Economic Reliability-Aware MPC-LPV for Operational Management of Flow-Based Water Networks Including Chance-Constraints Programming

Abstract

1. Introduction

2. EMPC for Transport Water Networks

2.1. Control-Oriented Model

2.2. EMPC Formulation

- Economic objective: Minimizing water production and transport costs while providing the demanded volume.

- Safety objective: The safety volumes in the tanks are preserved guaranteeing, up to some level, the water supply under connected variations in the demand.

- Smoothness objective: For avoiding overpressures in pipes and damage in actuators, the actuators are managed based on the smooth control actions.

2.2.1. Economic Cost Minimization

2.2.2. Safety Management

2.2.3. Control Action Smoothness

2.2.4. EMPC Optimization Problem Formulation

3. Chance-Constrained Model Predictive Control

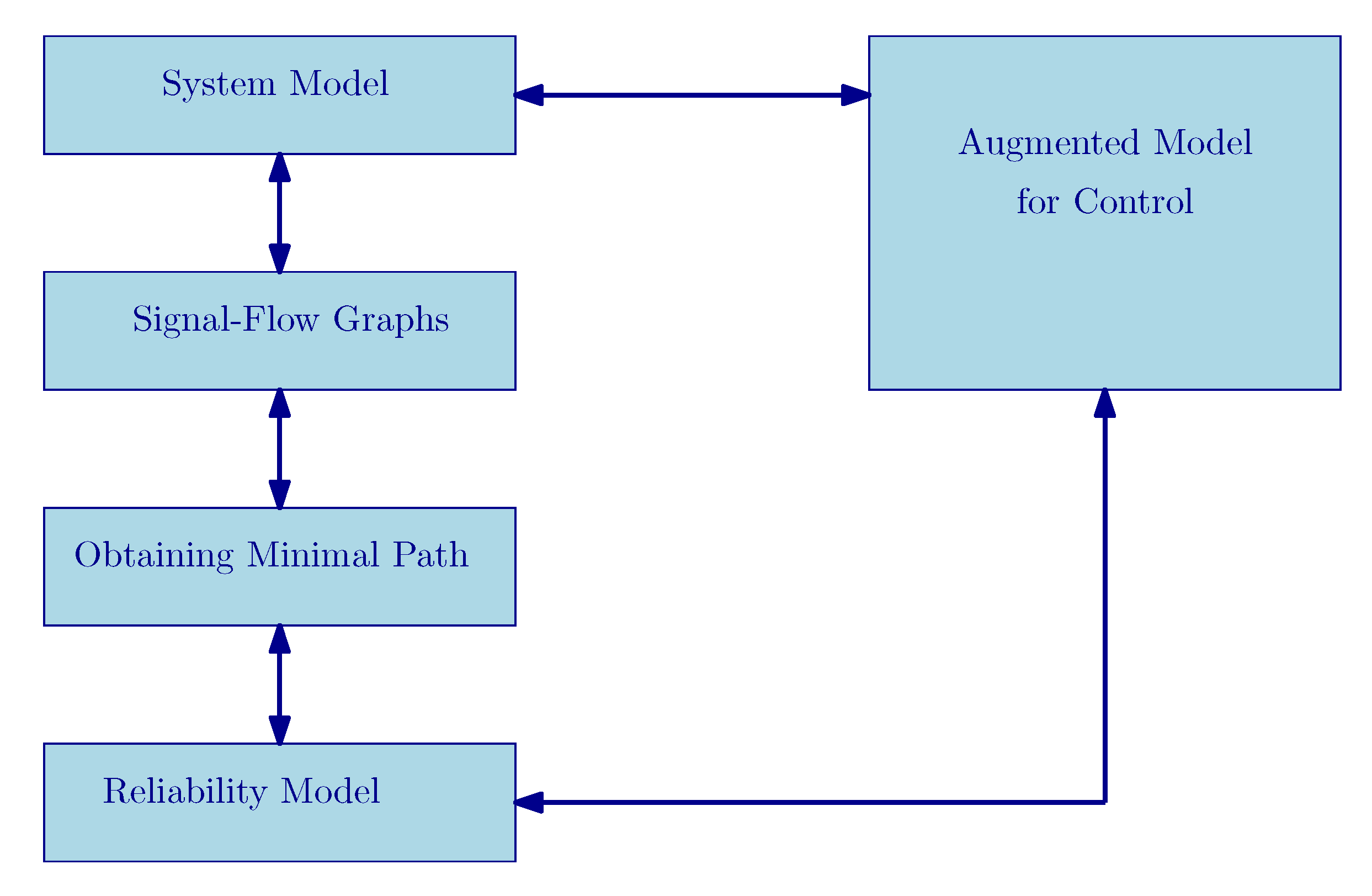

4. Augmenting Network Model with the Reliability Model

4.1. Reliability Model

4.2. Overall Reliability

4.3. System Reliability Modeling

5. Economic Reliability-Aware MPC-LPV Using Chance-Constraints

5.1. Economic Reliability Aware MPC-LPV

| Algorithm 1 LPV-based MPC strategy |

5.2. Including Demand Uncertainty Using Chance Constraints

5.3. Enhancing System Reliability Using Chance Constraints

5.4. Chance-Constraints Reliability-Aware EMPC-LPV Reformulation

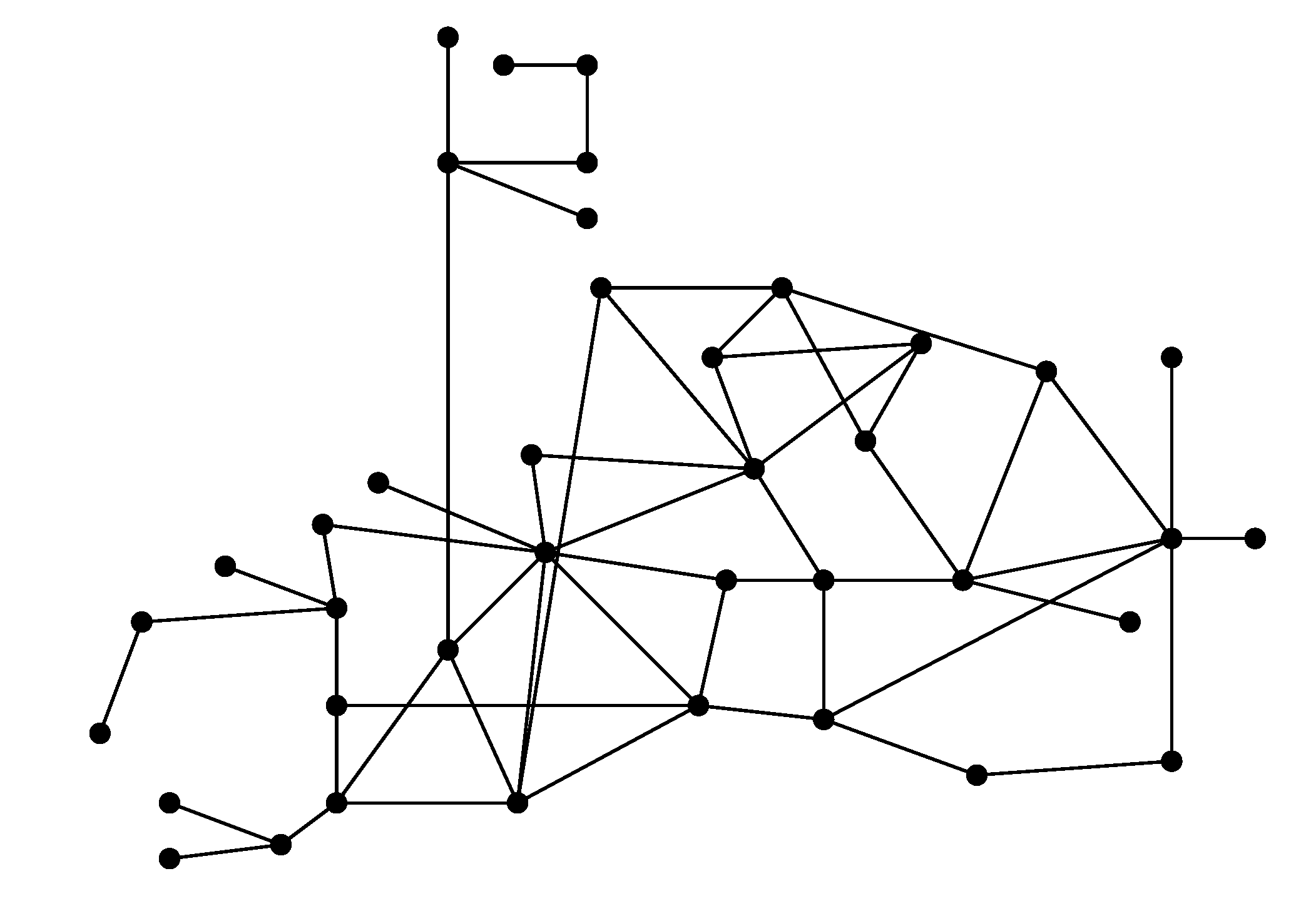

6. Application

6.1. Case Study

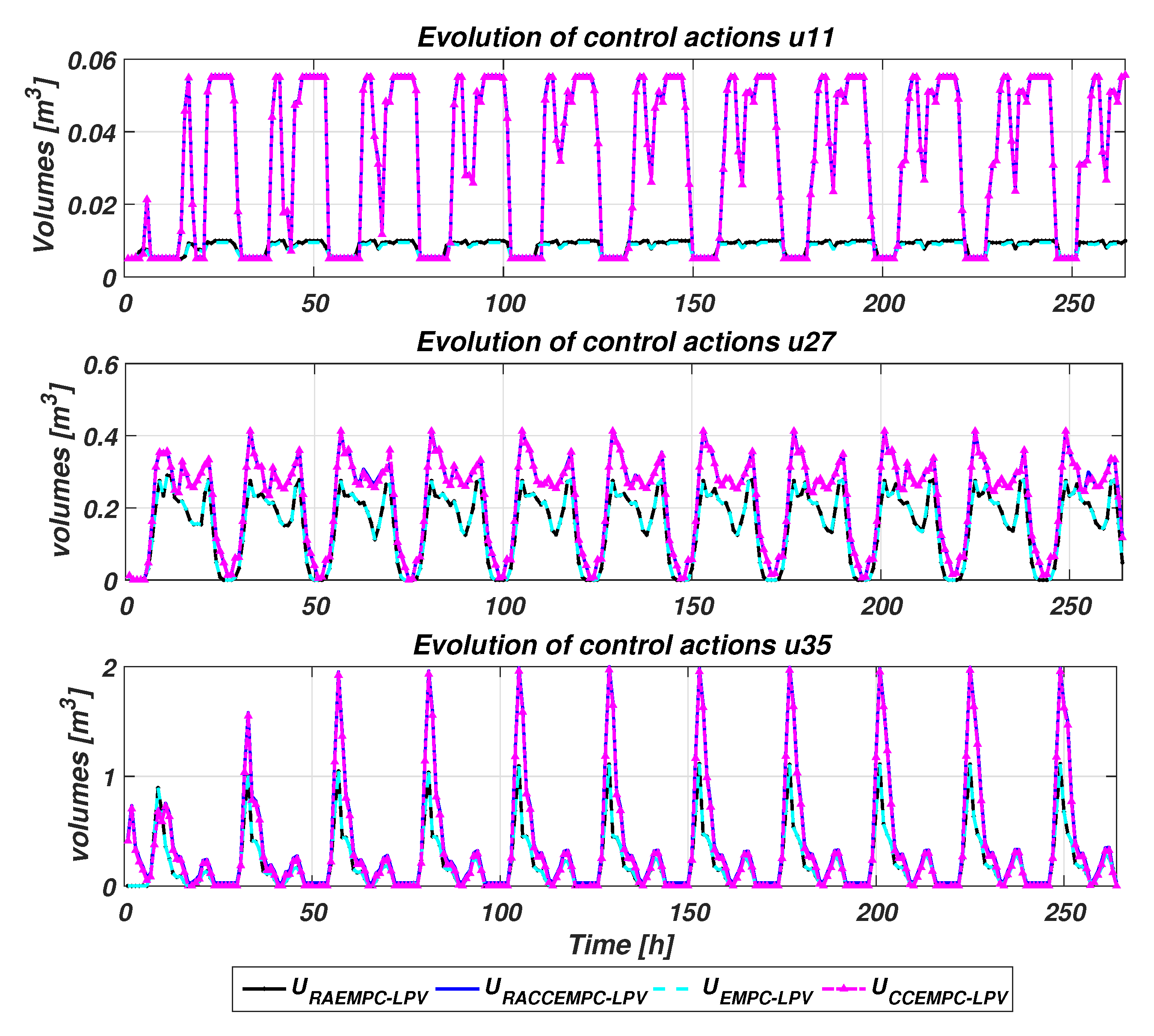

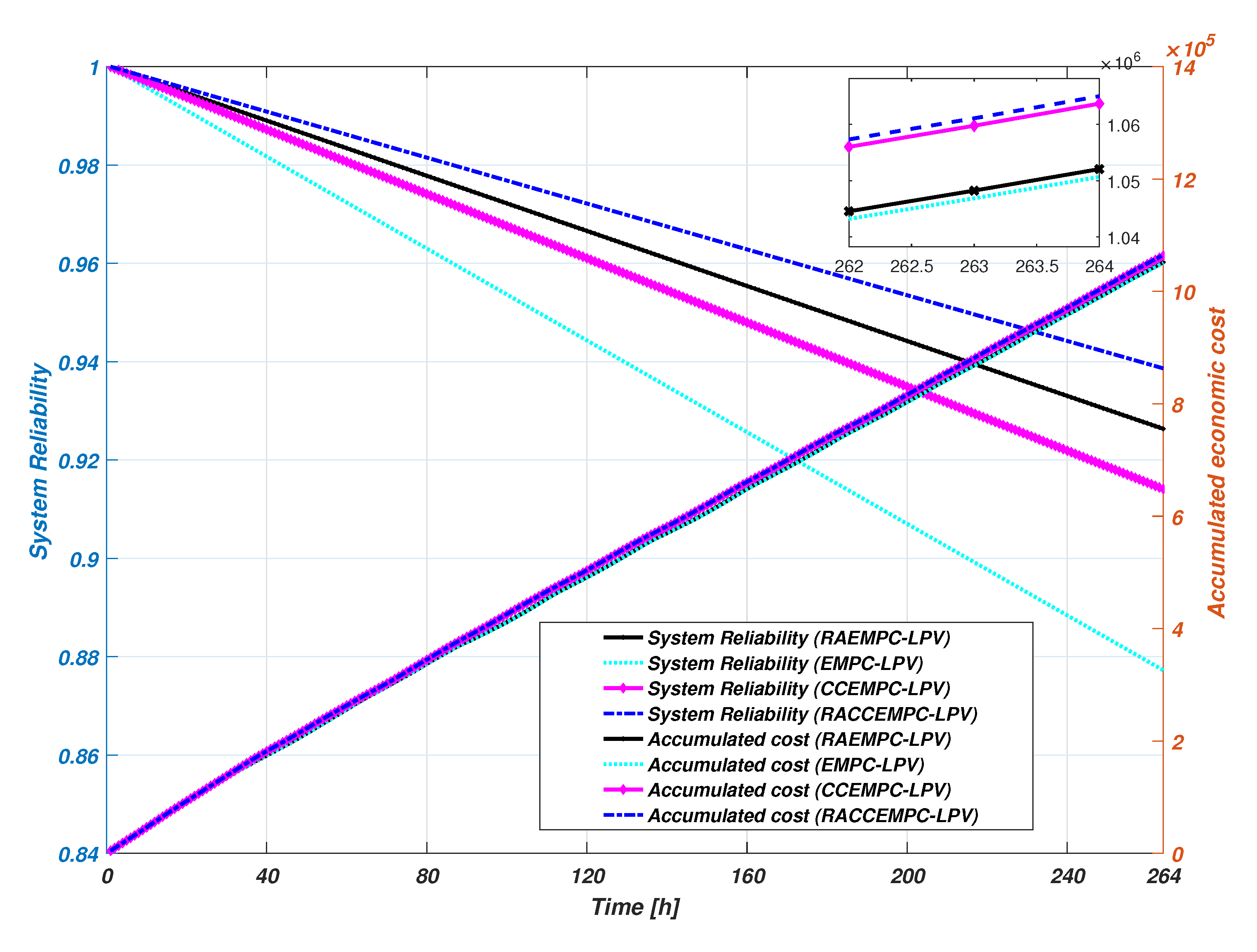

6.2. Results and Discussion

- Reliability-Aware Chance-constrained Economic MPC-LPV (RACCEMPC-LPV): This is the approach proposed in this paper that is based on solving the optimization problem (54). This approach allows the consideration of nonstationary stochastic demand uncertainty and stochastic whole reliability of the system. Therefore, the base stock constraint, the hard bounds of the states and the terminal constraint of the system reliability are formulated in the framework of chance constraints.

- Economic MPC-LPV (EMPC-LPV): This approach is based the optimization problem (45) without including the reliability objective. Moreover, it is not considering the stochastic demand uncertainty, chance constraints, and terminal constraint of the system reliability of the network.

- Chance-constrained Economic MPC-LPV (CCEMPC-LPV): This approach is included robustness only for demand uncertainty by replacing the state deterministic constraints with chance-constraints. Moreover, the CCEMPC-LPV controller does not include neither the reliability objective nor the terminal constraint of the system reliability of the network.

- Reliability-aware economic MPC-LPV (RAEMPC-LPV): This approach relies on solving problem (45a). In this approach, an additional goal is included to the controller in order to extend the components and system reliability. However, the stochastic demand uncertainty and chance constraints associated to the system reliability are not considered.

7. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Ocampo-Martinez, C.; Puig, V.; Cembrano, G.; Quevedo, J. Application of predictive control strategies to the management of complex networks in the urban water cycle [applications of control]. IEEE Control Syst. 2013, 33, 15–41. [Google Scholar]

- Karimi Pour, F.; Puig, V.; Ocampo-Martinez, C. Health-aware Model Predictive Control of Pasteurization Plant. J. Phys. 2017, 783, 12030. [Google Scholar]

- Maciejowski, J.M. Predictive Control: With Constraints; Pearson Education: London, UK, 2002. [Google Scholar]

- Cembrano, G.; Quevedo, J.; Puig, V.; Pérez, R.; Figueras, J.; Verdejo, J.; Escaler, I.; Ramón, G.; Barnet, G.; Rodríguez, P.; et al. PLIO: A generic tool for real-time operational predictive optimal control of water networks. Water Sci. Technol. 2011, 64, 448–459. [Google Scholar] [CrossRef] [PubMed]

- Ocampo-Martinez, C.; Ingimundarson, A.; Puig, V.; Quevedo, J. Objective prioritization using lexicographic minimizers for MPC of sewer networks. IEEE Trans. Control Syst. Technol. 2008, 16, 113–121. [Google Scholar] [CrossRef]

- Pascual, J.; Romera, J.; Puig, V.; Cembrano, G.; Creus, R.; Minoves, M. Operational predictive optimal control of Barcelona water transport network. Control Eng. Pract. 2013, 21, 1020–1034. [Google Scholar] [CrossRef]

- Puig, V.; Ocampo-Martinez, C.; De Oca, S.M. Hierarchical temporal multi-layer decentralised MPC strategy for drinking water networks: Application to the barcelona case study. In Proceedings of the 2012 20th Mediterranean Conference on Control & Automation (MED), Barcelona, Spain, 3–6 July 2012; pp. 740–745. [Google Scholar]

- Rawlings, J.B.; Mayne, D.Q. Model Predictive Control: Theory and Design; Nob Hill Pub.: Santa Barbara, CA, USA, 2009. [Google Scholar]

- Karimi Pour, F.; Puig, V.; Ocampo-Martinez, C. Economic Predictive Control of a Pasteurization Plant using a Linear Parameter Varying Model. In Computer Aided Chemical Engineering; Elsevier: Amsterdam, The Netherlands, 2017; Volume 40, pp. 1573–1578. [Google Scholar]

- Gertsbakh, I. Theory of Reliability with Applications to Preventive Maintenance; Springer: Berlin/Heidelberg, Germany, 2000. [Google Scholar]

- Gokdere, L.; Chiu, S.L.; Keller, K.J.; Vian, J. Lifetime control of electromechanical actuators. In Proceedings of the 2005 IEEE Aerospace Conference, Big Sky, MT, USA, 5–12 March 2005; pp. 3523–3531. [Google Scholar]

- Pereira, E.B.; Galvão, R.K.H.; Yoneyama, T. Model predictive control using prognosis and health monitoring of actuators. In Proceedings of the 2010 IEEE International Symposium on Industrial Electronics (ISIE), Bari, Italy, 4–7 July 2010; pp. 237–243. [Google Scholar]

- Karimi Pour, F.; Puig, V.; Ocampo-Martinez, C. Multi-layer health-aware economic predictive control of a pasteurization pilot plant. Int. J. Appl. Math. Comput. Sci. 2018, 28, 97–110. [Google Scholar] [CrossRef]

- Gallestey, E.; Stothert, A.; Antoine, M.; Morton, S. Model predictive control and the optimization of power plant load while considering lifetime consumption. IEEE Trans. Power Syst. 2002, 17, 186–191. [Google Scholar] [CrossRef]

- Khelassi, A.; Theilliol, D.; Weber, P.; Sauter, D. A novel active fault tolerant control design with respect to actuators reliability. In Proceedings of the 2011 50th IEEE Conference on Decision and Control and European Control Conference (CDC-ECC), Orlando, FL, USA, 12–15 December 2011; pp. 2269–2274. [Google Scholar]

- Salazar, J.C.; Sarrate, R.; Nejjari, F.; Weber, P.; Theilliol, D. Reliability computation within an MPC health-aware framework. IFAC-PapersOnLine 2017, 50, 12230–12235. [Google Scholar] [CrossRef]

- Salazar, J.C.; Weber, P.; Sarrate, R.; Theilliol, D.; Nejjari, F. MPC design based on a DBN reliability model: Application to drinking water networks. IFAC-PapersOnLine 2015, 48, 688–693. [Google Scholar] [CrossRef]

- Karimi Pour, F.; Puig, V.; Cembrano, G. Health-aware LPV-MPC based on system reliability assessment for drinking water networks. In Proceedings of the 2nd IEEE Conference on Control Technology and Applications, Copenhagen, Denmark, 21–24 August 2018. [Google Scholar]

- Chamseddine, A.; Theilliol, D.; Sadeghzadeh, I.; Zhang, Y.; Weber, P. Optimal reliability design for over-actuated systems based on the MIT rule: Application to an octocopter helicopter testbed. Reliab. Eng. Syst. Saf. 2014, 132, 196–206. [Google Scholar] [CrossRef]

- Grosso, J.M.; Ocampo-Martínez, C.; Puig, V. A service reliability model predictive control with dynamic safety stocks and actuators health monitoring for drinking water networks. In Proceedings of the 2012 IEEE 51st Annual Conference on Decision and Control (CDC), Maui, HI, USA, 10–13 December 2012; pp. 4568–4573. [Google Scholar]

- Karimi Pour, F.; Puig Cayuela, V.; Ocampo-Martínez, C. Comparative assessment of LPV-based predictive control strategies for a pasteurization plant. In Proceedings of the 4th—2017 International Conference on Control, Decision and Information Technologies, Barcelona, Spain, 5–7 April 2017; pp. 1–6. [Google Scholar]

- Calafiore, G.C.; Dabbene, F.; Tempo, R. Research on probabilistic methods for control system design. Automatica 2011, 47, 1279–1293. [Google Scholar] [CrossRef]

- Schwarm, A.T.; Nikolaou, M. Chance-constrained model predictive control. AIChE J. 1999, 45, 1743–1752. [Google Scholar] [CrossRef]

- Geletu, A.; Klöppel, M.; Zhang, H.; Li, P. Advances and applications of chance-constrained approaches to systems optimization under uncertainty. Int. J. Syst. Sci. 2013, 44, 1209–1232. [Google Scholar] [CrossRef]

- Ouarda, T.; Labadie, J. Chance-constrained optimal control for multireservoir system optimization and risk analysis. Stoch. Environ. Res. Risk Assess. 2001, 15, 185–204. [Google Scholar] [CrossRef]

- Mays, L. Urban Stormwater Management Tools; McGraw Hill Professional: New York, NY, USA, 2004. [Google Scholar]

- Brdys, M.; Ulanicki, B. Operational Control of Water Systems: Structures, Algorithms and Applications. Automatica 1996, 32, 1619–1620. [Google Scholar]

- Cembrano, G.; Quevedo, J.; Salamero, M.; Puig, V.; Figueras, J.; Martı, J. Optimal control of urban drainage systems. A case study. Control Eng. Pract. 2004, 12, 1–9. [Google Scholar] [CrossRef]

- Kall, P.; Mayer, J. Stochastic Linear Programming; Springer: Berlin/Heidelberg, Germany, 1976; Volume 7. [Google Scholar]

- Grosso, J.M.; Velarde, P.; Ocampo-Martinez, C.; Maestre, J.M.; Puig, V. Stochastic model predictive control approaches applied to drinking water networks. Optim. Control Appl. Methods 2017, 38, 541–558. [Google Scholar] [CrossRef]

- Nemirovski, A.; Shapiro, A. Convex approximations of chance constrained programs. SIAM J. Optim. 2006, 17, 969–996. [Google Scholar] [CrossRef]

- Shapiro, A.; Dentcheva, D.; Ruszczyński, A. Lectures on Stochastic Programming: Modeling and Theory; SIAM: Phhiladelphia, PA, USA, 2009. [Google Scholar]

- Jiang, R.; Jardine, A.K. Health state evaluation of an item: A general framework and graphical representation. Reliab. Eng. Syst. Saf. 2008, 93, 89–99. [Google Scholar] [CrossRef]

- Gertsbakh, I. Reliability Theory: With Applications to Preventive Maintenance; Springer: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

- Baecher, G.B.; Christian, J.T. Reliability and Statistics in Geotechnical Engineering; John Wiley & Sons: Hoboken, NJ, USA, 2005. [Google Scholar]

- Ocampo-Martínez, C.; Puig, V.; Cembrano, G.; Creus, R.; Minoves, M. Improving water management efficiency by using optimization-based control strategies: The Barcelona case study. Water Sci. Technol. Water Supply 2009, 9, 565–575. [Google Scholar] [CrossRef]

- Siljak, D.D. Decentralized Control of Complex Systems; Courier Corporation: Chelmsford, MA, USA, 2011. [Google Scholar]

- Weber, P.; Simon, C.; Theilliol, D.; Puig, V. Fault-Tolerant Control Design for over-actuated System conditioned by Reliability: A Drinking Water Network Application. IFAC Proc. Vol. 2012, 45, 558–563. [Google Scholar] [CrossRef]

- Robles, D.; Puig, V.; Ocampo-Martinez, C.; Garza-Castañón, L.E. Reliable fault-tolerant model predictive control of drinking water transport networks. Control Eng. Pract. 2016, 55, 197–211. [Google Scholar] [CrossRef]

| No. | Name | No. | Name | No. | Name | No. | Name |

|---|---|---|---|---|---|---|---|

| VALVA | VALVA309 | CC130 | VPSJ | ||||

| CPIV | bPousE | CC70 | CMO | ||||

| bMS | CGIV | VB | VMC | ||||

| CPII | CPLANTA50 | CF176 | VALVA60 | ||||

| VALVA47 | PLANTA10 | VCO | VALVA56 | ||||

| bCast | CRE | CCO | VALVA57 | ||||

| VCR | CC100 | VS | CRO | ||||

| bPouCast | VALVA64 | V | VBMC | ||||

| CCA | VALVA50 | VCT | bPousB | ||||

| CB | CC50 | CA | VALVA53 | ||||

| VALVA308 | VF | VP | VALVA54 | ||||

| VALVA48 | CF200 | VBSLL | VALVA61 | ||||

| VCA | VE | CPR | VALVA55 | ||||

| CPLANTA70 | VZF | VCOA | VCON |

| No. | Name | No. | Name | No. | Name | No. | Name |

|---|---|---|---|---|---|---|---|

| VALVA45 | VSJD-29 | CE | VRM | ||||

| VALVA312 |

| Path | Component Set |

|---|---|

| ⋮ | ⋮ |

| Controller | Simulation Time | |||||

|---|---|---|---|---|---|---|

| EMPC-LPV | 3779.81 | 0.5271 | 28951.72 | 0.8772 | 1.5628 | 412.599 |

| CCEMPC-LPV | 4029.09 | 0.4910 | 28955.69 | 0.9186 | 1.9051 | 502.952 |

| RAEMPC-LPV | 3980.07 | 0.5317 | 28952.62 | 0.9263 | 1.78348 | 470.841 |

| RACCEMPC-LPV | 4029.19 | 0.4903 | 28955.90 | 0.9386 | 1.9664 | 519.147 |

| MPC Approach | Water Average Cost | Electric Average Cost | Daily Average Cost |

|---|---|---|---|

| (e.u./day) | (e.u./day) | (e.u./day) | |

| EMPC-LPV | 44162.44 | 3053.08 | 47215.53 |

| CCEMPC-LPV | 51237.98 | 3262.43 | 54500.42 |

| RAEMPC-LPV | 44369.90 | 3121.84 | 47491.75 |

| RACCEMPC-LPV | 51438.13 | 3262.64 | 54700.77 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pour, F.K.; Puig, V.; Cembrano, G. Economic Reliability-Aware MPC-LPV for Operational Management of Flow-Based Water Networks Including Chance-Constraints Programming. Processes 2020, 8, 60. https://doi.org/10.3390/pr8010060

Pour FK, Puig V, Cembrano G. Economic Reliability-Aware MPC-LPV for Operational Management of Flow-Based Water Networks Including Chance-Constraints Programming. Processes. 2020; 8(1):60. https://doi.org/10.3390/pr8010060

Chicago/Turabian StylePour, Fatemeh Karimi, Vicenç Puig, and Gabriela Cembrano. 2020. "Economic Reliability-Aware MPC-LPV for Operational Management of Flow-Based Water Networks Including Chance-Constraints Programming" Processes 8, no. 1: 60. https://doi.org/10.3390/pr8010060

APA StylePour, F. K., Puig, V., & Cembrano, G. (2020). Economic Reliability-Aware MPC-LPV for Operational Management of Flow-Based Water Networks Including Chance-Constraints Programming. Processes, 8(1), 60. https://doi.org/10.3390/pr8010060