1. Introduction

Green innovation has become a familiar and popular topic of interest throughout the world due to increasing environmental concerns [

1]. Furthermore, increasing population, globalization, urbanization, and industrialization have presented numerous problems, such as damage to the environment, economy, and living conditions of society [

2]. Sustainable supply chain management (SSCM) practices can help industries reduce their environmental issues and increase sustainable activities by making them obligated to consider green innovation aspects. The concept of green innovation is appearing in many industries because of growing public awareness, market pressure, stringent governmental policies, and environmental practitioners who seek to integrate sustainability into their own supply chain operations [

3]. In this regard, various industrial sectors, such as those of agriculture, manufacturing, mining, and construction, are applying green innovation practices to SSCM [

4,

5]. Industries are keenly responsible for their supply chain operations since they are significant contributors to polluting the environment. Thus, to prevent such hazardous environmental practices, industries should apply more eco-standards and regulations for adopting green innovation and sustainable supply chain operations [

6].

Sustainable innovation mainly relies on three criteria: economic, environmental, and social [

7]. These terms can be defined as the industrial supply chain practices needed to increase profit, reduce negative eco impacts, and enhance social well-being [

8]. Moreover, the manufacturing sector’s production process is considered to be very complex, as it involves many phases [

9]. However, many practitioners have criticized this industry due to its unfriendly supply chain practices. Consequently, the manufacturing sector faces high pressure from environmental regulatory bodies, industrial managers, governments, and policymakers to implement sustainable innovation processes in its supply chain management [

10]. In this context, it is important for industries to transform their current supply chains into sustainable supply chain operations. This will lead to fewer adverse impacts on the environment via sustainable supply chain practices [

11]. The successful adoption of green innovation aspects can assist manufacturing companies in ameliorating their operational and production losses through SSCM practices [

12]. Asian countries like China, Bangladesh, Vietnam, and India are producing a large number of textile products; however, few are concerned about eco-friendly supply chain operations.

The present research targeted eight textile manufacturing companies in China due to their vast supply chain operations and future growth potential [

13]. Notably, the manufacturing sector is one of the leading sectors in the country, and it provided almost 29.41% of China’s total GDP in 2018 [

14]. The production value of the textile manufacturing industry comprised 7% of China’s GDP in 2015 [

15]. Furthermore, the country’s manufacturing sector is considered the pillar for the national economy and is ranked as the third-largest manufacturing market in the world [

16]. However, further industrial practices and technological improvements are needed for sustainable supply chain operations. This will increase future production potential with more investments because traditional supply chains are affecting the environment [

17]. Sustainable supply chain practices, along with green innovation, can help industries grow in the competitive market for sustainable economic, environmental, and social development [

18]. This study investigated a relevant decision framework by introducing green innovation criteria into the sustainable supply chain practices of the industry. The objective of this research was to identify green innovation criteria to develop an integrated decision model for SSCM practices in the context of Chinese manufacturing companies. Then, this study identified and evaluated how traditional suppliers of raw materials and products can adopt green innovation in the SSCM. Theoretical background information is also provided for a better understanding of the aim of the current study, i.e., green innovation implementation into sustainable supply chains of the manufacturing industry. To accomplish the aims of this study, we reviewed the most relevant studies on green innovation and SSCM practices. From the literature, we identified and finalized the green innovation criteria and sub-criteria for SSCM practices. These identified green innovation criteria were then assessed by experts. Finally, we selected a supplier that could implement these green innovation criteria into the SSCM practices of the manufacturing industry.

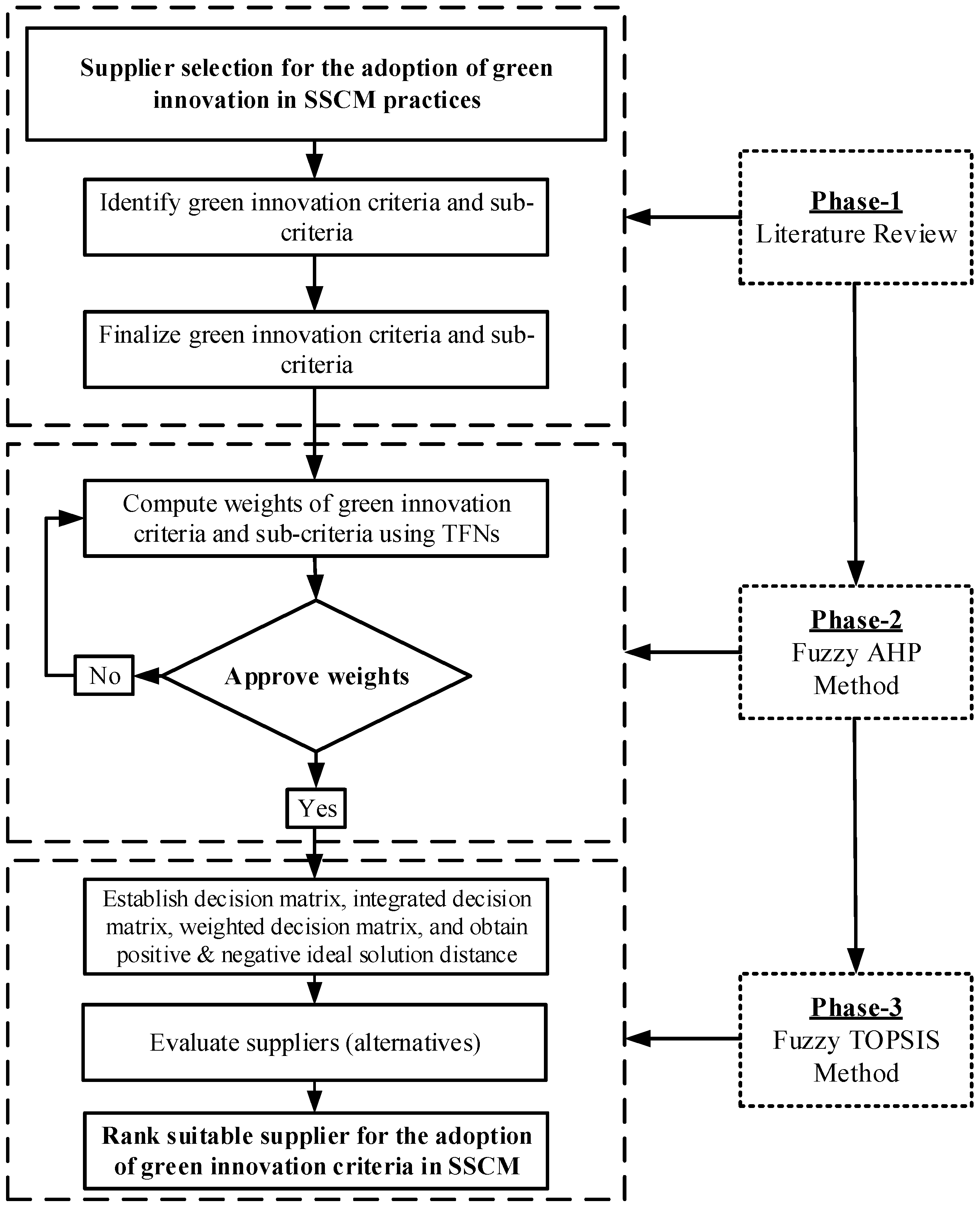

Selecting a significant supplier is a very crucial problem because this industry completely relies on the supplier to implement green practices in the SSCM. Moreover, the selection of a supplier for the adoption of green innovation criteria in the SSCM of the manufacturing industry remains a crucial problem since it involves numerous uncertainties and complexities. Thus, in this research, we developed a decision methodology that can enable industries to analyze green innovation criteria for SSCM and prioritize the supplier for green practices. This study used the fuzzy analytical hierarchy process (FAHP) and fuzzy technique for order of preference by similarity to ideal solution (FTOPSIS) approaches to analyze and prioritize sustainable suppliers based on green innovation criteria. This research contributes to the state of the art in two ways. First, this study’s FAHP method evaluates and ranks the green innovation criteria framework for SSCM in the manufacturing industry. The employed the FTOPSIS approach to investigate and rank suitable suppliers based on green innovation criteria for implementing SSCM practices. These proposed FAHP and FTOPSIS are novel multi-criteria decision making (MCDM) methods for examining decision making problems. We applied the proposed decision methodology using empirical data in the context of the manufacturing industry in China.

The rest of this paper is organized as follows:

Section 2 provides the theoretical background.

Section 3 presents the research methodology of the study.

Section 4 shows the results and discussion. Finally,

Section 5 presents the conclusions.

4. Results and Discussion

In the research, we adopted a hybrid decision methodology based on the FAHP and FTOPSIS to evaluate green innovation criteria for the SSCM.

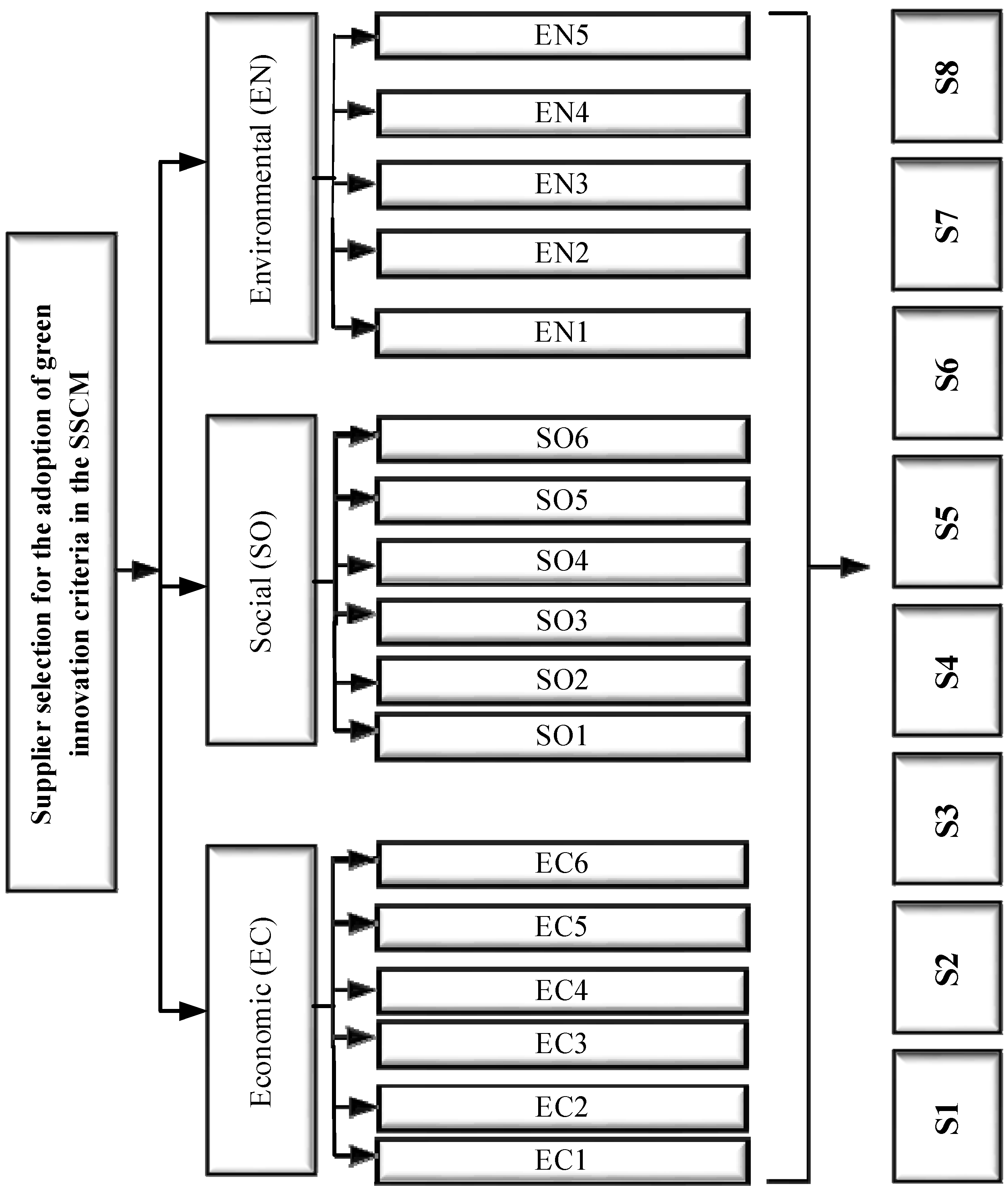

Figure 2 presents the hierarchically structured decision framework for this study. To achieve this objective, the FAHP approach was used to analyze and rank the three green innovation criteria and seventeen green innovation sub-criteria. Then, the FTOPSIS technique was utilized to identify suitable suppliers for implementing SSCM practices in the manufacturing industry in China.

4.1. Case Analysis

This case study used eight suppliers from Chinese textile manufacturing companies. These companies belong to the textile industry and have been operating over the last thirty years. We selected companies whose aim is to reduce their environmental degradation activities, increase their socio–economic development, and improve the impact of their products using green technologies. It was ensured that these selected textile manufacturing companies had continuously operated over the last twenty years and that each had more than five thousand employees. To avoid any conflict, the managers of the companies were not consulted to avoid conflicts of interest. In this regard, professional and experienced managers, analysts, professors, and stakeholders were consulted to provide their feedback on the questionnaire. The details of each criterion, sub-criterion, and objective of the research were presented to each expert through a webmail service. The experts were asked to compare the fuzzy pairwise comparison matrices of the criteria to those of other criteria using TFNs scales. A similar process was applied to the sub-criteria. After obtaining feedback from all experts, the average of the weights and final ranking of the sub-criteria, as well as the main criteria, were obtained. Finally, the experts were asked to provide feedback for alternatives based on the overall sub-criteria.

4.2. FAHP Results

In this section, the results of three green innovation criteria and seventeen sub-criteria are identified using the FAHP methodology. These determined green innovations are suitable for SSCM practices in the manufacturing industry. Detailed results are provided in the following sub-sections.

4.2.1. Green Innovation Criteria Results

This section provides the green innovation criteria results for the adoption of sustainable supply chain practices. The three green innovation results were analyzed using the FAHP method.

Table 6 presents a ranking of the green innovation criteria. As shown in

Table 6, EC was the most suitable green innovation criterion with a weight of 0.386 (38.60%). The EN criterion was ranked second with a weight of 0.346 (34.60%), whereas the SO criteria had the least importance with a weight of 0.268 (26.80%). The analysis showed that all these green innovation criteria are important for implementing sustainable supply chain practices in the manufacturing industry.

The detailed results, i.e., the fuzzy pairwise comparison matrix of the green innovation criteria and sub-criteria, were then constructed and are presented in

Appendix C.

4.2.2. Green Innovation Sub-Criteria Results

This section provides the results of the green innovation sub-criteria with respect to each main criteria after analyzing the green innovation criteria results.

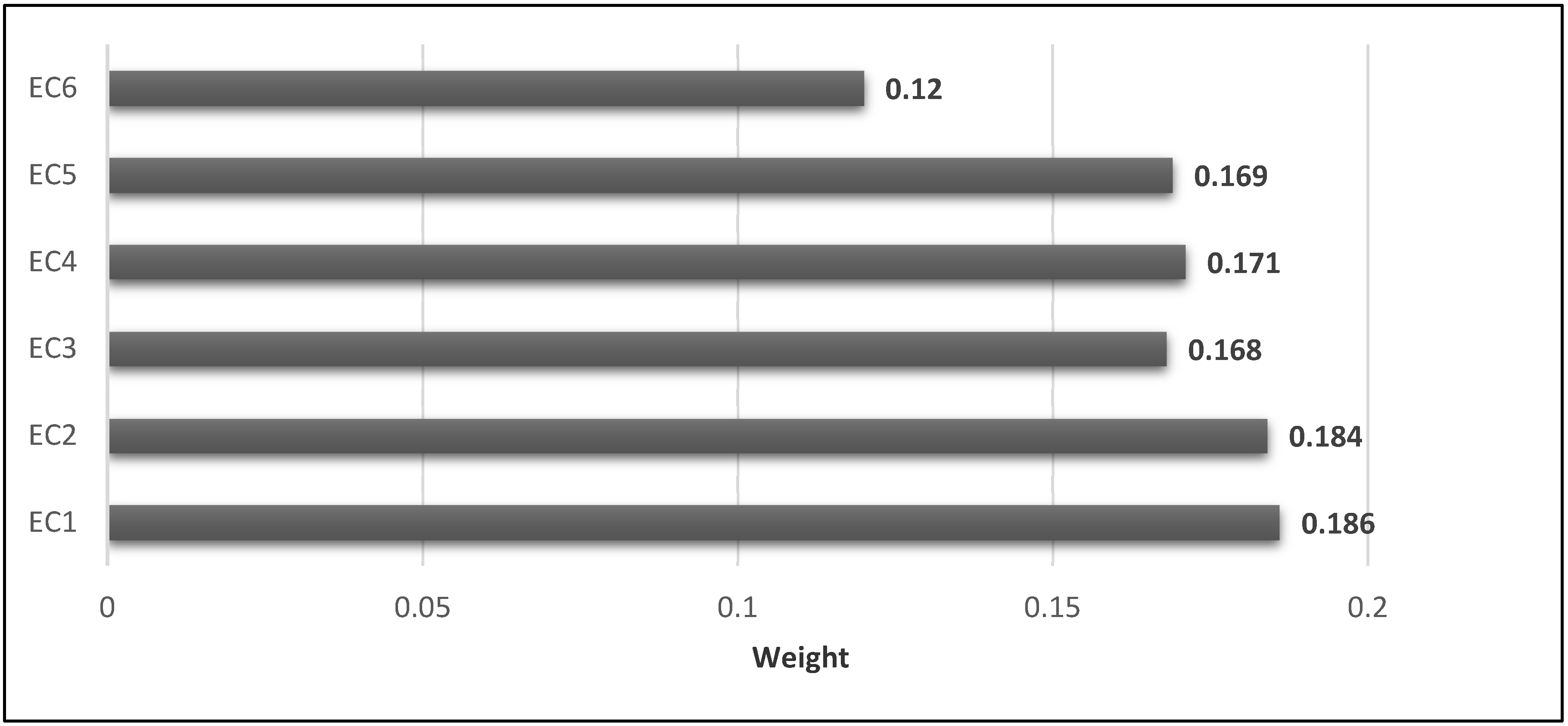

Figure 3 presents a ranking of the green innovation sub-criteria with respect to the EC criteria. According to the results, financial availability (EC1), with a weight of 0.186 (18.60%), was the priority green innovation sub-criterion. Investment in research and development for green practice (EC2) sub-criterion, with a weight of 0.184 (18.40%), was the second important green innovation sub-criterion. Designing green products to decrease material costs and consumption (EC4) was the third most vital sub-criterion, with a weight of 0.171 (17.10%). The return on investment for green practices (EC5) and reducing green product cost (EC3) were considered moderately necessary for SSCM practices in the manufacturing industry of China. Finally, improving the sustainability value to customers (EC6) obtained the least importance, with a weight of 0.12 (12%). The results indicated that all these economic sub-criteria are very significant for the development of SSCM practices.

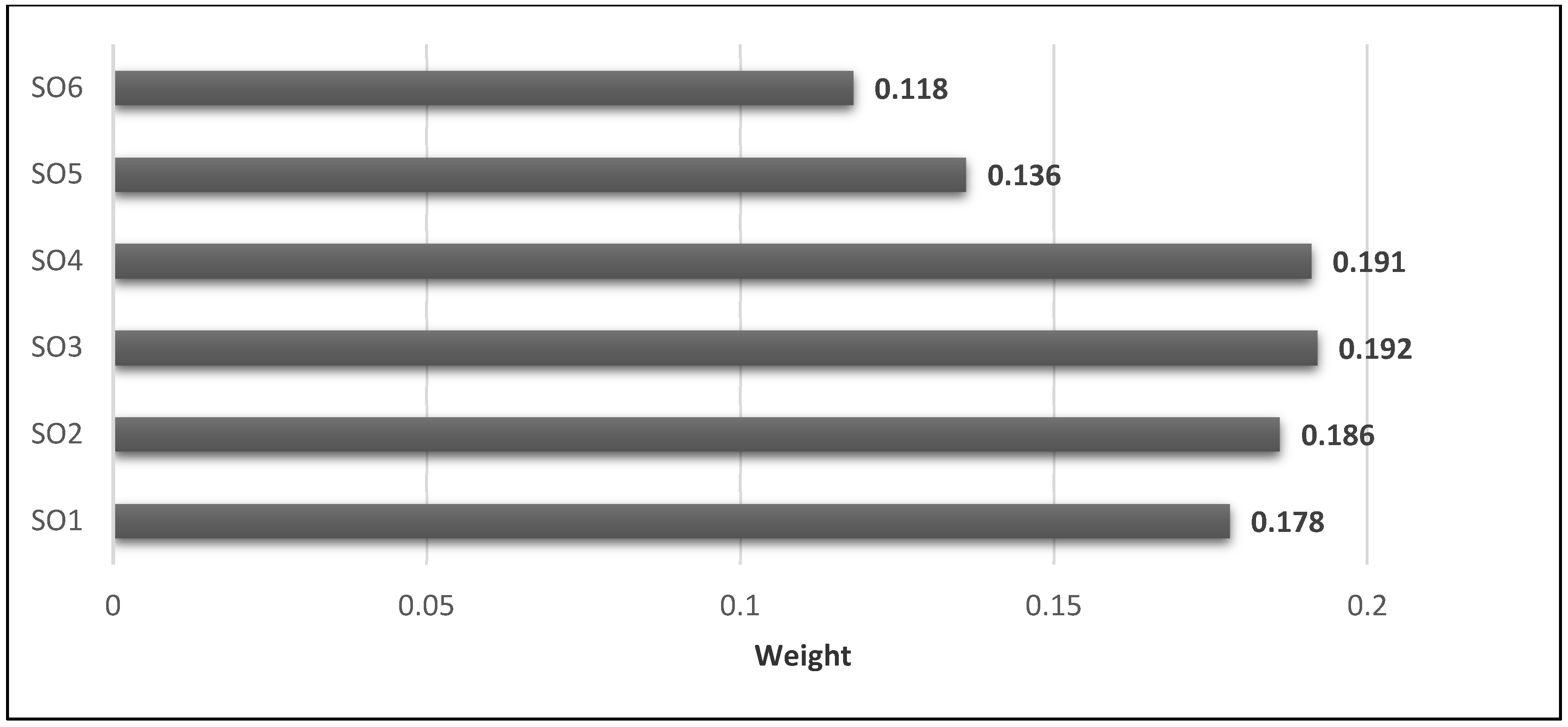

Figure 4 displays the ranking of the green innovation sub-criteria under the SO criteria. The findings showed that adopting socio–environmental policies in industry (SO3), with a weight of 0.19 (19.20%) was the highest-ranked green innovation sub-criterion. The response to stakeholders who pressure companies to produce green products (SO4), with a weight of 0.191 (19.10%), was the second most crucial green innovation sub-criterion. Responses to customers and the market demand for green products (SO2) was the third highest sub-criterion. Improving the social image of the industry (SO1) was recognized as the fourth most important green innovation sub-criterion, whereas the health and safety of employees (SO5) and cultural norms and social values (SO6) were considered the least significant green innovation sub-criteria.

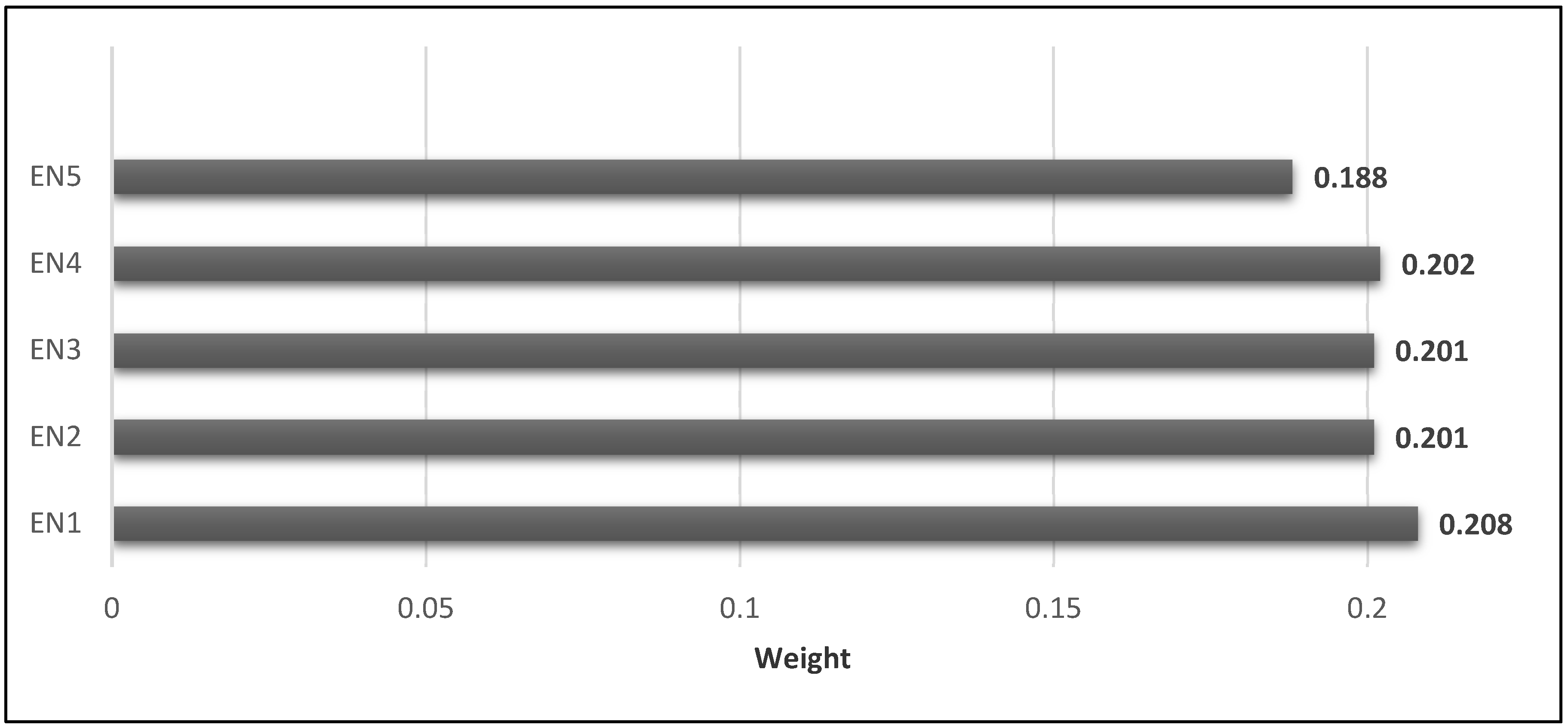

Figure 5 presents the ranking of sub-criteria under the EN criteria. The results indicated that the commitment to develop an environmental management system (EN1) was the top-ranked green innovation sub-criterion, with a weight of 0.208 (20.80%). The availability of technical expertise (EN4) was considered the second most important green innovation sub-criterion, with a weight of 0.202 (20.20%). Furthermore, the designing and developing green products (EN2) and developing green manufacturing and operational practices (EN3) were found to have equal weights of 0.201 (20.10%). The collaboration among industries (EN5) was the least important sub-criterion, with a weight of 0.188 (18.80%). Thus, most green innovation sub-criteria with respect to the environmental criteria are very important for the implementation of SSCM processes.

4.2.3. Overall Green Innovation Sub-Criteria Results

Table 7 shows the priority order of the overall sub-criteria based on the goals of this study. The final weights of the seventeen sub-criteria were obtained by multiplying the local weight of the sub-criteria with those of each green innovation criterion. The analysis showed that the commitment to developing an environmental management system (EN1) sub-criterion achieved the highest weight at 0.0720 (7.20%). The financial availability of the green innovation (EC1) sub-criterion achieved the second-highest weight at 0.0718 (7.18%). Investment in research and development for green practices (EC2) was the third most vital green innovation sub-criterion.

The remaining green innovation sub-criteria were prioritized as follows: EN4 < EN2 < EN3 < EC4 < EC5 < EN5 < EC3 < SO3 < SO4 < SO2 < SO1 < EC6 < SO5 < SO6. Most green innovation sub-criteria are thus very important for the sustainable adoption of supply chain operations in the manufacturing industry of China. Based on these analyses, the FTOPSIS approach was used to analyze and rank suitable suppliers for the adoption of SSCM activities.

4.3. FTOPSIS Results

In this section, we used the FTOPSIS approach to analyze and prioritize eight suppliers (alternatives) for the adoption of SSCM practices in the manufacturing industry of China. The ranking of the suppliers was identified after evaluating the green innovation criteria and sub-criteria. The suppliers were mainly ranked by the green innovation sub-criteria. In the FTOPSIS process, the experts were again asked to rate each supplier’s performance with respect to the seventeen green innovation sub-criteria. The detailed analyses, i.e., the fuzzy decision matrix, the fuzzy normalized decision matrix, and the fuzzy integrated normalized decision matrix, are presented in

Appendix D. The final step of the FTOPSIS method was to obtain the closeness coefficient (CCi) scores of the suppliers.

Table 8 shows the ranking of suppliers based on their CCi scores. The results indicated that supplier 5 (S5) obtained the highest CCi score of 0.727, which means that S5 is the most suitable supplier for implementing green innovation criteria in the SSCM practices of the manufacturing industry. Supplier 7 (S7) was ranked second with a CCi score of 0.691. Supplier 1 (S1) was the third most vital alternative with a score of 0.638. The order ranking of the remaining suppliers was as follows: S6 < S8 < S2 < S3 < S4. S6 and S8 obtained the same CCi, which means that both are equally important in implementing green innovation practices. The final analysis showed that S5, S7, and S1 are the top priority suppliers, while the others are considered moderately important to unimportant for implementing green innovation criteria in SSCM practices.

4.4. Sensitivity Analysis

In this study, we conducted a sensitivity analysis to assess the feasibility and reliability of the obtained results from the FAHP and FTOPSIS methods. This was done by changing the weights of the main criteria to check the final ranking of the suppliers (alternatives). In the sensitivity process, the main criteria weights were varied to analyze the order ranking of the alternatives. In total, six cases were proposed and assessed by changing the weights of the main criteria to investigate the final ranking of the alternatives. The varying weights of the main criteria in the six cases are shown in

Table 9. The main criteria weights are provided in column 2 of

Table 9, followed by six other cases evaluated under a sensitivity analysis. After varying the weights, we observed that the priority order of alternatives remained the same with no changes in the final rankings.

Table 10 presents the final ranking of alternatives based on the six cases of the sensitivity analysis. The rankings of the alternatives remained identical to the original case results. Thus, the sensitivity analysis showed that the obtained results were significant and reliable.

4.5. Discussion

This research identified the critical green innovation criteria and sub-criteria for sustainable supply chain practices. Previously, it was very complex to identify and evaluate such criteria. However, the present study was able to properly analyze this decision making problem by using the FAHP and FTOPSIS methodologies. This research conducted a detailed literature study to select the most vital green innovation criteria for the selection of a suitable supplier in sustainable supply chain practices. Assessing any decision making problem in real-life cases is very complicated. In this regard, an integrated decision model was proposed to assess and rank suppliers in terms of green innovation criteria. The developed model can assist in minimizing uncertainties and inadequacies during the decision making process.

The main results of the FAHP method are provided in the above sections. Among the three green innovation criteria, the EC criteria were found to be the most suitable options for sustainable supply chain practices. The overall (seventeen) green innovation sub-criteria results showed that commitment to developing an environmental management system (EN1) is the most crucial sub-criterion. At the same time, cultural norms and social values (SO6) was found to be the least significant sub-criterion for the adoption of sustainable supply chain practices in the manufacturing industry of China. After evaluating the green innovation criteria and sub-criteria, this study further assessed eight suppliers using the FTOPSIS method. The findings showed that supplier 5 (S5) is a suitable supplier for implementing sustainable supply chain practices.

In previous studies, authors have analyzed similar types of research problems pertaining to green innovation for SSCM practices in industry. However, the goal of the decision making problem in each study was different. For example, some authors identified the important aspects of green innovation, green innovation barriers, green strategies, and sustainable dimensions to implement green supply chain operations in the industry. Moreover, researchers have used several MCDM methods to investigate decision problems. In a previous study, Gupta and Barua [

23] analyzed the use of green innovation enablers for sustainable supply chain operations in the manufacturing industry by using the grey decision making trial and evaluation laboratory (DEMATEL) technique; their study results showed that developing green manufacturing capabilities is the most vital green innovation enabler for the adoption of green supply chain practices. Another study by Gupta and Barua [

24] revealed the barriers that impede the development of green innovation in small and medium enterprises (SMEs) using the best worst method (BWM) and FTOPSIS methodologies; their research findings showed that technological, resource, financial, and economic factors are the most significant barriers that obstruct green innovation. These findings are improved by the current study results. Moreover, the sustainability innovation dimensions were analyzed in the SSCM of the manufacturing industry based on the BWM method [

25]. The research revealed that financial availability is the most crucial sustainable innovation sub-criterion. The findings of the current study also demonstrated that financial availability for the development of green innovation is the most suitable sub-criteria for SSCM practices. A recent study by Almalki et al. [

28], which identified the barriers and strategies to implementing green innovation in SMEs, showed that political barriers impede the adoption of green innovation practices, while developing R&D practices is considered to be a significant strategy for overcoming barriers to the sustainable development of SMEs. Another study by Almalki et al. [

30] revealed that green innovation initiatives are a top priority for the selection of green suppliers among SMEs in Saudi Arabia.

Furthermore, several important studies, along with their findings, have already been provided in the theoretical background section. This makes it easy to compare the results and analyze the feasibility of the current study. This study will be very useful for industrial managers and decision-makers to select a suitable supplier for the adoption of green innovation criteria in sustainable supply chains. Several previous studies have analyzed the green innovation criteria for implementing sustainable supply chain practices. Nevertheless, none of these studies identified the green innovation criteria themselves (i.e., EN, SO, and EN) to identify and analyze suppliers on the basis of these criteria. This proposed integrated decision framework thus provides meaningful insights to help managers and policymakers adopt sustainable supply chain practices in the manufacturing industry of China.

5. Conclusions

At present, many manufacturing companies are facing sustainability problems throughout their supply chain systems. Green innovation helps industries overcome sustainability issues in supply chains by adopting green practices. This research accordingly developed a green innovation criteria decision framework comprising economic, social, and environmental factors to help ameliorate the green innovation problems within the manufacturing industry of China. SSCM practices could help companies reduce their environmental damage. In this study, the FAHP and FTOPSIS methods were used to analyze and prioritize the three green innovation criteria, seventeen sub-criteria, and eight suppliers to implement green innovation into the sustainable supply chain practices of the industry. The findings indicated that economic criteria are the most important green innovation criteria for implementing SSCM practices in the manufacturing industry of China because China is a developing country. Environmental criteria were ranked second because the industrial manufacturing system fully relies on traditional supply chain practices. These supply chain practices are, however, dangerous to the environment. Social criteria were considered the least important for the implementation of green innovation practices.

Moreover, the evaluation of the FAHP method indicated that economic criteria are the most significant green innovation criteria, followed by environmental and social criteria, for adopting sustainable chain practices in the manufacturing industry of the country. Commitment to developing an environmental management system (EN1), financial availability for green innovation (EC1), and investment in research and development for green practices (EC2) were found to be important sub-criteria for implementing green innovation in sustainable supply chain operations. The FTOPSIS results revealed that supplier 5 (S5) is the best-suited supplier for the adoption of green innovation criteria in the SSCM practices of the manufacturing industry. The findings of this study revealed that green innovation criteria and sub-criteria are very important for developing sustainable industrial practices in the manufacturing sector. These criteria could help the industry achieve sustainable development and a competitive advantage.

Furthermore, this research offers several key contributions that have been discussed. Though the presented concerns of this study will be very significant and useful for future research on the given subject, there were some limitations. Firstly, this research used the FAHP and FTOPSIS methods to analyze the decision problem. However, there are several other important MCDM methods that can be used to determine the decision making problem. Secondly, in this study, we identified the green innovation criteria pertaining to the manufacturing sector of China. Therefore, in future research, we could identify and assess more green innovation criteria for some other sectors.