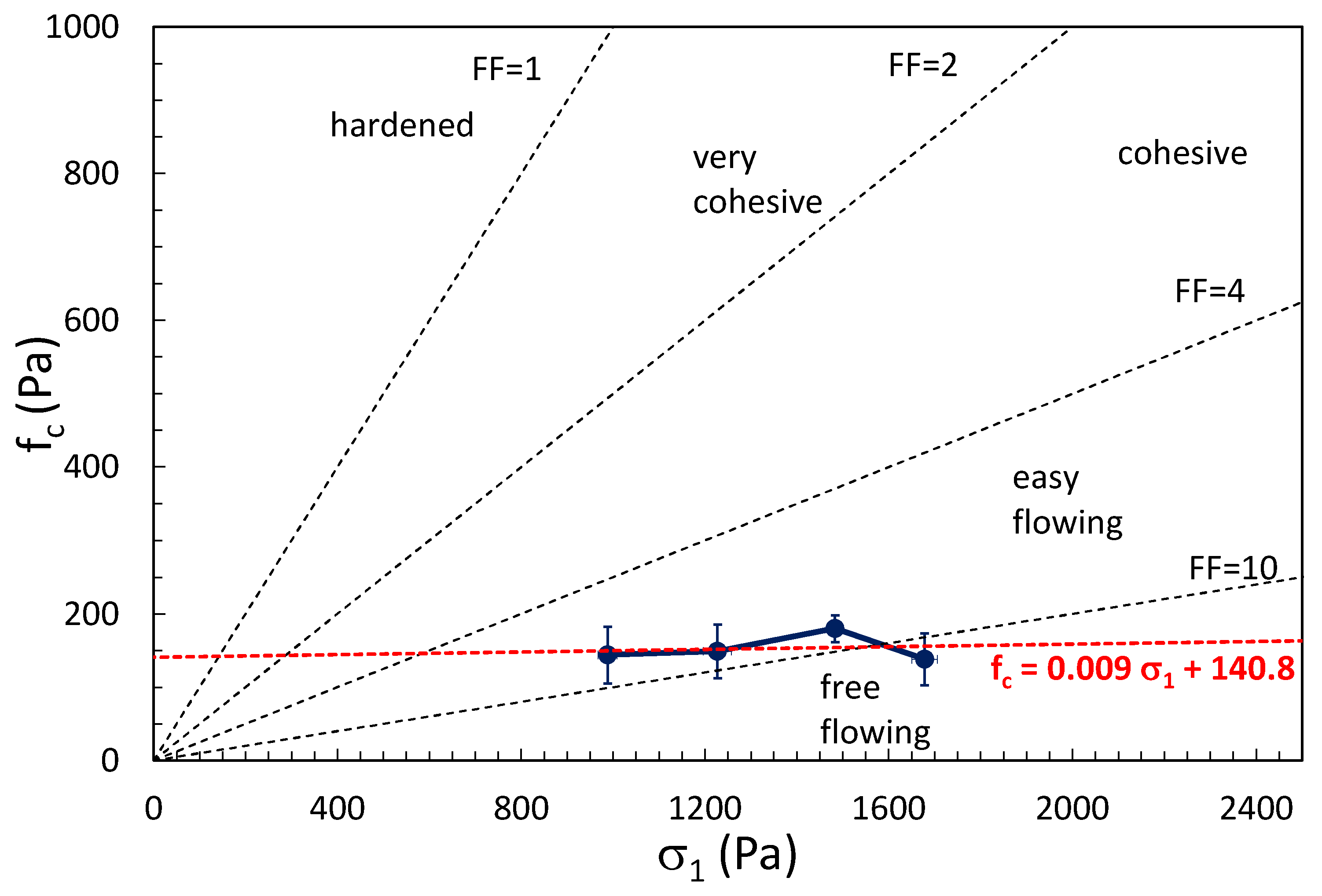

3.2. Calibration According to the Unconfined Yield Strength

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive Manufacturing (3D Printing): A Review of Materials, Methods, Applications and Challenges. Compos. Part B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Tofail, S.A.M.; Koumoulos, E.P.; Bandyopadhyay, A.; Bose, S.; O’Donoghue, L.; Charitidis, C. Additive Manufacturing: Scientific and Technological Challenges, Market Uptake and Opportunities. Mater. Today 2017, 21, 22–37. [Google Scholar] [CrossRef]

- Liu, S.; Shin, Y.C. Additive Manufacturing of Ti6Al4V Alloy: A Review. Mater. Des. 2019, 164, 107552. [Google Scholar] [CrossRef]

- Wong, K.V.; Hernandez, A. A Review of Additive Manufacturing. ISRN Mech. Eng. 2012, 2012. [Google Scholar] [CrossRef] [Green Version]

- Sofia, D.; Lupo, M.; Barletta, D.; Poletto, M. Validation of an Experimental Procedure to Quantify The Effects of Powder Spreadability on Selective Laser Sintering Process. Chem. Eng. Trans. 2019, 74, 397–402. [Google Scholar] [CrossRef]

- Kumbhar, N.N.; Mulay, A.V. Post Processing Methods Used to Improve Surface Finish of Products Which Are Manufactured by Additive Manufacturing Technologies: A Review. J. Inst. Eng. Ser. C 2018. [Google Scholar] [CrossRef]

- Nan, W.; Pasha, M.; Bonakdar, T.; Lopez, A.; Zafar, U.; Nadimi, S.; Ghadiri, M. Jamming during Particle Spreading in Additive Manufacturing. Powder Technol. 2018, 99, 481–487. [Google Scholar] [CrossRef]

- Di Renzo, A.; Di Maio, F.P. Comparison of Contact-Force Models for the Simulation of Collisions in DEM-Based Granular Flow Codes. Chem. Eng. Sci. 2004, 59, 525–541. [Google Scholar] [CrossRef]

- Cundall, P.A.; Strack, O.D.L. A Discrete Numerical Model for Granular Assemblies. Géotechnique 1979, 29, 47–65. [Google Scholar] [CrossRef]

- Tomas, J. Mechanics of Nanoparticle Adhesion—A Continuum Approach. Part. Surf. Detect. Adhes. Removal. 2003, 8, 1–47. [Google Scholar]

- Hertz, H. Über Die Berührung Fester Elastischer Körper. J. Die Reine Und Angew. Math. 1881, 92, 156–171. [Google Scholar]

- Dintwa, E.; Tijskens, E.; Ramon, H. On the Accuracy of the Hertz Model to Describe the Normal Contact of Soft Elastic Spheres. Granul. Matter 2008, 10, 209–221. [Google Scholar] [CrossRef]

- Mindlin, R.D.; Deresiewicz, H. Elastic Spheres in Contact Under Varying Oblique Forces. In The Collected Papers of Raymond D. Mindlin Volume I; Springer: New York, NY, USA, 1989; Volume 20, pp. 269–286. [Google Scholar] [CrossRef]

- Mindlin, R.D. Compliance of Elastic Bodies in Contact. J. Appl. Mech. 1989, 16, 197–206. [Google Scholar] [CrossRef]

- Johnson, K.L.L.; Kendall, K.; Roberts, A.D.D. Surface Energy and the Contact of Elastic Solids. Proc. R. Soc. Lond. A Math. Phys. Sci. 1971, 324, 301–313. [Google Scholar] [CrossRef] [Green Version]

- Coetzee, C.J. Review: Calibration of the Discrete Element Method. Powder Technol. 2017, 310, 104–142. [Google Scholar] [CrossRef]

- Nan, W.; Ghadiri, M. Numerical Simulation of Powder Flow during Spreading in Additive Manufacturing. Powder Technol. 2019. [Google Scholar] [CrossRef]

- Zafar, U.; Hare, C.; Hassanpour, A.; Ghadiri, M. Drop Test: A New Method to Measure the Particle Adhesion Force. Powder Technol. 2014, 264, 236–241. [Google Scholar] [CrossRef] [Green Version]

- Üzüm, M.S.M.; Hamburg, I. Metal/Polymer Hybrids: Multiscale Adhesion Behaviour and Polymer Dynamics Vorgelegt Von. Master’s Thesis, Technical University of Berlin, Berlin, Germany, 2015. [Google Scholar]

- Wang, L.; Li, R.; Wu, B.; Wu, Z.; Ding, Z. Determination of the Coefficient of Rolling Friction of an Irregularly Shaped Maize Particle Group Using Physical Experiment and Simulations. Particuology 2018, 38, 185–195. [Google Scholar] [CrossRef]

- Wang, L.; Zhou, W.; Ding, Z.; Li, X.; Zhang, C. Experimental Determination of Parameter Effects on the Coefficient of Restitution of Differently Shaped Maize in Three-Dimensions. Powder Technol. 2015, 284, 187–194. [Google Scholar] [CrossRef]

- Teffo, V.B.; Naudé, N. Determination of the Coefficients of Restitution, Static and Rolling Friction of Eskom-Grade Coal for Discrete Element Modelling. J. S. Afr. Inst. Min. Metall. 2013, 113, 351–356. [Google Scholar]

- Lupo, M.; Sofia, D.; Barletta, D.; Poletto, M. Calibration of DEM Simulation of Cohesive Particles. Chem. Eng. Trans. 2019, 74. [Google Scholar] [CrossRef]

- Salehi, H.; Sofia, D.; Schütz, D.; Barletta, D.; Poletto, M. Experiments and Simulation of Torque in Anton Paar Powder Cell. Part. Sci. Technol. 2018, 36, 501–512. [Google Scholar] [CrossRef]

- Grima, A.P.; Wypych, P.W. Development and Validation of Calibration Methods for Discrete Element Modelling. In Granular Matter; Springer: Birmingham, UK, 2011. [Google Scholar] [CrossRef] [Green Version]

- Alizadeh, M.; Asachi, M.; Ghadiri, M.; Bayly, A.; Hassanpour, A. A Methodology for Calibration of DEM Input Parameters in Simulation of Segregation of Powder Mixtures, a Special Focus on Adhesion. Powder Technol. 2018, 339, 789–800. [Google Scholar] [CrossRef] [Green Version]

- Roessler, T.; Katterfeld, A. DEM Parameter Calibration of Cohesive Bulk Materials Using a Simple Angle of Repose Test. Particuology 2019, 45, 105–115. [Google Scholar] [CrossRef]

- Karkala, S.; Davis, N.; Wassgren, C.; Shi, Y.; Liu, X.; Riemann, C.; Yacobian, G.; Ramachandran, R. Calibration of Discrete-Element-Method Parameters for Cohesive Materials Using Dynamic-Yield-Strength and Shear-Cell Experiments. Processes 2019, 7, 278. [Google Scholar] [CrossRef] [Green Version]

- Coetzee, C. Calibration of the Discrete Element Method: Strategies for Spherical and Non-Spherical Particles. Powder Technol. 2020, 364, 851–878. [Google Scholar] [CrossRef]

- Chen, H.; Wei, Q.; Wen, S.; Li, Z.; Shi, Y. Flow Behavior of Powder Particles in Layering Process of Selective Laser Melting: Numerical Modeling and Experimental Verification Based on Discrete Element Method. Int. J. Mach. Tools Manuf. 2017, 123, 146–159. [Google Scholar] [CrossRef]

- Angus, A.; Yahia, L.A.A.; Maione, R.; Khala, M.; Hare, C.; Ozel, A.; Ocone, R. Calibrating Friction Coefficients in Discrete Element Method Simulations with Shear-Cell Experiments. Powder Technol. 2020, 372, 290–304. [Google Scholar] [CrossRef]

- Polyamide 6-Nylon 6-PA 6. Available online: https://www.azom.com/article.aspx?ArticleID=442 (accessed on 13 January 2020).

- Lupo, M. Preparation of Powder Layers in Selective Laser Sintering Process; University of Salerno: Salerno, Italy, 2021. [Google Scholar]

- Haeri, S. Optimisation of Blade Type Spreaders for Powder Bed Preparation in Additive Manufacturing Using DEM Simulations. Powder Technol. 2017, 321, 94–104. [Google Scholar] [CrossRef] [Green Version]

- Weon, J., II. Mechanical and Thermal Behavior of Polyamide-6/Clay Nanocomposite Using Continuum-Based Micromechanical Modeling. Macromol. Res. 2009, 17, 797–806. [Google Scholar] [CrossRef]

- Lakes, R. Foam Structures with a Negative Poisson’s Ratio. Science 1987, 235, 1038–1041. [Google Scholar] [CrossRef]

- Xu, B.H.; Yu, A.B. Numerical Simulation of the Gas-Solid Flow in a Fluidized Bed by Combining Discrete Particle Method with Computational Fluid Dynamics. Chem. Eng. Sci. 1997, 52, 2785–2809. [Google Scholar] [CrossRef]

- Thornton, C. Granular Dynamics, Contact Mechanics and Particle System Simulations: A DEM Study; Springer: Birmingham, UK, 2015; Volume 24. [Google Scholar] [CrossRef]

- Chirone, R.; Barletta, D.; Lettieri, P.; Poletto, M. Bulk Flow Properties of Sieved Samples of a Ceramic Powder at Ambient and High Temperature. Powder Technol. 2016, 288, 379–387. [Google Scholar] [CrossRef]

- Macrì, D.; Barletta, D.; Lettieri, P.; Poletto, M. Experimental and Theoretical Analysis of TiO2 Powders Flow Properties at Ambient and High Temperatures. Chem. Eng. Sci. 2017, 167, 172–190. [Google Scholar] [CrossRef] [Green Version]

- Favier, J.F.; Abbaspour-Fard, M.H.; Kremmer, M.; Raji, A.O. Shape Representation of Axi-Symmetrical, Non-Spherical Particles in Discrete Element Simulation Using Multi-Element Model Particles. Eng. Comput. 1999, 16, 467–480. [Google Scholar] [CrossRef]

- Pasha, M.; Hare, C.; Ghadiri, M.; Gunadi, A.; Piccione, P.M. Effect of Particle Shape on Flow in Discrete Element Method Simulation of a Rotary Batch Seed Coater. Powder Technol. 2016, 296, 29–36. [Google Scholar] [CrossRef] [Green Version]

- Marigo, M.; Stitt, E.H. Discrete Element Method (DEM) for Industrial Applications: Comments on Calibration and Validation for the Modelling of Cylindrical Pellets. KONA Powder Part. J. 2015, 32, 236–252. [Google Scholar] [CrossRef] [Green Version]

- Barletta, D.; Poletto, M.; Santomaso, A.C. Chapter 4. Bulk Powder Flow Characterisation Techniques. In Powder Flow; Hare, C., Hassanpour, A., Pasha, M., Eds.; Royal Society of Chemistry: Cambridge, UK, 2019; pp. 64–146. [Google Scholar] [CrossRef]

- Parrella, L.; Barletta, D.; Boerefijn, R.; Poletto, M. Comparison between a Uniaxial Compaction Tester and a Shear Tester for the Characterization of Powder Flowability. KONA Powder Part. J. 2008, 26, 178–189. [Google Scholar] [CrossRef] [Green Version]

- Ruggi, D.; Lupo, M.; Sofia, D.; Barrès, C.; Barletta, D.; Poletto, M. Flow Properties of Polymeric Powders for Selective Laser Sintering. Powder Technol. 2020, 370, 288–297. [Google Scholar] [CrossRef]

- Jenike, A.W. Storage and Flow of Solids. Bull. Univ. Utah 1964, 53, 26. [Google Scholar]

| Material | (μm) | (μm) | (μm) | (kg m−3) | (kg m−3) |

|---|---|---|---|---|---|

| PA6 | 25 | 55 | 95 | 1140 [32] | 525 |

| Material | PA6 | Aluminium |

|---|---|---|

| (-) | 0.5 [34] | - |

| (-) | 0.5 [34] | |

| (-) | 0.57 | - |

| (-)(UYS) | 1 × 10−4 ÷ 1 | |

| (-)(AOR) | 0.33 | |

| (-) | 1 × 10−5 ÷ 1 | - |

| (-) | 1 × 10−4 ÷ 1 | |

| (-) | 0.35 [35] | 0.33 [36] |

| (GPa) | 3.4 | 69 [36] |

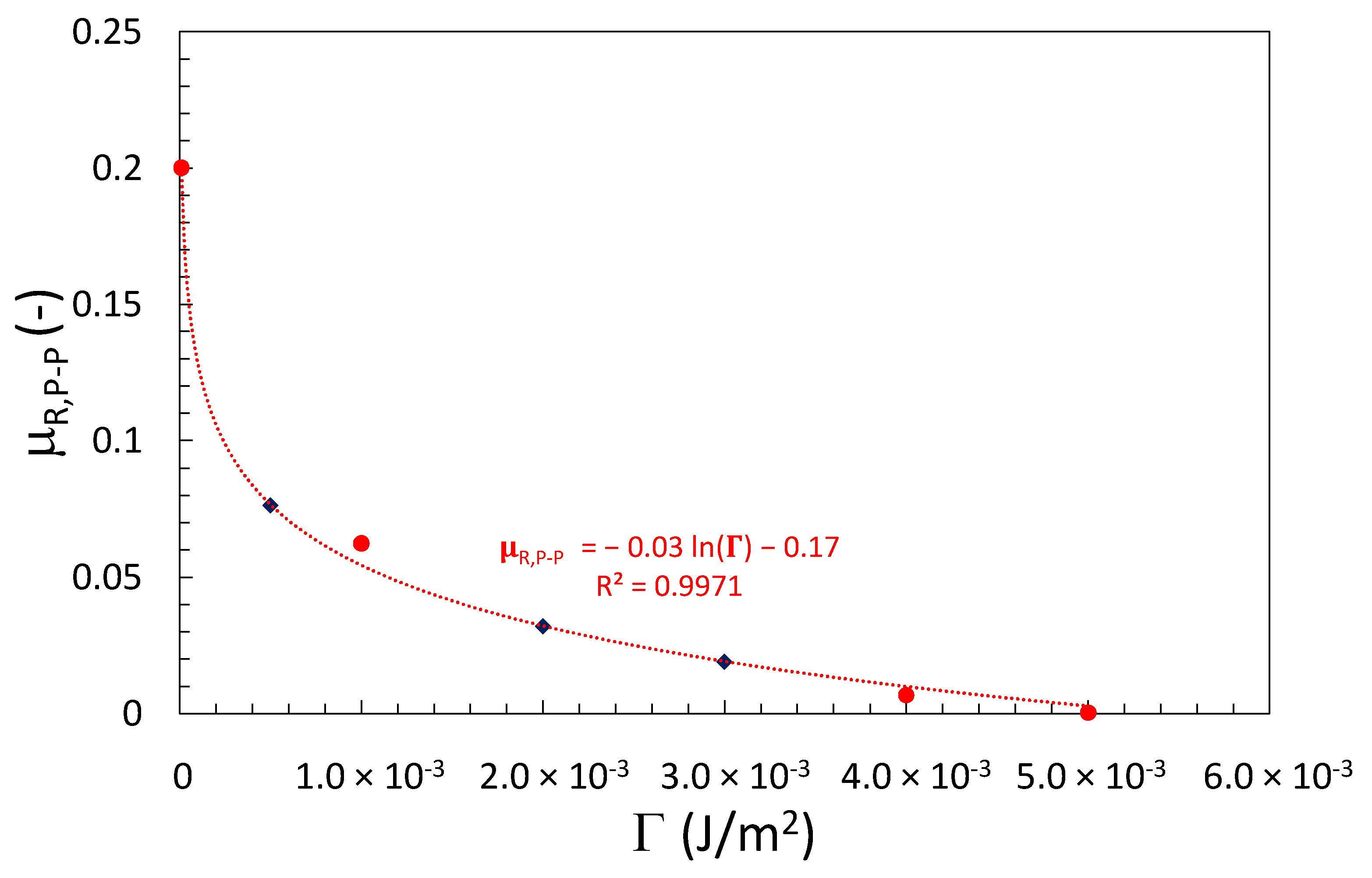

| Γ (J/m2) | μR, P−P (-) | from the Polynomial (°) | (°) | (°) |

|---|---|---|---|---|

| 1 × 10−5 | 2 × 10−1 | 36.96 | 39.36 | 5.90 |

| 1 × 10−3 | 6.2 × 10−2 | 36.96 | 36.09 | 2.16 |

| 4 × 10−3 | 6.7 × 10−3 | 36.96 | 35.75 | 0.30 |

| 5 × 10−3 | 2.2 × 10−4 | 36.96 | 41.02 | 0.10 |

| (J/m2) | (-) | (°) | (°) | (°) |

|---|---|---|---|---|

| 2 × 10−3 | 3.2 × 10−2 | 36.96 | 38.63 | 0.05 |

| 3 × 10−3 | 1.9 × 10−2 | 36.96 | 39.18 | 2.33 |

| 5 × 10−4 | 7.6 × 10−2 | 36.96 | 39.39 | 0.78 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lupo, M.; Barletta, D.; Sofia, D.; Poletto, M. Calibration of DEM for Cohesive Particles in the SLS Powder Spreading Process. Processes 2021, 9, 1715. https://doi.org/10.3390/pr9101715

Lupo M, Barletta D, Sofia D, Poletto M. Calibration of DEM for Cohesive Particles in the SLS Powder Spreading Process. Processes. 2021; 9(10):1715. https://doi.org/10.3390/pr9101715

Chicago/Turabian StyleLupo, Marco, Diego Barletta, Daniele Sofia, and Massimo Poletto. 2021. "Calibration of DEM for Cohesive Particles in the SLS Powder Spreading Process" Processes 9, no. 10: 1715. https://doi.org/10.3390/pr9101715

APA StyleLupo, M., Barletta, D., Sofia, D., & Poletto, M. (2021). Calibration of DEM for Cohesive Particles in the SLS Powder Spreading Process. Processes, 9(10), 1715. https://doi.org/10.3390/pr9101715