Effects of Operating Parameters on the Cut Size of Turbo Air Classifier for Particle Size Classification of SAC305 Lead-Free Solder Powder

Abstract

:1. Introduction

2. Materials and Methods

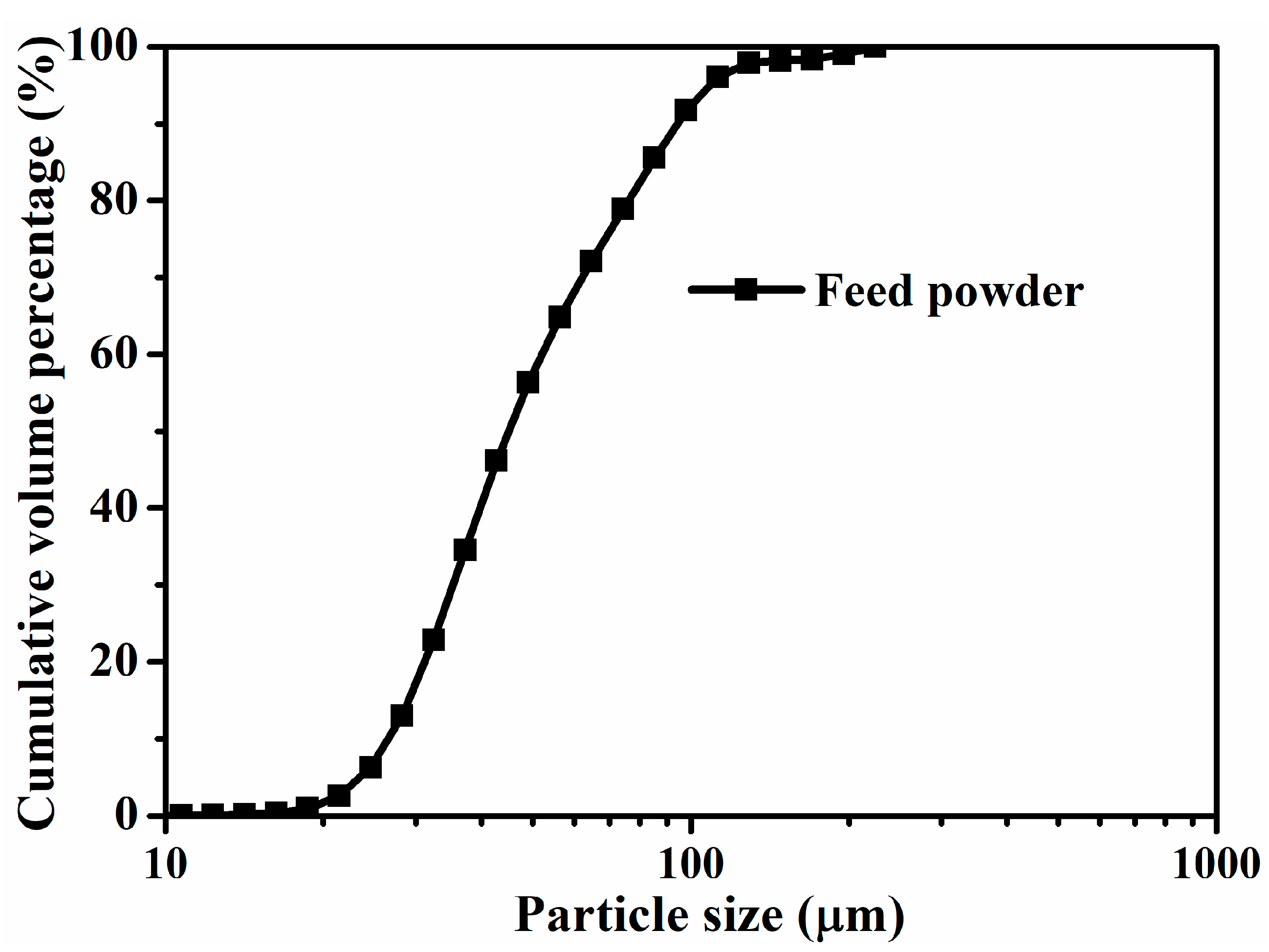

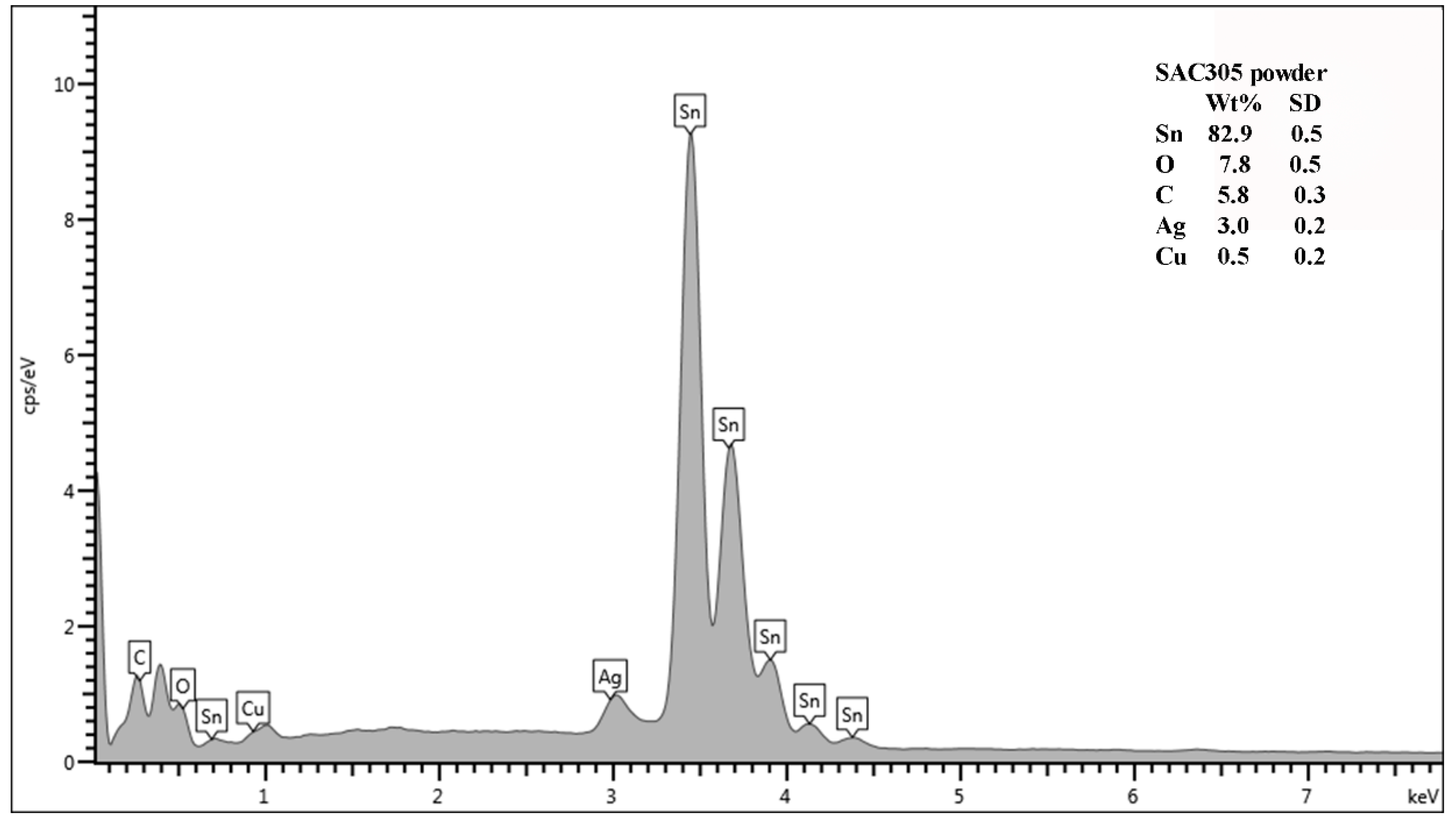

2.1. Materials

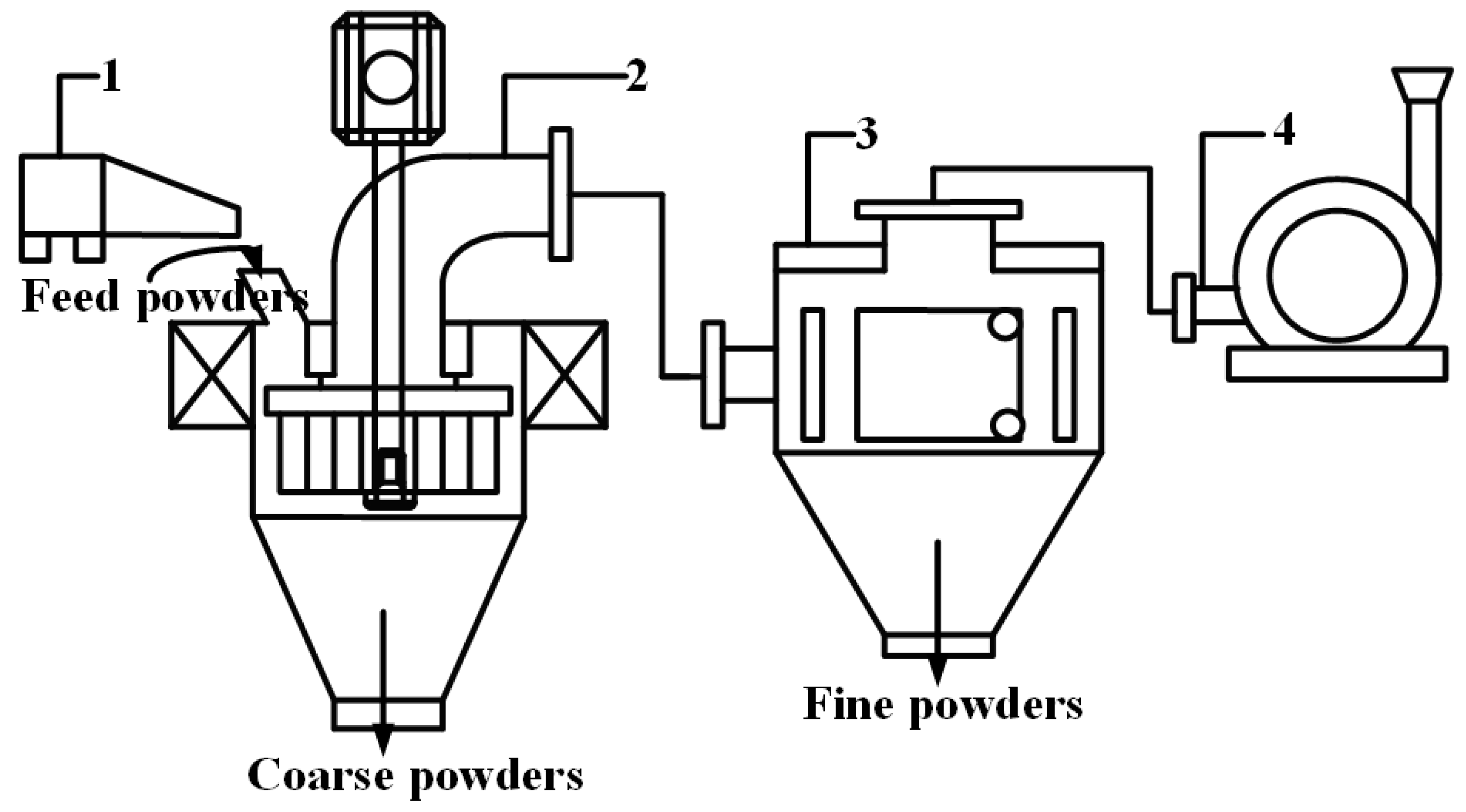

2.2. Experimental Procedure

2.3. Experimental Design

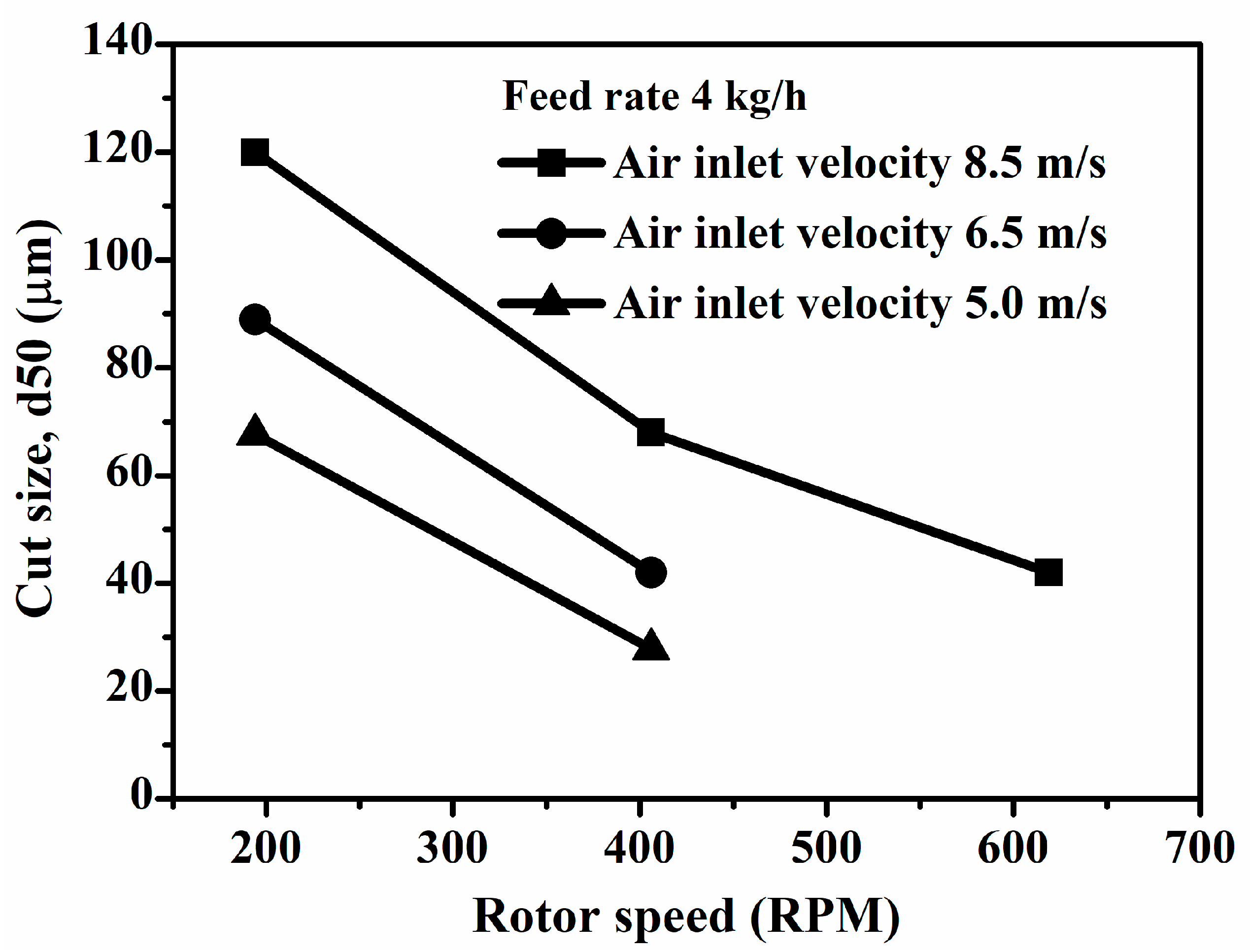

3. Results and Discussion

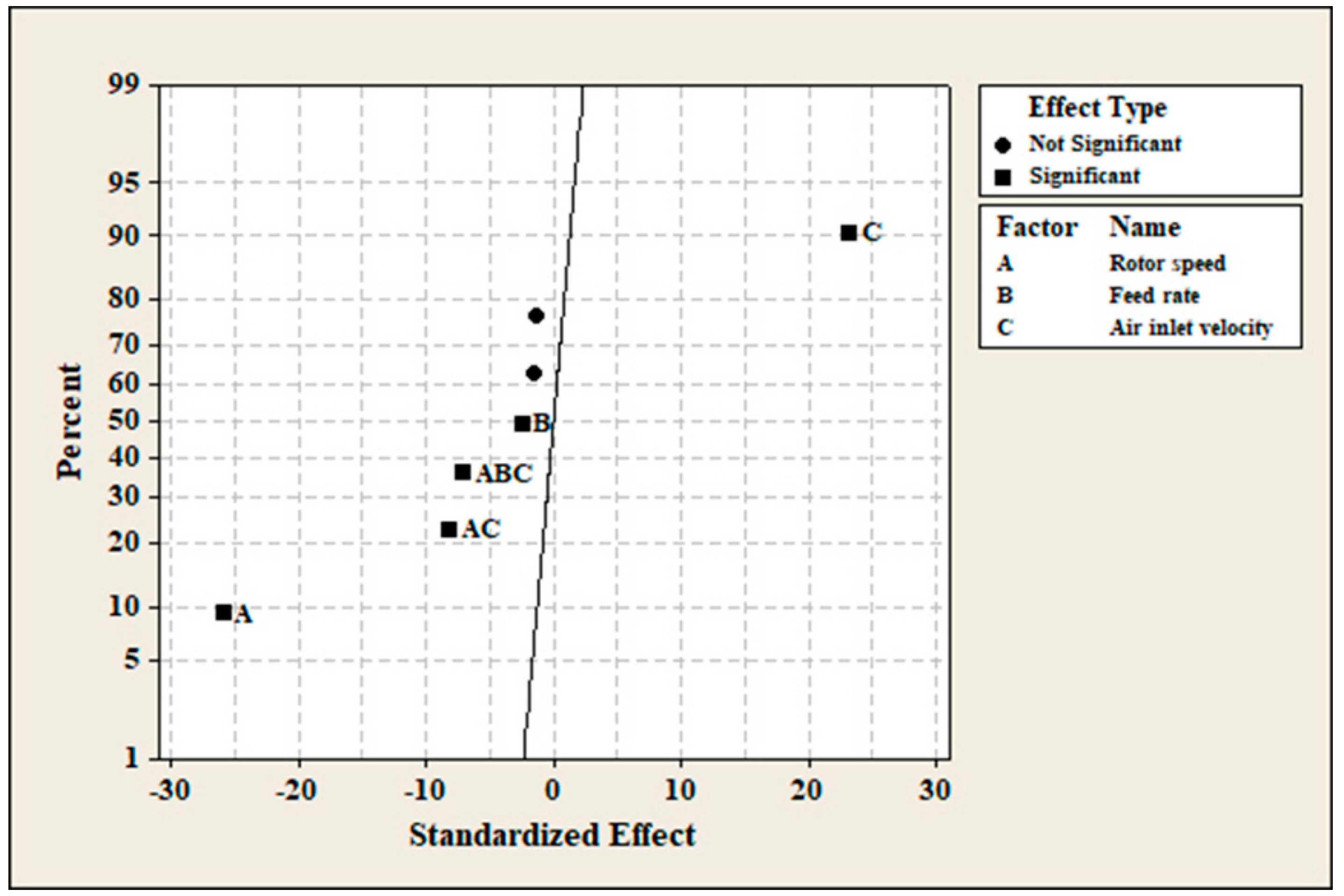

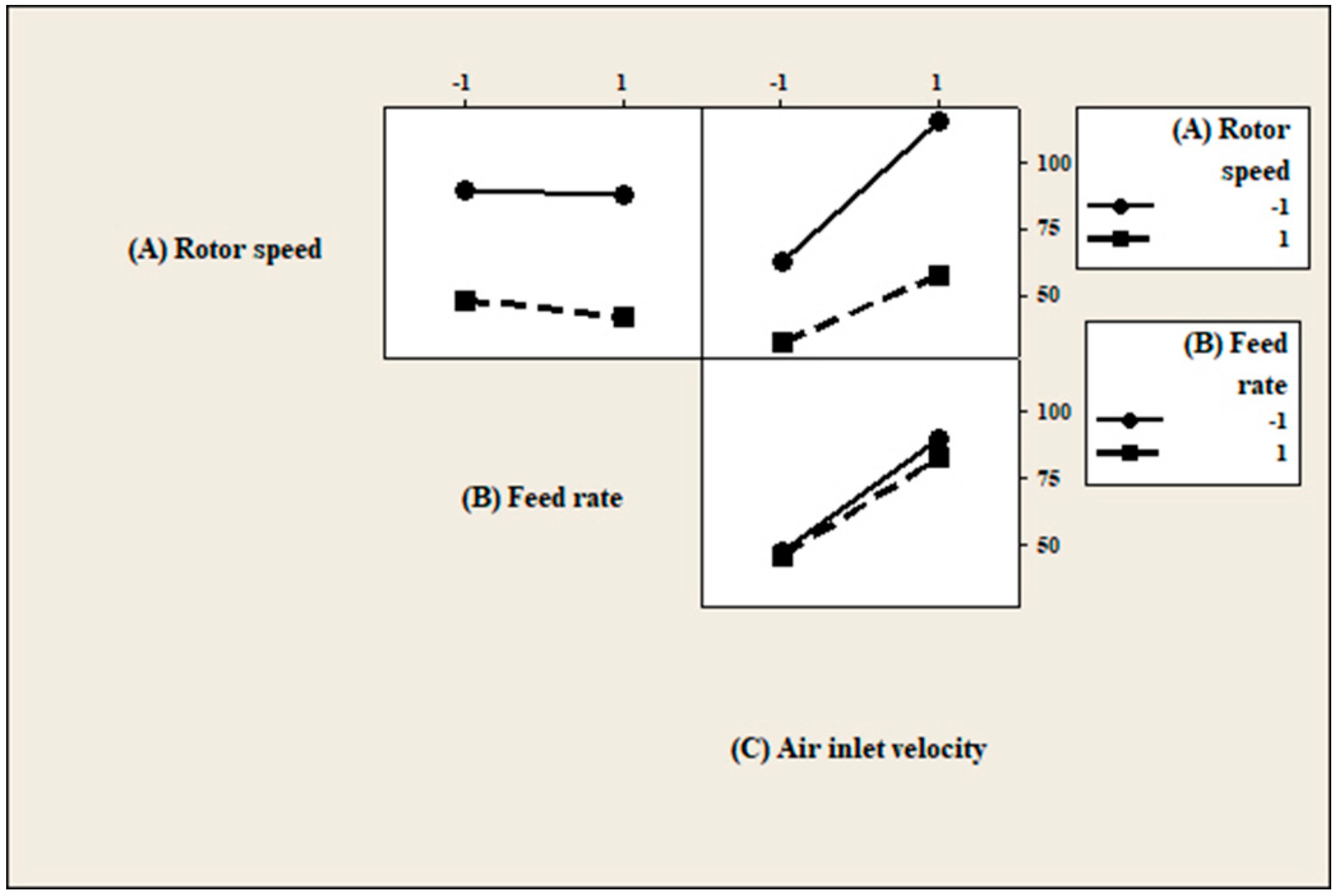

3.1. Statistical Analysis

3.2. Analysis of Variance

3.3. Experimental Verification

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kim, K.; Huh, S.; Suganuma, K. Effects of intermetallic compounds on properties of Sn–Ag–Cu lead-free soldered joints. J. Alloy. Compd. 2003, 352, 226–236. [Google Scholar] [CrossRef]

- Park, Y.; Bang, J.H.; Oh, C.M.; Hong, W.S.; Kang, N. Effect of eutectic structure on creep properties of Sn-3.0Ag-0.5Cu and Sn-8.0Sb-3.0Ag solders. Metals 2017, 7, 540. [Google Scholar] [CrossRef]

- Basak, A.K.; Pramanik, A.; Rizzi, H.; Silakhori, M.; Netting, K.O. Development of Pb-free nanocomposite solder alloys. J. Compos. Sci. 2018, 2, 28. [Google Scholar] [CrossRef]

- Farooq, M.; Ray, S.; Sarkhel, A.; Goldsmith, C. Evaluation of lead (Pb)-free ceramic ball grid array (CBAG): Wettability, microstructure and reliability. In Proceedings of the 51st Electronic Components and Technology Conference, Orlando, FL, USA, 29 May–1 June 2001; pp. 978–986. [Google Scholar]

- Neikov, O.D. Atomization and Granulation. In Handbook of Non-Ferrous Metal Powders, 1st ed.; Neikov, O.D., Naboychenko, S.S., Dowson, G., Eds.; Elsevier: Oxford, UK, 2009; pp. 102–142. [Google Scholar]

- Shapiro, M.; Galperin, V. Air classification of solid particle: A review. Chem. Eng. Process. Intensif. 2005, 44, 279–285. [Google Scholar] [CrossRef]

- Chen, C.; Wang, L.; Luo, Z.; Zhao, Y.; Lv, B.; Fu, Y.; Xu, X. The effect of the characteristics of the partition plate unit on the separation process of -6 mm fine coal in the compound dry separator. Minerals 2019, 9, 215. [Google Scholar] [CrossRef]

- Wang, Q.; Melaaen, M.C.; Silva, S.R.D. Investigation and simulation of a cross-flow air classifier. Powder Technol. 2001, 120, 273–280. [Google Scholar] [CrossRef]

- Wang, X.; Ge, X.; Zhao, X.; Wang, Z. Study on horizontal turbine classification. Powder Technol. 1999, 102, 166–170. [Google Scholar] [CrossRef]

- Galk, J.; Peukert, W.; Krahnen, J. Industrial classification in a new impeller wheel classifier. Powder Technol. 1999, 105, 186–189. [Google Scholar] [CrossRef]

- Kolacz, J. Investigating flow conditions in dynamic air classification. Miner. Eng. 2002, 15, 131–138. [Google Scholar] [CrossRef]

- Wang, X.; Ge, X.; Zhao, X.; Wang, Z. A model for performance of the centrifugal countercurrent air classifier. Powder Technol. 1998, 98, 171–176. [Google Scholar] [CrossRef]

- Lai, W.H.; Lu, W.F.; Chen, C.C. The new expression of the effectiveness of powder classification. Adv. Powder Technol. 2005, 16, 611–620. [Google Scholar] [CrossRef]

- Guo, L.; Liu, J.; Liu, S.; Wang, J. Velocity measurements and flow field characteristic analyses in a turbo air classifier. Powder Technol. 2007, 178, 10–16. [Google Scholar] [CrossRef]

- Eswaraiah, C.; Angadi, S.I.; Mishra, B.K. Mechanism of particle separation and analysis of fish-hook phenomenon in a circulating air classifier. Powder Technol. 2012, 218, 57–63. [Google Scholar] [CrossRef]

- Huang, Q.; Liu, J.; Yu, Y. Turbo air classifier guide vane improvement and inner flow field numerical simulation. Powder Technol. 2012, 226, 10–15. [Google Scholar] [CrossRef]

- Ren, W.; Liu, J.; Yu, Y. Design of a rotor cage with non-radial arc blades for turbo air classifiers. Powder Technol. 2016, 292, 46–53. [Google Scholar] [CrossRef]

- Yu, Y.; Liu, J.; Zhang, K. Establishment of a prediction model for the cut size of turbo air classifiers. Powder Technol. 2014, 254, 274–280. [Google Scholar] [CrossRef]

- Box, G.E.P.; Hunter, W.G.; Hunter, J.S. Statistics for Experiments; Wiley: New York, NY, USA, 1978; pp. 313–316. [Google Scholar]

- Mejeoumov, G.G. Improved Cement Quality and Grinding Efficiency by Means of Closed Mill Circuit Modelling. Ph.D. Thesis, Texas A&M University, College Station, TX, USA, 2007. [Google Scholar]

- Yu, Y.; Ren, W.; Gao, L.; Liu, J. Analysis and optimization of process parameters affecting classification performances indices of the turbo air classifier. Materialwissenschaft und Werkstofftechnik 2015, 46, 970–977. [Google Scholar] [CrossRef]

- Singh, B.P.; Besra, L.; Bhattacharjee, S. Factorial design of experiments on the effect of surface charges on stability of aqueous colloidal ceramic suspension. Colloids Surf. A Physicochem. Eng. Asp. 2002, 204, 175–181. [Google Scholar] [CrossRef]

- Carmona, M.E.R.; da Silva, M.A.P.; Leite, S.G.F. Biosorption of chromium using factorial experimental design. Process Biochem. 2005, 40, 779–788. [Google Scholar] [CrossRef]

- Turan, N.G.; Elevli, S.; Messi, B. Adsorption of copper and zinc ions on illite: Determination of the optimal conditions by the statistical design of experiments. Appl. Clay Sci. 2011, 52, 392–399. [Google Scholar] [CrossRef]

- Meet Minitab Tutorial-SlideShare. Available online: https://www.slideshare.net/shanmu31/meet-minitab-tutorial (accessed on 20 May 2019).

- Montgomery, D.C. Design and Analysis of Experiments, 5th ed.; Wiley: New York, NY, USA, 2001; pp. 170–171. [Google Scholar]

- Dong, L.; Jin, Q.; Liu, X.; Ahangarkani, M.; Zheng, C.; Zhang, Y. Experimental and theoretical analysis of the classification of Sn0.3Ag0.7Cu lead-free solders powder. Vacuum 2018, 156, 277–282. [Google Scholar] [CrossRef]

- Neesse, T.; Dueck, J.; Minkov, L. Separation of finest in hydrocyclones. Miner. Eng. 2004, 17, 689–696. [Google Scholar] [CrossRef]

- Plookphol, T.; Wisutmethangoon, S.; Gonsrang, S. Influence of process parameters on SAC305 lead-free solder powder produced by centrifugal atomization. Powder Technol. 2011, 214, 506–512. [Google Scholar] [CrossRef]

| Parameters | Parameter Name (unit) | Level | |

|---|---|---|---|

| Low (−1) | High (+1) | ||

| A | Rotor speed (RPM) | 194 | 406 |

| B | Feed rate (kg/h) | 4 | 27 |

| C | Air inlet velocity (m/s) | 5 | 8.5 |

| Std Order | Run Order | Center Pt | Blocks | (A) Rotor Speed (RPM) | (B) Feed Rate (kg/h) | (C) Air Inlet Velocity (m/s) | Cut Size (μm) |

|---|---|---|---|---|---|---|---|

| 13 | 1 | 1 | 1 | −1 | −1 | 1 | 112.1 |

| 8 | 2 | 1 | 1 | 1 | 1 | 1 | 46.9 |

| 11 | 3 | 1 | 1 | −1 | 1 | −1 | 57.0 |

| 9 | 4 | 1 | 1 | −1 | −1 | −1 | 66.7 |

| 4 | 5 | 1 | 1 | 1 | 1 | −1 | 39.4 |

| 6 | 6 | 1 | 1 | 1 | −1 | 1 | 63.8 |

| 12 | 7 | 1 | 1 | 1 | 1 | −1 | 31.7 |

| 10 | 8 | 1 | 1 | 1 | −1 | −1 | 30.8 |

| 5 | 9 | 1 | 1 | −1 | −1 | 1 | 111.2 |

| 16 | 10 | 1 | 1 | 1 | 1 | 1 | 46.6 |

| 3 | 11 | 1 | 1 | −1 | 1 | −1 | 55.5 |

| 7 | 12 | 1 | 1 | −1 | 1 | 1 | 117.9 |

| 1 | 13 | 1 | 1 | −1 | −1 | −1 | 68.7 |

| 14 | 14 | 1 | 1 | 1 | −1 | 1 | 72.2 |

| 15 | 15 | 1 | 1 | −1 | 1 | 1 | 121.1 |

| 2 | 16 | 1 | 1 | 1 | −1 | −1 | 24.7 |

| Sources | Degree of Freedom | Sum of Squares | Mean Squares | F | P |

|---|---|---|---|---|---|

| A: Rotor speed | 1 | 7847.7 | 7847.75 | 674.86 | 0.000 |

| B: Feed rate | 1 | 72.9 | 72.89 | 6.27 | 0.037 |

| C: Air inlet velocity | 1 | 6292.9 | 6292.85 | 541.15 | 0.000 |

| A × B | 1 | 24.6 | 24.58 | 2.11 | 0.184 |

| A × C | 1 | 777.4 | 777.43 | 66.85 | 0.000 |

| B × C | 1 | 23.4 | 23.35 | 2.01 | 0.194 |

| A × B × C | 1 | 581.9 | 581.90 | 50.04 | 0.000 |

| Pure error | 8 | 93.0 | 11.63 | ||

| Total | 15 | 15,713.8 |

| Terms | Effects | Coefficients | Standard Error Coefficients | T | P |

|---|---|---|---|---|---|

| Constant | 66.66 | 0.8525 | 78.19 | 0.000 | |

| A | −44.29 | −22.15 | 0.8525 | −25.98 | 0.000 |

| B | −4.27 | −2.13 | 0.8525 | −2.50 | 0.037 |

| C | 39.66 | 19.83 | 0.8525 | 23.26 | 0.000 |

| AB | −2.46 | −1.24 | 0.8525 | −1.45 | 0.184 |

| AC | −13.94 | −6.97 | 0.8525 | −8.18 | 0.000 |

| BC | −2.42 | −1.21 | 0.8525 | −1.42 | 0.194 |

| ABC | −12.06 | −6.03 | 0.8525 | −7.07 | 0.000 |

| S | 3.41008 | ||||

| R-Sq | 0.9941 | ||||

| R-Sq (adj) | 0.9889 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Denmud, N.; Baite, K.; Plookphol, T.; Janudom, S. Effects of Operating Parameters on the Cut Size of Turbo Air Classifier for Particle Size Classification of SAC305 Lead-Free Solder Powder. Processes 2019, 7, 427. https://doi.org/10.3390/pr7070427

Denmud N, Baite K, Plookphol T, Janudom S. Effects of Operating Parameters on the Cut Size of Turbo Air Classifier for Particle Size Classification of SAC305 Lead-Free Solder Powder. Processes. 2019; 7(7):427. https://doi.org/10.3390/pr7070427

Chicago/Turabian StyleDenmud, Nipon, Kradsanai Baite, Thawatchai Plookphol, and Somjai Janudom. 2019. "Effects of Operating Parameters on the Cut Size of Turbo Air Classifier for Particle Size Classification of SAC305 Lead-Free Solder Powder" Processes 7, no. 7: 427. https://doi.org/10.3390/pr7070427

APA StyleDenmud, N., Baite, K., Plookphol, T., & Janudom, S. (2019). Effects of Operating Parameters on the Cut Size of Turbo Air Classifier for Particle Size Classification of SAC305 Lead-Free Solder Powder. Processes, 7(7), 427. https://doi.org/10.3390/pr7070427