2. Problem Description

The OLMP considered in this study is the same with the problem studied in [

12], i.e., the problem of assigning items in lots currently being processed to orders with the objective of minimizing the total tardiness of the orders. Items can be assigned to any order if their product types are the same as that of the order. When the orders cannot be satisfied with lots in process, additional lots are to be released into the production system to satisfy all orders with the given production capacity.

| Parameters | | number of orders |

| number of lots in process |

| length of the planning time horizon (unit: day) |

| i | index for order |

| l | index for lot |

| t | index for time period (unit: day) |

| quantity of order i |

| limit on the total number of items that can be released at time t |

| due date of order i (unit: hour) |

| CT | (estimated) production cycle time from release to finish (unit: hour) |

| Variables | | number of items included in lot l |

| (estimated) remaining time of lot l (unit: hour) |

| completion time of order i (unit: hour) |

| tardiness of order i (unit: hour) |

| number of items in lot l assigned to order i |

| number of items newly released lot into the production system at time t for order i |

| equals 1 if lot l is used to satisfy order i, 0 otherwise |

| equals 1 if there exist some lots newly released at time t to satisfy order i, 0 otherwise |

The OLMP is formulated as a mixed integer linear program as below.

[OLMP] Minimize

subject to

The objective of the problem is to minimize the total tardiness of all orders. Constraint (2) is for satisfying the order quantity with existing lots of items and/or newly released ones. Constraint (3) specifies the maximum possible number of items in a lot that can be assigned to orders. Constraint (4) represents a capacity of the production system, i.e., the maximum number of items that can be released at each period. Constraint (5) specifies the number of items in each lot assigned to different orders. Constraint (6) limits the total number of newly released items in each time period. Constraints (7) and (8) specify the completion time of each order. Note that in (7) is an estimated value, which can be calculated by the sum of processing time and waiting time. The waiting time varies dynamically according to the WIP level, so the estimated waiting time by the average of historical waiting time can be applicable. Constraint (9) represents the tardiness of each order. Equations (10)– (14) as constraints specify the ranges of the decision variables.

In [

11], the authors proved the NP-hardness of the OLMP and the existence of an optimal order sequence for matching with lots. The order sequence represents processing priorities of orders; orders with higher priorities appear earlier in the sequence. They also proposed the order-lot assignment method called the compact pegging method for a given order sequence. In the compact pegging method, items (in lots) with less remaining time are assigned to orders with higher priorities, which results in the best lot-order assignment for the given order sequence.

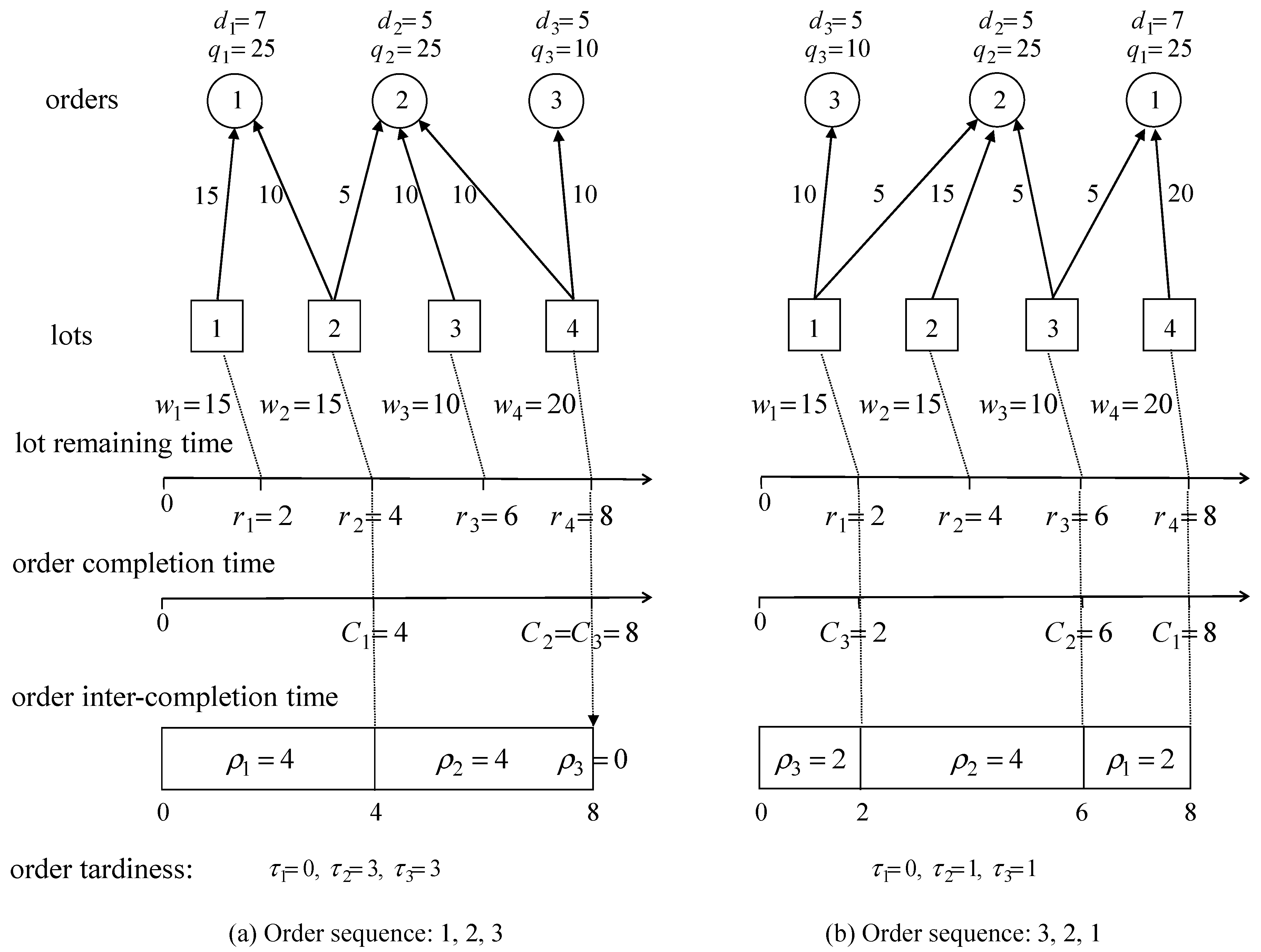

Figure 1 illustrates how lots are assigned to orders using the compact pegging method for two order sequences. With the compact pegging method, the completion time of an order is equal to the largest remaining time of lots, which are assigned to the order and it is less than or equal to those of orders at later positions in the order sequence. As can be seen in the figure, orders with higher priorities have less completion times. Order completion times are subject to not only the order sequence but also order quantities, the number of lots, and the remaining times of lots, while job completion times in

are determined only by the job sequence. Let

be the inter-completion time of order

i, which is defined as the time duration between the completion times of order

i and its precedent in the order sequence. The inter-completion time can be considered as the job processing time in

. However, it is sequence dependent and can be equal to zero, unlike the job processing time:

in

Figure 1a and

in

Figure 1b although the sum of the inter-completion times is equal to the total completion time and it is a sequence-independent constant (

in the example). Therefore, the OLMP cannot be converted into

but can be considered as a new type of machine scheduling problem with many similarities to

.

Since the OLMP is an NP-hard problem, it is effective to develop efficient heuristic algorithms, such as [

12], for solving large-sized problems. However, we can obtain optimal solutions for small and moderate-sized problems if there exist dominance conditions that can reduce the solution space significantly without affecting optimal solutions. In the following sections, we suggest dominance conditions for the OLMP and show how they can used to find the optimal solution.

3. Dominance Conditions

Since the OLMP has similar characteristics to

, we exploit the dominance conditions of

to develop those of the OLMP.

is one of the most extensively studied problems in the literature, and, as a result, many theoretical theorems have been proposed to establish precedence relations among jobs in optimal job sequences. Among them, the most seminal ones are the Emmons’s dominance conditions [

13] and the Lawler’s decomposition principle [

14]. In this section, we show that the dominance conditions of Emmons [

13] and Lawler [

14] can be also applied to the OLMP. Since the dominance conditions for

cannot be directly applied to the OLMP due to the differences between the OLMP and

as mentioned before, we modified the dominance conditions of Emmons [

13] and Lawler [

14] for their application to the OLMP following the same manner of developing theories as Emmons [

13] and Lawler [

14].

At first, we propose theorems and derived corollaries that correspond to the Emmons’s dominance conditions [

13]. Let

be the earliest possible total completion time for orders in order set

, i.e., the earliest possible time when all orders in order set

can be completed. For example,

,

,

,

,

,

, and

in

Figure 1. Let

Bi and

Ai be the sets of orders that have been shown, at any point, to precede and follow order

j in an optimal order sequence, respectively, and let

be a set of orders that precedes order

i in

.

Theorem 1. For anytwo orders j and k with, if , then order j precedes order k in at least one optimal order sequence (that is, and ).

Proof. Consider order sequence

in which all orders in B

K precede order k, and order k precedes order j with

. Let

and

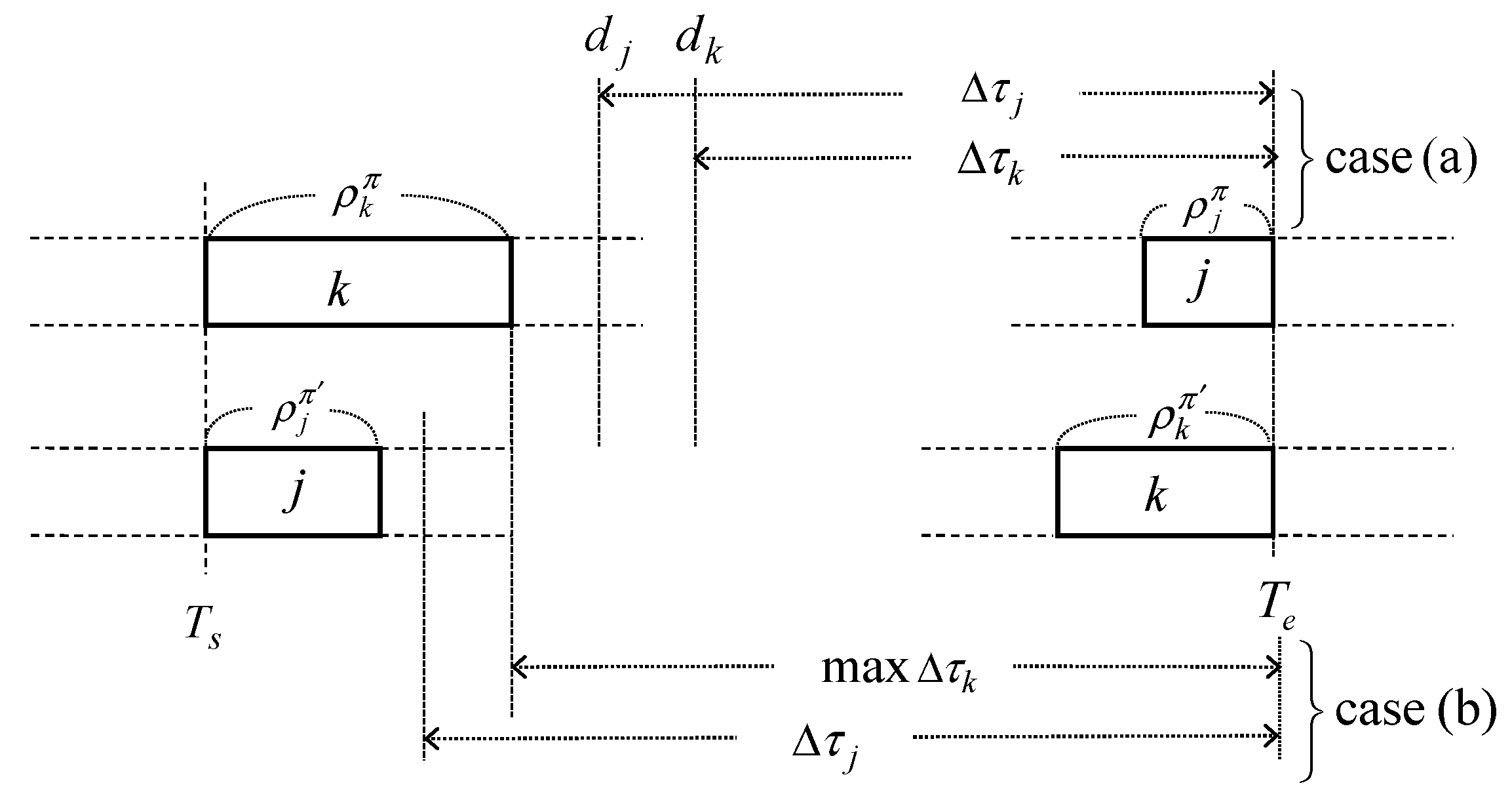

be the times at which order k starts and order j ends, respectively (see

Figure 2). Then,

and

. Additionally, let

and

be inter-completion times of orders k and j in order sequence

, respectively. Let

be an order sequence that is obtained by interchanging orders j and k in

. Then, we have

and

. Since

,

and

. Note there exists no (in) equality relationship between

and

(or

and

) since they are sequence dependent. □

We show that interchanging the two orders does not increase the total tardiness. It is clear that all orders that precede order k or follow order j in the original sequence are unaffected when the two orders are interchanged. All orders between order k and j are completed earlier with their tardiness decreased or unchanged. We consider the following two cases to investigate the changes in tardiness of orders j and k after the interchange:

- (a)

Suppose . We consider the following three subcases:

- (a1)

If

, as illustrated in

Figure 2, then the decrease of tardiness of order j is

, the increase of tardiness of order k is

, and the net decrease due to the tow changes is

, which is nonnegative since

and

.

- (a2)

If , .

- (a3)

If , . Thus, in all cases, the total decrease of tardiness is positive, or at worst zero, so the change should be made.

- (b)

Suppose

, as also illustrated in

Figure 2. Since

,

. Then, again,

is nonnegative since

.

According to Theorem 1, we can reduce the total tardiness by interchanging the positions of order

j and

k in the order sequence if order

k precedes order

j,

, and

. In

Figure 1a, order 1 precedes order 3,

and

, so we can reduce the total tardiness from six to two by interchanging order 1 and order 3 as shown in

Figure 1b.

Corollary 1.1. If order j has the properties andfor all, then order j is the first in an optimal order sequence.

Proof. It is obvious by Theorem 1. □

Corollary 1.2. If order j has properties andfor all, then order j is the last in an optimal order sequence.

Proof. It is obvious by Theorem 1. □

Corollary 1.3. Let the least quantity sequence be an order sequence in which orders of fewer quantities are placed earlier in the sequence. Then, the least quantity sequence is optimal if it is identical with the earliest due date sequence.

Proof. It is straightforward by case (a) in the proof of Theorem 1. □

Theorem 2. For any two orders j and k with, if, where, then order j precedes order k (that is,and).

Proof. Consider sequence

in which order k precedes order j, all orders in

precede order j, and order j precedes all orders in

. Let

and

be the times at which order k begins and order j ends, respectively. Since

,

and

. Consider sequence

, which is obtained by moving order k to a position immediately after order j in

(see

Figure 3 ). Again, orders before

and after

are unaffected. Order j and all orders between orders k and j are now processed earlier, which can decrease their tardiness or leave it unchanged. Only order k can have an increase in tardiness (Equation (15)):

□

Since

and

, we have the following inequalities (Equation (16)):

Therefore, the alternative, , is ruled out. If , then moving order k after order j does not increase the total tardiness. For , since , we have . It follows that the decrease of tardiness of order j is .

Thus, . Since and , , i.e., . Thus, postponing order k after order j is advantageous in this case.

Corollary 2.1. If order j has propertiesfor alland, where is a set of all orders, then order j is the last in an optimal sequence.

Proof. If , order i precede order j by Theorem 1. Otherwise, order i precedes order j by Theorem 2. □

Theorem 3. For any two orders j and k with, if, where, then order j precedes order k (that is,and).

Proof. Consider any sequence in which order j precedes all orders in and follows order k. We show that interchanging orders j and k can only decrease the total tardiness. Let be the time at which order j ends. Since and , . This means that order k maintains zero tardiness after the interchange. Since all other orders are either remained unmoved or are advanced in time, the only possible change in tardiness is decreasing. □

Now, we propose properties and a theorem that correspond to the Lawler’s decomposition principle [

14]. Let

be the completion time of order

j in order sequence

.

Property 1. Letbe any order sequence which is optimal with respect to the given due dates, and be chosen such that

Then, any sequence which is optimal with respect to the due dates is also optimal with respect to (but not conversely).

Proof. This property came from Theorem 1 of Lawler [

14] and can be directly applied to the OLMP when jobs are substituted as orders. Refer to the proof of Theorem 1 of Lawler [

14].

Property 2. There exists an optimal order sequencein which all on time orders are in non-decreasing due date order.

Proof. Suppose order i follows order j in an optimal sequence , where orders i and j under are both on time in . Then, moving order j after order i yields a sequence for which the total tardiness is no greater. □

Theorem 4. Suppose that the orders are numbered in non-decreasing due date order, i.e.,(where wheneverand). Let order k be such that. Then, there exists an optimal order sequence in which order k can be set in position and the orders preceding and following order k are determined asand.

Proof. Let be any order sequence that is optimal with respect to the given due dates , and let be an order sequence which is optimal with respect to the due dates . By Property 1, is also optimal with respect to the original due dates. It follows that and thus . By Theorem 1, any order j with precedes order k in . Any order j such that would be on time if it precedes order k in , which means that such order follows order k in by Property 2. Thus, order k is preceded by all orders j such that in . Let h be chosen to be the largest integer such that , and the theorem is proved. □

Property 3. Suppose that orders are numbered in non-decreasing due date order, i.e.,(wherewheneverand). Let order k be such that. Then, there exists at least one optimal order sequence in which order k is not placed in position h, whereand.

Proof. By Theorem 4, there exists an optimal order sequence in which , where

. If , set . Then, by Property 1, an optimal order sequence with respect to (say ) is also optimal with respect to . By Theorem 4, order k is placed in position m in where and . Since , , which means that order k is not placed in position h in . □

According to Theorem 4, the order set can be decomposed into two subsets by order

k, i.e.,

and

. Thus, a DP model can be used to find the optimal order sequence, as was done in [

14]. The following notation is used to define the DP model:

: the total tardiness for an optimal sequence of the orders in when the most progressed Q items, i.e., Q items with the least remaining work, were already assigned to other orders and thus were not available any longer.

: the total completion time for orders in S when the most progressed Q items were already assigned to other orders and thus they are not available any longer.

The DP model is given as:

To select in Equation (18), ties are broken by choosing an order with the earliest due date. To apply the DP model, we set , , and at first. The initial conditions for e Equation (15) are , , , and .

By Property 3, it is sufficient to consider only values of

satisfying inequality

. As a result, there may be a considerable reduction in the number of subproblems that must be solved. Let

. (Here, it is assumed that

for completeness of

.) Then, Equation (18) can be rewritten as

Since the development of Lawler’s decomposition theorem [

14], there have been further theoretical developments in the decomposition theorem for

by many researchers, such as [

15,

16,

17,

18]. See [

19] for a review on the latest theoretical developments on

. The variants of Lawler’s decomposition theorem [

14] could be also applied to the OLMP similarly.

4. Examples

We give two examples of the OLMP that can be solved optimally using the dominance rules and the DP model explained in

Section 3.

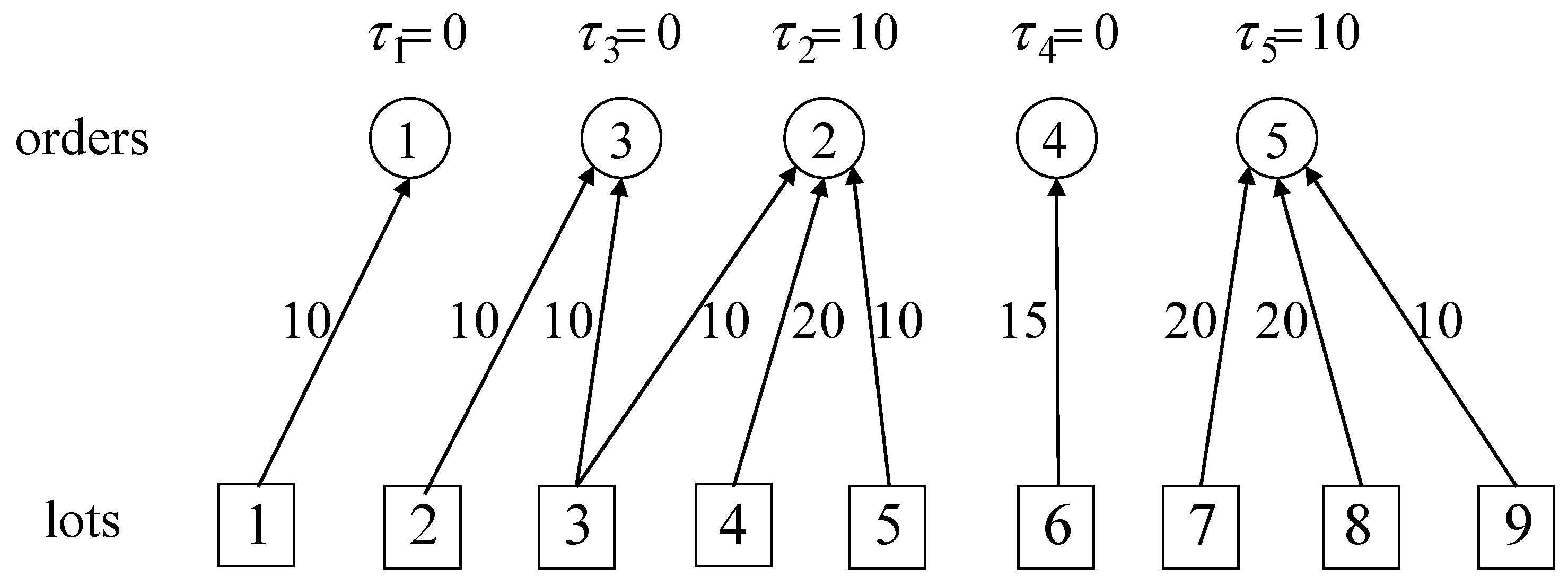

<Example 1>

We apply the dominance rules corresponding to Emmons’s rule [

13] to Example 1.

- (a)

By Corollary 1.1, order 1 is the first since and for all , which implies .

- (b)

By Corollary 1.2, order 5 is the last since and for all , which implies .

- (c)

By Theorem 1, order 3 precedes order 2 since and , which implies and .

- (d)

By Theorem 2, order 2 precedes order 4 since , . It follows that and . that and .

According to (a)–(d), the optimal order sequence is 1, 3, 2, 4, 5 with the total tardiness of 20.

Figure 4 illustrates the optimal order-lot matching for Example 1.

<Example 2>

Table 3 and

Table 4 show data for Example 2. We apply the DP model based on the dominance rules corresponding to Lawler’s rules [

14] to Example 2.

To apply the DP model, the initial conditions for Equation (16) are given as , , , , , , and .

We consider order set . Since order 3 has the largest quantity among the considered orders, we obtain . And since , and , we obtain . Thus, Equation (16) yields:

Note that

and

.

We set and consider order set . We obtain and . Equation (16) yields:

Note that

,

,

,

, and

. Since

,

. Thus, we obtain

when an optimal order sequence is 1, 2, 4, 3.

Figure 5 illustrates the optimal order-lot matching for Example 2.