Numerical Investigation of a Portable Incinerator: A Parametric Study

Abstract

1. Introduction

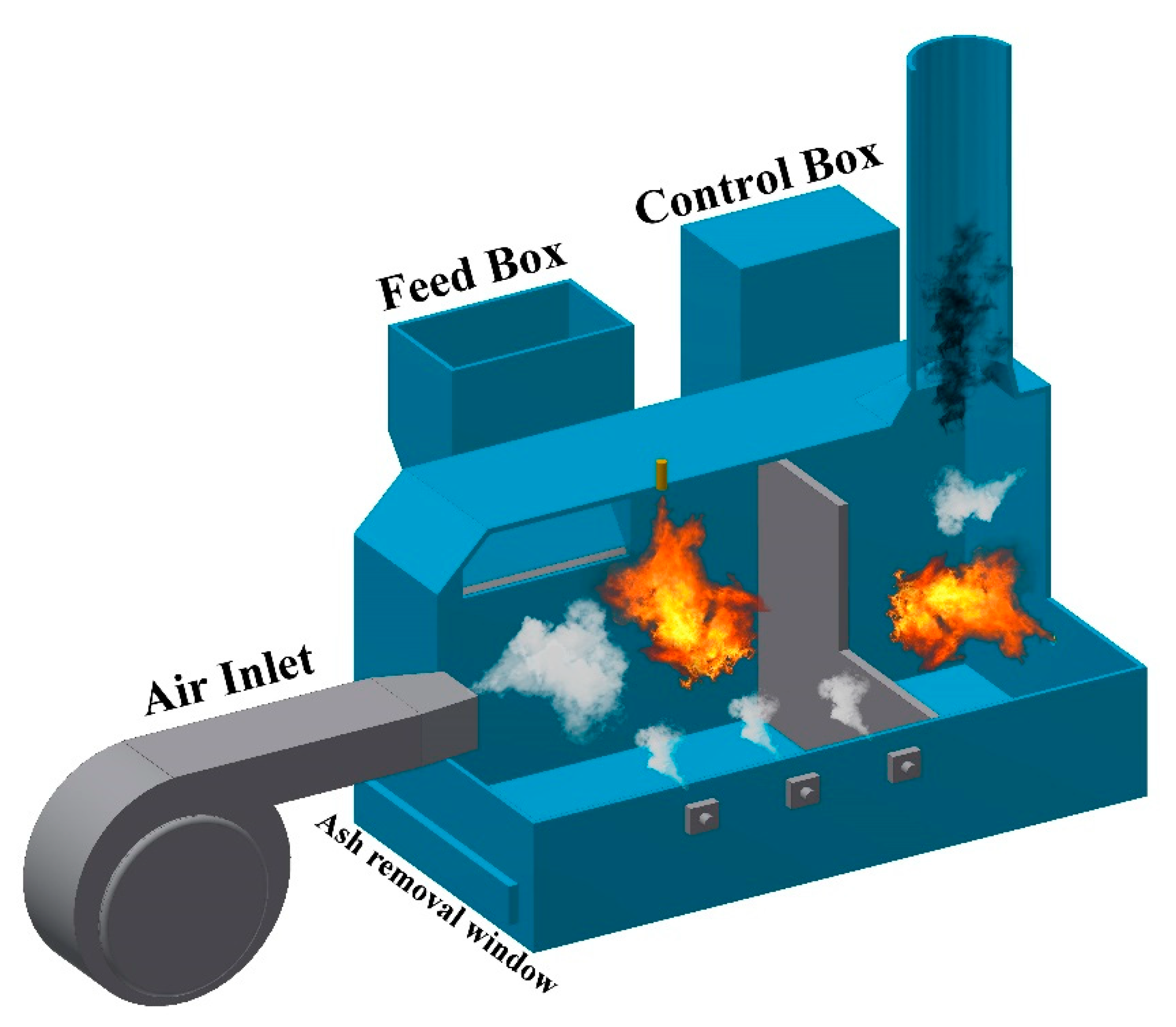

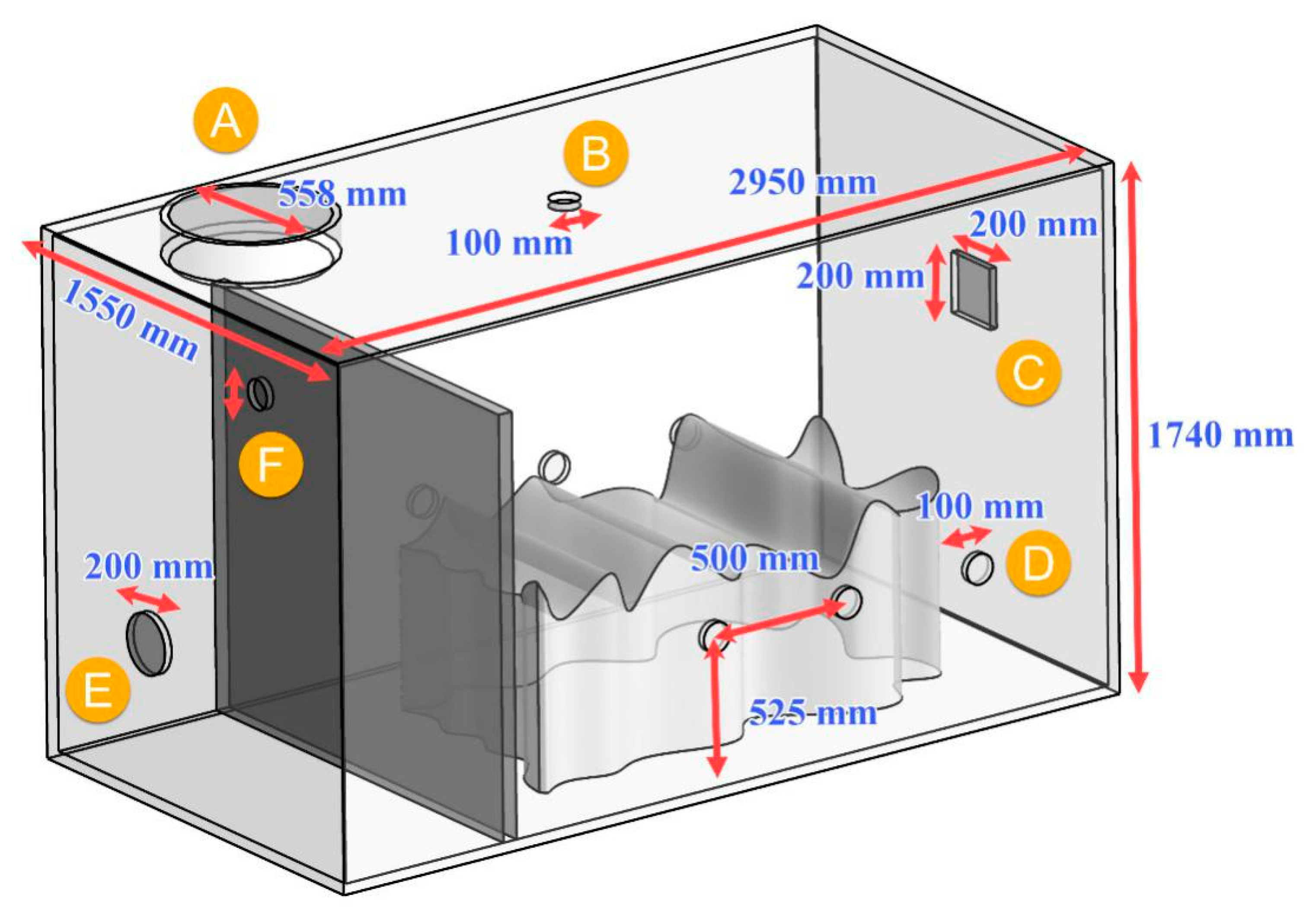

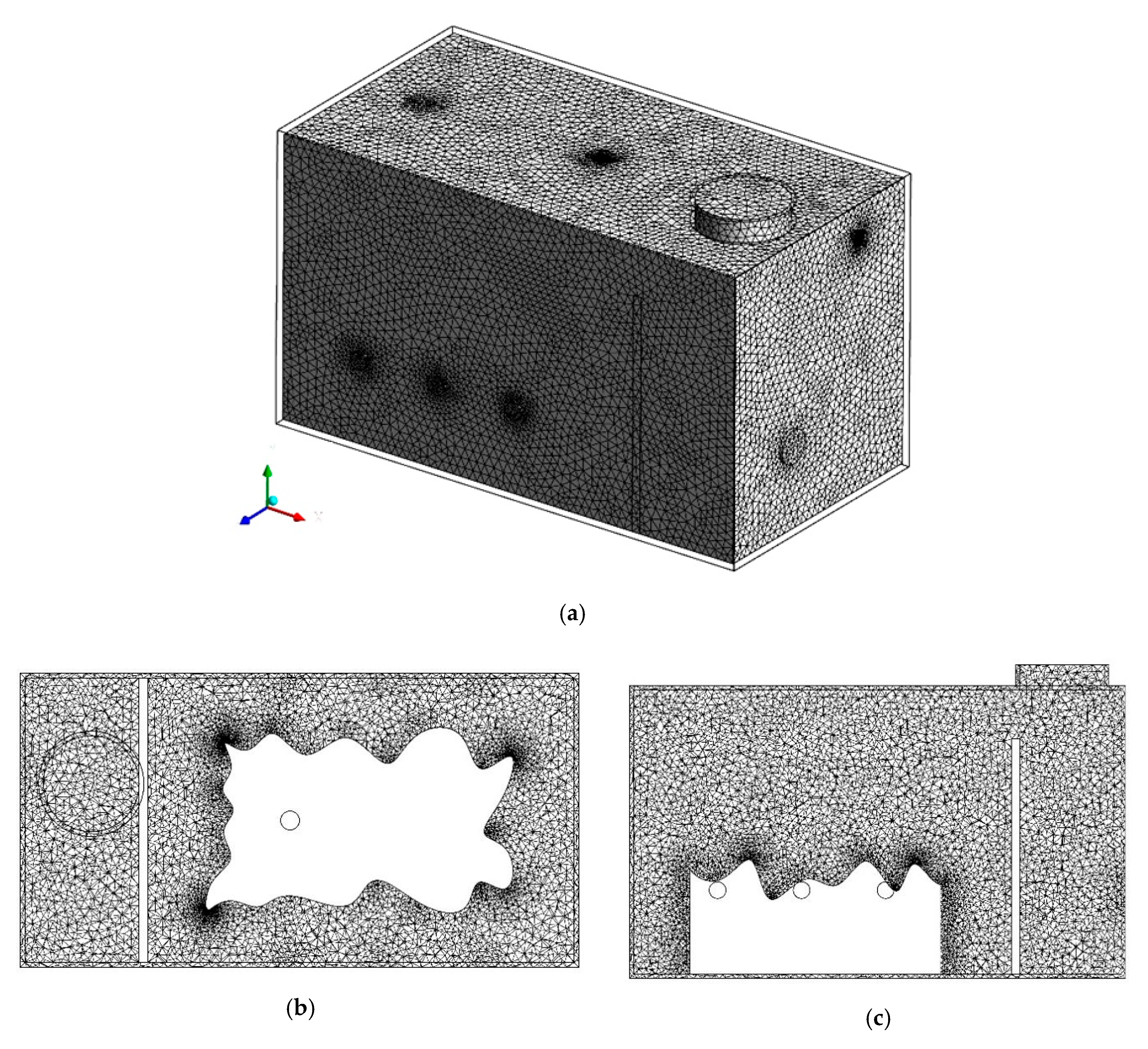

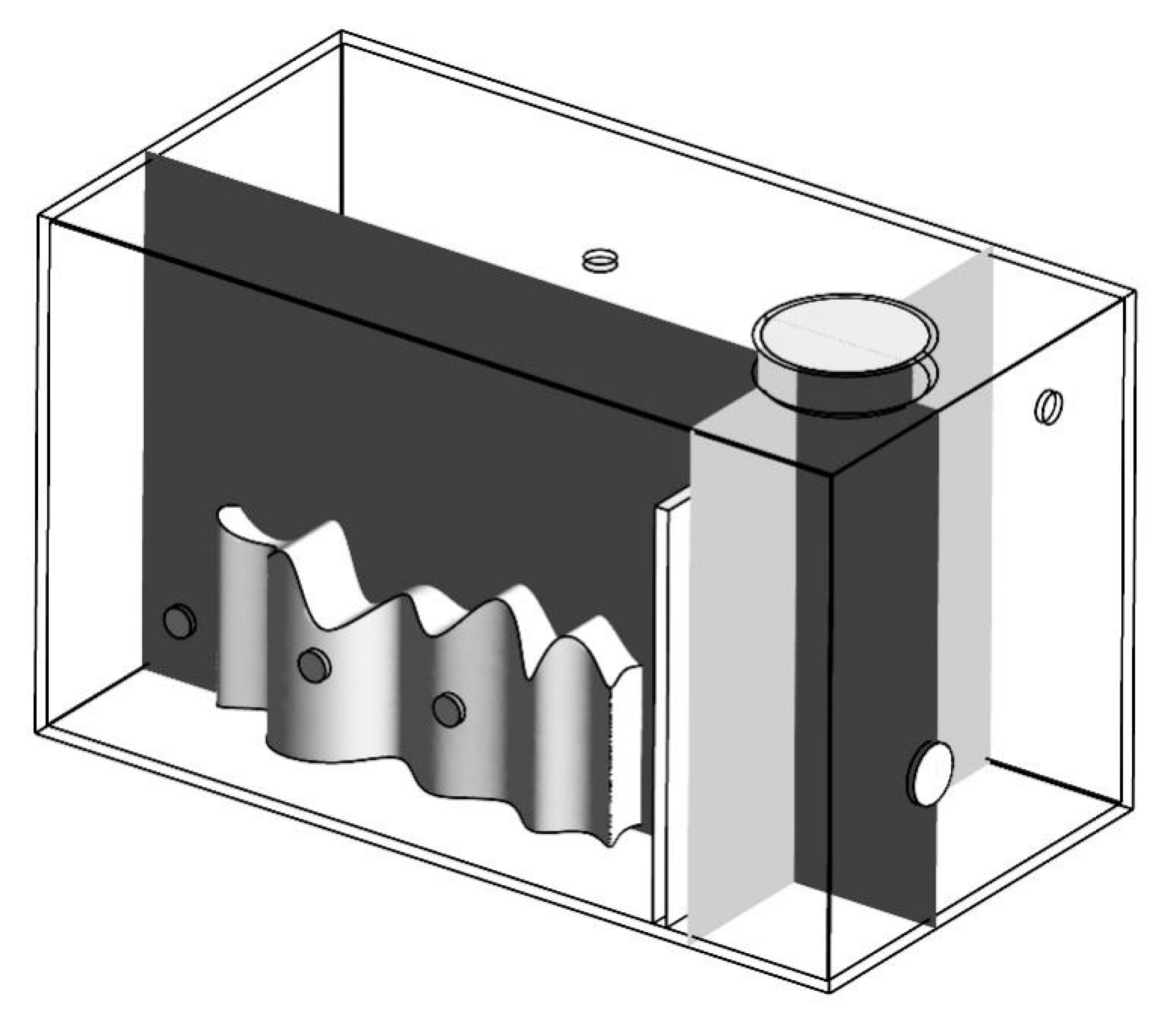

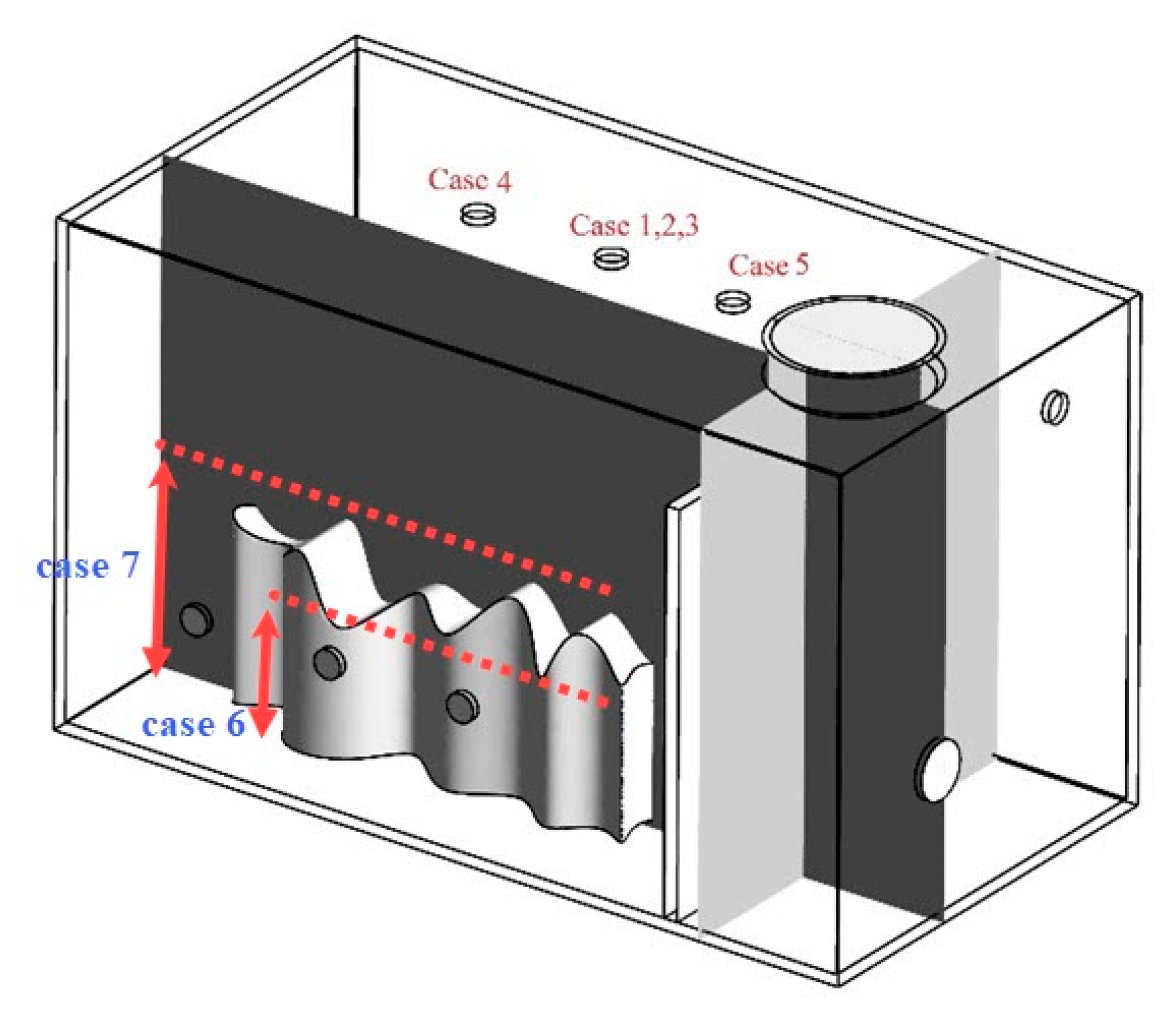

2. Geometry Creation

3. Waste Properties

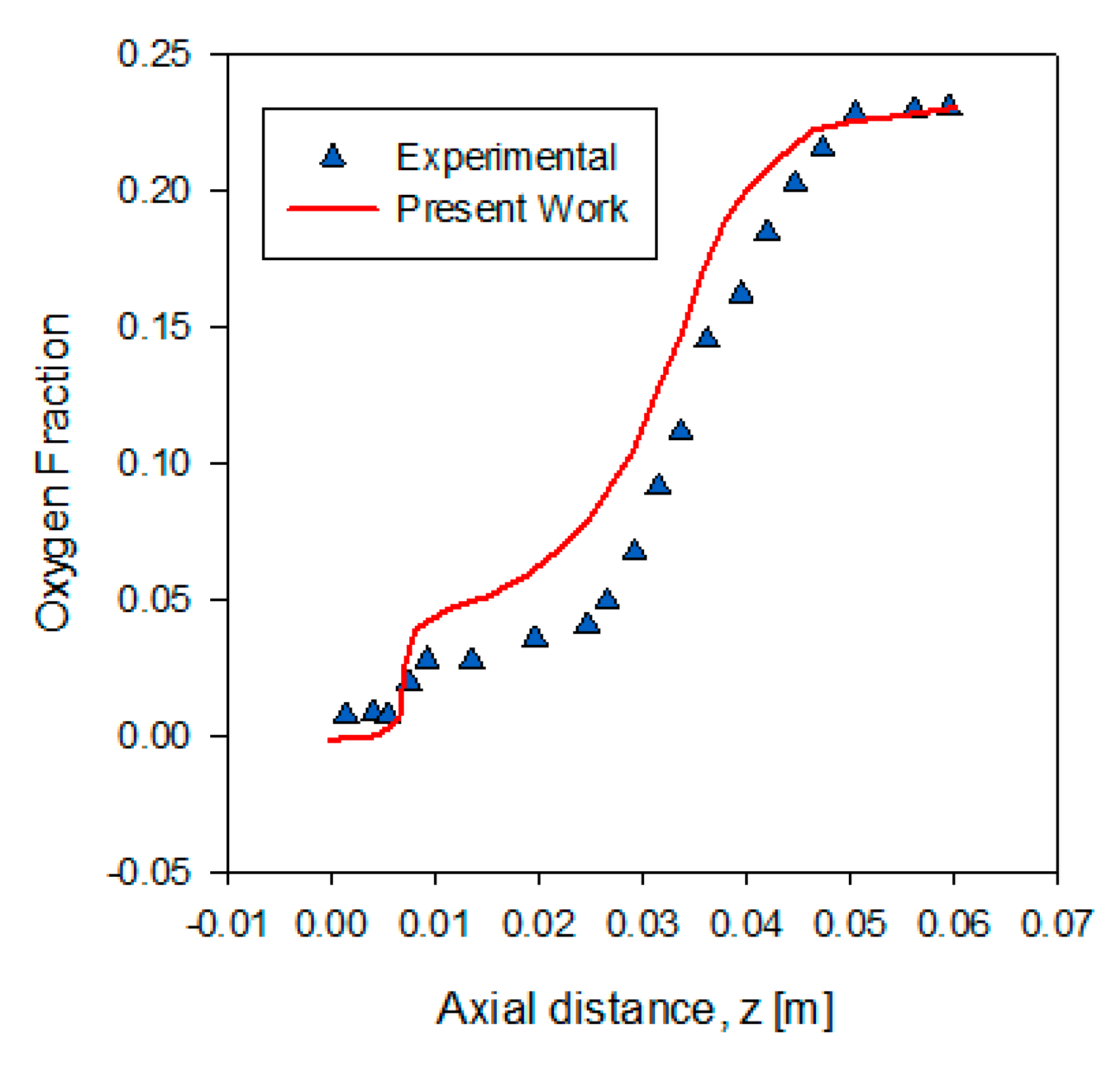

4. Governing Equations

5. Results and Discussion

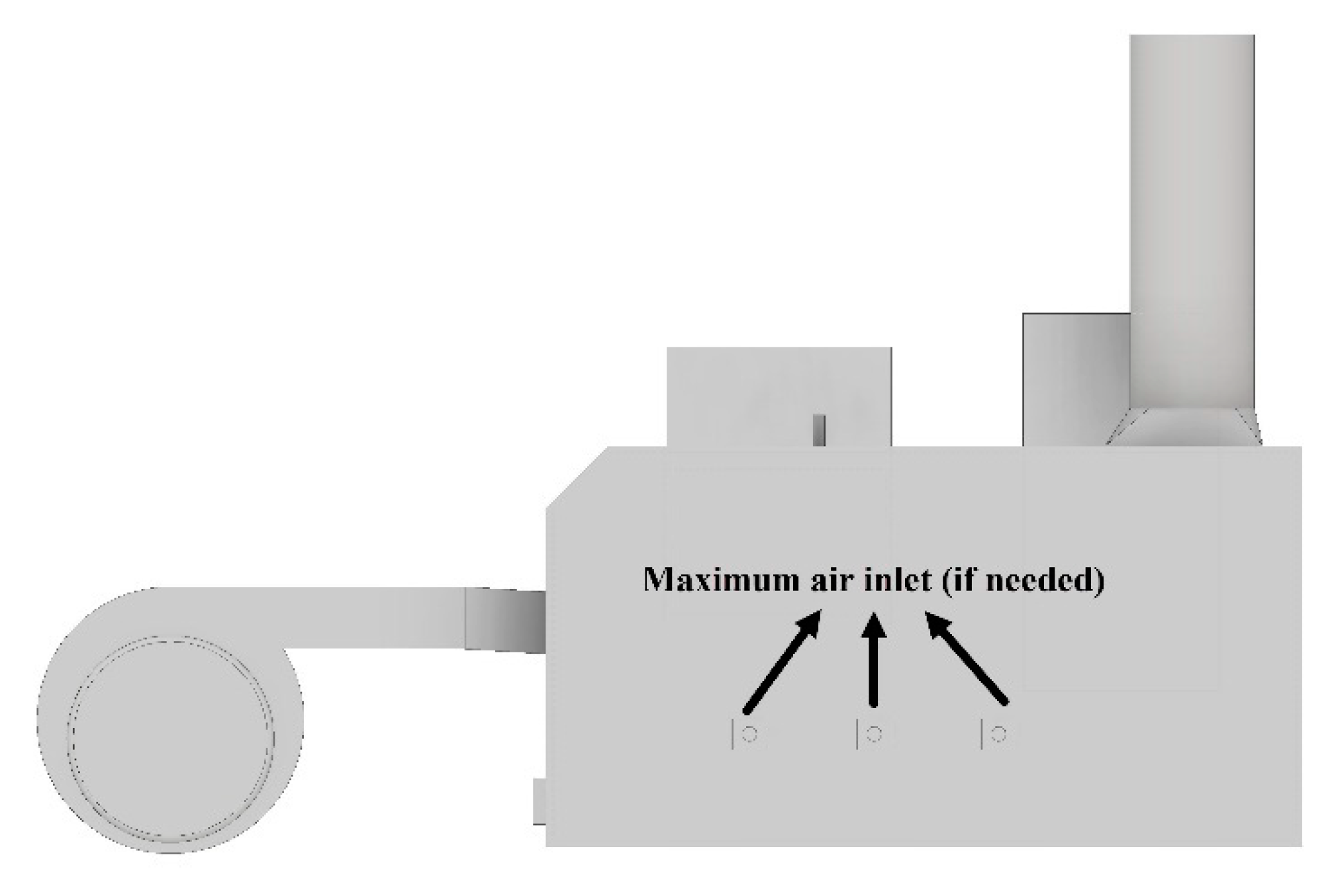

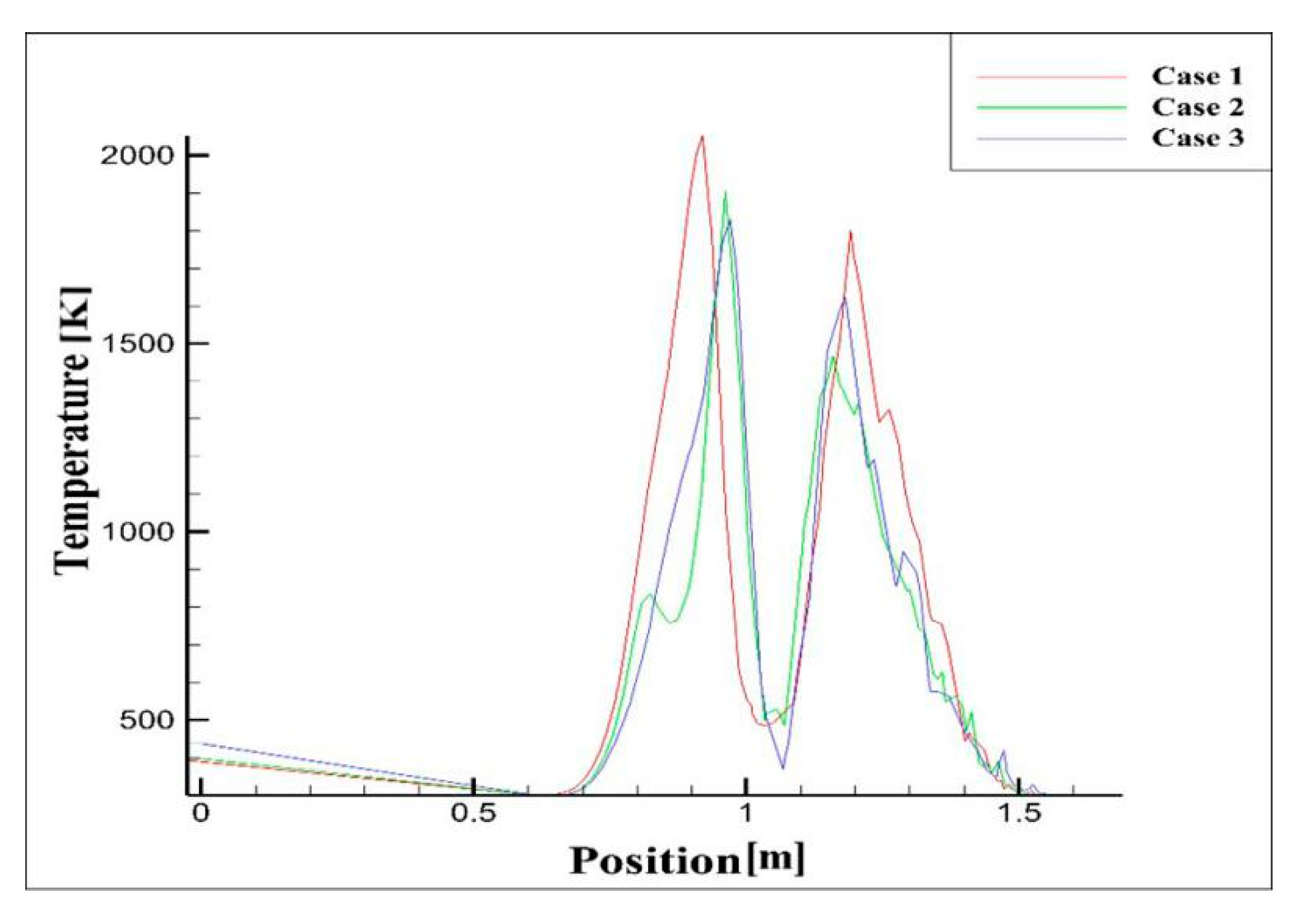

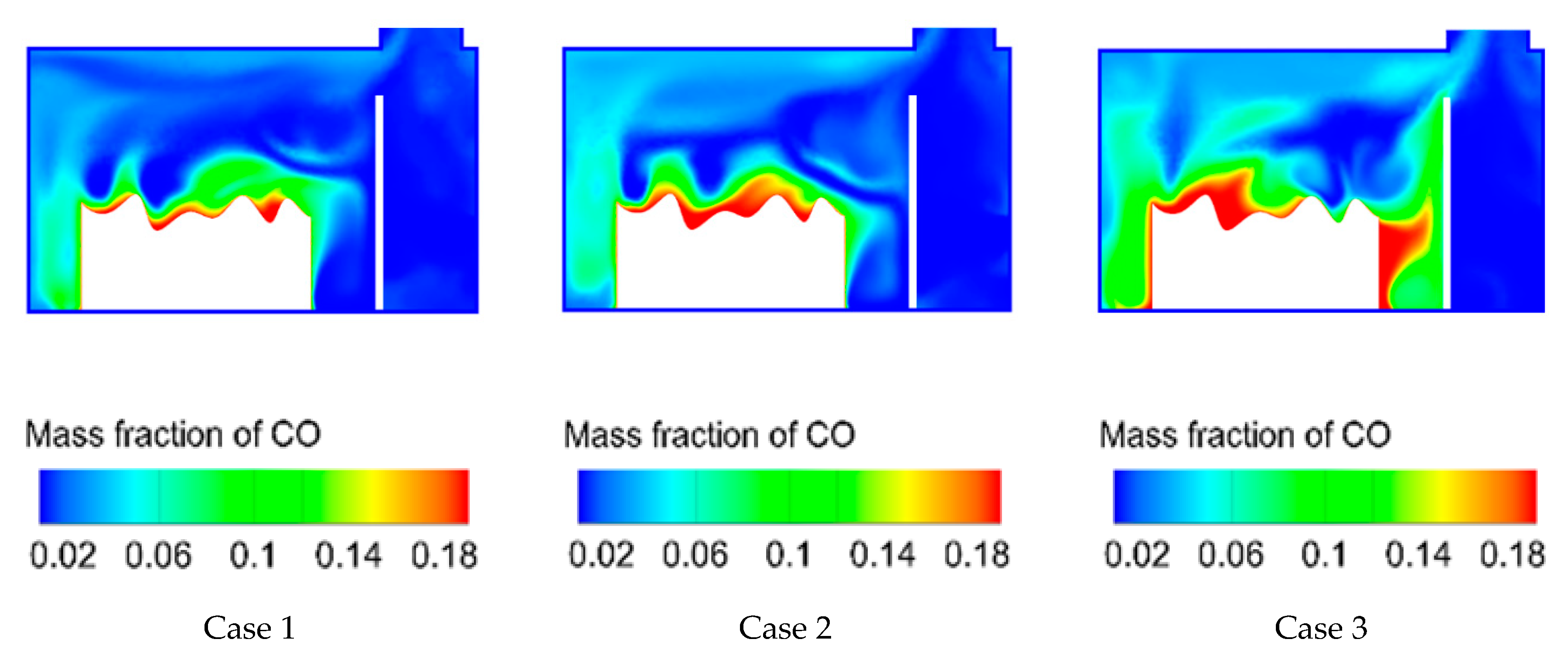

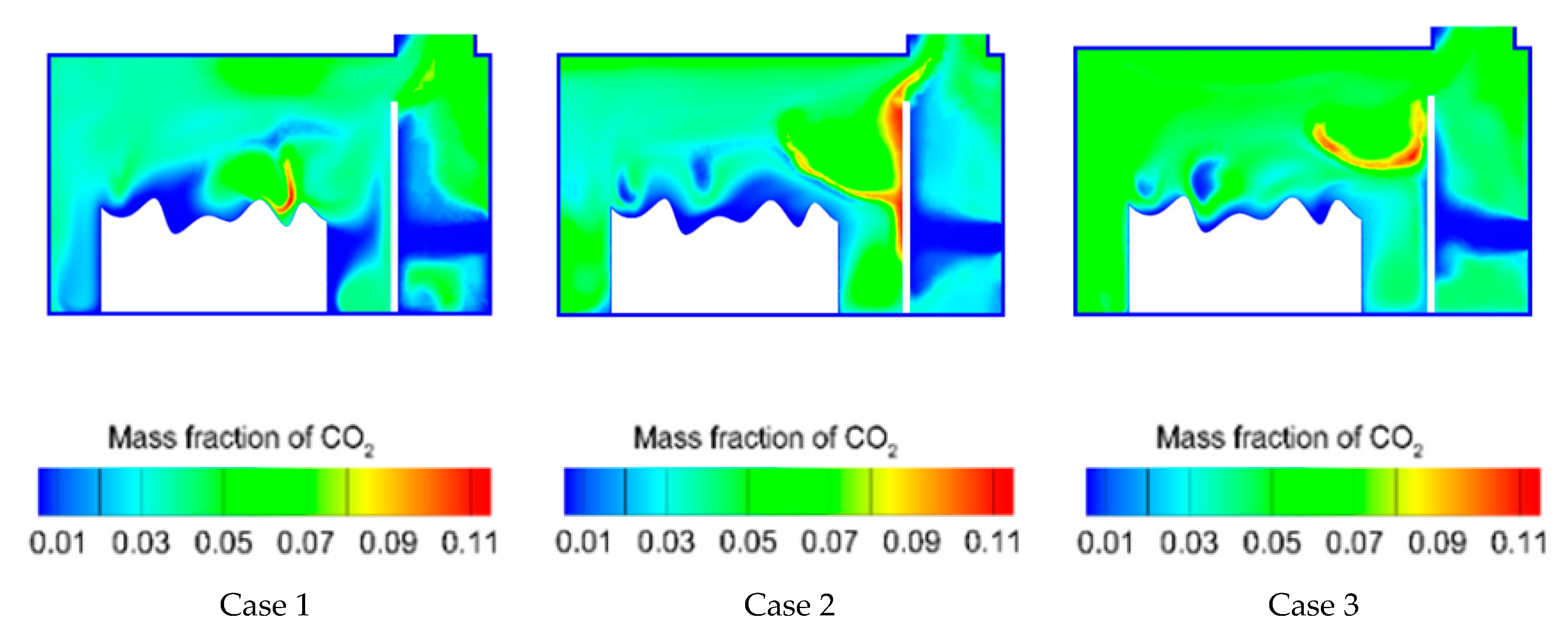

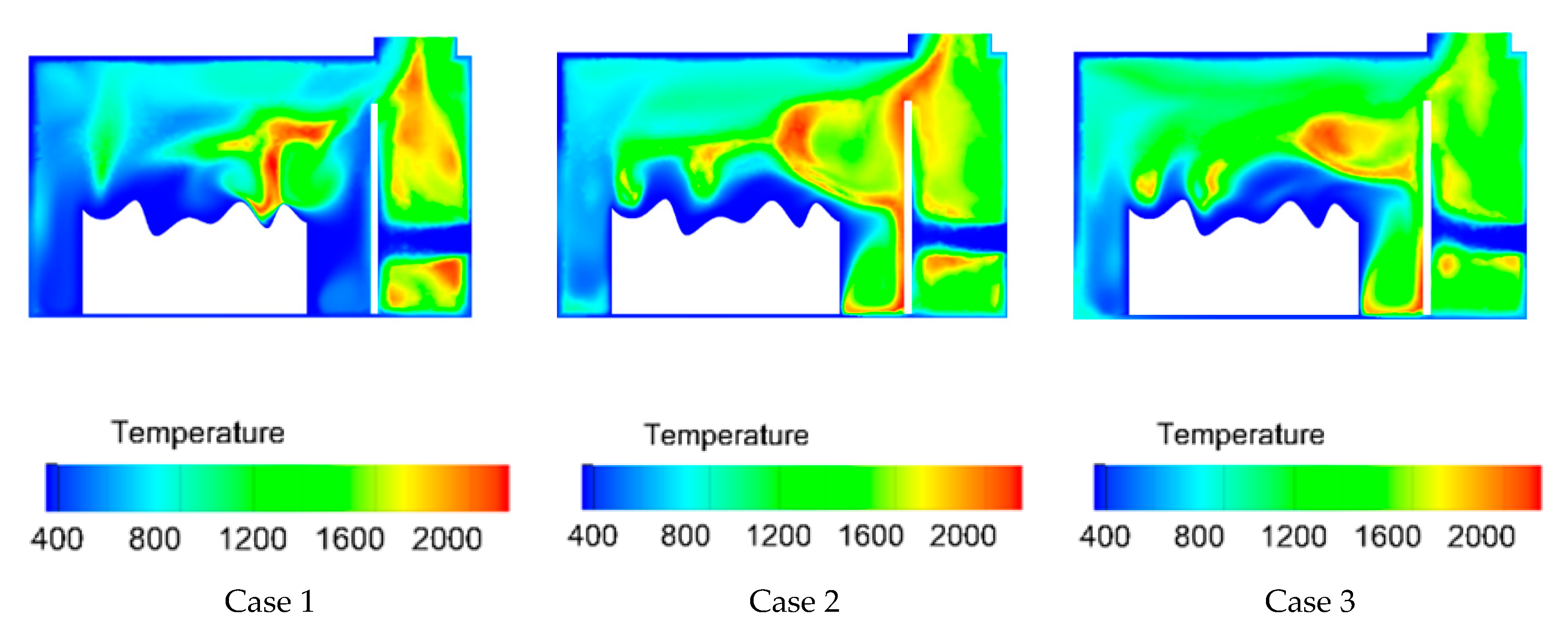

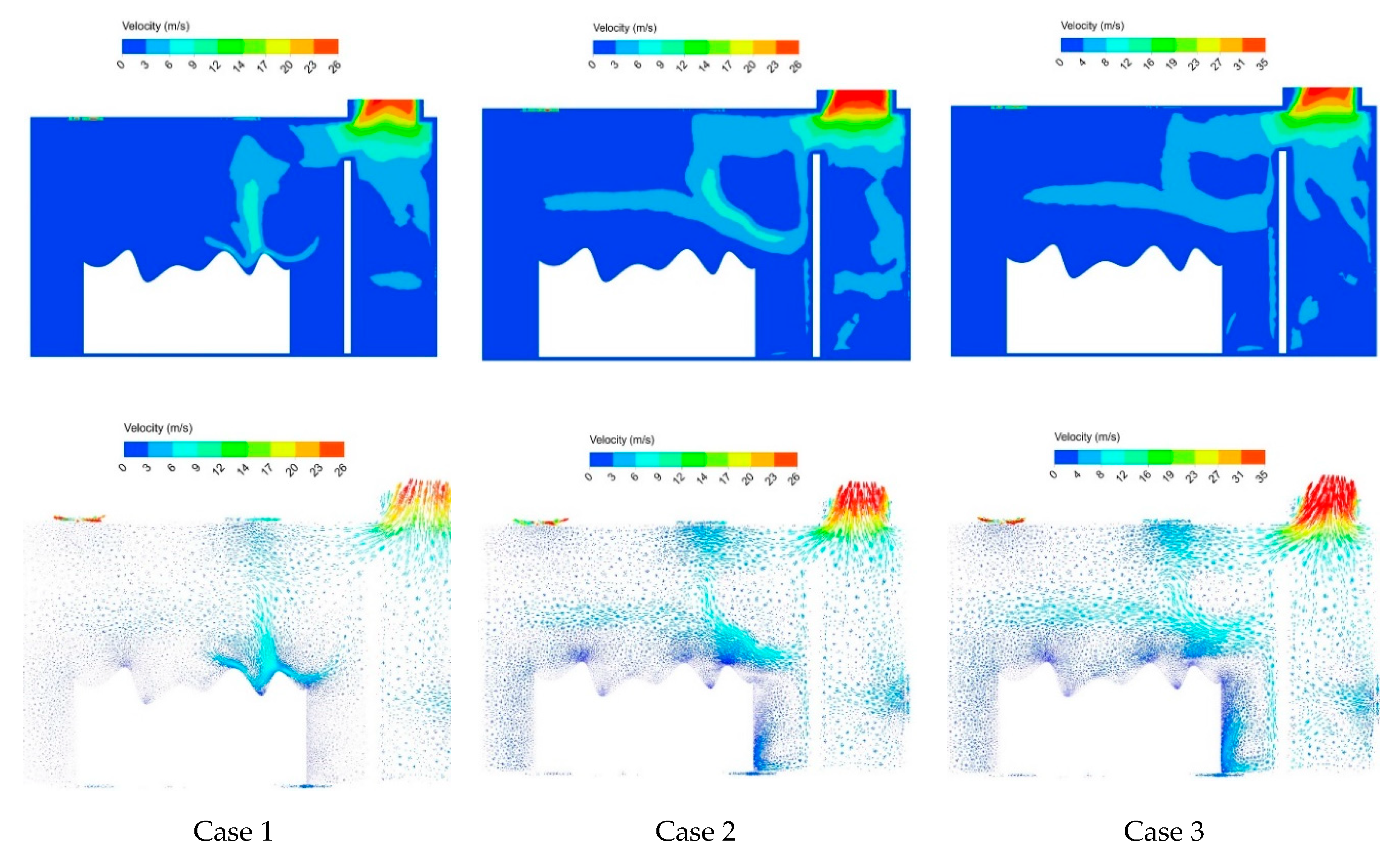

5.1. Effects of Cooling Air

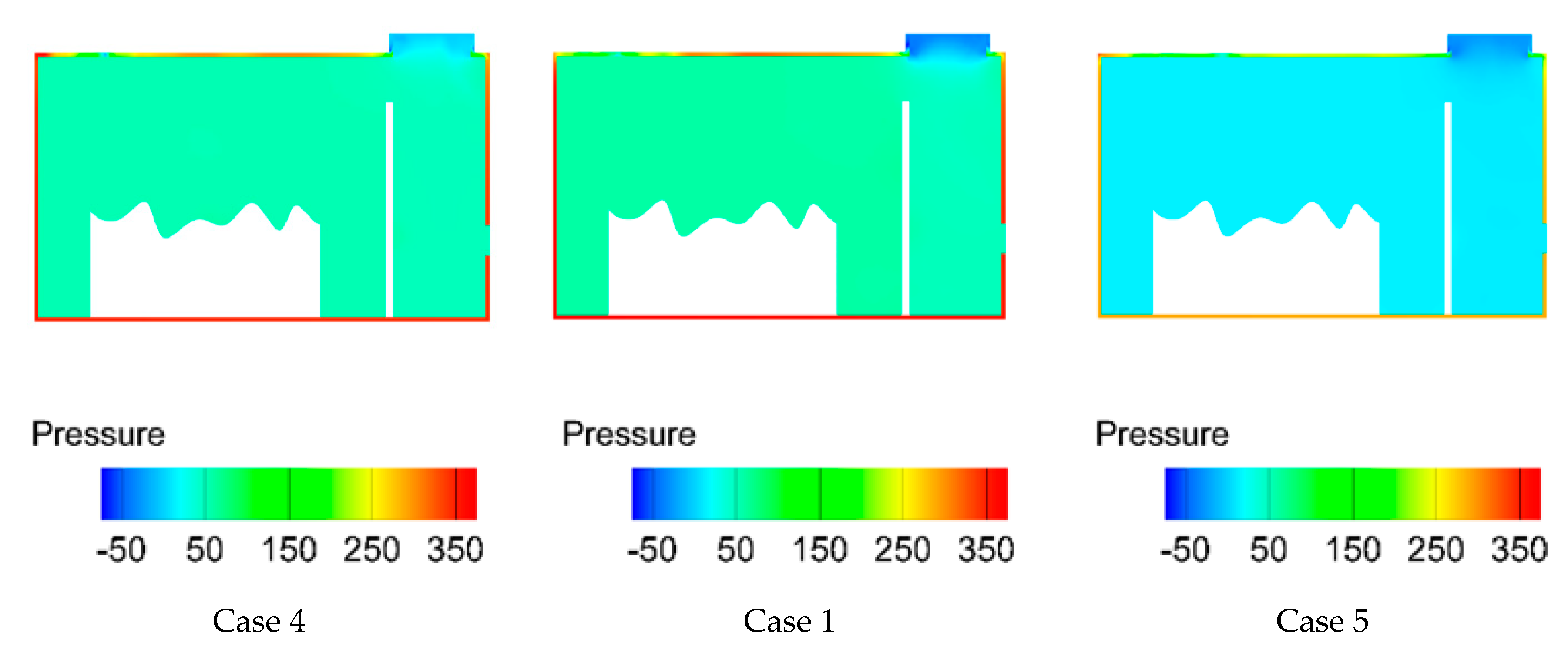

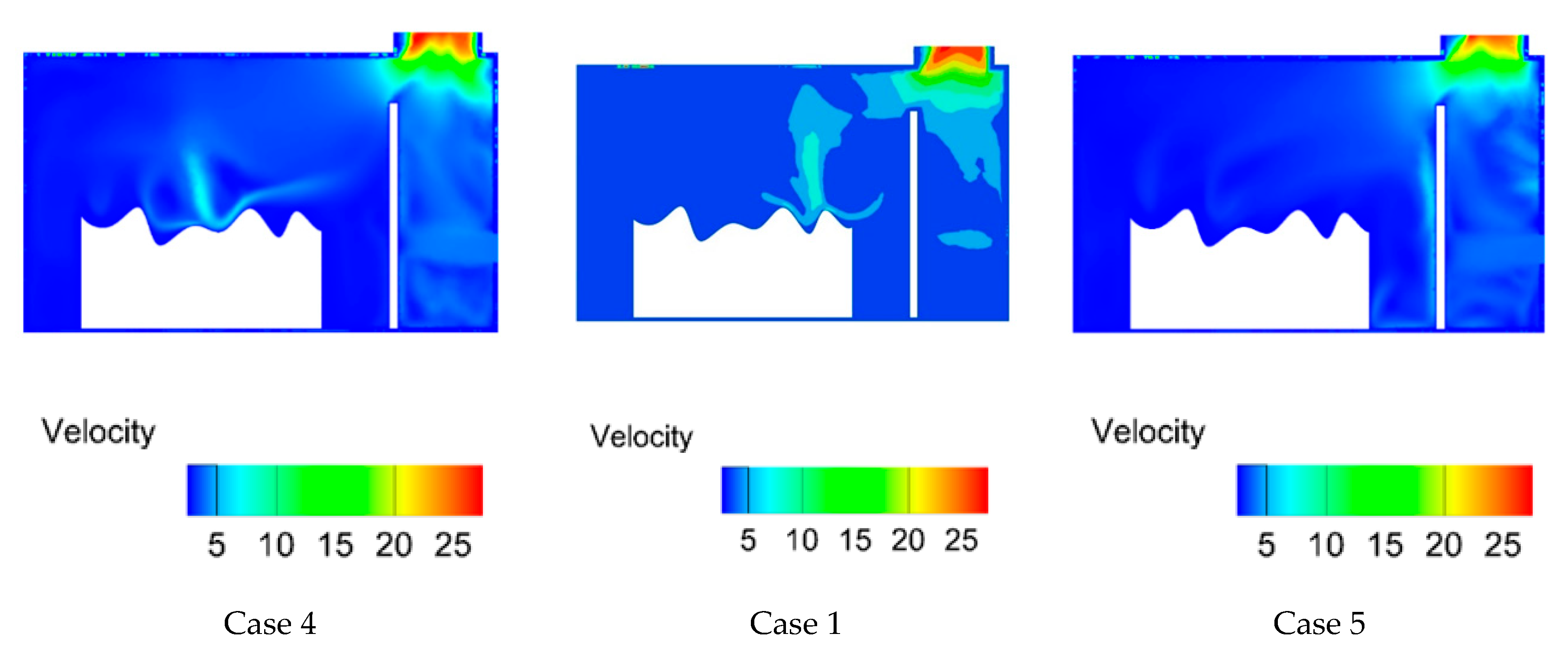

5.2. Effects of Primary Burner Position

5.3. Effects of Rubbish Height

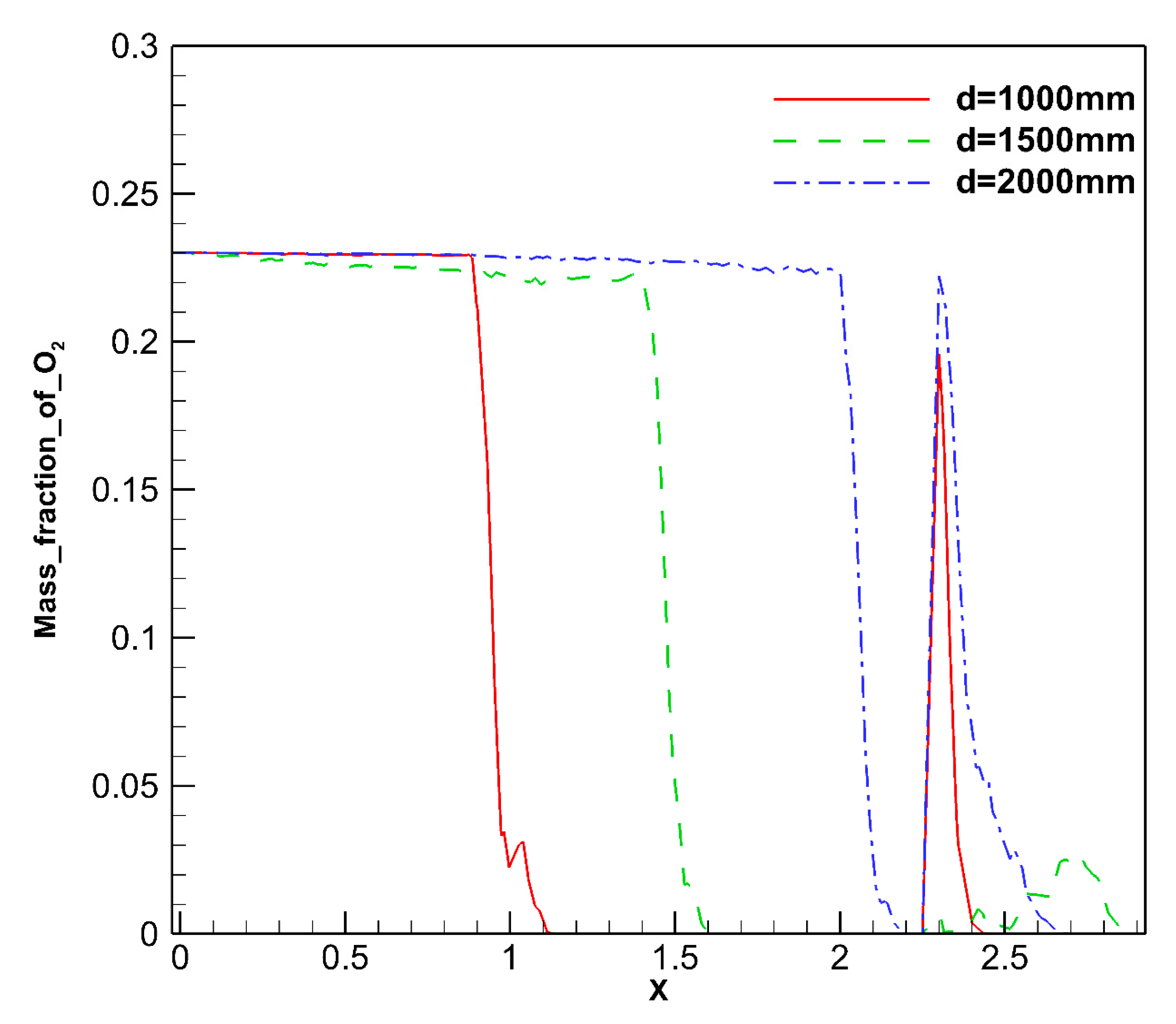

5.4. Comparison of All Cases by Oxygen Concentration

6. Conclusions

- By introducing the higher mass flow rate of the cooling air, the hot spots inside the combustion chamber reduced, and an even temperature distribution has been achieved.

- By introducing the higher mass flow rate of the cooling air, not only the air velocities inside the combustion chambers have been improved, but also the negative pressure, which helps the evacuation of hazardous gases, decreased drastically.

- By increasing the rubbish volume, the incinerator is still able to burn the waste but this burning would face some limitations, which could affect the fluid dynamics parameters of the incinerator.

- According to the investigations, the optimum place of the primary burner at the ceiling of the primary chamber is found to be 1500 mm from the main air inlet.

- By increasing the burner distance from the main air inlet, all thermo-chemical parameters of the incinerator are affected.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| Notations | ||

| Particle surface area | [] | |

| Specific heat capacity of particle | [] | |

| Volumetric heat sources | [] | |

| Total internal energy | [] | |

| Inverse of relaxation time | [] | |

| Other forces per unit mass of particle | [] | |

| Other forces per unit volume of gas | [] | |

| g | Gravity | [] |

| Convective coefficient | [] | |

| Favre-Averaged enthalpy | [] | |

| Diffusive flux of species | [] | |

| Thermal conductivity | [] | |

| Mass of particle | [] | |

| Pressure | [] | |

| Reynolds-Averaged pressure | [] | |

| Prandtl number | [] | |

| Net production rate of species | [] | |

| Additional created source rate of species | [] | |

| Other volumetric heat sources | [] | |

| Temperature of gas mixture | [°C] | |

| Temperature of particle | [°C] | |

| Temperature far from surface of particle | [°C] | |

| Gas mixture velocity | [] | |

| Favre-Averaged gas mixture velocity | [] | |

| Fluid flow velocity | [] | |

| Gas mixture velocity fluctuations | [] | |

| Particle velocity | [] | |

| Local mass fraction of each species | [] | |

| Favre-Averaged mass fraction of species | [] | |

| Greek symbols | ||

| Particle emissivity | [] | |

| Dynamic gas viscosity | ||

| Reynolds-Averaged density of species | ||

| Density of species i | ||

| Density of gas mixture | ||

| Density of particle | ||

| Stefan-Boltzmann constant | [] | |

| Viscous diffusion tensor | [] | |

| Net production rate of species | [] | |

| Subscripts | ||

| f | Gas | |

| p | Particle | |

| Abbreviations | ||

| CFD | Computational fluid dynamics | |

| NG | Natural Gas | |

| DO | Discrete ordinate | |

| LHV | Lower heating value | |

| MSW | Municipal solid waste | |

References

- Energy Recovery—Basic Information; US EPA: Washington, DC, USA, 2016. Available online: https://archive.epa.gov/epawaste/nonhaz/municipal/web/html/index-11.html (accessed on 23 July 2020).

- Stephenson, J.W. Some Recent Developments in Disposal of Solid Wastes by High Temperature Incineration, Pyrolysis, and Fluid Bed Reactor; New York State Action for Clean Air Committee: Schenectady, NY, USA, 7 May 1971. [Google Scholar]

- Knox, A. An overview of incineration and EFW technology as applied to the management of municipal solid waste (MSW). ONEIA Energy Subcommitte 2005. Available online: https://web.archive.org/web/20081205164320/http://www.oneia.ca/files/EFW%20-%20Knox.pdf (accessed on 23 July 2020).

- Herbert, L. Centenary History of Waste and Waste Managers in London and South East England. Chart. Inst. Wastes Manag. 2007. Available online: https://www.ciwm.co.uk/Custom/BSIDocumentSelector/Pages/DocumentViewer.aspx?id=QoR7FzWBtitMKLGdXnS8mUgJfkM0vi6KMAYwUqgqau3ztZeoed%252bsdmKIqDzPOm8yAXgBZR%252fn1fYhL%252bTNdjUq9g2xwY63C2g8GcAQQyfpf3SImIrrED%252bTfsUM91bKsogr (accessed on 23 July 2020).

- Lapčík, V.; Lapčíková, M. Possibilities of Energy Recovery from Municipal Waste, Možnosti Energetického Využití Komunálního Odpadu. GeoSci. Eng. 2012, 58, 49–58. (In Czech) [Google Scholar]

- Directive of the European Parliament and of the Council (EC) 76/2000; on Incineration of Waste; European Parliament, Council of the European Union: Brussels, Belgium, 2000.

- Directive of the European Parliament and of the Council (EU) 75/2010; on Industrial Emissions; European Parliament, Council of the European Union: Brussels, Belgium, 2010.

- Directive of the European Parliament and of the Council (EC) 98/2008; on Waste; European Parliament, Council of the European Union: Brussels, Belgium, 2008.

- Kavian, S.; Saffari Pour, M.; Hakkaki-Fard, A. Optimized Design of the District Heating System by Considering the Techno-Economic Aspects and Future Weather Projection. Energies 2019, 12, 1733. [Google Scholar] [CrossRef]

- The EPA-ORD Mobile Incineration System. In Proceedings of the 1982 National Waste Processing Conference; ASME: New York, NY, USA, 1982; pp. 199–212.

- Zeraatpisheh, M.; Arababadi, R.; Saffari Pour, M. Economic Analysis for Residential Solar PV Systems Based on Different Demand Charge Tariffs. Energies 2018, 11, 3271. [Google Scholar] [CrossRef]

- Leskens, M.; van Kessel, L.B.M.; Bosgra, O.H. Model predictive control as a tool for improving the process operation of MSW combustion plants. Waste Manag. 2005, 25, 788–798. [Google Scholar] [CrossRef]

- Asthana, A.; Menard, Y.; Sessiecq, P.; Patisson, F. Modeling On-Grate MSW Incineration with Experimental Validation in a Batch Incinerator. Ind. Eng. Chem. Res. 2010, 49, 7597–7604. [Google Scholar] [CrossRef][Green Version]

- Pershing, D.W.; Lighty, J.S.; Silcox, G.D.; Heap, M.P.; Owens, W.D. Solid waste incineration in rotary kilns. Comb. Sci. Technol. 2007, 93, 245–276. [Google Scholar] [CrossRef]

- Goh, Y.R.; Yang, Y.B.; Zakaria, R.; Siddall, R.G.; Nasserzadeh, V.; Swithenbank, J. Development of an incinerator bed model for municipal solid waste incineration. Combust. Sci. Technol. 2000, 162, 37–58. [Google Scholar] [CrossRef]

- Goh, Y.R.; Siddall, R.G.; Nasserzadeh, V.; Zakaria, R.; Swithenbank, J.; Lawrence, D.; Garrod, N.; Jones, B. Mathematical modelling of the burning bed of a waste incinerator. J. Inst. Energy 1998, 71, 110–118. [Google Scholar]

- Shin, D.; Choi, S. The combustion of simulated waste particles in a fixed bed. Combust. Flame 2000, 121, 167–180. [Google Scholar] [CrossRef]

- Shin, D.; Ryu, C.K.; Choi, S. Computational fluid dynamics evaluation of good combustion performance in waste incinerators. J. Air Waste Manag. Assoc. 1998, 48, 345–351. [Google Scholar] [CrossRef]

- Wissing, F.; Wirtz, S.; Scherer, V. Simulating municipal solid waste incineration with a DEM/CFD method–influences of waste properties, grate and furnace design. Fuel 2017, 206, 638–656. [Google Scholar] [CrossRef]

- Ryu, C.; Shin, D.; Choi, S. Combined simulation of combustion and gas flow in a grate-type incinerator. J. Air Waste Manag. Assoc. 2002, 52, 189–197. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Ryu, C.; Yang, Y.B.; Nasserzadeh, V.; Swithenbank, J. Thermal reaction modeling of a large municipal solid waste incinerator. Combust. Sci. Technol. 2004, 176, 1891–1907. [Google Scholar] [CrossRef]

- Lai, A.C.H.; Law, A.W.-K. Numerical modeling of municipal waste bed incineration. Int. J. Numer. Methods Heat Fluid Flow 2019, 29, 504–522. [Google Scholar] [CrossRef]

- National Research Council. Waste Incineration and Public Health; The National Academies Press: Washington, DC, USA, 2000. [Google Scholar]

- Chen, D.-M.; Ran, J.-Y.; Niu, J.-T.; Yang, Z.; Pu, G.; Yang, L. Numerical Study on Separation Performance of Cyclone Flue Used in Grate Waste Incinerator. Processes 2019, 7, 866. [Google Scholar] [CrossRef]

- Ali, R.A.; Ibrahim, N.N.L.N.; Lam, H.L. Conversion Technologies: Evaluation of Economic Performance and Environmental Impact Analysis for Municipal Solid Waste in Malaysia. Processes 2019, 7, 752. [Google Scholar] [CrossRef]

- Wei, G.; Liu, H.; Liu, F.; Zeng, T.; Liu, G.; Zhou, J. Experimental Investigation of the Decarburization Behavior of Medical Waste Incinerator Fly Ash (MWIFA). Processes 2018, 6, 186. [Google Scholar] [CrossRef]

- Liu, F.; Liu, H.-Q.; Wei, G.-X.; Zhang, R.; Zeng, T.-T.; Liu, G.-S.; Zhou, J.-H. Characteristics and Treatment Methods of Medical Waste Incinerator Fly Ash: A Review. Processes 2018, 6, 173. [Google Scholar] [CrossRef]

- ANSYS Workbench Theory Guide. Available online: http://www.ansys.com (accessed on 23 April 2019).

- Khodabandeh, E.; Pourramezan, M.; Pakravan, M.H. Effects of excess air and preheating on the flow pattern and efficiency of the radiative section of a fired heater. Appl. Therm. Eng. 2016, 105, 537–548. [Google Scholar] [CrossRef]

- Frey, H.H.; Peters, B.; Hunsinger, H.; Vehlow, J. Characterization of municipal solid waste combustion in a grate furnace. Waste Manag. 2003, 23, 689–701. [Google Scholar] [CrossRef]

- Orsino, S.; Weber, R.; Bollettini, U. Numerical Simulation of Combustion of Natural Gas with High-Temperature Air. Combust. Sci. Technol. 2001, 170, 1–34. [Google Scholar] [CrossRef]

- Saffari Pour, M. Producer Gas Implementation in Steel Reheating Furnaces from Lab to Industrial Scale: A Computational Fluid Dynamics and Thermodynamics Approach. Ph.D. Thesis, KTH Royal Institute of Technology, Stockholm, Sweden, 2016. [Google Scholar]

- Hautman, A.N.; Dryer, F.L.; Schlug, K.P.; Glassman, I. A multiple step overall kinetic mechanism for the oxidation of hydrocarbons. Combust. Sci. Technol. 1981, 25, 219. [Google Scholar] [CrossRef]

- Frassoldati, A.; Sharma, P.; Cuoci, A.; Faravelli, T.; Ranzi, E. Kinetic and fluid dynamics modeling of methane/hydrogen jet flames in diluted coflow. Appl. Therm. Eng. 2010, 30, 376–383. [Google Scholar] [CrossRef]

- Ho, M.D.; Perdek, J.M.; Stumbar, J.P.; Sawyer, R.H. Field Demonstration of the Linde Oxygen Combustion System on the EPA Mobile Incinerator. J. Air Waste Manag. Assoc. 1992, 42, 493–499. [Google Scholar] [CrossRef][Green Version]

| Solid Materials | MJ/kg |

| Car tire | 37 |

| Food waste | 4.2 |

| Glass fiber-reinforced polyester (GRP) | 15 |

| Leather | 18.9 |

| Newspaper | 18.6 |

| Paraffin wax | 42 |

| Sawdust | 19 |

| Plastics | MJ/kg |

| Acrylonitrile butadiene styrene (ABS) | 39 |

| Cellulose | 16 |

| Nylon, polyamide (PA) | 28 |

| Polyester (PET), textiles, bottles | 23 |

| Polyethylene (PE) | 46 |

| Polypropylene (PP) | 43 |

| Polystyrene (PS) | 46 |

| Polyurethane (PU) | 36 |

| Polyvinyl chloride (PVC) | 18.9 |

| Liquid | MJ/kg |

| Acetic acid | 15.8 |

| Acetone | 22.4 |

| Kerosene/Paraffin | 34.8 |

| White spirit | 34.8 |

| Equations Name | Material Phase | Governing Equations |

|---|---|---|

| Continuity (Mass balance) | Solid | Devolatilization and char burnout |

| Fluid | (EDC model) | |

| Momentum | Solid | |

| Fluid | ||

| Energy | Solid | |

| Fluid |

| Equations Name | Material Phase | Governing Equations |

|---|---|---|

| Continuity (Mass balance) | Gas Mixture | |

| Momentum | Ash Solid | |

| Gas Mixture | ||

| Energy | Gas Mixture |

| Location | Type | Value |

|---|---|---|

| A | Pressure gauge | P = 0 kPa |

| B | Burner | mass flow rate of air = 8 (kg/s) mass flow rate of fuel = 5 (kg/s) |

| C | Air inlet | V = 1.75 (m/s) |

| D | Air inlet | V = 1.5 (m/s) This value for all air inlets is the same. |

| E | Burner | mass flow rat of air = 6 (kg/s) mass flow rate of fuel = 3 (kg/s) |

| F | Air inlet | V = 3 (m/s) |

| Case Numbers | Rubbish Height | Burner Position | Mass Flow Rate |

|---|---|---|---|

| Case 1 | 800 mm | 1500 mm | 0.07 kg/s |

| Case 2 | 800 mm | 1500 mm | 0.14 kg/s |

| Case 3 | 800 mm | 1500 mm | 0.21 kg/s |

| Case Numbers | Rubbish Height | Burner Position | Mass Flow Rate |

|---|---|---|---|

| Case 4 | 800 mm | 1000 mm | 0.07 kg/s |

| Case 1 | 800 mm | 1500 mm | 0.07 kg/s |

| Case 5 | 800 mm | 2000 mm | 0.07 kg/s |

| Case Numbers | Rubbish Height | Burner Position | Mass Flow Rate |

|---|---|---|---|

| Case 6 | 700 mm | 1500 mm | 0.07 kg/s |

| Case 1 | 800 mm | 1500 mm | 0.07 kg/s |

| Case 7 | 900 mm | 1500 mm | 0.07 kg/s |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Saffari Pour, M.; Hakkaki-Fard, A.; Firoozabadi, B. Numerical Investigation of a Portable Incinerator: A Parametric Study. Processes 2020, 8, 923. https://doi.org/10.3390/pr8080923

Saffari Pour M, Hakkaki-Fard A, Firoozabadi B. Numerical Investigation of a Portable Incinerator: A Parametric Study. Processes. 2020; 8(8):923. https://doi.org/10.3390/pr8080923

Chicago/Turabian StyleSaffari Pour, Mohsen, Ali Hakkaki-Fard, and Bahar Firoozabadi. 2020. "Numerical Investigation of a Portable Incinerator: A Parametric Study" Processes 8, no. 8: 923. https://doi.org/10.3390/pr8080923

APA StyleSaffari Pour, M., Hakkaki-Fard, A., & Firoozabadi, B. (2020). Numerical Investigation of a Portable Incinerator: A Parametric Study. Processes, 8(8), 923. https://doi.org/10.3390/pr8080923