Numerical Simulations of Molten Breakup Behaviors of a de Laval-Type Nozzle, and the Effects of Atomization Parameters on Particle Size Distribution

Abstract

1. Introduction

2. Model Description

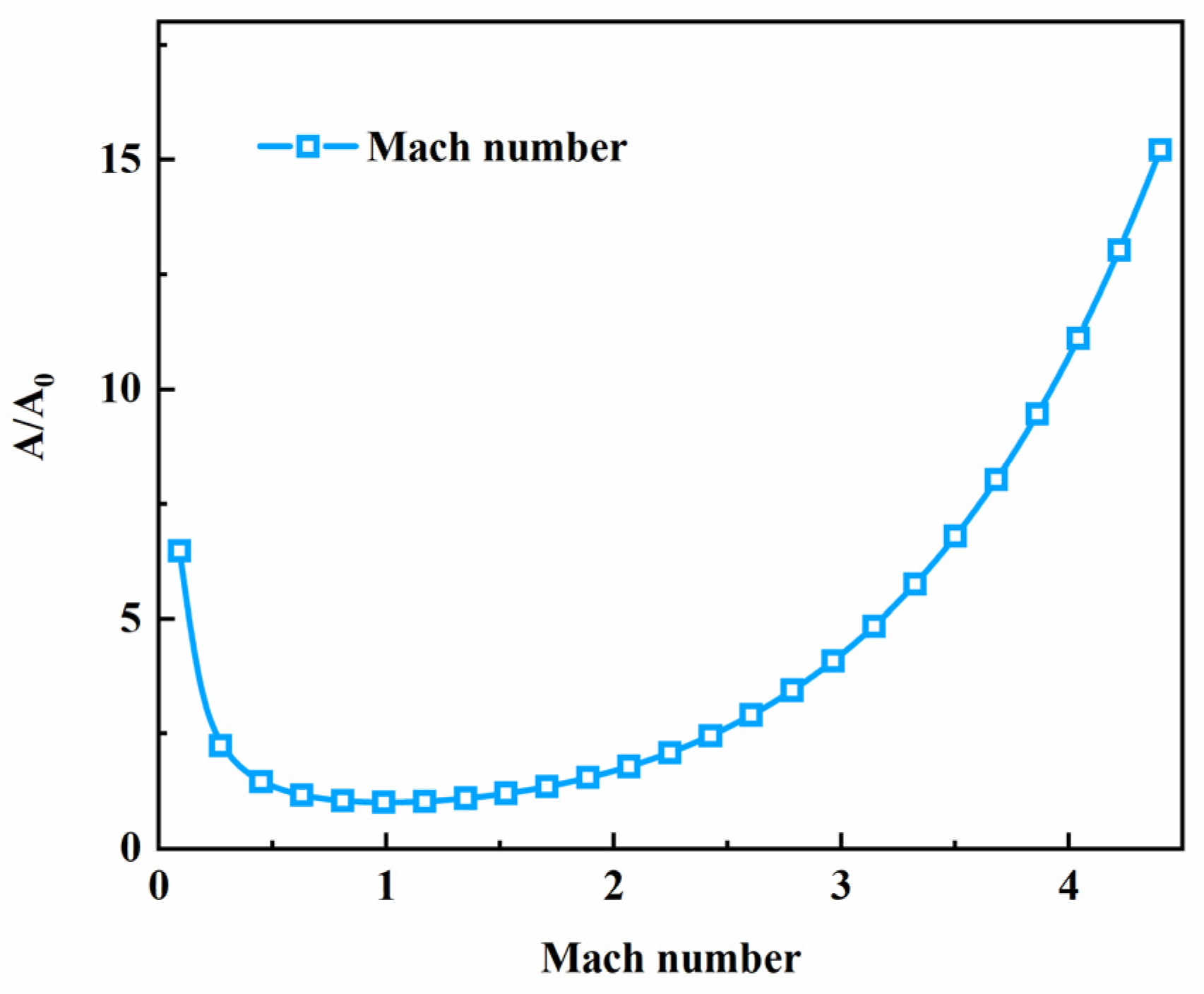

2.1. Design of de Laval-Type Atomizer

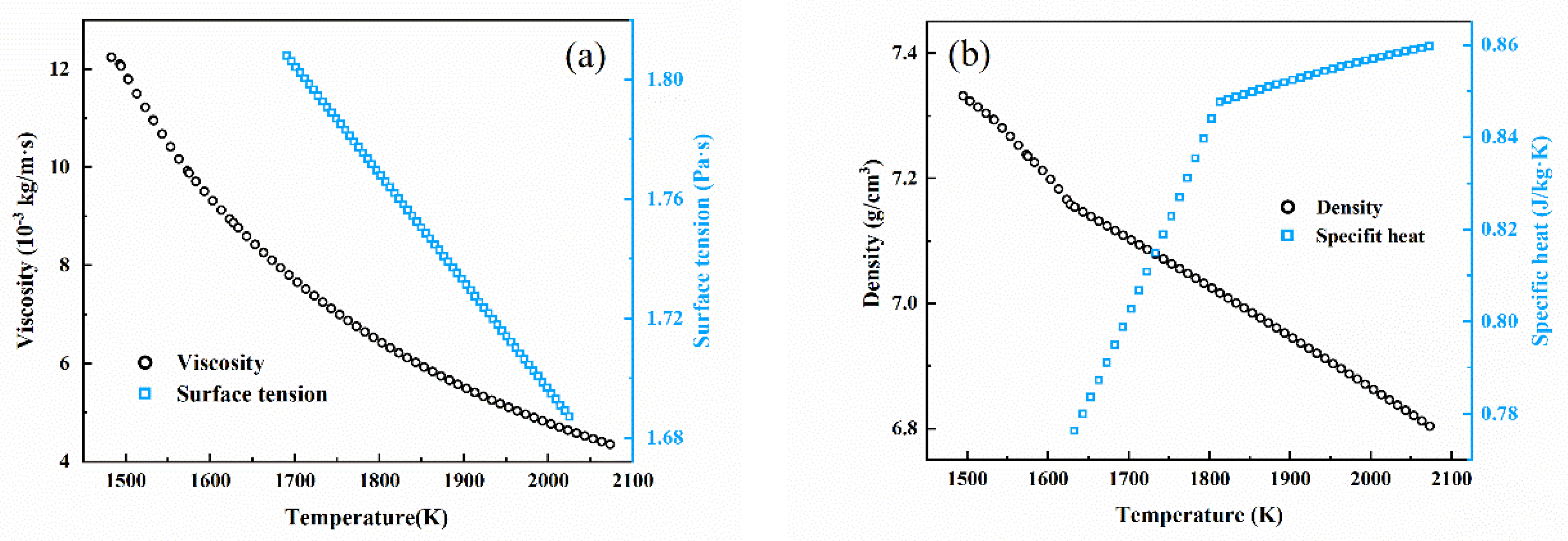

2.2. Modelling the Fluids

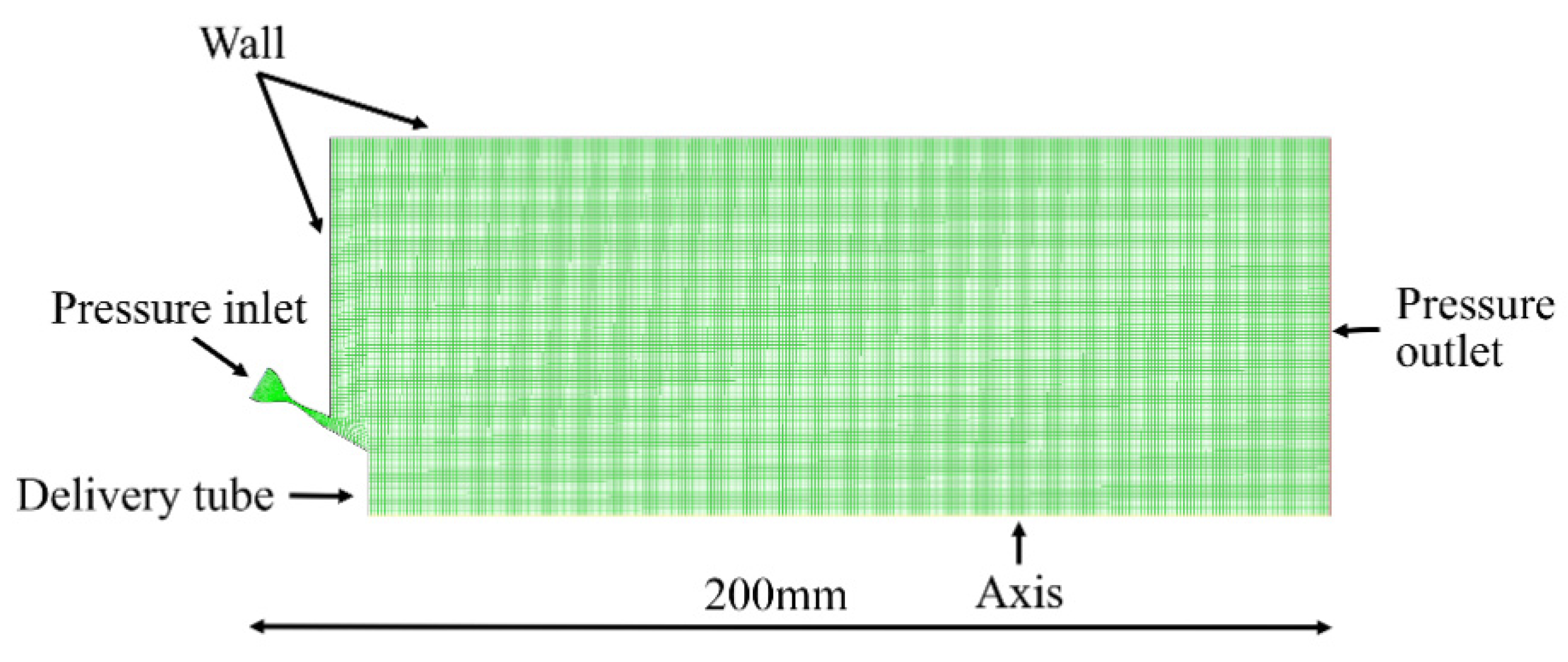

2.3. Model Implementation

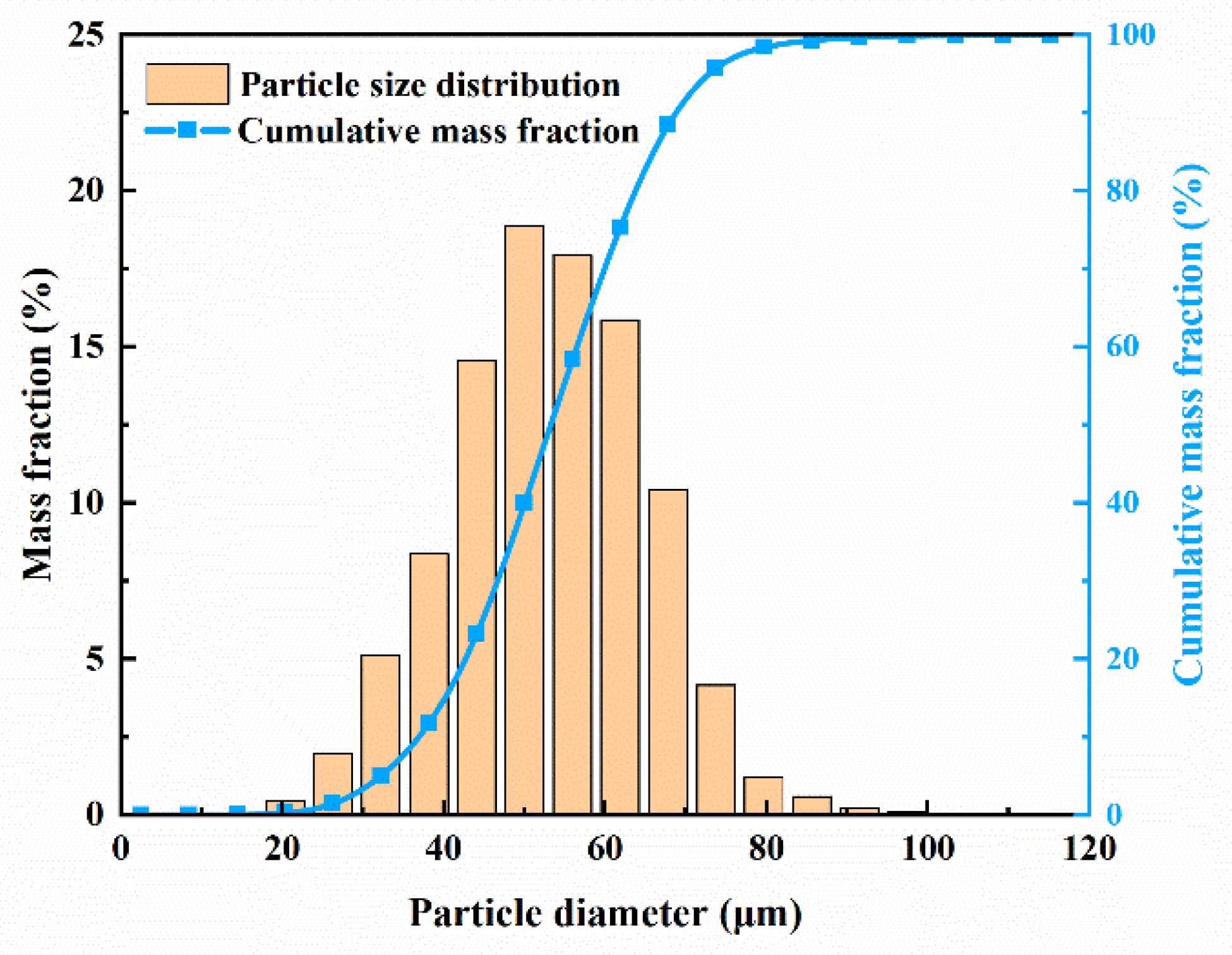

3. Results

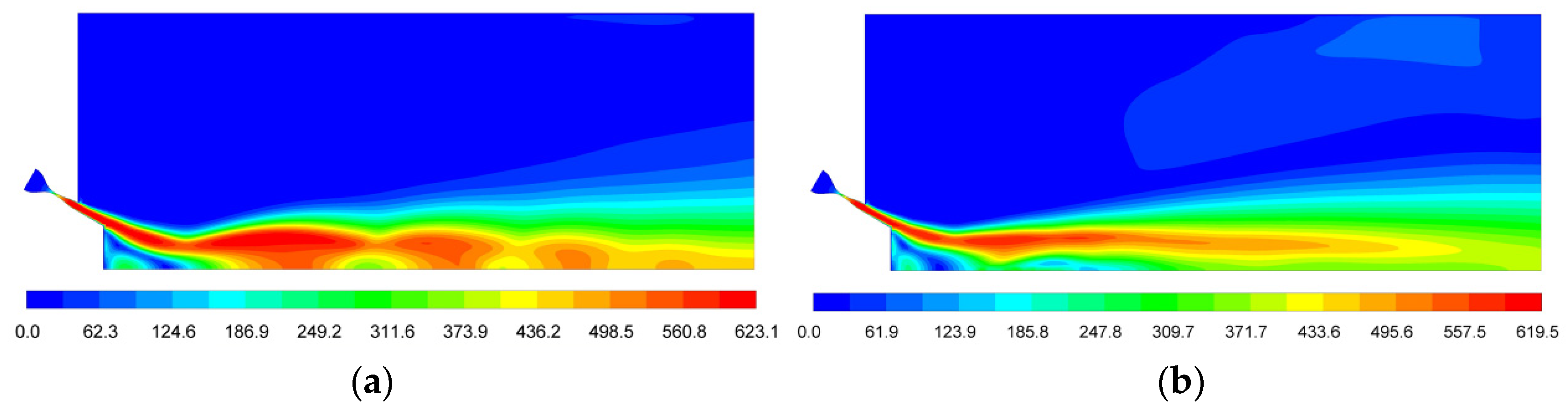

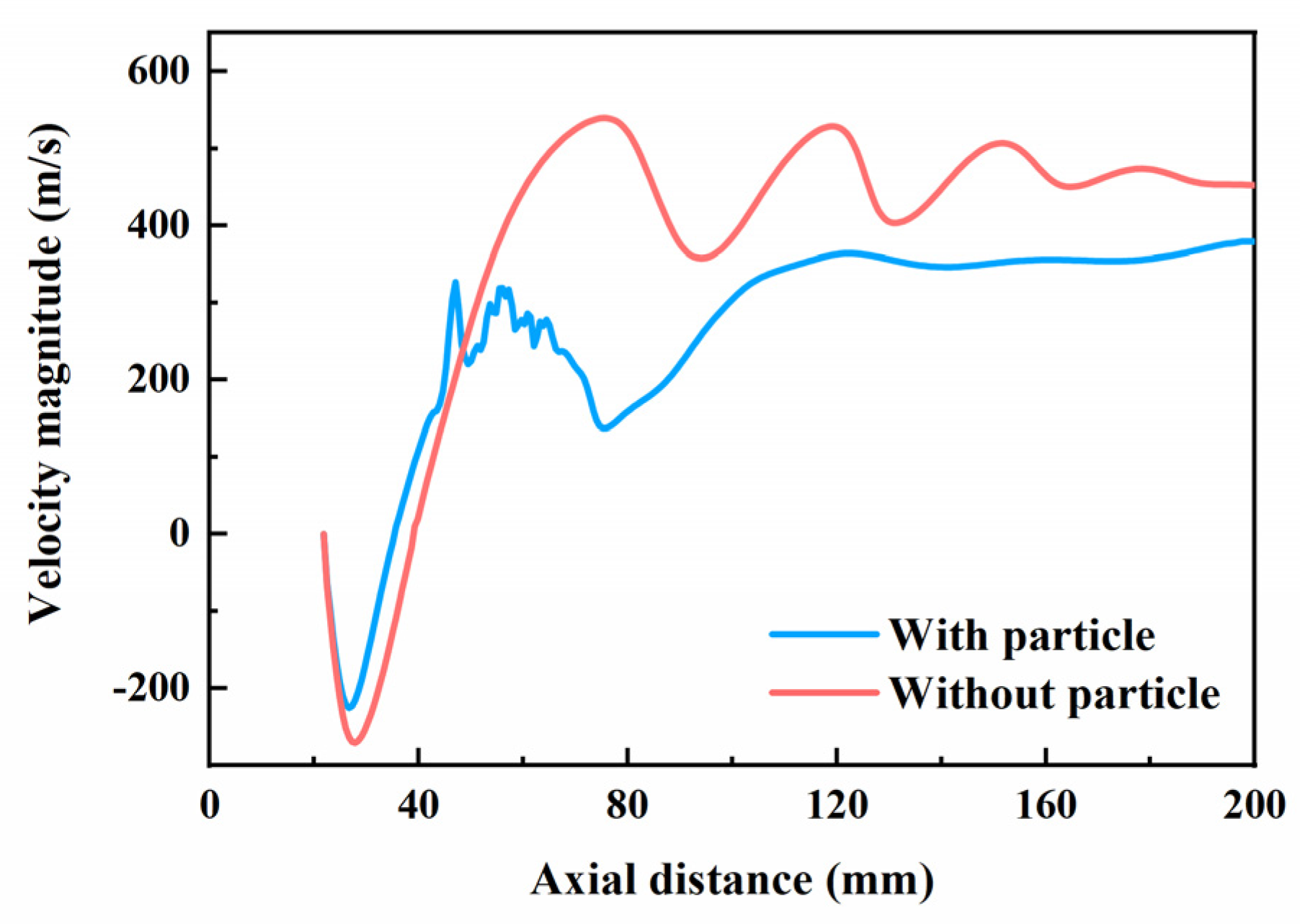

3.1. Flow Field Analysis

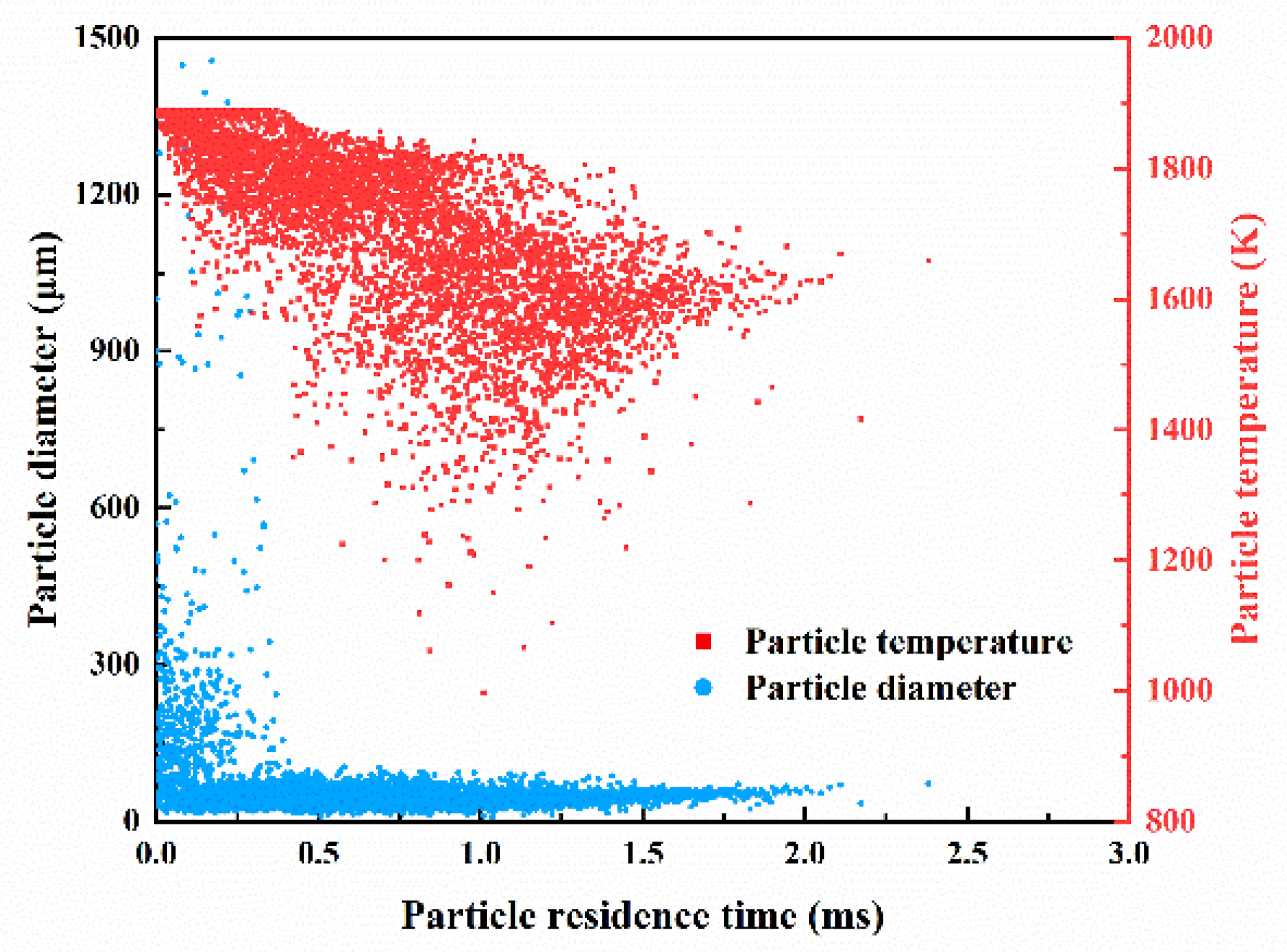

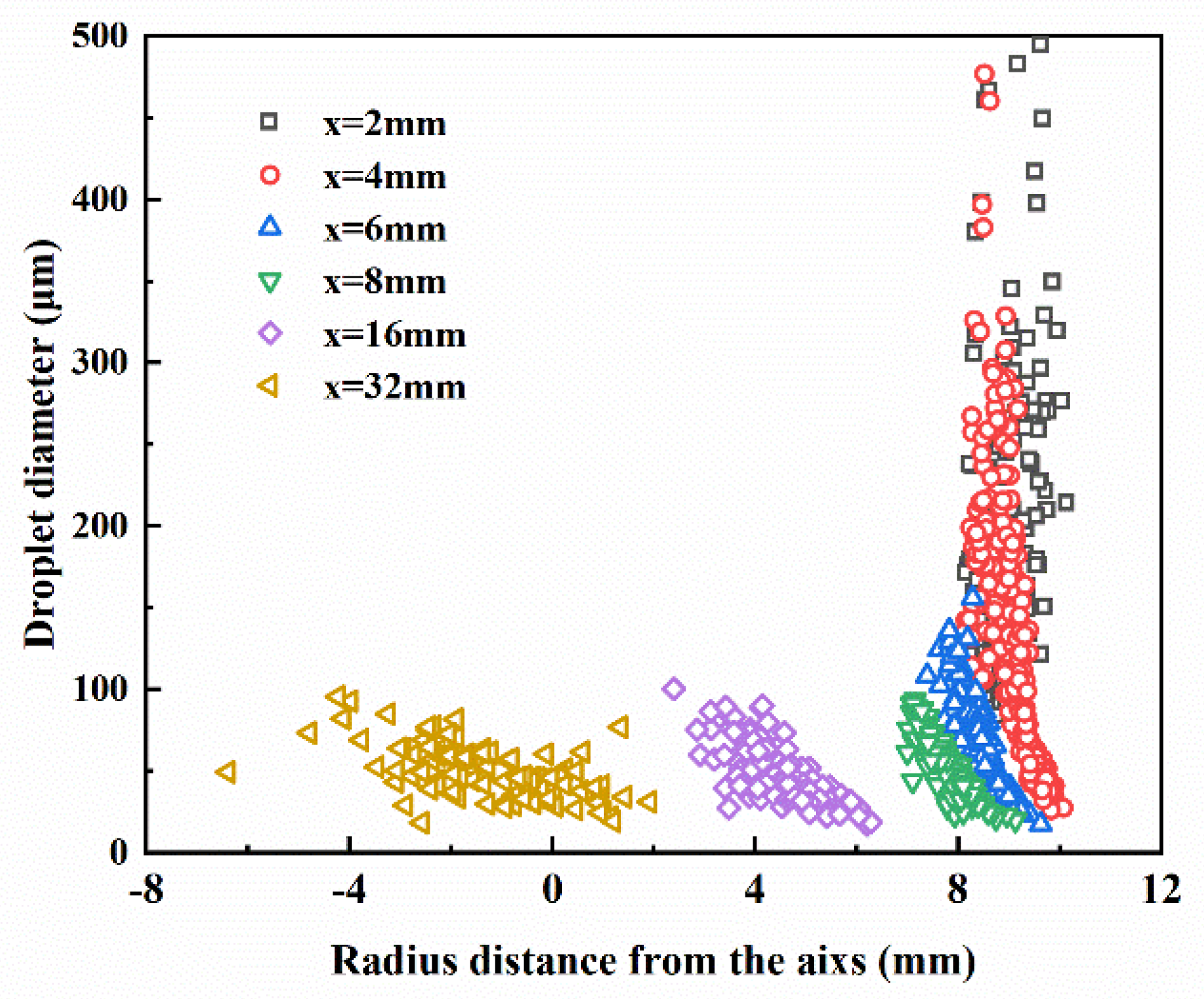

3.2. Breakup Behavior

4. Effect of Atomizing Parameters

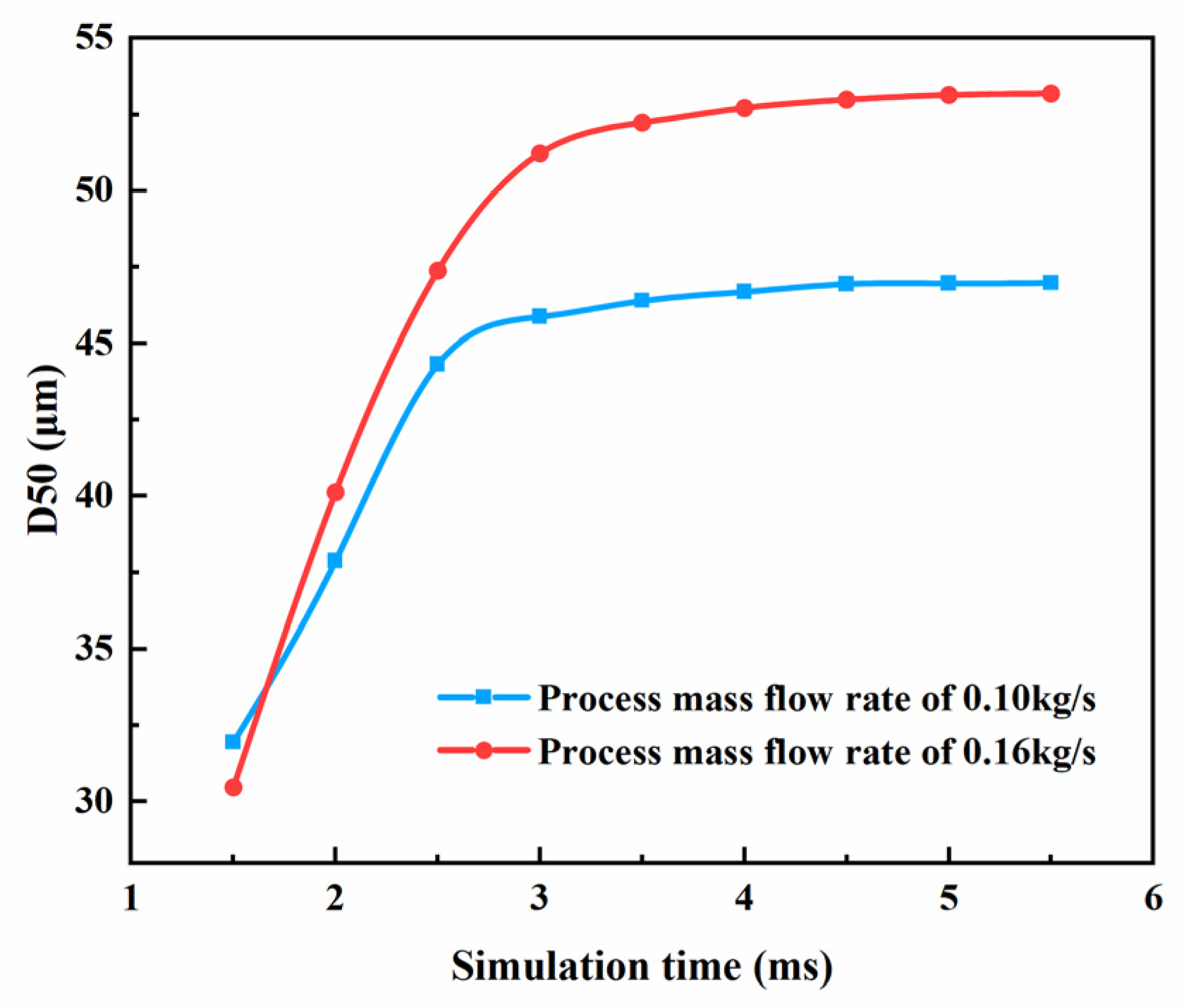

4.1. Effect of GMR

4.2. Effect of Operating Pressure

4.3. Effect of Operating Gas Temperature

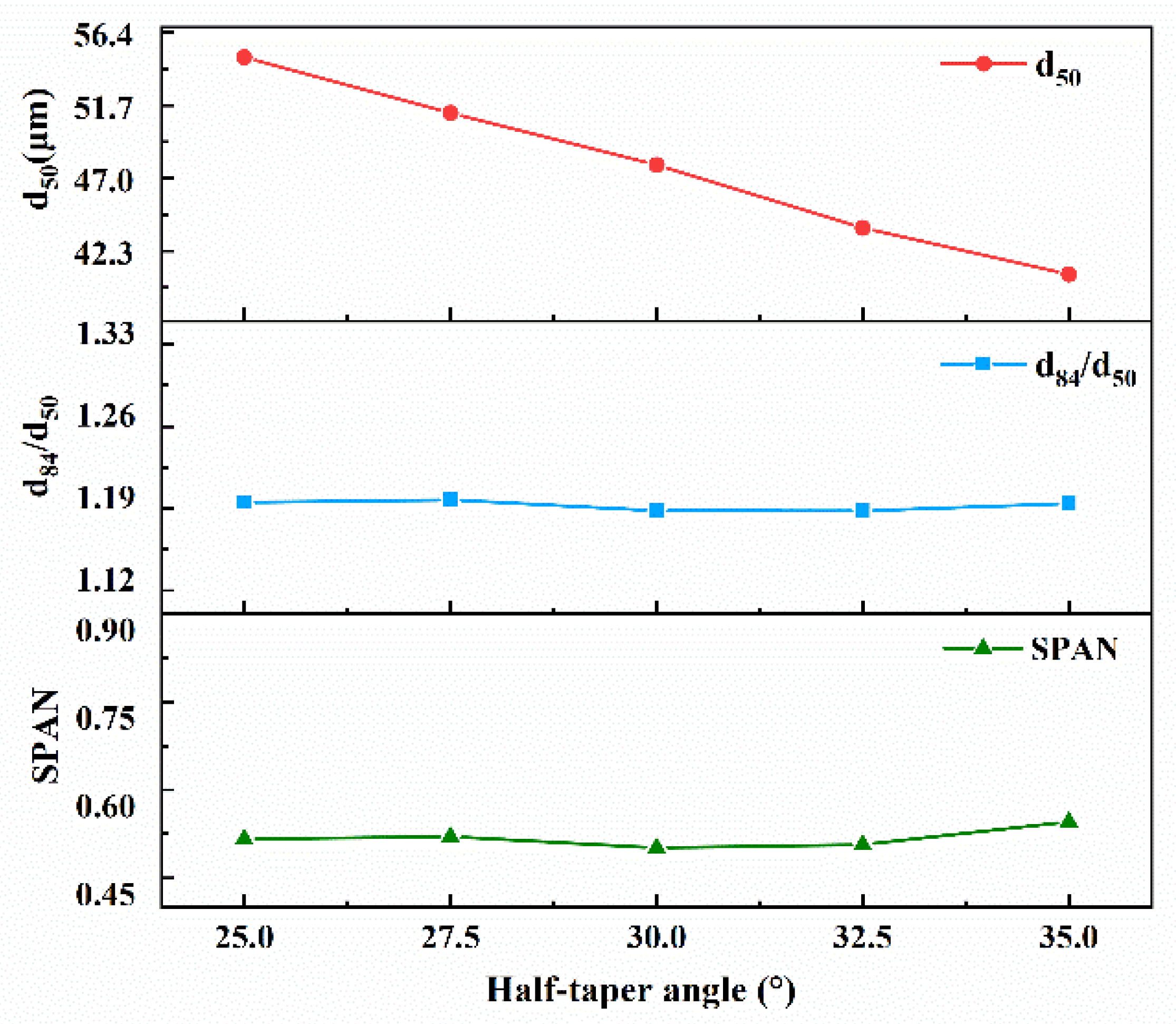

4.4. Effect of the Half-Taper Angle

4.5. Effect of Protrusion Length

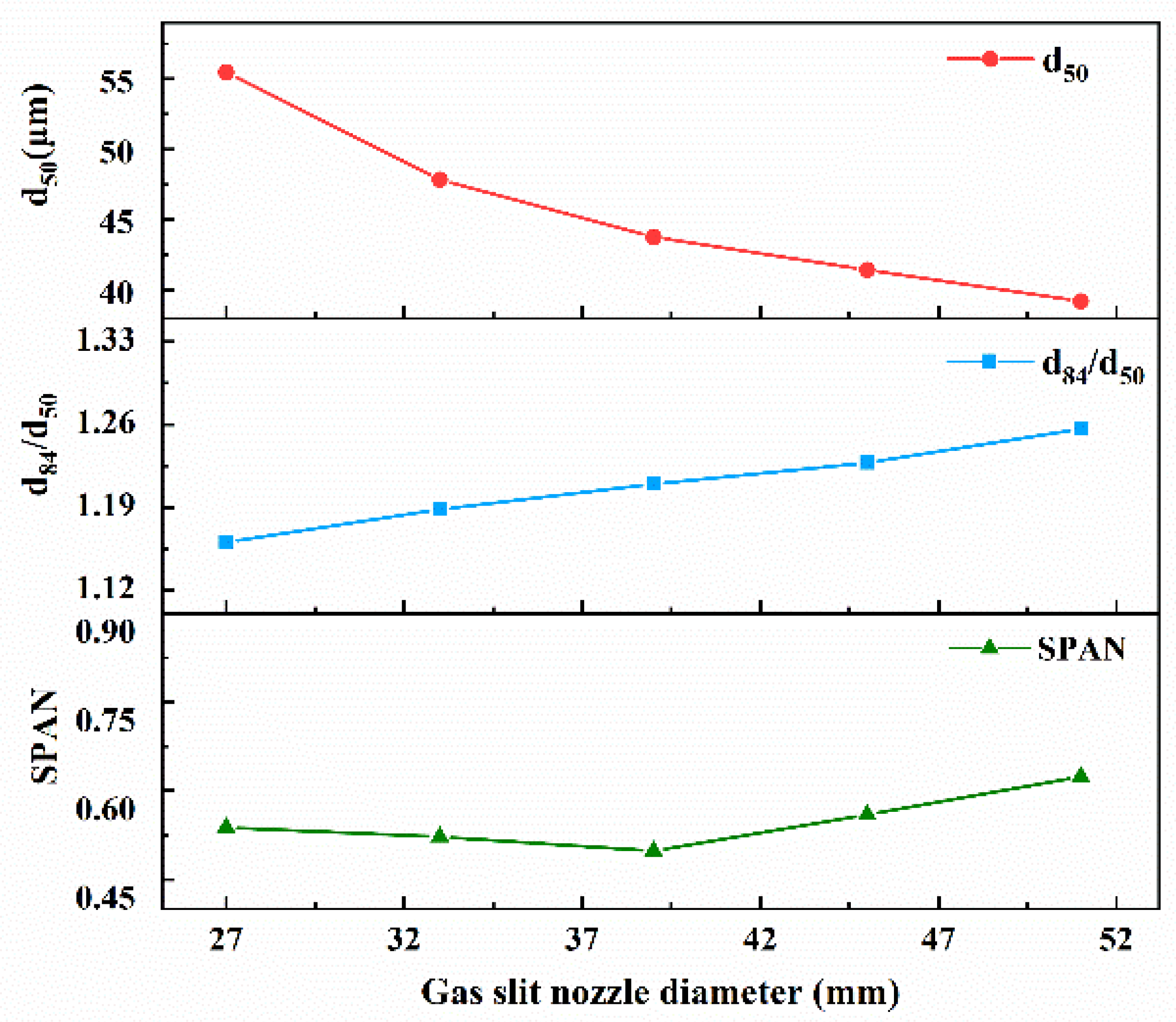

4.6. Effect of the Gas Slit Nozzle Diameter

5. Discussion

6. Conclusions

- A higher GMR results in a decrease in d50 and standard deviation.

- At relatively low pressures, increasing the operating pressure results in a decrease in particle size and reduces the standard deviation. However, the increase will become invalid at high pressures.

- Increasing the operating gas temperature and the half-taper angle leads to a decrease in d50, but the standard deviation remains stable. Additionally, a half-taper angle of 30° is more suitable for the de Laval-type atomization nozzle.

- Increasing the protrusion length within a certain range leads to a decrease in particle size, which increases suddenly when the protrusion length is increased to 12 mm.

- When the gas slit nozzle diameter is increased, the d50 value exhibits a decreasing trend. However, it also causes a wider spread of the particle size distribution. For the consideration of tight coupling, we intend to choose a relatively small diameter, e.g., 32.8 mm in atomization.

Author Contributions

Funding

Conflicts of Interest

References

- Attar, H.; Prashanth, K.G.; Chaubey, A.K.; Calin, M.; Zhang, L.C.; Scudino, S.; Eckert, J. Comparison of wear properties of commercially pure titanium prepared by selective laser melting and casting processes. Mater. Lett. 2015, 142, 38–41. [Google Scholar] [CrossRef]

- Antipas, G.S.E. Review of gas atomisation and spray forming phenomenology. Powder Metall. 2013, 56, 317–330. [Google Scholar] [CrossRef]

- Sabard, A.; de Lovelock, H.L.; Hussain, T. Microstructural Evolution in Solution Heat Treatment of Gas-Atomized Al Alloy (7075) Powder for Cold Spray. J. Therm. Spray Technol. 2017, 27, 145–158. [Google Scholar] [CrossRef]

- Song, C.; Li, K.; Xie, K.; Lu, W.; Zhao, S.; Han, Q.; Zhai, Q. The effect of the nucleation ability on solidified microstructures of gas-atomized Fe–6.5wt.%Si alloy powder. Powder Technol. 2014, 263, 31–36. [Google Scholar] [CrossRef]

- Mates, S.P.; Settles, G.S. A Study of Liquid Metal Atomization Using Close-Coupled Nozzles, Part 1: Gas Dynamic Behavior. At. Sprays 2005, 15, 19–40. [Google Scholar] [CrossRef]

- Motaman, S.; Mullis, A.M.; Cochrane, R.F.; Borman, D.J. Numerical and Experimental Investigations of the Effect of Melt Delivery Nozzle Design on the Open-to Closed-Wake Transition in Closed-Coupled Gas Atomization. Metall. Mater. Trans. B 2015, 46, 1990–2004. [Google Scholar] [CrossRef]

- Ting, J.; Perett, M.W.; Eisen, W.B. The effect of wake-closure phenomenon on gas atomization performance. Mater. Sci. Eng. A (Struct. Mater. Prop. Microstruct. Process.) 2002, 326, 110–121. [Google Scholar] [CrossRef]

- Zhao, W.; Cao, F.; Ning, Z.; Zhang, G.; Li, Z.; Sun, J. A computational fluid dynamics (CFD) investigation of the flow field and the primary atomization of the close coupled atomizer. Comput. Chem. Eng. 2012, 40, 58–66. [Google Scholar] [CrossRef]

- Si, C.R.; Zhang, X.J.; Wang, J.B.; Li, Y.J. Design and evaluation of a Laval-type supersonic atomizer for low-pressure gas atomization of molten metals. Int. J. Miner. Metall. Mater. 2014, 21, 627–635. [Google Scholar] [CrossRef]

- Xu, L.H.; Zhou, X.L.; Li, J.H.; Du, K.P.; Ma, Y.; Yu, Y.G. Design of atomizing nozzle and Simulation of its flow field structure. Therm. Spray Technol. 2019, 3, 5–12. [Google Scholar] [CrossRef]

- Anderson, I.E.; Rieken, J.; Meyer, J.; Byrd, D.; Heidloff, A. Visualization of Atomization Gas Flow and Melt Break-up Effects in Response to Nozzle Design. Ames Lab. (AMES) Ames IA 2011. [Google Scholar] [CrossRef]

- Antipas, G.S.E. Modelling of the break up mechanism in gas atomization of liquid metals. Part I: The surface wave formation model. Comput. Mater. Sci. 2006, 35, 416–422. [Google Scholar] [CrossRef]

- Jain, S.S.; Tyagi, N.; Prakash, R.S.; Ravikrishna, R.V.; Tomar, G. Secondary breakup of drops at moderate Weber numbers: Effect of Density ratio and Reynolds number. Int. J. Multiph. Flow 2019, 117, 25–41. [Google Scholar] [CrossRef]

- Zeoli, N.; Gu, S. Numerical modelling of droplet break-up for gas atomization. Comput. Mater. Sci. 2006, 38, 282–292. [Google Scholar] [CrossRef]

- Firmansyah, D.A.; Kaiser, R.; Zahaf, R.; Coker, Z.; Choi, T.-Y.; Lee, D. Numerical simulations of supersonic gas atomization of liquid metal droplets. Jpn. J. Appl. Phys. 2014, 53, 05HA09. [Google Scholar] [CrossRef]

- Antipas, G.S.E. Modelling of the break up mechanism in gas atomization of liquid metals Part II, The gas flow model. Comput. Mater. Sci. 2009, 46, 955–959. [Google Scholar] [CrossRef]

- Thompson, J.S.; Hassan, O.; Rolland, S.A.; Sienz, J. The identification of an accurate simulation approach to predict the effect of operational parameters on the particle size distribution (PSD) of powders produced by an industrial close-coupled gas atomizer. Powder Technol. 2016, 291, 75–85. [Google Scholar] [CrossRef]

- Komrakova, A.E.; Shardt, O.; Eskin, D.; Derksen, J.J. Lattice Boltzmann simulations of drop deformation and breakup in shear flow. Int. J. Multiph. Flow 2014, 59, 24–43. [Google Scholar] [CrossRef]

- Tsuge, N. Existence of Global Solutions for Unsteady Isentropic Gas Flow in a Laval Nozzle. Arch. Ration. Mech. Anal. 2012, 205, 151–193. [Google Scholar] [CrossRef]

- Holten, V.; Heiligers, H.; Jaeken, A. Choking phenomena in a vortex flow passing a Laval tube: An analytical treatment. J. Fluids Eng. 2009, 131, 041201. [Google Scholar] [CrossRef]

- Man, H.C.; Duan, J.; Yue, T.M. Design and characteristic analysis of supersonic nozzles for high gas pressure laser cutting. J. Mater. Process. Technol. 1997, 63, 217–222. [Google Scholar] [CrossRef]

- Mikhail, M.N.; Rainbird, W. Optimum design of wind tunnel contractions. AIAA J. 2013, 17, 471–477. [Google Scholar] [CrossRef]

- Morel, T. Comprehensive design of axisymmetric wind tunnel contractions. ASME 10 Trans. 1975, 99, 225–233. [Google Scholar] [CrossRef]

- Wolf, T. Design of a variable contraction for a full-scale automotive wind tunnel. J. Wind Eng. Ind. Aerodyn. 1995, 56, 1–21. [Google Scholar] [CrossRef]

- Foelsch, K. The analytical design of axially symmetric Laval nozzle for parallel and uniform jet. J. Aeronaut. Sci. 1949, 16, 161–166. [Google Scholar] [CrossRef]

- Zhang, L.; Shao, J.; Chen, X. CFD simulation of nozzle characteristics in a gas aggregation cluster source. Vacuum 2016, 129, 105–110. [Google Scholar] [CrossRef]

- Versteeg, H.K.; Malalasekera, W. An Introduction to Computational Fluid Dynamics: The Finite Volume Method; Pearson Education: New York, NY, USA, 2007. [Google Scholar]

- Fluent, A. Ansys Fluent Theory Guide v15.0; ANSYS, Inc.: Pittsburgh, PA, USA, 2015. [Google Scholar]

- Taylor, G.I. The shape and acceleration of a drop in a high speed air stream. Sci. Pap. G I Taylor 1963, 3, 457–464. [Google Scholar]

- Turner, M.R.; Sazhin, S.S.; Healey, J.J.; Crua, C.; Martynov, S.B. A breakup model for transient Diesel fuel sprays. Fuel 2012, 97, 288–305. [Google Scholar] [CrossRef]

- Apte, S.V.; Gorokhovski, M.; Moin, P. LES of atomizing spray with stochastic modeling of secondary breakup. Int. J. Multiph. Flow 2003, 29, 1503–1522. [Google Scholar] [CrossRef]

- Haber, S. Physicochemical hydrodynamics. Int. J. Multiph. Flow 1997, 23, 1004–1005. [Google Scholar] [CrossRef]

- Reitz, R.D. Modeling atomization processes in high-pressure vaporizing sprays. At. Spray Technol. 1988, 3, 309–337. [Google Scholar]

- Markus, S.; Fritsching, U.; Bauckhage, K. Jet break up of liquid metal in twin fluid atomization. Mater. Sci. Eng. A (Struct. Mater. Prop. Microstruct. Process.) 2002, 326, 122–133. [Google Scholar] [CrossRef]

- Si, C.; Tang, X.; Zhang, X.; Wang, J.; Wu, W. Characteristics of 7055Al alloy powders manufactured by gas-solid two-phase atomization: A comparison with gas atomization process. Mater. Des. 2017, 118, 66–74. [Google Scholar] [CrossRef]

- Ciftci, N.; Ellendt, N.; Barreto, E.S.; Mädler, L.; Uhlenwinkel, V. Increasing the amorphous yield of {(Fe 0.6 Co 0.4 ) 0.75 B 0.2 Si 0.05} 96 Nb 4 powders by hot gas atomization. Adv. Powder Technol. 2018, 29, 380–385. [Google Scholar] [CrossRef]

- Wei, M.; Chen, S.; Liang, J.; Liu, C. Effect of atomization pressure on the breakup of TA15 titanium alloy powder prepared by EIGA method for laser 3D printing. Vacuum 2017, 143, 185–194. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, L.; Zhou, X.; Li, J.; Hu, Y.; Qi, H.; Wen, W.; Du, K.; Ma, Y.; Yu, Y. Numerical Simulations of Molten Breakup Behaviors of a de Laval-Type Nozzle, and the Effects of Atomization Parameters on Particle Size Distribution. Processes 2020, 8, 1027. https://doi.org/10.3390/pr8091027

Xu L, Zhou X, Li J, Hu Y, Qi H, Wen W, Du K, Ma Y, Yu Y. Numerical Simulations of Molten Breakup Behaviors of a de Laval-Type Nozzle, and the Effects of Atomization Parameters on Particle Size Distribution. Processes. 2020; 8(9):1027. https://doi.org/10.3390/pr8091027

Chicago/Turabian StyleXu, Lianghui, Xianglin Zhou, Jinghao Li, Yunfei Hu, Hang Qi, Wei Wen, Kaiping Du, Yao Ma, and Yueguang Yu. 2020. "Numerical Simulations of Molten Breakup Behaviors of a de Laval-Type Nozzle, and the Effects of Atomization Parameters on Particle Size Distribution" Processes 8, no. 9: 1027. https://doi.org/10.3390/pr8091027

APA StyleXu, L., Zhou, X., Li, J., Hu, Y., Qi, H., Wen, W., Du, K., Ma, Y., & Yu, Y. (2020). Numerical Simulations of Molten Breakup Behaviors of a de Laval-Type Nozzle, and the Effects of Atomization Parameters on Particle Size Distribution. Processes, 8(9), 1027. https://doi.org/10.3390/pr8091027