An All-Factors Analysis Approach on Energy Consumption for the Blast Furnace Iron Making Process in Iron and Steel industry

Abstract

1. Introduction

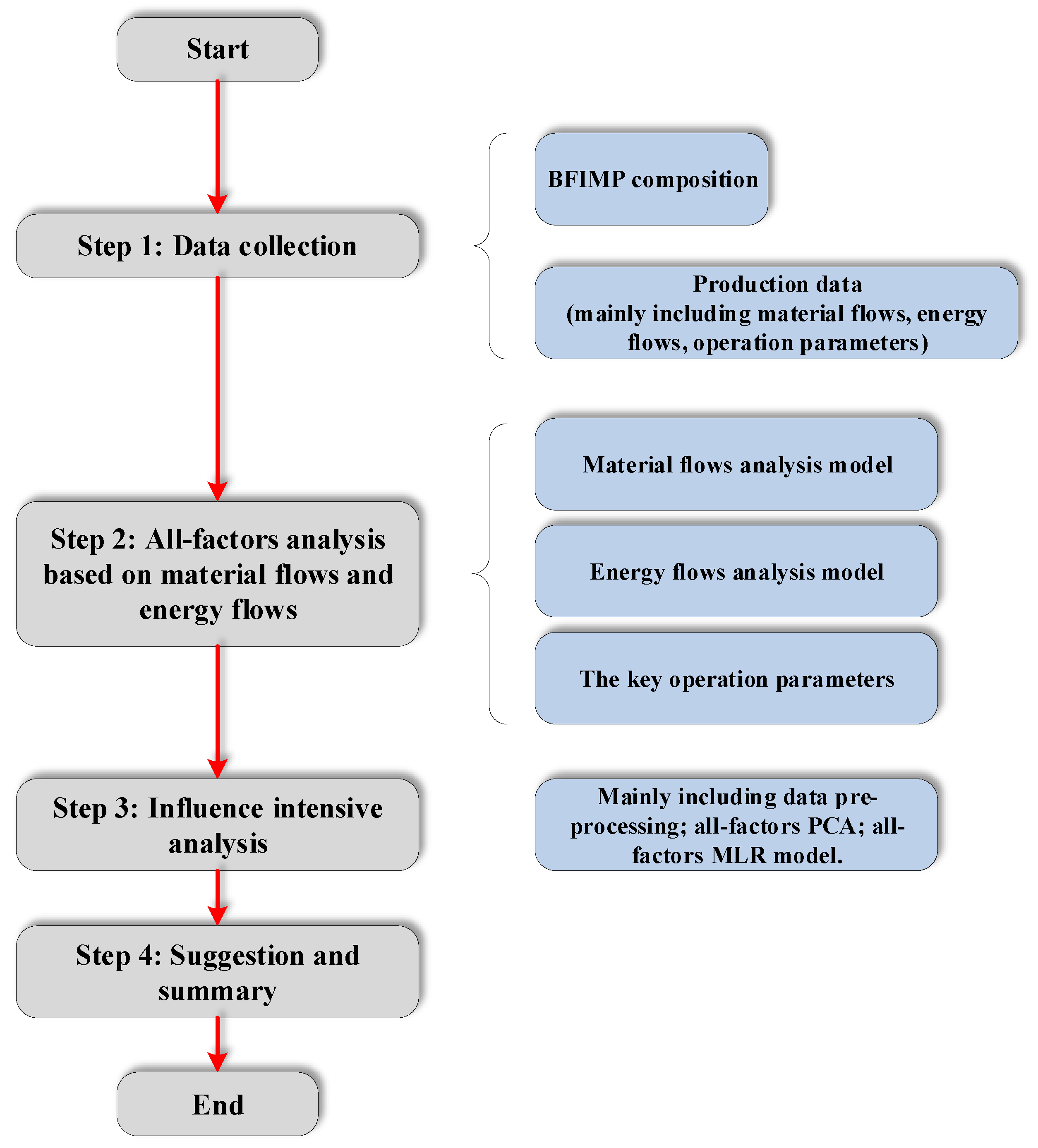

2. Methods

2.1. Data Collection

2.2. All-Factors Analysis Based on Material Flows and Energy Flows

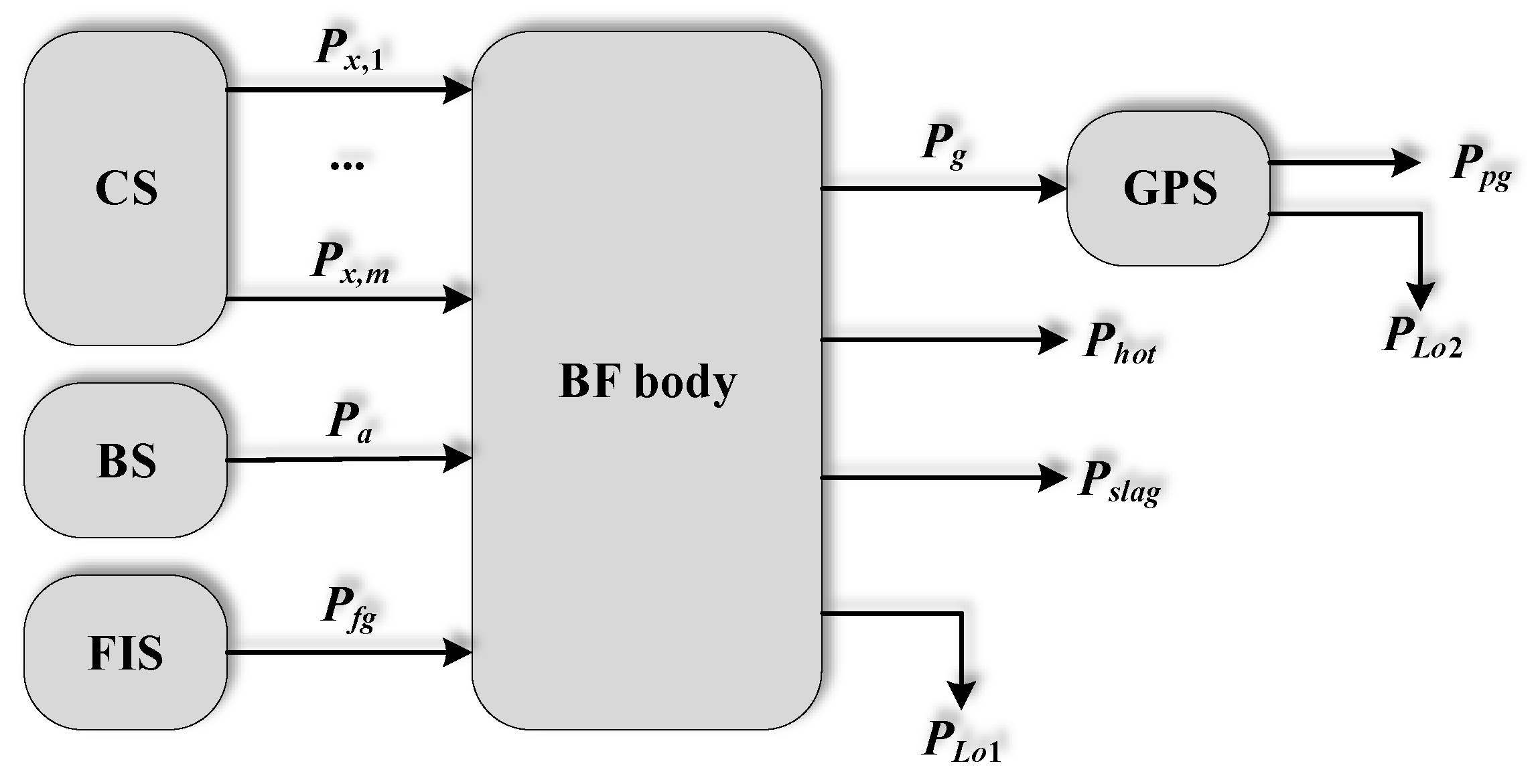

2.2.1. Material Flows Analysis Model

- : The amount of various materials, t/t;

- and : The amount of blast and fuel injection into the furnace, respectively, t/t;

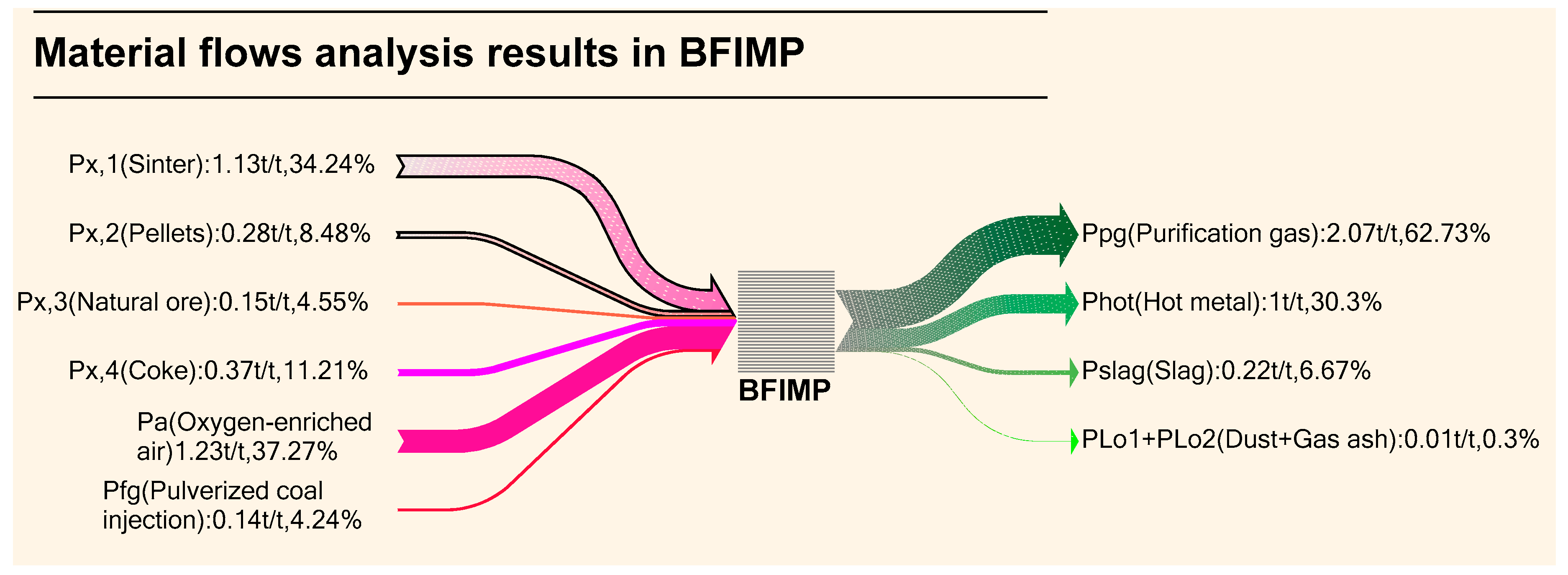

- , and : The mount of gas, hot metal and slag, respectively, t/t, and ;

- : The mount of gas after purification, t/t;

- and : The loss amount of various systems, t/t.

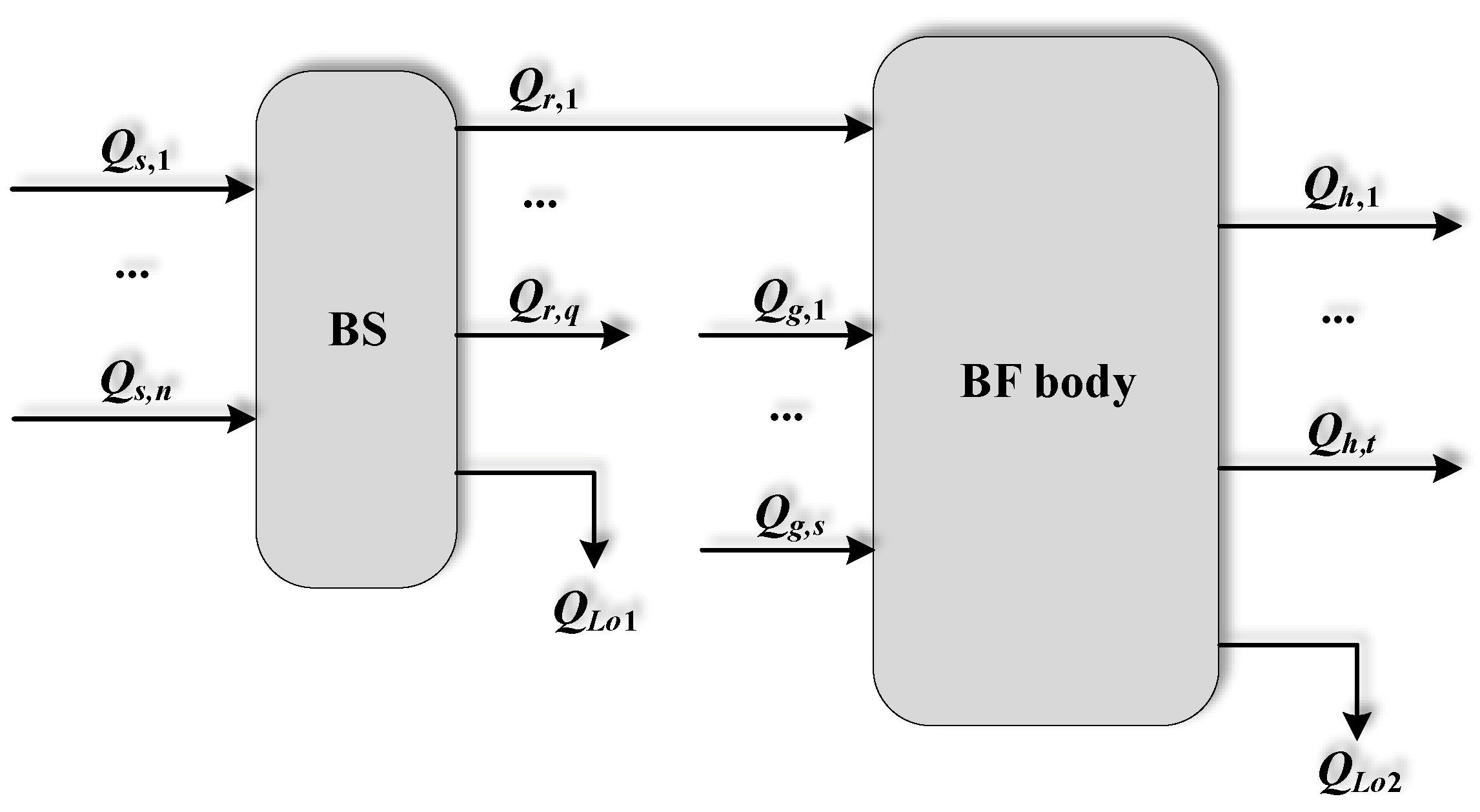

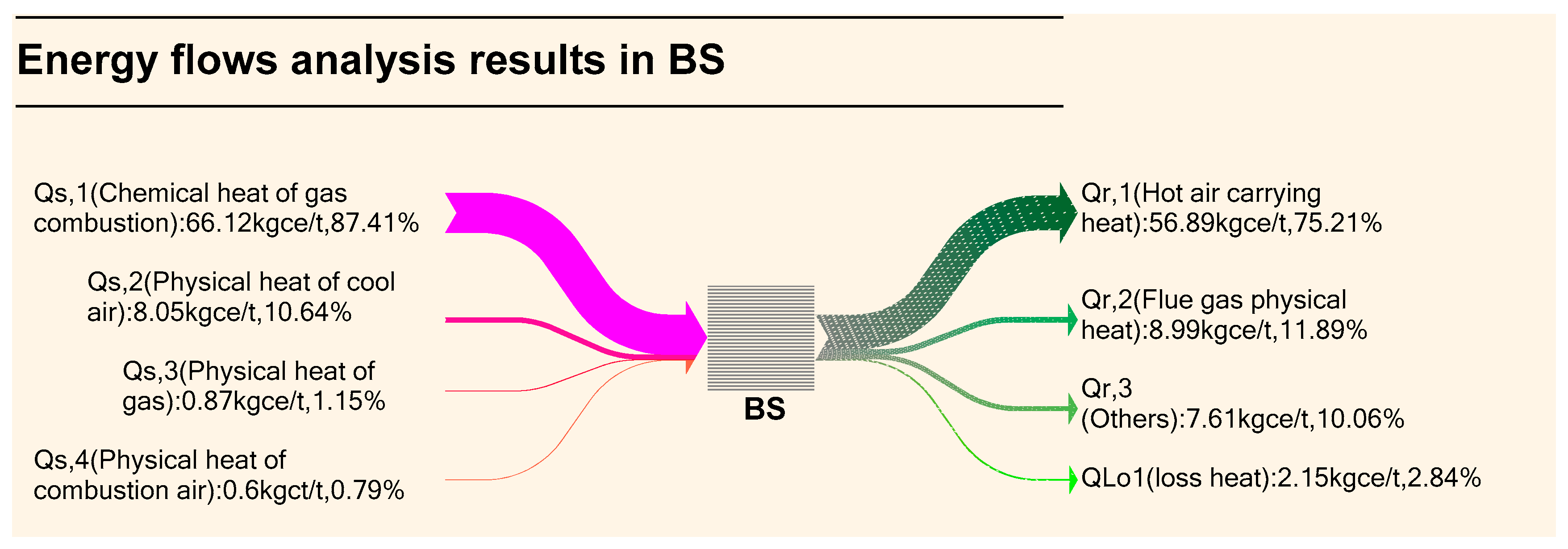

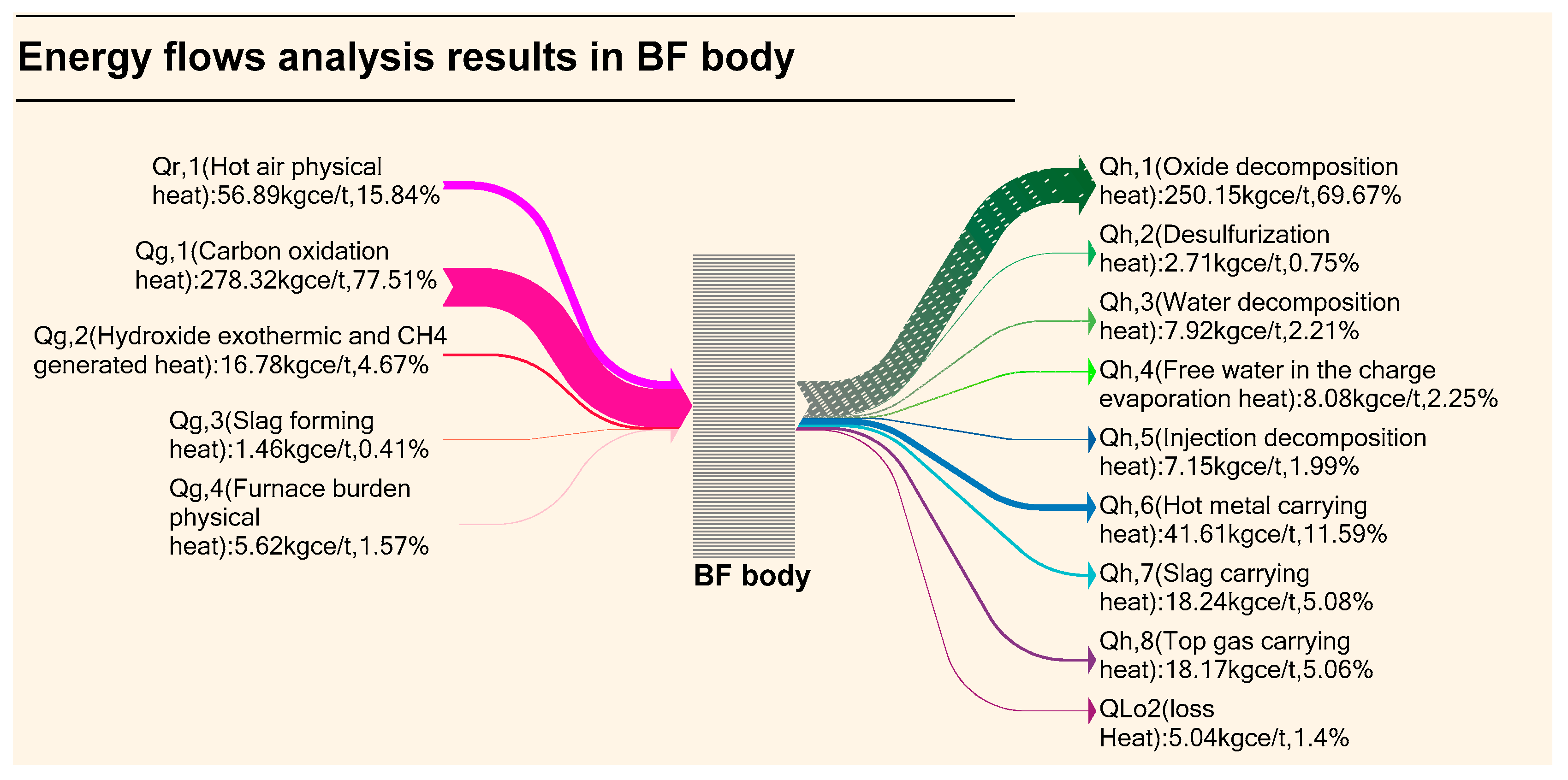

2.2.2. Energy Flows Analysis Model

- : The input heat items and the output heat items of the BS, kgce/t (kgce: Kilogram coal equivalent);

- : The input heat items and the output heat items of the BF Body, kgce/t;

- : The loss heat items of the BS and the BF Body, kgce/t.

2.2.3. The Key Operation Parameters

2.3. All-FactorsAnalysis on Energy Consumption in BFIMP

2.3.1. Data Pre-Processing

- (1)

- Some data were recorded manually. Inevitably, there would be some mistakes in the recording process, such as unrecorded, omitted and incorrectly annotated. Therefore, these data should be eliminated or modified.

- (2)

- The study was discussed based on the normal production [5] in this paper, so the data of equipment overhauls and failures should be stripped out.

- (3)

- Other abnormal data, which was caused by the damage of the detection or data transmission equipment, should also be eliminated.

2.3.2. PCA

2.3.3. MLR Model

- : Energy consumption of the group sample, kgce/t;

- : The 1st material flows variable of the group sample;

- and :Constant term;

- , , , , , : Regression coefficient;

- : Error term.

- : The residual of the group sample between and its fitting model;

- : The residual of the group sample between and its fitting model;

- : The covariance between the vector and vector;

- : The variance of the vector;

- : The variance of the vector.

3. Results and Discussion

3.1. Data Sources and Related Instructions

3.2. Material Flows Analysis and Energy Flows Analysis Results

3.2.1. Material Flows Analysis Results

3.2.2. Energy Flows Analysis Results

3.3. All-Factors Analysis on Energy Consumption in BFIMP

3.3.1. PCA

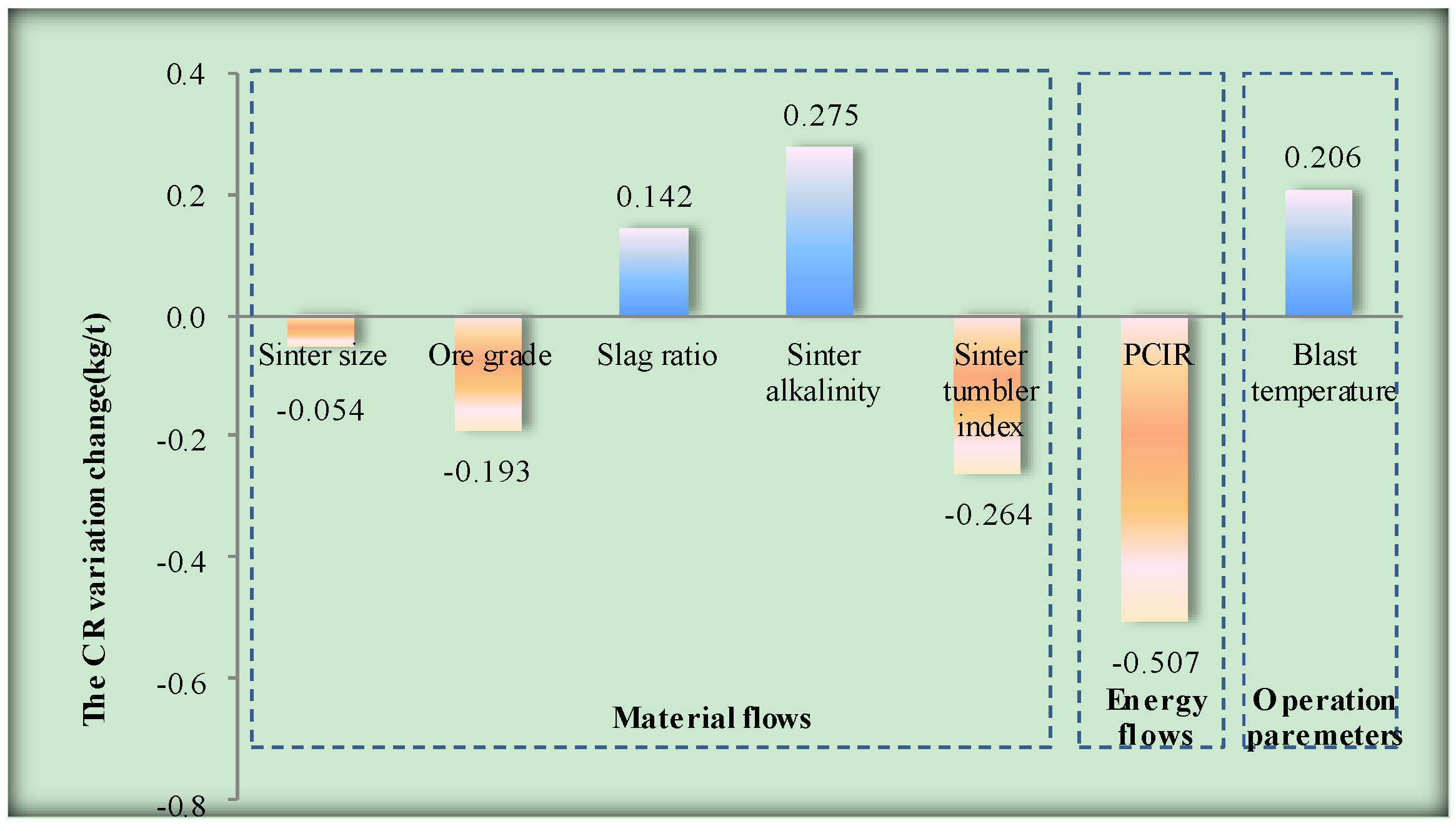

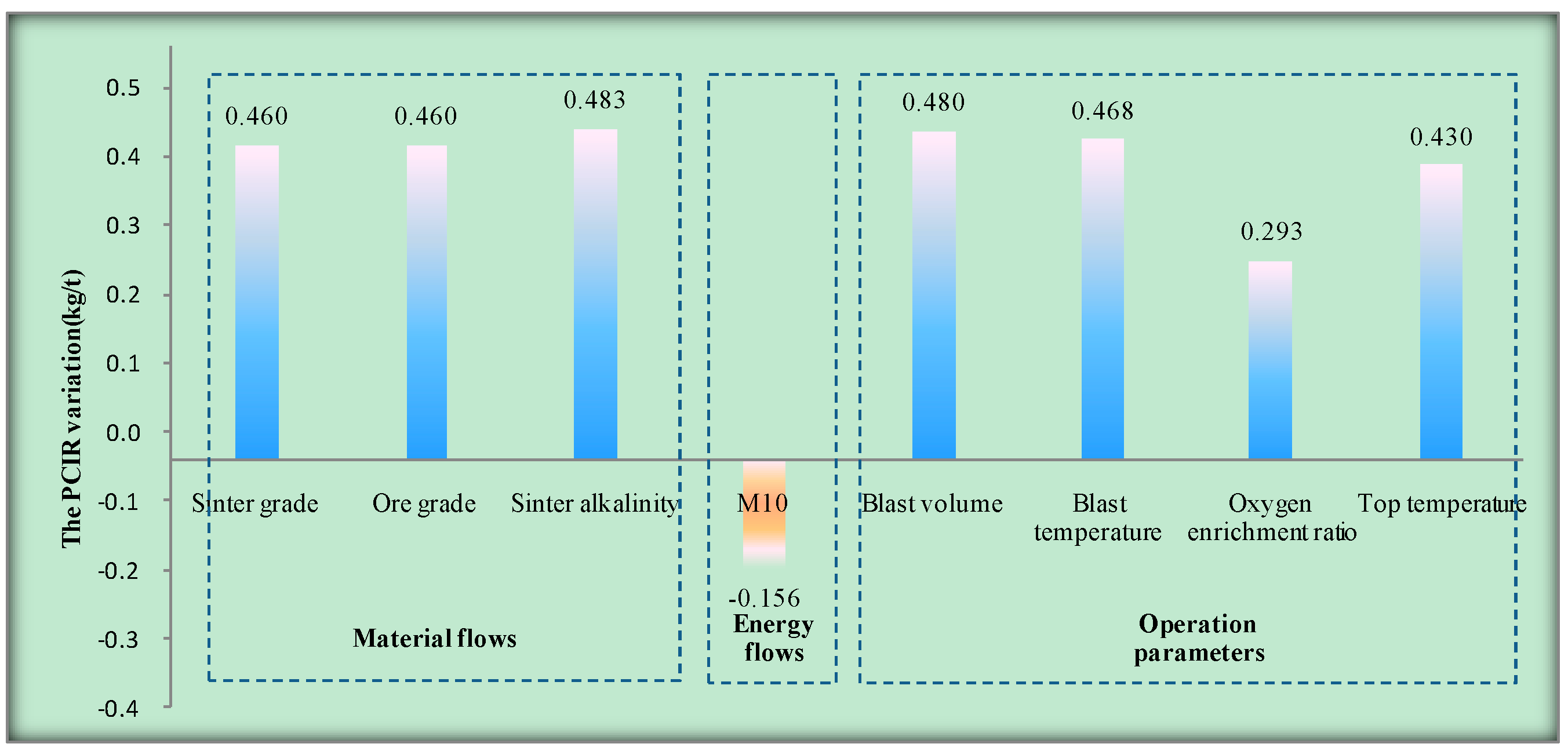

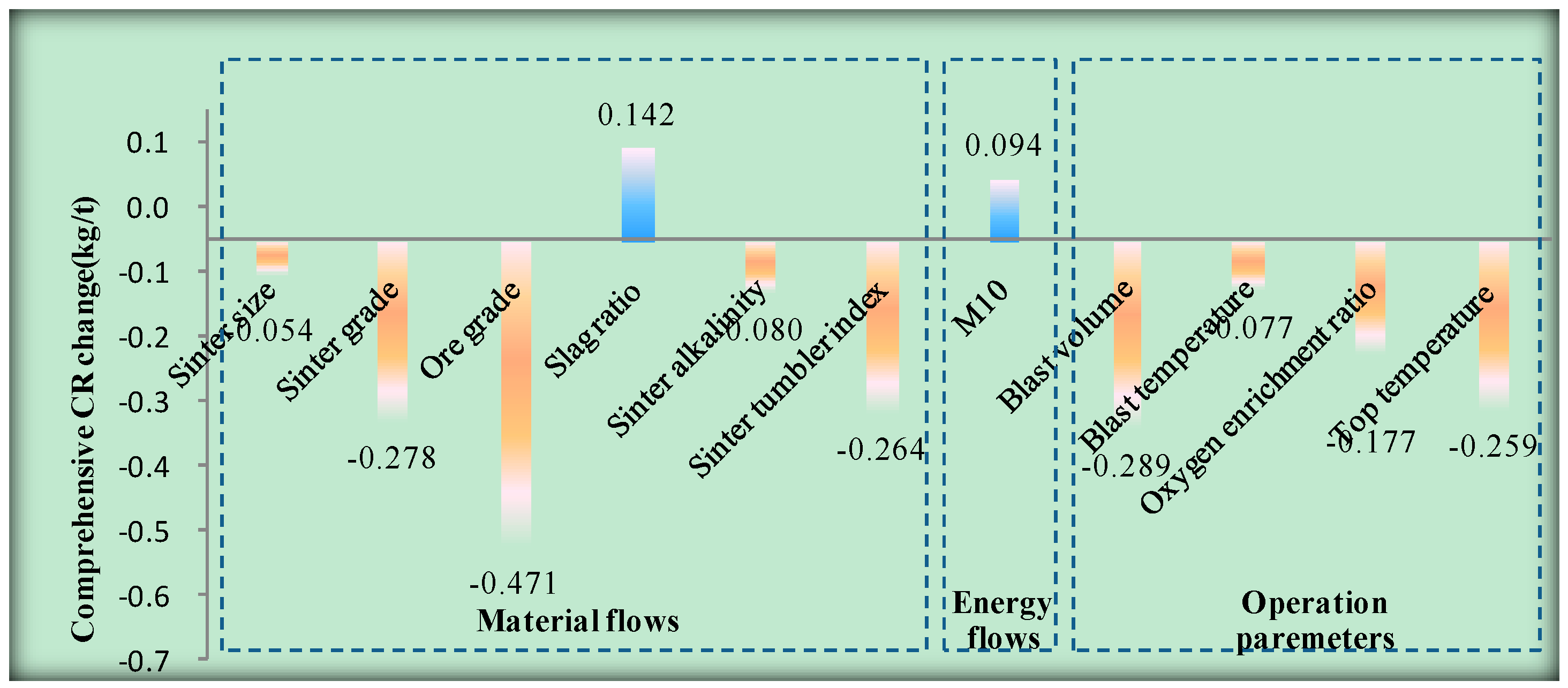

3.3.2. MLR Models on CR and PCIR

4. Discussion

- (1)

- The effective energy saving measures could be achieved through the all-factors analysis approach.

- (2)

- The case study shows that there were 26 influence factors on energy consumption in BFIMP. Nevertheless, the seven influence factors were highly correlated with CR, and the eight influence factors had highly correlation on PCIR through the PCA analysis.

- (3)

- The PCIR improvement was the most effective measure for reducing CR, and the increase of sinter alkalinity was the most favorable for PCIR in the case BFIMP.

5. Conclusions

- (1)

- An all-factors analysis approach on energy consumption was proposed in BFIMP in this paper. This method mainly included four steps: Data collection, all-factors analysis based on material flows and energy flows, influence intensity analysis on energy consumption in BFIMP and suggestion and summary. The availability of this method was validated by a case BFIMP.

- (2)

- The case study shows that the improvement of PCIR was conducive to a reduction of CR very much. The increase of sinter alkalinity was the most effective measure for PCIR.

- (3)

- The proposed all-factors analysis approach on energy consumption, which provided an effective measure of energy saving, could widely be used in various BFIMPs, too.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Mauricio, R.; Mikko, H.; Henrik, S. Principal Component Analysis of Blast Furnace Drainage Patterns. Processes 2019, 7, 519. [Google Scholar] [CrossRef]

- Lu, B.; Tang, K.; Chen, D.; Han, Y.; Wang, S.; He, X.; Chen, G. A Novel Approach for Lean Energy Operation Based on Energy Apportionment Model in Reheating Furnace. Energy 2019, 182, 1239–1249. [Google Scholar] [CrossRef]

- Matsuda, K.; Tanaka, S.; Endou, M.; Iiyoshi, T. Energy saving study on a large steel plant by total site based pinch technology. Appl. Therm. Eng. 2012, 43, 14–19. [Google Scholar] [CrossRef]

- Lu, B.; Chen, G.; Chen, D.; Yu, W. An energy intensity optimization model for production system in iron and steel industry. Appl. Therm. Eng. 2016, 100, 285–295. [Google Scholar] [CrossRef]

- Chen, D.; Lu, B.; Chen, G.; Yu, W. Influence of the production fluctuation on the process energy intensity in iron and steel industry. Adv. Prod. Eng. Manag. 2017, 12, 75–87. [Google Scholar] [CrossRef]

- Chen, W.; Yin, X.; Ma, D. A bottom-up analysis of China’s iron and steel industrial energy consumption and CO2 emissions. Appl. Energy 2014, 136, 1174–1183. [Google Scholar] [CrossRef]

- Li, Y.; Zhu, L. Cost of energy saving and CO2 emissions reduction in China’s iron and steel sector. Appl. Energy 2014, 130, 603–616. [Google Scholar] [CrossRef]

- Cai, W.; Liu, C.; Lai, K.; Li, L.; Cunha, J.; Hu, L. Energy performance certification in mechanical manufacturing industry: A review and analysis. Energy Convers. Manag. 2019, 186, 415–432. [Google Scholar] [CrossRef]

- Emi, T. Optimizing Steelmaking System for Quality Steel Mass Production for Sustainable Future of Steel Industry. Steel Res. Int. 2014, 85, 1274–1282. [Google Scholar] [CrossRef]

- Liu, X.; Chen, L.; Feng, H.; Qin, X.; Sun, F. Constructal design of a blast furnace iron-making process based on multi-objective optimization. Energy 2016, 109, 137–151. [Google Scholar] [CrossRef]

- Yilmaz, C.; Wendelstorf, J.; Turek, T. Modeling and simulation of hydrogen injection into a blast furnace to reduce carbon dioxide emissions. J. Clean. Prod. 2017, 154, 488–501. [Google Scholar] [CrossRef]

- Hou, Q.; Dianyu, E.; Kuang, S.; Li, Z.; Yu, A.B. DEM-based virtual experimental blast furnace: A quasi-steady state model. Powder Technol. 2017, 314, 557–566. [Google Scholar] [CrossRef]

- Jin, P.; Jiang, Z.; Bao, C.; Lu, Y.; Zhang, J.; Zhang, X. Mathematical Modeling of the Energy Consumption and Carbon Emission for the Oxygen Blast Furnace with Top Gas Recycling. Steel Res. Int. 2016, 87, 320–329. [Google Scholar] [CrossRef]

- Zhou, P.; Yuan, M.; Wang, H.; Chai, T. Data-Driven Dynamic Modeling for Prediction of Molten Iron Silicon Content Using ELM with Self-Feedback. Math. Probl. Eng. 2015, 2015, 326160. [Google Scholar] [CrossRef]

- Yin, R. The essence function and future development model of steel manufacturing process. Sci. China Technol. Sci. 2008, 38, 1365–1377. [Google Scholar]

- Zetterholm, J.; Ji, X.; Sundelin, B.; Martin, P.M.; Wang, C. Model development of a blast furnace stove. Energy Procedia 2015, 75, 1758–1765. [Google Scholar] [CrossRef][Green Version]

- Liu, X.; Chen, L.; Qin, X.; Sun, F. Exergy loss minimization for a blast furnace with comparative analyses for energy flows and exergy flows. Energy 2015, 93, 10–19. [Google Scholar] [CrossRef]

- Zhou, B.; Ye, H.; Zhang, H.; Li, M. Process monitoring of iron-making process in a blast furnace with PCA-based methods. Control Eng. Pract. 2016, 47, 1–14. [Google Scholar] [CrossRef]

- Jin, P.; Jiang, Z.; Bao, C.; Hao, S.; Zhang, X. The energy consumption and carbon emission of the integrated steel mill with oxygen blast furnace. Resour. Conserv. Recy. 2017, 117, 58–65. [Google Scholar] [CrossRef]

- Kuang, S.B.; Li, Z.Y.; Yan, D.L.; Qi, Y.H.; Yu, A.B. Numerical study of hot charge operation in iron making blast furnace. Miner. Eng. 2014, 63, 45–56. [Google Scholar] [CrossRef]

- Liao, J.; Yu, A.B.; Shen, Y. Modelling the injection of upgraded brown coals in an ironmaking blast furnace. Powder Technol. 2017, 314, 550–556. [Google Scholar] [CrossRef]

- Dong, Z.; Wang, J.; Zuo, H.; She, X.; Xue, Q. Analysis of gas–solid flow and shaft-injected gas distribution in an oxygen blast furnace using a discrete element method and computational fluid dynamics coupled model. Particuology 2017, 32, 63–72. [Google Scholar] [CrossRef]

- Miao, Z.; Zhou, Z.; Yu, A.B.; Shen, Y. CFD-DEM simulation of raceway formation in an ironmaking blast furnace. Powder Technol. 2017, 314, 542–549. [Google Scholar] [CrossRef]

- Yeh, C.-P.; Du, S.-W.; Tsai, C.-H.; Yang, R.-J. Numerical analysis of flow and combustion behavior in tuyere and raceway of blast furnace fueled with pulverized coal and recycled top gas. Energy 2012, 42, 233–240. [Google Scholar] [CrossRef]

- Shen, Y.S.; Yu, A.B. Modelling of injecting a ternary coal blend into a model ironmaking blast furnace. Miner. Eng. 2016, 90, 89–95. [Google Scholar] [CrossRef]

- Shen, Y.; Yu, A.; Austin, P.; Zulli, P. Modelling in-furnace phenomena of pulverized coal injection in ironmaking blast furnace: Effect of coke bed porosities. Miner. Eng. 2012, 33, 54–65. [Google Scholar] [CrossRef]

- Zhao, H.; Bai, Y.; Cheng, S. Effect of Coke Reaction Index on Reduction and Permeability of Ore Layer in Blast Furnace Lumpy Zone Under Non-Isothermal Condition. J. Iron Steel Res. Int. 2013, 20, 6–10. [Google Scholar] [CrossRef]

- De Castro, J.A.; de Mattos Araújo, G.; de Oliveira da Mota, I.; Sasaki, Y.; Yagi, J. Analysis of the combined injection of pulverized coal and charcoal into large blast furnaces. J. Mater. Res. Technol. 2013, 2, 308–314. [Google Scholar] [CrossRef]

- Gupta, S.; Ye, Z.; Kim, B.; Kerkkonen, O.; Kanniala, R.; Sahajwalla, V. Mineralogy and reactivity of cokes in a working blast furnace. Fuel Process. Technol. 2014, 117, 30–37. [Google Scholar] [CrossRef]

- Jiang, S.; Shen, X.; Zheng, Z. Gaussian Process-Based Hybrid Model for Predicting Oxygen Consumption in the Converter Steelmaking Process. Processes 2019, 7, 352. [Google Scholar] [CrossRef]

- Bahgat, M.; Halim, K.S.A.; Heba, A.E.-K.; Mahmoud, I.N. Blast Furnace Operating Conditions Manipulation for Reducing Coke Consumption and CO2 Emission. Steel Res. Int. 2012, 83, 686–694. [Google Scholar] [CrossRef]

- SJung, S.; Chang, W. Clustering stocks using partial correlation coefficients. Phys. A Stat. Mech. Appl. 2016, 462, 410–420. [Google Scholar]

- Shen, Y.S.; Yu, A.B.; Austin, P.R.; Zulli, P. CFD study of in-furnace phenomena of pulverised coal injection in blast furnace: Effects of operating conditions. Powder Technol. 2012, 223, 27–38. [Google Scholar] [CrossRef]

- Lomas, H.; Roest, R.; Gupta, S.; Pearson, R.A.; Fetscher, R.; Jenkins, D.R.; Pearce, R.; Kanniala, R.; Merrick, M.R. Petrographic analysis and characterisation of a blast furnace coke and its wear mechanisms. Fuel 2017, 200, 89–99. [Google Scholar] [CrossRef]

- Gasparinia, V.M.; de Castro, L.F.A.; Quintas, A.C.B.; de Souza Moreira, V.E.; Viana, A.O.; Andrade, D.H.B. Thermo-chemical model for blast furnace process control with the prediction of carbon consumption. J. Mater. Res. Technol. 2017, 6, 220–225. [Google Scholar] [CrossRef]

- Zou, C.; She, Y.; Shi, R. Particle size-dependent properties of a char produced using a moving-bed pyrolyzer for fueling pulverized coal injection and sintering operations. Fuel Process. Technol. 2019, 190, 1–12. [Google Scholar] [CrossRef]

| Classification of Influence Factors | Influence Factors | CR | PCIR | ||

|---|---|---|---|---|---|

| p Value | Correlation Degree | p Value | Correlation Degree | ||

| Constant | 0.002 | 0.000 | |||

| MaterialFlows Parameters | Sinter grade | 0.44 | −0.062 | 0.000 | 0.299 |

| Sinter size | 0.023 | −0.185 | 0.203 | −0.104 | |

| Pellet grade | 0.506 | −0.054 | 0.800 | 0.021 | |

| Ore grade | 0.047 | −0.161 | 0.002 | 0.253 | |

| Sinter alkalinity | 0.001 | 0.277 | 0.000 | 0.334 | |

| Sinter tumbler index | 0.000 | −0.419 | 0.758 | −0.025 | |

| Sinter screening index | 0.135 | −0.122 | 0.571 | −0.046 | |

| Clinker ratio | 0.426 | 0.065 | 0.695 | 0.032 | |

| Slag ratio | 0.021 | 0.187 | 0.334 | −0.079 | |

| PCIR | 0.000 | −0.598 | |||

| Energy Flows Parameters | Coke size | 0.343 | 0.077 | 0.131 | 0.123 |

| Coke ash | 0.471 | −0.059 | 0.175 | −0.110 | |

| Coke volatile | 0.227 | −0.098 | 0.093 | −0.136 | |

| Coke sulfur | 0.811 | 0.020 | 0.165 | 0.113 | |

| M40 | 0.641 | 0.038 | 0.904 | 0.010 | |

| M10 | 0.579 | −0.045 | 0.013 | −0.201 | |

| Coal ash | 0.534 | −0.051 | 0.075 | −0.144 | |

| Coal volatile | 0.146 | −0.118 | 0.468 | 0.059 | |

| Operation Parameters | Blast volume | 0.411 | 0.067 | 0.000 | 0.398 |

| Blast temperature | 0.004 | 0.233 | 0.001 | 0.273 | |

| Blast pressure | 0.719 | −0.029 | 0.071 | 0.146 | |

| Oxygen enrichment ratio | 0.449 | 0.062 | 0.000 | 0.319 | |

| Permeability | 0.353 | 0.076 | 0.947 | −0.005 | |

| Top gas pressure | 0.103 | −0.133 | 0.341 | 0.078 | |

| Top temperature | 0.199 | −0.105 | 0.000 | 0.457 | |

| Classification of Influence Factors | Influence Factors | CR | PCIR | ||||

|---|---|---|---|---|---|---|---|

| Unstandardized Coefficients | Standardized Coefficients | Correlation Degree | Unstandardized Coefficients | Standardized Coefficients | Correlation Degree | ||

| Constant | 996.644 | −2148.358 | |||||

| Material Flows Parameters | Sinter grade | 21.425 | 0.539 | 0.425 | |||

| Sinter size | −1.019 | −0.053 | −0.117 | ||||

| Ore grade | −0.403 | −0.093 | −0.193 | 0.960 | 0.241 | 0.365 | |

| Sinter alkalinity | 55.195 | 0.281 | 0.516 | 97.098 | 0.538 | 0.429 | |

| Sinter tumbler index | −11.523 | −0.277 | −0.477 | ||||

| Slag ratio | 0.267 | 0.139 | 0.264 | ||||

| PCIR | −0.603 | −0.554 | −0.725 | ||||

| Energy Flows Parameters | M10 | −7.424 | −0.135 | −0.223 | |||

| Operation Parameters | Blast volume | 0.068 | 0.485 | 0.577 | |||

| Blast temperature | 0.125 | 0.147 | 0.289 | 0.285 | 0.365 | 0.414 | |

| Oxygen enrichment ratio | 7.766 | 0.305 | 0.321 | ||||

| Top temperature | 0.254 | 0.330 | 0.486 | ||||

| Classification of Influence Factors | Influence Factors | Min Value (xmin,i) | Max Value (xmax,i) | 1% Increment (xmax,i-xmin,i)/100 |

|---|---|---|---|---|

| Material Flows Parameters | Sinter grade (%) | 55.7 | 57.8 | 0.021 |

| Sinter size (mm) | 25 | 30.3 | 0.053 | |

| Ore grade (%) | 41.6 | 89.6 | 0.48 | |

| Sinter alkalinity (%) | 1.8 | 2.3 | 0.005 | |

| Sinter tumbler index (%) | 76.9 | 79.9 | 0.03 | |

| Slag ratio (kg/t) | 286 | 339 | 0.53 | |

| PCIR (kg/t) | 87.9 | 171.9 | 0.84 | |

| Energy Flows Parameters | M10 (%) | 4.6 | 6.7 | 0.021 |

| Operation Parameters | Blast volume (m3/min) | 5955 | 6664 | 7.09 |

| Blast temperature (℃) | 1086 | 1250 | 1.64 | |

| Oxygen enrichment ratio (%) | 0.8 | 4.6 | 0.038 | |

| Top temperature (℃) | 119 | 288 | 1.69 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, B.; Wang, S.; Tang, K.; Chen, D. An All-Factors Analysis Approach on Energy Consumption for the Blast Furnace Iron Making Process in Iron and Steel industry. Processes 2019, 7, 607. https://doi.org/10.3390/pr7090607

Lu B, Wang S, Tang K, Chen D. An All-Factors Analysis Approach on Energy Consumption for the Blast Furnace Iron Making Process in Iron and Steel industry. Processes. 2019; 7(9):607. https://doi.org/10.3390/pr7090607

Chicago/Turabian StyleLu, Biao, Suojin Wang, Kai Tang, and Demin Chen. 2019. "An All-Factors Analysis Approach on Energy Consumption for the Blast Furnace Iron Making Process in Iron and Steel industry" Processes 7, no. 9: 607. https://doi.org/10.3390/pr7090607

APA StyleLu, B., Wang, S., Tang, K., & Chen, D. (2019). An All-Factors Analysis Approach on Energy Consumption for the Blast Furnace Iron Making Process in Iron and Steel industry. Processes, 7(9), 607. https://doi.org/10.3390/pr7090607