Numerical Simulation on the Brake Effect of FAC-EMBr and EMBrRuler in the Continuous Casting Mold

Abstract

:1. Introduction

2. Numerical Setup

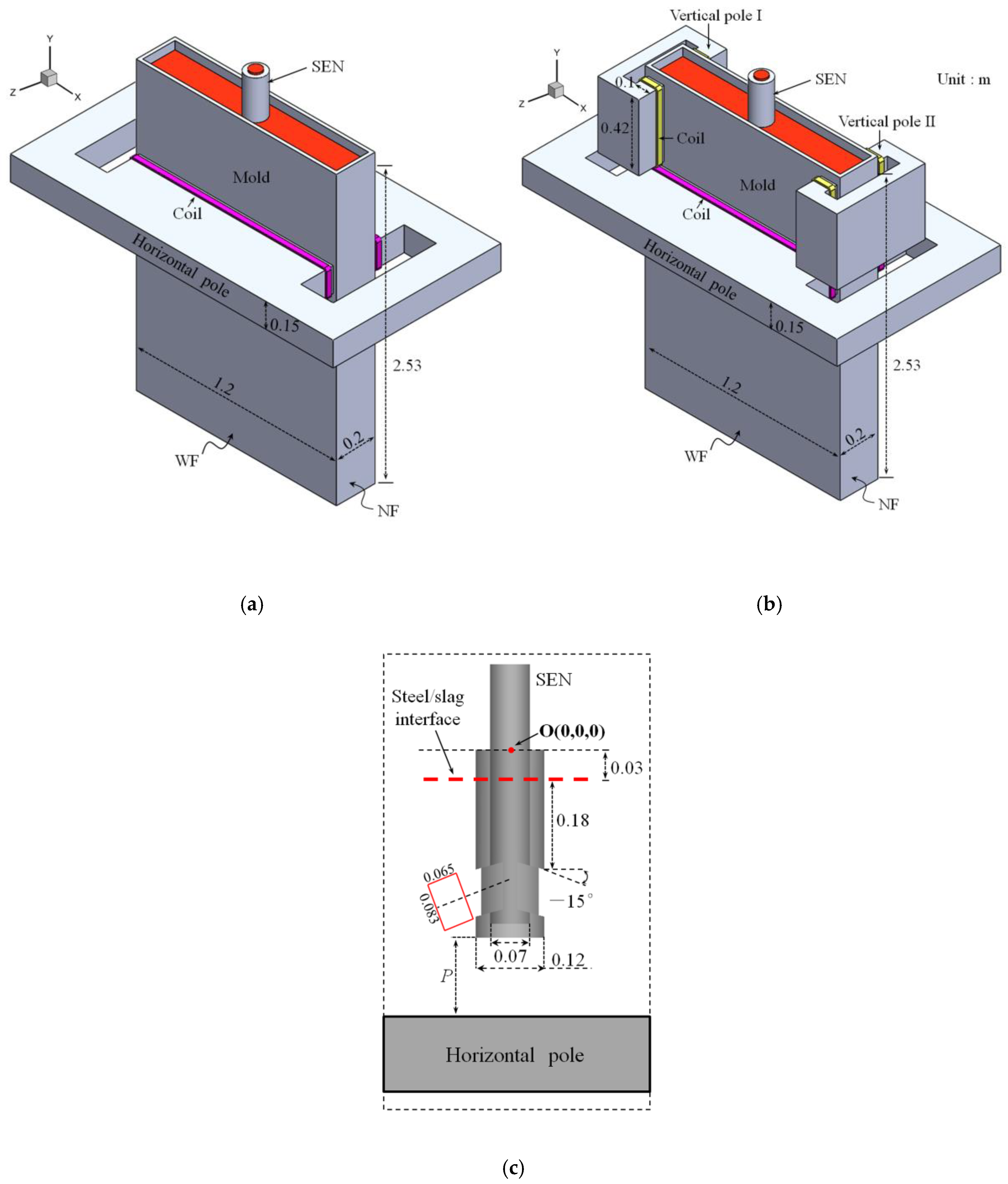

2.1. Configuration of EMBr Ruler and FAC-EMBr

2.2. MathematicalModel

2.3. Boundary Condition Setup and Mesh of Computational Domain

2.4. Model Validation

3. Simulation Result and Discussion

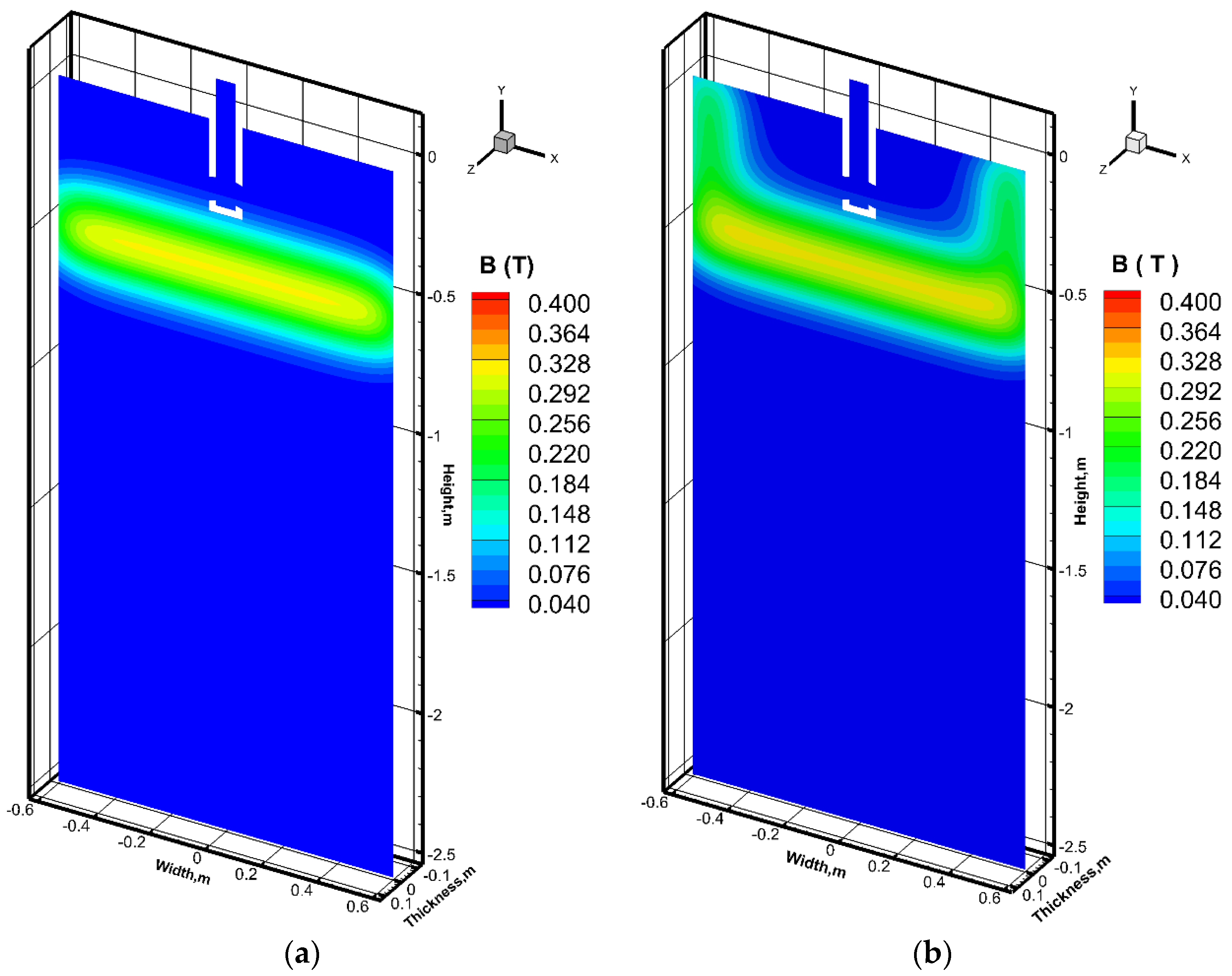

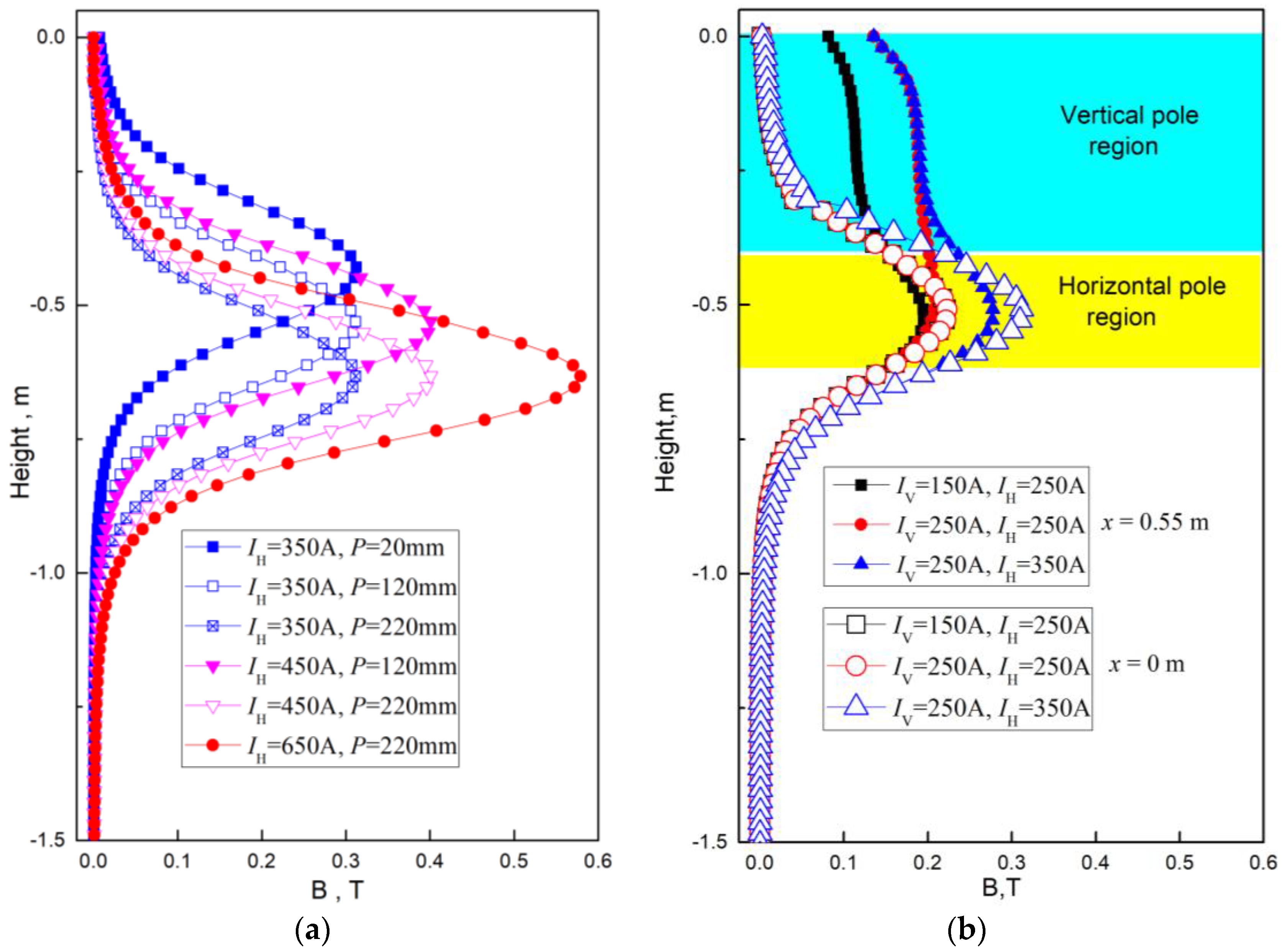

3.1. Distribution of Electromagnetic Field

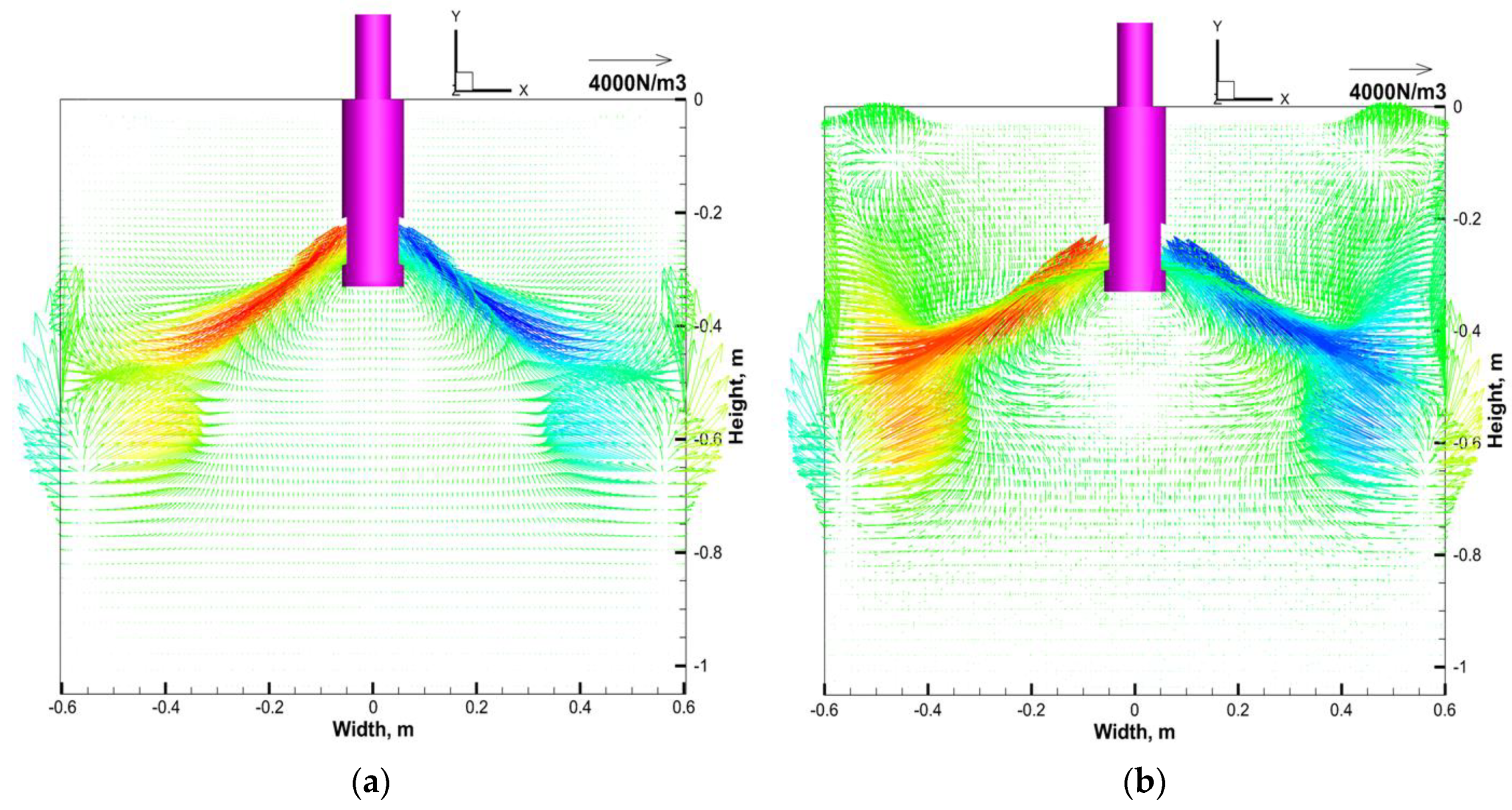

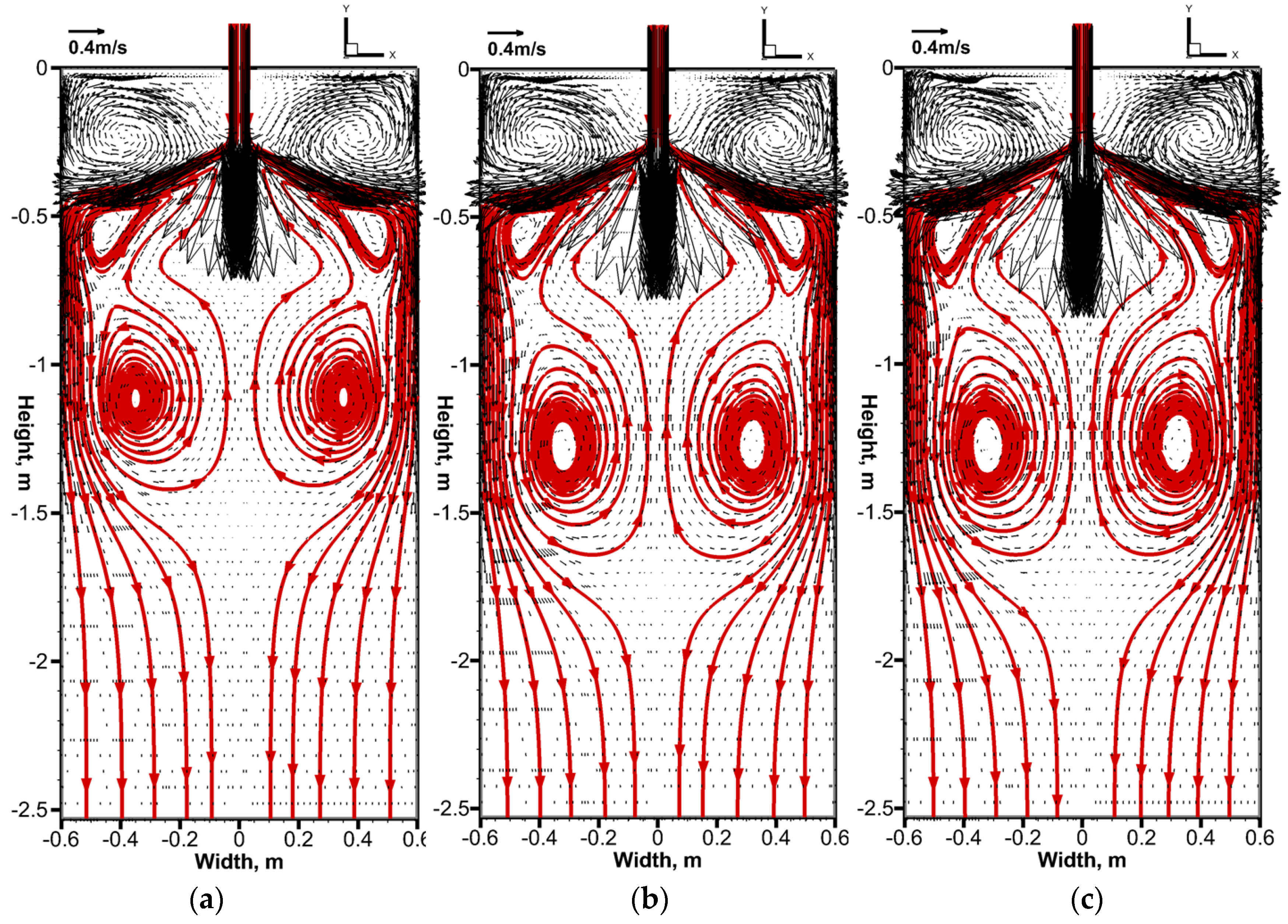

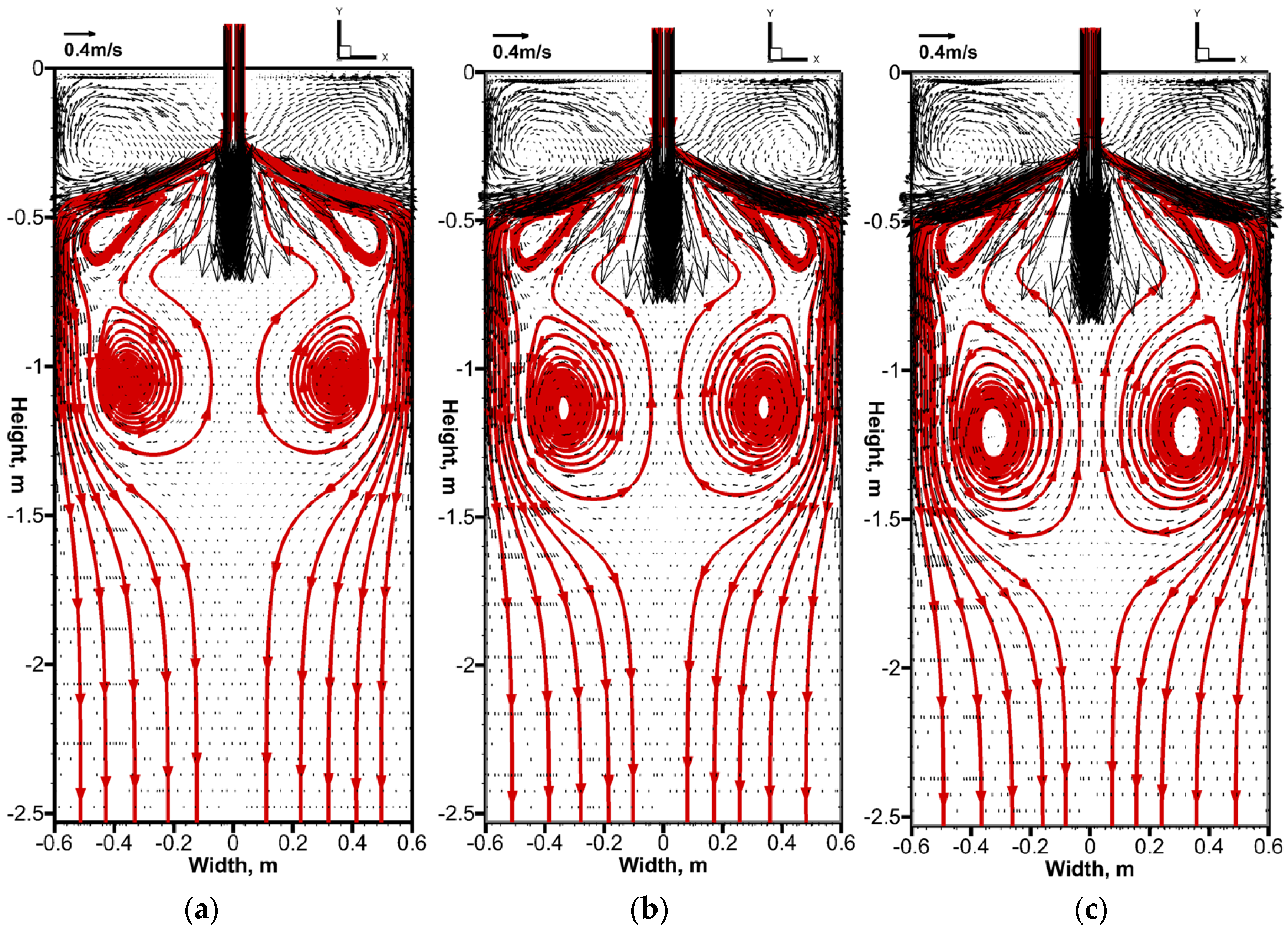

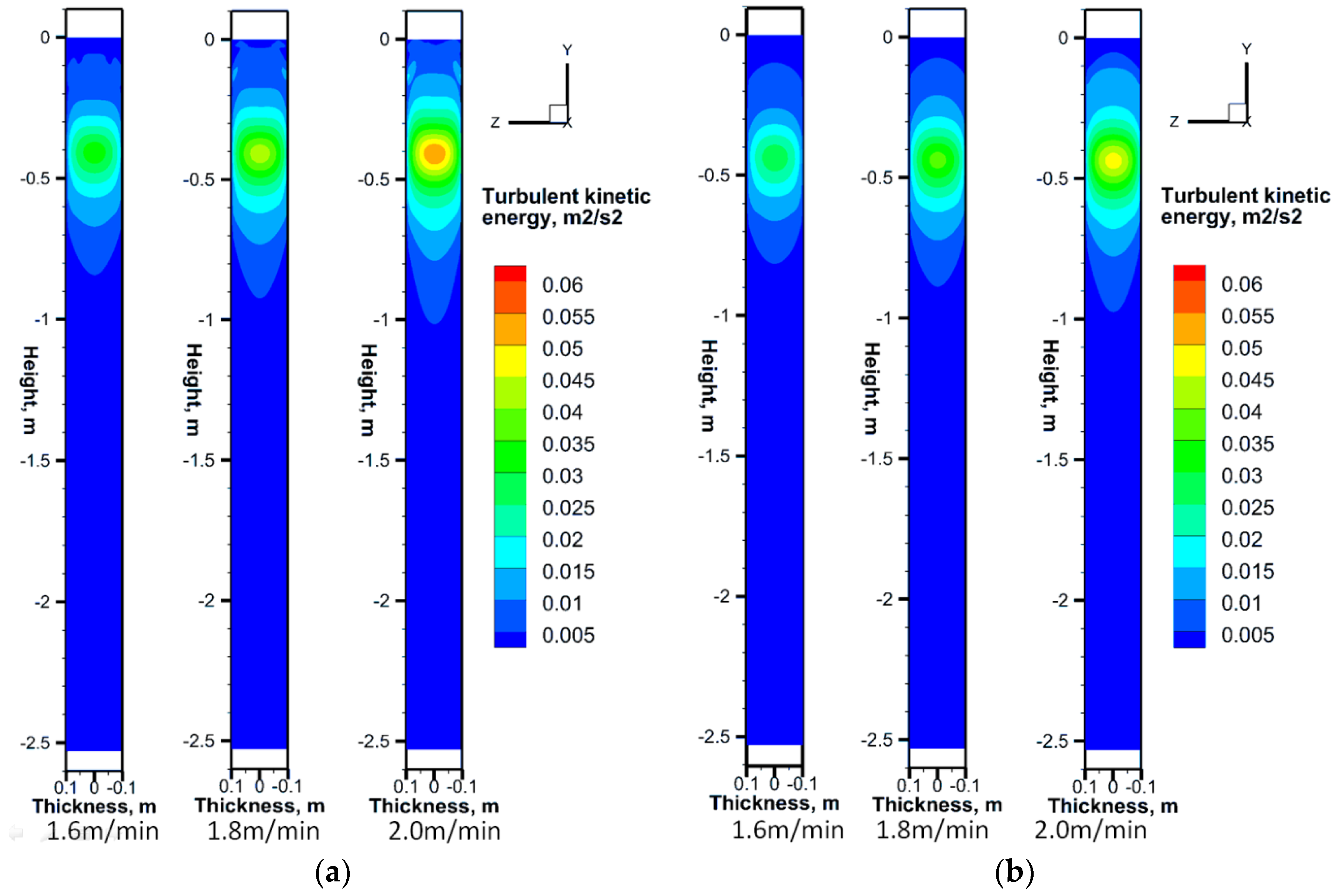

3.2. Influence of EMBr Ruler and FAC-EMBr on the Molten Steel Flow Field

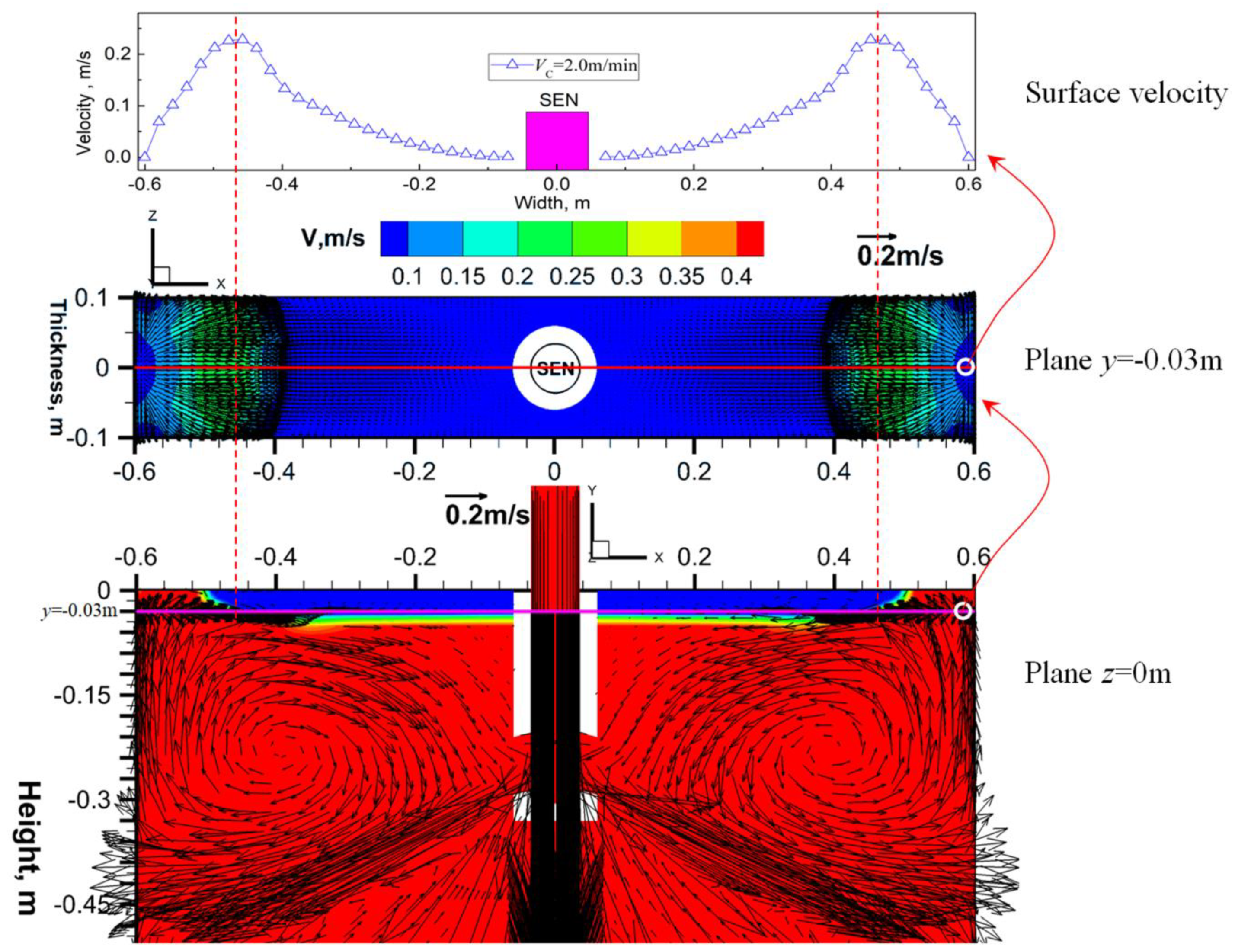

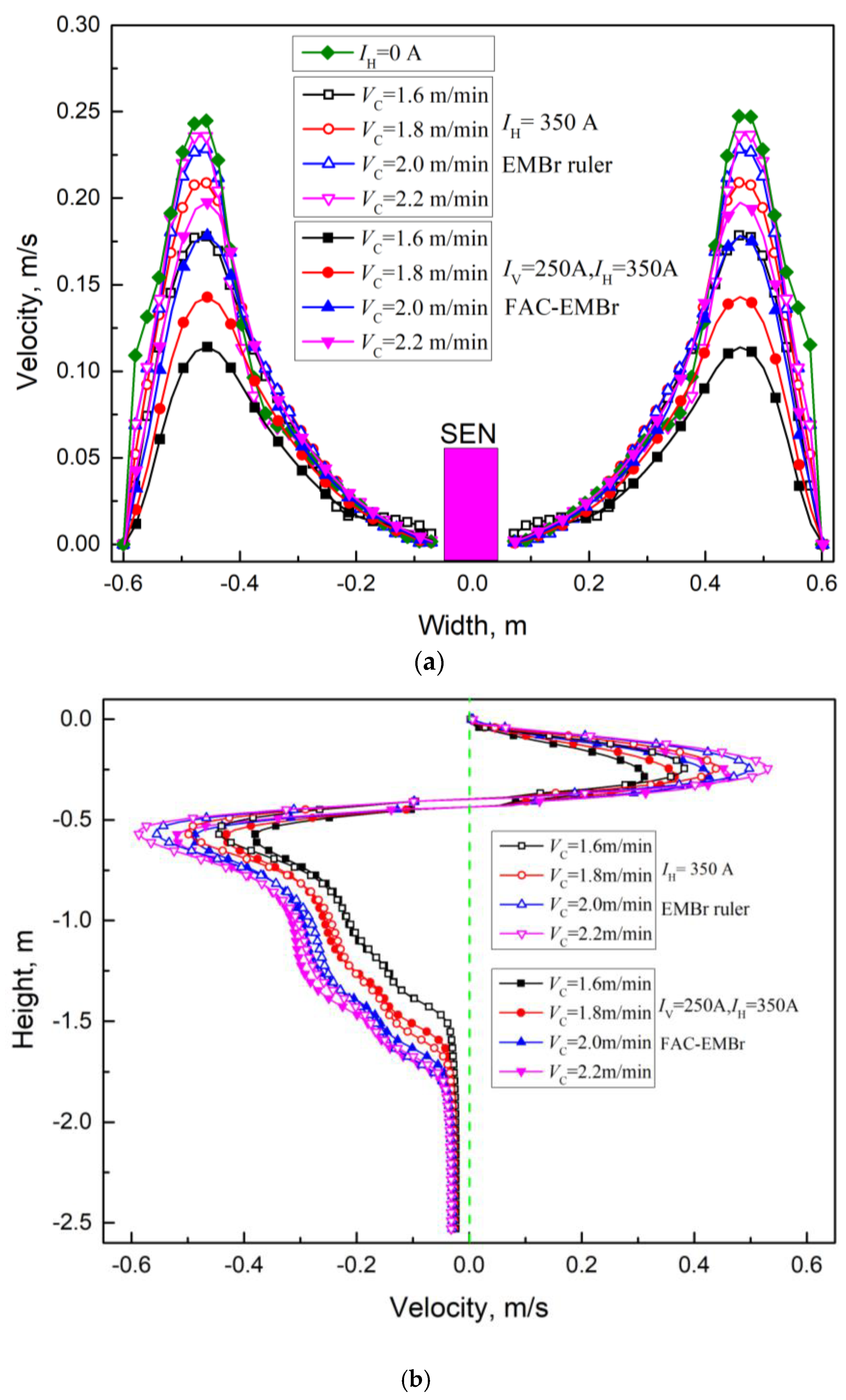

3.3. Effects of the EMBr Ruler and FAC-EMBr on the Flow Velocity

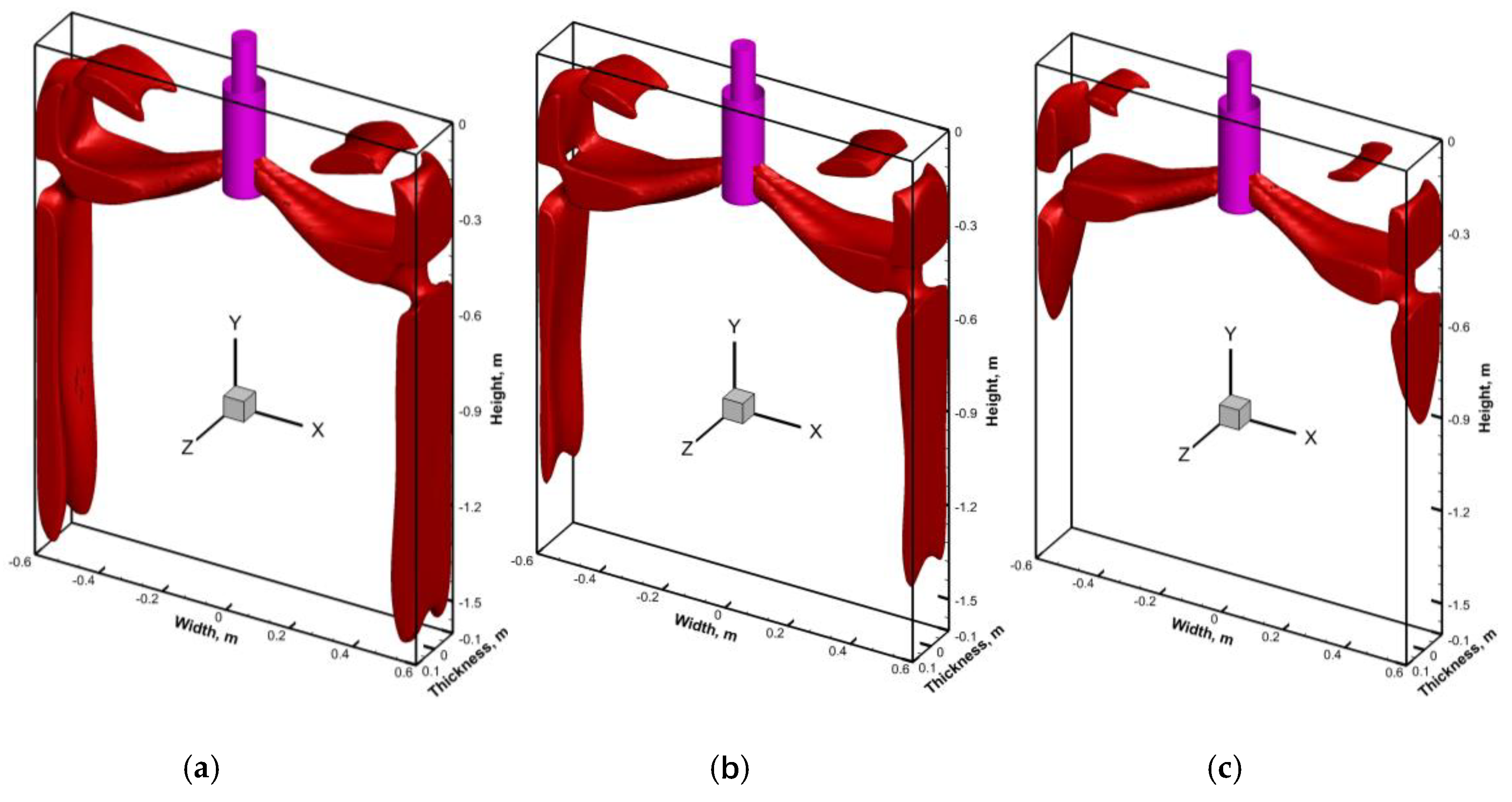

3.4. Influence of the EMBr Ruler and FAC-EMBr on the Jet Flow

3.5. Effects of the EMBr Ruler and FAC-EMBr on the Level Fluctuation

4. Conclusions

- The electromagnetic field of the EMBr ruler was mainly distributed in the horizontal magnetic pole area. The magnetic induction intensity in the upper roll and meniscus regions was very small. The Lorentz force was mainly distributed in the molten steel jet impact region and the downwards roll-flow region near the jet impingement point on both sides of the SEN. The electromagnetic force was very small in the upper roll and meniscus regions.

- With the application of the FAC-EMBr, the steady magnetic field was formed in the horizontal magnetic pole region and the upper roll and meniscus regions, and a strong Lorentz force could be formed in these regions, so the velocity of the molten steel in these regions could be significantly reduced.

- As the distance between the SEN and the horizontal magnetic pole was far (case 2 and case 3), the application of the EMBr ruler could not effectively brake the upper roll flow and reduce the meniscus wave height.

- For the FAC-EMBr, increasing the current intensity IV could significantly reduce the molten steel velocity in the upper roll and meniscus regions, decrease the meniscus wave height, and stabilize the level fluctuations; increasing the current intensity IH could effectively decrease the impingement of the jet and the molten steel velocity, which was beneficial to the formation of the piston flow.

- The FAC-EMBr had independent adjustable characteristics, which made it possible to control the molten steel flow in the key areas comprehensively and flexibly and achieve a more appropriate flow state in the mold.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Calderón-Ramos, I.; Morales, R.D.; Servín-Castañeda, R.; Pérez-Alvarado, A.; García-Hernández, S.; Barreto, J.D.J.; Arreola-Villa, S.A. Modeling study of turbulent flow in a continuous casting slab mold comparing three ports SEN designs. ISIJ Int. 2019, 59, 76–85. [Google Scholar] [CrossRef] [Green Version]

- Yang, H.; Vanka, S.P.; Thomas, B.G. Mathematical modeling of multiphase flow in steel continuous casting. ISIJ Int. 2019, 59, 956–972. [Google Scholar] [CrossRef] [Green Version]

- Li, B.K. Study on turbulent flow field of liquid steel and its electromagnetic control in continuous casting mold at high casting speed. Iron Steel 2005, 40, 33–36. [Google Scholar]

- Singh, V.; Das, S.K. Mathematical model and plant investigation to characterize effect of casting speed on thermal and solidification behavior of an industrial slab caster. ISIJ Int. 2018, 58, 2308–2317. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.F.; Zhang, L.F. Fluid flow-related transport phenomena in steel slab continuous casting strands under electromagnetic brake. Metall. Mater. Trans. B 2011, 42, 1319–1351. [Google Scholar] [CrossRef]

- Cho, S.-M.; Thomas, B.G. Electromagnetic forces in continuous casting of steel slabs. Metals 2019, 9, 471. [Google Scholar] [CrossRef] [Green Version]

- Thomas, B.G. Continuous casting of steel. In Modeling for Casting and Solidification Processing; Kuang-Oscar, Y., Ed.; Marcel Dekker: New York, NY, USA, 2001; Chapter 15; pp. 499–540. [Google Scholar]

- Jin, K.; Vanka, S.P.; Thomas, B.G. Large eddy simulations of the effects of EMBr and SEN submergence depth on turbulent flow in the mold region of a steel caster. Metall. Mater. Trans. B 2017, 48, 162–178. [Google Scholar] [CrossRef]

- Thomas, B.G.; Yuan, Q.; Mahmood, S. Transport and entrapment of particles in steel continuous casting. Metall. Mater. Trans. B 2014, 45, 22–35. [Google Scholar] [CrossRef]

- Cho, S.-M.; Thomas, B.G.; Kim, S.-H. Bubble behavior and size distributions in stopper-rod nozzle and mold during continuous casting of steel slabs. ISIJ Int. 2018, 58, 1443–1452. [Google Scholar] [CrossRef] [Green Version]

- Miki, Y.; Takeuchi, S. Internal defects of continuous casting slabs caused by asymmetric unbalanced steel flow in mold. ISIJ Int. 2003, 43, 1548–1555. [Google Scholar] [CrossRef] [Green Version]

- Choi, S.L.; Ryu, K.J.; Park, H.S. Numerical simulation on the effect of an electromagnetic brake to continuous thin slab casting. Met. Mater. Int. 2002, 18, 527–533. [Google Scholar]

- Sarkar, S.; Singh, V.; Ajmani, S.K.; Ranjan, R.; Rajasekar, K. Effect of double ruler magnetic field in controlling meniscus flow and turbulence intensity distribution in continuous slab casting mold. ISIJ Int. 2016, 56, 2181–2190. [Google Scholar] [CrossRef] [Green Version]

- Hwang, Y.-S.; Cha, P.-R.; Nam, H.-S.; Moon, K.-H.; Yoon, Y.-K. Numerical analysis of on the fluid flow and the influences meniscus shape of operational parameters in slab caster with EMBR. ISIJ Int. 1997, 37, 659–667. [Google Scholar] [CrossRef]

- Idogawa, A.; Sugizawa, M.; Takeuchi, S.; Sorimachi, K.; Fujii, T. Control of molten steel flow in continuous casting mold by two static magnetic fields imposed on whole width. Mat. Sci. Eng. A Struct. 1993, 173, 293–297. [Google Scholar] [CrossRef]

- Wang, Y.F.; Dong, A.P.; Zhang, L.F. Effect of slide gate and EMBr on the transport of inclusions and bubbles in slab continuous casting strands. Steel Res.Int. 2011, 82, 428–439. [Google Scholar] [CrossRef]

- Jin, K.; Vanka, S.P.; Thomas, B.G. Large eddy simulations of electromagnetic braking effects on argon bubble transport and capture in a steel continuous casting mold. Metall. Mater. Trans. B 2018, 49, 1360–1377. [Google Scholar] [CrossRef]

- Yu, H.Q.; Zhu, M.Y. Numerical simulation of the effects of electromagnetic brake and argon gas injection on the three-dimensional multiphase flow and heat transfer in slab continuous casting mold. ISIJ Int. 2008, 48, 548–591. [Google Scholar] [CrossRef] [Green Version]

- Harada, H.; Toh, T.; Ishii, T.; Kaneko, K.; Takeuchi, E. Effect of magnetic field conditions on the electromagnetic braking efficiency. ISIJ Int. 2001, 41, 1236–1244. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, L.T.; Ma, D.Z.; Wang, E.G. Numerical simulation on flow characteristic of molten steel in the mold with freestanding adjustable combination electromagnetic brake. Metall. Mater. Trans. B 2020, 51, 2609–2627. [Google Scholar] [CrossRef]

- Yu, H.Q.; Zhu, M.Y.; Wang, J. Interfacial fluctuation behavior of steel/slag in medium-thin slab continuous casting mold with argon gas injection. J. Iron Steel Res. Int. 2010, 17, 5–11. [Google Scholar] [CrossRef]

- Li, Z.; Wang, E.G.; Xu, Y. Behavior of molten steel flow in continuous casting mold with different static magnetic field configurations. J. Iron Steel Res. Int. 2018, 25, 366–377. [Google Scholar] [CrossRef]

- Li, Z.; Wang, E.G.; Zhang, L.T.; Xu, Y.; Deng, A.Y. Influence of vertical electromagnetic brake on the steel/slag interface behavior in a slab mold. Metall. Mater. Trans. B 2017, 48, 2389–2402. [Google Scholar] [CrossRef]

- Schurmann, D.; Glavinić, I.; Willers, B.; Timmel, K.; Eckert, S. Impact of the electromagnetic brake position on the flow structure in a slab continuous casting mold: An experimental parameter study. Metall. Mater. Trans. B 2020, 51, 61–78. [Google Scholar] [CrossRef]

| Material | Density ρ (kg m s−1) | Dynamic Viscosity μ (kg m−1 s−1) | Electrical Conductivity σ (S m−1) |

|---|---|---|---|

| Steel | 7100 | 0.006 | 7.14 × 105 |

| Slag | 2700 | 0.2 | 1 × 10−5 |

| Variables | Values |

|---|---|

| Current I(EMBr ruler), A | IH = 350, 450, 650 |

| Current I(FAC-EMBr), A | (IV = 100, IH = 350), (IV = 150, IH = 350), (IV = 250, IH = 350), (IV = 350, IH = 350) |

| Pole position(EMBrruler)P, mm | 20, 120, 220 |

| Immersion depth of SENDSEN, m | 0.18 |

| Port angle of SEN θP, deg | −15 |

| Dimension of the SEN port, m | 0.065 × 0.083 |

| Inner/outer diameter of the SEN, m | 0.07/0.12 |

| Casting speed VC, m/min, | 1.6, 1.8, 2.0, 2.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Z.; Zhang, L.; Bao, Y.; Ma, D. Numerical Simulation on the Brake Effect of FAC-EMBr and EMBrRuler in the Continuous Casting Mold. Processes 2020, 8, 1620. https://doi.org/10.3390/pr8121620

Li Z, Zhang L, Bao Y, Ma D. Numerical Simulation on the Brake Effect of FAC-EMBr and EMBrRuler in the Continuous Casting Mold. Processes. 2020; 8(12):1620. https://doi.org/10.3390/pr8121620

Chicago/Turabian StyleLi, Zhuang, Lintao Zhang, Yanming Bao, and Danzhu Ma. 2020. "Numerical Simulation on the Brake Effect of FAC-EMBr and EMBrRuler in the Continuous Casting Mold" Processes 8, no. 12: 1620. https://doi.org/10.3390/pr8121620

APA StyleLi, Z., Zhang, L., Bao, Y., & Ma, D. (2020). Numerical Simulation on the Brake Effect of FAC-EMBr and EMBrRuler in the Continuous Casting Mold. Processes, 8(12), 1620. https://doi.org/10.3390/pr8121620