Wheat Grinding Process with Low Moisture Content: A New Approach for Wholemeal Flour Production

Abstract

1. Introduction

2. Materials and Methods

2.1. Material

2.2. Characterization of Wheat Grains Using the Single Kernel Characterization System (SKCS)

2.3. Grain Drying

2.4. Grinding Process

2.5. Physical Properties of the Dough

2.6. Statistical Analysis

3. Results and Discussion

3.1. Moisture Content and Physical Properties of Wheat Grains

3.2. Grinding Results

3.2.1. Particle Size Distribution

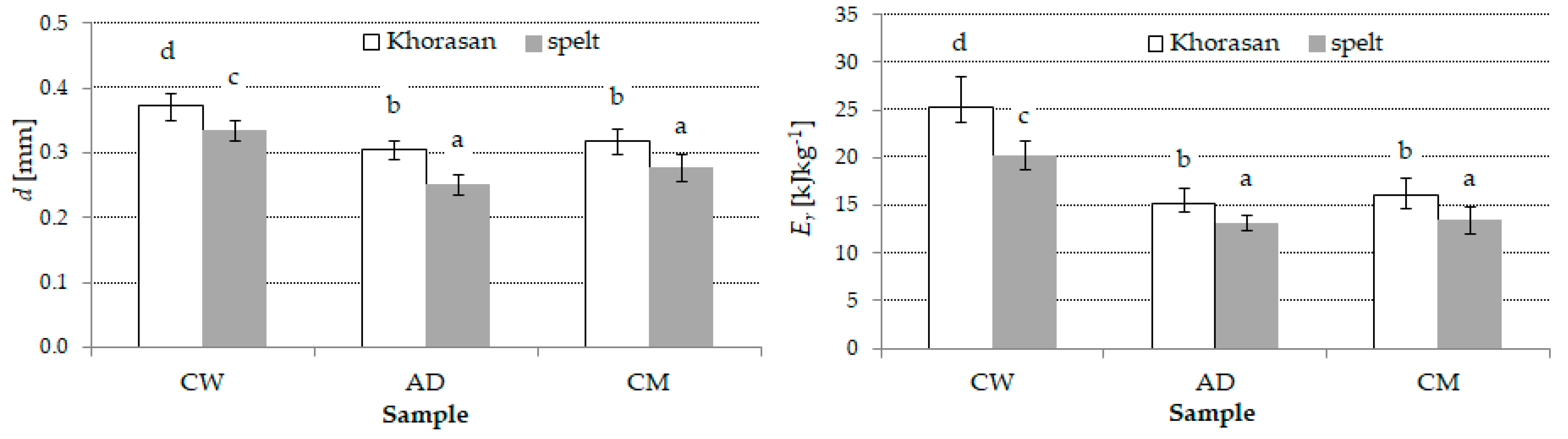

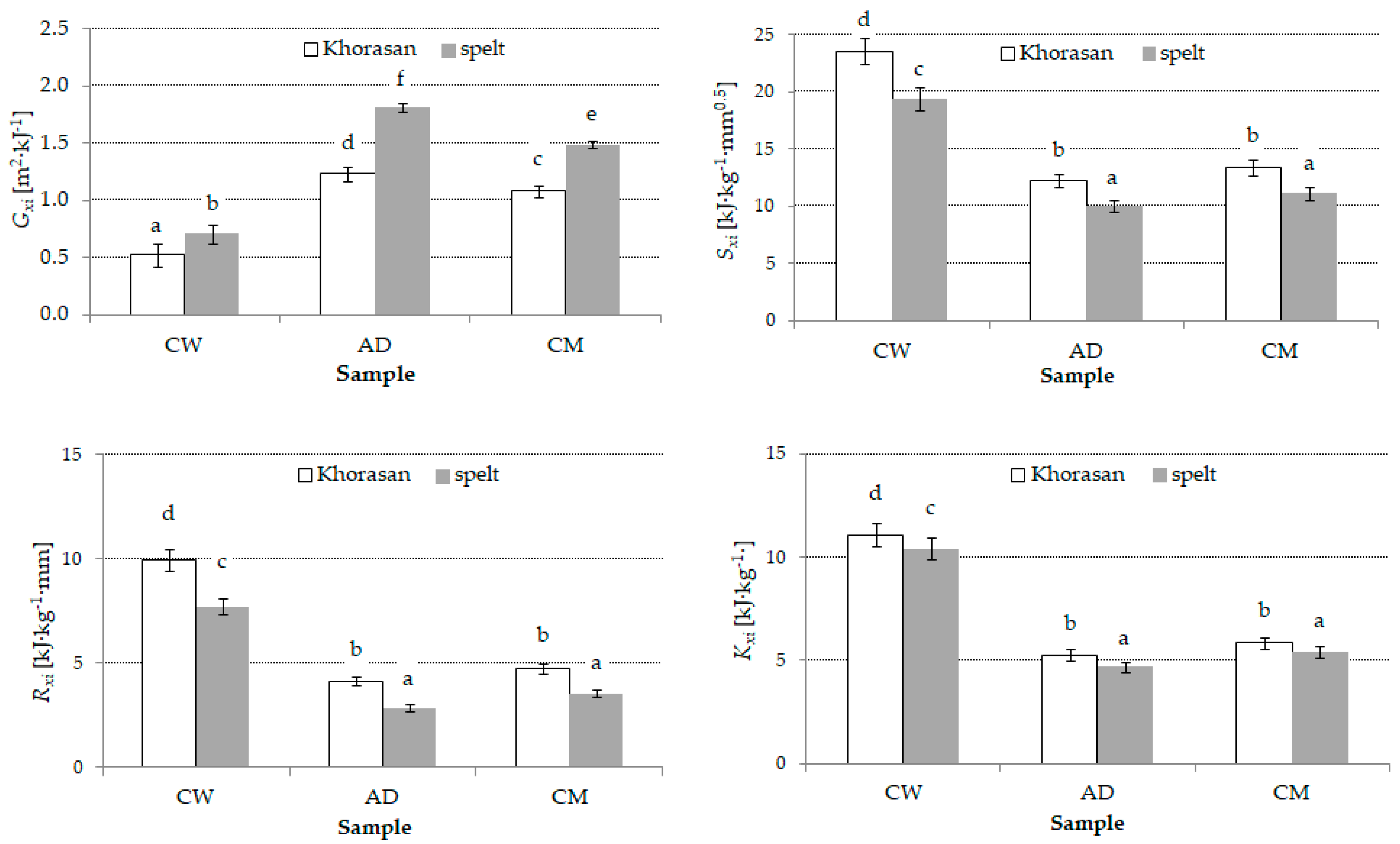

3.2.2. Average Particle Size and Grinding Energy

3.2.3. Grinding Energy Indices

3.3. Farinograph Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| ADI | air drying |

| CM | wheat stored in climatic chamber |

| DT | development time |

| d | average particle size |

| Er | specific grinding energy |

| MC | moisture content |

| ST | dough stability time |

| WA | water absorption of flour |

References

- Giraldo, P.; Benavente, E.; Manzano-Agugliaro, F.; Gimenez, E. Worldwide research trends on wheat and barley: A bibliometric comparative analysis. Agronomy 2019, 9, 352. [Google Scholar] [CrossRef]

- Seal, C.J.; Nugent, A.P.; Tee, E.S.; Thielecke, F. Whole-grain dietary recommendations: The need for a unified global approach. Br. J. Nutr. 2016, 115, 2031–2038. [Google Scholar] [CrossRef] [PubMed]

- Doblado-Maldonado, A.F.; Pike, O.A.; Sweley, J.C.; Rose, D.J. Key issues and challenges in whole wheat flour milling and storage. J. Cereal Sci. 2012, 56, 119–126. [Google Scholar] [CrossRef]

- Adom, K.K.; Sorrells, M.E.; Rui, H.L. Phytochemicals and antioxidant activity of milled fractions of different wheat varieties. J. Agric. Food Chem. 2005, 53, 2297–2306. [Google Scholar] [CrossRef]

- Călinoiu, L.F.; Vodnar, D.C. Whole grains and phenolic acids: A review on bioactivity, functionality, health benefits and bioavailability. Nutrients 2018, 10, 1615. [Google Scholar] [CrossRef]

- Niu, M.; Hou, G.G.; Wang, L.; Chen, Z. Effects of superfine grinding on the quality characteristics of whole-wheat flour and its raw noodle product. J. Cereal Sci. 2014, 60, 382–388. [Google Scholar] [CrossRef]

- Talbert, L.E.; Hofer, P.; Nash, D.; Martin, J.M.; Lanning, S.P.; Sherman, J.D.; Giroux, M.J. Hard white versus hard red wheats: Taste tests and milling and baking properties. Cereal Chem. 2013, 90, 249–255. [Google Scholar] [CrossRef]

- Prabhasankar, P.; Haridas Rao, P. Effect of different milling methods on chemical composition of whole wheat flour. Eur. Food Res. Technol. 2001, 213, 465–469. [Google Scholar] [CrossRef]

- Dziki, D.; Cacak-Pietrzak, G.; Miś, A.; Jończyk, K.; Gawlik-Dziki, U. Influence of wheat kernel physical properties on the pulverizing process. J. Food Sci. Technol. 2012, 51, 2648–2655. [Google Scholar] [CrossRef]

- Choy, A.L.; Walker, C.K.; Panozzo, J.F. Investigation of wheat milling yield based on grain hardness parameters. Cereal Chem. 2015, 92, 544–550. [Google Scholar] [CrossRef]

- Dziki, D. Effect of preliminary grinding of the wheat grain on the pulverizing process. J. Food Eng. 2011, 104, 585–591. [Google Scholar] [CrossRef]

- Baasandorj, T.; Ohm, J.B.; Manthey, F.; Simsek, S. Effect of kernel size and mill type on protein, milling yield, and baking quality of hard red spring wheat. Cereal Chem. 2015, 92, 81–87. [Google Scholar] [CrossRef]

- Haddad, Y.; Mabille, F.; Mermet, A.; Abecassis, J.; Benet, J.C. Rheological properties of wheat endosperm with a view on grinding behaviour. Powder Technol. 1999, 105, 89–94. [Google Scholar] [CrossRef]

- Dziki, D.; Cacak-Pietrzak, G.; Gawlik-Dziki, U.; Świeca, M.; Miś, A.; Rózyło, R.; Jończyk, K. Physicochemical properties and milling characteristics of spring wheat from different farming systems. J. Agric. Sci. Technol. 2017, 19, 1253–1266. [Google Scholar]

- Jung, H.; Lee, Y.J.; Yoon, W.B. Effect of moisture content on the grinding process and powder properties in food: A review. Processes 2018, 6, 69. [Google Scholar] [CrossRef]

- Warechowska, M.; Markowska, A.; Warechowski, J.; Miś, A.; Nawrocka, A. Effect of tempering moisture of wheat on grinding energy, middlings and flour size distribution, and gluten and dough mixing properties. J. Cereal Sci. 2016, 69, 306–312. [Google Scholar] [CrossRef]

- Cappelli, A.; Guerrini, L.; Parenti, A.; Palladino, G.; Cini, E. Effects of wheat tempering and stone rotational speed on particle size, dough rheology and bread characteristics for a stone-milled weak flour. J. Cereal Sci. 2020, 91, 102879. [Google Scholar] [CrossRef]

- Kweon, M.; Martin, R.; Souza, E. Effect of tempering conditions on milling performance and flour functionality. Cereal Chem. 2009, 86, 12–17. [Google Scholar] [CrossRef]

- Dziki, D. The crushing of wheat kernels and its consequence on the grinding process. Powder Technol. 2008, 185, 181–186. [Google Scholar] [CrossRef]

- Acquisgrana, M.D.R.; Gomez Pamies, L.C.; Martinez Amezaga, N.M.J.; Quiroga, F.M.; Ribotta, P.D.; Benítez, E.I. Impact of moisture and grinding on yield, physical, chemical and thermal properties of wholegrain flour obtained from hydrothermally treated sorghum grains. Int. J. Food Sci. Technol. 2020, 55, 2901–2909. [Google Scholar] [CrossRef]

- Bressiani, J.; Oro, T.; Da Silva, P.M.L.; Montenegro, F.M.; Bertolin, T.E.; Gutkoski, L.C.; Gularte, M.A. Influence of milling whole wheat grains and particle size on thermo-mechanical properties of flour using Mixolab. Czech J. Food Sci. 2019, 37, 276–284. [Google Scholar] [CrossRef]

- Kihlberg, I.; Johansson, L.; Kohler, A.; Risvik, E. Sensory qualities of whole wheat pan bread—Influence of farming system, milling and baking technique. J. Cereal Sci. 2004, 39, 67–84. [Google Scholar] [CrossRef]

- Doblado-Maldonado, A.F.; Flores, R.A.; Rose, D.J. Low moisture milling of wheat for quality testing of wholegrain flour. J. Cereal Sci. 2013, 58, 420–423. [Google Scholar] [CrossRef]

- Khalid, K.H.; Manthey, F.; Simsek, S. Whole grain wheat flour production using an ultracentrifugal mill. Cereal Chem. 2017, 94, 1001–1007. [Google Scholar] [CrossRef]

- Romankiewicz, D.; Hassoon, W.H.; Cacak-Pietrzak, G.; Sobczyk, M.B.; Wirkowska-WojdyBa, M.; CegliNska, A.; Dziki, D. The effect of chia seeds (Salvia hispanica L.) addition on quality and nutritional value of wheat bread. J. Food Qual. 2017, 2017, 1–7. [Google Scholar] [CrossRef]

- Sissons, M.J.; Osborne, B.G.; Hare, R.A.; Sissons, S.A.; Jackson, R. Application of the single-kernel characterization system to durum wheat testing and quality prediction. Cereal Chem. 2000, 77, 4–10. [Google Scholar] [CrossRef]

- Kraszewski, A.W.; Nelson, S.O. Determination of Moisture Content and Bulk Density of Shelled Corn by Measurement of Microwave Parameters. J. Agric. Eng. Res. 1994, 58, 37–46. [Google Scholar] [CrossRef]

- Ziemichód, A.; Wójcik, M.; Różyło, R. Seeds of Plantago psyllium and Plantago ovata: Mineral composition, grinding, and use for gluten-free bread as substitutes for hydrocolloids. J. Food Process Eng. 2019, 42, e12931. [Google Scholar] [CrossRef]

- Dziki, D.; Laskowski, J. Study to analyze the influence of sprouting of the wheat grain on the grinding process. J. Food Eng. 2010, 96, 562–567. [Google Scholar] [CrossRef]

- Velu, V.; Nagender, A.; Prabhakara Rao, P.G.; Rao, D.G. Dry milling characteristics of microwave dried maize grains (Zea mays L.). J. Food Eng. 2006, 74, 30–36. [Google Scholar] [CrossRef]

- Dziki, D.; Gładyszewska, B.; Różyło, R.; Polak, R.; Rudy, S.; Krzykowski, A. The size reduction theories of solid foods. Teka Comm. Mot. Power Ind. Agric. 2012, 12, 41–45. [Google Scholar]

- Miś, A.; Nawrocka, A.; Dziki, D. Behaviour of Dietary Fibre Supplements During Bread Dough Development Evaluated Using Novel Farinograph Curve Analysis. Food Bioprocess Technol. 2017, 10, 1031–1041. [Google Scholar] [CrossRef]

- Miś, A. Interpretation of mechanical spectra of carob fibre and oat wholemeal-enriched wheat dough using non-linear regression models. J. Food Eng. 2011, 102, 369–379. [Google Scholar] [CrossRef]

- Pearson, T.; Wilson, J.; Gwirtz, J.; Maghirang, E.; Dowell, F.; McCluskey, P.; Bean, S. Relationship between single wheat kernel particle-size distribution and Perten SKCS 4100 hardness index. Cereal Chem. 2007, 84, 567–575. [Google Scholar] [CrossRef]

- Muhamad, I.I.; Campbell, G.M. Effects of kernel hardness and moisture content on wheat breakage in the single kernel characterisation system. Innov. Food Sci. Emerg. Technol. 2004, 5, 119–125. [Google Scholar] [CrossRef]

- Dziki, D.; Laskowski, J. Wheat kernel physical properties and milling process. Acta Agrophys. 2005, 6, 59–71. [Google Scholar]

- Pasha, I.; Anjum, F.M.; Morris, C.F. Grain hardness: A major determinant of wheat quality. Food Sci. Technol. Int. 2010, 16, 511–522. [Google Scholar] [CrossRef]

- Świeca, M.; Dziki, D.; Gawlik-Dziki, U.; Rózyło, R.; Andruszczak, S.; Kraska, P.; Kowalczyk, D.; Pałys, E.; Baraniak, B. Grinding and nutritional properties of six spelt (Triticum aestivum ssp. Spelta L.) cultivars. Cereal Chem. 2014, 91, 247–254. [Google Scholar] [CrossRef]

- Wang, N.; Hou, G.G.; Dubat, A. Effects of flour particle size on the quality attributes of reconstituted whole-wheat flour and Chinese southern-type steamed bread. LWT Food Sci. Technol. 2017, 82, 147–153. [Google Scholar] [CrossRef]

- Fang, C.; Campbell, G.M. On predicting roller milling performance V: Effect of moisture content on the particle size distribution from first break milling of wheat. J. Cereal Sci. 2003, 37, 31–41. [Google Scholar] [CrossRef]

- Zhang, D.; Moore, W. Wheat bran particle size effects on bread baking performance and quality. J. Sci. Food Agric. 1999, 79, 805–809. [Google Scholar] [CrossRef]

- Walde, S.G.; Balaswamy, K.; Velu, V.; Rao, D.G. Microwave drying and grinding characteristics of wheat (Triticum aestivum). J. Food Eng. 2002, 55, 271–276. [Google Scholar] [CrossRef]

- Ahmed, Z.A.; Nadulski, R.; Kobus, Z.; Zawiślak, K. The Influence of Grain Moisture Content on Specific Energy During Spring Wheat Grinding. Agric. Agric. Sci. Procedia 2015, 7, 309–312. [Google Scholar] [CrossRef]

- Turnbull, K.M.; Rahman, S. Endosperm texture in wheat. J. Cereal Sci. 2002, 36, 327–337. [Google Scholar] [CrossRef]

- Topin, V.; Radjaï, F.; Delenne, J.Y.; Mabille, F. Mechanical modeling of wheat hardness and fragmentation. Powder Technol. 2009, 190, 215–220. [Google Scholar] [CrossRef]

- Topin, V.; Radjaï, F.; Delenne, J.Y.; Sadoudi, A.; Mabille, F. Wheat endosperm as a cohesive granular material. J. Cereal Sci. 2008, 47, 347–356. [Google Scholar] [CrossRef]

- Pujol, R.; Létang, C.; Lempereur, I.; Chaurand, M.; Mabille, F.; Abecassis, J. Description of a micromill with instrumentation for measuring grinding characteristics of wheat grain. Cereal Chem. 2000, 77, 421–427. [Google Scholar] [CrossRef]

- Miś, A.; Grundas, S.; Dziki, D.; Laskowski, J. Use of farinograph measurements for predicting extensograph traits of bread dough enriched with carob fibre and oat wholemeal. J. Food Eng. 2012, 108, 1–12. [Google Scholar] [CrossRef]

- Temea, A.M.; Pircu, N.; Simion, A.I.; Grigoraş, C.G.; Ungureanu, R.E.; Alexe, P. Improvement of flour and dough rheological properties by maturation process. Rom. Biotechnol. Lett. 2016, 21, 11381–11392. [Google Scholar]

- Bakare, A.H.; Osundahunsi, O.F.; Olusanya, J.O. Rheological, baking, and sensory properties of composite bread dough with breadfruit (Artocarpus communis Forst) and wheat flours. Food Sci. Nutr. 2016, 4, 573–587. [Google Scholar] [CrossRef]

- Dapcevic, T.; Pojic, M.; Hadnaev, M.; Torbic, A. The Role of Empirical Rheology in Flour Quality Control. In Wide Spectra of Quality Control; IntechOpen: London, UK, 2011. [Google Scholar]

- Sanz Penella, J.M.; Collar, C.; Haros, M. Effect of wheat bran and enzyme addition on dough functional performance and phytic acid levels in bread. J. Cereal Sci. 2008, 48, 715–721. [Google Scholar] [CrossRef]

- Yang, X.; Wu, L.; Zhu, Z.; Ren, G.; Liu, S. Variation and trends in dough rheological properties and flour quality in 330 Chinese wheat varieties. Crop J. 2014, 2, 195–200. [Google Scholar] [CrossRef][Green Version]

- Kalnina, S.; Rakcejeva, T.; Kunkulberga, D. Rheological properties of whole grain wheat, rye and hull-less barley flour blends for pasta production. Res. Rural Dev. 2015, 1, 150–156. [Google Scholar]

- Rosell, C.M.; Santos, E.; Collar, C. Mixing properties of fibre-enriched wheat bread doughs: A response surface methodology study. Eur. Food Res. Technol. 2006, 223, 333–340. [Google Scholar] [CrossRef]

- Bae, W.; Lee, B.; Hou, G.G.; Lee, S. Physicochemical characterization of whole-grain wheat flour in a frozen dough system for bake off technology. J. Cereal Sci. 2014, 60, 520–525. [Google Scholar] [CrossRef]

- Boita, E.R.F.; Oro, T.; Bressiani, J.; Santetti, G.S.; Bertolin, T.E.; Gutkoski, L.C. Rheological properties of wheat flour dough and pan bread with wheat bran. J. Cereal Sci. 2016, 71, 177–182. [Google Scholar] [CrossRef]

- Noort, M.W.J.; van Haaster, D.; Hemery, Y.; Schols, H.A.; Hamer, R.J. The effect of particle size of wheat bran fractions on bread quality—Evidence for fibre-protein interactions. J. Cereal Sci. 2010, 52, 59–64. [Google Scholar] [CrossRef]

| Type of Wheat | Moisture Content | Hardness Index | Diameter | Mass of Kernel (mg) | Bulk Density (kg m−3) |

|---|---|---|---|---|---|

| (% w.b.) | (-) | (mm) | |||

| Khorasan | 11.52 ± 0.82 a,* | 70.0 ± 13.11 b | 3.12 ± 0.33 b | 50.87 ± 10.12 b | 793 ± 42 b |

| Spelt | 11.68 ± 0.84 a | 24.9 ± 15.63 a | 2.16 ± 0.44 a | 40.21 ± 11.61 a | 745 ± 15 a |

| Type of Wheat | Sample | Range of Class (mm) | ||||

|---|---|---|---|---|---|---|

| >0.8 | 0.6–0.8 | 0.4–0.6 | 0.2–0.4 | <0.2 | ||

| Khorasan | CW | 2.06 ± 0.08 c,* | 12.44 ± 0.46 f | 27.40 ± 0.63 e | 34.62 ± 0.57 a | 23.48 ± 0.35 b |

| AD | 0.66 ± 0.05 a | 4.46 ± 0.05 e | 23.75 ± 0.33 d | 44.08 ± 0.54 b | 32.17 ± 0.60 c | |

| CM | 0.85 ± 0.05 b | 7.50 ± 0.22 d | 23.11 ± 0.40 c | 36.94 ± 0.73 a | 31.60 ± 0.66 c | |

| Spelt | CW | 3.35 ± 0.08 d | 7.69± 0.23 d | 19.01 ± 0.31 b | 41.68 ± 0.77 c | 28.27 ± 0.68 b |

| AD | 0.71 ± 0.06 a | 3.70 ± 0.06 a | 13.84 ± 0.25 a | 34.18 ± 0.84 a | 47.57 ± 1.52 e | |

| CM | 1.04 ± 0.03 b | 5.06 ± 0.18 c | 13.10 ± 0.25 a | 43.12 ± 0.88 b | 37.68 ± 0.73 d | |

| Type of Wheat | Sample | Water Absorption [%] | Development Time (min) | Stability of Dough (min) | Degree of Softening (FU) |

|---|---|---|---|---|---|

| Spelt | CW | 58.2 ± 0.41 a,* | 5.2 ± 0.24 a | 5.8 ± 0.16 a | 62.0 ± 2.65 d |

| Spelt | AD | 62.3 ± 0.82 c | 7.3 ± 0.35 b | 10.3 ± 0.80 c | 27.0 ± 4.53 b |

| Spelt | CM | 61.6 ± 0.64 c | 6.8 ± 0.41 b | 8.7 ± 0.15 b | 38.3 ± 2.51c |

| Khorasan | CW | 57.4 ± 0.46 a | 19.5 ± 0.52 c | 15.6 ± 0.49 d | 0.00 + 0.00 a |

| Khorasan | AD | 61.6 ± 0.97 b,c | 19.7 ± 0.46 c | 14.8 ± 0.36 d | 0.00 + 0.00 a |

| Khorasan | CM | 60.9 ± 0.52 b | 20.2 ± 0.63 c | 15.2 ± 0.52 d | 0.00 + 0.00 a |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hassoon, W.H.; Dziki, D.; Miś, A.; Biernacka, B. Wheat Grinding Process with Low Moisture Content: A New Approach for Wholemeal Flour Production. Processes 2021, 9, 32. https://doi.org/10.3390/pr9010032

Hassoon WH, Dziki D, Miś A, Biernacka B. Wheat Grinding Process with Low Moisture Content: A New Approach for Wholemeal Flour Production. Processes. 2021; 9(1):32. https://doi.org/10.3390/pr9010032

Chicago/Turabian StyleHassoon, Waleed H., Dariusz Dziki, Antoni Miś, and Beata Biernacka. 2021. "Wheat Grinding Process with Low Moisture Content: A New Approach for Wholemeal Flour Production" Processes 9, no. 1: 32. https://doi.org/10.3390/pr9010032

APA StyleHassoon, W. H., Dziki, D., Miś, A., & Biernacka, B. (2021). Wheat Grinding Process with Low Moisture Content: A New Approach for Wholemeal Flour Production. Processes, 9(1), 32. https://doi.org/10.3390/pr9010032