Effect of Mixed Commercial Cold Flow Improvers on Flow Properties of Biodiesel from Waste Cooking Oil

Abstract

1. Introduction

2. Experimental

2.1. Reagents and Instruments

2.2. Experimental Part

2.2.1. Experimental Materials and Instruments

2.2.2. Determination of the Solidifying Point and Cold Filter Plugging Point of Biodiesel

2.2.3. Differential Scanning Calorimetry Analysis

2.2.4. Low Temperature Polarization Microscope Analysis

3. Results and Discussion

3.1. The Effect of Various CFIs on Biodiesel

3.2. Orthogonal Test and Analysis

3.3. Analysis on the Enhancing Mechanism of Mixed CFI on Biodiesel Flow Properties

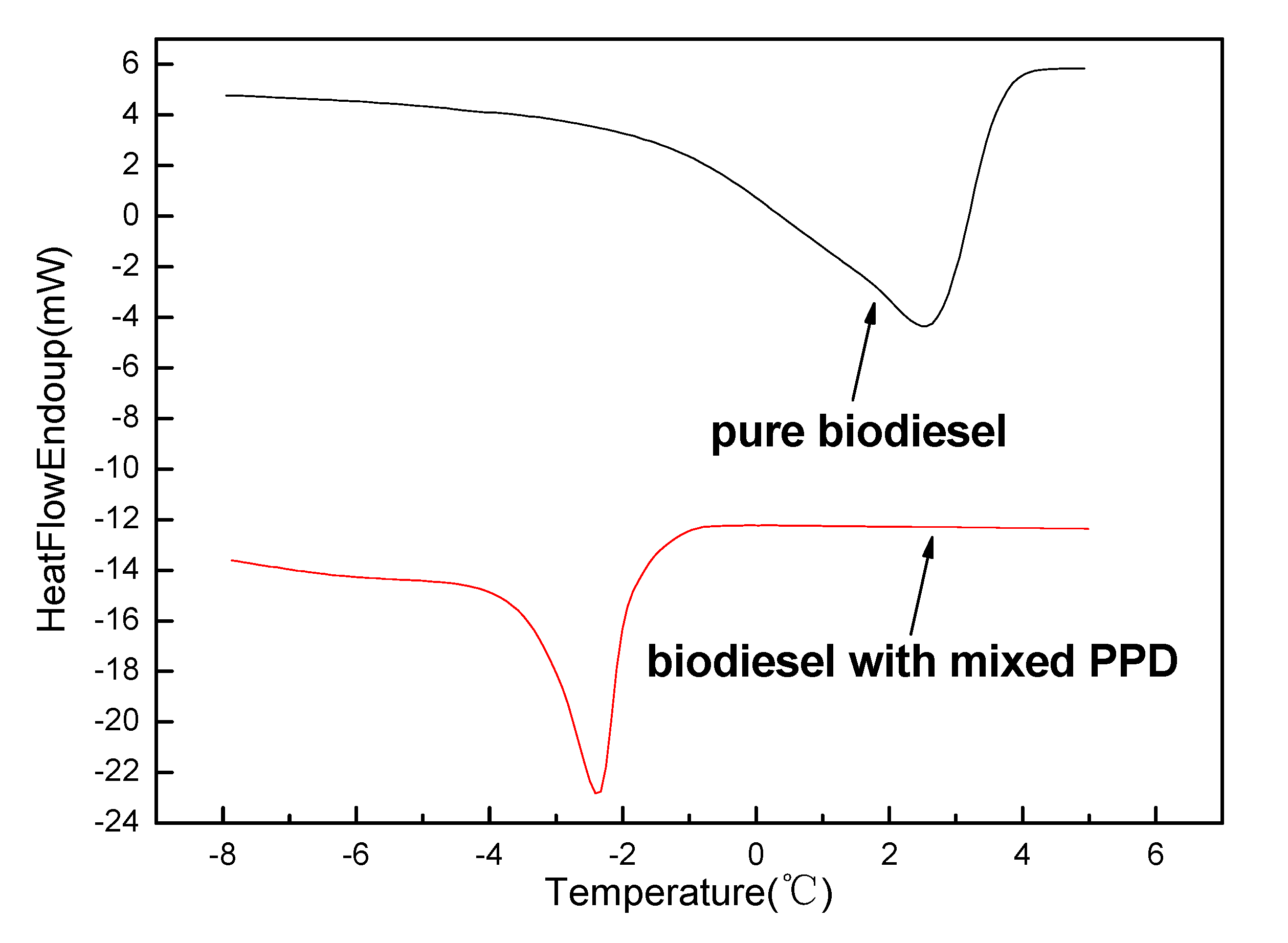

3.3.1. DSC Analysis

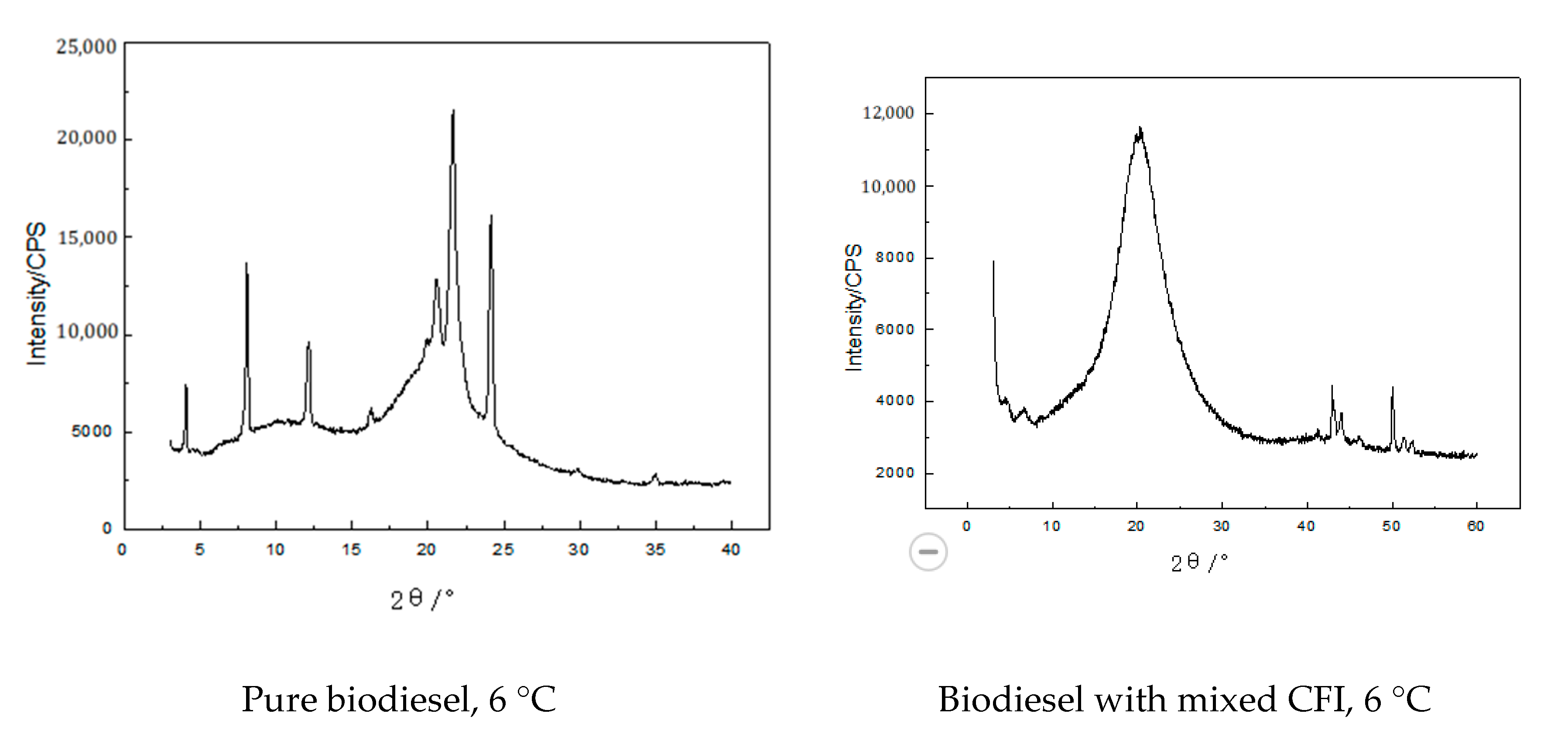

3.3.2. XRD Analysis

3.3.3. Polarized Light Microscope Analysis

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Dwivedi, G.; Sharma, M.P. Investigation and improvement in cold flow properties of pongamia biodiesel. Waste Biomass Valori. 2015, 6, 73–79. [Google Scholar] [CrossRef]

- Unlu, D.; Boz, N.; Ilgen, O.; Hilmioglu, N. Improvement of fuel properties of biodiesel with bioadditive ethyl levulinate. Open Chem. 2018, 16, 647–652. [Google Scholar] [CrossRef]

- Xue, Y.; Yang, C.; Xu, G.W.; Zhao, Z.C.; Lian, X.; Sheng, H.; Lin, H.L. The influence of polymethyl acrylate as a pour point depressant for biodiesel. Energy Source Part A 2017, 39, 17–22. [Google Scholar] [CrossRef]

- Lapuerta, M.; Gonzalez-Garcia, I.; Cespedes, I.; Estevez, C.; Bayarri, N. Improvement of cold flow properties of a new biofuel derived from glycerol. Fuel 2019, 242, 794–803. [Google Scholar] [CrossRef]

- Cao, L.C.; Zhang, S.C. Production and characterization of biodiesel derived from Hodgsonia macrocarpa seed oil. Appl. Energy 2015, 146, 135–140. [Google Scholar] [CrossRef]

- Curran, M.A. Assessing environmental impacts of biofuels using lifecycle-based approaches. Manag. Environ. Qual. 2012, 24, 34–52. [Google Scholar] [CrossRef]

- Milazzo, M.F.; Spina, F. The use of the risk assessment in the life cycle assessment framework Human health impacts of a soy-biodiesel production. Manag. Environ. Qual. 2015, 26, 389–406. [Google Scholar] [CrossRef]

- Nemanashi, M.; Noh, J.H.; Meijboom, R. Hydrogenation of biomass-derived levulinic acid to gamma-valerolactone catalyzed by mesoporous supported dendrimer-derived Ru and Pt catalysts: An alternative method for the production of renewable biofuels. Appl. Catal. A Gen. 2018, 550, 77–89. [Google Scholar] [CrossRef]

- Milazzo, M.F.; Spina, F.; Cavallaro, S.; Bart, J.C.J. Sustainable soy biodiesel. Renew. Sustain. Energy Rev. 2013, 27, 806–852. [Google Scholar] [CrossRef]

- Mohanan, A.; Bouzidi, L.; Li, S.J.; Narine, S.S. Mitigating crystallization of saturated fames in biodiesel: 1. Lowering crystallization temperatures via addition of metathesized soybean oil. Energy 2016, 96, 335–345. [Google Scholar] [CrossRef]

- Wang, J.N.; Zhao, W.N.; Ai, Y.N.; Chen, H.Y.; Cao, L.C.; Han, S. Improving the fuel properties of biodiesel via complementary blending with diesel from direct coal liquefaction. RSC Adv. 2015, 5, 45575–45581. [Google Scholar] [CrossRef]

- Kim, D.S.; Hanifzadeh, M.; Kumar, A. Trend of Biodiesel Feedstock and Its Impact on Biodiesel Emission Characteristics. Environ. Prog. Sustain. Energy 2018, 37, 7–19. [Google Scholar] [CrossRef]

- Zhou, M.A.; He, Y.; Chen, Y.W.; Yang, Y.P.; Lin, H.L.; Han, S. Synthesis and Evaluation of Terpolymers Consist of Methacrylates with Maleic Anhydride and Methacrylic Morpholine and Their Amine Compound as Pour Point Depressants in Diesel Fuels. Energy Fuel 2015, 29, 5618–5624. [Google Scholar] [CrossRef]

- Abe, M.; Hirata, S.; Komatsu, H.; Yamagiwa, K.; Tajima, H. Thermodynamic selection of effective additives to improve the cloud point of biodiesel fuels. Fuel 2016, 171, 94–100. [Google Scholar] [CrossRef]

- Hosseinzadeh-Bandbafha, H.; Tabatabaei, M.; Aghbashlo, M.; Khanali, M.; Demirbas, A. A comprehensive review on the environmental impacts of diesel/biodiesel additives. Energy Convers. Manag. 2018, 174, 579–614. [Google Scholar] [CrossRef]

- Maglinao, R.L.; Resurrection, E.P.; Kumar, S.; Maglinao, A.L.; Capareda, S.; Moser, B.R. Hydrodeoxygenation-Alkylation Pathway for the Synthesis of a Sustainable Lubricant Improver from Plant Oils and Lignin-Derived Phenols. Ind. Eng. Chem. Res. 2019, 58, 4317–4330. [Google Scholar] [CrossRef]

- Srikanth, H.V.; Venkatesh, J.; Godiganur, S.; Venkateswaran, S.; Manne, B. Bio-based diluents improve cold flow properties of dairy washed milk-scum biodiesel. Renew. Energy 2017, 111, 168–174. [Google Scholar] [CrossRef]

- Li, H.; Wang, J.G.; Shen, B.X. The rheological properties of biodiesel derived from cottonseed oil. Energy Source Part A 2016, 38, 3181–3186. [Google Scholar] [CrossRef]

- Lian, X.; Xue, Y.; Xu, G.W.; Zhao, Z.C.; Sheng, H.; Lin, H.L. Effect of methyl acetoacetate as a potential cold flow improver for biodiesel. Energy Source Part A 2017, 39, 97–102. [Google Scholar] [CrossRef]

- Evcil, A.; Al-Shanableh, F.; Savas, M.A. Variation of solid fraction with cold flow properties of biodiesel produced from waste frying oil. Fuel 2018, 215, 522–527. [Google Scholar] [CrossRef]

- Zhou, M.A.; He, Y.; Lin, H.L.; Han, S. Effect of MC-MA polymer pour point depressants on the flow properties of biodiesel. Energy Source Part A 2016, 38, 1962–1968. [Google Scholar] [CrossRef]

- Srikanth, H.V.; Venkatesh, J.; Godiganur, S.; Manne, B. Acetone and Diethyl ether: Improve cold flow properties of Dairy Washed Milkscum biodiesel. Renew. Energy 2019, 130, 446–451. [Google Scholar] [CrossRef]

- Liu, H.; Jiang, S.S.; Guo, H.S.; Han, S.; Yang, C.; Jiang, J.Z. A new kind of pour point depressant: Diesel from direct coal liquefaction. Fuel Process. Technol. 2016, 149, 285–289. [Google Scholar] [CrossRef]

- Zhao, Z.C.; Xue, Y.; Xu, G.W.; Zhou, J.W.; Lian, X.; Liu, P.; Chen, D.M.; Han, S.; Lin, H.L. Effect of the nano-hybrid pour point depressants on the cold flow properties of diesel fuel. Fuel 2017, 193, 65–71. [Google Scholar] [CrossRef]

- Imdadul, H.K.; Masjuki, H.H.; Kalam, M.A.; Zulkifli, N.W.M.; Rashed, M.M.; Rashedul, H.K.; Monirul, I.M.; Mosarof, M.H. A comprehensive review on the assessment of fuel additive effects on combustion behavior in CI engine fuelled with diesel biodiesel blends. RSC Adv. 2015, 5, 67541–67567. [Google Scholar] [CrossRef]

- Abe, M.; Komatsu, H.; Yamagiwa, K.; Tajima, H. Effect of nonionic surfactants on the low temperature winterization separation of fatty acid methyl ester mixtures. Fuel 2017, 190, 351–358. [Google Scholar] [CrossRef]

- Roy, M.M.; Calder, J.; Wang, W.; Mangad, A.; Diniz, F.C.M. Emission analysis of a modern Tier 4 DI diesel engine fueled by biodiesel-diesel blends with a cold flow improver (Wintron Synergy) at multiple idling conditions. Appl. Energy 2016, 179, 45–54. [Google Scholar] [CrossRef]

- Eiadtrong, S.; Maliwan, K.; Prateepchaikul, G.; Kattiyawan, T.; Thephsorn, P.; Leevijit, T. Preparation, important fuel properties, and comparative use of un-preheated palm fatty acid distillate-diesel blends in a single cylinder diesel engine. Renew. Energy 2019, 134, 1089–1098. [Google Scholar] [CrossRef]

- Zhao, W.N.; Xue, Y.; Ma, P.; Ma, W.F.; Wang, J.N.; Lu, D.L.; Han, S. Improving the cold flow properties of high-proportional waste cooking oil biodiesel blends with mixed cold flow improvers. RSC Adv. 2016, 6, 13365–13370. [Google Scholar] [CrossRef]

- Cao, L.C.; Wang, J.N.; Liu, K.J.; Han, S. Ethyl acetoacetate: A potential bio-based diluent for improving the cold flow properties of biodiesel from waste cooking oil. Appl. Energy 2014, 114, 18–21. [Google Scholar] [CrossRef]

- Tasic, I.; Tomic, M.D.; Aleksic, A.L.; Durisic-Mladenovic, N.; Martinovic, F.L.; Micic, R.D. Improvement of low-temperature characteristics of biodiesel by additivation. Hem. Ind. 2019, 73, 103–114. [Google Scholar] [CrossRef]

- Wang, W.C.; Li, F.S.; Li, Y. Effect of biodiesel ester structure optimization on low temperature performance and oxidation stability. J. Mater. Res. Technol. 2020, 9, 2727–2736. [Google Scholar] [CrossRef]

- Rajaeifar, M.A.; Abdi, R.; Tabatabaei, M. Expanded polystyrene waste application for improving biodiesel environmental performance parameters from life cycle assessment point of view. Renew. Sustain. Energy Rev. 2017, 74, 278–298. [Google Scholar] [CrossRef]

- Verma, P.; Sharma, M.P.; Dwivedi, G. Evaluation and enhancement of cold flow properties of palm oil and its biodiesel. Energy Rep. 2016, 2, 8–13. [Google Scholar] [CrossRef]

- Dunn, R.O.; Ngo, H.L.; Haas, M.J. Branched-Chain Fatty Acid Methyl Esters as Cold Flow Improvers for Biodiesel. J. Am. Oil Chem. Soc. 2015, 92, 853–869. [Google Scholar] [CrossRef]

- Cao, L.C.; Wang, J.N.; Liu, C.; Chen, Y.W.; Liu, K.J.; Han, S. Ethylene vinyl acetate copolymer: A bio-based cold flow improver for waste cooking oil derived biodiesel blends. Appl. Energy 2014, 132, 163–167. [Google Scholar] [CrossRef]

- Madihalli, C.; Sudhakar, H.; Doble, M. Mannosylerythritol Lipid-A as a Pour Point Depressant for Enhancing the Low-Temperature Fluidity of Biodiesel and Hydrocarbon Fuels. Energy Fuel 2016, 30, 4118–4125. [Google Scholar] [CrossRef]

- Wang, J.N.; Cao, L.C.; Han, S. Effect of polymeric cold flow improvers on flow properties of biodiesel from waste cooking oil. Fuel 2014, 117, 876–881. [Google Scholar] [CrossRef]

- Mohanan, A.; Bouzidi, L.; Narine, S.S. Harnessing the synergies between lipid-based crystallization modifiers and a polymer pour point depressant to improve pour point of biodiesel. Energy 2017, 120, 895–906. [Google Scholar] [CrossRef]

| Name of CFI | Numbering | SP (°C) | ΔSP (°C) | CFPP (°C) | ΔCFPP (°C) |

|---|---|---|---|---|---|

| No dosage | --- | 0 | --- | 2 | --- |

| P388 | PAO-1 | 0 | 0 | 2 | 0 |

| A132 | PAO-2 | −1 | 1 | 1 | 1 |

| A134 | PAO-3 | −2 | 2 | 2 | 0 |

| A146 | PAO-4 | −3 | 3 | 0 | 2 |

| A148 | PAO-5 | −1 | 1 | 1 | 1 |

| T803 | PAO-6 | −1 | 1 | 2 | 0 |

| V-300 | PPD-1 | 0 | 0 | 1 | 1 |

| IX-248 | PPD-2 | 0 | 0 | 3 | 0 |

| LZ-7749 | PPD-3 | −2 | 2 | 2 | 0 |

| CS-1 | PPD-4 | −1 | 1 | 2 | 0 |

| Haut | PPD-5 | −2 | 2 | 0 | 2 |

| AH-BSFH | PPD-6 | −4 | 4 | −1 | 3 |

| HL21 | PPD-7 | 0 | 0 | 1 | 1 |

| 10-320 | PMA-1 | −3 | 3 | 0 | 2 |

| 10-330 | PMA-2 | −4 | 4 | 0 | 2 |

| A-4 | PMA-2 | −4 | 4 | 1 | 1 |

| T1804D | EVA | −3 | 3 | 0 | 2 |

| V-385 | HPMA | 0 | 0 | 2 | 0 |

| Level | 1 | 2 | 3 | 4 | 5 |

|---|---|---|---|---|---|

| PMA series (A) | PMA-1 | PMA-2 | PMA-3 | PAO-2 | PAO-4 |

| EVA series (B) | EVA | PPD-4 | PPD-5 | PPD-6 | PPD-7 |

| Mixed ratio (C) | 8:1 | 4:1 | 1:1 | 1:4 | 1:8 |

| Experiment Number | PMA Series (A) | EVA Series (B) | Mixed Ratio (C) | ΔSP (°C) | ΔCFPP (°C) |

|---|---|---|---|---|---|

| 1 | PMA-1 | EVA | 8:1 | 0 | 1 |

| 2 | PMA-1 | PPD-4 | 4:1 | 0 | 0 |

| 3 | PMA-1 | PPD-5 | 1:1 | 1 | 0 |

| 4 | PMA-1 | PPD-6 | 1:4 | 2 | 3 |

| 5 | PMA-1 | PPD-7 | 1:8 | 3 | 1 |

| 6 | PMA-2 | EVA | 4:1 | 2 | 1 |

| 7 | PMA-2 | PPD-4 | 1:1 | 4 | 2 |

| 8 | PMA-2 | PPD-5 | 1:4 | 0 | 1 |

| 9 | PMA-2 | PPD-6 | 1:8 | 5 | 3 |

| 10 | PMA-2 | PPD-7 | 8:1 | 3 | 1 |

| 11 | PMA-3 | EVA | 1:1 | 1 | 0 |

| 12 | PMA-3 | PPD-4 | 1:4 | 0 | 0 |

| 13 | PMA-3 | PPD-5 | 1:8 | 1 | 2 |

| 14 | PMA-3 | PPD-6 | 8:1 | 3 | 1 |

| 15 | PMA-3 | PPD-7 | 4:1 | 3 | 0 |

| 16 | PA-2 | EVA | 1:4 | 1 | 2 |

| 17 | PA-2 | PPD-4 | 1:8 | 0 | 2 |

| 18 | PA-2 | PPD-5 | 8:1 | 2 | 1 |

| 19 | PA-2 | PPD-6 | 4:1 | 4 | 1 |

| 20 | PA-2 | PPD-7 | 1:1 | 1 | 1 |

| 21 | PA-4 | EVA | 1:8 | 3 | 2 |

| 22 | PA-4 | PPD-4 | 8:1 | 1 | 0 |

| 23 | PA-4 | PPD-5 | 4:1 | 1 | 1 |

| 24 | PA-4 | PPD-6 | 1:1 | 2 | 1 |

| 25 | PA-4 | PPD-7 | 1:4 | 1 | 2 |

| ΔSP (°C) | ΔCFPP (°C) | ||||||

|---|---|---|---|---|---|---|---|

| PMA (A) | EVA (B) | Mixed Ratio (C) | PMA (A) | EVA (B) | Mixed Ratio (C) | ||

| K1 | 6 | 7 | 9 | K1 | 5 | 6 | 4 |

| K2 | 14 | 5 | 10 | K2 | 8 | 4 | 3 |

| K3 | 8 | 5 | 9 | K3 | 3 | 5 | 4 |

| K4 | 8 | 16 | 4 | K4 | 7 | 9 | 8 |

| K5 | 8 | 11 | 12 | K5 | 6 | 5 | 10 |

| R1 | 1.2 | 1.4 | 1.8 | R1 | 1 | 1.2 | 0.8 |

| R2 | 2.8 | 1 | 2 | R2 | 1.6 | 0.8 | 0.6 |

| R3 | 1.6 | 1 | 1.8 | R3 | 0.6 | 1 | 0.8 |

| R4 | 1.6 | 3.2 | 0.8 | R4 | 1.4 | 1.8 | 1.6 |

| R5 | 1.6 | 2.2 | 2.4 | R5 | 1.2 | 1 | 2 |

| R | 1.6 | 2.2 | 1.6 | R | 1 | 1 | 1.4 |

| Optimal level | A2 | B4 | C5 | Optimal level | A2 | B4 | C5 |

| Sample | Onset/°C | Peak/°C | Endset/°C | ΔH/J·g−1 | Area/mJ |

|---|---|---|---|---|---|

| Pure biodiesel | 2.56 | 4.26 | −17.546 | −55.369 | 538.189 |

| Biodiesel with mixed CFI | −1.86 | −2.41 | −14.915 | −32.218 | 299.947 |

| Temperature (°C) | Pure Biodiesel | Add Mixed CFI Biodiesel | ||||

|---|---|---|---|---|---|---|

| 2θ | d(A) | Peak Area | 2θ | d(A) | Peak Area | |

| 6 | 4.073 | 21.678 | 15,735 | 4.639 | 19.033 | 7625 |

| 8.083 | 10.929 | 57,856 | 6.737 | 13.109 | 13,513 | |

| 12.169 | 7.627 | 39,714 | 20.261 | 4.379 | 919 | |

| 16.255 | 5.448 | 7338 | 41.246 | 2.187 | 2857 | |

| 20.569 | 4.315 | 42,258 | 42.878 | 2.107 | 13,782 | |

| 21.628 | 4.106 | 178,891 | 43.985 | 2.057 | 8680 | |

| 24.125 | 3.686 | 86,422 | 46.084 | 1.968 | 2773 | |

| 29.838 | 2.992 | 2901 | 50.048 | 1.821 | 16,083 | |

| 34.946 | 2.565 | 5203 | 51.388 | 1.777 | 6039 | |

| 36.913 | 2.433 | 966 | 52.379 | 1.745 | 3447 | |

| Pure Biodiesel | Add Mixed CFI Biodiesel | ||

|---|---|---|---|

| S | A | S | A |

| 0.720 | 437,284 | 0.012 | 75,718 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nie, S.; Cao, L. Effect of Mixed Commercial Cold Flow Improvers on Flow Properties of Biodiesel from Waste Cooking Oil. Processes 2020, 8, 1094. https://doi.org/10.3390/pr8091094

Nie S, Cao L. Effect of Mixed Commercial Cold Flow Improvers on Flow Properties of Biodiesel from Waste Cooking Oil. Processes. 2020; 8(9):1094. https://doi.org/10.3390/pr8091094

Chicago/Turabian StyleNie, Siyu, and Leichang Cao. 2020. "Effect of Mixed Commercial Cold Flow Improvers on Flow Properties of Biodiesel from Waste Cooking Oil" Processes 8, no. 9: 1094. https://doi.org/10.3390/pr8091094

APA StyleNie, S., & Cao, L. (2020). Effect of Mixed Commercial Cold Flow Improvers on Flow Properties of Biodiesel from Waste Cooking Oil. Processes, 8(9), 1094. https://doi.org/10.3390/pr8091094