1. Introduction

Global warming is the main driving force for researchers in finding ways to curb greenhouse gas (GHGs) emissions. A growing number of countries are paving ways for sustainable future by turning to renewable energy [

1]. Another source of energy that has been gaining interest globally is hydrogen. The latter has been widely recognised as a future energy carrier due to factors such as being environmental-friendly and consisting of high-energy capacity; it can be synthesised using diverse resources (including renewable energy sources). In the chemical process industries, hydrogen is a common feedstock for ammonia and methanol, as well as for oil refineries [

2]. In addition, hydrogen is a promising fuel source for transportation. Among the various hydrogen production technologies, steam methane reforming (SMR) remains the most well established process for hydrogen production [

3]. It is anticipated that by the year 2030, 40% of the global hydrogen production will be generated via SMR process, dominating other routes such as electrolysis, gasification, and partial oxidation process [

4]. The conventional SMR process utilises natural gas as feedstock and often leads to gigantic GHG emissions, leading to low sustainability [

5]. This drives the research to seek for a more sustainable hydrogen production process, which considers both the environmental aspect as well as the scalability of the process. Hydrogen productions from biological sources, such as biomass or biogas, has received good attention since it is eco-friendly, as compared to the conventional SMR process [

6].

Biogas consists of a large portion of methane, which acts as a good replacement for natural gas. In the seminal work, Hwangbo et al. [

7] proposed a hydrogen production network for South Korea using mathematical programming (MP) approach, in which biogas from wastewater treatment plant is used as the main resource. Alternatively, landfill gas is another potential source for biogas production. In the compacted and covered environment of landfills, anaerobic bacteria decompose the municipal solid waste (MSW), which results in the generation of methane and carbon dioxide [

8]. In the Malaysian context, daily waste generation has been estimated as 0.5–0.8 kg per capita in the rural area, while the amount is double in the urban areas [

9]. Besides, it is predicted that MSW in Malaysia will achieve 31,000 t/d in year 2020, and further increase to 51,700 t/d by year 2025 [

9]. Therefore, there is a need to treat or valorise the landfill gas in order to prevent it from emitting into the atmosphere. It is possible to harness heat and electricity from the produced landfill gas by channelling it to combustion engines or alternator [

10,

11]. In a recent work, Hoo et al. [

12] explored the potential of the integration of bio-methane into existing natural gas grid in Malaysia for power generation. However, due to limitations of the local electricity load demand, the captured landfill gas is under-utilised. Thus, the use of landfill gas for hydrogen generation becomes an attractive option for bio-methane utilisation in Malaysia.

Malaysia is the second largest producer of palm oil in the world, accounting for 39% of world palm oil production and 44% of world exports [

13]. However, the mass production of palm oil further leads to a gigantic generation of oil palm waste, which accounted for about 86% of the total biomass available in the country [

14]. Among the palm oil wastes, palm oil mill effluent (POME) is the largest contributor. Although it is non-toxic, it still poses a severe environmental issue due to its large oxygen depleting capabilities [

15]. Fortunately, due to its high organic content, POME can serve as a prominent source for methane generation via anaerobic digestion (AD). Similar to landfill gas, the generated bio-methane can then be converted into hydrogen through SMR process. Therefore, a bio-hydrogen supply network that incorporates the use of biogas (from landfill and AD process) should be considered to improve the sustainability of the existing network.

Several models have been reported on hydrogen production from biogas sources. Borisov et al. [

16] developed a model that describes the simultaneous production of methane and hydrogen from AD of organic waste. A study by Woo et al. [

17] demonstrated optimal design and operation of four types of biomass in a hydrogen supply chain. In addition, Hwangbo et al. [

6] utilized MP for hydrogen production from biogas under demand uncertainty. On the other hand, Robles et al. [

18] modelled the demand uncertainty in a hydrogen supply network with fuzzy MP. More recently, MP was used to determine a sustainable hydrogen supply network with the consideration of fuelling station planning [

19]. Most of these models are developed using MP, where only a single solution is produced unless further constraints are added to the model [

20]. Besides, model solving with the conventional method becomes progressively difficult as the problem size increases [

21].

A bio-hydrogen network is considerably a large network, as it includes (i) the decision of selecting the feedstock for hydrogen production—either natural gas or biogas obtained through landfill/AD process; and (ii) the decision of locating the compressor sub-stations between the sources and sinks. Therefore, to solve this network problem across a country, a rigorous combinatorial tool called P-graph [

22] is used. P-graph determines and showcases the maximal structure of a given network, and aids in visualising the full network model. It was developed by Friedler et al. [

23] to solve the process network synthesis problem. In general, its feature, which exploits the combinatorial nature of the problem instead of transforming it into a set of equations, is the key advantage of P-graph over other conventional MP approaches [

24]. Coupled with three algorithms [

25] and five axioms [

23] embedded in the P-graph framework, it is capable to perform rigorous combinatorial computation tasks efficiently [

26]. It is capable to provide multiple feasible network structures simultaneously, which had proved invaluable in various works. For instance, Voll et al. [

27] utilised this additional information to yield rational decisions for a given network. Lam et al. [

28], on the other hand, identified the bottleneck of a given technology, while near-optimal criteria weights were considered by Low et al. [

29] during the evaluation of various negative emission technologies. The P-graph framework is explained in depth in

Section 3.

In this works, P-graph approach is utilised to synthesise an optimal bio-hydrogen network, which integrate the use of landfill gas and POME into the conventional hydrogen supply network. This work contributes in: (i) extending the P-graph methodology to solve hybrid bio-hydrogen network that incorporates the use of two biogas sources (landfill gas and POME) in Malaysia; and (ii) evaluating the feasibility of such hybrid hydrogen production network.

The paper is structured as follows. In the following section, a clear problem statement is defined. The research methodology is presented in

Section 3, while the descriptions of the two case studies are presented in

Section 4. The obtained results are then shown and analysed in

Section 5, before the work is finally concluded.

3. Methodology

P-graph is a directed bipartite (multicomponent) graph that represents the structure of a process system [

30]. The direction of the arcs represents the direction of the materials flow in the network of the process system. The method for optimising a complex network has traditionally relied on MP. However, as aforementioned, applying MP for large problems becomes progressively difficult [

31]. Moreover, in some complex cases, MP is time consuming, error-prone and may miss advantageous options. The structural infeasibilities in the evaluated combinations are discovered by the solvers only after evaluating the constraints. Therefore, practical problems often become too complex to solve. In the case where the problem is simplified to be solvable, the resulting formulation is usually no longer representative of the original task [

31]. The P-graph framework [

23] was then been developed to address these combinatorial challenges for optimising process networks. The recent works done by Cabezas et al. [

32] on design and engineering of sustainable process system, Lam et al. [

33] on creating biomass network, and Vance et al. [

34] on designing sustainable energy supply chains are some of the examples that attempted to address supply chain issues using P-graph methodology. P-graph is capable of unambiguously representing process structures for sequential, parallel, and alternative activities. In addition to graphical representation, the P-graph framework provides a set of rigorous and effective algorithms for supply chain network synthesis [

22]. A considerable advantage of the P-graph model is its potential in solving real life industrial problems related to the design of supply chain, while incorporating various process-engineering problems, such as reaction and separation engineering and transportation operations. The P-graph model evaluates the maximal structure and generates feasible optimised results, which can be ranked based on certain parameters, such as cost and energy potential. A general direction of the P-graph is from input materials to operating units and from operating units to its output materials. The vertices used in the P-graph are denoted as operating units and materials. The vertices used for materials have several different types or subsets such as raw materials, which is the input elements of the entire process, product materials, which gather the required input and represents the results of the process, and lastly, the intermediate materials, which are the elements generated or used in between processing phases. Meanwhile, operating units are required to carry out certain tasks in between processing phases [

22]. The applied operating unit and materials element notations in P-graph are represented in

Table 1. The P-graph framework is based on the five axioms below [

23]:

Every final product is represented in the graph.

A vertex of the M-type has no input if and only if it represents a raw material.

Every vertex of the O-type represents an operating unit defined in the synthesis problem.

Every vertex of the O-type has at least one path leading to a vertex of the M-type representing a final product

If a vertex of the M-type belongs to the graph, it must be an input to or output from at least one vertex of the O-type in the graph.

P-graph uses three main algorithms, which are explained below:

Maximal Structure Generation (MSG): This algorithm identifies the maximal structure of the network, which is based on five axioms and represents the union of all possible networks [

26].

Solution Structure Generation (SSG): This algorithm determines all combinatorial feasible networks, which are the subsets of maximal structure [

25].

Accelerated Brand and Bound (ABB): This algorithm optimises the network efficiently, which excludes search of infeasible and redundant network structures. As a result, both the search space and computational effort are typically reduced, significantly, compared to the conventional branch-and-bound algorithm [

35].

The detailed explanation and demonstration of the P-graph framework is given in the following subsections.

3.1. Development of P-Graph Model for Large-Scale Bio-Hydrogen Network

In the process to produce bio-methane, the captured landfill gas goes through biogas upgrader to increase its purity. The clean bio-methane is then compressed and transported through pipelines to the suitable substation for further recompression. The bio-methane flows through the pipelines and is delivered to hydrogen sinks. Finally, the collected gas will be fed into SMR to produce hydrogen. On the other hand, POME sources also follow the similar path as landfill gas with a small difference that POME source will be converted into bio-methane via AD instead of being fed to biogas upgrader. P-graph framework is utilised to obtain the most economically feasible route that can fulfil the demand of the hydrogen sinks. The procedure for the bio-hydrogen network synthesis follows the flowchart illustrated in

Figure 2. To apply the P-graph approach, various information has to be pre-determined and specified (see detailed information in case study section).

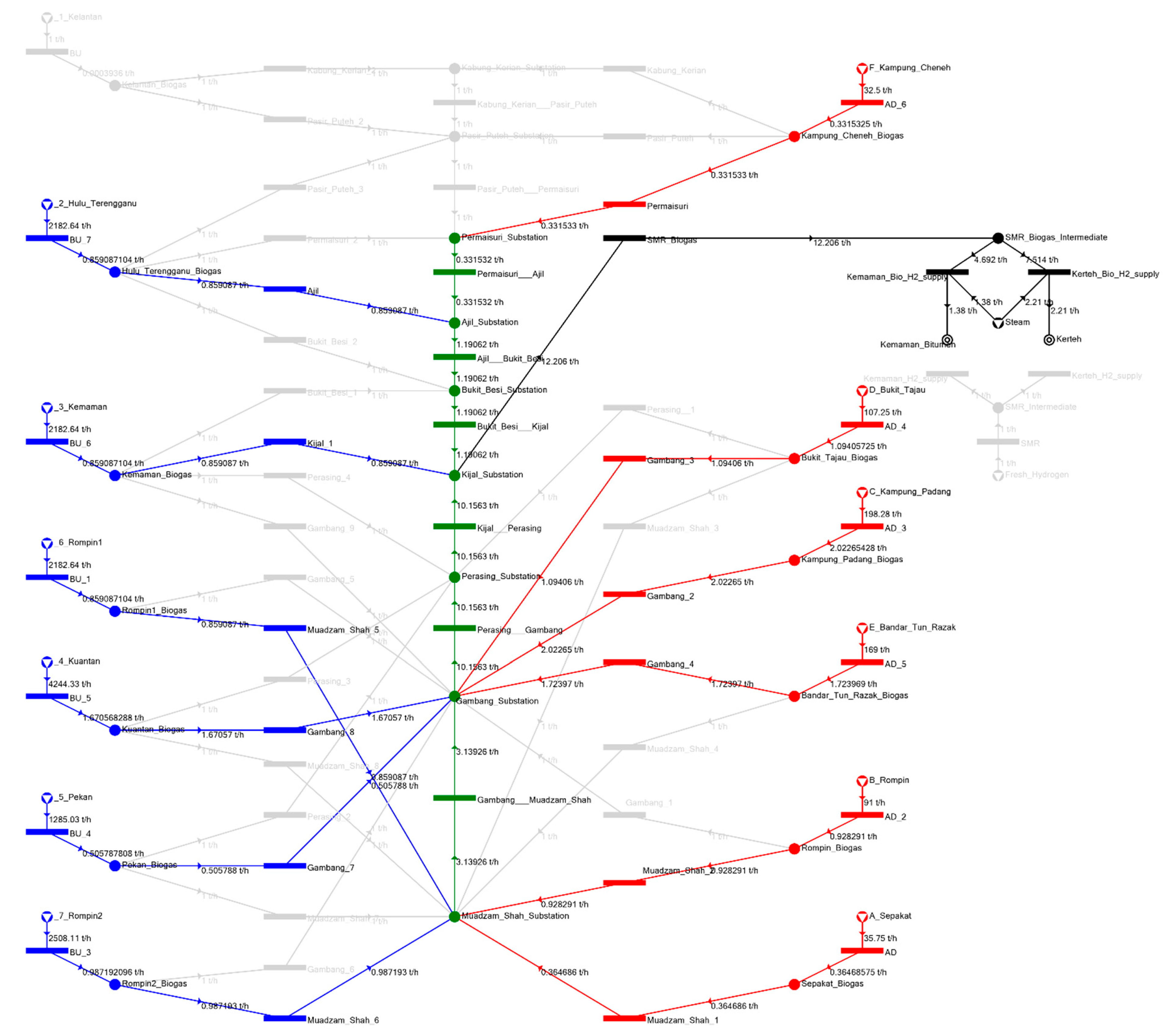

As the initial step, the available landfill and POME sites are identified (Layer 1). As shown in

Figure 3, the sources (in green) are connected to biogas upgraders (BGUG) or AD in order to produce bio-methane (Layer 2, in orange). The investment and operating costs of BGUG and AD are the input of its operating unit. The generated bio-methane is represented as the M-vertex (in blue), while the conversion ratio of landfill gas to bio-methane and POME to bio-methane are defined along the corresponding arcs. The second operating unit (in purple), accounts for the compressor and pipeline costs for sending bio-methane to the substations (Layer 3).

To ensure that bio-methane flows through the pipelines optimally, it must be periodically compressed and pushed through the pipeline (see

Figure 4). Thus, each bio-methane source is connected to several substations located within an 80 km radius distance from the source [

36]. P-graph will then decide what substation the bio-methane should be delivered to, based on the overall operating and capital costs. Note that the compressor and pipeline costs are input to the O-vertex (in maroon; Layer 4). From

Figure 4, “Substation 6” is served as the last substation that is located near to the hydrogen sink. In other words, bio-methane collected from the South region will be transferred upwards, while the bio-methane collected from the North region will be delivered downward, in order to approach this “final station”. Note that the substation arrangement shown in

Figure 4 is merely an illustrative example. It can be changed according to the specific case study.

Finally, the collected bio-methane will be distributed to the hydrogen sinks. For illustration purposes, four hydrogen demand sites are shown in

Figure 5. The distribution of bio-methane to each demand site is determined by P-graph. Note that the grey O-vertex represents the SMR processes, which convert the bio-methane into bio-hydrogen (Layer 5). In the case where the produced bio-hydrogen is insufficient to cover the hydrogen demand, fresh hydrogen from conventional fossil fuel (i.e., brown M-vertex) can be purchased from third parties. Note that the model might decide not to produce bio-hydrogen if the fresh hydrogen from conventional fossil fuel is much cheaper (Layer 6).

3.2. Model Formulation

This section summarises the mathematical formulations that are embedded in the constructed P-graph model.

3.2.1. Network Design

Equation (1) describes the demand of hydrogen (

, t/h) in each sink

. The hydrogen demand of the latter can be fulfilled by fresh hydrogen (

, t/h) and/or produced bio-hydrogen (

, t/h). The latter can be mathematically expressed as Equation (2):

where

refers to the flowrate of bio-methane sent to hydrogen sink

j from substation

l (t/h); while

represents the methane-to-hydrogen conversion ratio (kg CH

4/kg H

2).

Equations (3) and (4) express the mass balance constraint across the sources, where

(t/h) and

(t/h) denote the bio-methane generated from landfill source

i and POME source

k respectively; while

(t/h) and

(t/h) refer to the methane flowrate sent from each source to substation

l.

On the other hand, the mass balance across the substations is presented in Equation (5), where

refers to the methane flowrate transported from substation

l to another substation

l’ (t/h).

Next, the conversion of landfill gas and POME to bio-methane modelled in P-graph can also be expressed mathematically. Due to the corrosive nature of landfill gas impurities, it is essential to improve methane purity via the biogas-upgrading unit prior to its delivery to the compressor substation. In this work, a high-pressure water scrubber is used as the biogas-upgrading unit. Water scrubbing can remove carbon dioxide and hydrogen sulphide since these components are more soluble in water than methane [

37]. Depending on the type of waste available in the landfill site, landfill gas (

, in t/h) generally contains 50–60 volume% methane [

12]. Therefore, the methane capacity in each source

i can be assumed as follows:

where

refers to the landfill gas-to-bio-methane conversion in terms of mass flowrate (wt.%). On the other hand, POME can be converted into bio-methane via AD process. Its conversion can be formulated as Equation (7):

where

refers to the available POME capacity in source

k (m

3/h); while

refers to the conversion ratio of AD process (t CH

4/m

3 POME).

3.2.2. Objective Function

The main objective of the model is to determine a bio-hydrogen network with minimum total annualised cost (

,

$/y). It is generally the sum of annual operating cost (

,

$/y), annualised investment cost (

,

$/y) and annual raw material cost (

,

$/y), given as in Equation (8).

where

is the product of the operating cost (

,

$/y) and annual operating hours (

), given as in Equation (9). Note that

encompasses of the operating cost of the involved operating units (Equation (10)):

where

,

,

and

refer to the unit operating costs for biogas upgrader (

$.h/t), AD (

$.h/m

3), compressor(

$.h/t), and SMR (

$.h/t)units respectively.

The

(

$/y), on the other hand, is a ratio of total investment cost (

,

$) over the life span of the plant (

).

The

(

$/h) considers the investment costs of biogas upgrader (

,

$/h), AD (

,

$/h), compressor (

,

$/h), pipeline (

,

$/h), and the SMR process (

,

$/h). These parameters can be computed using Equations (12)–(17):

where

,

,

,

, and

refer to the unit operating costs for biogas upgrader (

$/t), AD (

$/m

3), compressor (

$/t), SMR (

$/t), and pipeline (t/km), respectively.

The

(

$/y) in Equation (8) is a product of total flow rate of external hydrogen supply (

, t/h), its unit cost (

,

$/t H

2), and

.

The above is an LP model, which may be solved to achieve global solution, if the solution exists.