Performance of Smokehouse Designed for Smoking Fish with the Indirect Method

Abstract

1. Introduction

2. Materials and Methods

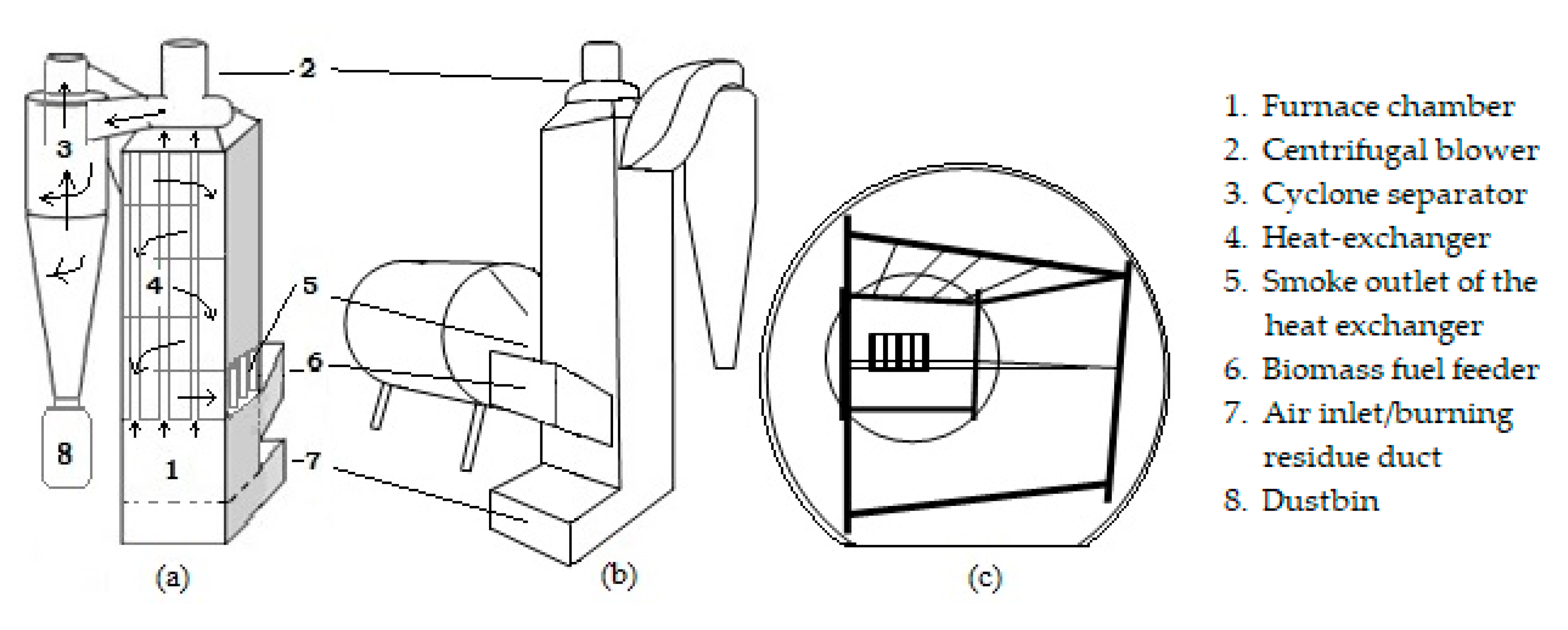

2.1. Smokehouse

2.2. Smoke–Heat Generator

2.3. Smoking Chamber and Fish Hanger

2.4. Pre-Treatment of Skipjack Fish

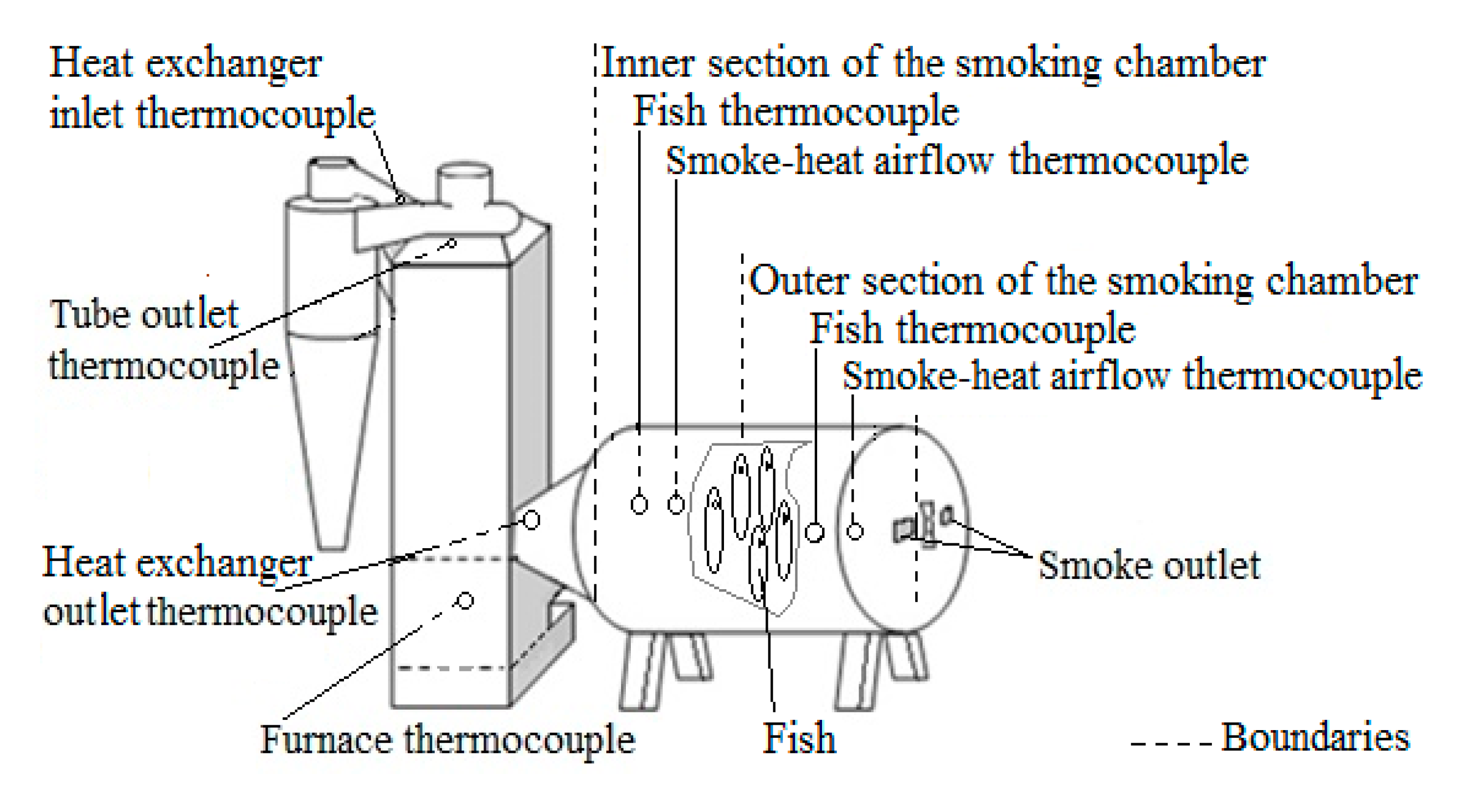

2.5. Instrumentation and Measurements

2.6. The Biomass Fuel of Coconut Shell

2.7. Heat Exchanger and Cyclone Separator

3. Results and Discussion

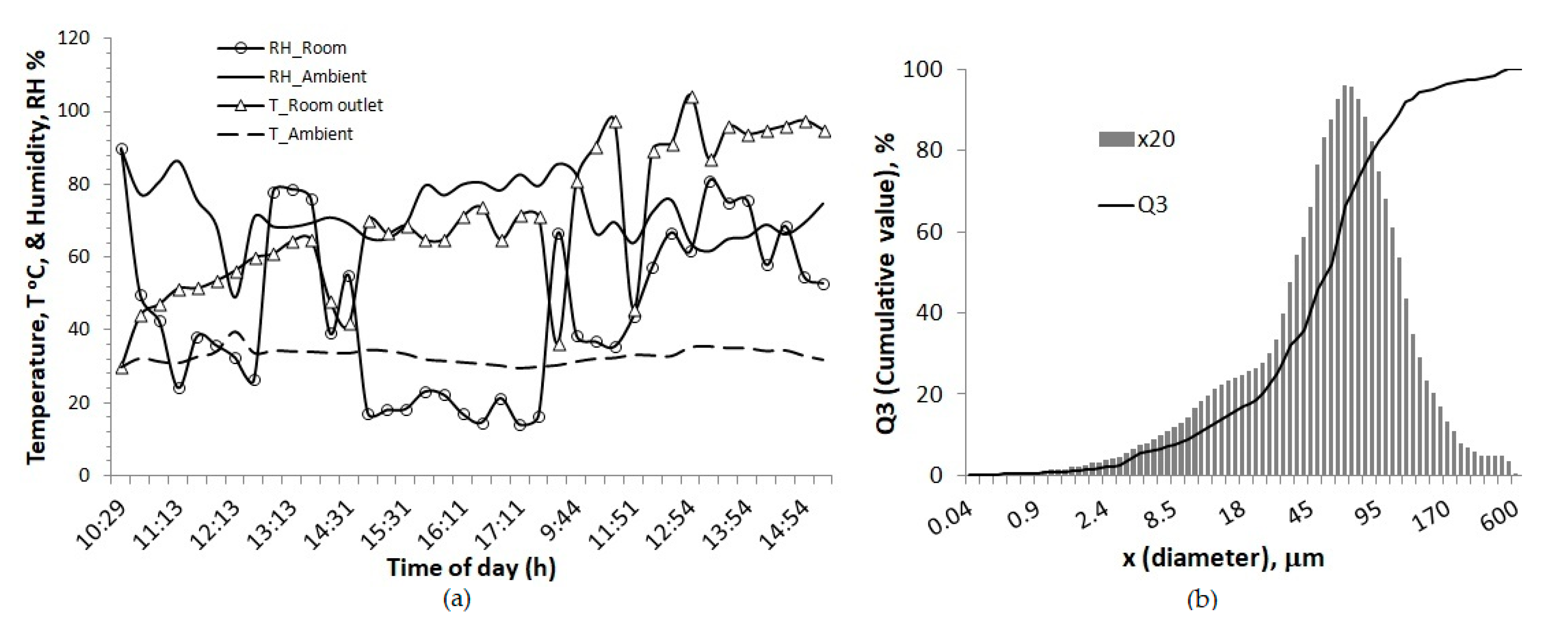

3.1. The Biomass Fuel of Coconut Shell

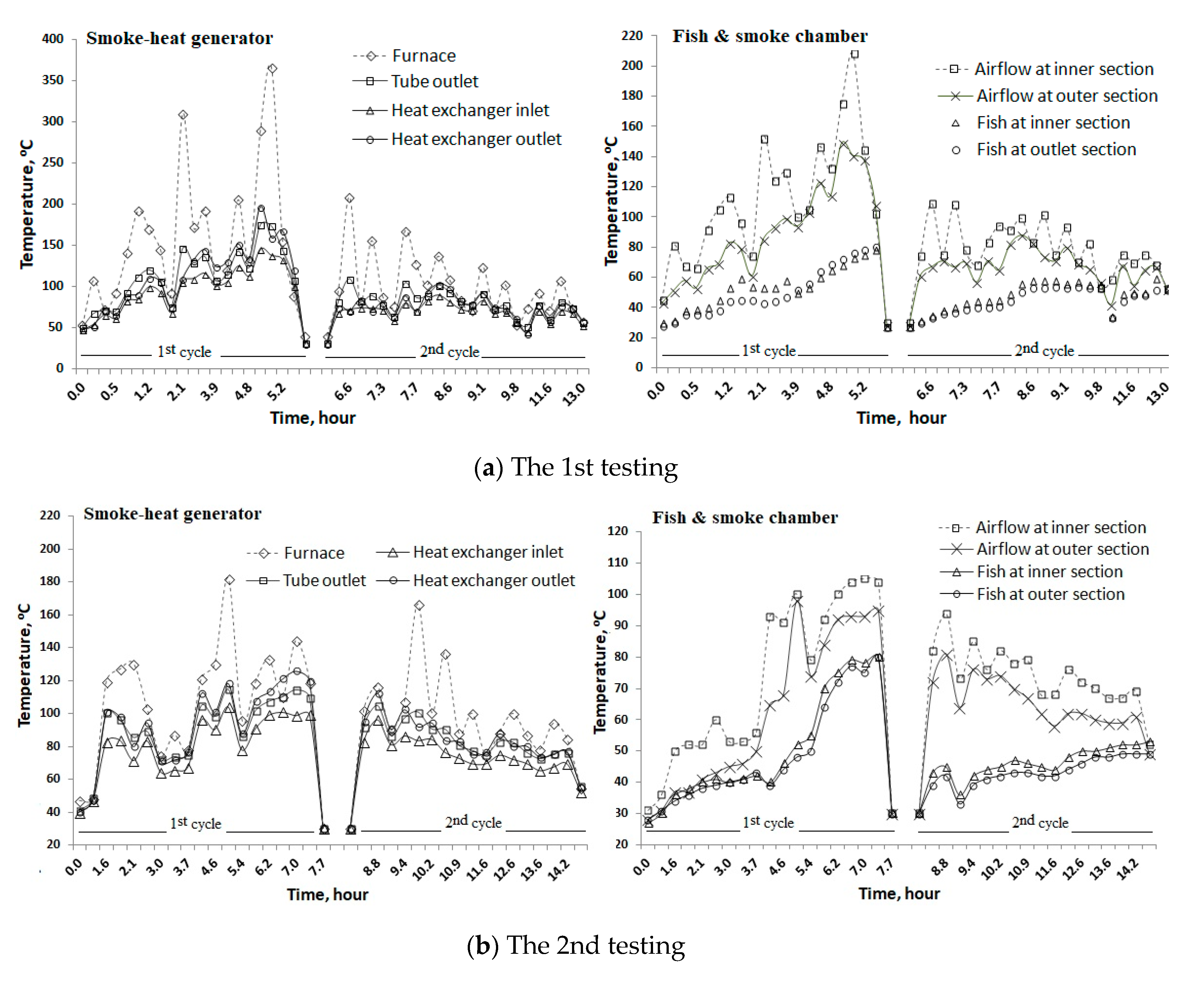

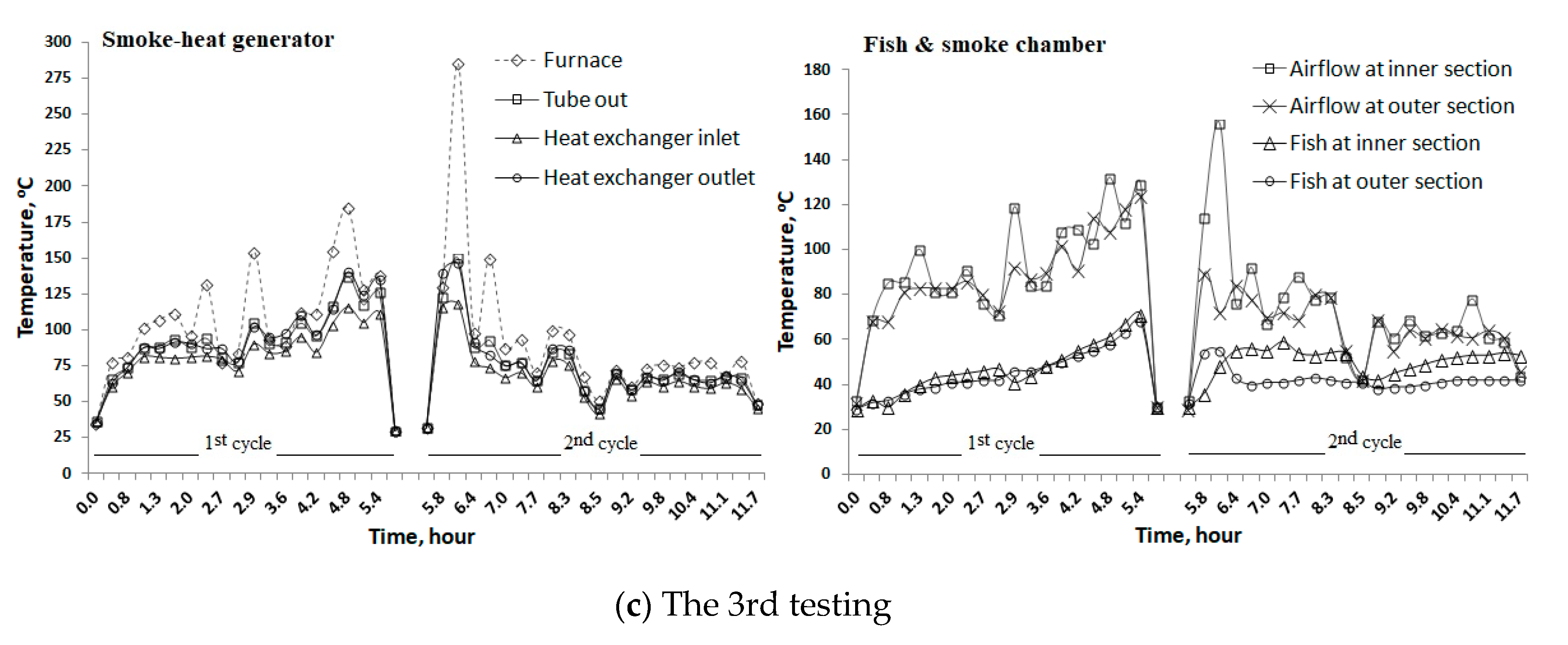

3.2. The Smoking Performance

3.3. Performances of the Heat Exchanger and the Cyclone Separator

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Forever, G. Torry Kiln Smokehouse: The First Smoking Device in Smoking History. Available online: http://grillsforever.com (accessed on 8 April 2017).

- Essumang, D.K.; Dodoo, D.K.; Adjei, J.K. Effective reduction of PAH contamination in smoke cured fish products using charcoal filters in a modified traditional kiln. Food Control 2014, 35, 85–93. [Google Scholar] [CrossRef]

- Hilderbrand, K.S. Fish Smoking Procedures for Forced Convection Smokehouses; Oregon State University Extension Service: Corvallis, OR, USA, 2001. [Google Scholar]

- Sikorski, Z.E.; Sinkiewicz, I. Smoking Traditional. In Encyclopedia of Meat Sciences, 2nd ed.; Academic Press: Oxford, UK, 2014; pp. 321–327. [Google Scholar]

- Ahmad, J.I. Smoked Foods Applications of Smoking. In Encyclopedia of Food Sciences and Nutrition, 2nd ed.; Academic Press: Oxford, UK, 2003; pp. 5309–5316. [Google Scholar]

- Sikorski, Z.E.; Kołakowski, E. Smoking. In Handbook of Meat Processing, 1st ed.; Toldrá, F., Ed.; Wiley-Blackwell: Ames, IA, USA, 2010; pp. 231–245. [Google Scholar]

- Rasco, B. Smoking Fish at Home Safely, PNW238. Pacific Northwest Extension publications—Washington State University Extension. 2009. Available online: http://www.uaf.edu (accessed on 21 September 2017).

- Kiczorowska, B.; Samoli´nska, W.; Grela, E.R.; Bik-Małodzi´nska, M. Nutrient and Mineral Profile of Chosen Fresh and Smoked Fish. Nutrients 2019, 11, 1448. [Google Scholar] [CrossRef] [PubMed]

- Oyerinde, A.S.; Ogunlowo, A.S.; Olukunle, O.J. Development of a Cross-Flow Fish Smoking Kiln Fired by Biomass Material. JAST 2013, 3, 531–541. [Google Scholar]

- Royani, D.S.; Marasabessy, I.; Santoso, J.; Nurimala, M. The Engineering of the fish smoking tool of cabinet type, (in Indonesian). J. Apl. Teknol. Pangan 2015, 4, 74–78. [Google Scholar]

- Tsai, W.T.; Lee, M.K.; Chang, Y.M. Fast pyrolysis of rice straw, sugarcane bagasse and coconut shell in an induction-heating reactor. J. Anal. Appl. Pyrolysis 2006, 76, 230–237. [Google Scholar] [CrossRef]

- Standar Nasional Indonesia. SNI No. 2725.1 Part 1: Quality Requirements of Smoked Fish, Revised with SNI 2725:2013—Smoked Fish with Hot Smoking Method; BSN: Jakarta, Indonesia, 2009; pp. 1–5. [Google Scholar]

- Badan Pengawasan Obat & Makanan (BPOM). Head Regulation of BPOM about benzo[a]pyrene; KBPOM RI No HK.03.1.23.11.11.09657 Tahun 2011. Available online: http://www.jdih.pom.go.id (accessed on 5 August 2018).

- European Commission. Commission Regulation (EC) No. 208/2005 Amending Regulation (EC) No. 466/2001 as Regards Polycyclic Aromatic Hydrocarbons. Off. J. Eur. Union L/34. Available online: http://eur-lex.europa.eu (accessed on 24 April 2018).

- FAO/WHO. Report of the Second Session of the Codex Committee on Contaminants in Foods; Joint FAO/WHO Food Standards Programme, Codex Alimentarius Commission: Hague, The Netherlands, 2008; pp. 1–30. [Google Scholar]

- Arason, S.; Nguyen, M.V.; Thorarinsdottir, K.A.; Thorkelsson, G. Preservation of Fish by Curing. In Seafood Processing, 1st ed.; Boziaris, I.S., Ed.; John Wiley & Sons Ltd: Hoboken, NJ, USA, 2014; pp. 129–160. [Google Scholar]

- Flick, G.J., Jr. Smoked fish—old product with new appeal offers enhanced taste, shelf life. Glob. Aquac. Advocate 2010, 13, 35–36. [Google Scholar]

- Granata, L.A.; Flick, G.J., Jr.; Martin, R.E. The Seafood Industry: Species, Products, Processing, and Safety, 2nd ed.; John Wiley & Sons: West Sussex, UK, 2012; pp. 105–426. [Google Scholar]

- Tahir, M. Design of Solar and Biomass Energy Dryer System with Temperature Controlling on Stemmed Corn Drying. JIAT 2009, 4, 11–16. [Google Scholar]

- Handoyo, E.A. The effect of using baffles on the shell and tubes heat exchanger (in Indonesian). JTM 2001, 3, 19–23. [Google Scholar]

- Tahir, M.; Kasim, R.; Bait, Y. Performance Test of the Integrated Design of Biomass Furnace and Heat Exchanger. J. Agritech 2013, 33, 219–225. [Google Scholar]

- Liyanage, C.D.; Pieris, M. A Physico-Chemical Analysis of Coconut Shell Powder. Procedia Chem. 2015, 16, 222–228. [Google Scholar] [CrossRef]

- Van Alkemade, I.; Loo, S.; Sulilatu, W. Exploratory Investigations into the Possibilities of Processing Ash Produced in the Combustion of Reject Wood. Available online: www.ieabcc.nl (accessed on 4 February 2017).

- Tahir, M.; Mursalim; Salengke; Metusalach. Design and Performance of a Cyclone Separator Integrated with Heat Exchanger for Smoked Fish Production. ARPN J. Eng. Appl. Sci. 2017, 12, 5396–5404. [Google Scholar]

- Seville, J.P.K.; Clift, R. Gas Cleaning in Demanding Applications, 1st ed.; Springer Science & Business Media: Birmingham, UK, 1997; pp. 1–13. [Google Scholar]

- Woolcock, P.J.; Brown, R.C. A review of cleaning technologies for biomass-derived syngas. Biomass Bioenergy 2013, 52, 54–84. [Google Scholar] [CrossRef]

| Ref. | Brief Descriptives | Advantages | Disadvantages |

|---|---|---|---|

| [1] | Torry kiln smokehouse |

|

|

| [2] | Modified traditional kiln using a charcoal filter |

|

|

| [7] | Home smoker |

|

|

| [9] | Cross-flow fish smoker |

| |

| [10] | Cabinet-type smoker |

|

| Components | Unit | 1st | 2nd | 3rd |

|---|---|---|---|---|

| Coconut shell mass | kg | 17.81 | 22.11 | 17.18 |

| Feed rate | kg/h | 1.37 | 1.51 | 1.43 |

| Moisture | % | 15.8 ± 1.5 | 15.2 ± 0.6 | 13.3 ± 0.7 |

| Long-time | h | 13.0 | 14.67 | 12.0 |

| Coconut shell energy | MJ | 327.50 | 406.58 | 315.82 |

| Electricity | MJ | 8.4 | 10.1 | 4.6 |

| Fish mass | kg | 31.2 | 33.0 | 29.3 |

| Evaporated water | kg | 14.0 | 15.0 | 11.0 |

| SEC * | MJ/kg | 23.99 | 27.78 | 29.13 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tahir, M.; Salengke, S.; Mursalim; Metusalach; Caesarendra, W. Performance of Smokehouse Designed for Smoking Fish with the Indirect Method. Processes 2020, 8, 204. https://doi.org/10.3390/pr8020204

Tahir M, Salengke S, Mursalim, Metusalach, Caesarendra W. Performance of Smokehouse Designed for Smoking Fish with the Indirect Method. Processes. 2020; 8(2):204. https://doi.org/10.3390/pr8020204

Chicago/Turabian StyleTahir, Muh., S. Salengke, Mursalim, Metusalach, and Wahyu Caesarendra. 2020. "Performance of Smokehouse Designed for Smoking Fish with the Indirect Method" Processes 8, no. 2: 204. https://doi.org/10.3390/pr8020204

APA StyleTahir, M., Salengke, S., Mursalim, Metusalach, & Caesarendra, W. (2020). Performance of Smokehouse Designed for Smoking Fish with the Indirect Method. Processes, 8(2), 204. https://doi.org/10.3390/pr8020204