Prediction Model of Suspension Density in the Dense Medium Separation System Based on LSTM

Abstract

:1. Introduction

2. Methodology

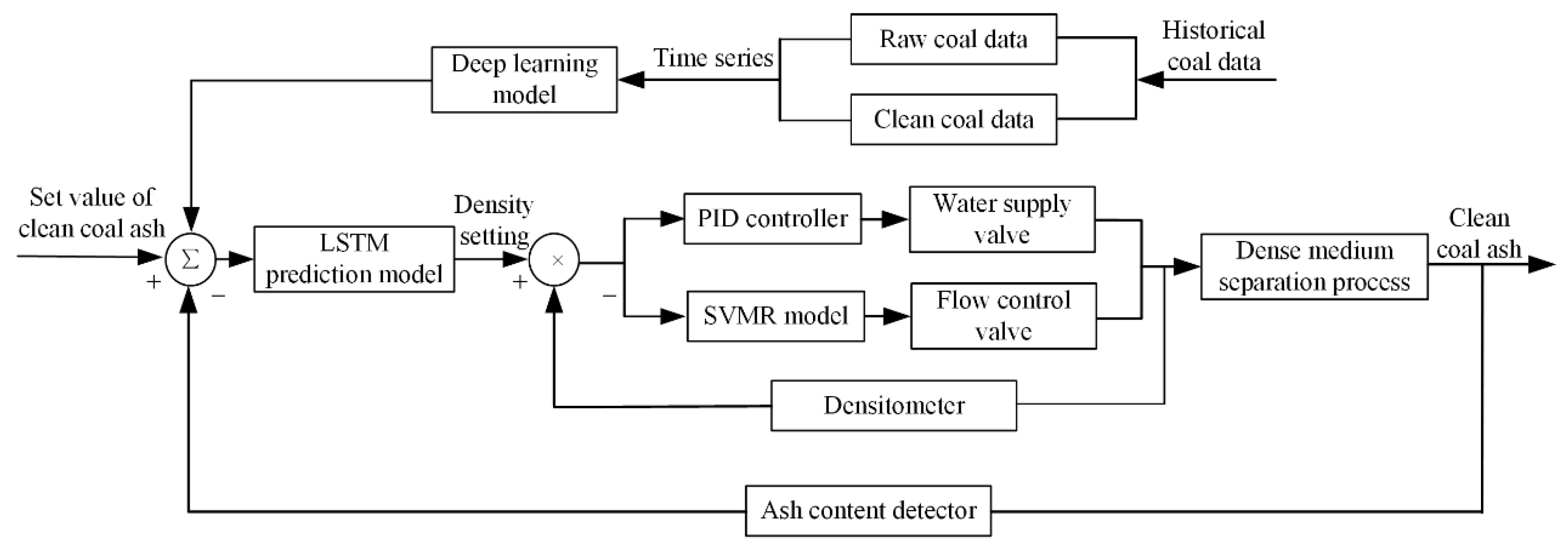

2.1. Process

2.2. LSTM Prediction Method

2.2.1. Dataset Preparation

2.2.2. LSTM Method

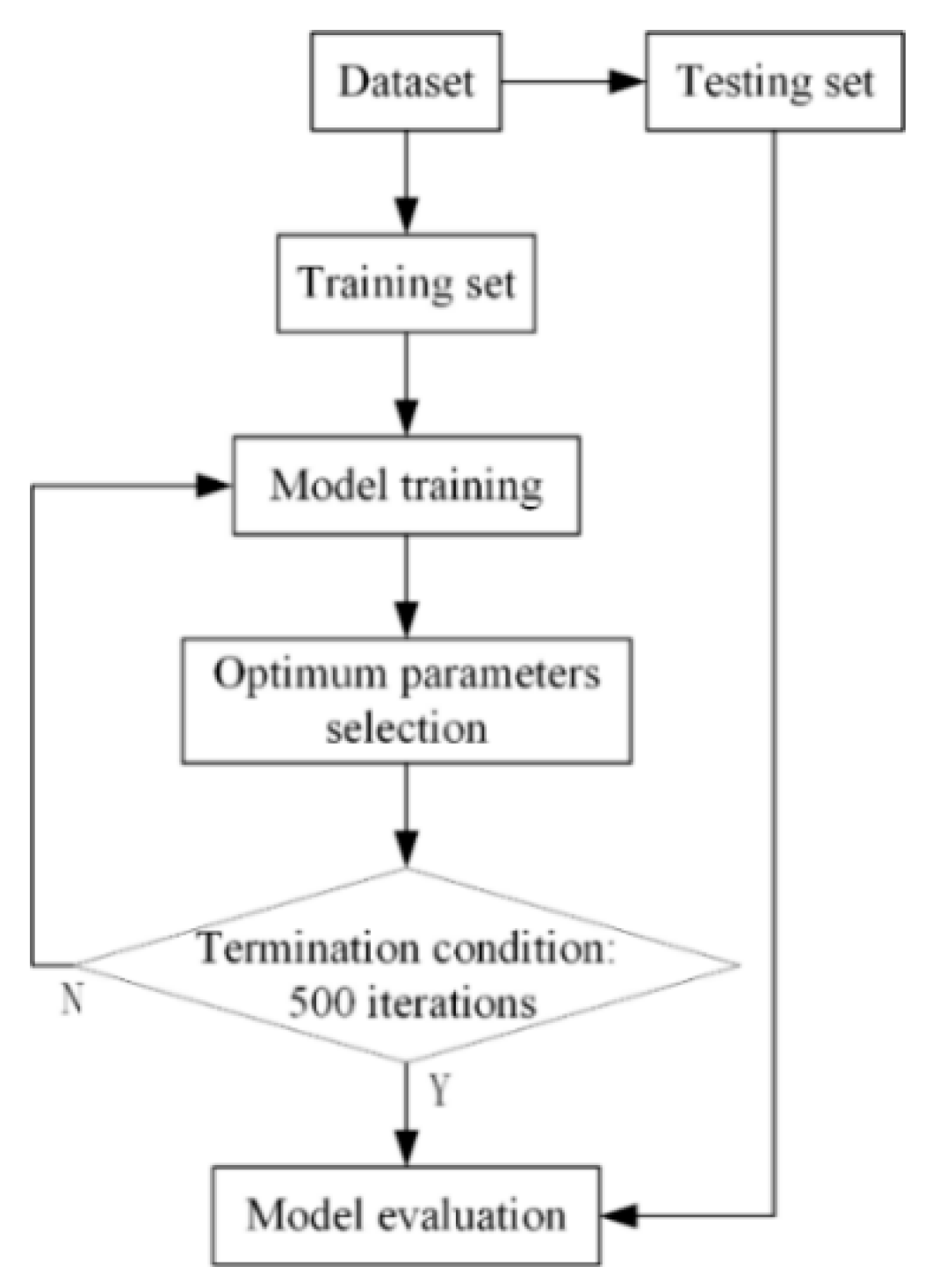

2.2.3. Modelling Methods

2.2.4. Comparison Algorithm

2.2.5. Prediction Performance Indicators

3. Results and Discussion

3.1. Data Preprocessing

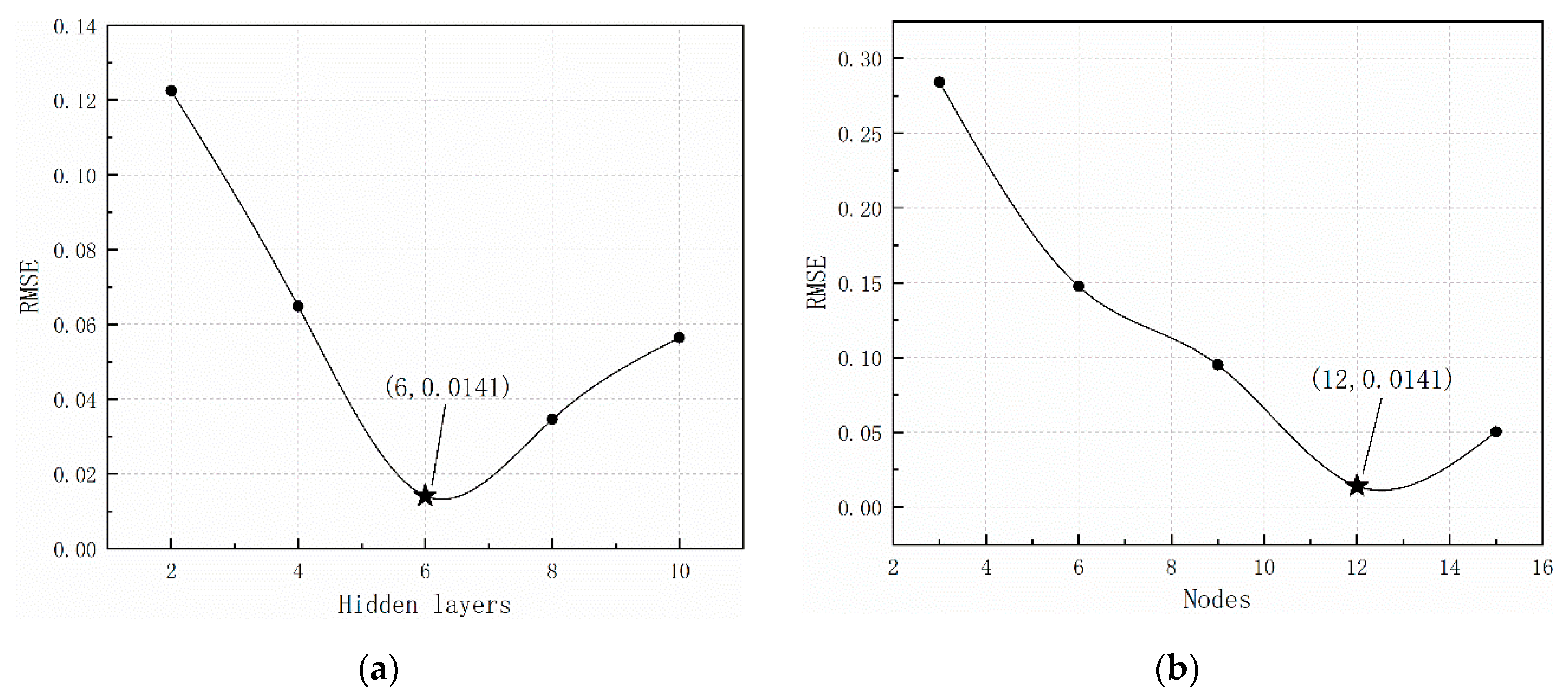

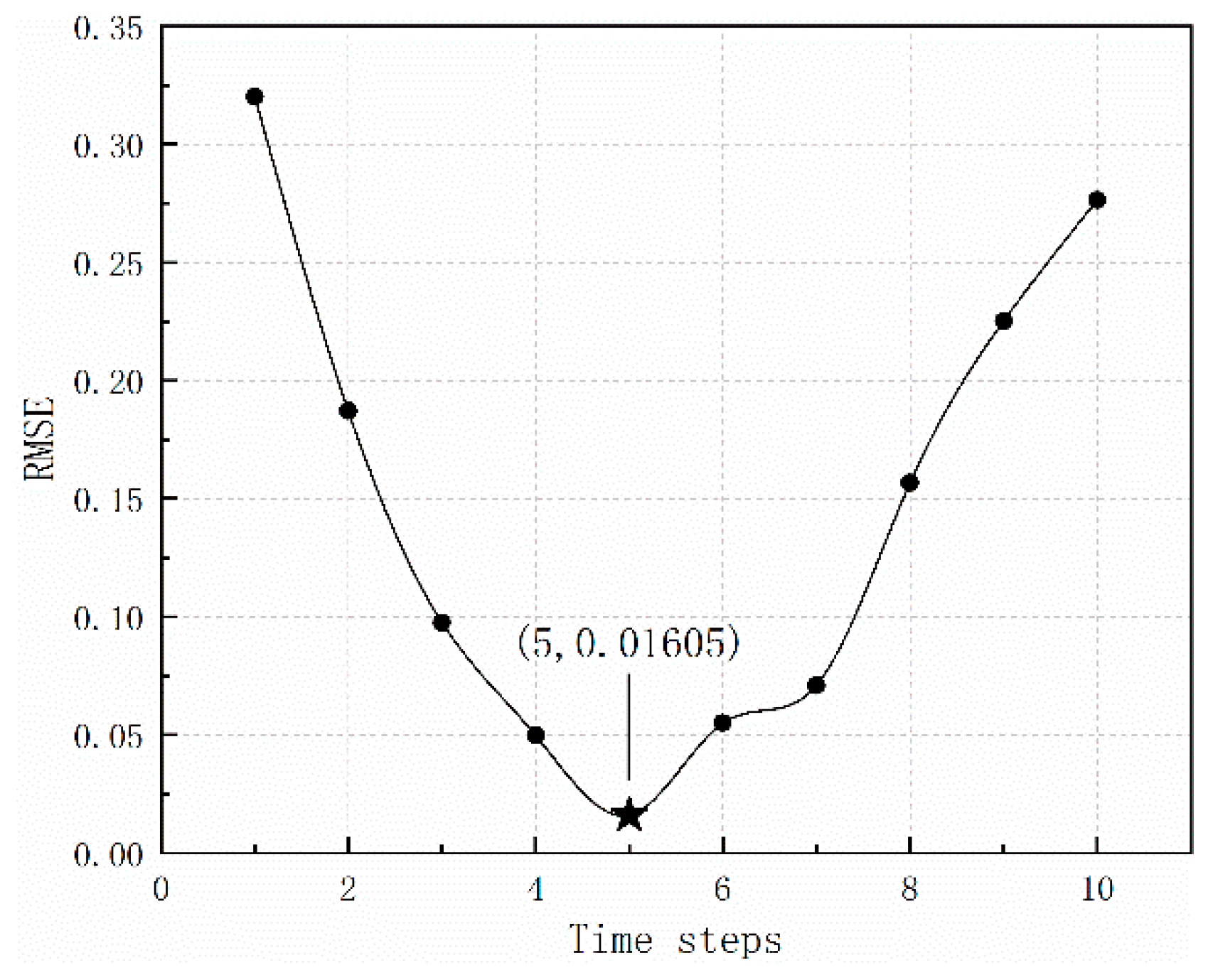

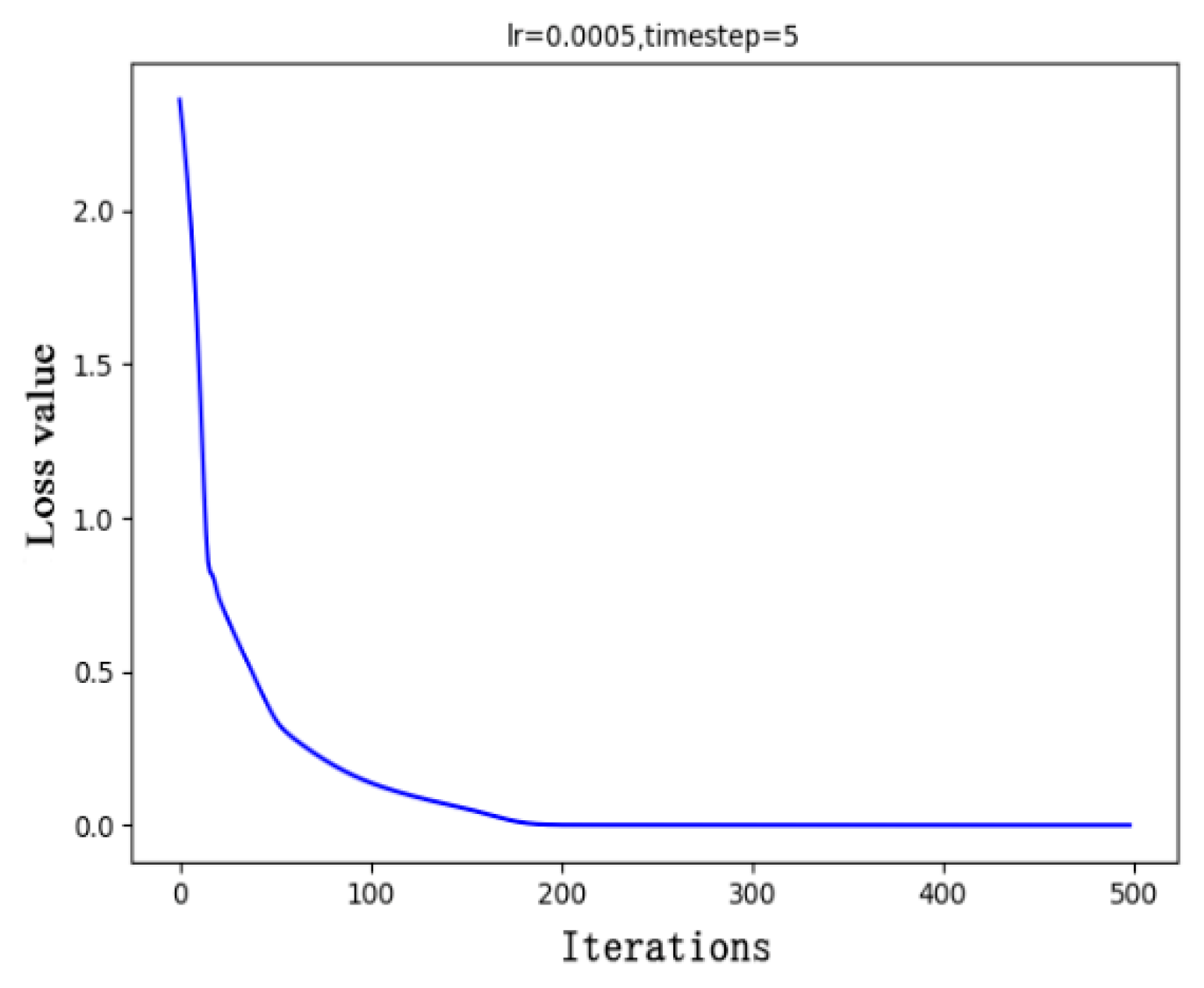

3.2. Optimum Parameter Selection

3.3. Modelling Performance

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Napier-Munn, T.J. Modelling and simulating dense medium separation processes—A progress report. Miner. Eng. 1991, 4, 329–346. [Google Scholar] [CrossRef]

- Sahu, A.K.; Biswal, S.K.; Parida, A. Development of air dense medium fluidized bed technology for dry beneficiation of coal—A review. Coal Prep. 2009, 29, 216–241. [Google Scholar] [CrossRef]

- Honaker, R.Q.; Singh, N.; Govindarajan, B. Application of dense-medium in an enhanced gravity separator for fine coal cleaning. Miner. Eng. 2000, 13, 415–427. [Google Scholar] [CrossRef]

- Dai, W.; Zhang, L.; Fu, J.; Chai, T.; Ma, X. Model-data-based switching adaptive control for dense medium separation in coal beneficiation. Control Eng. Pract. 2020, 98, 104241. [Google Scholar] [CrossRef]

- Wang, Z.; Kuang, Y.; Deng, J.; Wang, G.; Ji, L. Research on the intelligent control of the dense medium separation process in coal preparation plant. Int. J. Miner. Process. 2015, 142, 46–50. [Google Scholar] [CrossRef]

- Meyer, E.J.; Craig, I.K. Coal dense medium separation dynamic and steady-state modelling for process control. Miner. Eng. 2014, 65, 98–108. [Google Scholar] [CrossRef] [Green Version]

- Sun, X.; Cao, Z.; Yue, Y.; Kuang, Y.; Zhou, C. Online prediction of dense medium suspension density based on phase space reconstruction. Part. Sci. Technol. 2018, 36, 989–998. [Google Scholar] [CrossRef]

- Fan, P.; Fan, M.; Liu, A. Using an axial electromagnetic field to improve the separation density of a dense medium cyclone. Miner. Eng. 2015, 72, 87–93. [Google Scholar] [CrossRef]

- Chu, K.; Wang, B.; Yu, A.; Vince, A. Modelling the Multiphase Flow in Dense Medium Cyclones. J. Comput. Multiph. Flows 2010, 2, 249–272. [Google Scholar] [CrossRef] [Green Version]

- Chu, K.; Wang, B.; Yu, A.; Vince, A. CFD-DEM modelling of multiphase flow in dense medium cyclones. Powder Technol. 2009, 193, 235–247. [Google Scholar] [CrossRef]

- Magwai, M.K.; Bosman, J. The effect of cyclone geometry and operating conditions on spigot capacity of dense medium cyclones. Int. J. Miner. Process. 2008, 86, 94–103. [Google Scholar] [CrossRef]

- Hu, S.; Firth, B.; Vince, A.; Lees, G. Prediction of dense medium cyclone performance from large size density tracer test. Miner. Eng. 2001, 14, 741–751. [Google Scholar] [CrossRef]

- Fanayi, A.R.; Nikbakht, A.M. Study of gas-solid flow in a cyclone separator. Int. J. Food Eng. 2015, 11, 71–77. [Google Scholar]

- Wang, G.; Kuang, Y.; Wang, Z.; Wang, Y.; Ji, L. A real-time prediction model for production index in process of dense-medium separation. Int. J. Coal Prep. Util. 2012, 32, 298–309. [Google Scholar]

- Meyer, E.J.; Craig, I.K. Dynamic model for a dense medium drum separator in coal beneficiation. Miner. Eng. 2015, 77, 78–85. [Google Scholar] [CrossRef] [Green Version]

- Chen, J.; Chu, K.; Zou, R.P.; Yu, A.; Vince, A. Prediction of the performance of dense medium cyclones in coal preparation. Miner. Eng. 2012, 31, 59–70. [Google Scholar] [CrossRef]

- Kumar, C.R.; Mohanan, S.; Tripathy, S.K.; Ramamurthy, Y.; Venugopalan, T.; Suresh, N. Prediction of process input interactions of floatex density separator performance for separating medium density particles. Int. J. Miner. Process. 2011, 200, 136–141. [Google Scholar] [CrossRef]

- Wang, J.; Yang, W.; Cheng, H.; Huang, L.; Gao, Y. The Optimal Configuration Scheme of the Virtual Power Plant Considering Benefits and Risks of Investors. Energies 2017, 10, 968. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.; Guo, E. The study of forecasting of cash flow in ATM based on cubic exponential smoothing method. Biotechnol. Indian J. 2014, 10, 2501–2506. [Google Scholar]

- Muzaffar, S.; Afshari, A. Short-Term Load Forecasts Using LSTM Networks. Energy Procedia 2019, 158, 2922–2927. [Google Scholar] [CrossRef]

- Li, X.; Peng, L.; Yao, X.; Cui, S.; Hu, Y.; You, C.; Chi, T. Long short-term memory neural network for air pollutant concentration predictions: Method development and evaluation. Environ. Pollut. 2017, 231, 997–1004. [Google Scholar] [CrossRef] [PubMed]

- Gers, F.A.; Schmidhuber, J.; Cummins, F. Learning to Forget: Continual Prediction with LSTM. Neural Comput. 2000, 12, 2451–2471. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Wang, F.; Su, S. Solar Irradiance Short-Term Prediction Model Based on BP Neural Network. Energy Procedia 2011, 12, 488–494. [Google Scholar] [CrossRef] [Green Version]

- Li, J.; Zhao, D.; Ge, B.; Yang, K.; Chen, Y. A link prediction method for heterogeneous networks based on BP neural network. Phys. A Stat. Mech. Appl. 2017, 496, 1–17. [Google Scholar] [CrossRef]

- Qi, C.; Ly, H.; Chen, Q.; Le, T.; Le, V.M.; Pham, B.T. Flocculation-dewatering prediction of fine mineral tailings using a hybrid machine learning approach. Chemosphere 2019, 244, 125450. [Google Scholar] [CrossRef]

- Qi, C.; Fourie, A.; Chen, Q.; Tang, X.; Zhang, Q.; Gao, R. Data-driven modelling of the flocculation process on mineral processing tailings treatment. J. Clean. Prod. 2018, 196, 505–516. [Google Scholar] [CrossRef]

- Massinaei, M.; Jahedsaravani, A.; Taheri, E.; Khalilpour, J. Machine vision based monitoring and analysis of a coal column flotation circuit. Powder Technol. 2019, 343, 330–341. [Google Scholar] [CrossRef]

| Statistics | Raw Coal Ash (%) | Clean Coal Ash (%) | Suspension Density (g/cm3) |

|---|---|---|---|

| Maximum Value | 11.56 | 6.67 | 1.681 |

| Minimum Value | 9.65 | 5.35 | 1.624 |

| Mean Value | 10.46 | 5.87 | 1.650 |

| Nodes | 3 | 6 | 9 | 12 | 15 | |

|---|---|---|---|---|---|---|

| Hidden Layers | ||||||

| 2 | 0.2298 | 0.1237 | 0.0975 | 0.1225 | 0.1572 | |

| 4 | 0.3143 | 0.1817 | 0.1149 | 0.0648 | 0.0872 | |

| 6 | 0.2841 | 0.1476 | 0.0950 | 0.0141 | 0.0503 | |

| 8 | 0.2020 | 0.1141 | 0.0707 | 0.0346 | 0.0200 | |

| 10 | 0.1865 | 0.0977 | 0.0479 | 0.0564 | 0.0721 | |

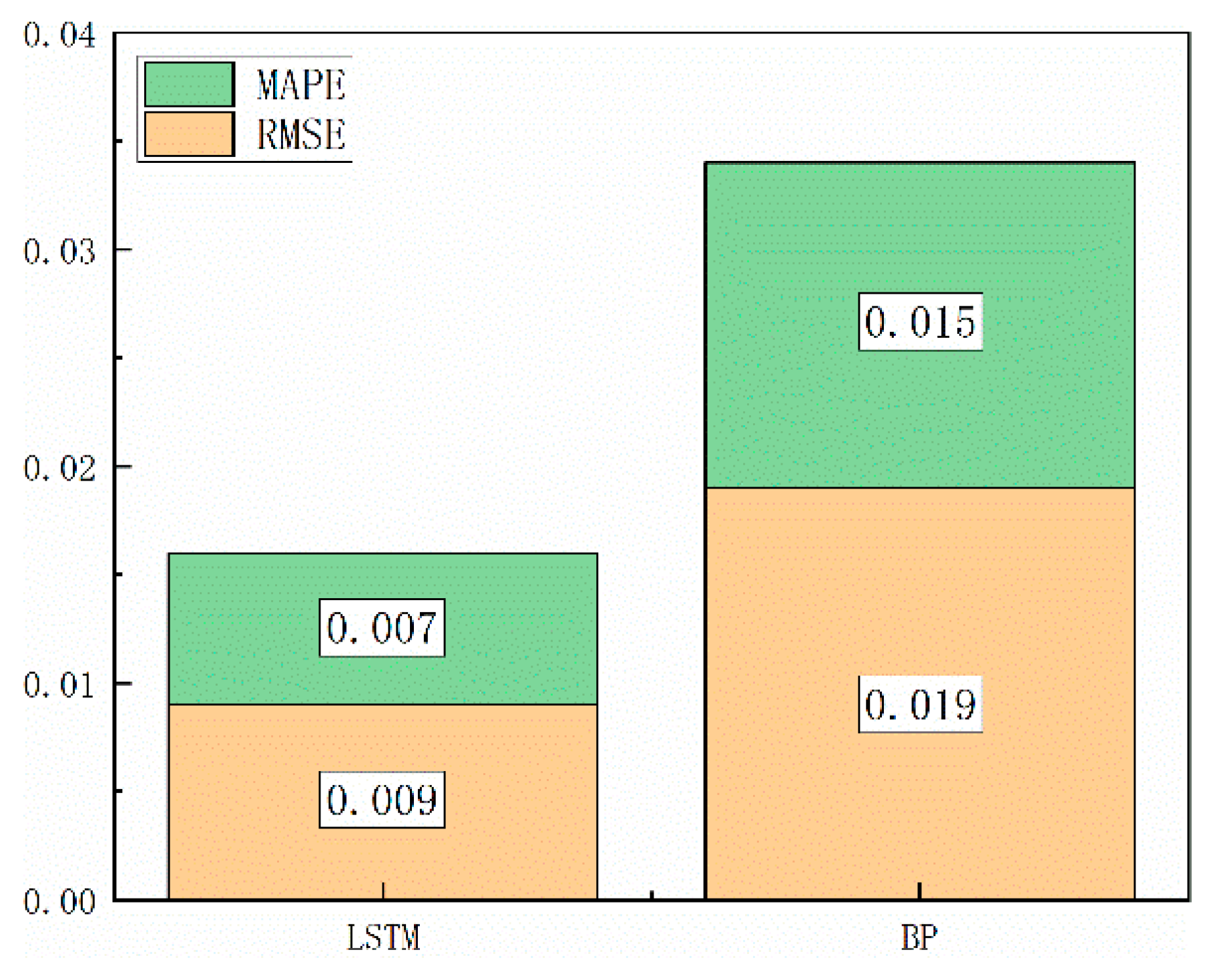

| Validation Criteria | LSTM | BP |

|---|---|---|

| RMSE | 0.009 | 0.019 |

| MAPE | 0.007 | 0.015 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zheng, C.; Deng, J.; Hong, Z.; Wang, G. Prediction Model of Suspension Density in the Dense Medium Separation System Based on LSTM. Processes 2020, 8, 976. https://doi.org/10.3390/pr8080976

Zheng C, Deng J, Hong Z, Wang G. Prediction Model of Suspension Density in the Dense Medium Separation System Based on LSTM. Processes. 2020; 8(8):976. https://doi.org/10.3390/pr8080976

Chicago/Turabian StyleZheng, Cheng, Jianjun Deng, Zhixin Hong, and Guanghui Wang. 2020. "Prediction Model of Suspension Density in the Dense Medium Separation System Based on LSTM" Processes 8, no. 8: 976. https://doi.org/10.3390/pr8080976

APA StyleZheng, C., Deng, J., Hong, Z., & Wang, G. (2020). Prediction Model of Suspension Density in the Dense Medium Separation System Based on LSTM. Processes, 8(8), 976. https://doi.org/10.3390/pr8080976