Experimental and Numerical Study of Double-Pipe Evaporators Designed for CO2 Transcritical Systems

Abstract

:1. Introduction

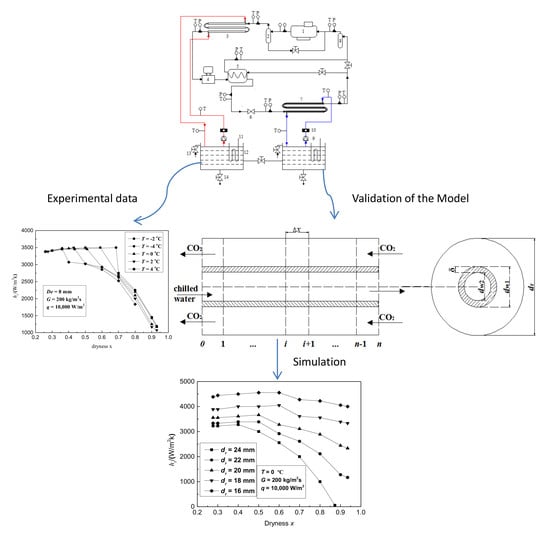

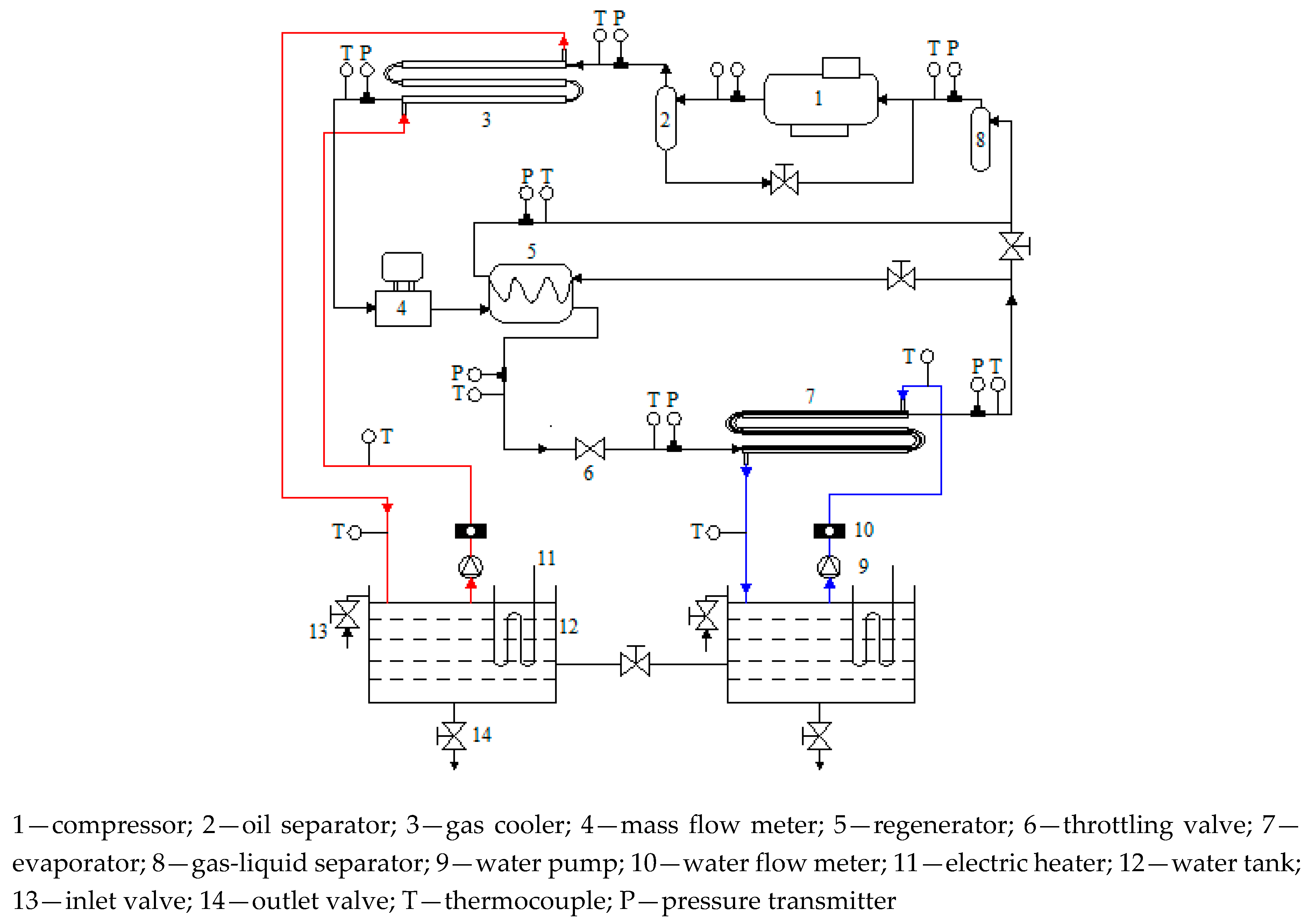

2. Experimental Installation and Test Procedure

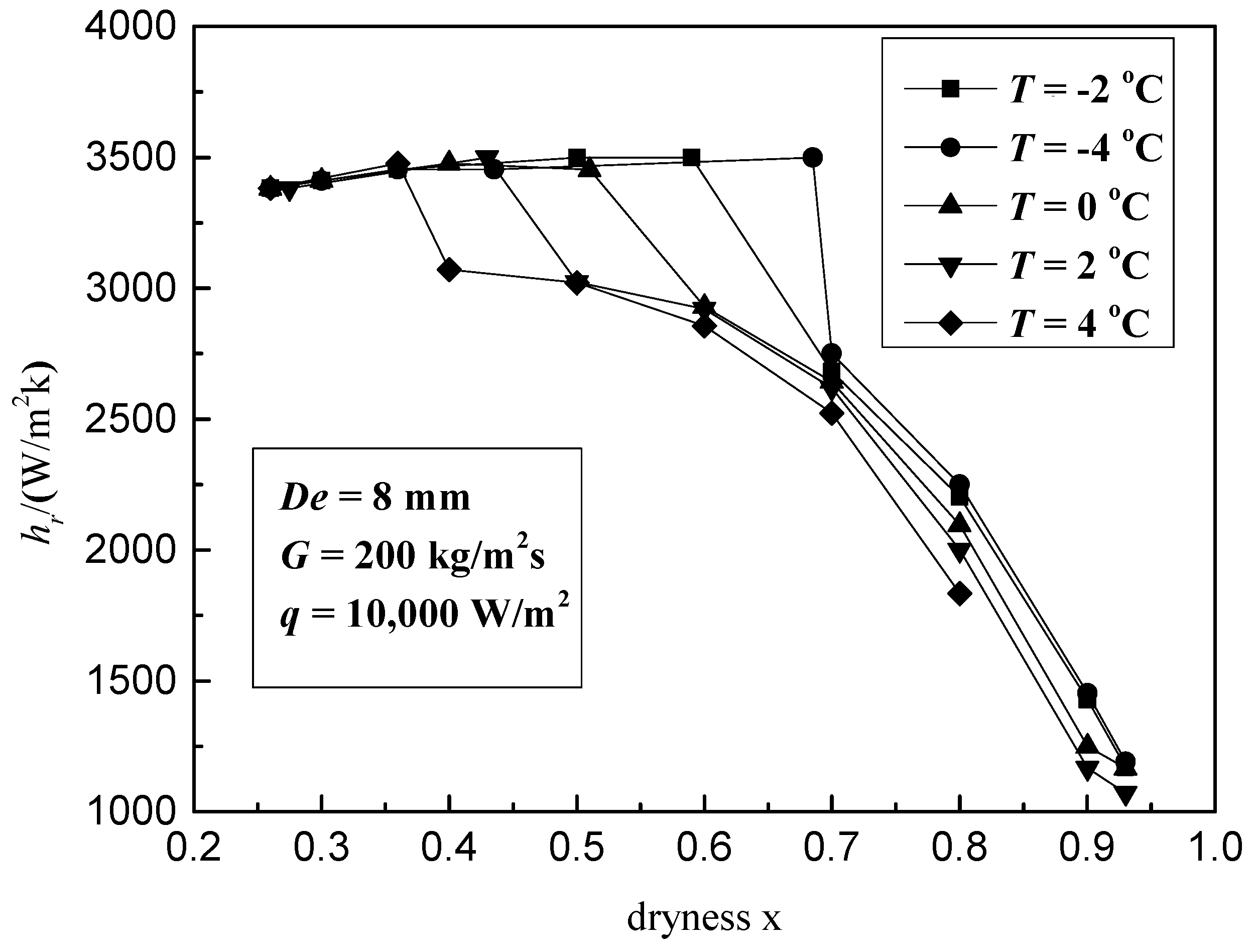

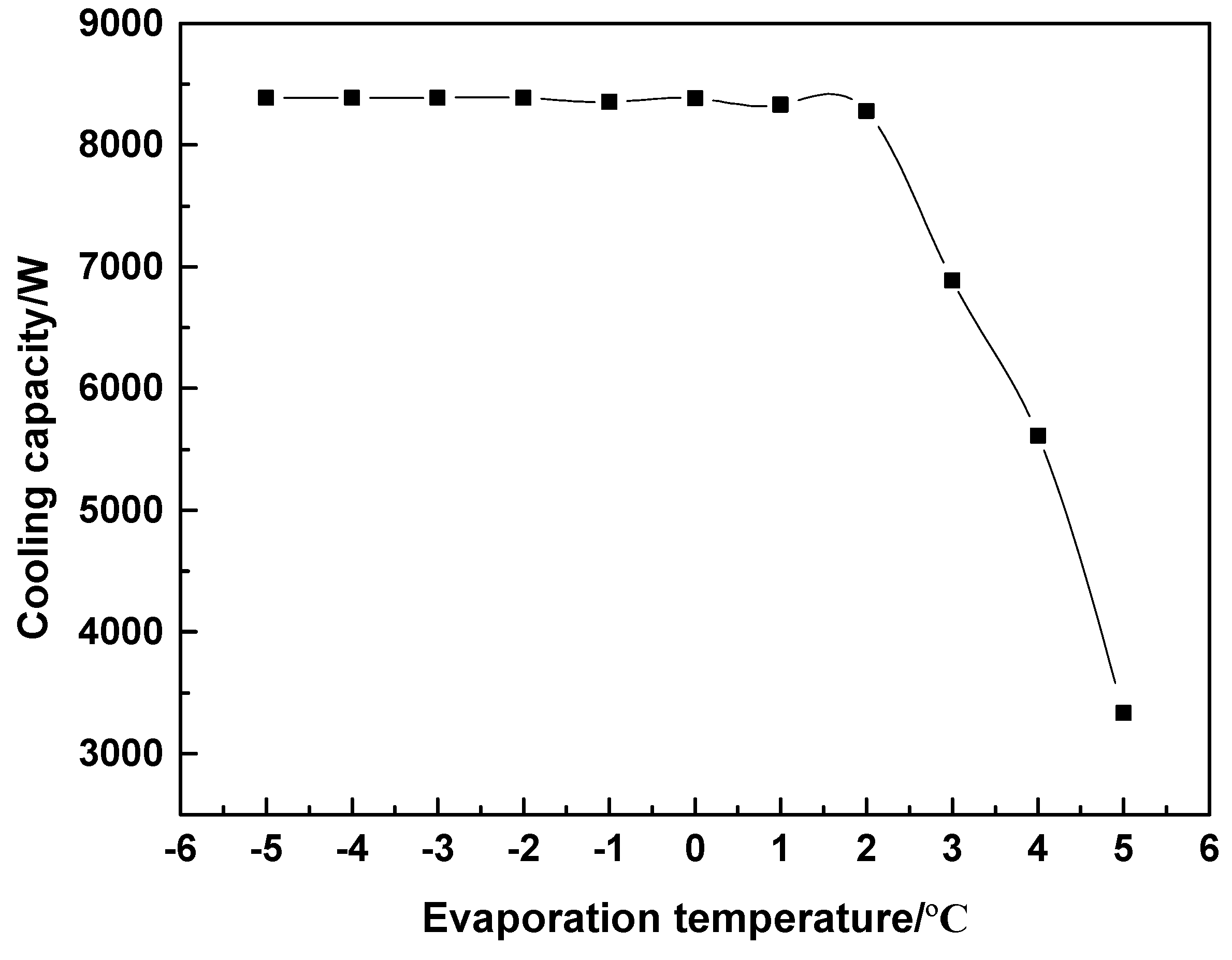

3. Experimental Results and Discussion

3.1. Effect of Evaporation Temperature

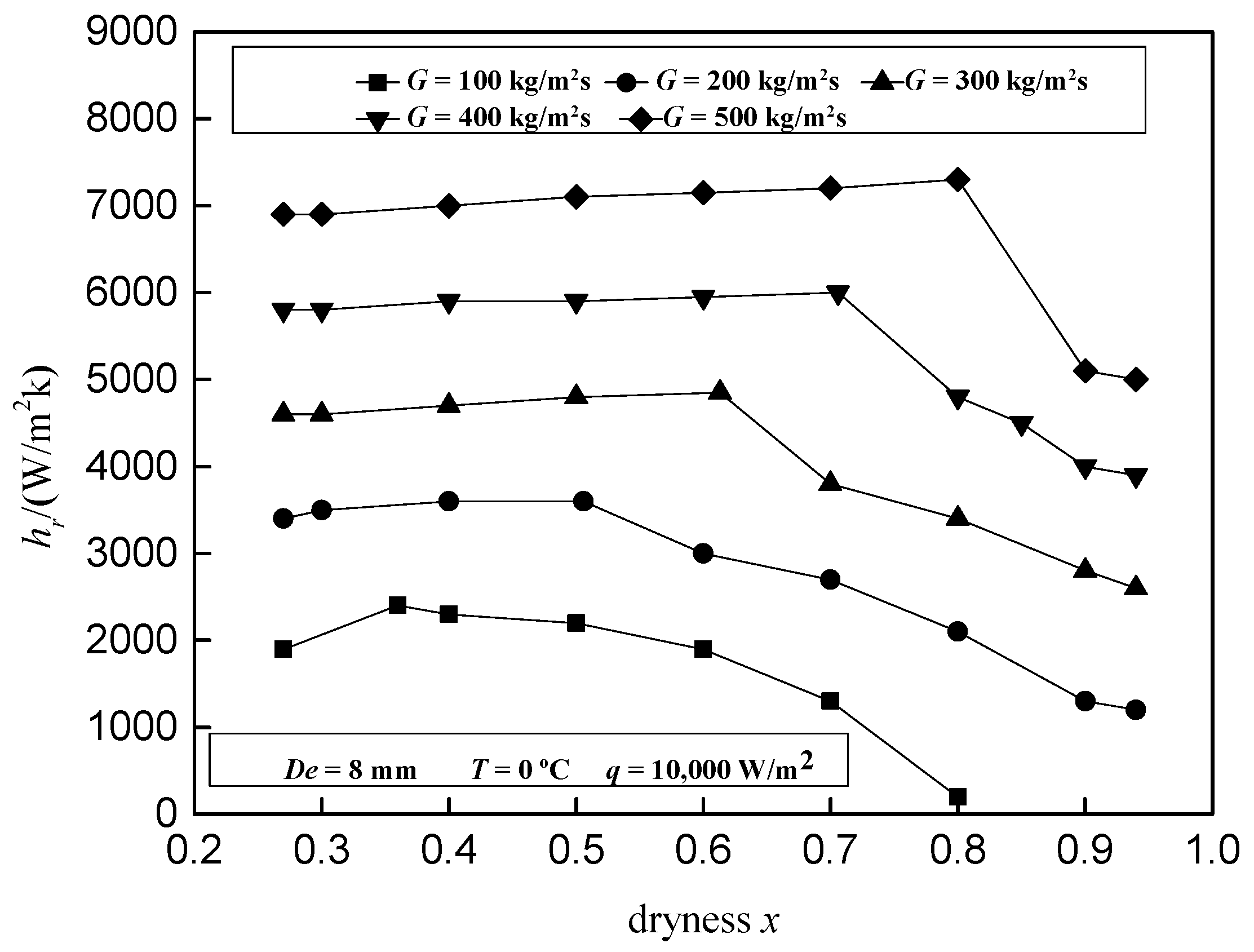

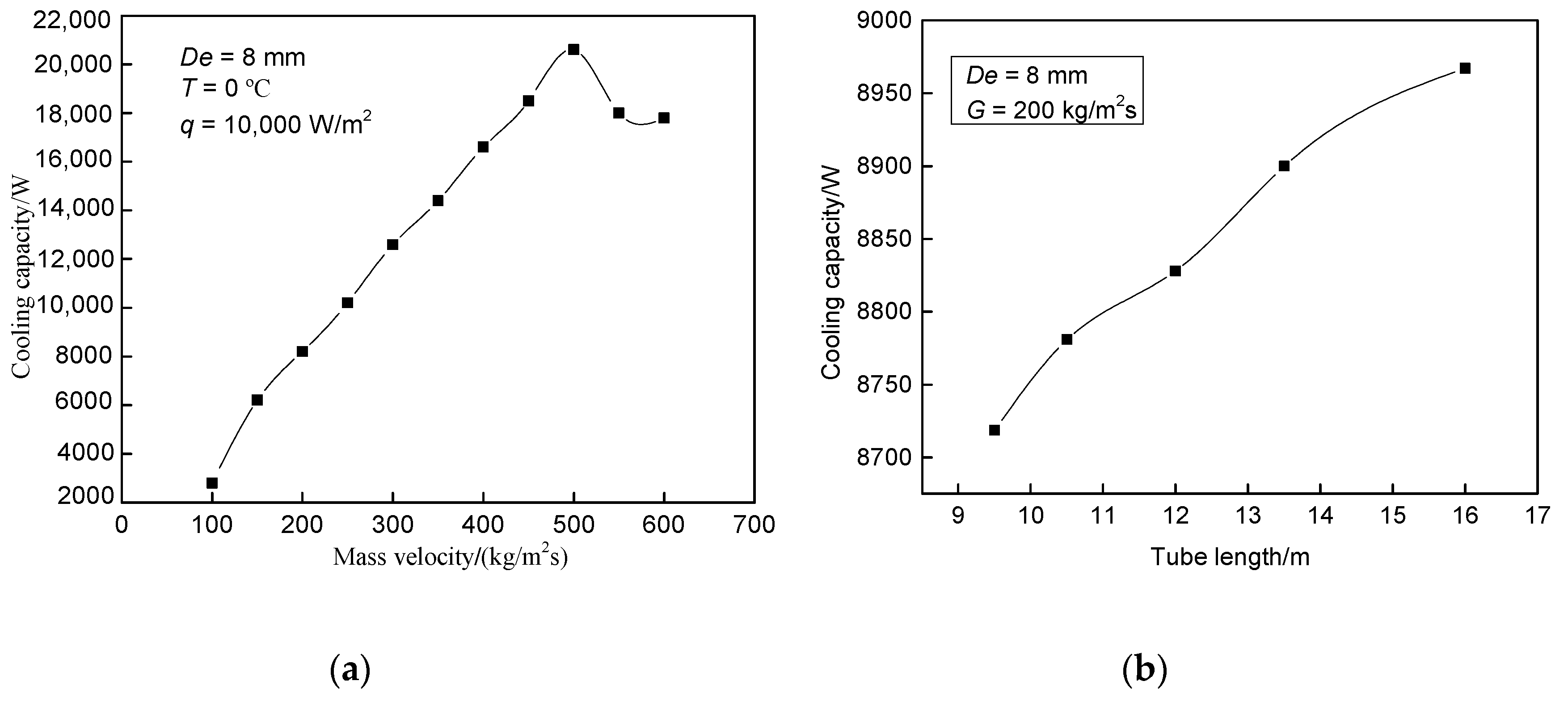

3.2. Effect of Mass Velocity

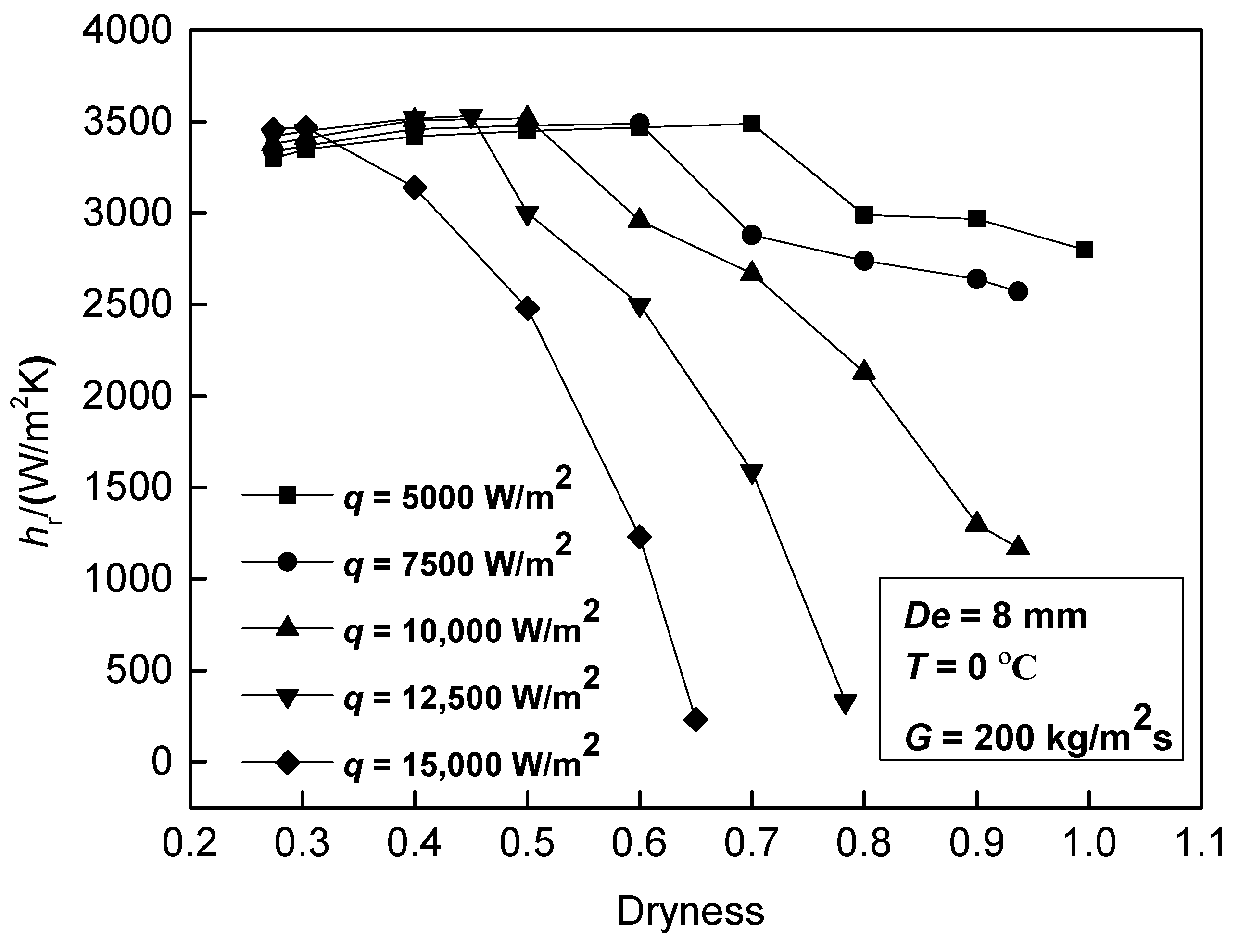

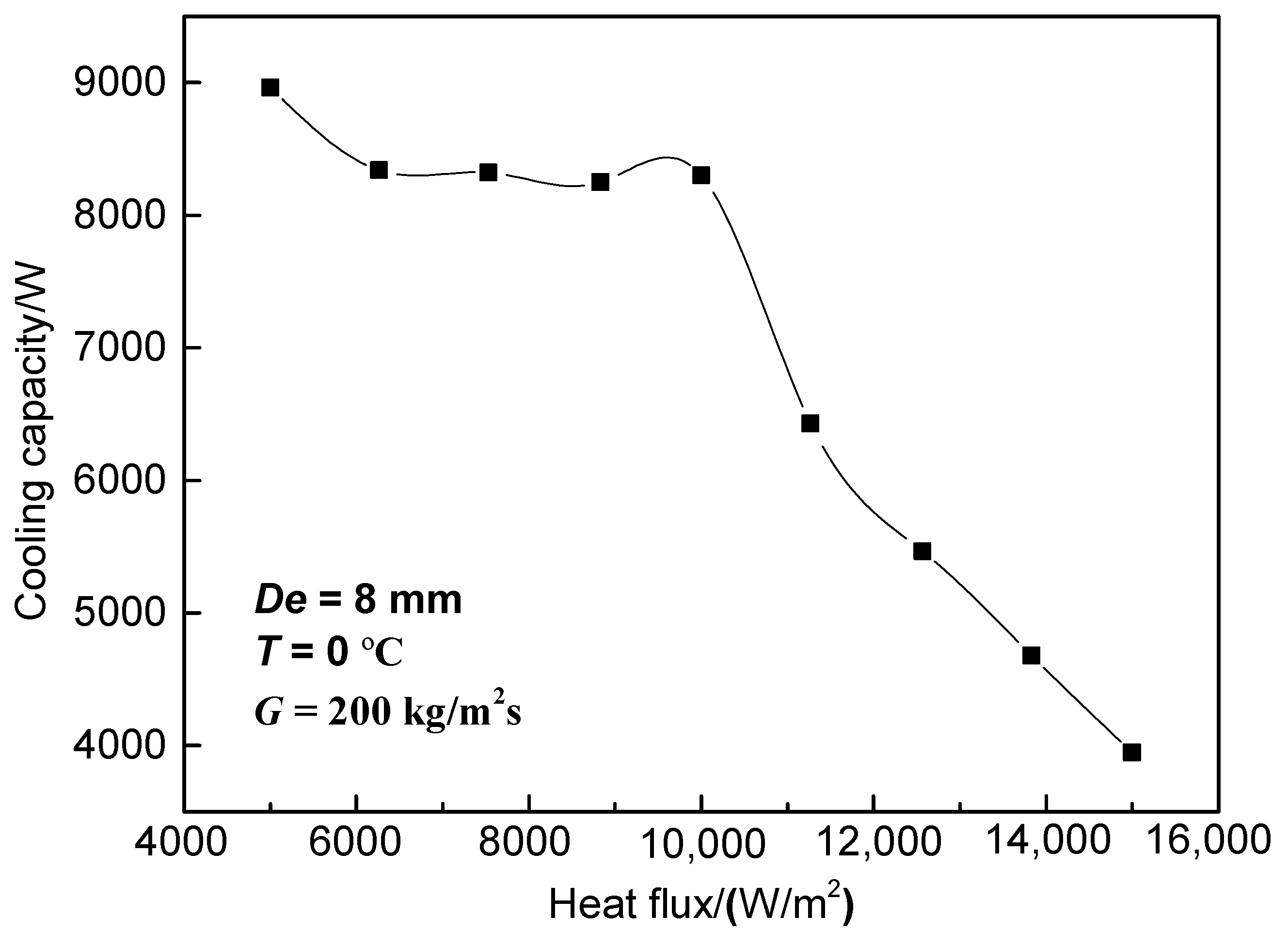

3.3. Effect of Heat Flux

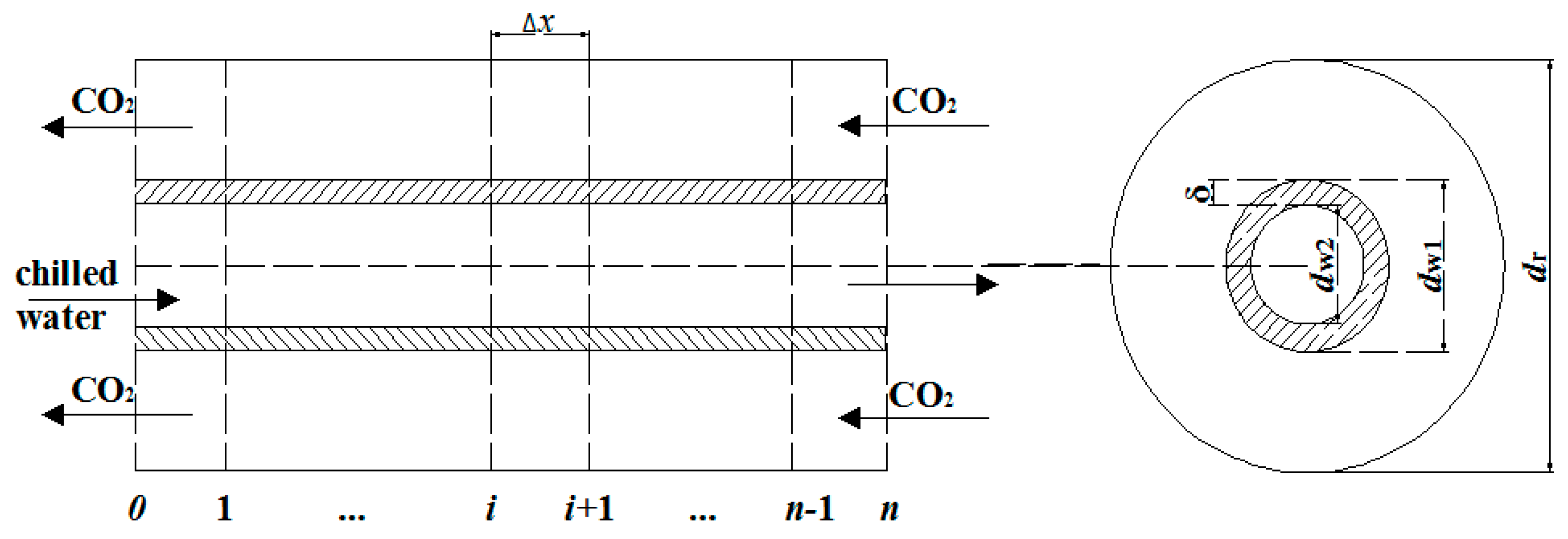

4. CO2 Double-Pipe Evaporator Model

4.1. Establishment of a CO2 Double-Pipe Evaporator Model

- (1)

- The flow of fluid in the inner and outer tubes was regarded as one-dimensional flow [26].

- (2)

- The outer wall was considered to be adiabatic without considering leakage heat loss.

- (3)

- The loss of water-side pressure drop in the evaporator and the momentum equation were not considered.

- (4)

- When the refrigerants underwent phase transition, the two phases of the fluid were in a state of thermal equilibrium.

- (5)

- The effect of the lubricating oil and other substances on all heat transfer processes was not considered [27].

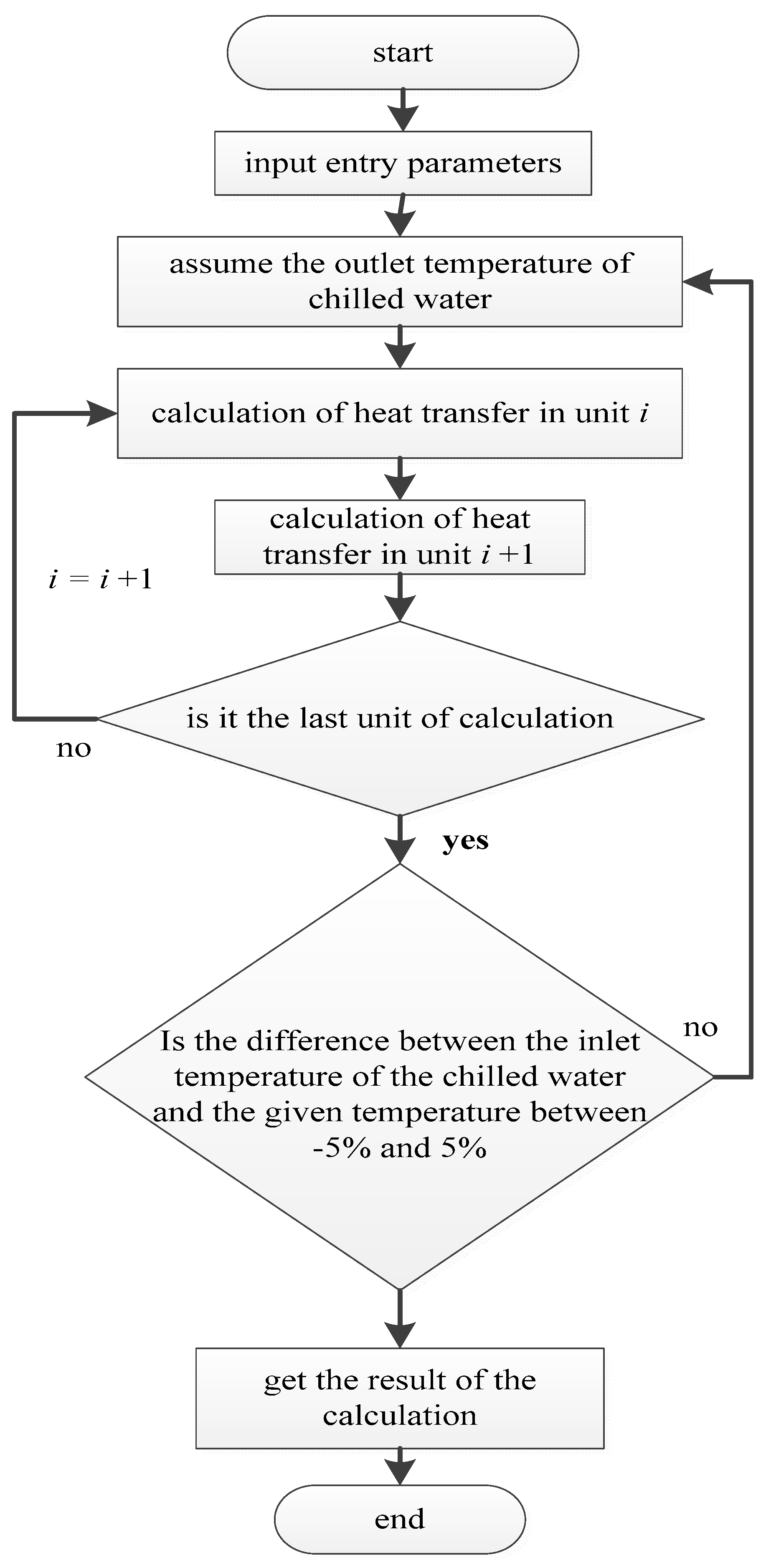

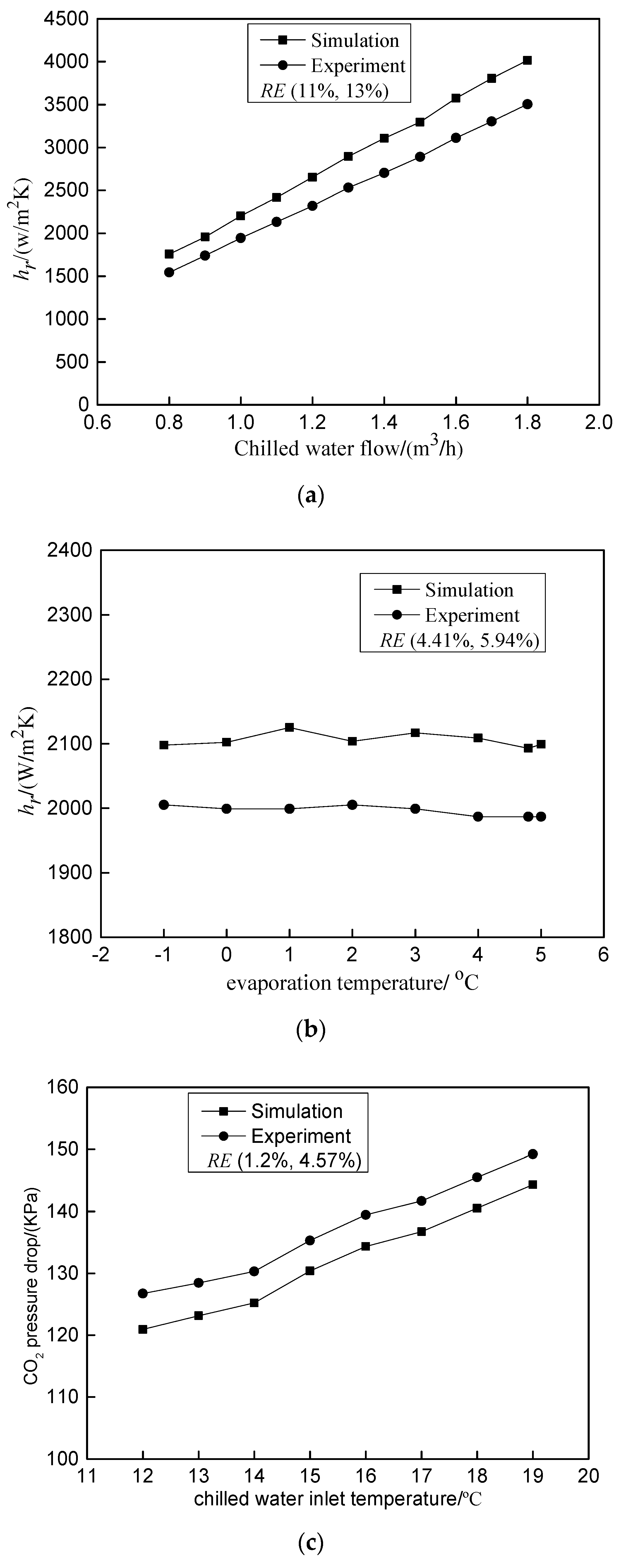

4.2. Validation of the Model

5. Simulation Results and Discussion

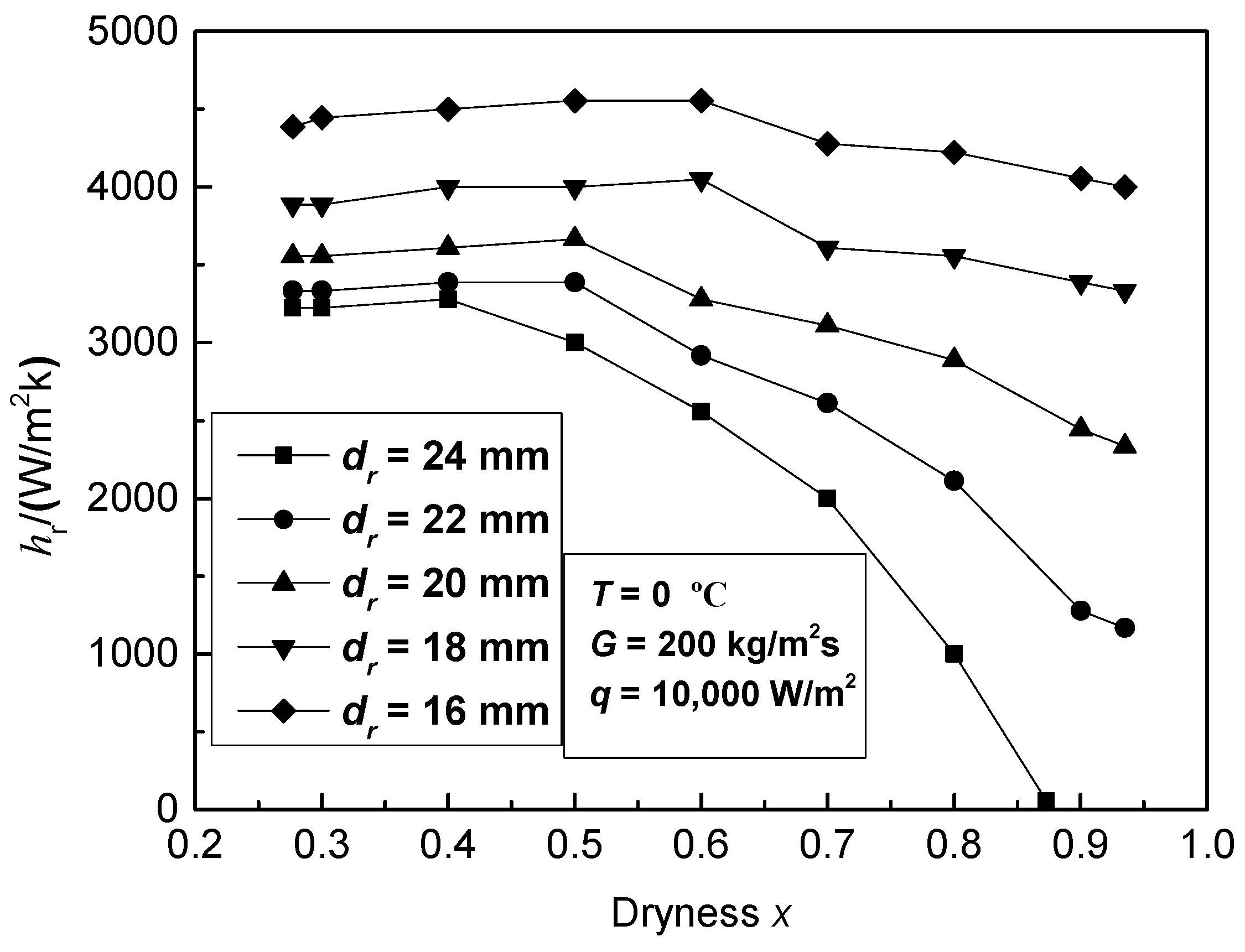

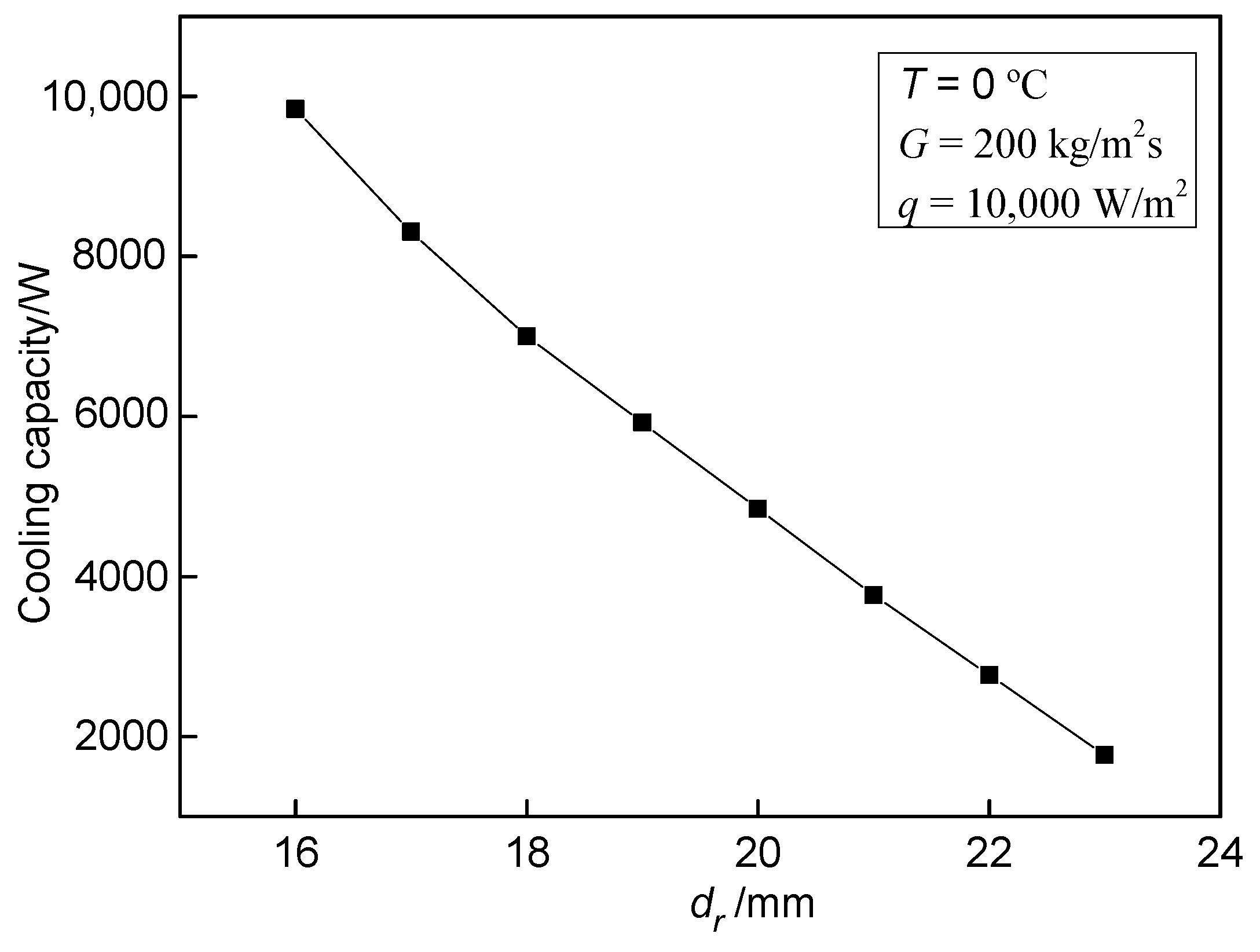

5.1. Effect of Outer Tube Diameter

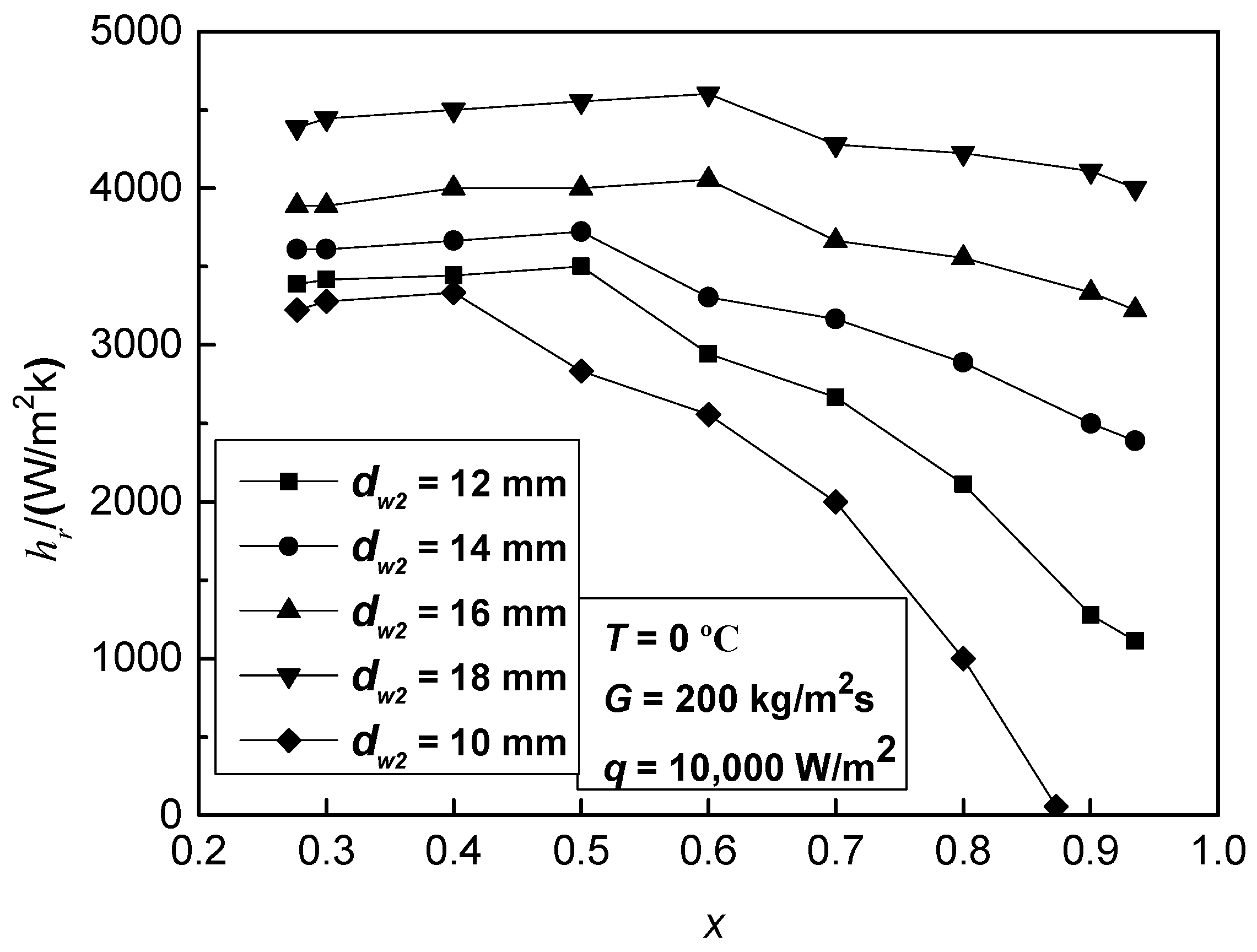

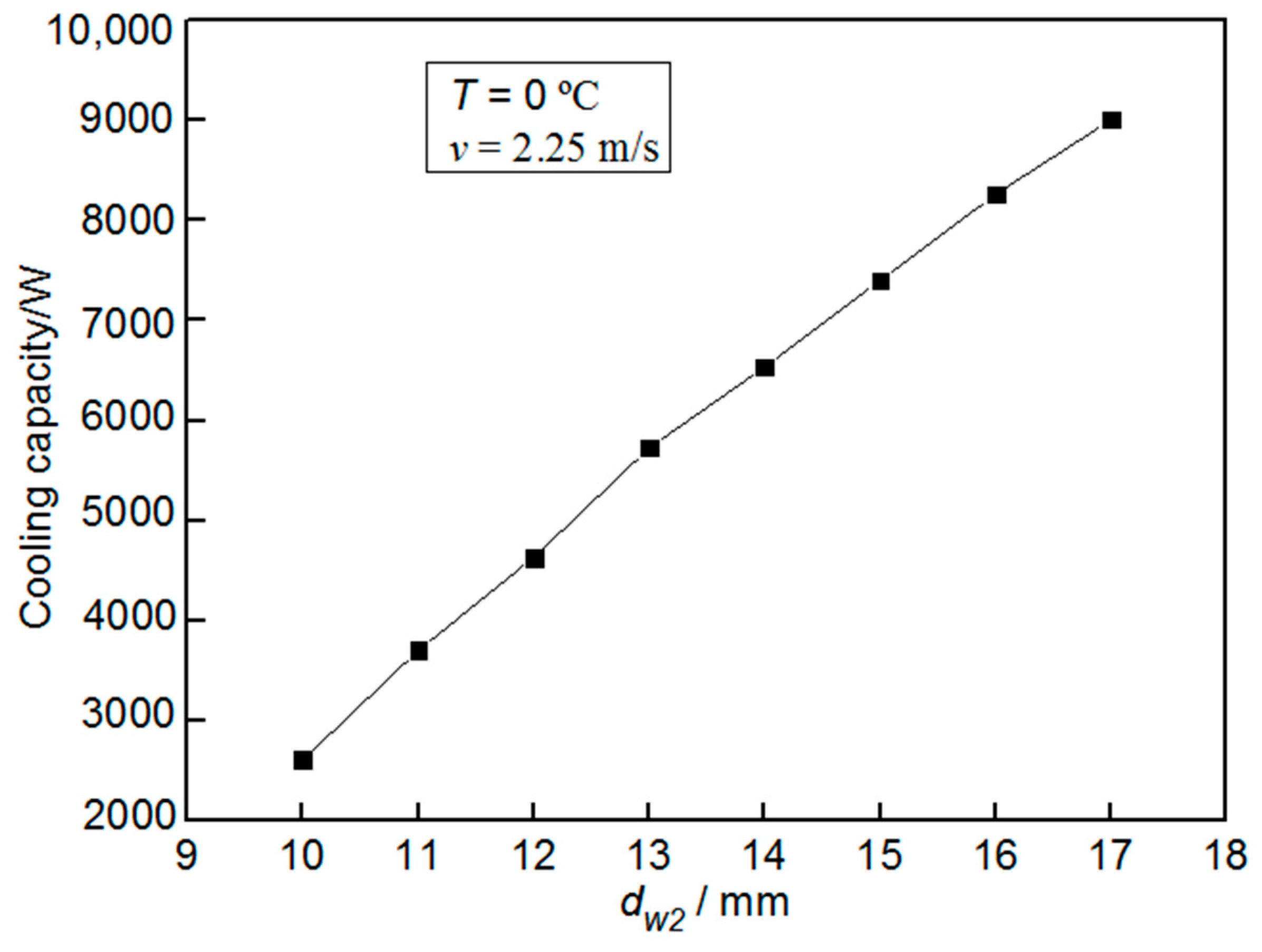

5.2. Effect of Inner Tube Diameter

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| A | area (m2) |

| Cp | specific heat (J/kg/K) |

| d | diameter (mm) |

| De | equivalent diameter (mm) |

| E | enhancement factor |

| G | mass velocity (kg/m2s) |

| g | gravity acceleration (m/s2) |

| hw | water heat transfer coefficient (W/m2/K) |

| h | enthalpy (kJ/kg) |

| hr | heat transfer coefficient (W/m2/K) |

| hl | heat transfer coefficient of liquid (W/m2/K) |

| hwet | heat transfer coefficient of wet pipe wall (W/m2/K) |

| hg | gas phase heat transfer coefficient (W/m2/K) |

| hpool | boiling heat transfer coefficient (W/m2/K) |

| K | total heat transfer coefficient (W/m2/K) |

| L | total tube length (m) |

| L1 | tube length in pre-dryout zone (m) |

| L2 | tube length in post-dryout zone (m) |

| m | mass flux (kg/s) |

| q | heat flux (W/m2) |

| Q | heat quantity (W) |

| RE | relative errors |

| S | suppression factor |

| t | temperature (°C) |

| T | evaporation temperature (°C) |

| v | volume flow (m3/h) |

| Greek symbols | |

| λ | thermal conductivity (W/m2/K) |

| ρ | density (kg/m3) |

| surface tension (N/m) | |

| Pr | Prandtl number |

| Re | Reynolds number |

| Nu | Nusselt number |

| δ | wall thickness (mm) |

| γ | dirty factor |

| x | mass quality |

| Bo | boiling number |

| Bd | Bond number |

| α | L1/L |

| θdry | dry angle |

| Subscripts | |

| w | water |

| w1 | refrigerant side wall |

| w2 | water side wall |

| m | mean |

| cr | critical |

| o; i | outlet; inlet |

| n | unit |

| r | refrigerant |

References

- Lillo, G.; Mastrullo, R.; Mauro, A.W.; Viscito, L. Multi criteria optimization of plate heat exchanger for super critical CO2 power systems. Energy Procedia 2017, 129, 979–986. [Google Scholar] [CrossRef]

- Ayad, F.; Benelmir, R.; Souayed, A. CO2 evaporators design for vehicle HVAC operation. Appl. Therm. Eng. 2012, 36, 330–344. [Google Scholar] [CrossRef]

- Oh, H.K.; Son, C.H. Flow boiling heat transfer and pressure drop characteristics of CO2 in horizontal tube of 4.57-mm inner diameter. Appl. Therm. Eng. 2011, 31, 163–172. [Google Scholar] [CrossRef]

- Choi, K.I.; Pamitran, A.S.; Oh, C.Y.; Oh, J.T. Boiling heat transfer of R-22, R-134, and CO2 in horizontal smooth minichannels. Int. J. Refrig. 2007, 30, 1336–1446. [Google Scholar] [CrossRef]

- In, S.; Jeong, S. Flow boiling haet transfer characteristics of R123 and R134a in a micro-channel. Int. J. Multipase Flow 2009, 35, 987–1000. [Google Scholar] [CrossRef]

- Oh, H.K.; Ku, H.G.; Roh, G.S.; Son, C.H.; Park, S.J. Flow boiling heat transfer characteristics of carbon dioxide in a horizontal tube. Appl. Therm. Eng. 2008, 28, 1022–1030. [Google Scholar] [CrossRef]

- Lorentzen, G.; Pettersen, J. New Possibilities for Non-CFC Refrigeration. In Proceedings of the IIR International Symposium on Refrigeration, Energy and Environment, Trondheim, Norway, 22–24 June 1992. [Google Scholar]

- Neksa, P.; Girotto, S. CO2 as refrigerant with incommercial refrigeration-theoretical consideration and experimental results. In Proceedings of the 5th IIR-Gustav Lorentzen Conference on Natural Working Fluids, Guangzhou, China, 17–20 September 2002; pp. 221–228. [Google Scholar]

- Jin, J.F.; Chen, J.P.; Chen, Z.J. Development and validation of a microchannel evaporator model for a CO2 air-conditioning system. Appl. Therm. Eng. 2011, 31, 137–146. [Google Scholar] [CrossRef]

- Yun, R.; Kim, Y.C.; Park, C. Numerical analysis on a microchannel evaporator designed for CO2 air-conditioning systems. Appl. Therm. Eng. 2007, 27, 1320–1326. [Google Scholar] [CrossRef]

- Jahar, S. Performance characteristics of multi-evaporator transcritical CO2 refrigeration cycles with hybrid compression/ejection. Proc. Inst. Mech. Eng. Part A Power Energy 2010, 224, 773–780. [Google Scholar]

- Bai, T.; Yan, G.; Yu, J. Thermodynamics analysis of modified dual-evaporator CO2 transcritical refrigeration cycle with two-stage ejector. Energy 2015, 84, 325–335. [Google Scholar] [CrossRef]

- Kravanja, G.; Zajc, G.; Knez, Ž.; Škerget, M.; Marčič, S.; Knez, M.H. Heat transfer performance of CO2, ethane and their azeotropic mixture under supercritical conditions. Energy 2018, 152, 190–201. [Google Scholar] [CrossRef]

- Pettersen, J.; Hafner, A.; Skaugen, G. Development of compact heat exchangers for CO2 air-conditioning systems. Int. J. Refrig. 1998, 21, 180–193. [Google Scholar] [CrossRef]

- Patiño, J.; Llopis, R.; Sánchez, D.; Sanz-Kock, C.; Cabello, R.; Torrella, E. A comparative analysis of a CO2 evaporator model using experimental heat transfer correlations and a flow pattern map. Int. J. Heat Mass Transf. 2014, 71, 361–375. [Google Scholar] [CrossRef]

- Minetto, S.; Brignoli, R.; Zilio, C.; Marinetti, S. Experimental analysis of a new method for overfeeding multiple evaporators in refrigeration systems. Int. J. Refrig. 2014, 38, 1–9. [Google Scholar] [CrossRef]

- Brix, W.; Kærn, M.R.; Elmegaard, B. Modelling distribution of evaporating CO2 in parallel minichannels. Int. J. Refrig. 2010, 33, 1086–1094. [Google Scholar] [CrossRef]

- Ge, Y.T.; Tassou, S.A. The impact of geometric structure and flow arrangement on the performance of CO2 evaporators in multi-deck medium temperature display cabinets. Int. J. Refrig. 2012, 35, 142–149. [Google Scholar] [CrossRef]

- Ke, H.; Xiao, Q.; Cao, Y.; Ma, T.; Lin, Y.; Zeng, M.; Wang, Q. Simulation of the printed circuit heat exchanger for S-CO2 by segmented methods. Energy Procedia 2017, 142, 4098–4103. [Google Scholar] [CrossRef]

- Son, S.; Heo, J.Y.; Lee, J.I. Prediction of inner pinch for supercritical CO2 heat exchanger using Artifical Neutral Network and evaluation of its impact on cycle design. Energy Convers. Manag. 2018, 163, 66–73. [Google Scholar] [CrossRef]

- Cui, X.; Guo, J.; Huai, X.; Cheng, K.; Zhang, H.; Xiang, M. Numerical study on novel airfoil fins for printed circuit heat exchanger using supercritical CO2. Int. J. Heat Mass Transf. 2018, 121, 354–366. [Google Scholar] [CrossRef]

- Paradis, P.L.; Rousse, D.R.; Lamarche, L.; Nesreddine, H. A hybrid PV/T solar evaporator using CO2: Numerical heat transfer model and simulation results. Solar Energy 2018, 170, 1118–1129. [Google Scholar] [CrossRef]

- Guo, J.F.; Huai, X. Coordination analysis of cross-flow heat exchger under high variations in thermodynamic properties. Int. J. Heat Mass Transf. 2017, 113, 935–942. [Google Scholar] [CrossRef]

- Li, H.; Tang, C.C.; Liu, W.; Yu, X.M.; Sun, H.Y. Establishment and simulation of dynamic mathmatical model of double-pipe heat exchanger. Liaoning Chem. Ind. 2018, 47, 651–654. [Google Scholar]

- Dittus, F.W.; Boelter, L.M.K. Heat transfer in automobile radiators of the tubular type. International Commun. Heat Mass Transf. 1985, 12, 3–22. [Google Scholar] [CrossRef]

- Liu, T.; Ding, G.L.; Zhang, P.; Wu, Z.G. Improved algorithm for dynamic distributed parameter model of near-phase flow in a double-tube heat exchanger. J. Shanghai Jiaotong Univ. 2008, 42, 122–127. [Google Scholar]

- Li, M.X.; Dang, C.B.; Hihara, E.J. Flow boiling heat transfer of carbon dioxide with polyalkylene glycol-type lubricating oil in pre-dryout region inside horizontal tube. Int. J. Refrig. 2014, 41, 45–49. [Google Scholar] [CrossRef]

- Yun, H.M.; Cheng, L.; Wang, L.Q.; Qu, Y. Numerical study of single-phase flow and heat transfer in smooth rectangular microchannels. J. Eng. Thermophys. 2007, S2, 33–36. [Google Scholar]

- Hu, H.T. Study on Flow Boiling Heat Transfer and Pressure Drop Characteristics in R410a-Lubricating Oil Mixture; Shanghai Jiaotong University: Shanghai, China, 2008; pp. 24–28. [Google Scholar]

- Yoon, S.H.; Cho, E.S.; Hwang, Y.W.; Kim, M.S.; Min, K.; Kim, Y. Characteristics of evaporative heat transfer and pressure drop of carbon dioxide and correlation development. Int. J. Refrig. 2004, 27, 111–119. [Google Scholar] [CrossRef]

| Components | Specifications | |

|---|---|---|

| Compressor | Manufacturer | Dorin |

| Model no. | CD380H | |

| Rated capacity (kW) | 3.3 | |

| Gas cooler and Evaporator | Manufacturer | Developed in house |

| Type | Double tube | |

| Diameter of inner tube (mm) | 12 | |

| Length of tube (mm) | 16,000 | |

| Regenerator | Manufacturer | Developed in house |

| Type | Double tube | |

| Diameter of inner tube (mm) | 12 | |

| Diameter of outer tube (mm) | 19 |

| Parameter | Device | Uncertainty | Full Scale |

|---|---|---|---|

| Temperature | Platinum resistance temperature sensor | ±0.01 °C | −50–400 °C |

| Pressure | Pressure sensor | ±0.25% | 1‒40 MPa |

| Power | Electric power transmitter | ±0.2% | 0‒866 W |

| Water flow | Turbine flowmeter | ±1.3% | 0‒1.6 m3·h−1 |

| CO2 mass flow | Electromagnetic mass flowmeter | ±0.2% | 0‒250 kg·h−1 |

| Parameters | Unit | Full Scale | Set Value |

|---|---|---|---|

| Compressor exhaust pressure | MPa | 8 | |

| Evaporation temperature | °C | −5 to 5 | 0 |

| CO2 mass velocity | kg/m2s | 100‒600 | 200 |

| Heat flux | kW/m2 | 5000‒15,000 | 10,000 |

| dr mm | 16 | 17 | 18 | 19 | 20 | 21 | 22 | 23 | 24 |

|---|---|---|---|---|---|---|---|---|---|

| 0.64 | 0.67 | 0.60 | 0.57 | 0.52 | 0.49 | 0.45 | 0.30 | 0.23 |

| dw2 mm | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 |

|---|---|---|---|---|---|---|---|---|---|

| 0.23 | 0.28 | 0.45 | 0.56 | 0.63 | 0.62 | 0.62 | 0.62 | 0.62 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, J.; Ning, S. Experimental and Numerical Study of Double-Pipe Evaporators Designed for CO2 Transcritical Systems. Processes 2019, 7, 547. https://doi.org/10.3390/pr7080547

Yang J, Ning S. Experimental and Numerical Study of Double-Pipe Evaporators Designed for CO2 Transcritical Systems. Processes. 2019; 7(8):547. https://doi.org/10.3390/pr7080547

Chicago/Turabian StyleYang, Junlan, and Shuying Ning. 2019. "Experimental and Numerical Study of Double-Pipe Evaporators Designed for CO2 Transcritical Systems" Processes 7, no. 8: 547. https://doi.org/10.3390/pr7080547

APA StyleYang, J., & Ning, S. (2019). Experimental and Numerical Study of Double-Pipe Evaporators Designed for CO2 Transcritical Systems. Processes, 7(8), 547. https://doi.org/10.3390/pr7080547