1. Introduction

Inventory management plays a vital role in supply chains. It is one of the activities associated with managing customer and vendor relationships and plays a major role in facilitating the balancing of demand and supply. Effective inventory management in supply chains can lead to an increase in profits by cutting inventory-holding costs, and this indicates the need for a general model to manage inventories within a supply chain.

In classical continuous inventory review models (

), demand and lead time are dealt with as constant input parameters or as random variables that follow a specific probability distribution. This could lead to an assumption that lead time is not subject to control and given as an input to the model. In practice, this assumption is not realistic since lead time can be controlled through some of its components, such as lot size, unit production cost, production time, and preparation time (setup, moving, and waiting times), as suggested by Kim and Benton [

1]. In addition, considering lead time as a controllable factor allows for lead time reductions; this can lead to better customer satisfaction by lowering the risk of shortages and reducing safety stock [

2]. Therefore, in many real-world systems, inventory models are stochastic and lead times are dependent and controllable. Several solution methodologies have been proposed to solve stochastic continuous inventory review models (

) with a dependent lead time. These methodologies are classified into two main types: analytical models and simulation-based optimization models.

One of the first approximation models developed to study the impact of order quantities in a continuous review inventory policy (

) on lead times was proposed by Kim and Benton [

1]. The authors assumed that demand is normally distributed, order quantity

is fixed, and the production lead time varies linearly with the order quantity. In addition, queue-waiting times were assumed to be a fixed fraction of the lead time. Based on an adjusted economic order quantity (EOQ), they developed an iterative algorithm to find the near-optimal order quantity (

) and safety stock (

). Results showed that significant savings could be achieved if the interrelationship between order quantity and lead time is taken into account. Hariga [

3] suggested a modification to the model by adjusting an expression related to annual backorder cost, in addition to proposing another relationship for the revised lot size. Both models assumed a constant processing time per unit. The model in [

4] assumed random processing times and the processing time of a lot was correlated with its size. An exact model was developed, and two cases of lead time dependency were discussed. In the first, the lead time depends on lot size, and in the second, on the reserved capacity, whereby a customer can secure shorter processing times by reserving capacity at the supplier’s manufacturing facility. Ben-Daya and Hariga [

5] proposed a model for an integrated production inventory problem for a vendor–buyer inventory system. A continuous review inventory policy was considered. Demand was assumed to be normally distributed and the lead time varied linearly with lot size. The lead time components were lot size-dependent run time and constant delay times, such as moving, waiting, and setup times. Moon and Cha [

6] studied lead time reduction by controlling the manufacturer’s regular production rate and taking the risk of paying an additional cost into account. The relationship between the lot size and the production rate of the manufacturer expressed the lead time. An analytical model was proposed to optimize a continuous review inventory policy, based on the assumption that demand is normally distributed. Song et al. [

7] proposed an integrated production inventory model for a supplier–buyer inventory system in which the buyer adopted a (

) continuous review inventory policy. Demand was assumed to be normally distributed, while the supplier and buyer jointly controlled the lead time. The supplier determines the production rate while the buyer controls the lot size (order quantity). Song et al. [

8] presented a Stackelberg game framework to model the interactions between a manufacturer and a retailer. Lead time and demand were distribution-free with only two known parameters: mean and variance. An iterative algorithm was developed to solve the proposed model. Sarkar et al. [

9] proposed an integrated vendor–buyer model with shortages. Demand was assumed to be normally distributed and lead time was assumed to be a stochastic variable that depends on the order size and production rate. Sarkar and Giri [

10] proposed an algorithm for finding the optimal solution of an integrated inventory model for a single-vendor single-buyer. The model assumed that demand follows a normal distribution and lead time is a linear function of batch size, setup time, and transport time.

Most of the proposed models were approximation models with the assumption that daily demand is normally distributed. However, it is extremely difficult to analytically solve the constrained optimization model that was developed by Hadley and Whitin [

11]. Due to these limitations and difficulties, simulation-based optimization models are utilized to model and analyze complex inventory systems in order to obtain more practical results without the need to make restrictive assumptions. Al-harkan and Hariga [

2] proposed a simulation-based optimization model for a single-supplier and single-retailer continuous review inventory system assuming a lead time dependent on lot size. The model was implemented for different daily demand distributions (normal, gamma, and log-normal). In addition, Tsai and Chen [

12] proposed a simulation-based optimization model for a multi-objective single-supplier and single-retailer inventory system. The proposed model aims to find the values of reorder point and order quantity that simultaneously minimize the total inventory cost, average inventory level, and frequency of inventory shortages. The demand and lead time were assumed to be random and follow a uniform distribution. Avci and Selim [

13] proposed a multi-objective simulation-based optimization approach for a three-echelon convergent supply chain system consisting of a customer, a manufacturer, and a number of suppliers. Kleijnen and Wan [

14] studied an (

) inventory system to optimize reorder level

and maximum inventory level

. A simulation-based optimization model was developed using Arena and

. The metric to be minimized was the expected inventory costs, which include holding, ordering, and shortage costs while satisfying service (fill rate) constraints. Simulation-based optimization methods in stochastic inventory systems have been used to minimize total inventory costs while satisfying service level constraints as in [

15,

16,

17,

18]. A comprehensive survey of simulation-based optimization approaches to solve inventory replenishment problems is presented in [

19].

Based on the literature review, we found that previous research solved the single-supplier and single-retailer continuous review inventory system. Most of the proposed models assumed that daily demand is normally distributed. Only studies that utilized simulation-based optimization models considered other distributions for daily demand. The lead time was considered as a variable and depended on several controllable factors in most previous studies. All the proposed models (analytical or simulation) aimed to minimize inventory costs.

In this paper, we solve a two-echelon three-stage supply chain stochastic continuous review inventory system with lot size-dependent lead time. The supply chain system has a supplier in the higher stage, a distributor in the middle stage, and two retailers in the lower stage. Different distributions for daily demand were considered. A simulation-based optimization model was developed to find near-optimal values of reorder point and order quantity that minimize the total inventory cost (holding, backlogging, and ordering costs). Hence, an efficient simulation-based optimization model is proposed for the first time for the problem considered herein.

The following section addresses the methodology.

Section 3 presents the results and discussions. Finally, the conclusions are stated in

Section 4.

3. Results and Discussion

As discussed in the previous section, a special case of the problem under consideration was solved analytically to validate the developed model. The solved case was a two-stage supply chain (one supplier and one retailer) with a lot size-dependent lead time. Moreover, it was assumed that the daily demand is normally distributed. However, it has been reported that the analytical solution to this special case is extremely difficult to arrive at [

2,

6]. Therefore, a simulation-based optimization model was developed to solve more complex real-world problems. In this study, we considered the stochastic inventory continuous review policy (

) in a three-stage two-echelon supply chain system with lot size-dependent lead time,

. The system has a supplier, a distributor, and two identical retailers (see

Figure 1).

In this section, an experimental study was conducted to solve the system. The developed model was run for different daily demand distributions to study the effects of the variability of daily demand and lead time on the simulated ATC of the inventory system. We used three distributions for daily demand: normal, gamma, and log-normal. The simulation runs are conducted using different values of the coefficient of variance

(

) for each of the three distributions of daily demand. Based on the relative conversion formulas reported in [

23] and the reported parameter values in [

2], the used parameters of the gamma and log-normal distributions were chosen so that they provide the same values for the normal distribution parameters (

and

).

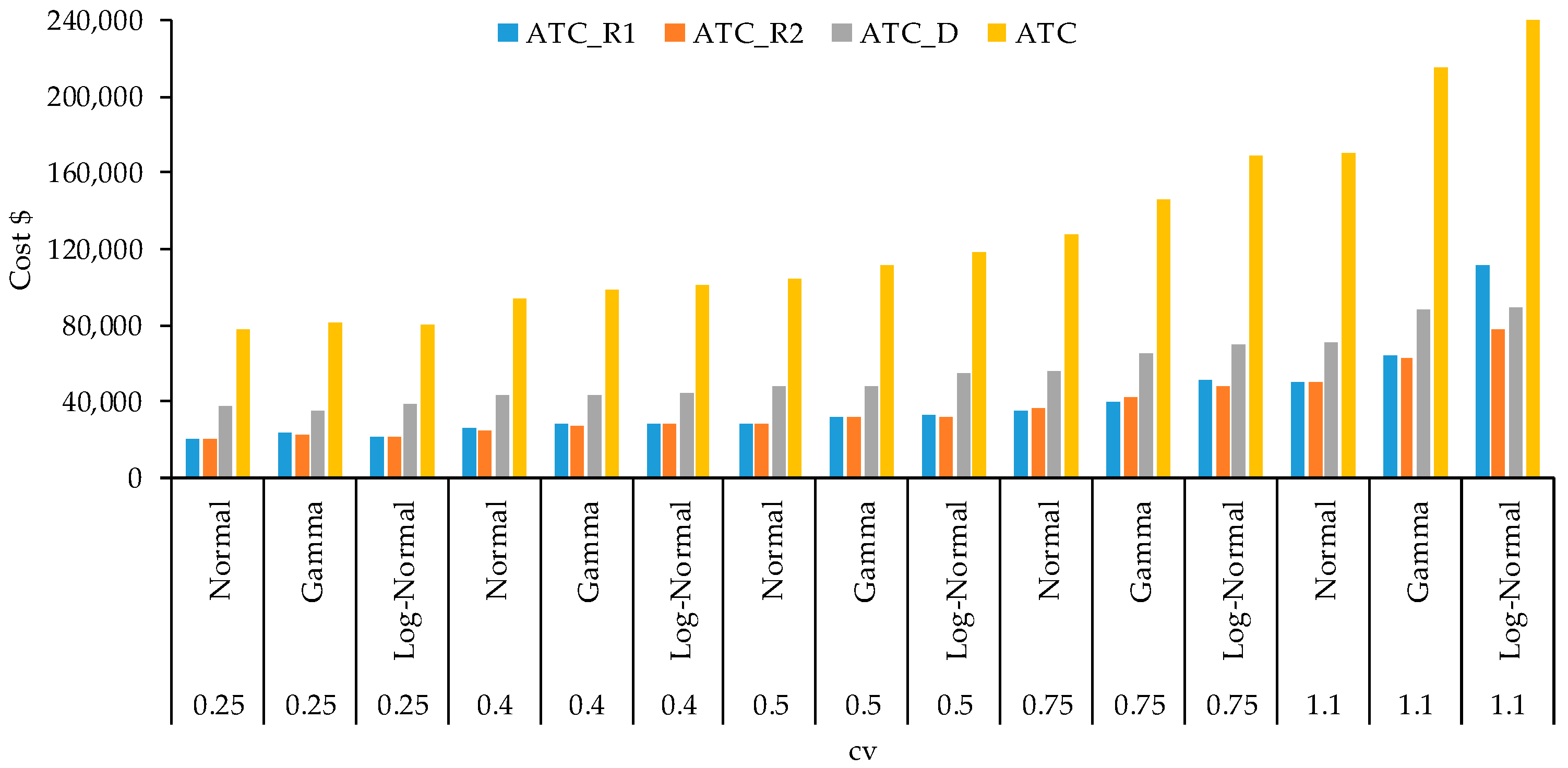

Table 5 provides a summary of the parameters used for the three distributions. The results of the experimental study are summarized in

Table 6 and

Figure 4.

As shown in

Figure 4, the ATC increases with the increase in the coefficient of variance (

) for all the distributions and increases the most when the daily demand follows log-normal. This indicates a significant effect of the

and the distribution type on the ATC. The results in

Table 6 demonstrate that the solutions generated (order sizes and reorder points) for different distributions of daily demand are not the same even if the associated total costs are close to each other. This explains the difficulty in solving inventory systems with a stochastic daily demand.

Moreover, results have been tested statistically using the analysis of variance (ANOVA) with 0.95 confidence to examine whether the or the type of the daily demand distribution has a significant effect on the simulated ATC. p-values less than 0.05 indicate model terms are significant.

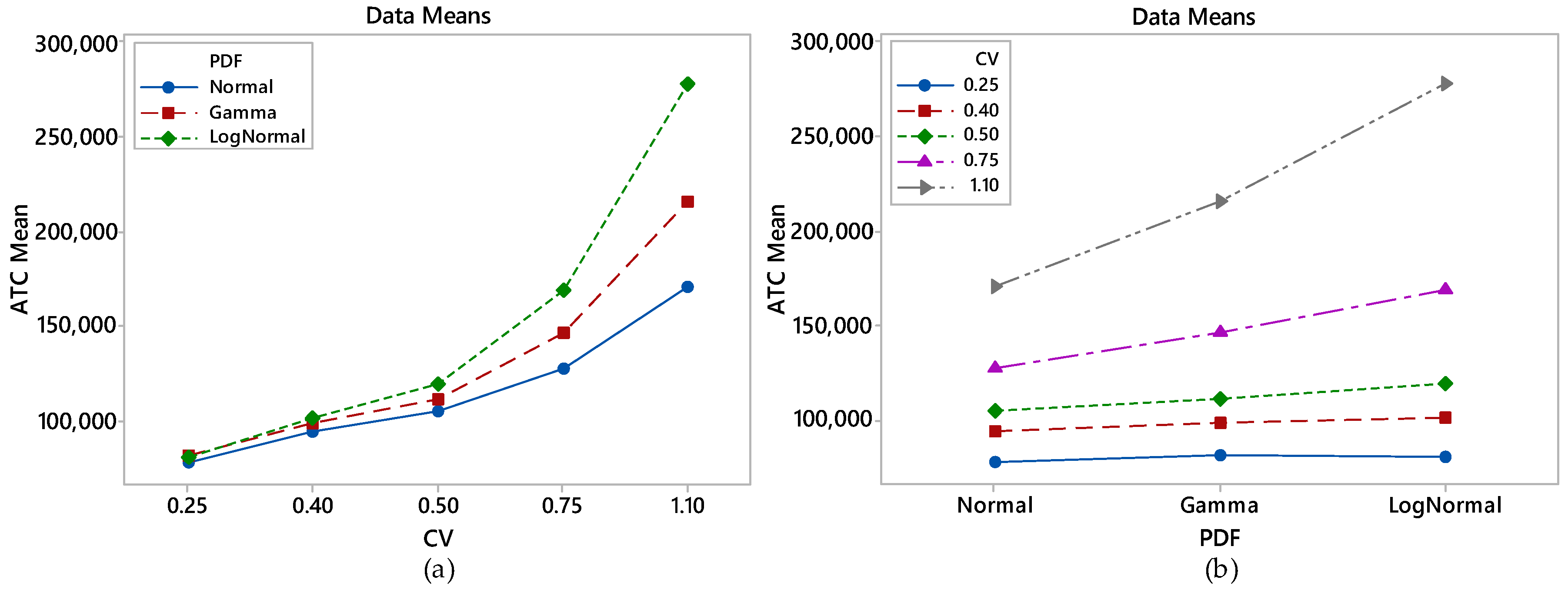

From

Table 7, ANOVA test results revealed a significant effect of

on ATC since its

p-value is 0.00, less than 0.05. Overall, the results showed that

has the most significant effect on ATC.

Figure 5a,b illustrate the interaction between the distribution types and

. From these interaction plots, it is evident that the ATC results difference between the three distributions is high with higher values of

(

Figure 5a). In addition, it is clear that the ATC increases with an increase in

(

Figure 5b).

4. Conclusions

In most inventory models, inventory costs are optimized with the assumption that the lead time is constant. Unfortunately, this is not the case in many real-world inventory systems. In practice, inventory systems are complex and difficult to formulate because of the stochastic nature of demand and lead times. In some cases, the lead time could have a few controllable components, such as lot size, production time, setup time, waiting and moving times, and lot size inspection time, which are related to order preparation and production. This study aimed to solve a complex inventory system that consists of two identical retailers, a distributor, and a supplier. The system is a stochastic inventory continuous review system () with the lead time depending on lot size, unit production time, setup time, and a shop floor factor that represents moving, waiting, and lot size inspection times. A simulation-based optimization model was developed using Arena and . A special case of the system was solved analytically to validate the model. Results indicate that the developed model was more accurate. Moreover, the model was tested for a more complex inventory system with different distributions of the system’s daily demand.

The results demonstrated that the optimized solutions (order sizes and reorder points) for different distributions of daily demand are not the same even if the associated total costs are close to each other. This explains the difficulty in solving inventory systems with a stochastic daily demand. Therefore, simulation-based optimization models can be considered as a powerful tool to optimize complex inventory systems without the need to make restrictive assumptions. Extensions of this work can be made by using different inventory control policies, taking into account supplier capacity, multi-products, and finally, cooperation between retailers.