Collaborative Control Applied to BSM1 for Wastewater Treatment Plants

Abstract

1. Introduction

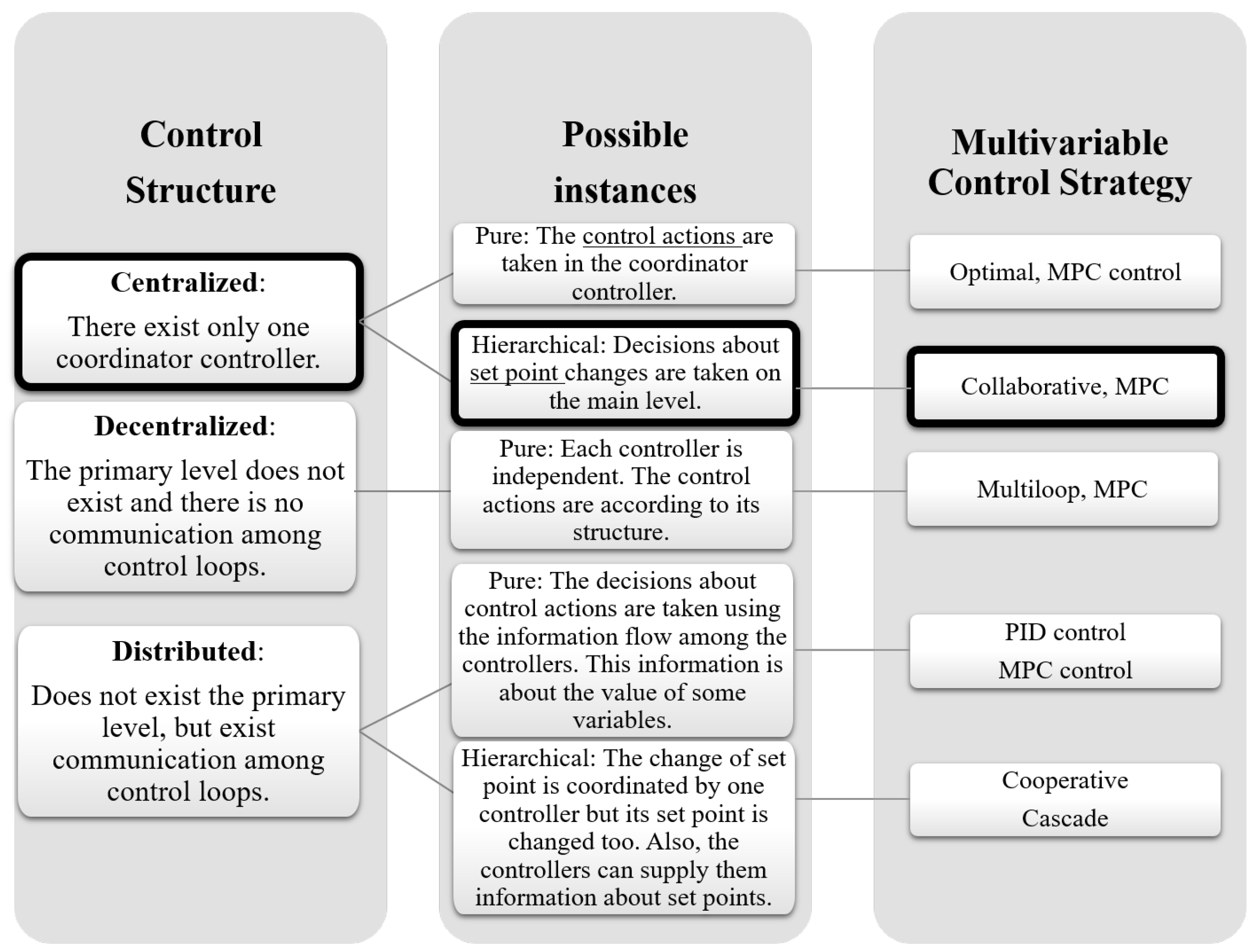

2. Collaborative Control Strategy

2.1. Process Analysis

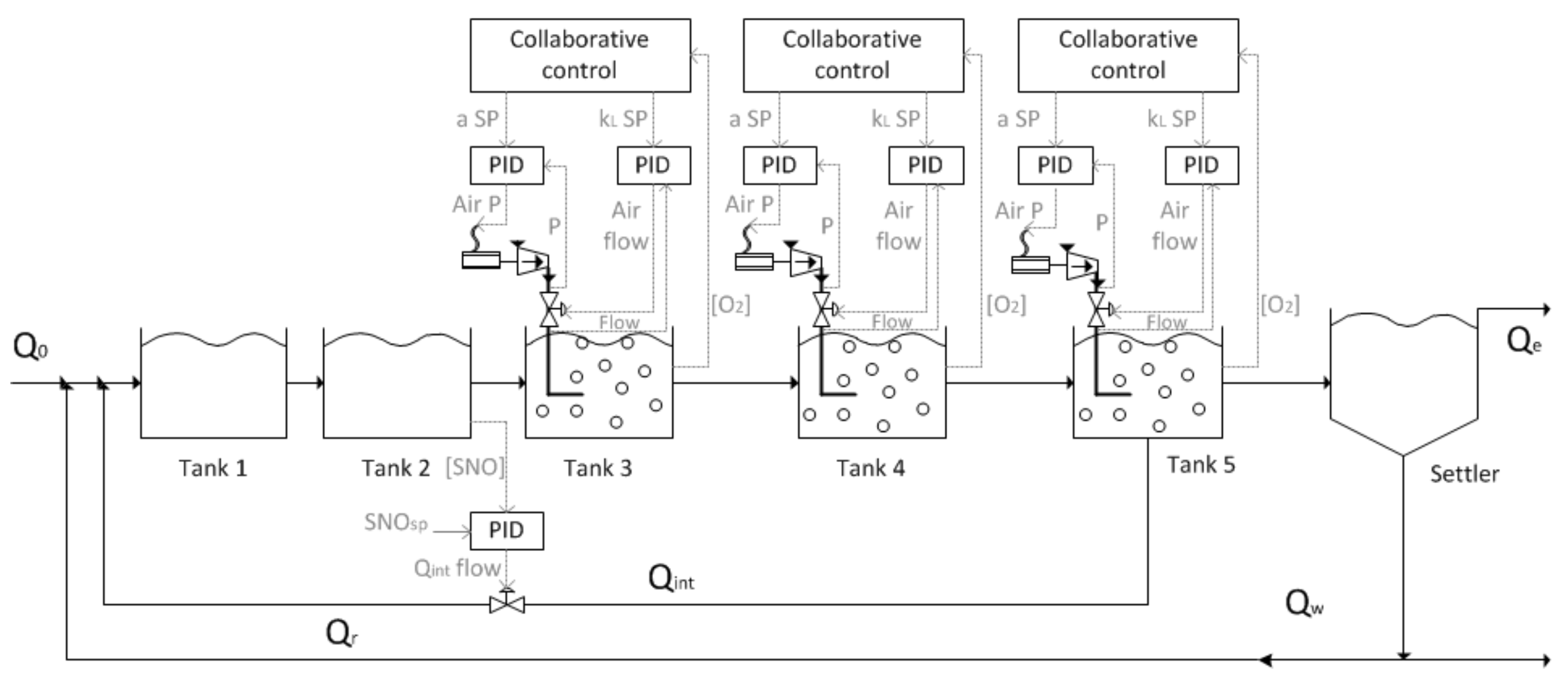

2.2. Regulatory Layer Design

2.3. Supervisory Layer Design

| S. t. |

3. Model Predictive Control (MPC)

| S. t. | |

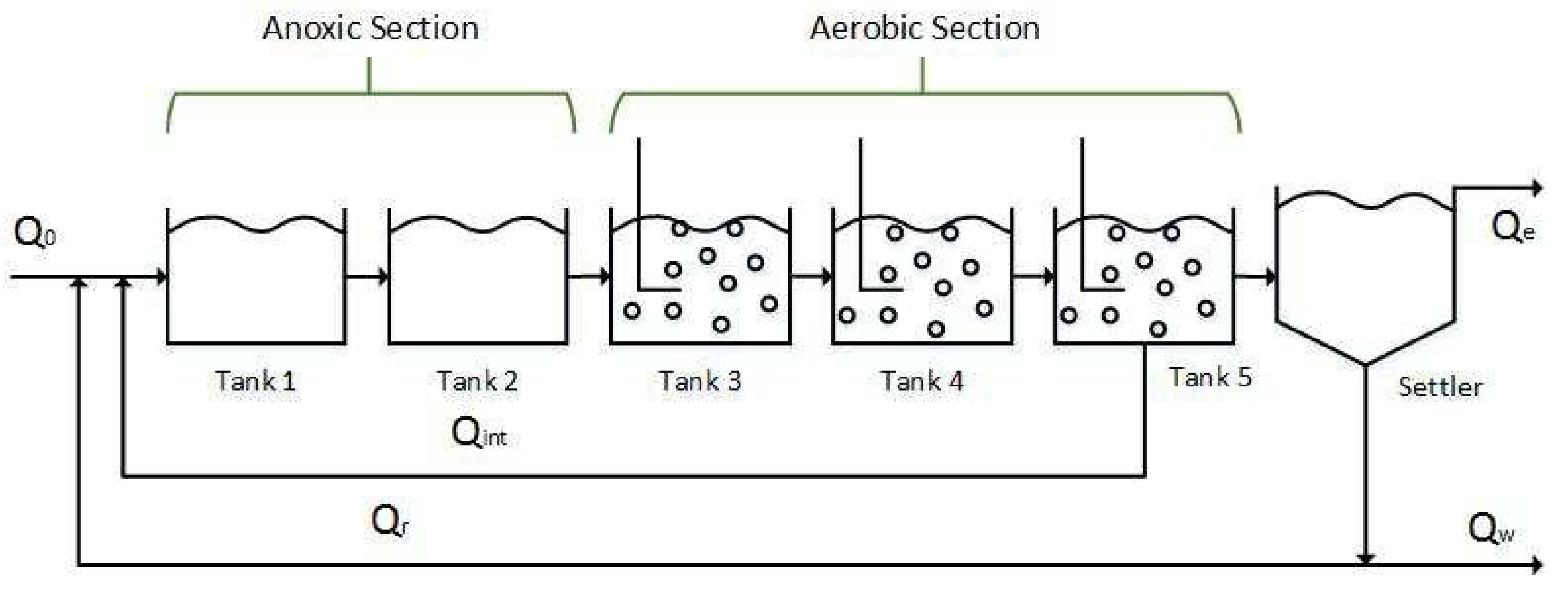

4. BSM1 Process Description Including the Mass Transfer Model

4.1. BSM1 Model

- Mass balance for reactor number one:

- From the second anoxic reactor to the fifth reactor (second reactor as an example):

- Special case for oxygen (fifth reactor as an example):

4.2. Mass Transfer Model

5. Application of the Methodology to BSM1

| s. t. |

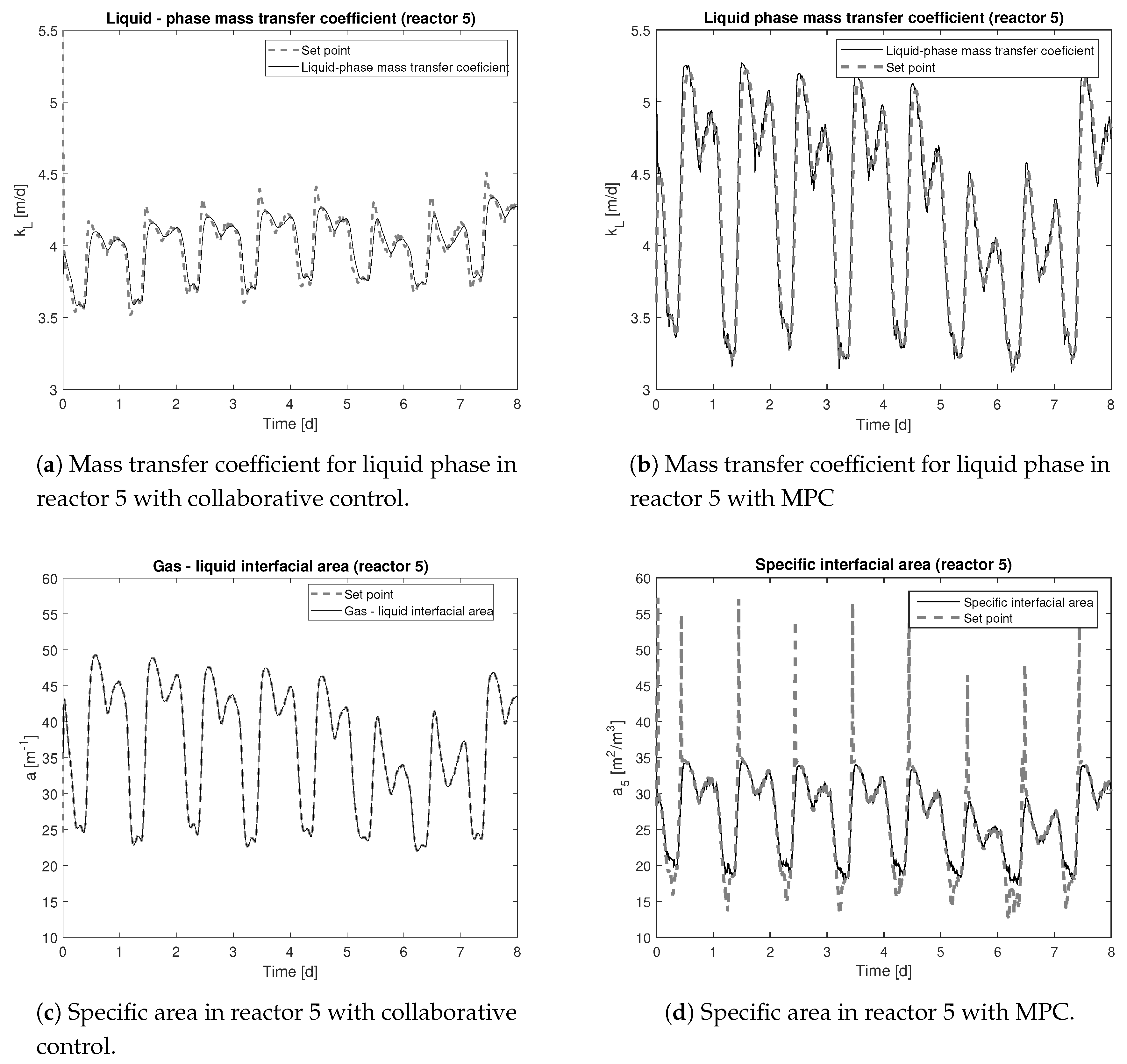

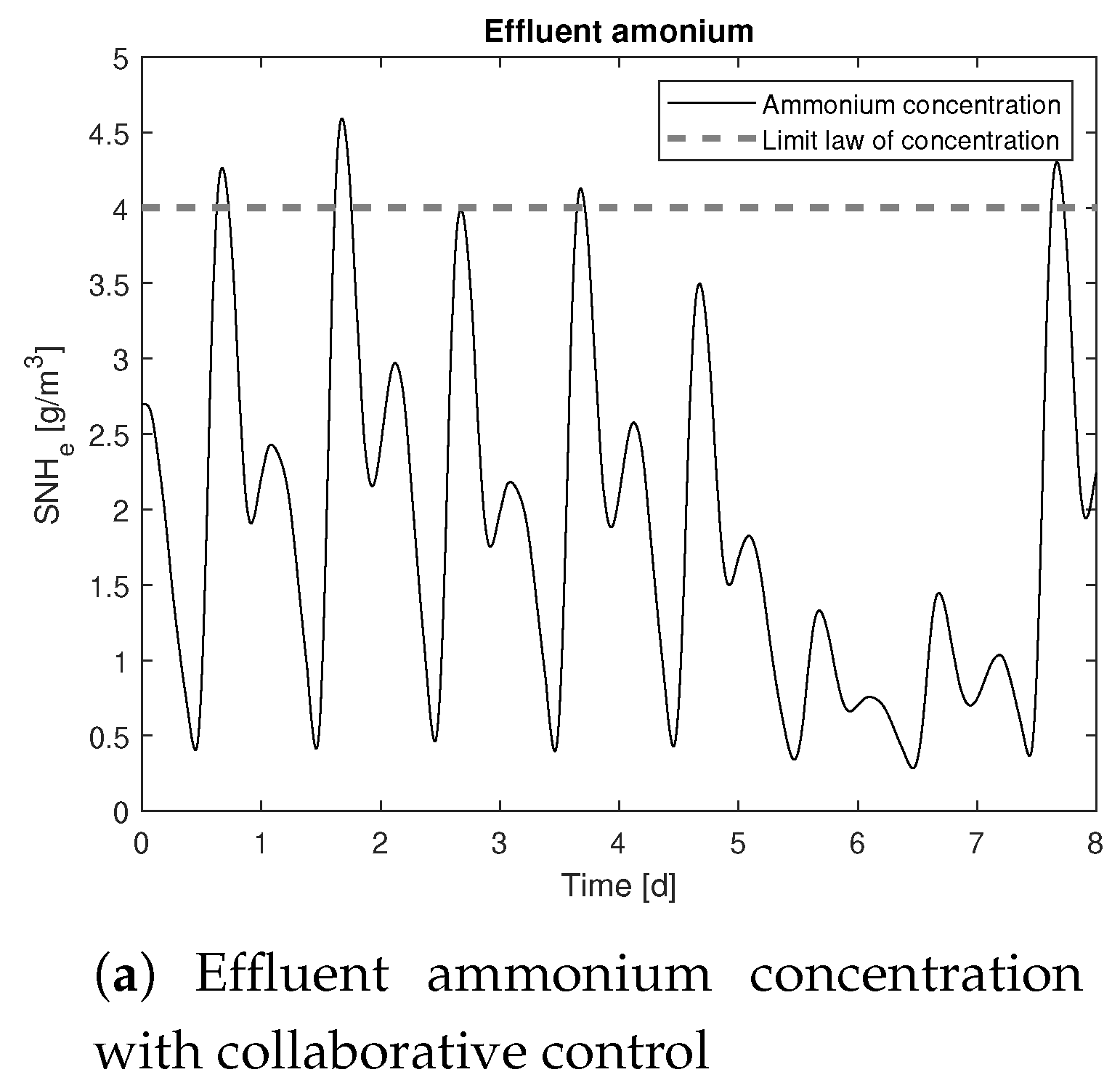

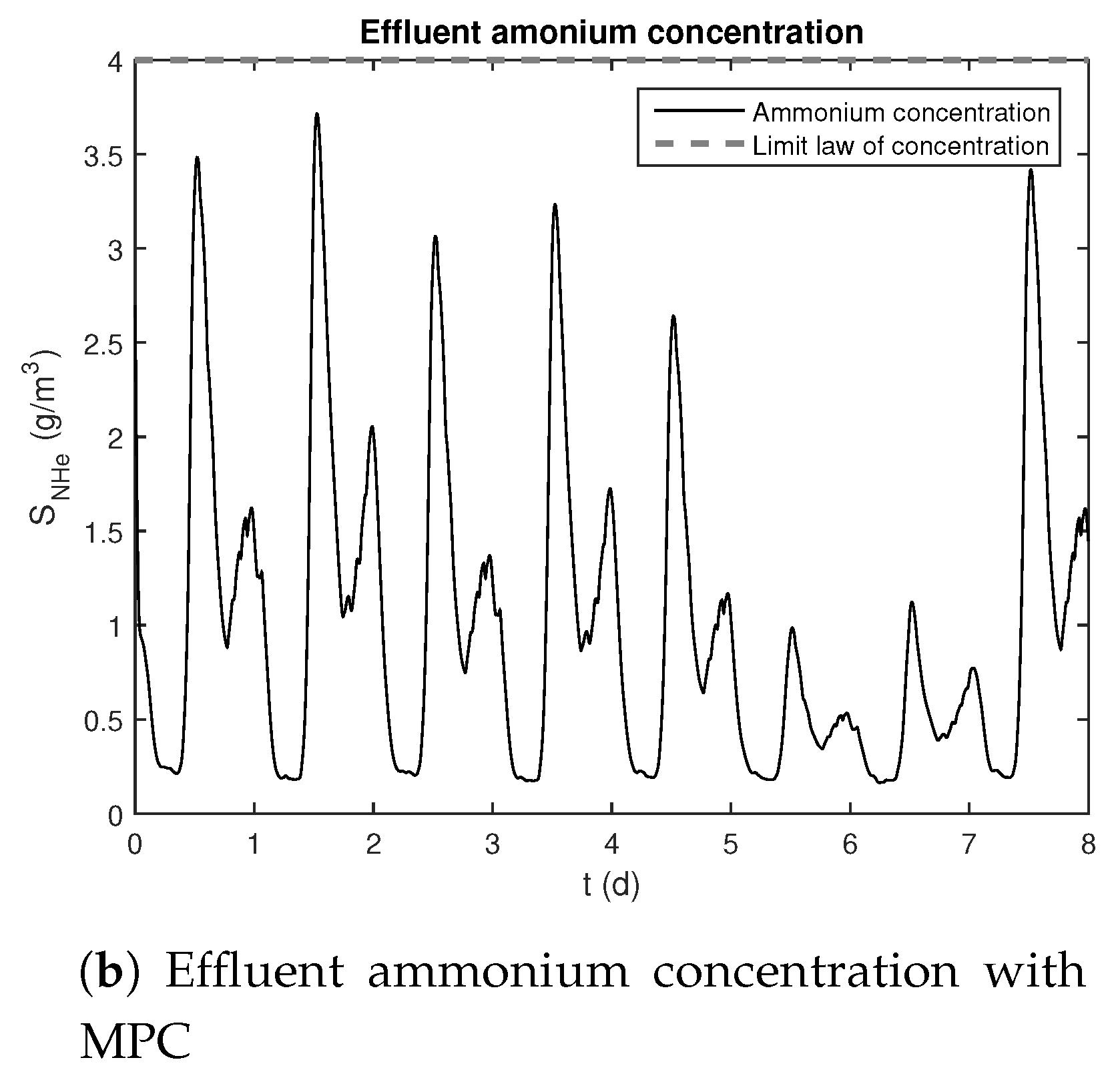

6. Results and Discussion

7. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Kariwala, G.P.R.V. Plantwide Control: Recent Developments and Applications; John Wiley & Sons: Hoboken, NJ, USA, 2012; p. 494. [Google Scholar]

- Zumoffen, D.A.R. Oversizing analysis in plant-wide control design for industrial processes. Comput. Chem. Eng. 2013, 59, 145–155. [Google Scholar] [CrossRef]

- Shaoyuan, L.; Zheng, Y. Distributed Model Predictive Control for Plant-Wide Systems, 1st ed.; John Wiley & Sons: Hoboken, NJ, USA, 2016; pp. 1–13. [Google Scholar]

- Scattolini, R. Architectures for distributed and hierarchical Model Predictive Control—A review. J. Process Control 2009, 19, 723–731. [Google Scholar] [CrossRef]

- Skogestad, S. Control structure design for complete chemical plants. Comput. Chem. Eng. 2004, 28, 219–234. [Google Scholar] [CrossRef]

- Moscoso-Vasquez, H.M.; Monsalve-Bravo, G.M.; Alvarez, H. Model-based supervisory control structure for plantwide control of a reactor-separator-recycle plant. Ind. Eng. Chem. Res. 2014, 53, 20177–20190. [Google Scholar] [CrossRef]

- Maciejowski, J.M. Predictive Control: With Constraints; Prentice Hall: Upper New Jersey River, NY, USA, 2002. [Google Scholar]

- Qin, S.J.; Badgwell, T.A. A survey of industrial model predictive control technology. Control Eng. Pract. 2003, 11, 733–764. [Google Scholar] [CrossRef]

- Devadasan, P.; Zhong, H.; Nof, S.Y. Expert systems with applications Collaborative intelligence in knowledge based service planning. Expert Syst. Appl. 2013, 40, 6778–6787. [Google Scholar] [CrossRef]

- Carlson, T.; Demiris, Y.; Member, S. Collaborative control for a robotic wheelchair: Evaluation of performance, Attention, and Workload. IEEE Trans. Syst. Man Cybern. Part B 2011, 42, 876–888. [Google Scholar] [CrossRef]

- Fong, T.; Grange, S.; Thorpe, C.; Baur, C. Multi-robot remote driving with collaborative control. In Proceedings of the 10th IEEE International Workshop on Robot and Human Interactive Communication, Paris, France, 18–21 September 2001; pp. 237–242. [Google Scholar] [CrossRef]

- Ochoa, S.; Wozny, G.; Repke, J.U. Plantwide optimizing control of a continuous bioethanol production process. J. Process. Control 2010, 20, 983–998. [Google Scholar] [CrossRef]

- Marquez, A.; Gomez, C.; Deossa, P.; Espinosa, J.J. Hierarchical control of large scale systems: A zone control approach. In Proceedings of the 13th IFAC Symposium on Large Scale Complex Systems: Theory and Applications, Shanghai, China, 7–10 July 2013; Volume 13, pp. 438–443. [Google Scholar]

- Dang, P.; Banjerdpongchai, D. Design of integrated real-time optimization and model predictive control for distillation column. In Proceedings of the 2011 8th Asian Control Conference (ASCC), Kaohsiung, Taiwan, 15–18 May 2011; Volume 1, pp. 988–993. [Google Scholar]

- Marti, R.; Sarabia, D.; Navia, D.; De Prada, C. Coordination of distributed model predictive controllers using price-driven coordination and sensitivity analysis. In Proceedings of the 10th IFAC International Symposium on Dynamics and Control of Process Systems, Mumbai, India, 18–20 December 2013; Volume 10, pp. 215–220. [Google Scholar] [CrossRef]

- Scheu, H.; Marquardt, W. Sensitivity-based coordination in distributed model predictive control. J. Process Control 2011, 21, 715–728. [Google Scholar] [CrossRef]

- Kadam, J.V.; Marquardt, W. Sensitivity-Based Solution Updates in Closed-Loop Dynamic Optimization. In Proceedings of the 7th IFAC Symposium on Dynamics and Control of Process Systems 2004 (DYCOPS -7), Cambridge, CA, USA, 5–7 July 2004; Volume 37, pp. 947–952. [Google Scholar] [CrossRef]

- Revollar, S.; Vega, P.; Vilanova, R.; Francisco, M. Optimal Control of Wastewater Treatment Plants Using Economic-Oriented Model Predictive Dynamic Strategies. Appl. Sci. 2017, 7, 813. [Google Scholar] [CrossRef]

- Zhang, A.; Yin, X.; Liu, S.; Zeng, J.; Liu, J. Chemical Engineering Research and Design Distributed economic model predictive control of wastewater treatment plants. Chem. Eng. Res. Des. 2018, 141, 144–155. [Google Scholar] [CrossRef]

- Holenda, B.; Domokos, E.; Rédey, Á.; Fazakas, J. Dissolved oxygen control of the activated sludge wastewater treatment process using model predictive control. Comput. Chem. Eng. 2008, 32, 1270–1278. [Google Scholar] [CrossRef]

- Rojas, J.D.; Flores-Alsina, X.; Jeppsson, U.; Vilanova, R. Application of multivariate virtual reference feedback tuning for wastewater treatment plant control. Control Eng. Pract. 2012, 20, 499–510. [Google Scholar] [CrossRef]

- Vega, P.; Revollar, S.; Francisco, M.; Martín, J.M. Integration of set point optimization techniques into nonlinear MPC for improving the operation of WWTPs. Comput. Chem. Eng. 2014, 68, 78–95. [Google Scholar] [CrossRef]

- Hoyos, E.; López, D.; Alvarez, H. A phenomenologically based material flow model for friction stir welding. Mater. Des. 2016, 111, 321–330. [Google Scholar] [CrossRef]

- Lema-Perez, L.; Muñoz-Tamayo, R.; Garcia-Tirado, J.; Alvarez, H. Informatics in Medicine Unlocked on parameter interpretability of phenomenological-based semiphysical models in biology. Inform. Med. Unlocked 2019, 15, 100158. [Google Scholar] [CrossRef]

- Monsalve-Bravo, G.M.; Moscoso-vasquez, H.M.; Alvarez, H. Scaleup of Batch Reactors Using Phenomenological-Based Models. Ind. Eng. Chem. Res. 2014, 53, 9439–9453. [Google Scholar] [CrossRef]

- Arkun, Y.; Downs, J. A general method to calculate input–output gains and the relative gain array for integrating processes. Comput. Chem. Eng. 1990, 14, 1101–1110. [Google Scholar] [CrossRef]

- Moscoso-Vásquez, H.M. A Design Procedure for a Supervisory Control Structure in Plantwide Control. Master’s Thesis, Universidad Nacional de Colombia, Bogotá, Colombia, 2013. [Google Scholar]

- Francisco, M.; Skogestad, S.; Vega, P. Model predictive control for the self-optimized operation in wastewater treatment plants: Analysis of dynamic issues. Comput. Chem. Eng. 2015, 82, 259–272. [Google Scholar] [CrossRef]

- Ramalho, R.S. Tratamiento de Aguas Residuales; Editorial Reverté: Barcelona, Spain, 1996. [Google Scholar]

- Henze, M.; Gujer, W.; Mino, T.; Van Loosdrecht, M. Activated Sludge Models ASM1, ASM2, ASM2d and ASM3; IWA Publishing: London, UK, 2000; pp. 5–37. [Google Scholar]

- Alex, J.; Benedetti, L.; Copp, J.; Gernaey, K.V.; Jeppsson, U.; Nopens, I.; Pons, M.; Rieger, L.; Rosen, C.; Steyer, J.P.; et al. Benchmark simulation model no. 1 (BSM1). Ind. Electr. Eng. Autom. 2008, TEIE-7229, 1–62. [Google Scholar]

- Dudle, J. Mass transfer in bubble columns: A comparasion os correlations. Water Res. 1995, 29, 1129–1138. [Google Scholar] [CrossRef]

- Bouaifi, M.; Hebrard, G.; Bastoul, D.; Roustan, M. A comparative study of gas hold-up, bubble size, interfacial area and mass transfer coefficients in stirred gas-liquid reactors and bubble columns. Chem. Eng. Process. Process. Intensif. 2001, 40, 97–111. [Google Scholar] [CrossRef]

- Ramakrishnan, S.; Kumar, R.; Kuloor, N. Studies in bubble formation—I bubble formation under constant flow conditions. Chem. Eng. Sci. 1969, 24, 731–747. [Google Scholar] [CrossRef]

- Müller-Fischer, N.; Suppiger, D.; Windhab, E.J. Impact of static pressure and volumetric energy input on the microstructure of food foam whipped in a rotor-stator device. J. Food Eng. 2007, 80, 306–316. [Google Scholar] [CrossRef]

- Prieve, D. Unit Operation of Chemical Engineering; Carnegie Mellon University Press: Pittsbugh, PA, USA, 2000; pp. 199–247. [Google Scholar]

- Yang, G.Q.; Luo, X.; Lau, R.; Fan, L.S. Bubble formation in high-pressure liquid—Solid suspensions with plenum pressure fluctuation. AIChE J. 2000, 46, 2162–2174. [Google Scholar] [CrossRef]

- Olsen, J.E.; Dunnebier, D.; Davies, E.; Skjetne, P.; Morud, J. Mass transfer between bubbles and seawater. Chem. Eng. Sci. 2017, 161, 308–315. [Google Scholar] [CrossRef]

- Higbie, R. The rate of absorption of a pure gas into a still liquid during short periods of exposure. AIChE J. 1935, 31, 365–389. [Google Scholar]

- Nedeltchev, S. Theoretical prediction of mass transfer coefficients in both gas-liquid and slurry bubble columns. Chem. Eng. Sci. 2017, 157, 169–181. [Google Scholar] [CrossRef]

- Manjrekar, O.N.; Hamed, M.; Dudukovic, M.P. Chemical Engineering Research and Design Gas hold-up and mass transfer in a pilot scale bubble column with and without internals. Chem. Eng. Res. Des. 2018, 135, 166–174. [Google Scholar] [CrossRef]

- Al-Ahmady, K.K. Analysis of oxygen transfer performance on sub-surface aeration systems. Int. J. Environ. Res. Public Health 2006, 3, 301–308. [Google Scholar] [CrossRef]

- Krishna, R.; Van Baten, J.M. Mass transfer in bubble columns. Catal. Today 2003, 79–80, 67–75. [Google Scholar] [CrossRef]

- Kawase, Y.; Halard, B.; Moo-Young, M. Theoretical prediction of volumetric mass transfer coefficients in bubble columns for Newtonian and non-newtonian fluids. Chem. Eng. Sci. 1987, 42, 1609–1617. [Google Scholar] [CrossRef]

- Akita, K.; Yoshida, F. Gas holdup and volumetric mass—Transfer coefficient in bubble columns—Effects of liquid properties. Ind. Eng. Chem. Process. Des. Dev. 1973, 12, 76–80. [Google Scholar] [CrossRef]

- Jin, B.; Yin, P.; Lant, P. Hydrodynamics and mass transfer coefficient in three-phase air-lift reactors containing activated sludge. Chem. Eng. Process. Process. Intensif. 2006, 45, 608–617. [Google Scholar] [CrossRef]

| State | Index Value |

|---|---|

| Soluble inert organic mater | |

| Readily biodegradable sustrate | |

| Particulate inert organic matter | |

| Slowly biodegradable substrate | |

| Active heterotrophic biomass | |

| Active autotrophic biomass | |

| Particulate products arising from biomass decay | |

| Oxygen | 48.73 |

| Nitrate and nitrite nitrogen | |

| NH4 + NH3 nitrogen | |

| Soluble biodegradable organic nitrogen | |

| Particulate biodegradable organic nitrogen | |

| Alkalinity |

| Control Loop | |||

| P | [days] | [days] | |

| Reactor 3 | 0.008 | 0.0001 | 0.001 |

| Reactor 4 | 0.009 | 0.0001 | 0.001 |

| Reactor 5 | 0.0008 | 0.0001 | 0.001 |

| Control Loop | |||

| P | [days] | [days] | |

| Reactor 3 | 60 | 0.0001 | 0.006 |

| Reactor 4 | 5 | 0.00005 | 0.006 |

| Reactor 5 | 600 | 0.0001 | 0.006 |

| Nitrite + Nitrate Control Loop | |||

| P | [days] | [days] | |

| Reactor 2 | 30 | 0.00009 | 0.006 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Morales-Rodelo, K.; Francisco, M.; Alvarez, H.; Vega, P.; Revollar, S. Collaborative Control Applied to BSM1 for Wastewater Treatment Plants. Processes 2020, 8, 1465. https://doi.org/10.3390/pr8111465

Morales-Rodelo K, Francisco M, Alvarez H, Vega P, Revollar S. Collaborative Control Applied to BSM1 for Wastewater Treatment Plants. Processes. 2020; 8(11):1465. https://doi.org/10.3390/pr8111465

Chicago/Turabian StyleMorales-Rodelo, Keidy, Mario Francisco, Hernan Alvarez, Pastora Vega, and Silvana Revollar. 2020. "Collaborative Control Applied to BSM1 for Wastewater Treatment Plants" Processes 8, no. 11: 1465. https://doi.org/10.3390/pr8111465

APA StyleMorales-Rodelo, K., Francisco, M., Alvarez, H., Vega, P., & Revollar, S. (2020). Collaborative Control Applied to BSM1 for Wastewater Treatment Plants. Processes, 8(11), 1465. https://doi.org/10.3390/pr8111465