1. Introduction

Gas-liquid reactors are used in a wide variety of applications in the chemical, petrochemical and metallurgy industries, etc. Because of its effectiveness, the gas injection processes have been widely investigated experimentally and numerically to understand the flow patterns of these systems.

Experimental studies are good options to understand the underlying mechanism in bubble dynamics. In certain regimes, interference appears in the measuring of characteristics relative to the flow, for instance, the pressure distribution and velocity field around the bubbles due to the rapid deformation that the bubble shape can undergo during its rise through the liquid. This problem poses limits for the scope of the experimental studies to the regime where only small bubble deformations exist, and the bubble shape is relatively stable [

1].

Analytic studies and empirical correlations are normally formulated to study the global characteristics of the process, such as the average bubble size, volume fraction, the frequency of bubble formation, etc.

Although experimental studies can observe a series of new phenomena [

2], they can take more time and have higher expenses than numerical studies [

3]. As a result, in the significant progress in modeling of two-phase flow and the increasing power of computational resources, the numerical simulation offers scope to study the complex phenomena in bubble dynamics for a wide range of conditions. Moreover, it has been shown that the computational fluid dynamics (CFD) modelling of two-phase flow could exhibit better accuracy than the empirical correlations in the predictions of global characteristics [

4]. Therefore, numerical studies have been widely used to extend the range of research into bubble formation, even beyond experimental studies [

5]. Consequently, the two-phase flow simulation and experimental studies complement each other efficiently to achieve a deep insight into the flow patterns and have made significant advances in recent decades.

At this time, there is a wide variety of models coupled to the Navier-Stokes equations for simulating two-phase flow and free surface problems. In two-phase flow it is well known that energy, mass and momentum transfer rates are quite sensitive to the flow patterns, hence the progress in understanding a wide range of phenomena in two-phase flow, such as in the case of the bottom gas injection process, requiring accurate information about the flow structure.

Two-phase flow predictions with contact lines may dramatically vary for the same system, depending on the modelling parameters; e.g., discretization, mesh density, boundary conditions and technical parameters of the method to track the interface such as the level of reinitialization, among others. Incorrect selection of parameters may yield a smooth solution without physical meaning, leading to misleading conclusions. Therefore, when using a method to track the interface of the fluids, there are many pitfalls may render the results invalid [

6]. In this context, validation and verification are fundamental concepts that determine the accuracy of the model and the numerical uncertainty of the solution, respectively. Moreover, complicated methods to track the interface means that much effort is needed to reproduce a result, therefore simple methods are preferable.

A popular technique in front capturing is the volume of fluid (VOF) method [

7,

8] because it ensures discrete mass conservation when accurate advection algorithms are used even for a relatively coarse mesh. Some approaches for the discrete solution of the VOF equation are the geometrical advection and a pseudo-Lagrangian technique. However, the drawbacks of the VOF method is that the local curvature computation of the interface is not satisfactory at all in some applications because of the discontinuity of the color function at the interface [

9], which puts constraints on the geometric advection algorithm to accurately evolve the VOF scalar. Therefore, when an explicit treatment of the surface tension is employed, the contact angle condition and the stringent stability constraint on the time step must be imposed accurately.

The standard level set (LS) method [

10,

11] is an efficient method to compute the local curvature more accurately than the VOF method because in the LS method the function

varies smoothly across the interface. With the LS method, the merging or break-up of the interface can be handled automatically without specific algorithms. However, a severe drawback to this method is that it is prone to a lose/gain mass of the fluid in a nonphysical manner. The technique called coupled level set volume of fluid (CLSVOF) method [

12,

13] combines the advantages of both the LS and the VOF. With this coupling, mass conservation from the VOF function and accurate computation of the curvature from the level set function are achieved. Although this method combines the complementary advantages of both the LS and the VOF method, it is more complicated because both the VOF and LS functions need to be solved and coupled. Moreover, as the modelling parameters increase, the pitfall arises while using complex methods.

Due to the simplicity and the ability of the standard LS method to accurately model two-phase flows, different techniques to overcome the mass conservation issue with the LS method were proposed by Sussman et al. [

14], Herrmann [

15,

16], Olsson and Kreiss [

17] and Wang et al. [

18] Among the different attempts to alleviate the mass conservation issue, the simplicity of the original method is retained in the conservative level set method (CLSM) of Olsson and Kreiss [

17]. In this signed distance function,

of the standard method [

10,

11] is replaced with a hyperbolic tangent profile, and the interface contour is represented by using a Heaviside function bounded to interval [0, 1] where the interface is defined on

, rather than the level set function. In a later work by Olsson et al. [

19], they improved the CLSM by the modification of the reinitialization step, besides a finite element discretization and an adaptive mesh control procedure that were also presented in that work. For the improvement of the LS method, a reinitialization procedure was formulated as a conservation law so that together with the regularized characteristic function (the Heaviside function as a piecewise constant function), oscillations are damped. Using the regularized function and its preserving of the smooth profile in the reinitialization procedure, the spurious currents and the oscillations in the pressure are not introduced as the interface is advected. The solution of the mass conservation issue of the LS method allows the model to be used successfully in applications such as bubble formation [

20], bubble rise [

17,

18,

21] and bubble bursting at the free surface [

14], among many others. It is important to remark that new formulations of the conservative level set method has been presented using different reinitialization procedures to improve the robustness of the CLSM [

22,

23].

There are published studies on some stages that occur in the gas injection process, such as the bubble formation, bubble rise and bubble bursting using an interface capturing method to track the interface. However, few studies that simulate the full process of bottom gas injection using front capturing methods are available in the literature. The Level Set formulated by Sussman et al. [

14] has been used to study at the same time the stages involved in the bottom gas injection [

24]. This study is focused on the rising behavior of gas bubbles and the bubble formation process from an orifice embedded to simulate the effects of solid concentrations on bubble formation and raise behavior. Valencia et al. [

25] simulated the full process of bottom gas injection using the VOF method implemented in the Fluent software. In this work, simulations to explore numerically the growth, rise and the interaction with the upper air-water interface of bubbles generated by injection with a submerged orifice, were used. Comparison against theoretical predictions showed non-negligible differences attributed to the effect of wall adhesion.

The requirements for design and optimization of the gas injection operations need accurate quantitative information about such flow. These phenomena depend strongly on the flow structure. Two phase-flow simulations are essential for the calculation of production rates to design a more efficient process, so the studies to verify the capability of the currently available numerical methods to describe interfacial motions are very useful. Especially considering that the key issue to achieve a comprehensive analysis of the problem is the tracking of the interfaces. To this date, owing to the complexity of two-phase flow, their simulations remain a great challenge [

26]. Based on the broad front capturing methods available to simulate two-phase flow, comparative testing studies have been carried out to identify the methods that are best suited for an accurate description and better predictions in modeling a particular problem. In [

20], the growth and detachment of an isolated air bubble injected through a single orifice in the axiymmetric domain were considered using the VOF method, the LS method and the coupled VOF with LS (CLSVOF). It was found that the LS method consistently predicted the bubble detachment volume and time, with errors lower than 2%, while the VOF method produces the least accurate results with earlier bubble detachment and smaller volumes, whereas the CLSVOF method modeled significant bubble oscillations, which were not observed experimentally. Carlson et al. [

27] tested the accuracy of both the VOF method and the LS method for the study of slug flow. The VOF method did not correctly predict the slug flow pattern under the conditions studied. The accuracy of the diffuse interface or phase-field approach and the CLSM to capture the coalescence process of two ferrodroplets, was investigated in [

28]. Comparison against analytical solutions showed that the phase-field approach results are more accurate than the results of CLSM when the magnetic effect dominates over the surface tension effect; that is to say, when there are large topological deformations produced by large uniform magnetic fields. More comparative testing studies and the feasibility to simulate a specific application can be found elsewhere [

29,

30].

In this work, the effectiveness of the CLSM to simulate the bottom gas injection process is tested. The aim is to examine the efficacy and accuracy of this (relatively simple) approach to capture complicated gas-liquid interface motions with challenging phenomena with fast changes in the surface tension force (associated to curvature changes) and buoyancy force [

31], such as those arising naturally in the gas injection process. Phenomena such as bubble formation from an orifice, the bubble rising close to the free surface and the bubble bursting into small droplets are covered. Therefore, this paper contributes to the documentation of applicability of the CLSM in complex two-phase multi-scale problems satisfyingly simulated.

For the conditions of the problem, the air is blown through an orifice placed at the center of the bottom of a recipient containing water. The problem also takes into account the deformation of the free surface gas-liquid caused by the impingement of the bubbles, which produce a jet of liquid when they break. For validation, the results were compared against numerical data computed with the VOF (using a Piecewise Linear Interface Calculation approach) method reported in the literature [

25]. Moreover, qualitative comparisons of the computational results for the free surface behavior against experimental observations were made to further validate the numerical model. The simulation accuracy is verified with the grid convergence index (GCI) approach and Richardson Extrapolation (RE).

2. Basic Equations and Numerical Scheme

The equations governing the motion of an unsteady, immiscible and incompressible two-phase flow are essentially the Navier-Stokes equations. In gas-liquid two-phase flow, the main body forces which govern are the surface tension force (

) and the acceleration due to gravity (

). The buoyancy effect arises from the source term (

). The equations can be written as

Together with the divergence-free condition.

where

denotes the velocity field and

the pressure field.

and

are the discontinuous density and viscosity fields, respectively. The density and viscosity are defined in terms of the level set function

to smooth the jump conditions in the properties of the materials across the interface. The function

is defined in the domains of the mixture of fluids and it is a Heaviside function that distinguishes the two phases varying smoothly from 0 to 1 across the interface.

The system is assumed to be isothermal. The gas density varies according to the ideal gas law, since the density of the liquid phase is three orders of magnitude higher than that of the gas phase. The surface tension is recast into a volume force in the Navier-Stokes equation and is formulated as the divergence of the capillary pressure tensor [

32]:

Here

is the identity matrix. The

-function is approximated by a smooth Dirac delta function centered at the 0.5 isocontour of

according to

The geometrical parameters as the curvature

and the normal

to the interface are calculated along the 0.5 isocontour of the level set variable as follows

The equation governing the transport of the

function is a hyperbolic partial differential equation, where the interface is advected by the local velocity field

. However, this convection equation is not very stable. Thus, to improve stability, a small amount of viscosity is added to avoid a discontinuity at the interfaces as well as an artificial compression flux in the normal direction [

16] (

). All of this is to maintain the resolution of sharp changes in properties at the interface. The equation governing the convection and the reinitialization of

is given as

The terms on the left-hand side represent the correct advection of the interface, while the terms on the right-hand side are necessary for the numerical stability control. The parameter

represents the thickness of the transition layer, and it is desirable to keep

as small as possible to give better conservation of the area bounded by the 0.5 contour of

. On the other hand, since the method is coupled with the incompressible Navier-Stokes equations, a small value of

will reduce the smearing of density, viscosity and surface tension [

19]. A recommended value is half the coarsest mesh size (in this work, the coarsest mesh size in the simulations was 0.4 mm). The parameter

determines the amount of reinitialization of the level set function and it helps to preserve the interface thickness constant.

is assumed to be an artificial diffusion parameter. In this step, the Equation (11) reaches a steady state by pure diffusion without any convection. A too-small value of

causes the interface to not maintain a constant value and oscillations can appear because of numerical instabilities. On the other hand, an excessively large value causes the interface to move incorrectly. A suitable value for

is the maximum magnitude of the velocity field

u [

33]. During the bubble formation stage, the maximum superficial velocity of the gas varies significantly because of the neck radius reduction. Therefore, the reinitialization parameter that is good at the time when the neck of the bubble is formed would be very high after the pinch-off stage. If

is represented by a piecewise function during the entire period of operation, the free surface moves nonphysically (jaggy interface) at the beginning, because it remains essentially quiescent until the first bubble impingement at the upper gas-liquid surface. Thus, after some ad hoc intervention, the choice of the

was set to a constant value of 1 m/s. With this value the interface dynamics of the overall process are not sensitive to

.

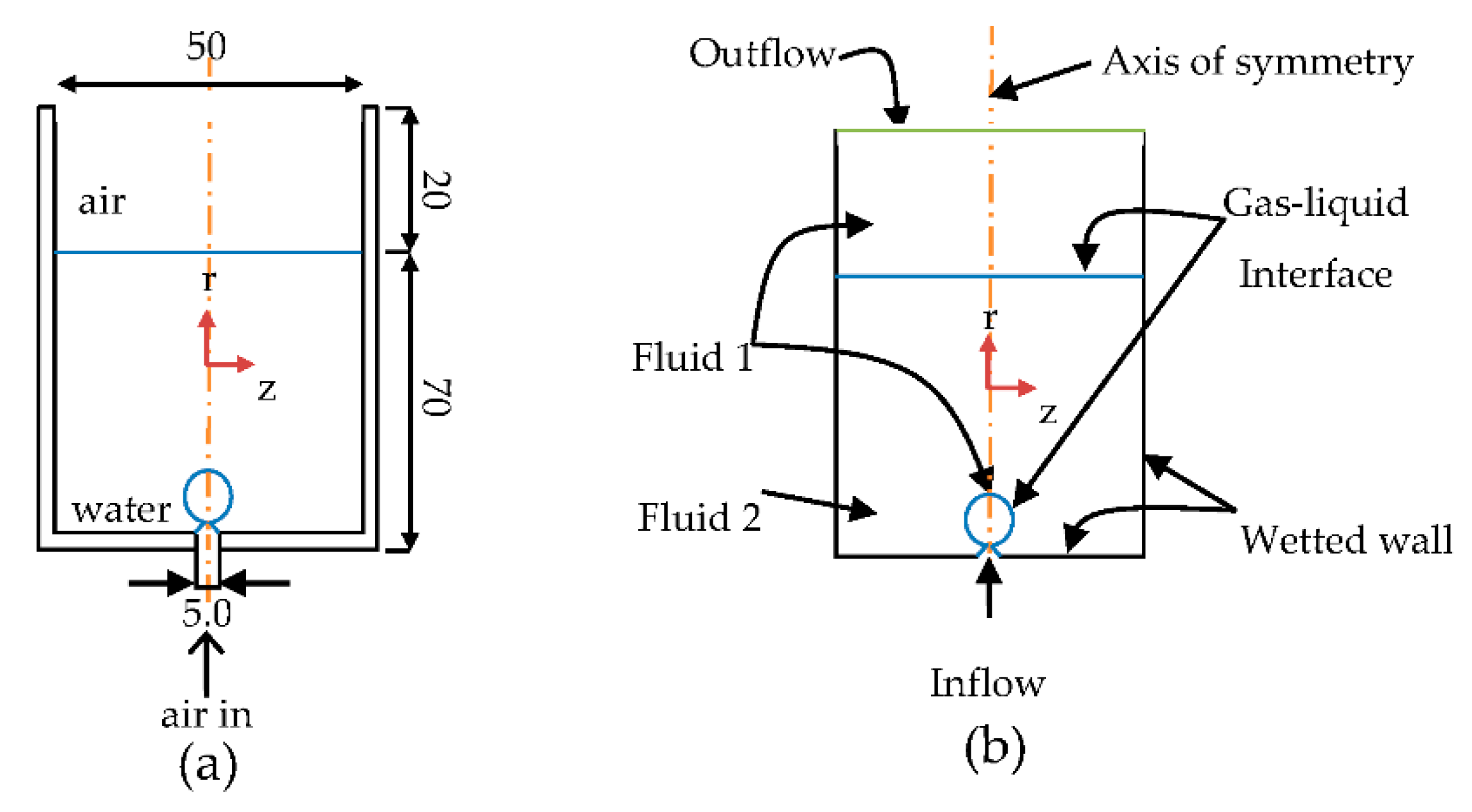

Figure 1 shows the solution domain used for the numerical computations of the bottom air injection into quiescent water. The physical dimensions are in millimeters and the boundary conditions used in this work are also shown. The diameter of the bottom orifice is 2.5 mm, and air flows through the orifice to a constant velocity of 0.2 m/s assuming a fully developed laminar flow where the average velocity profile is parabolic. It is assumed that the vessel to be made of a polymer and the contact angle between the liquid and solid walls is 110°. The parameters employed to perform the simulation were based on the conditions numerically studied in [

25] using the VOF method. The gas is let go from the solution domain at the upper part of the vessel where outflow pressure was set to 1 Pa.

Due to the symmetry of the system about the vertical axis, a two-dimensional axisymmetric problem was used to solve in time-dependent and spatially the governing equations of fluid flow and interface capturing. Effects of azimuthal instabilities are ignored and may be important. This model was developed using the CFD module of COMSOL Multiphysics, where equations are solved using the Galerkin finite element method. The momentum and continuity equations were coupled in terms of the primitive variables

u and p. The use of Galerkin formulation in problems which involve advection terms that dominate over diffusive terms tend to produce numerical instabilities. These result in spurious node to node oscillations in the velocity field, so the inclusion of the Streamline Upwind/Petrov-Galerkin method was used to stabilize the Navier-Stokes equations and the level set equations. The stabilization is achieved by adding a term to the Galerkin formulation for both incompressible and compressible flow by modifying the standard Galerkin weighting functions. This additional term prevents the oscillations caused by the presence of the advection term by adding a streamline upwind perturbation, which acts only in the flow direction [

34].

The level set equation requires initialization at time

and

to define the initial position of the interface and to ensure the smooth initial solution of the level set variable, and then this initial solution is used to start the time-dependent simulations. The numerical algorithm employs the same methodology as presented in [

19], with the main difference that they used the projection method to overcome the incompressibility constraint in the Navier-Stokes equations. The projection method is well suited for low Reynolds number calculations. It allows resolving the equations for the velocity and pressure in a segregated manner at each time step, reducing the amount of memory needed in the computing. The CFD solver of COMSOL Multiphysics (5.2a, COMSOL Inc. Burlington, MA, USA, 2016) is for general problems, which can include complicated boundary conditions. It uses by default a fully coupled solution strategy for the primitive variables (

, p) using mixed methods. In mixed methods, the interpolation functions for pressure and velocity are chosen one order lower for pressure than those for the velocity to avoid pressure oscillations in the pressure field (due to the Babuska-Brezzi (B-B) inf-sup condition [

35]). However, the software also allows for the use of combinations of an equal or higher order of interpolation functions for the velocity components and pressure field. Moreover, it also includes the incremental pressure correction scheme version of the projection method to solve in a segregated manner. In this work, the interpolation functions to represent the velocity and pressure were of the type P2-P1 even though the Petrov-Galerkin formulation of the problem circumvents the B-B inf-sup condition and piecewise quadratic P2 finite elements for the level set function.

2.1. Temporal Discretization

The temporal terms in the Navier-Stokes equations and level set equation were discretized in an implicit fashion by using a second-order backward difference formula (BDF) technique. The time steps are controlled by the numerical solver (adaptive time-stepping), but the numerical accuracy was checked by doing a convergence study where further mesh refinement and the decrease in the values of the relative tolerance (to lower the adaptive time step size in the solver) do not produce visible changes in the results (to ensure mesh independent, a mesh with a total of elements has been retained). As mentioned above, in this work the adaptive time stepping option was used (BFD) since this implicit method is stable and has an efficient time step control. Thus, the appropriated Courant Friedrich Lewy (CFL) number was determined by the solver. Then, the time steps are updated as needed to achieve numerical stability, and according to the accuracy of the solution while it meets the specified relative tolerance (). From the convergence plot reported by the solver (not shown here), it was observed that the smallest time step in the computation was , while the bigger time step was about . To accelerate the convergence rate, scaling factors for the variables u and p were set to 1 and 1000, respectively. With these values in the scaling variables, the convergence was accelerated. Convergence within each time step was tracked in the solver log where no failures were reported. Fixed meshes with unstructured triangular elements were used. The system of nonlinear equations was solved using the damped Newton method with a constant value equal to one for the damping factor. With such values for the damping factor, the nonlinear solver was stable and convergences were reasonably fast. The linear system of equations that arises at each Newton iteration was solved by a direct solver such as PARDISO. The full solution shown in the figures of the results section was obtained by mirroring in the symmetry plane.

2.2. Mesh Resolution

Simulations were run over three fixed meshes: coarse (

= 5900 elements), intermediate (

= 21,196 elements) and fine (

= 175,202 elements). A convergence study of mesh refinement was performed to quantify the discretization error of the solutions. Uncertainty estimates were calculated with the Grid Convergence Index (GCI) and performed with a Richardson extrapolation (RE). Detailed information for the performing of the later methods GCI and RE can be found at ASME V and V 20-2009 (this standard address verification and validation (V and V) in CFD and HT) [

36] and [

37]. The bubble frequency (dynamic gas pressure at the nozzle) was chosen as the critical variable (

= 12 [1/s],

=10 [1/s] and

= 9.8 [1/s]).

Table 1 presents convergence parameters calculated from the gathered information of the three studies. The verification of the numerical model using a global variable such as the bubble frequency shows that the mesh resolution is appropriated based on the value of the GCI computed. It is desirable that the GCI value would be as low as possible to ensure that the numerical solution will not change with further refinement of the mesh. A GCI value of 6.4% is small and the results are likely to approach to the asymptotic range of convergence. Then, it is expected that further refinement does not substantially change the tracking of the interfaces. However, the presence of discontinuities or singularities can complicate grid convergences studies with the GCI approach [

37]. In this study, the singularities arise when the bubble neck’s pinch-off (a finite time singularity in the flow where pressure, velocity, and curvature diverge), consequently this gives non-conservative estimates of discretization errors since the convergence condition

[

38] corresponds to divergence with

, where

and

. Despite that a divergence condition was obtained because of the singularities arising in the study, the verification of numerical accuracy was considered acceptable based on the GCI value and the extrapolated critical variable value (

). The study was also validated by comparing the numerical values of the bubble frequency against those predicted by the analytical equation reported in [

25].

4. Conclusions

In this work, the capabilities of the CLSM to simulate gas-liquid complex interactions were explored by simulating the bottom gas injection process. Since singularities arise in the study, the divergence condition was obtained in the verification of numerical accuracy, nevertheless, it was considered acceptable since the GCI value was small.

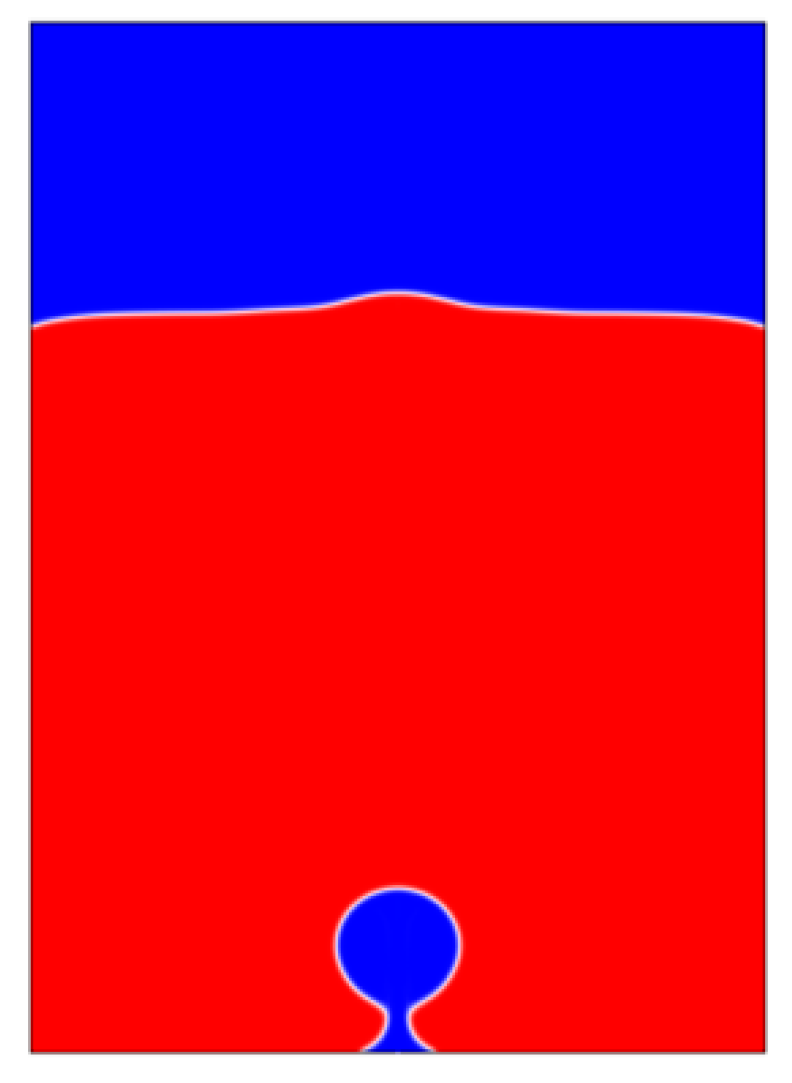

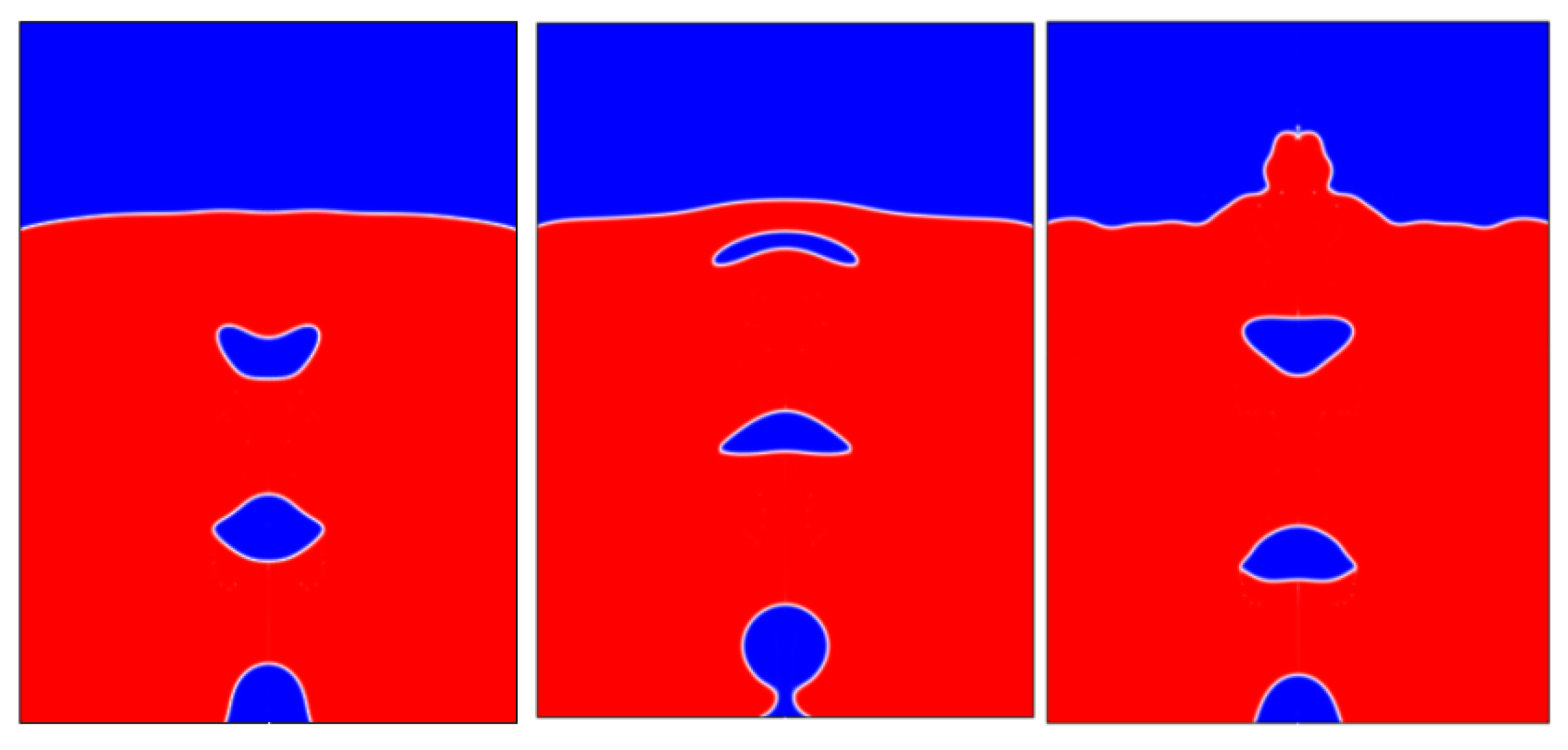

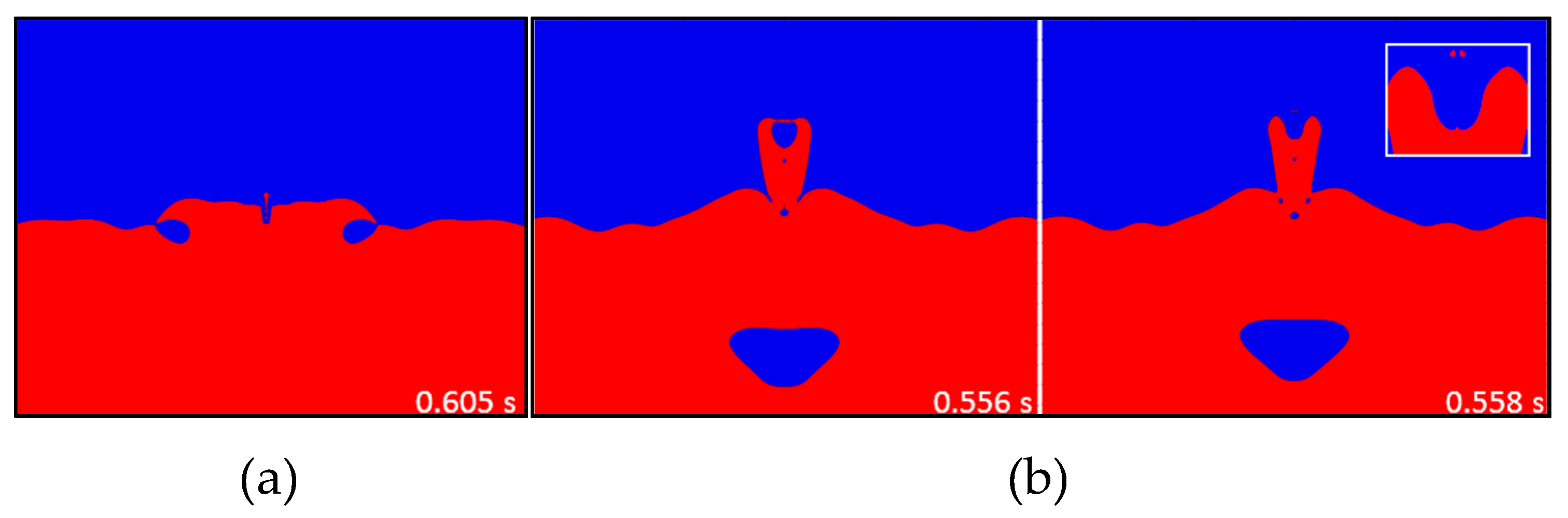

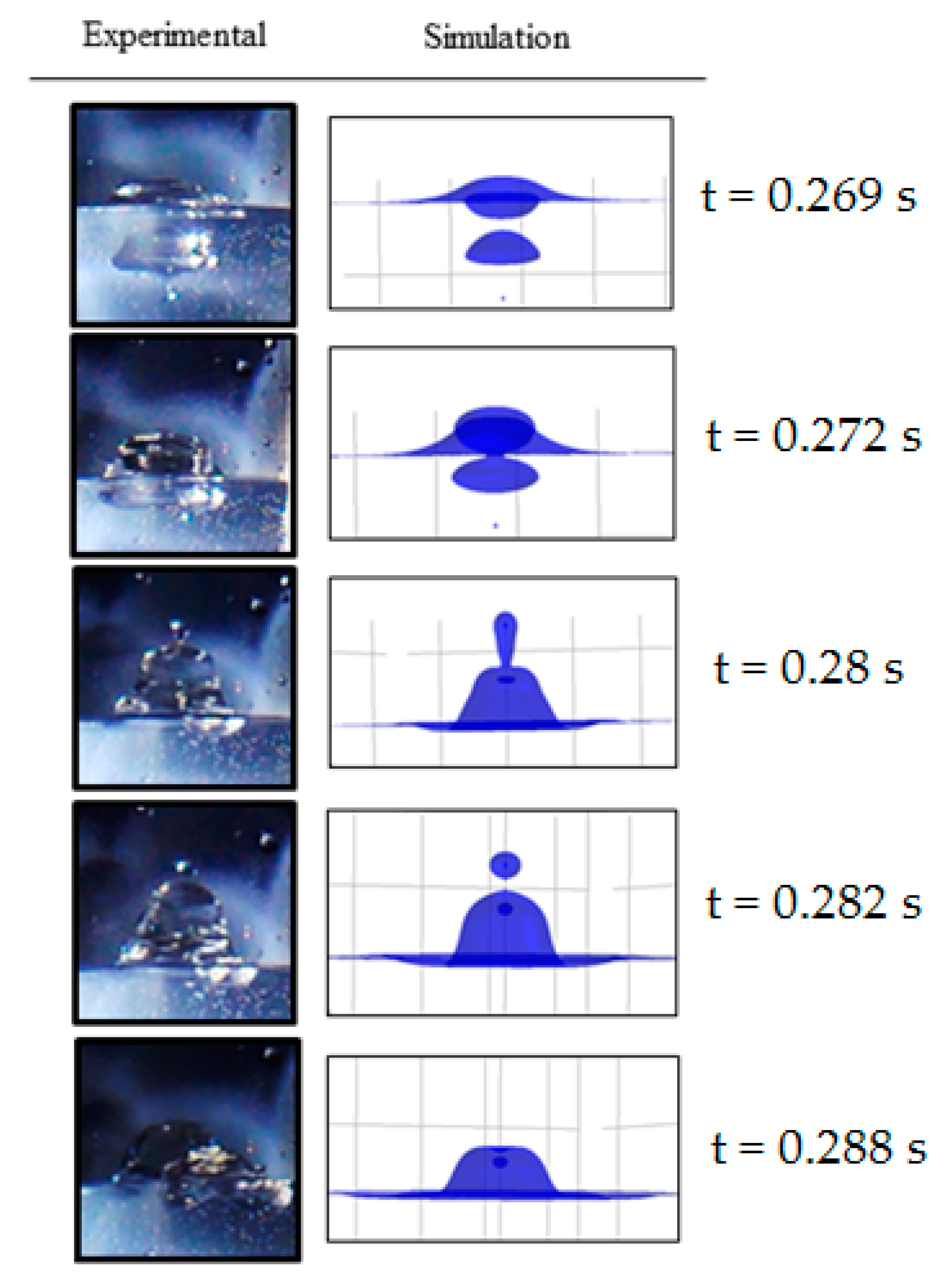

Results were compared with those reported in the literature using the volume of fluid method (VOF), and with those obtained by physically simulating the process to validate the numerical model. The velocity field was obtained numerically and the bubble sizes were very similar between the VOF and CLSM. However, the present study shows that the CLSM presents notable capabilities to simulate accurately the important physical features of the gas injection process.

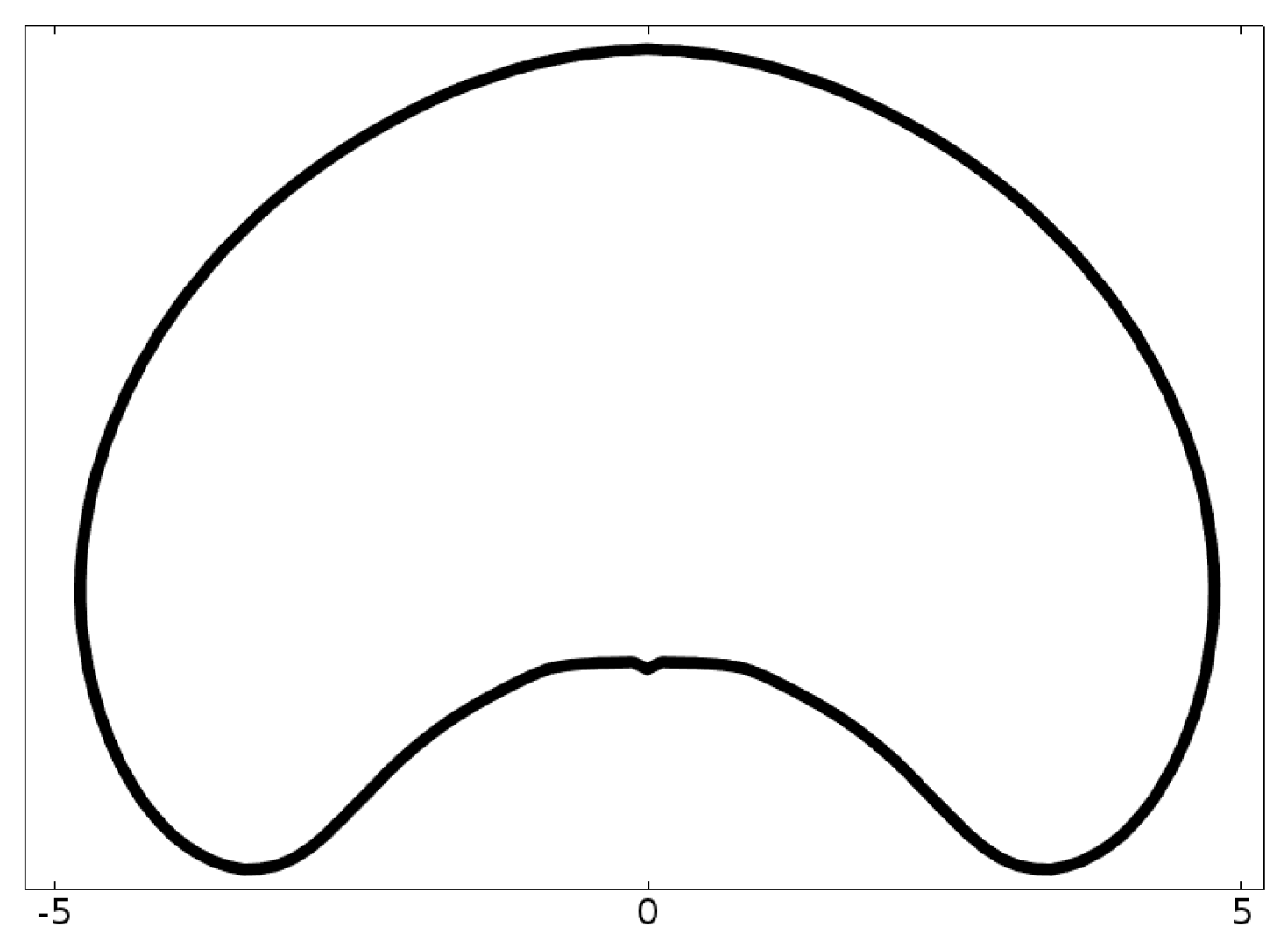

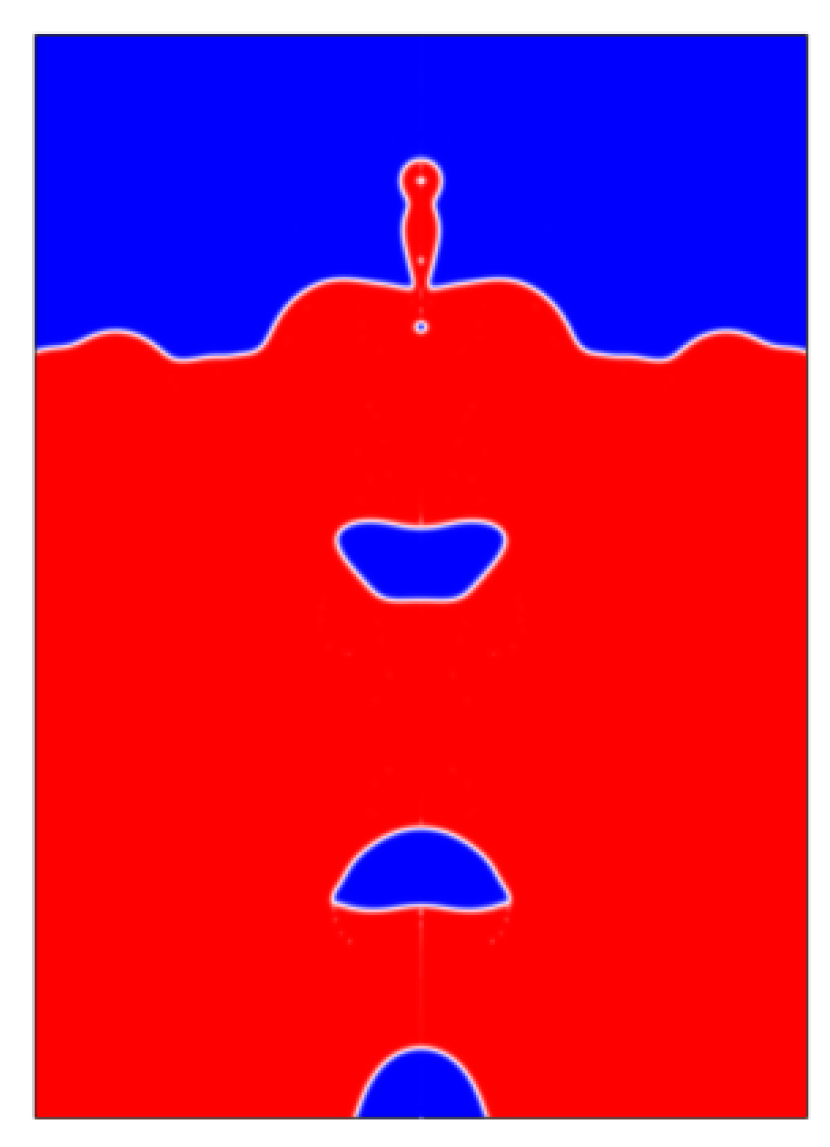

Predictions are accurate even for those regimes where capillary forces do not dominate at all since the LS computes very well the local balance of the forces around the gas-liquid interface. This allows the CLSM to accurately predict the bubble frequency formation and the bubble rise dynamics, as is shown by the complex bubble shapes captured along with the wobbling effect, which was theoretically expected. It was found that the CLSM suffers from the drawback that it predicts the formation of nonphysical satellite bubbles in the pinch-off dynamics of bubbles.

The simulation of the impingement event of the gas bubbles at the free surface compared very well with the physical images obtained in this work. The mass loss is small 0.018325 showing good mass conservation. Therefore, based on extrapolated and validation errors—5%, and 2% respectively—the CLSM has the accuracy and robustness to capture with a high level of detail the physical phenomena related to gas-liquid complex interactions in fairly complicated systems such as gas injection.