Minimize the Route Length Using Heuristic Method Aided with Simulated Annealing to Reinforce Lean Management Sustainability

Abstract

1. Introduction

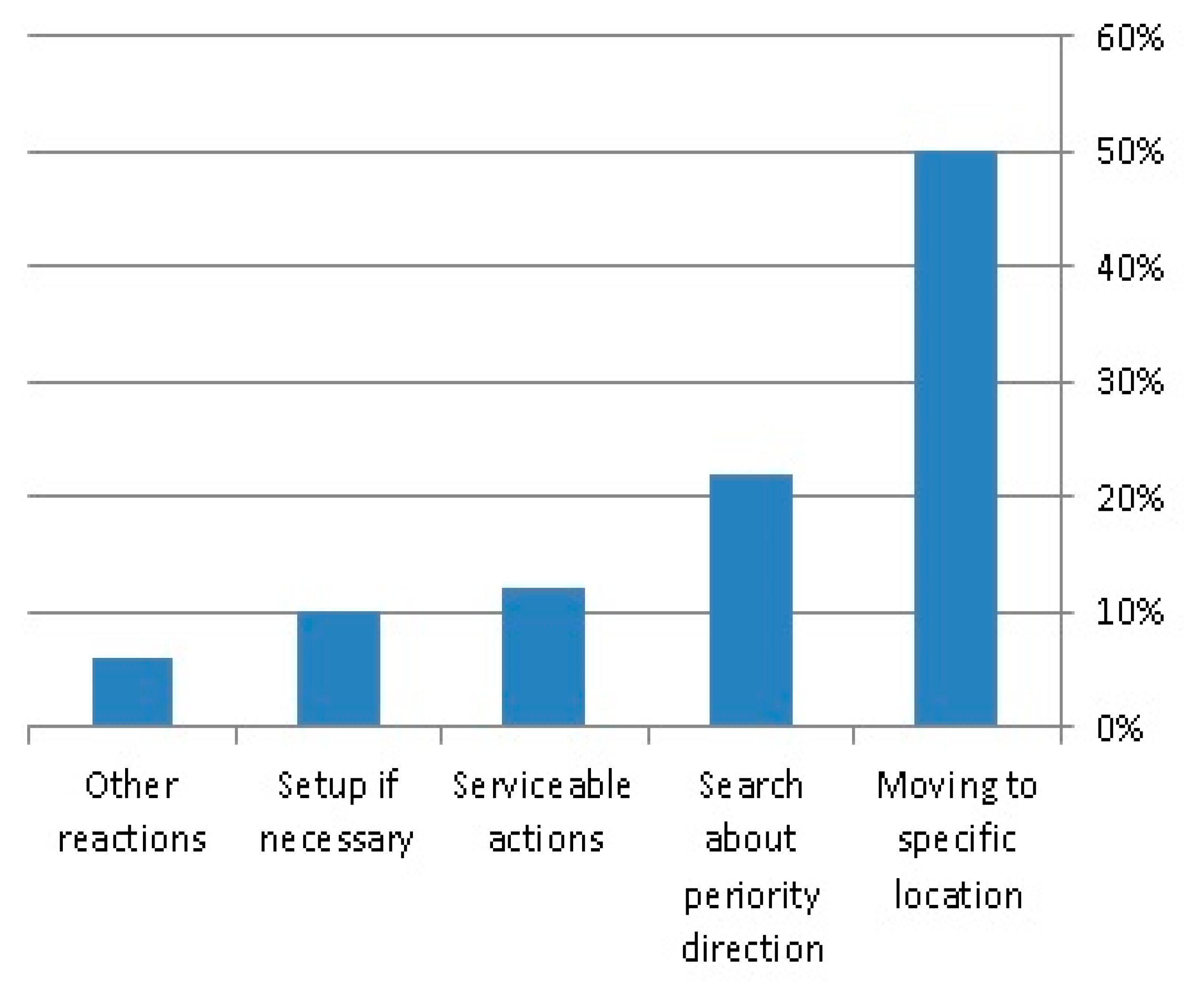

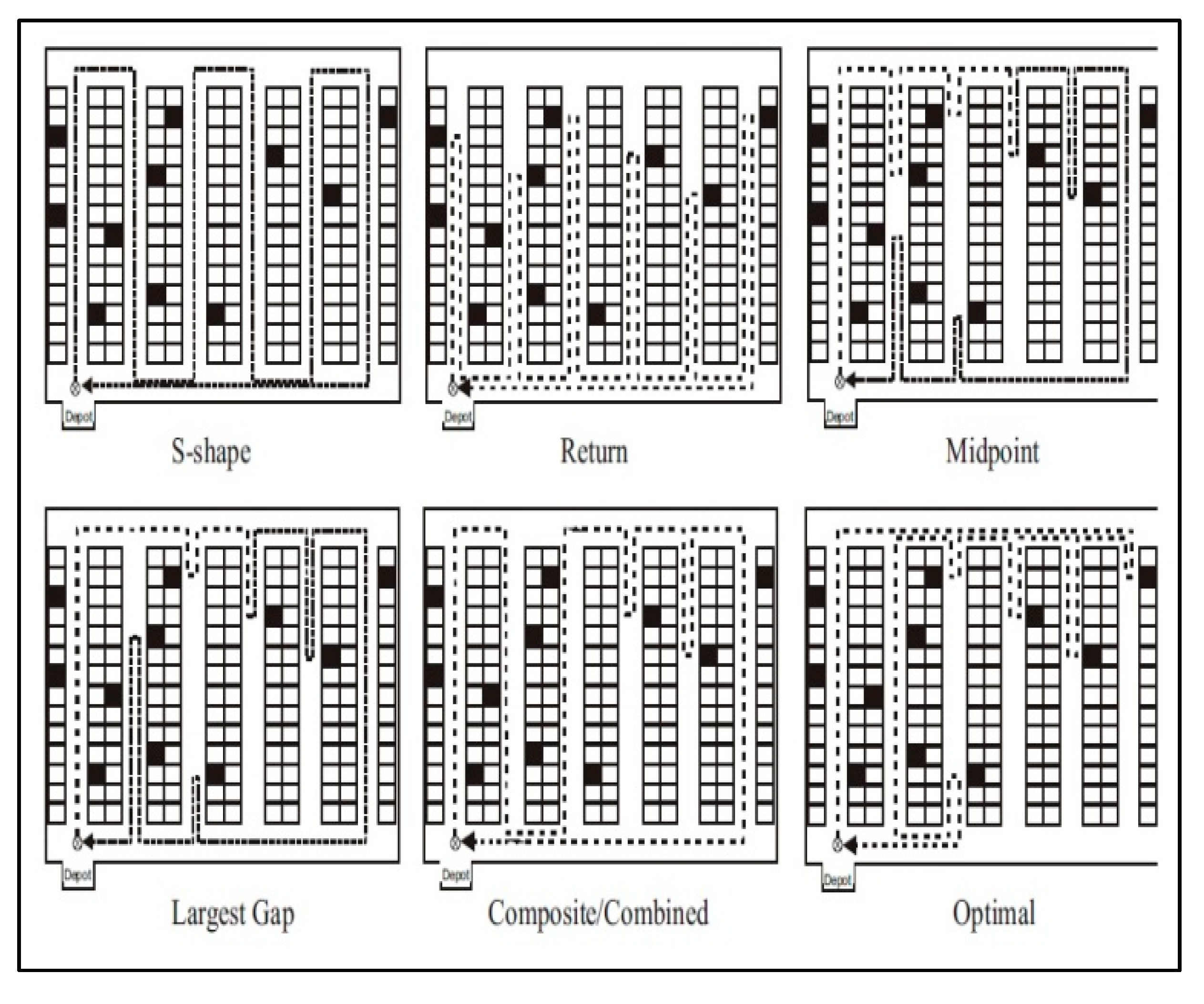

2. Serviceable Sequence Actions for Route Direction

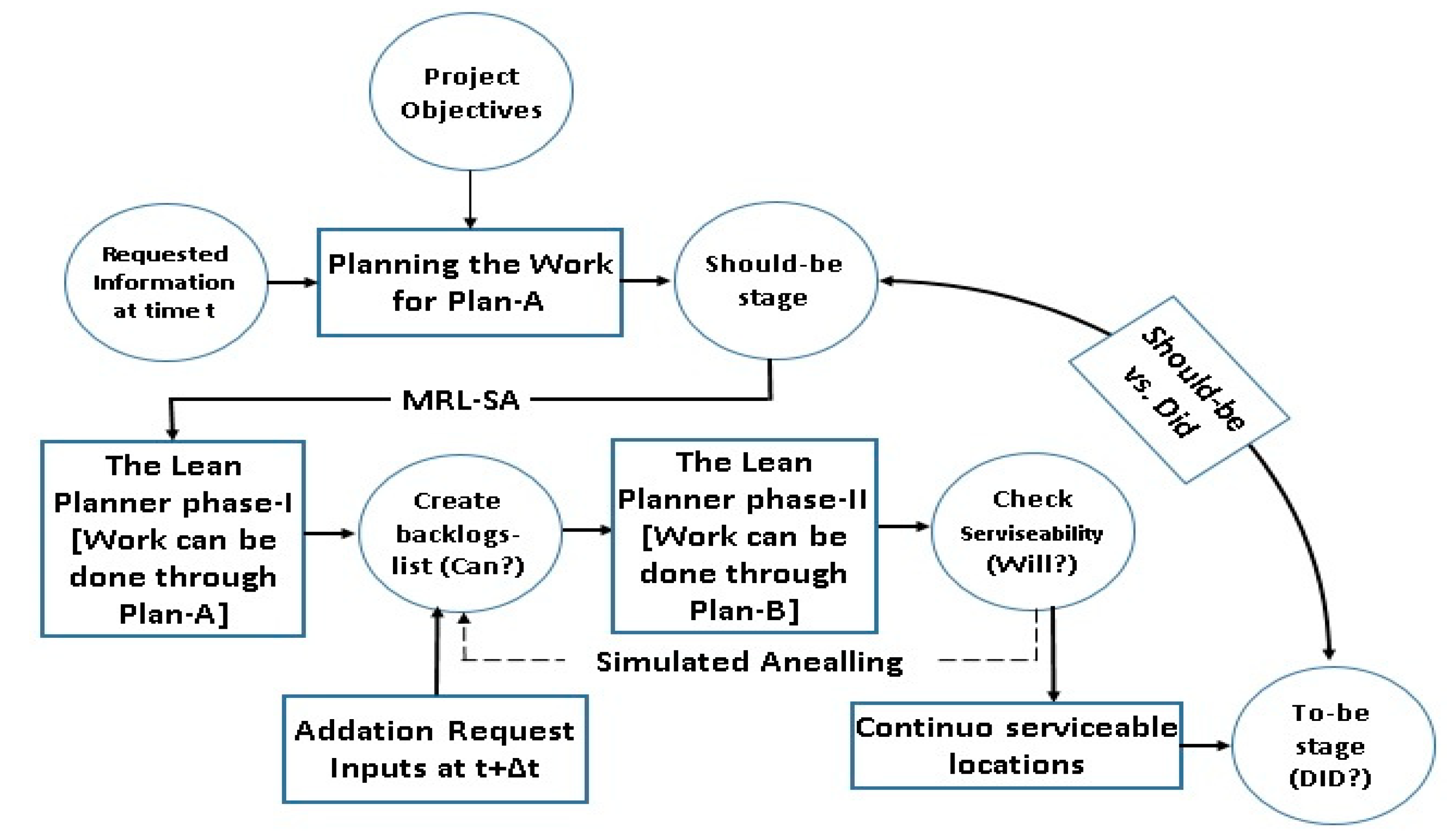

3. Problem Statement in Lean Planner System

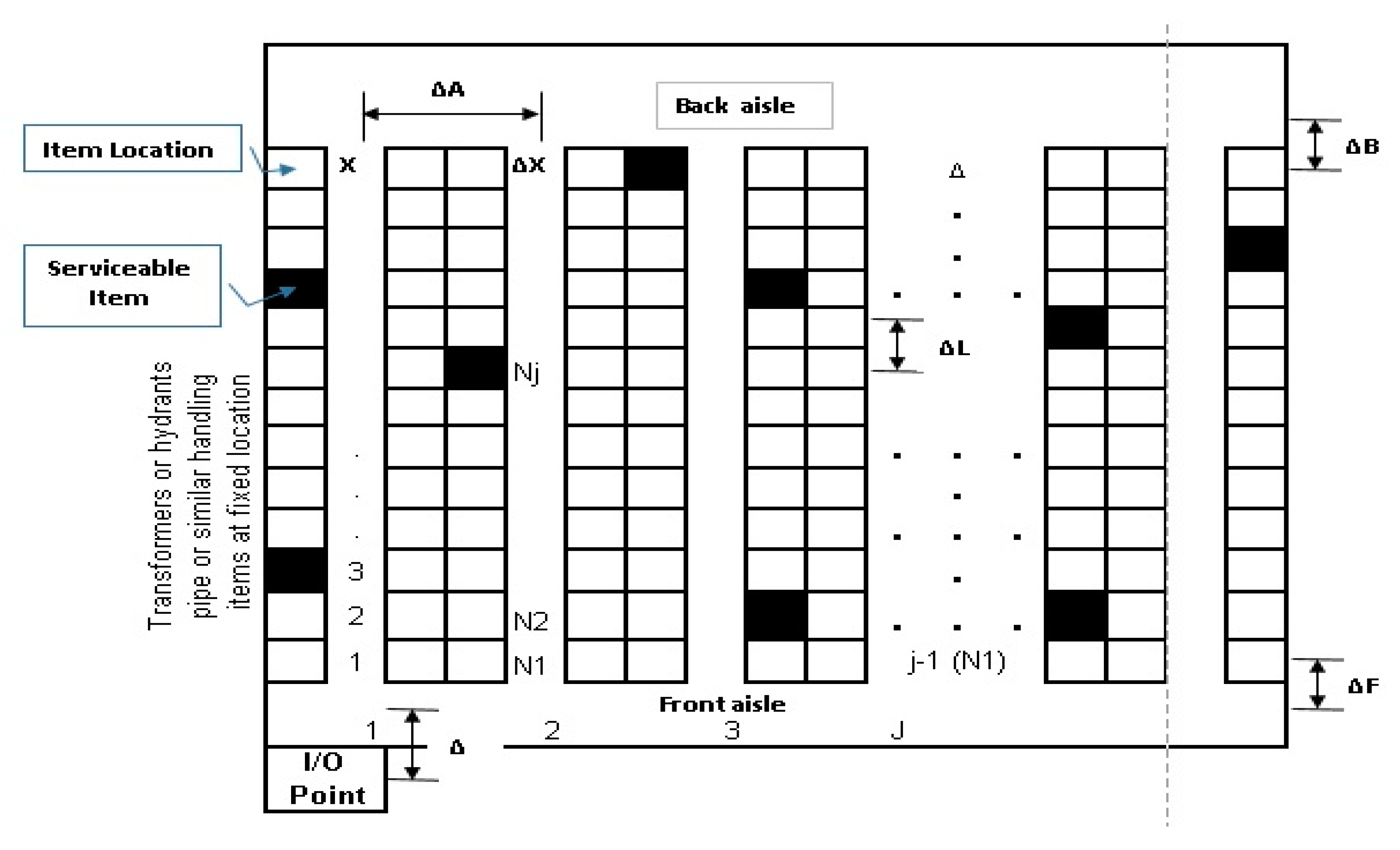

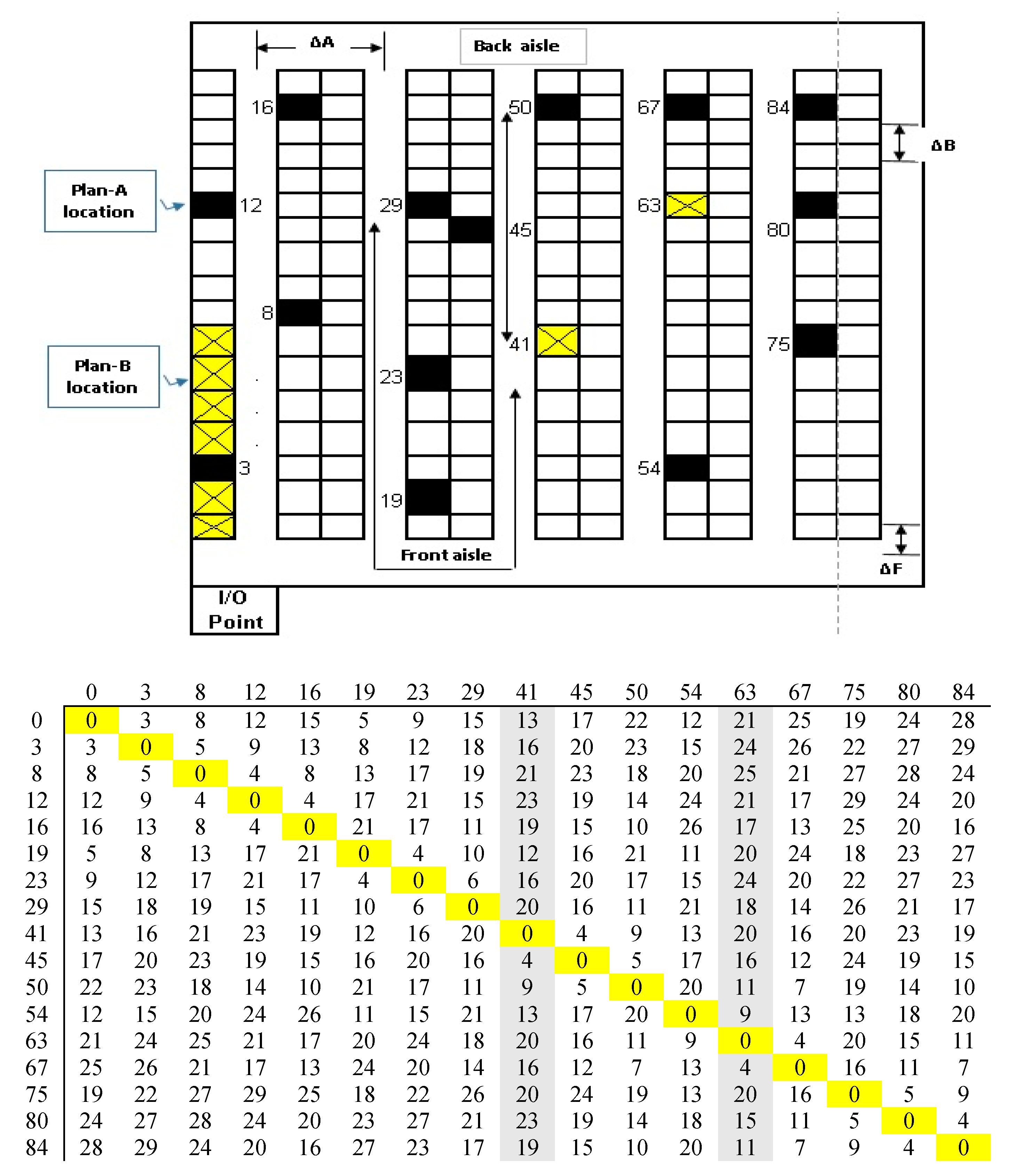

3.1. Structure and Layout

| Shape: | Rectangular |

| Number of blocks: | 2 < X < 2000 |

| Main source point location: | Lower left corner |

| Avenue width: | As OSHA instructed |

| Service assignment: | Random/proposed |

| Proposed policy: | Single or groups |

| Zoning: | None |

| Proposed system: | Stochastic and dynamic |

| or Electrical transformers, hydrants valves, etc. | |

The Layout Assumption

3.2. Parameters of Proposed Cost Analysis Plan for Branching Case

- Cost of distance drilling (route length) to item locations in Plan-A requested.

- Cost of distance drilling (route length) to item locations in Plan-B that executes through Plan-A and in its route.

- Cost of distance drilling for disposing locations that serviced plan-A or were canceled during Plan-B.

- Item processing cost to serviceable at locations in plan-A for requested list L at period t.

- Item processing cost to serviceable locations appeared at plan-B, if in the same proposed route.

- Item backlogging cost to serviceable locations at plan-B after finishing Plan-A.

- Number of locations of plan-A at the beginning of the proposed planning horizon at time (t).

- Number of locations of plan-B at the beginning of the proposed planning horizon at time (t’).

- Uncertain number of locations in plan-B and serviceable or hybrid at plan-A in period t + Δt.

- Estimate of the mean number of + locations updated to serviceable in period t.

- Maximum deviation from the mean published number of locations updated to serviceable in period t.

- Uncertain serviceable locations’ requested for the list L in period t.

- Estimate of the mean requested list L in period t.

- Maximum deviation from the mean requested list L in period t.

- Maximum number of uncertain requested and uncertain (re)request # of locations (route length) that can simultaneously deviate from their mean (i.e., ) until the end of period t.

Decision Variables

- # of serviceable locations that are distributed in period t of Plan-A.

- # of serviceable locations at Plan-B that is updated of Plan-A in period t’.

- # of disposed items from the list L in period t’ due to cancelation or against cost analysis step and backlogged to end of the route activities.

- # of backlogging locations for requested all locations at the end of period t of Plan-A and Plan-B.

3.3. The Contribution of This Study

- 1-.

- Proposed new routing heuristic method [23] to avoid demurrage and control those costs.

- 2-.

- Investigating the impact of proposed regions on the performance of routing heuristics.

- The traversed distance (backtrack), the current avenue to the back avenue, then going to the next serviceable location .

- The distance if the returned to the front avenue, then going the next serviceable location.

3.4. Cost Analysis Formulation

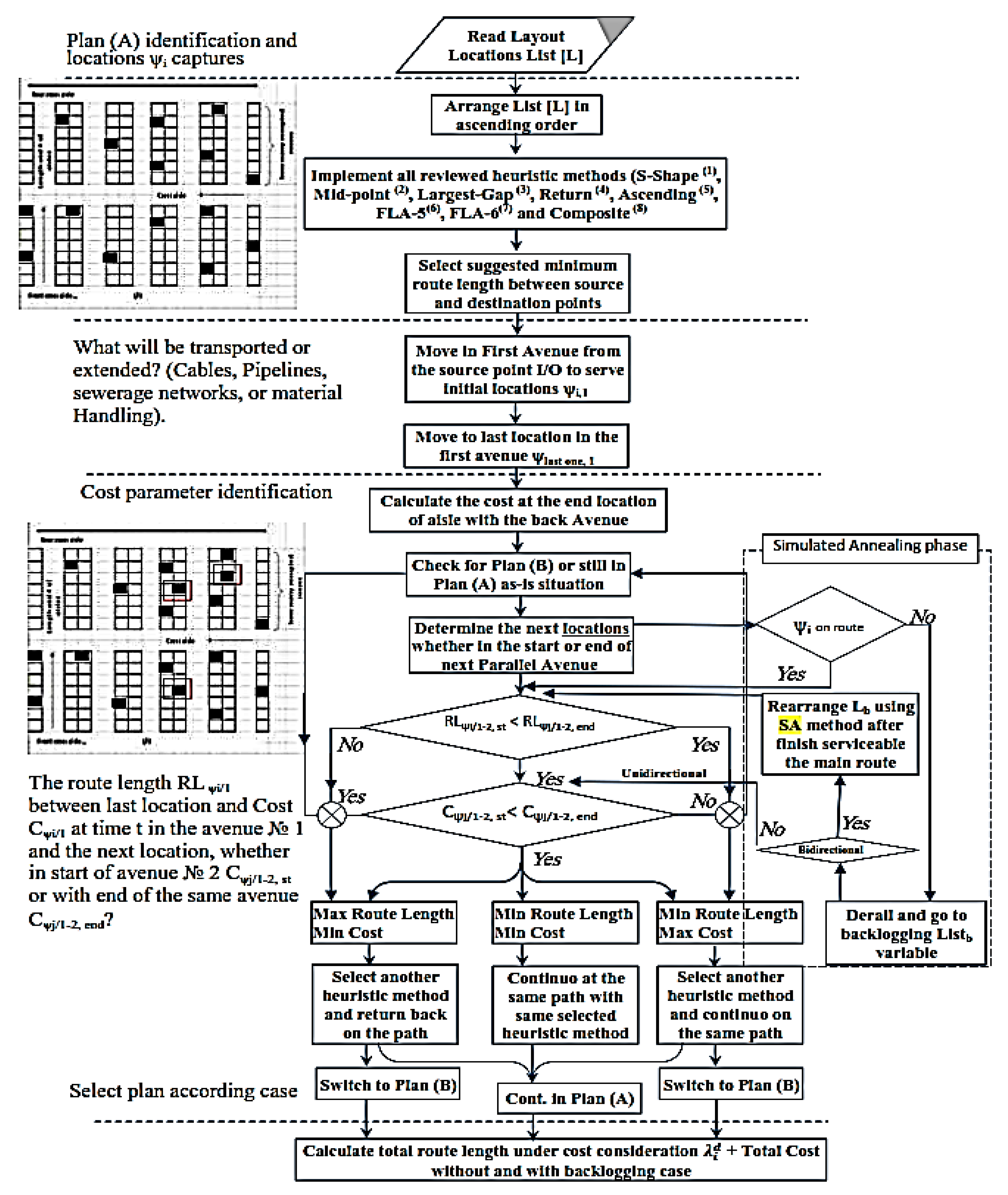

4. Lean Planner System-Phase I [Proposed MRL Heuristic Method]

| Step1: | Arrange the requested list L of (Plan-A) according to the serviceable locations in an ascending according to specific layout. |

| Step2: | The route starts from the feeding source point to the first location in L |

| Step3: | The serviceable all in (Plan-A) list is subject to one of previous published methods (such as: S-Shape, Mid-point, Return, L-Gap, Return, Composite or Ascending) and uses the same method that have minimum route to service in (Plan-B) that id in the same proposed direction and stops at the last one in the last avenue, then goes to step 10. |

| Step4: | Resolve serviceable (which are on the proposed route) items in (Plan-B) and considers last is the starting point, and keeps the previous calculated distance route in variable via the same published method stated in step 3. |

| Step5: | If there are not on the proposed route, a backlogs list is created for them |

| Step6: | is the distance between the current location I and m, where m is the first serviceable location in the next avenue, according to the list L of (Plan-A). is the distance between the current location j and n, where n is the last serviceable location in the next avenue, according to the list L of (Plan-B), which is based on resolving the new distribution of serviceable on the same route. |

| Step7: | If the is not on the (Plan-A) route, and needs to reverse its direction, it must be subject to the step 7 analysis. |

| Step8: | If , select (Plan-A) items branch and neglect (Plan B) items to backlogging after completing all (Plan-A) proposal items , or carry out hybrid modification of items into (Plan-B) and merge the suggested routes. |

| Step9: | If min [( > + )] < y, reverse the sequence of the next avenue in list L. |

| Step10: | Continue serviceable the next item in L, then go to step 3 again. |

| Step11: | Go back to the front avenue, then go to the feeding source point. |

4.1. Performance Measure

4.2. Illustrative Example for implementing MRL-SA ( Distribution)

4.2.1. Lean Planner System—Phase-I: Route Based on the Proposed MRL Heuristic

- Step1:

- Arrange the locations list in an ascending order L = (3, 8, 12, 16, 19, 23, 29, 45, 50, 54, 67, 75, 80, 84)

- Step2:

- The plan aims to go from the feeding source point to the location (the distance = 3 units)

- Step3:

- The plan aims to service all in the current avenue, and stop at the last in the same avenue in this illustrative example (the distance = 3 + 5 + 4 + 4 = 16 units).

- Step4:

- Calculates the distance between the location (, ), which is 20 units, and (, ), which is 10 units to arrive at the same location (Plan-A). [Take into account costs analysis equations]

- Step5:

- The direction will reverse locations in this avenue because 10 < 20, and go to location (the total distance = 16 + 10 = 26 units).

- Step6:

- The proposed plan will collect from locations , , and the total travelling distance at end of this avenue is = 16 + 10 = 26 units.

- Step7:

- At t’, the location is added to the layout and placed on the track route. Therefore, there is no need to use cost analysis equations and continue with the MRL method.

- Step8:

- Calculates the distance between locations (, ), which is 11 units, while the distance between (, ) is 20 units. [Take into account costs analysis equations]

- Step9:

- The track route will follow the ascending arrangement and go to location 4, because 11< 20. Therefore, the travelling distance = 37 + 11 = 48 units.

- Step10:

- The track route will collect from the locations , , and continue on route (the total distance = 48 + 4 + 5 = 57 units).

- Step11:

- Calculates the distance between locations (, ), which is 21 units, while (, ) is only six units. [Take into account costs analysis equations]

- Step12:

- The direction will reverse the ascending arrangement, because 6<21, and go to location (the route distance = 57 + 6 = 63 units).

- Step13:

- At t’, location is added to layout (Plan B), but not effects on direction because it between two terminal locations (, ). Therefore, this location will be serviced on the track route.

- Step14:

- The proposed route will serve locations , , , and the route distance will reach = 65 + 4 + 9 = 78 units.

- Step15:

- Calculates the distance between the locations (, ), which is 12 units, while (, ) is 19 units. [Take into account costs analysis equations]

- Step16:

- The route will follow the ascending arrangement, because 12 < 19, and go to location . Therefore, the route distance = 78 + 13 = 91 units.

- Step17:

- The proposed plan will collect from locations , , and the total route distance = 91 + 5 + 4 = 100 units.

- Step18:

- The proposed route direction will return to the front avenue and back to the main upstream source distance = 100 + 16 = 116 units.

- Step19:

- The proposed route will return to the feeding source point and the route distance = 116 + 12 = 128 units.

4.2.2. Lean Planner System Phase-II: Backlogs List Tackling Via SA

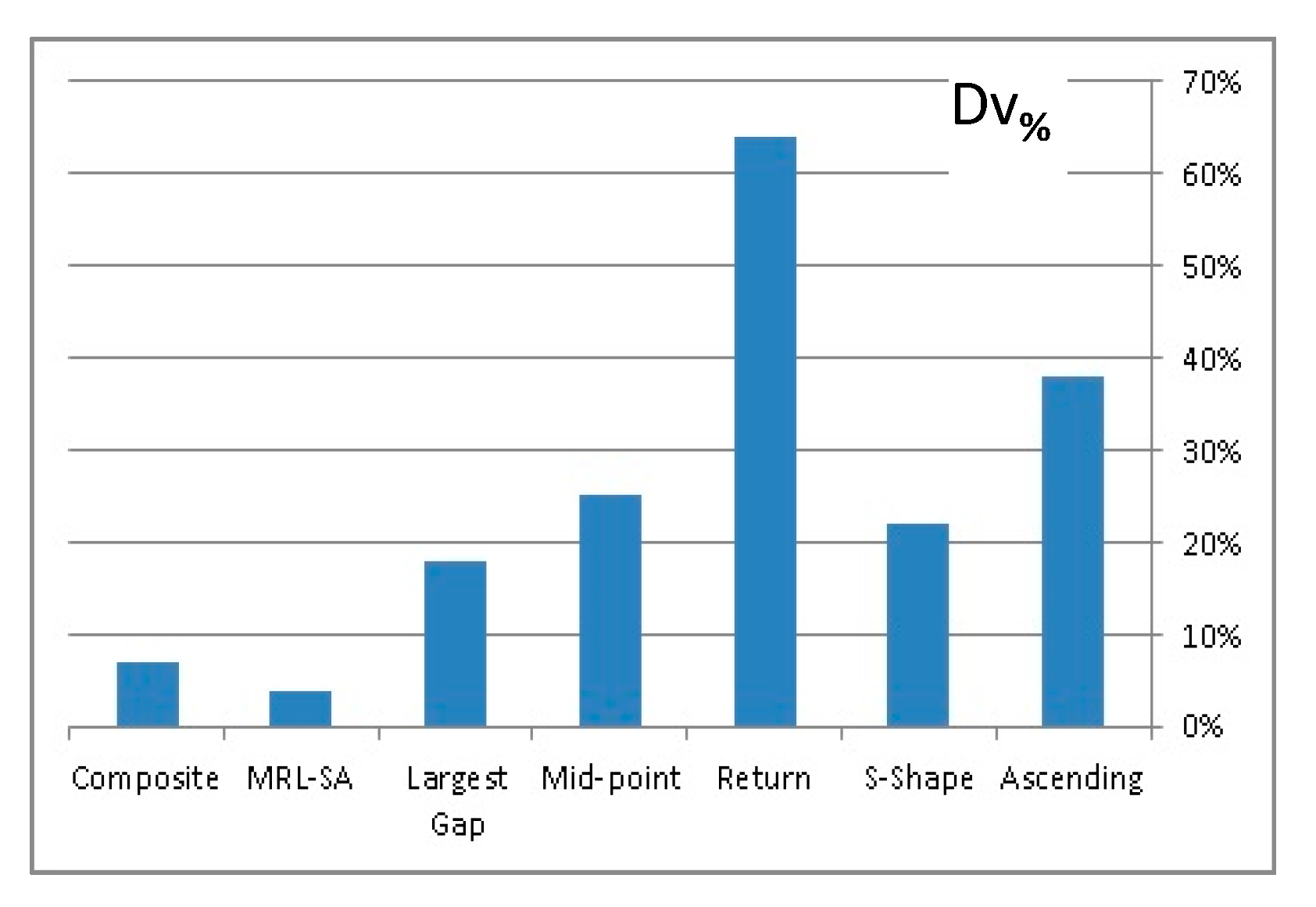

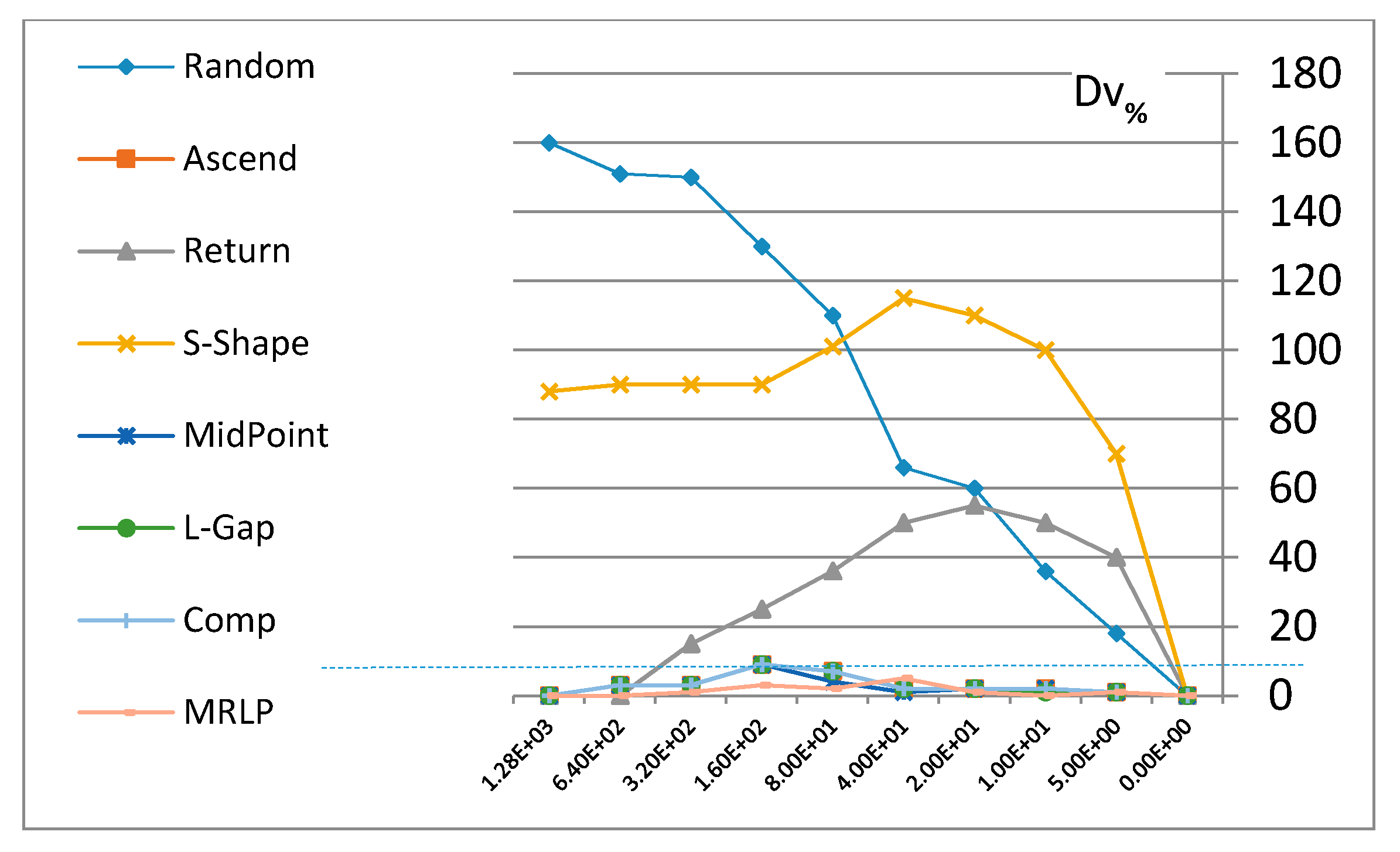

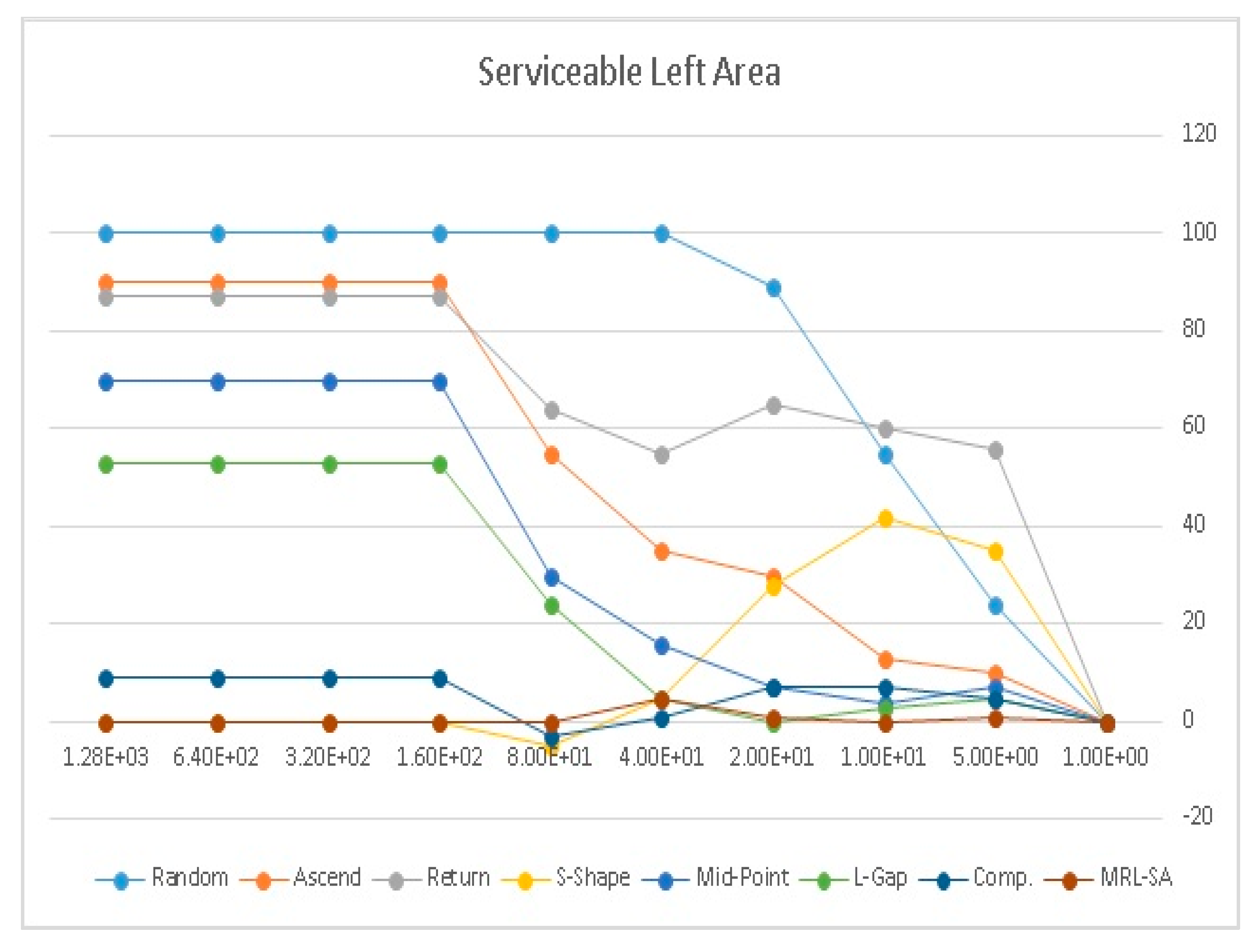

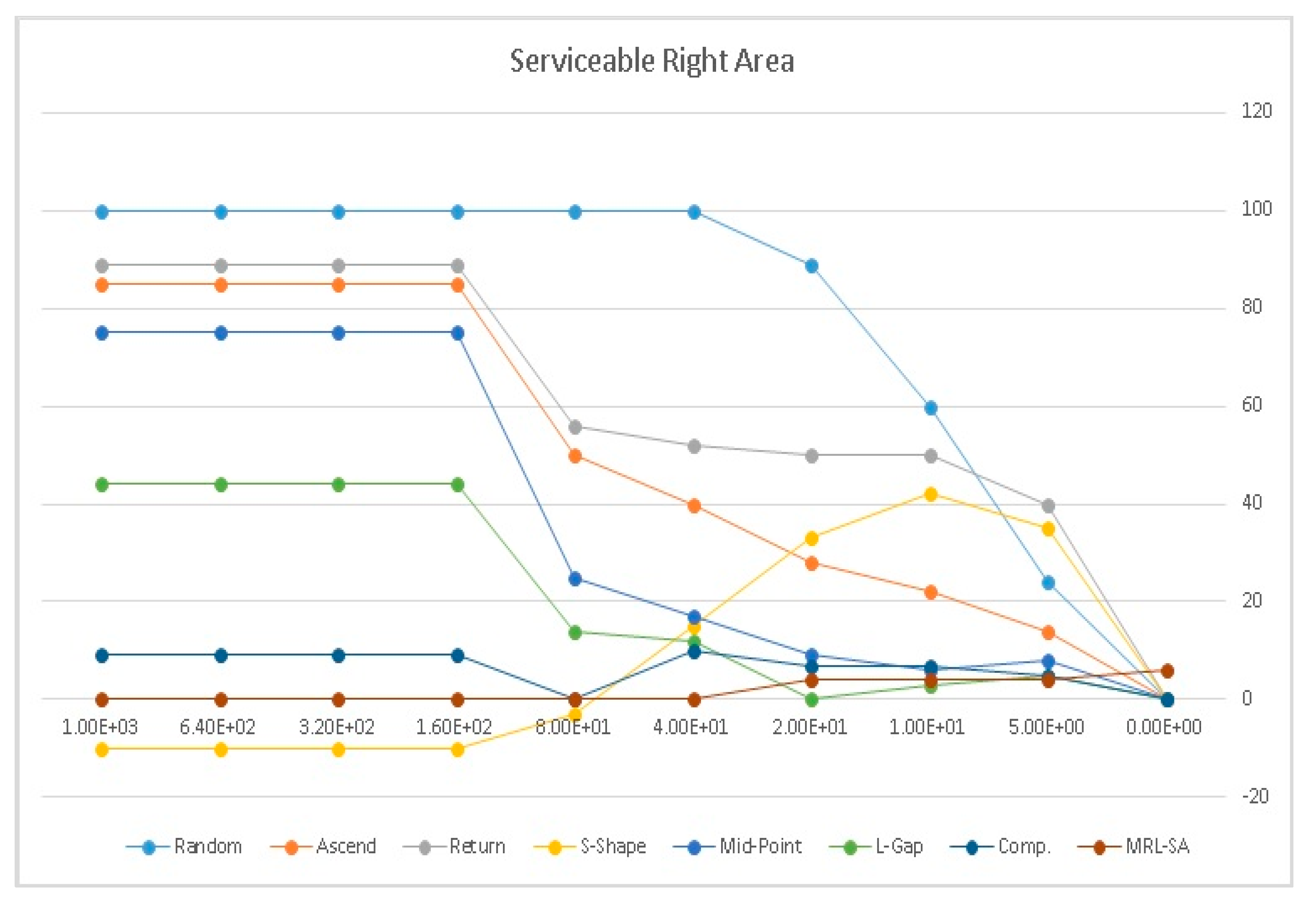

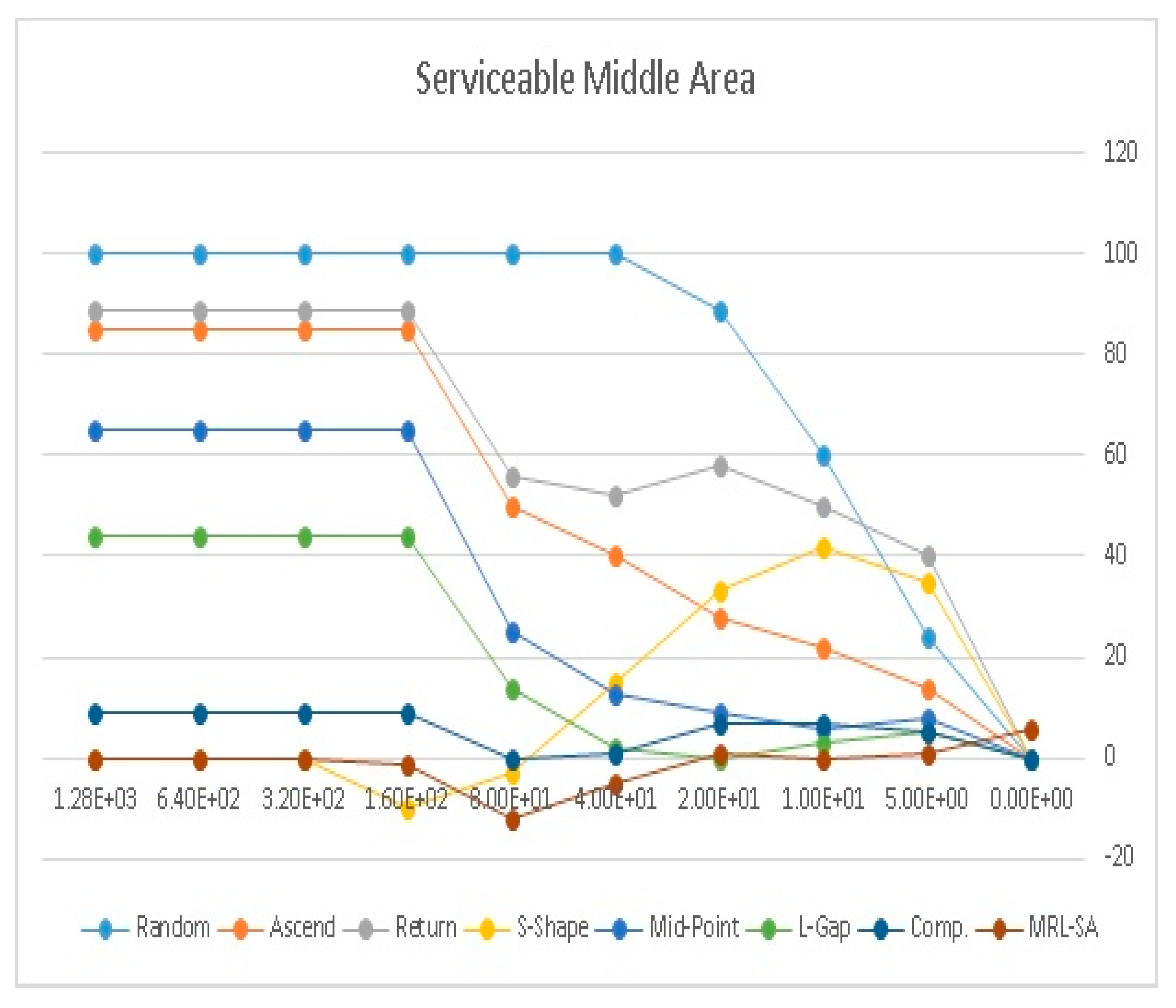

5. MRL-SA Verification

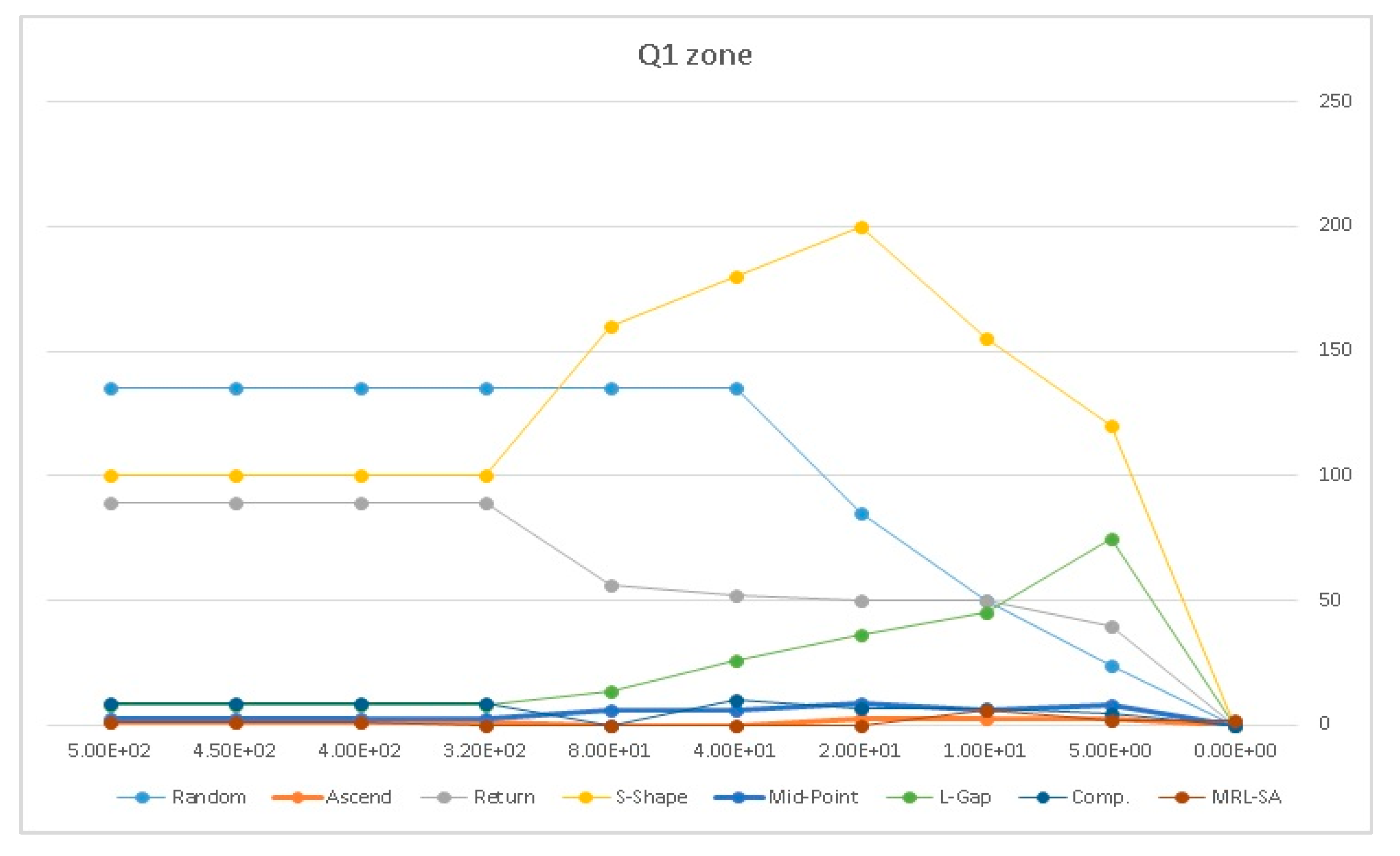

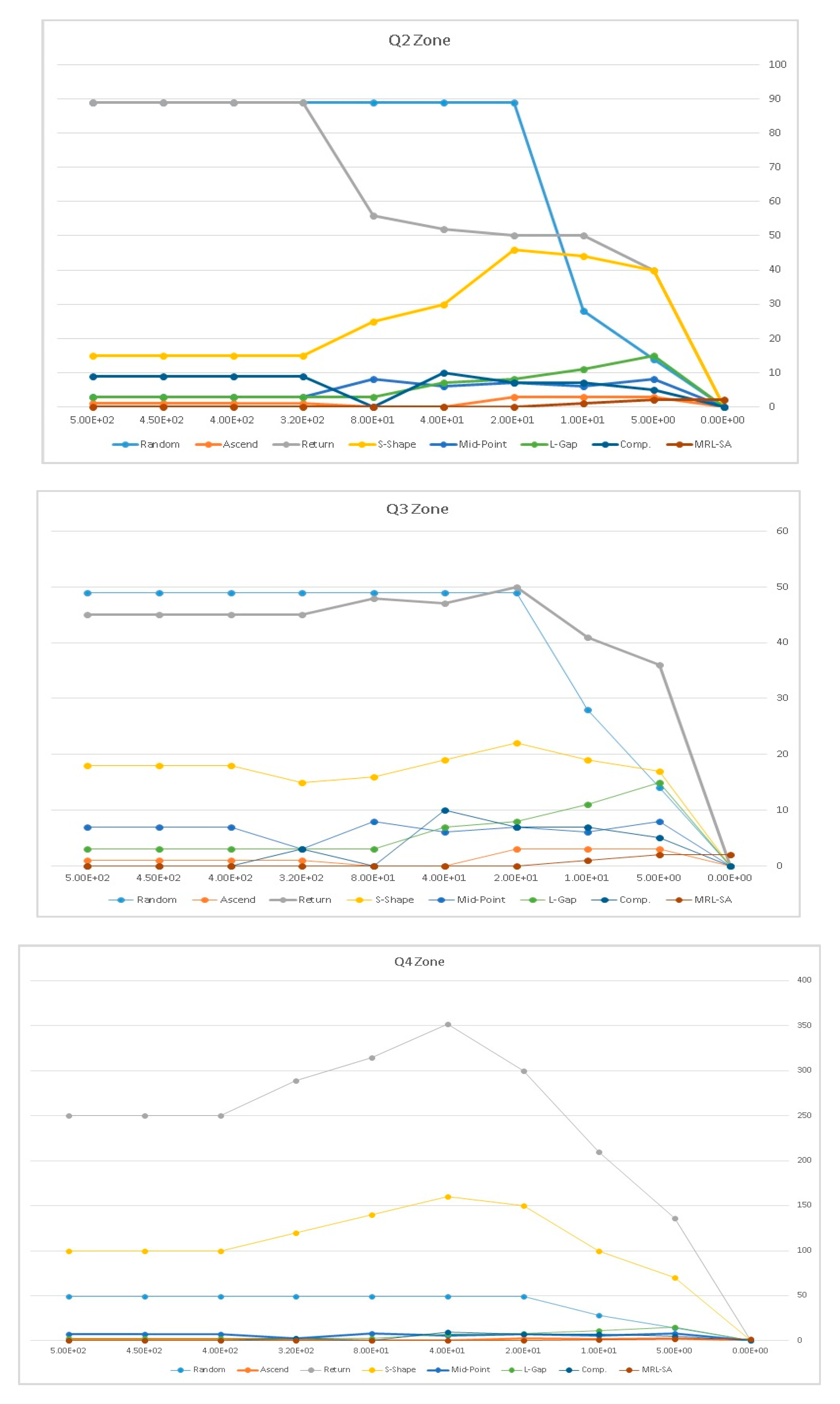

Computational Verification Results

6. Conclusions

7. Future Work

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Alshaimi, A.; Koskela, L. “Critical Evaluation if the Previous Delay Studies in Construction”. Proceedings of BuHu 8th International Postgraduate Research Conference, Prague, Czech Republic, 26–27 June 2008; Czech Technical University: Prague, Czech Republic, 2008. [Google Scholar]

- Azevedo, S.G.; Carvalho, H.; Duarte, S.; Cruz-Machado, V. Influence of Green and Lean upstream suplly chain management practices on business sustainability. IEEE Trans. Eng. Manag. 2012, 59, 753–765. [Google Scholar] [CrossRef]

- Remon, F.A.; Sherif, M.H. Applying lean thinking in construction and performance Improvement. Alex. Eng. J. 2013, 52, 679–695. [Google Scholar]

- Mohammad, H.E.; Islam, A.; Yasmine, A. A heuristics-based solution to the continuous berth allocation and crane assignment problem. Alex. Eng. J. 2013, 52, 671–677. [Google Scholar]

- Dassonville, L. Handbook for Implementing a Quality Management System in a National Mapping Agency. World Wide Web. Available online: http://www.eurographics.org/sites/default/files/handbook_V1.pdf (accessed on 10 January 2016).

- Laila, M.; Khodeir, R.O. Examining the interaction between lean and sustainability principles in the management process of AEC industry. Ain Shams Eng. J. 2018, 9, 1627–1634. [Google Scholar]

- Rodriguez, D.; Buyens, D.; Van Landeghem, H.; Lasio, V. Impact of lean production o n perceived job autonomy and job satisfaction: An experimental study. Hum. Factors Ergon. Manuf. Serv. Ind. 2016, 6, 159–176. [Google Scholar] [CrossRef]

- Cherrafi, A.; Elfezazi, S.; Chiarini, A. The integration of lean manufacturing, Six Sigma and sustainability: A literature review and future research directions for developing a specific model. J. Clean. Prod. 2016, 139, 828–846. [Google Scholar] [CrossRef]

- Brandstنtter, G.; Kahr, M.; Leitner, M. Determining optimal locations for charging stations of electric car-sharing systems under stochastic demand. Transp. Res. Part B 2017, 104, 17–35. [Google Scholar] [CrossRef]

- Jayawickrama, M.; Jayatilaka, P.R.; Kulatunga, A.K. Investigation of Level of Adaptation of Sustainability Concepts in Local Manufacturing Sector: A Case Study. In Proceedings of the 2nd Roundtable on SCP, Colombo, Sri Lanka, 21–22 February 2013. [Google Scholar]

- Ozcelik, F.A. Hybrid genetic algorithm for the single row layout problem. Int. J. Prod. Res. 2012, 50, 5872–5886. [Google Scholar] [CrossRef]

- Lenin, N.; Siva Kumar, M.; Islam, M.N.; Ravindran, D. Multi-objective optimization in single row layout design using a genetic algorithm. Int. J. Adv. Manuf. Technol. 2013, 67, 1777–1790. [Google Scholar] [CrossRef][Green Version]

- Chen, R.; Qian, X. Optimal charging facility location and capacity for electric vehicles considering route choice and charging time equilibrium. Comput. Oper. Res. 2020, 113, 104776. [Google Scholar] [CrossRef]

- Lenin, N.; Kumar, M.S.; Ravindran, D.; Islam, M.N.A. Tabu search for multi objective single row facility layout problem. J. Adv. Manuf. Syst. 2014, 13, 17–40. [Google Scholar] [CrossRef]

- Iliya, M. Waste collection inventory routing with non-stationary stochastic demands. Comput. Oper. Res. 2020, 113, 104798. [Google Scholar]

- Wang, W. Robotics and Computer Integrated Manufacturing. Robot. Comput. Integr. Manuf. 2020, 61, 101849. [Google Scholar] [CrossRef]

- Brevet, D. A dial-a-ride problem using private vehicles and alternative nodes. J. Veh. Routing Algorithms 2019, 2, 89–107. [Google Scholar] [CrossRef][Green Version]

- Benkebir, N. On a multi-trip vehicle routing problem with time windows integrating European and French driver regulations. J. Veh. Routing Algorithms 2019, 2, 55–74. [Google Scholar] [CrossRef]

- Gagarin, A.; Corcoran, P. 2018. Multiple domination models for placement of electric vehicle charging stations in road networks. Comput. Oper. Res. 2018, 96, 69–79. [Google Scholar] [CrossRef]

- Wu, F.; Sioshansi, R. A stochastic flow-capturing model to optimize the location of fast-charging stations with uncertain electric vehicle flows. Transp. Res. Part D 2017, 53, 354–376. [Google Scholar] [CrossRef]

- Blair, E.H. Regulation time Culture. Professional Regulation time. J. Prof. Saf. 2013, 58, 59–65. [Google Scholar]

- Shang, Y. Subgraph Robustness of Complex Networks Under Attacks. IEEE Trans. Syst. Man Cybern. Syst. 2019, 49, 821–832. [Google Scholar] [CrossRef]

- Tran, T.H.; Nagy, G.; Nguyen, T.B.T.; Wassan, N.A. An efficient heuristic algorithm for the alternative-fuel station location problem. Eur. J. Oper. Res. 2018, 269, 159–170. [Google Scholar] [CrossRef]

- Ahmed, M.A.; Adel, A.-E.I. Defect Control via Forecasting of Processes’ Deviation as JIDOKA Methodology. In Proceedings of the International Conference on Industrial Engineering and Operations Management, Bandung, Indonesia, 6–8 March 2018. [Google Scholar]

- Lu, C.C.; Yu, V.F. Data envelopment analysis for evaluating the efficiency of genetic algorithms on solving the vehicle routing problem with soft time windows. Comput. Ind. Eng. 2013, 63, 520–529. [Google Scholar] [CrossRef]

- Joël, R. Solving a real-life roll-on–roll-off waste collection problem with column generation. J. Veh. Routing Algorithms 2019, 2, 41–54. [Google Scholar] [CrossRef]

| x, y | Coordinates of serviceable items such as electrical transformers or hydrants or any similar items. | ΔB | The distance between the last in the vertical avenue and the back avenue. |

| j | Avenue number on suggest layout plan | ΔA | The distance between two adjacent avenues. |

| N | Number of serviceable targeted locations at each avenue whether in Plan A/plan B | Δl | The distance between two adjacent locations: . |

| J | Total number of avenues, whether horizontal, vertical, or diagonal | ΔF | The distance between the first location and the front avenue. |

| i | Number of the location at the avenue where number of locations is (1,2,3…, i, … N) | ΔD | The distance between the feeding/departure point (I/O point) and the front avenue. |

| Targeted Location items in plan-A and plan-B | ΔS | The distance between the feeding source point (I/O point) and the point in the straight line of front avenue. | |

| Variable keeps back calculated distance | L | List of requested locations to be served | |

| Lb | List of backlogged locations to be served | ||

| Route length | Route length under cost analysis test |

| Simulated Annealing Steps Technique | S.No. | SA Sequences | Objective Values | Δ Length/unit | Δ Cost^3 | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1. Take an initial solution of S from implementing published heuristic method and choose the least value | 1 | 1 | 6 | 3 | 2 | 4 | 7 | 5 | 42 | −6 | −1.6 |

| 2. Set an initial temperature, T > 0 | 2 | 2 | 6 | 1 | 3 | 4 | 7 | 5 | 42 | −6 | −1.6 |

| 3. While not frozen do the following: | 3 | 2 | 1 | 3 | 6 | 4 | 7 | 5 | 40 | −10 | −1 |

| 3.1 serviceable all locations ψi at the following L list every avenue: | 4 | 2 | 1 | 6 | 4 | 3 | 7 | 5 | 36 | −18 | −1.6 |

| 3.1.1 allow to enter new locations ψj | 5 | 1 | 2 | 6 | 3 | 4 | 5 | 7 | 38 | −14 | −1.4 |

| 3.1.2 Sample backlogs at S’ | 6 | 2 | 1 | 6 | 3 | 4 | 5 | 7 | 43 | −4 | −0.4 |

| 3.1.3 Let ∆ = S’-S | 7 | 1 | 2 | 6 | 3 | 4 | 7 | 5 | 42 | −6 | −0.6 |

| 3.1.4 If ∆ ≤ 0 | 8 | 6 | 2 | 1 | 3 | 4 | 7 | 5 | 40 | −10 | −1 |

| Then set S ≤ S’ | 9 | 2 | 3 | 1 | 6 | 4 | 5 | 7 | 41 | −8 | −0.8 |

| else set S← S’ with a probability of exp (-∆/t) | 10 | 4 | 2 | 1 | 6 | 3 | 7 | 5 | 37 | −16 | −1.6 |

| 3.2 Set T = r*T, where r is the reduction factor. | 11 | 2 | 7 | 1 | 6 | 3 | 4 | 5 | 36 | −20 | −1.9 |

| 4. Return S. | 12 | 5 | 2 | 1 | 6 | 3 | 7 | 4 | 40 | −10 | −1 |

| No. | Heuristic Methods | N | Mini. | Max. | ∑ Route | SD |

|---|---|---|---|---|---|---|

| 1 | S-Shape CW | 185 | 3.45 | 4.62 | 4.068448 | 0.302306 |

| 2 | S-Shape CCW | 185 | 4.13 | 5 | 4.673793 | 0.249862 |

| 3 | Flow Line Analysis FLA-5 | 185 | 2.97 | 4.54 | 3.816207 | 0.438494 |

| 4 | Mid-point, CCW | 185 | 3.56 | 4.7 | 4.222586 | 0.333508 |

| 5 | Largest Gap, CW | 185 | 2.65 | 4.44 | 3.825 | 0.436466 |

| 6 | Largest Gap, CCW | 185 | 3.55 | 5 | 4.525 | 0.363131 |

| 7 | Return, CW | 185 | 3.08 | 4.24 | 3.747931 | 0.329134 |

| 8 | Flow Line Analysis FLA-6 | 185 | 4.22 | 5.2 | 4.881034 | 0.204302 |

| 9 | Composite CW | 185 | 3.58 | 5 | 4.627931 | 0.394616 |

| 10 | Ascending, CW | 185 | 1.81 | 5 | 3.82 | 0.924127 |

| 11 | Ascending, CCW | 185 | 3.47 | 4.89 | 4.065862 | 0.304677 |

| 12 | MRL-SA | 185 | 2.65 | 4.5 | 3.782759 | 0.1501061 |

| The obvious outcomes | ||||||

| 13 | Losses cost | 185 | 3.45 | 4.9 | 4.544828 | 0.205 |

| 14 | Route length | 185 | 3.65 | 4.9 | 4.49569 | 0.402 |

| 15 | Traveling time | 185 | 3.045 | 4.74 | 4.209052 | 0.518 |

| 16 | processing time | 185 | 2.3 | 4.4 | 3.691954 | 0.562 |

| Effect on (Influence) | Losses Cost | Route Length | Traveling Time | Processes Time | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Is These Methods | Objectives Profile | Reduce Disposal | Backlogging | Satisfaction Case | Supplement and Drilling | Avoid Demurrage | Enhancing Reputation | Reliability | Downtime | Over Processing | Effective Profile λi (0.562) | Measured Impact Profile μi (0.35311) | ||

| Affected by | c.1. | c.2. | c.3. | c.4. | c.5. | c.6. | c.7. | c.8. | c.9. | Objectives Weight | ||||

| S-Shape CW | 3.1 | 3 | 5 | 3 | 4 | 4 | 3 | ϕ | ϕ | ϕ | 88.06 | 3.74 | 80.36 | 3.41 |

| Mid-point, CCW | 3.8 | 3 | 3 | 2 | 4 | 2 | 3 | 4 | 2 | 4 | 69.89 | 2.97 | 85.88 | 3.65 |

| Flow Line Analysis FLA-5 | 4.1 | 4 | 3 | 3 | 2 | 5 | 2 | 3 | 5 | ϕ | 113.65 | 4.83 | 99.05 | 4.21 |

| S-Shape CCW | 3.9 | 5 | 4 | 4 | 3 | 3 | 3 | 3 | 4 | 3 | 83.77 | 3.56 | 106.17 | 4.51 |

| Largest Gap, CW | 3.6 | 5 | 4 | 4 | 5 | 2 | 2 | 3 | 3 | 5 | 93.08 | 3.95 | 82.7 | 3.51 |

| Largest Gap, CCW | 3.8 | 3 | 4 | 4 | 3 | 3 | 3 | 3 | 3 | ϕ | 64.59 | 2.74 | 93.37 | 3.96 |

| MRL-SA | 4.3 | 4 | 2 | 4 | 4 | 3 | 5 | 4 | 3 | 3 | 74.98 | 3.18 | 92.47 | 3.93 |

| Composite CW | 5 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 5 | 99.27 | 4.22 | 116.56 | 4.95 |

| Flow Line Analysis FLA-6 | 3.6 | 5 | 3 | 4 | 3 | 3 | 4 | 3 | 3 | ϕ | 117.75 | 2.74 | 86.87 | 3.69 |

| Composite CCW | 4.1 | 3 | 3 | 5 | 4 | 3 | 4 | 4 | 2 | 3 | 43.99 | 1.87 | 99.87 | 4.24 |

| Ascending, CW | 3.9 | 2 | 3 | ϕ | 5 | 4 | 4 | 5 | 3 | 5 | 81.65 | 3.47 | 94.46 | 4.01 |

| Return, CW | 3.6 | 3 | 1 | 3 | 4 | 4 | 4 | 3 | 3 | ϕ | 64.5 | 5 | 83.56 | 3.55 |

| Losses cost | 195.5 | 139.4 | 130.6 | 154.5 | 124.6 | 113.3 | 89.6 | 103.3 | 78.2 | |||||

| Traveling distance^1000 units | 5 | 3.6 | 3.3 | 4 | 3.19 | 2.9 | 2.3 | 2.6 | 2 | |||||

| Traveling time | −34.2 | 3.2 | −26.7 | −26.7 | −25 | −56.6 | −63.6 | −28.4 | −29.2 | 0.562 | ||||

| Proposed time | 4.6 | 4.1 | 4.5 | 5 | 4.27 | 4.8 | 4.4 | 3.8 | 3.1 | |||||

| Mid-Point, CCW | FLA-6 | S-Shape CCW | Largest Gap, CW | Composite CW | FLA-5 | Largest Gap, CCW | MRL-SA | Composite CCW | Ascending, CW | Return, CW | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| S-Shape CW | 0.267 | −0.084 | −0.066 | 0.507 | −0.209 | −0.701 | 0.418 | 0.463 | −0.226 | 0.308 | |

| Mid-point, CCW | −0.279 | −0.423 | 0.167 | 0.655 | −0.423 | −0.144 | 0.693 | −0.311 | |||

| FLA-6 | −0.696 | 0.7 | −0.348 | −0.627 | 0.7 | 0.075 | −0.286 | 0.685 | |||

| S-Shape CCW | −0.164 | 0.057 | 0.491 | −0.286 | 0.473 | −0.52 | −0.661 | −0.215 | |||

| Largest Gap, CW | −0.471 | −0.739 | 0.501 | −0.499 | 0.707 | 0.154 | −0.2 | −0.306 | −0.102 | −0.488 | |

| Composite CW | 0.162 | −0.212 | −0.67 | 0.799 | 0.305 | −0.409 | 0.606 | ||||

| FLA-5 | 0 | 0.212 | −0.346 | 0.104 | |||||||

| Largest Gap, CCW | −0.67 | −0.094 | 0.529 | −0.52 | |||||||

| MRL-SA | 0.214 | −0.574 | 0.672 | ||||||||

| Composite CCW | −0.125 | ||||||||||

| Ascending, CW | −0.06 | ||||||||||

| Return, CW | 0.478 |

| Comp. | MRL-SA | Comp. | MRL-SA | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| #b | σ | dt | rt | Imp% | Average | Standard Dev. | Average | Standard Dev. | #b | σ | dt | rt | Imp% | Average | Standard Dev. | Average | Standard Dev. |

| 3 | 2 | 18 | 14 | 51.5 | 5121.1 | 648.4 | 2482.2 | 24.4 | 5 | 2 | 18 | 14 | 53 | 5464.5 | 632.3 | 2569.3 | 16.3 |

| 3 | 2 | 18 | 16 | 52.4 | 5012.7 | 592.8 | 2342.8 | 26.3 | 5 | 2 | 18 | 16 | 52.7 | 5209.6 | 588 | 2465.2 | 22.7 |

| 3 | 2 | 18 | 18 | 52.9 | 4971.8 | 510 | 2342.8 | 23.2 | 5 | 2 | 18 | 18 | 54.6 | 5295.5 | 609.7 | 2402.7 | 28.5 |

| 3 | 2 | 20 | 14 | 49.4 | 5439.6 | 523.3 | 2754.3 | 19.3 | 5 | 2 | 20 | 14 | 49.4 | 5539.5 | 532 | 2802.2 | 18.9 |

| 3 | 2 | 20 | 16 | 50.3 | 5378.3 | 584 | 2671 | 19.1 | 5 | 2 | 20 | 16 | 50.4 | 5475.5 | 569.1 | 2714.9 | 16.3 |

| 3 | 2 | 20 | 18 | 51.2 | 5248.1 | 591.3 | 2562.3 | 23.5 | 5 | 2 | 20 | 18 | 51.4 | 5392 | 606.7 | 2620.3 | 23.6 |

| 3 | 2 | 22 | 14 | 48.2 | 5698.3 | 630 | 2953.4 | 31.4 | 5 | 2 | 22 | 14 | 50 | 5901.3 | 547.9 | 2950.2 | 26.3 |

| 3 | 2 | 22 | 16 | 48.1 | 5633.5 | 532.5 | 2926.3 | 25 | 5 | 2 | 22 | 16 | 48.8 | 5798.9 | 588.4 | 2971.8 | 21.3 |

| 3 | 2 | 22 | 18 | 49.2 | 5537 | 600.6 | 2811.3 | 24.6 | 5 | 4 | 22 | 18 | 50.1 | 5779.6 | 549 | 2884.7 | 23.1 |

| 3 | 4 | 18 | 14 | 58.1 | 8569 | 1145.4 | 3592.7 | 75.1 | 5 | 4 | 18 | 14 | 59.1 | 8912.3 | 1163.6 | 3645.7 | 67.1 |

| 3 | 4 | 18 | 16 | 59.4 | 8670 | 960.5 | 3523.8 | 70.4 | 5 | 4 | 18 | 16 | 59.6 | 8857.2 | 1088 | 3577.9 | 76.3 |

| 3 | 4 | 18 | 18 | 59.5 | 8222.7 | 1035.2 | 3329.3 | 77 | 5 | 4 | 18 | 18 | 60.8 | 8844 | 1042.7 | 3469.4 | 74.6 |

| 3 | 4 | 20 | 14 | 58.7 | 9093.1 | 964.4 | 3756.3 | 73.8 | 5 | 4 | 20 | 14 | 59 | 9404.5 | 1212.4 | 3857.5 | 61.8 |

| 3 | 4 | 20 | 16 | 58.4 | 8773.2 | 1056.2 | 3649 | 60.4 | 5 | 4 | 20 | 16 | 58.5 | 9083.6 | 1096.2 | 3773.5 | 69.2 |

| 3 | 4 | 20 | 18 | 59 | 8653 | 1082.9 | 3548.8 | 63.7 | 5 | 4 | 20 | 18 | 59.6 | 9028.6 | 1205.5 | 3644.7 | 65.6 |

| 3 | 4 | 22 | 14 | 56.8 | 9173.6 | 1103.5 | 3963.5 | 60.6 | 5 | 4 | 22 | 14 | 57.4 | 9505.5 | 1038 | 4044.8 | 44.8 |

| 3 | 4 | 22 | 16 | 57.3 | 9008.5 | 1143 | 3848.7 | 53.3 | 5 | 4 | 22 | 16 | 57.6 | 9296.4 | 1176.8 | 3942.7 | 50.1 |

| 3 | 4 | 22 | 18 | 58.3 | 8933.6 | 1094 | 3726.5 | 61.2 | 5 | 2 | 22 | 18 | 58 | 9132.1 | 1229 | 3835.2 | 53.4 |

| 4 | 2 | 18 | 14 | 51.8 | 5277.9 | 603.7 | 2543.2 | 17 | 6 | 2 | 18 | 14 | 52.2 | 5389.6 | 662.6 | 2573.8 | 16.6 |

| 4 | 2 | 18 | 16 | 51.5 | 5066.4 | 532 | 2457.8 | 21.9 | 6 | 2 | 18 | 16 | 54.2 | 5399.4 | 624.2 | 2471 | 19.8 |

| 4 | 2 | 18 | 18 | 52.6 | 4998.4 | 625.1 | 2368 | 25.8 | 6 | 2 | 18 | 18 | 53.3 | 5167.9 | 631.3 | 2412.9 | 25.3 |

| 4 | 2 | 20 | 14 | 48.8 | 5498.3 | 576.7 | 2814.8 | 16.6 | 6 | 2 | 20 | 14 | 49.8 | 5586.9 | 570.8 | 2807.3 | 21.5 |

| 4 | 2 | 20 | 16 | 49.5 | 5343.2 | 520.8 | 2697.8 | 18 | 6 | 2 | 20 | 16 | 51.7 | 5626.9 | 600.1 | 2716.4 | 19.9 |

| 4 | 2 | 20 | 18 | 50.4 | 5262 | 537.7 | 2609.4 | 19.7 | 6 | 2 | 20 | 18 | 51.6 | 5474.8 | 638.1 | 2650.5 | 23.4 |

| 4 | 2 | 22 | 14 | 48.6 | 5764.7 | 566.4 | 2960.4 | 25.2 | 6 | 2 | 22 | 14 | 50.6 | 6062.4 | 590.5 | 2996.5 | 28.2 |

| 4 | 2 | 22 | 16 | 47.8 | 5686.9 | 600.1 | 2969.5 | 16 | 6 | 2 | 22 | 16 | 49.7 | 5900 | 564.4 | 2968.6 | 20.9 |

| 4 | 2 | 22 | 18 | 48.6 | 5551.5 | 575.6 | 2851.1 | 18.5 | 6 | 4 | 22 | 18 | 50.3 | 5798.6 | 618.7 | 2879.2 | 19.3 |

| 4 | 4 | 18 | 14 | 59.4 | 8868.4 | 1074.1 | 3610.7 | 75.8 | 6 | 4 | 18 | 14 | 59.8 | 9213.1 | 1171.4 | 3705.3 | 68.3 |

| 4 | 4 | 18 | 16 | 59.2 | 8750.2 | 1117.4 | 3566.9 | 65.9 | 6 | 4 | 18 | 16 | 60.9 | 9202.5 | 1107.5 | 3602 | 77.5 |

| 4 | 4 | 18 | 18 | 59.4 | 8583.1 | 1183.6 | 3481.6 | 69.3 | 6 | 4 | 18 | 18 | 60.9 | 8900.1 | 1263 | 3477.1 | 81 |

| 4 | 4 | 20 | 14 | 58.6 | 9270.4 | 1144.3 | 3834.2 | 54.4 | 6 | 4 | 20 | 14 | 59.2 | 9478.6 | 1236.9 | 3868 | 63.1 |

| 4 | 4 | 20 | 16 | 57.7 | 8917.1 | 1093.1 | 3768 | 57.5 | 6 | 4 | 20 | 16 | 59.7 | 9293.8 | 1181.2 | 3749 | 63.6 |

| 4 | 4 | 20 | 18 | 59.7 | 9041.8 | 1241 | 3648.3 | 52.1 | 6 | 4 | 20 | 18 | 59.8 | 9205 | 1114.9 | 3696.7 | 59.7 |

| 4 | 4 | 22 | 14 | 56.3 | 9252.7 | 1109.8 | 4042.3 | 50.6 | 6 | 4 | 22 | 14 | 57.2 | 9507.2 | 1207.6 | 4068.3 | 47.5 |

| 4 | 4 | 22 | 16 | 57.9 | 9335.4 | 1210.8 | 3927.2 | 49.5 | 6 | 4 | 22 | 16 | 59.6 | 9770.2 | 1127.3 | 3949.7 | 58.1 |

| 4 | 4 | 22 | 18 | 59.3 | 9420.8 | 1044.5 | 3830.7 | 44.9 | 6 | 4 | 22 | 18 | 58.5 | 9304.7 | 1088.6 | 3863.4 | 53.2 |

| Ascend | MRL-SA | Return | L-Gap | Mid-point | S-Shape | Comp. | |

|---|---|---|---|---|---|---|---|

| Count | 270 | 270 | 270 | 270 | 270 | 270 | 270 |

| Sum | 10629.34 | 1723.28 | 17541.7 | 6388.035 | 7177.268 | 5186.399 | 2790.102 |

| Average | 39.368 | 6.383 | 64.969 | 23.66 | 23.5824 | 19.20889 | 10.33371 |

| Variance | 841.66 | 90.1069 | 548.7855 | 605.4917 | 924.444 | 691.3697 | 189.5498 |

| Source of Variation | SS | df | MS | F | p-Value | F Crit |

|---|---|---|---|---|---|---|

| Sample | 200566.1 | 8 | 25070.77 | 247.6 | 8.00*10^−285 | 1.944 |

| Columns | 639676.2 | 6 | 106612.7 | 1053 | 0 | 2.105 |

| Interaction | 661237 | 48 | 13775.77 | 136.1 | 0 | 1.368 |

| Within | 184985.9 | 1827 | 101.2512 | |||

| Total | 1686470 | 1886 |

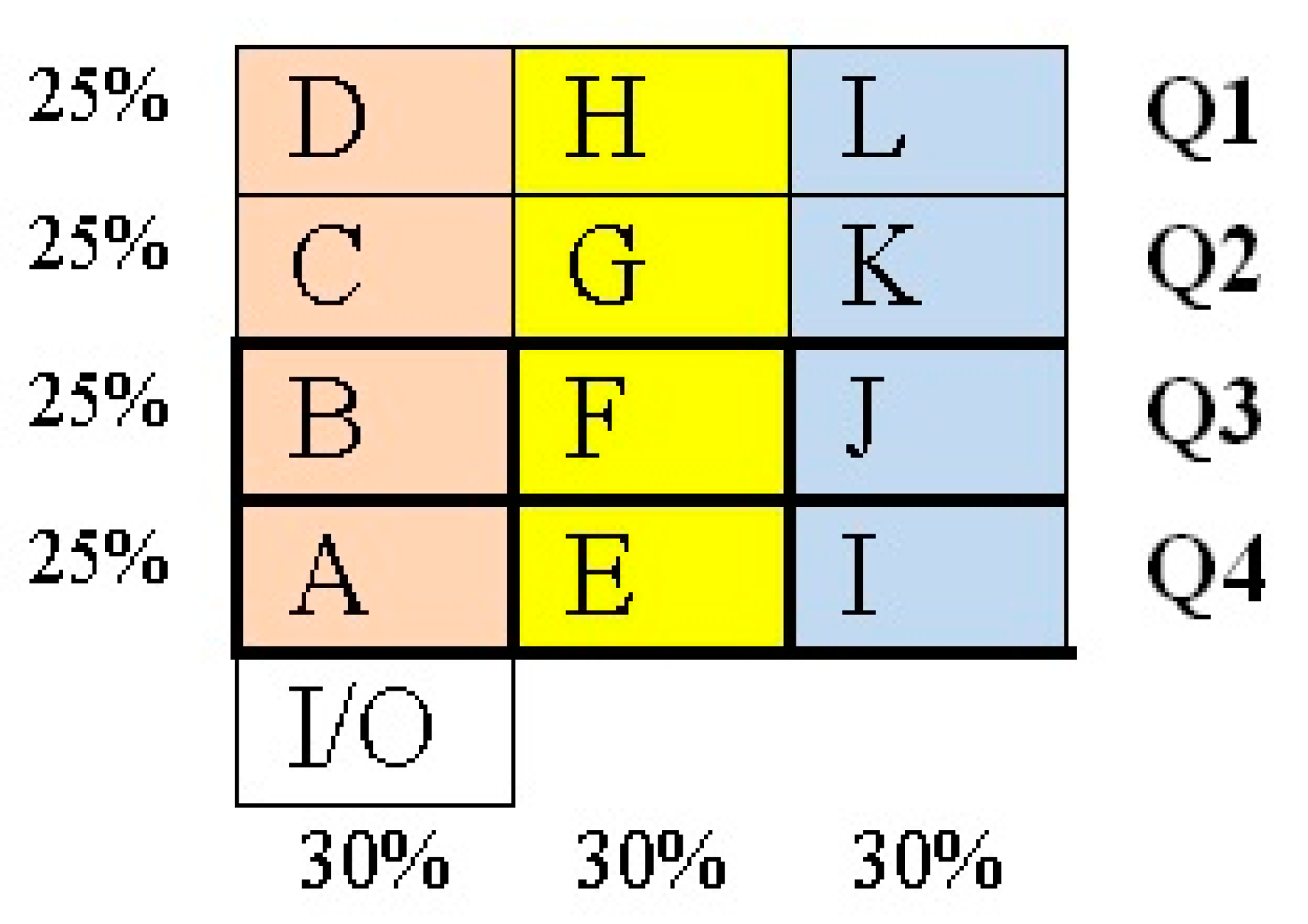

| Requested Area | # of Regions | Regions | # of Locations | |

|---|---|---|---|---|

| 1 | Upper half | 6 | C,D,G,H,K,L | 1000 |

| Lower half | 6 | A,B,E,F,I,J | 1000 | |

| 2 | Left area | 4 | A,B,C,D | 350 |

| Middle area | 4 | E,F,G,H | 1300 | |

| Right area | 4 | I,J,K,L | 350 | |

| 3 | Q1 | 3 | A,E,I | 500 |

| Q2 | 3 | B,F,J | 500 | |

| Q3 | 3 | C,G,K | 500 | |

| Q4 | 3 | D,H,L | 500 |

| Source of Variation | SS | df | MS | F | p-Value | F Crit |

|---|---|---|---|---|---|---|

| Sample | 200566.1 | 8 | 25070.77 | 247.6 | 8e−285 | 1.944 |

| Columns | 639676.2 | 6 | 106612.7 | 1053 | 0 | 2.105 |

| Interaction | 661237 | 48 | 13775.77 | 136.1 | 0 | 1.368 |

| Within | 184985.9 | 1827 | 101.2512 | |||

| Total | 1686470 | 1886 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abed, A.M.; Elattar, S. Minimize the Route Length Using Heuristic Method Aided with Simulated Annealing to Reinforce Lean Management Sustainability. Processes 2020, 8, 495. https://doi.org/10.3390/pr8040495

Abed AM, Elattar S. Minimize the Route Length Using Heuristic Method Aided with Simulated Annealing to Reinforce Lean Management Sustainability. Processes. 2020; 8(4):495. https://doi.org/10.3390/pr8040495

Chicago/Turabian StyleAbed, Ahmed M., and Samia Elattar. 2020. "Minimize the Route Length Using Heuristic Method Aided with Simulated Annealing to Reinforce Lean Management Sustainability" Processes 8, no. 4: 495. https://doi.org/10.3390/pr8040495

APA StyleAbed, A. M., & Elattar, S. (2020). Minimize the Route Length Using Heuristic Method Aided with Simulated Annealing to Reinforce Lean Management Sustainability. Processes, 8(4), 495. https://doi.org/10.3390/pr8040495