Optimizing Xylindein from Chlorociboria spp. for (Opto)electronic Applications

Abstract

1. Introduction

2. Materials and Methods

2.1. Preliminary Media Screen

2.2. Growth Conditions Testing

2.2.1. Liquid Shaking

2.2.2. Liquid Static

2.2.3. Solid State Woodchip Plates

2.3. Analysis of Pigment Concentration for Growth Conditions Testing

2.4. Comparisons of Species and Strain Pigmentation

2.4.1. Liquid Shaking Cultures for Strain Comparison

2.4.2. Solid State Woodchip Plates for Strain Comparison

2.5. Data Analysis for Comparisons of Species and Strain

2.6. Color Reading and Difference Calculation

2.7. Optical Absorption of Extracted Pigment Solutions

2.8. Measurement of Electronic Properties

3. Results and Discussion

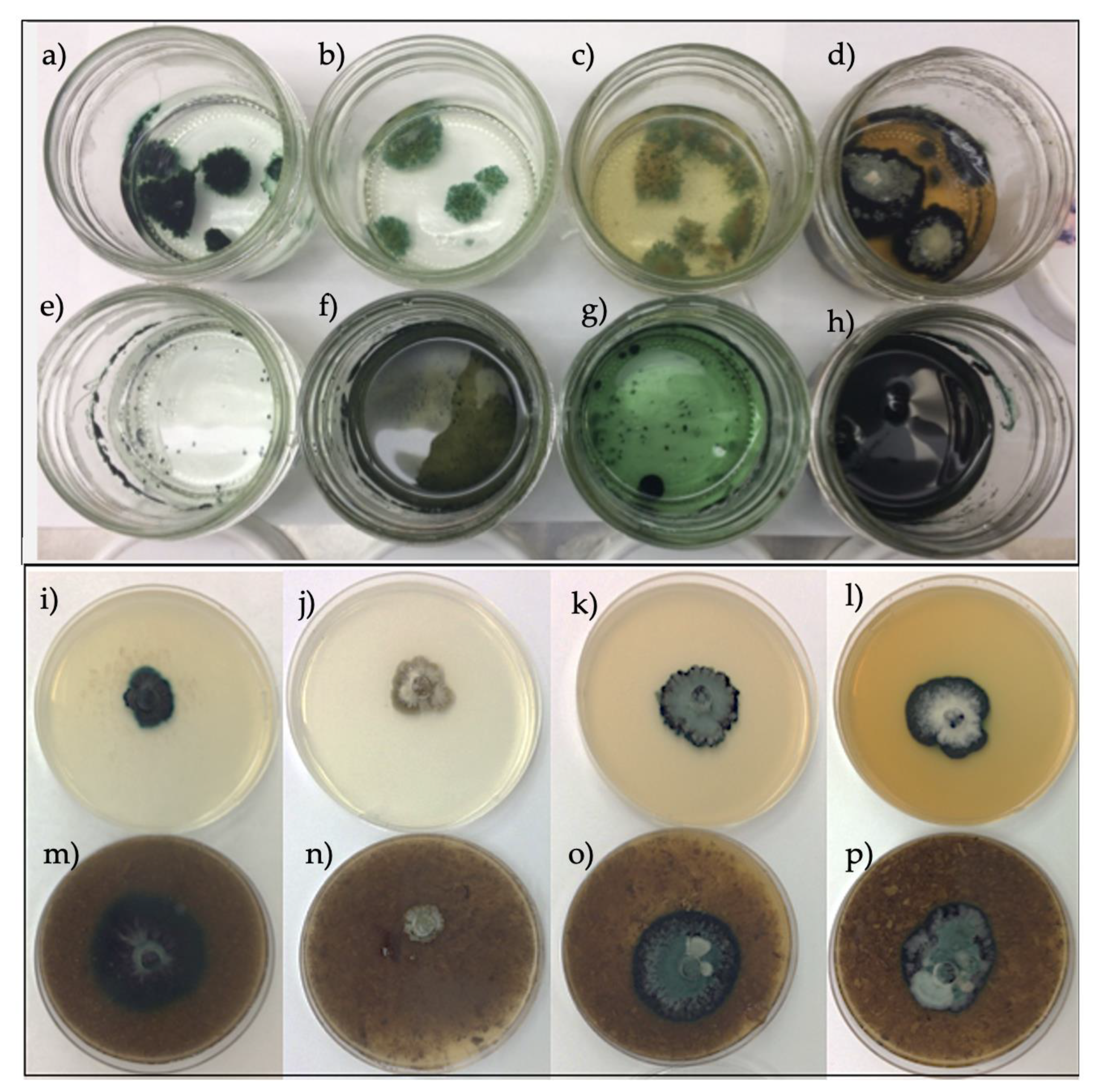

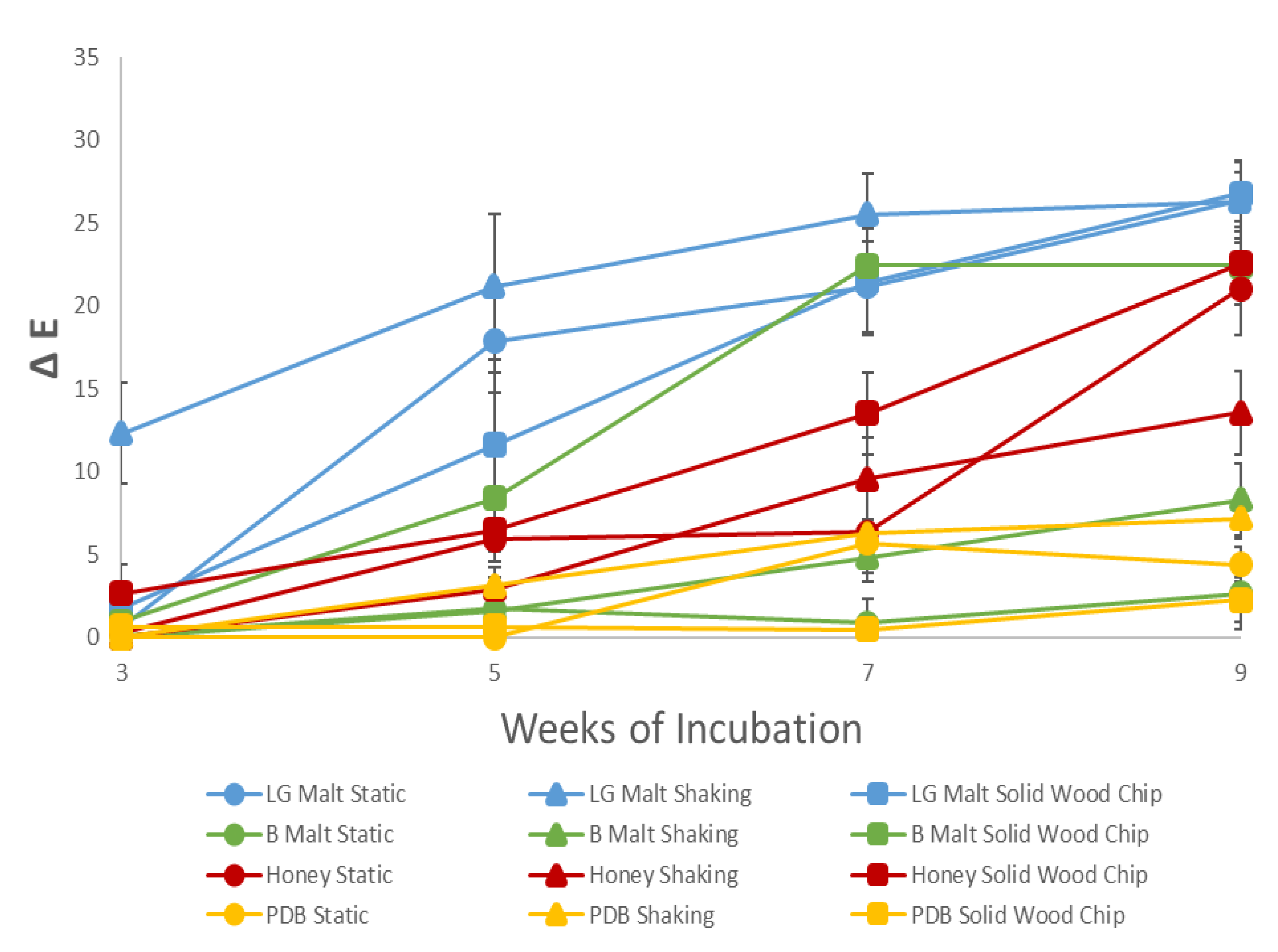

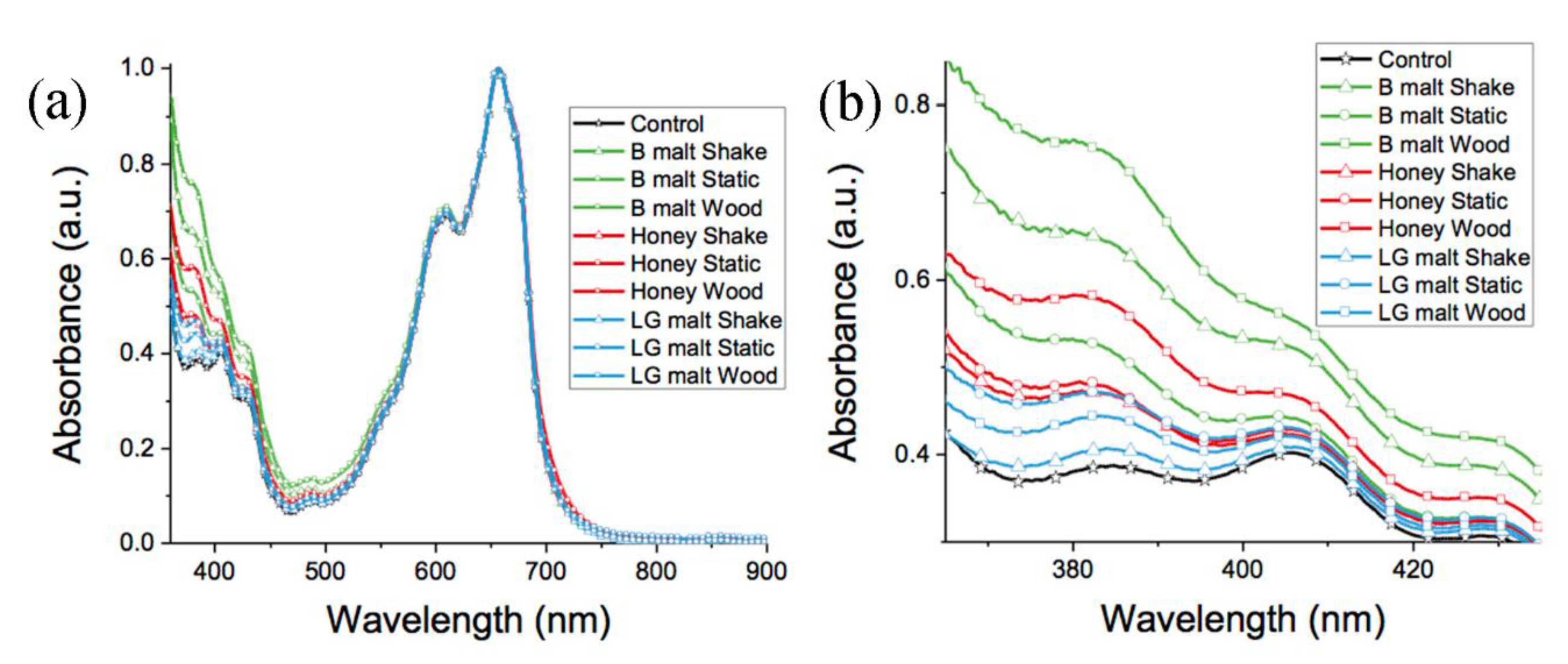

3.1. Pigment Variation across Growth Conditions

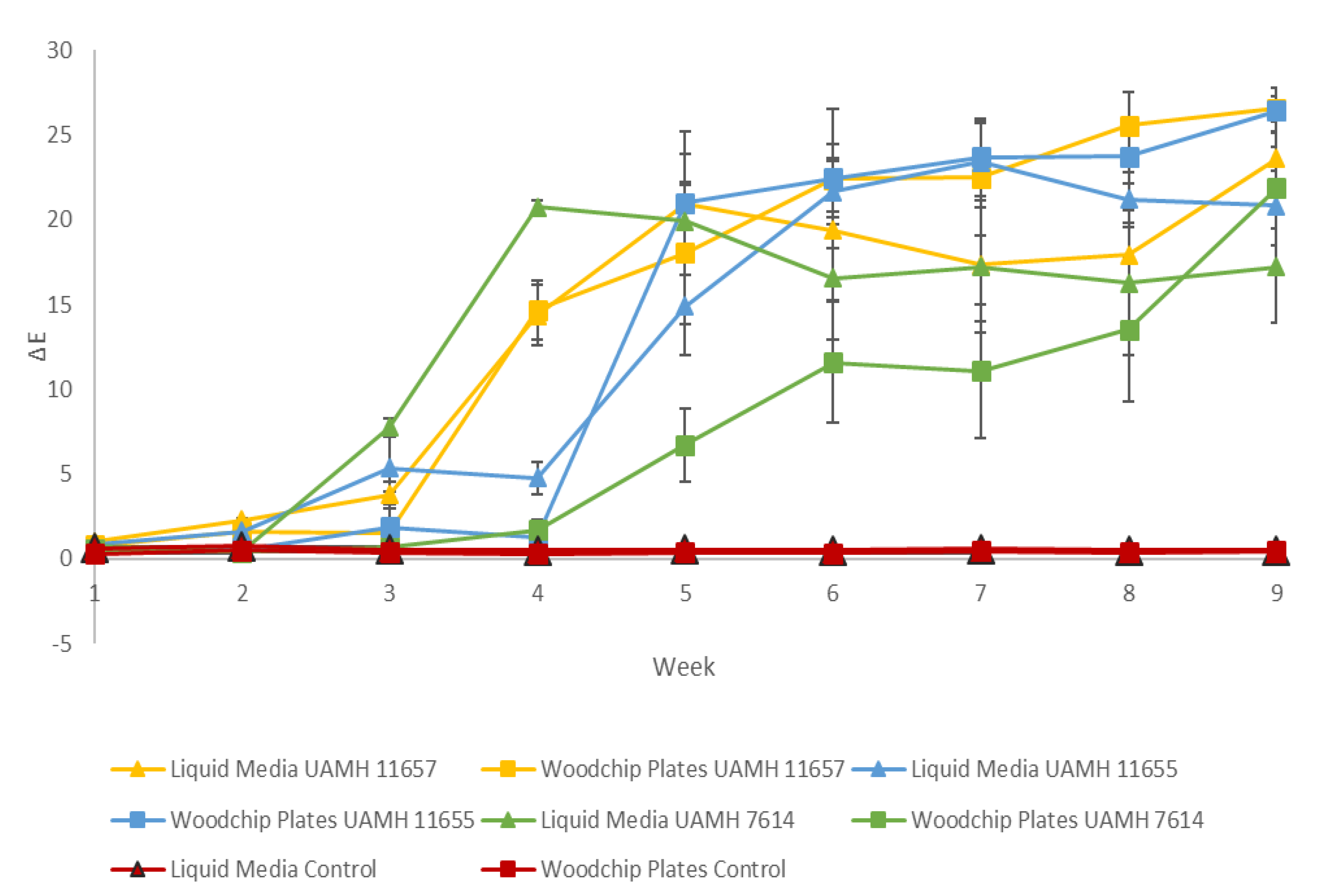

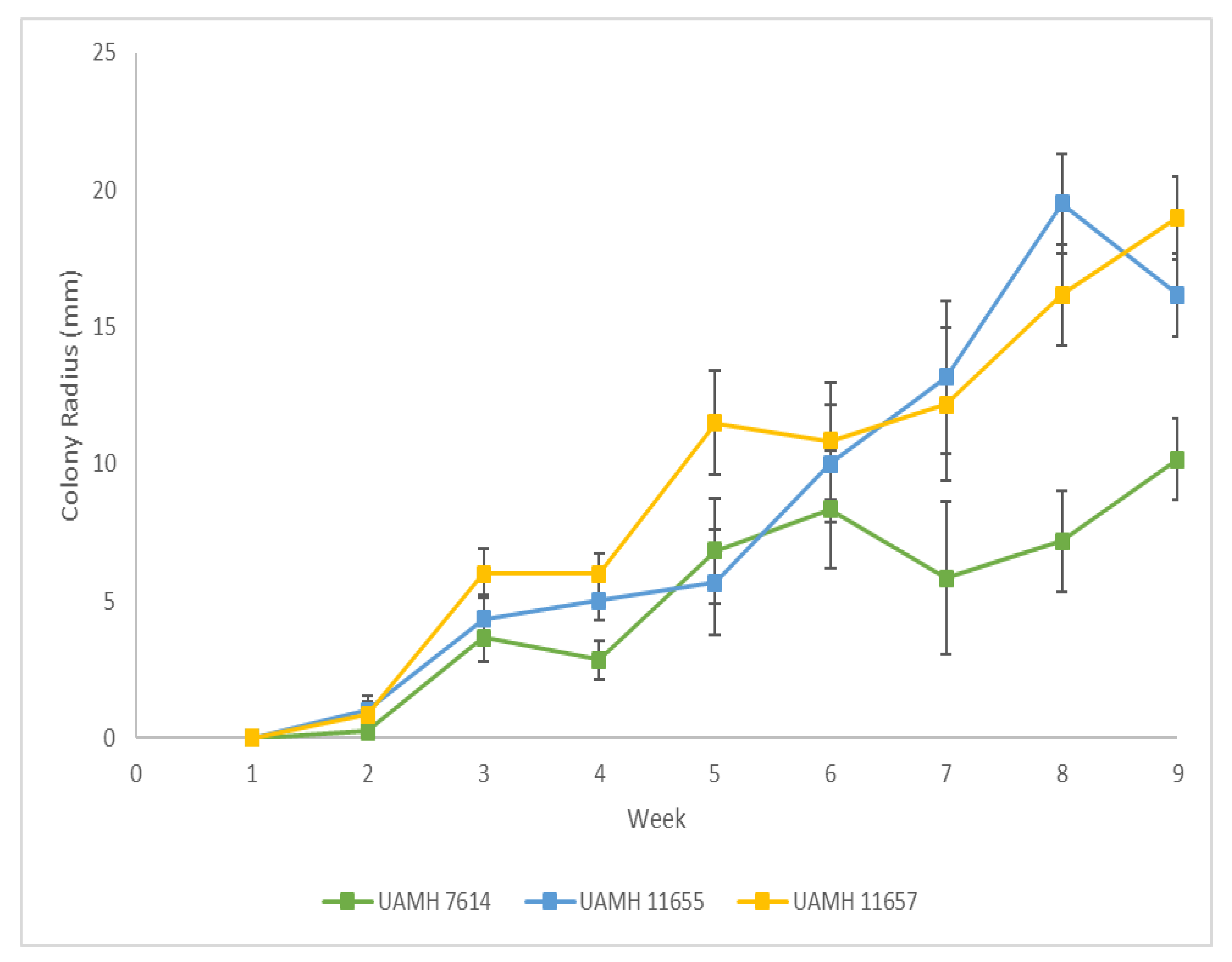

3.2. Pigment Variation across Chlorociboria Species and Strains

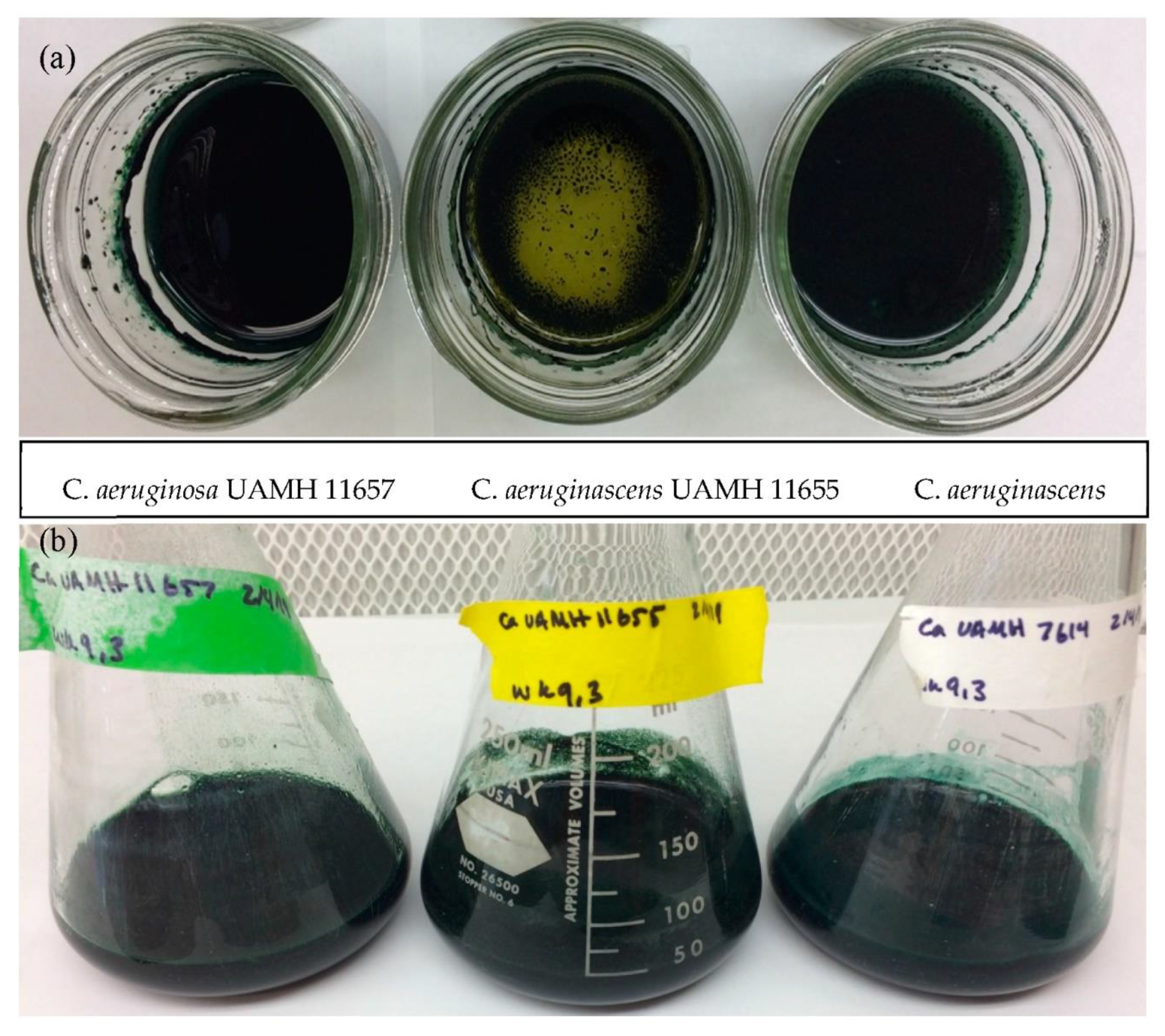

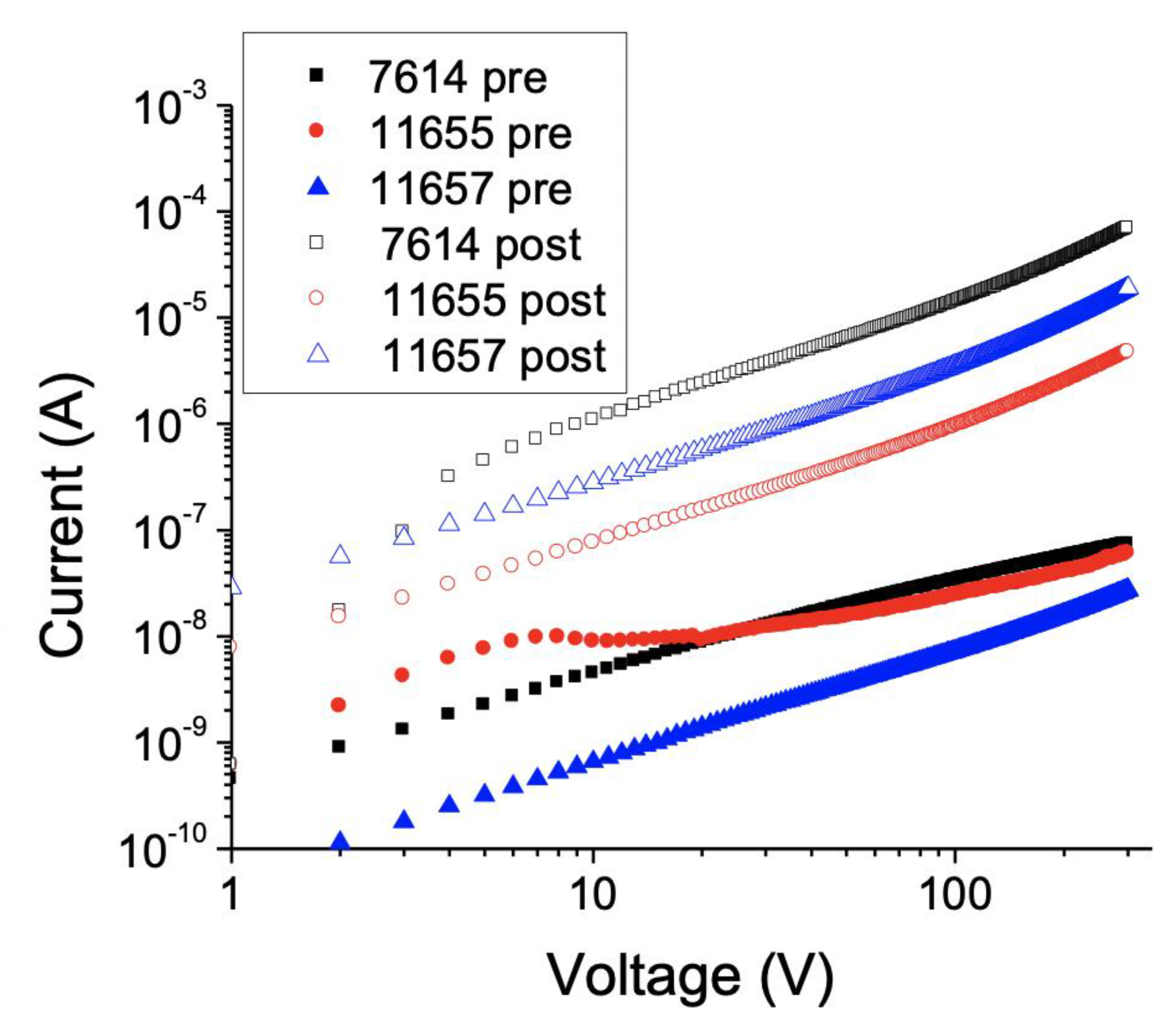

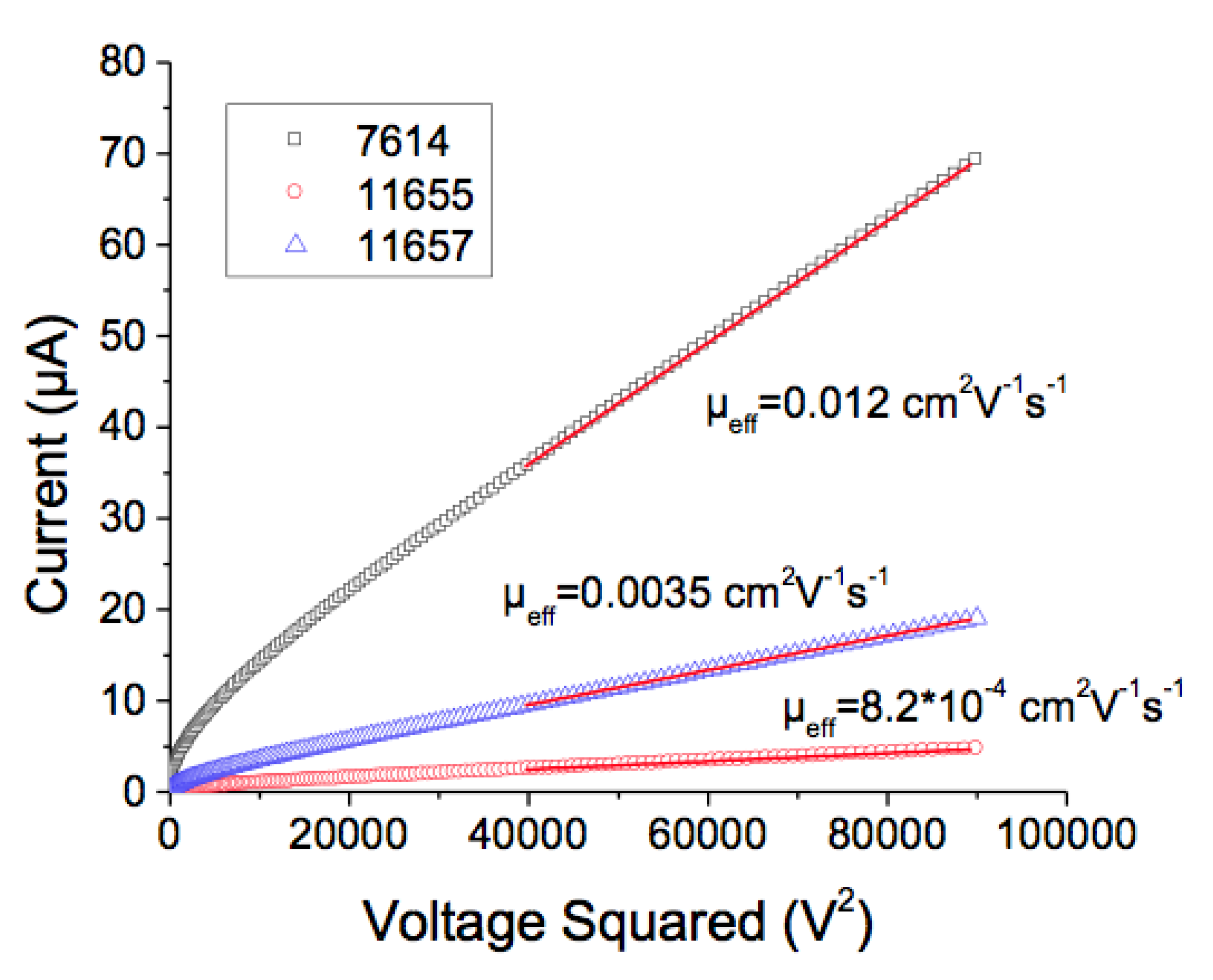

3.3. Comparison of Extracted Xylindein Purity and Electronic Activity

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Vega Gutierrez, T.P.; Robinson, C.S. Determining the Presence of Spalted Wood in Spanish Marquetry Woodworks of the 1500s through the 1800s. Coatings 2017, 7, 188. [Google Scholar] [CrossRef]

- Blanchette, R.A.; Wilmering, A.M.; Baumeister, M. The use of green-stained wood caused by the fungus Chlorociboria in Intarsia masterpieces from the 15th century. Holzforschung 1992, 46, 225–232. [Google Scholar] [CrossRef]

- Robinson, S.C.; Hinsch, E.; Weber, G.; Leipus, K.; Cerney, D. Wood Colorization through Pressure Treating: The Potential of Extracted Colorants from Spalting Fungi as a Replacement for Woodworkers’ Aniline Dyes. Materials 2014, 7, 5427–5437. [Google Scholar] [CrossRef] [PubMed]

- Robinson, S.C.; Vega Gutierrez, S.M.; Garcia, R.A.C.; Iroume, N.; Vorland, N.R.; Andersen, C.; de Oliveira Xaxa, I.D.; Kramer, O.E.; Huber, M.E. Potential for fungal dyes as colorants in oil and acrylic paints. J. Coat. Technol. Res. 2018, 15, 845–849. [Google Scholar] [CrossRef]

- Palomino Agurto, E.M.; Vega Gutierrez, M.S.; Chen, H.-L.; Robinson, C.S. Wood-Rotting Fungal Pigments as Colorant Coatings on Oil-Based Textile Dyes. Coatings 2017, 7, 152. [Google Scholar] [CrossRef]

- Hinsch, E.M. A Comparative Analysis of Extracted Fungal Pigments and Commercially Available Dyes for Colorizing Textiles. Ph.D. Thesis, Oregon State University, Corvallis, OR, USA, 2015. [Google Scholar]

- Hinsch, E.M.; Weber, G.; Chen, H.-L.; Robinson, S.C. Colorfastness of Extracted Wood-staining Fungal Pigments on Fabrics: A new potential for textile dyes. J. Text. Appar. Technol. Manag. 2015, 9. [Google Scholar] [CrossRef]

- Weber, G.; Chen, H.-L.; Hinsch, E.; Freitas, S.; Robinson, S. Pigments extracted from the wood-staining fungi Chlorociboria aeruginosa, Scytalidium cuboideum, and S. ganodermophthorum show potential for use as textile dyes. Coloration Technol. 2014, 130, 445–452. [Google Scholar] [CrossRef]

- Hinsch, E.; Robinson, S. Comparing Colorfastness to Light of Wood-Staining Fungal Pigments and Commercial Dyes: An Alternative Light Test Method for Color Fastness. Coatings 2018, 8, 189. [Google Scholar] [CrossRef]

- Giesbers, G.; Van Schenck, J.; Vega Gutierrez, M.S.; Robinson, S.; Ostroverkhovaa, O. Fungi-Derived Pigments for Sustainable Organic (Opto)Electronics. MRS Adv. 2018, 3. [Google Scholar] [CrossRef]

- Giesbers, G.; Van Schenck, J.; Quinn, A.; Van Court, R.; Vega Gutierrez, S.M.; Robinson, S.C.; Ostroverkhova, O. Xylindein: Naturally Produced Fungal Compound for Sustainable (Opto)electronics. ACS Omega 2019, 4, 13309–13318. [Google Scholar] [CrossRef]

- Giesbers, G.; Krueger, T.; Schenck, J.V.; Court, R.V.; Moore, J.; Fang, C.; Robinson, S.; Ostroverkhova, O. Fungi-derived xylindein: Effect of purity on optical and electronic properties. MRS Adv. 2019, 4, 1769–1777. [Google Scholar] [CrossRef]

- Harrison, R.; Quinn, A.; Weber, G.; Johnson, B.; Rath, J.; Remcho, V.; Robinson, S.; Ostroverkhovaa, O. Fungi-derived pigments as sustainable organic (opto)electronic materials. In Organic Photonic Materials and Devices XIX; International Society for Optics and Photonics: Bellingham, WA, USA, 2017; Volume 10101, p. 101010U. [Google Scholar]

- Giles, R.G.F.; Green, I.R.; Hugo, V.I. Model studies towards xylindein precursors. S. Afr. J. Chem. 1990, 48, 28–33. [Google Scholar]

- Giles, R.G.F.; Reuben, M.K.; Roos, G.H.P. A quinonoid napthtopyranone as a model for the synthesis of the pigment xylindeine. Photochemical formation of the lactone ring. S. Afr. J. Chem. 1979, 32, 127–129. [Google Scholar]

- Donner, C.D.; Cuzzupe, A.N.; Falzon, C.L.; Gill, M. Investigations towards the synthesis of xylindein, a blue-green pigment from the fungus Chlorociboria aeruginosa. Tetrahedron 2012, 68, 2799–2805. [Google Scholar] [CrossRef]

- Robinson, S.C.; Tudor, D.; Snider, H.; Cooper, P.A. Stimulating growth and xylindein production of Chlorociboria aeruginascens in agar-based systems. AMB Express 2012, 2, 1–7. [Google Scholar] [CrossRef]

- Dixon, J.R. Chlorosplenium and its segregates. The genera chlorociboria and chlorencoelia. Mycotaxon 1975, 1, 193–237. [Google Scholar]

- Fenwick, G.A. Chlorociboria aeruginascens in laboratory culture. Mycologist 1993, 7, 172–175. [Google Scholar] [CrossRef]

- Frenzel, W. Ernährung und Farbstoffbildung von Chlorosplenium aeruginosum (O ed.); Hölder-Pichler-Tempsky: Vienna, Austria, 1928; pp. 717–746. [Google Scholar]

- Stange, S.; Steudler, S.; Delenk, H.; Werner, A.; Walther, T.; Wagenführ, A. Influence of the Nutrients on the Biomass and Pigment Production of Chlorociboria aeruginascens. J. Fungi 2019, 5, 40. [Google Scholar] [CrossRef]

- Tudor, D.; Margaritescu, S.; Sánchez-Ramírez, S.; Robinson, S.C.; Cooper, P.A.; Moncalvo, J.M. Morphological and molecular characterization of the two known North American Chlorociboria species and their anamorphs. Fungal Biol. 2014, 118, 732–742. [Google Scholar] [CrossRef]

- Robinson, S.C.; Hinsch, E.; Weber, G.; Freitas, S. Method of extraction and resolubilisation of pigments from Chlorociboria aeruginosa and Scytalidium cuboideum, two prolific spalting fungi. Coloration Technol. 2014, 130, 221–225. [Google Scholar] [CrossRef]

- Weber, G.; Boonloed, A.; Naas, K.M.; Koesdjojo, M.T.; Remcho, V.T.; Robinson, S.C. A method to stimulate production of extracellular pigments from wood-degrading fungi using a water carrier. Curr. Res. Environ. Appl. Mycol. 2016, 6, 218–230. [Google Scholar] [CrossRef]

- Stange, S.; Steudler, S.H.; Delenk, H.; Stange, R.; Werner, A.; Walther, T.; Bley, T.; Wagenfuhr, A. Optimierung der Pigmentbildung vom holzverfärbenden Pilz Chlorociboria aeruginascens—Teil 1: Biomasse- und Pigmentbildung auf Agar und in Flüssigmedien. Holtztechnologie 2018, 59, 52–60. [Google Scholar]

- Stange, S.; Steudler, S.; Delenk, H.; Stange, R.; Werner, A.; Walther, T.; Bley, T.; Wagenfuhr, A. Optimierung der Pigmentbildung von dem holzverfärbenden Pilz Chlorociboria aeruginascens Teil 2: Pigmentbildung im Holzsubstrat. Holtztechnologie 2018, 59, 47–54. [Google Scholar]

- Boonloed, A.; Weber, G.L.; Ramzy, K.M.; Dias, V.R.; Remcho, V.T. Centrifugal partition chromatography: A preparative tool for isolation and purification of xylindein from Chlorociboria aeruginosa. J. Chromatogr. A 2016, 1478, 19–25. [Google Scholar] [CrossRef] [PubMed]

- Liu, D.; Wang, H.; Park, J.S.; Hur, J.-S. The Genus Chlorociboria, Blue-Green Micromycetes in South Korea. Mycobiology 2017, 45, 57–63. [Google Scholar] [CrossRef] [PubMed]

- Ramamurthi, C.S.; Korf, R.P.; Batra, L.R. A revision of the North American species of Chlorociboria (Sclerotiniaceae). Mycologia 1957, 49, 854–863. [Google Scholar] [CrossRef]

- Vega Gutierrez, M.S.; Hazell, K.K.; Simonsen, J.; Robinson, C.S. Description of a Naphthoquinonic Crystal Produced by the Fungus Scytalidium cuboideum. Molecules 2018, 23, 1905. [Google Scholar] [CrossRef] [PubMed]

- Vega Gutierrez, P.; Almurshidi, B.; Huber, M.; Andersen, C.; Van Court, R.C.; Robinson, S.C. Understanding color vatiation in the pigment produced by Scytalidium ganodermophthorum for artistic applications. International Wood Products 2020. [Google Scholar] [CrossRef]

- Johnston, P.R.; Park, D. Chlorociboria(Fungi, Helotiales) in New Zealand. New Zealand J. Bot. 2005, 43, 679–719. [Google Scholar] [CrossRef]

- De Carvalho, J.C.; Oishi, B.O.; Pandey, A.; Soccol, C.R. Biopigments from Monascus: Strains selection, citrinin production and color stability. Braz. Arch. Biol. Technol. 2005, 48, 885–894. [Google Scholar] [CrossRef]

- Campoy, S.; Rumbero, A.; Martín, J.F.; Liras, P. Characterization of an hyperpigmenting mutant of Monascus purpureus IB1: Identification of two novel pigment chemical structures. Appl. Microbiol. Biotechnol. 2006, 70, 488–496. [Google Scholar] [CrossRef] [PubMed]

- Jongrungruangchok, S.; Kittakoop, P.; Yongsmith, B.; Bavovada, R.; Tanasupawat, S.; Lartpornmatulee, N.; Thebtaranonth, Y. Azaphilone pigments from a yellow mutant of the fungus Monascus kaoliang. Phytochemistry 2004, 65, 2569–2575. [Google Scholar] [CrossRef] [PubMed]

- Marrocchi, A.; Facchetti, A.; Lanari, D.; Petrucci, C.; Vaccaro, L. Current methodologies for a sustainable approach to π-conjugated organic semiconductors. Energy Environ. Sci. 2016, 9, 763–786. [Google Scholar] [CrossRef]

- Irimia-Vladu, M. “Green” electronics: Biodegradable and biocompatible materials and devices for sustainable future. Chem. Soc. Rev. 2014, 43, 588–610. [Google Scholar] [CrossRef]

- Kippelen, B.; Brédas, J.-L. Organic photovoltaics. Energy Environ. Sci. 2009, 2, 251–261. [Google Scholar] [CrossRef]

- Dou, L.; You, J.; Hong, Z.; Xu, Z.; Li, G.; Street, R.A.; Yang, Y. 25th Anniversary Article: A Decade of Organic/Polymeric Photovoltaic Research. Adv. Mater. 2013, 25, 6642–6671. [Google Scholar] [CrossRef]

- Irimia-Vladu, M.; Głowacki, E.D.; Troshin, P.A.; Schwabegger, G.; Leonat, L.; Susarova, D.K.; Krystal, O.; Ullah, M.; Kanbur, Y.; Bodea, M.A.; et al. Indigo - A Natural Pigment for High Performance Ambipolar Organic Field Effect Transistors and Circuits. Adv. Mater. 2011, 24, 375–380. [Google Scholar] [CrossRef]

- Głowacki, E.D.; Leonat, L.; Irimia-Vladu, M.; Schwödiauer, R.; Ullah, M.; Sitter, H.; Bauer, S.; Sariciftci, N.S. Intermolecular hydrogen-bonded organic semiconductors—Quinacridone versus pentacene. Appl. Phys. Lett. 2012, 101, 023305. [Google Scholar] [CrossRef]

- Głowacki, E.D.; Tangorra, R.R.; Coskun, H.; Farka, D.; Operamolla, A.; Kanbur, Y.; Milano, F.; Giotta, L.; Farinola, G.M.; Sariciftci, N.S. Bioconjugation of hydrogen-bonded organic semiconductors with functional proteins. J. Mater. Chem. C 2015, 3, 6554–6564. [Google Scholar] [CrossRef]

- Anaf, W.; Schalm, O.; Janssens, K.; De Wael, K. Understanding the (in)stability of semiconductor pigments by a thermodynamic approach. Dye. Pigment. 2015, 113, 409–415. [Google Scholar] [CrossRef]

- Gsänger, M.; Bialas, D.; Huang, L.; Stolte, M.; Würthner, F. Organic Semiconductors based on Dyes and Color Pigments. Adv. Mater. 2016, 28, 3615–3645. [Google Scholar] [CrossRef] [PubMed]

- Tsang, M.P.; Sonnemann, G.; Bassani, D.M. A comparative human health, ecotoxicity, and product environmental assessment on the production of organic and silicon solar cells. Prog. Photovoltaics Res. Appl. 2015, 24, 645–655. [Google Scholar] [CrossRef]

- Robinson, S.C.; Gutierrez, S.M.V.; Garcia, R.A.C.; Iroume, N.; Vorland, N.R.; McClelland, A.; Huber, M.E.; Stanton, S. Potential for carrying dyes derived from spalting fungi in natural oils. J. Coat. Technol. Res. 2017, 14, 1107–1113. [Google Scholar] [CrossRef]

- Robinson, S.C.; Laks, P.E. Wood species affects laboratory colonization rates of Chlorociboria sp. Int. Biodeterior. Biodegrad. 2010, 64, 305–308. [Google Scholar] [CrossRef]

- Stange, S.; Steudler, S.; Delenk, H.; Werner, A.; Walther, T.; Wagenführ, A. Influence of Environmental Growth Factors on the Biomass and Pigment Production of Chlorociboria aeruginascens. J. Fungi 2019, 5, 46. [Google Scholar] [CrossRef] [PubMed]

- Tudor, D.; Robinson, S.C.; Cooper, P.A. The influence of pH on pigment formation by lignicolous fungi. Int. Biodeterior. Biodegradation 2013, 80, 22–28. [Google Scholar] [CrossRef]

- López, J.L.C.; Pérez, J.S.; Sevilla, J.F.; Porcel, E.R.; Chisti, Y. Pellet morphology, culture rheology and lovastatin production in cultures of Aspergillus terreus. J. Biotechnol. 2005, 116, 61–77. [Google Scholar] [CrossRef]

- Dronawat, S.N.; Svihla, C.K.; Hanley, T.R. The effects of agitation and aeration on the production of gluconic acid byAspergillus niger. Appl. Biochem. Biotechnol. 1995, 51, 347–354. [Google Scholar] [CrossRef]

- Gutierrez, S.M.V.; Van Court, R.C.; Stone, D.W.; Konkler, M.J.; Groth, E.N.; Robinson, S.C. Relationship between Molarity and Color in the Crystal (‘Dramada’) Produced by Scytalidium cuboideum, in Two Solvents. Molecules 2018, 23, 2581. [Google Scholar] [CrossRef]

- Edwards, R.; Kale, N. The structure of xylindein. Tetrahedron 1965, 21, 2095–2107. [Google Scholar] [CrossRef]

- Gutierrez, S.M.V.; Gutierrez, P.T.V.; Godinez, A.; Pittis, L.; Huber, M.E.; Stanton, S.; Robinson, S.C. Feasibility of Coloring Bamboo with the Application of Natural and Extracted Fungal Pigments. Coatings 2016, 6, 37. [Google Scholar] [CrossRef]

| Growth Condition | Honey | Brewer’s Malt | Lab-Grade Malt | PDB |

|---|---|---|---|---|

| Pre-growth | 6 | 6 | 6 | 5 |

| Static post-growth | 7 | 6 | 5 | 5 |

| Shaking post-growth | 7 | 6 | 5 | 6 |

| Chlorociboria Source | Week | L* | a* | b* | Color |

|---|---|---|---|---|---|

| Standard (Hinsch 2015) * | 8–12 | 82.28 (±2.00) | −11.06 (±2.00) | −5.40 (±2.00) |  |

| C. aeruginosa UAMH 11657 woodchip plate * | 7 | 82.83 (±7.18) | −10.43 (±3.08) | −6.68 (±1.40) |  |

| C. aeruginosa UAMH 11657 woodchip plate | 8 | 77.36 (±1.37) | −7.68 (±2.62) | −6.47 (±1.04) |  |

| C. aeruginosa UAMH 11657 woodchip plate | 9 | 75.96 (±1.61) | −6.96 (±2.04) | −6.17 (±0.75) |  |

| C. aeruginosa UAMH 11657 liquid media | 9 | 83.05 (±4.45) | −13.32 (±3.20) | −6.62 (±2.09) |  |

| C. aeruginascens UAMH 11655 woodchip plate | 7 | 83.97 (±6.40) | −13.47 (±4.70) | −7.65 (±0.76) |  |

| C. aeruginascens UAMH 11655 woodchip plate | 8 | 83.62 (±5.22) | −13.74 (±3.87) | −7.44 (±0.04) |  |

| C. aeruginascens UAMH 11655 liquid media | 7 | 83.06 (±6.74) | −13.28 (±0.05) | 6.67 (±0.89) |  |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Court, R.C.V.; Giesbers, G.; Ostroverkhova, O.; Robinson, S.C. Optimizing Xylindein from Chlorociboria spp. for (Opto)electronic Applications. Processes 2020, 8, 1477. https://doi.org/10.3390/pr8111477

Court RCV, Giesbers G, Ostroverkhova O, Robinson SC. Optimizing Xylindein from Chlorociboria spp. for (Opto)electronic Applications. Processes. 2020; 8(11):1477. https://doi.org/10.3390/pr8111477

Chicago/Turabian StyleCourt, R.C. Van, Gregory Giesbers, Oksana Ostroverkhova, and Seri C. Robinson. 2020. "Optimizing Xylindein from Chlorociboria spp. for (Opto)electronic Applications" Processes 8, no. 11: 1477. https://doi.org/10.3390/pr8111477

APA StyleCourt, R. C. V., Giesbers, G., Ostroverkhova, O., & Robinson, S. C. (2020). Optimizing Xylindein from Chlorociboria spp. for (Opto)electronic Applications. Processes, 8(11), 1477. https://doi.org/10.3390/pr8111477