Experimental Development of Coal-Like Material with Solid-Gas Coupling for Quantitative Simulation Tests of Coal and Gas Outburst Occurred in Soft Coal Seams

Abstract

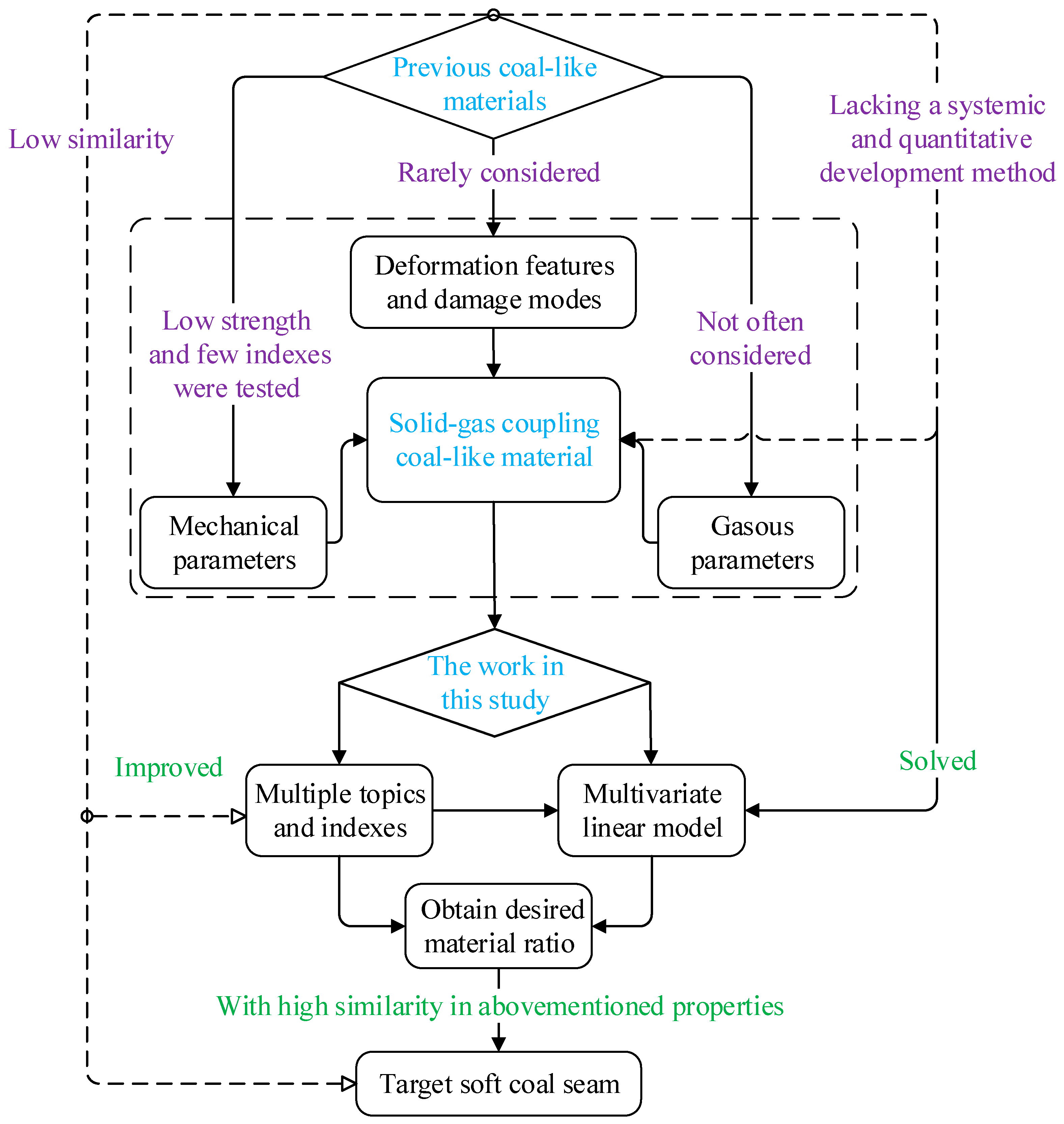

1. Introduction

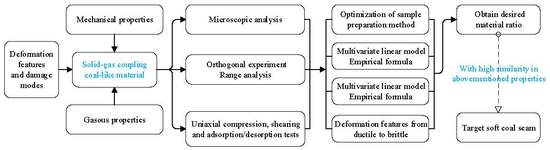

2. Materials and Methods

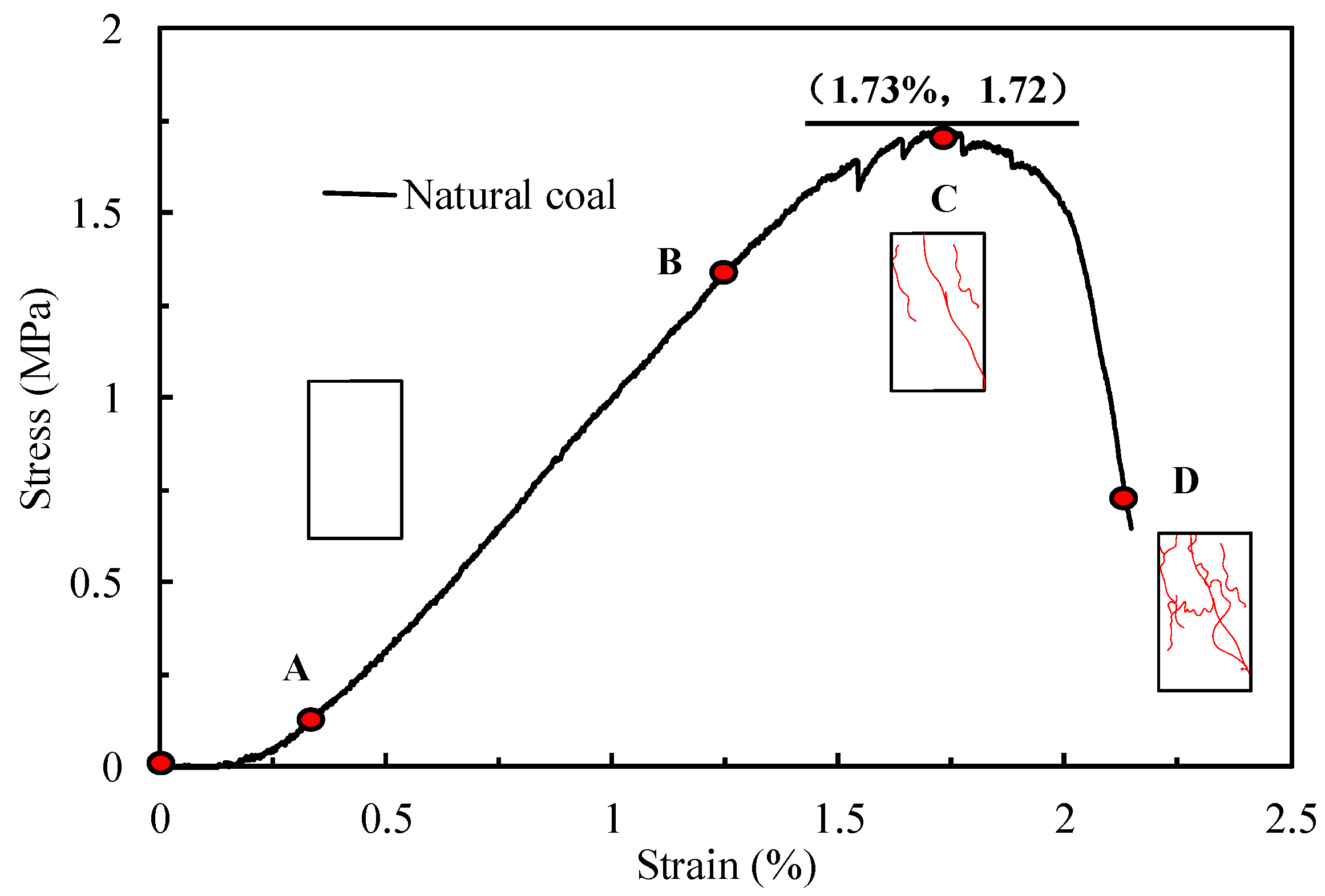

2.1. Preparation and Testing of Natural Coal Samples

2.2. Similarity Criteria and Index

2.3. Preparation of Coal-Like Material Samples

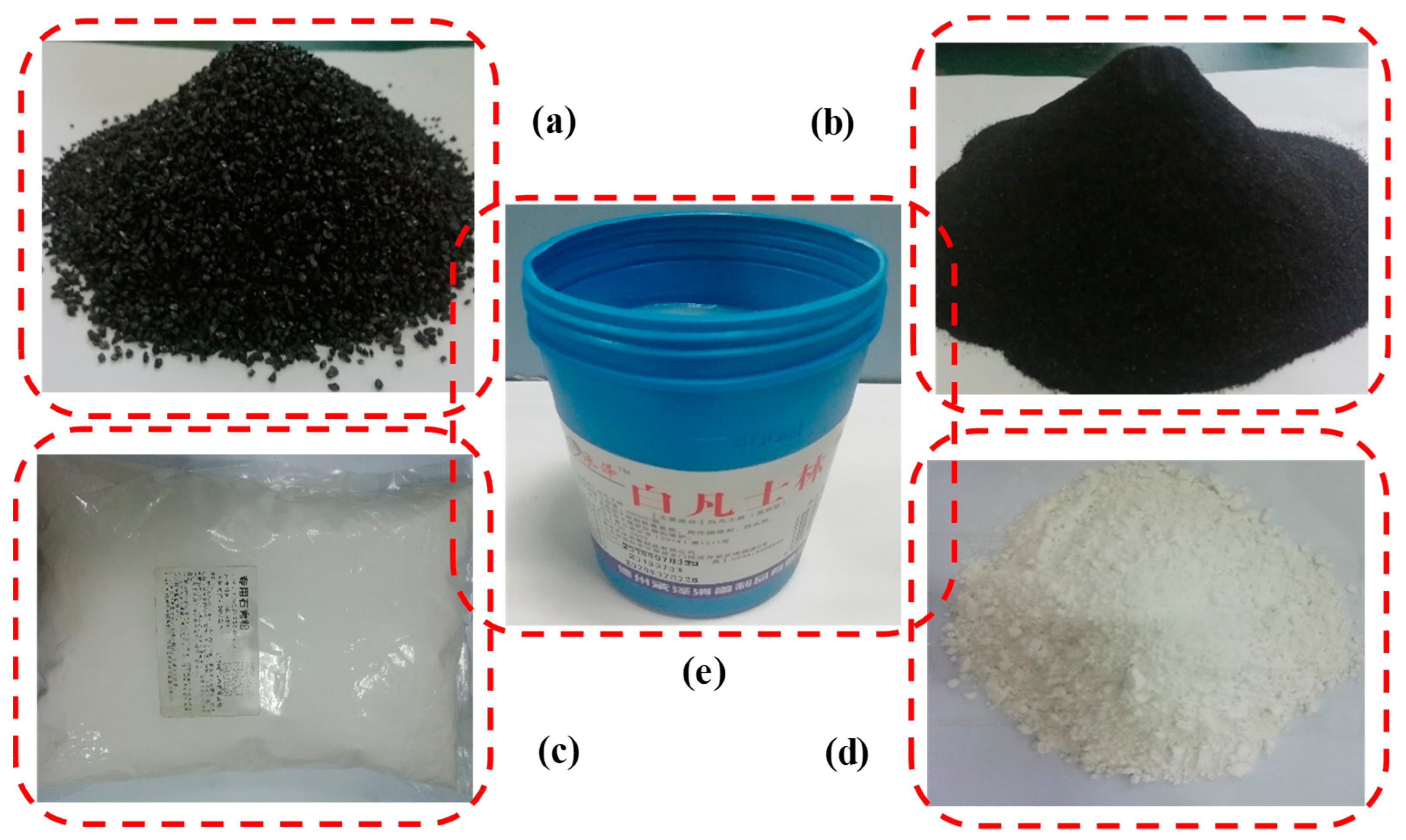

2.3.1. Composition Selection

2.3.2. Design Scheme

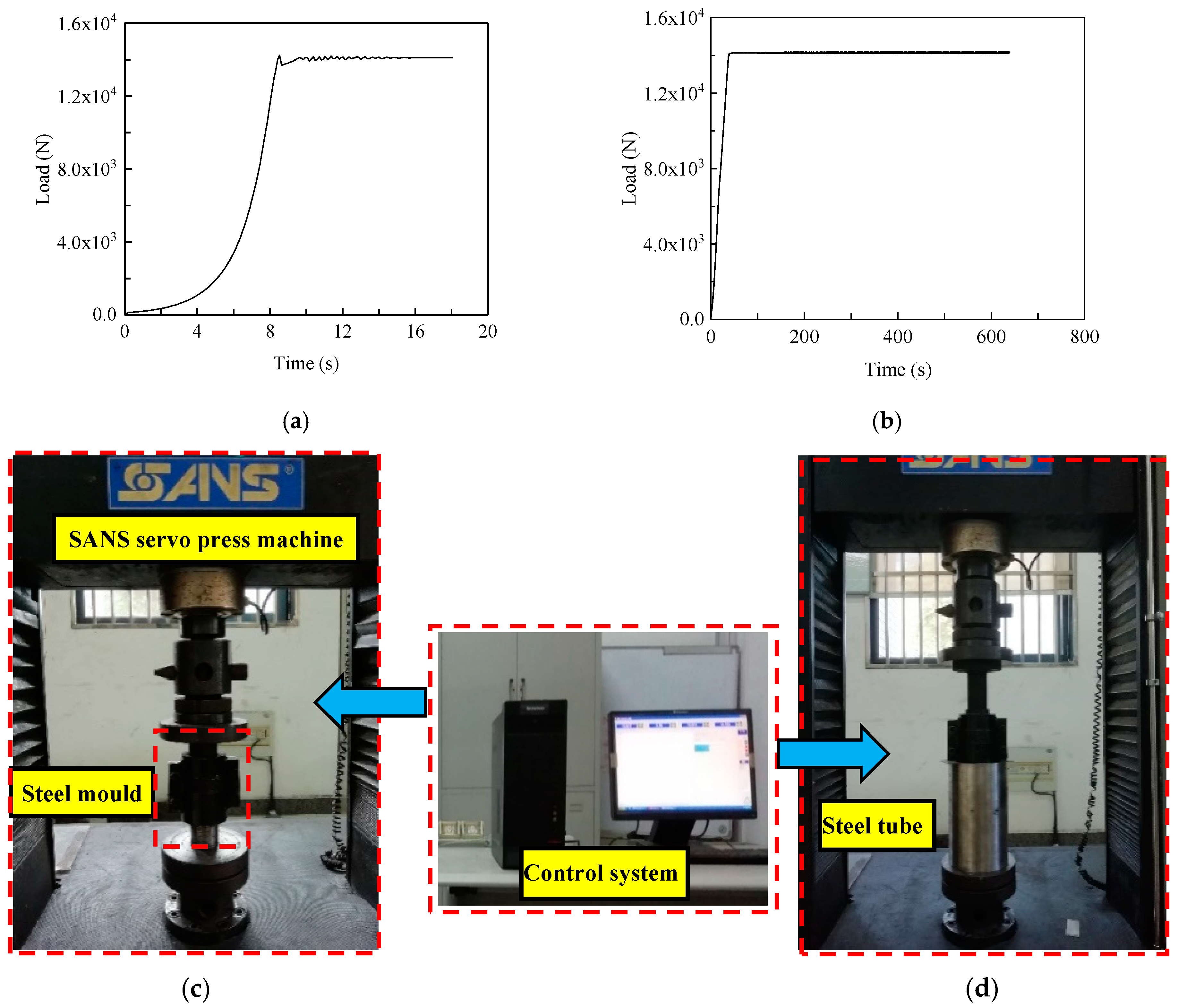

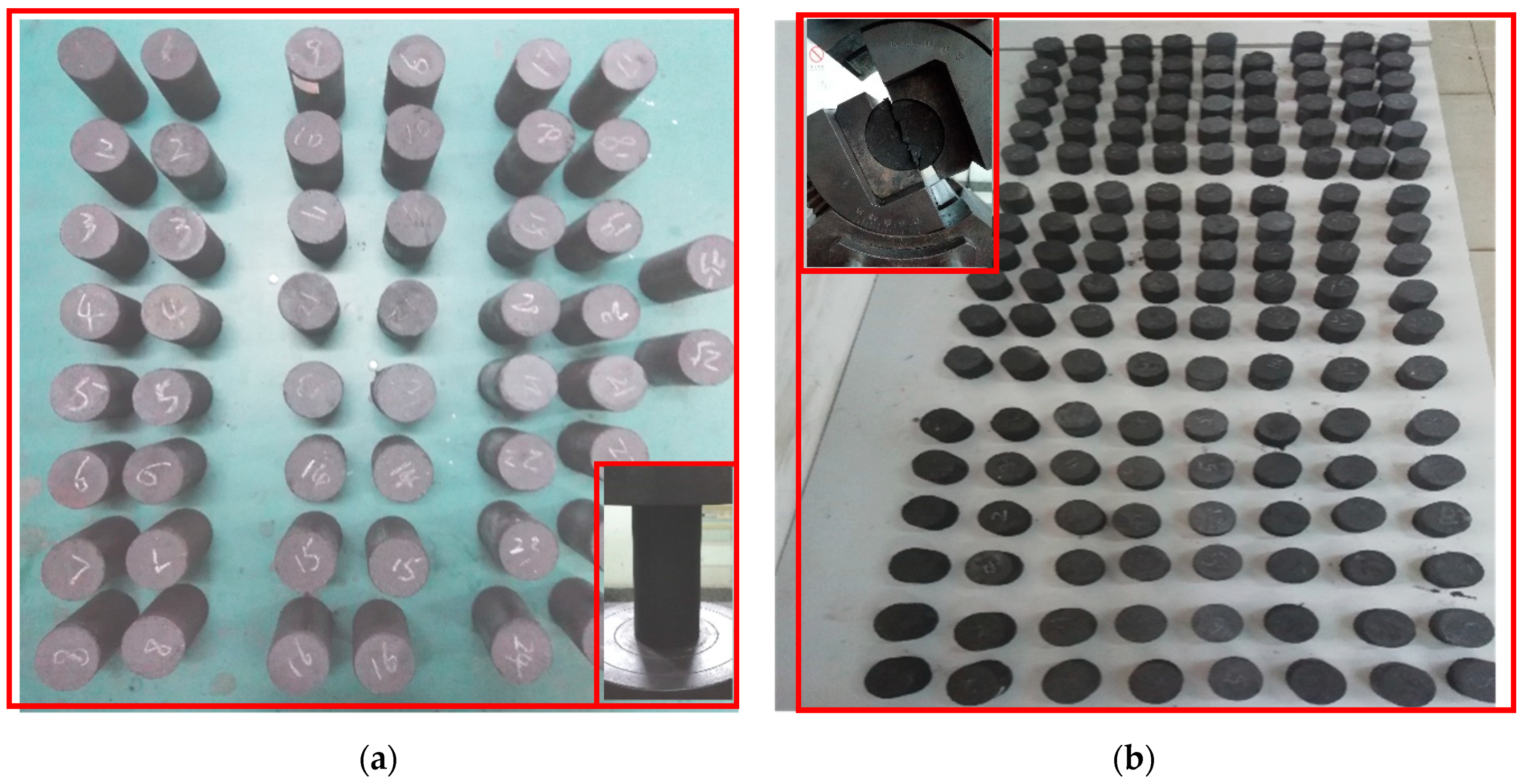

2.3.3. Sample Preparation Method

2.3.4. Sample Tests

3. Result Analysis and Discussion

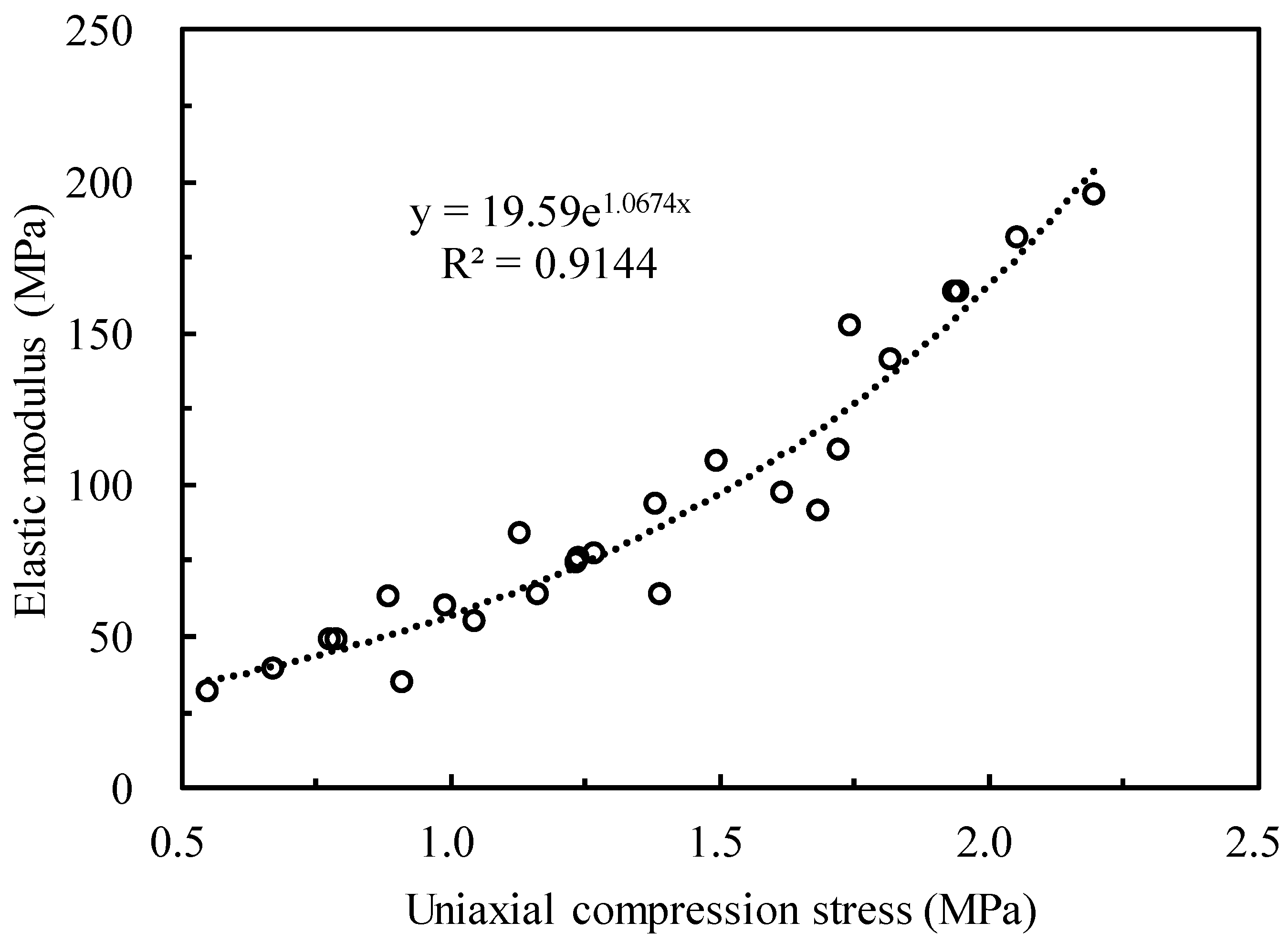

3.1. Mechanical Properties

3.1.1. Results of Orthogonal Test

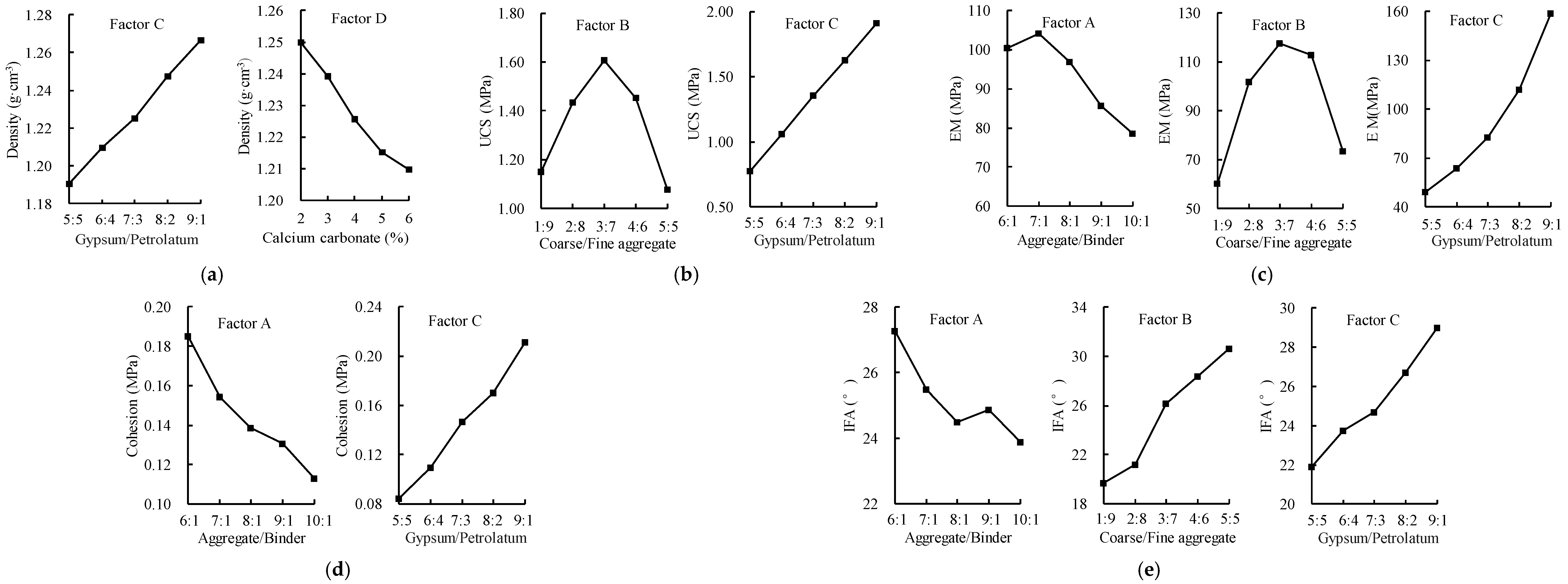

3.1.2. Range Analysis

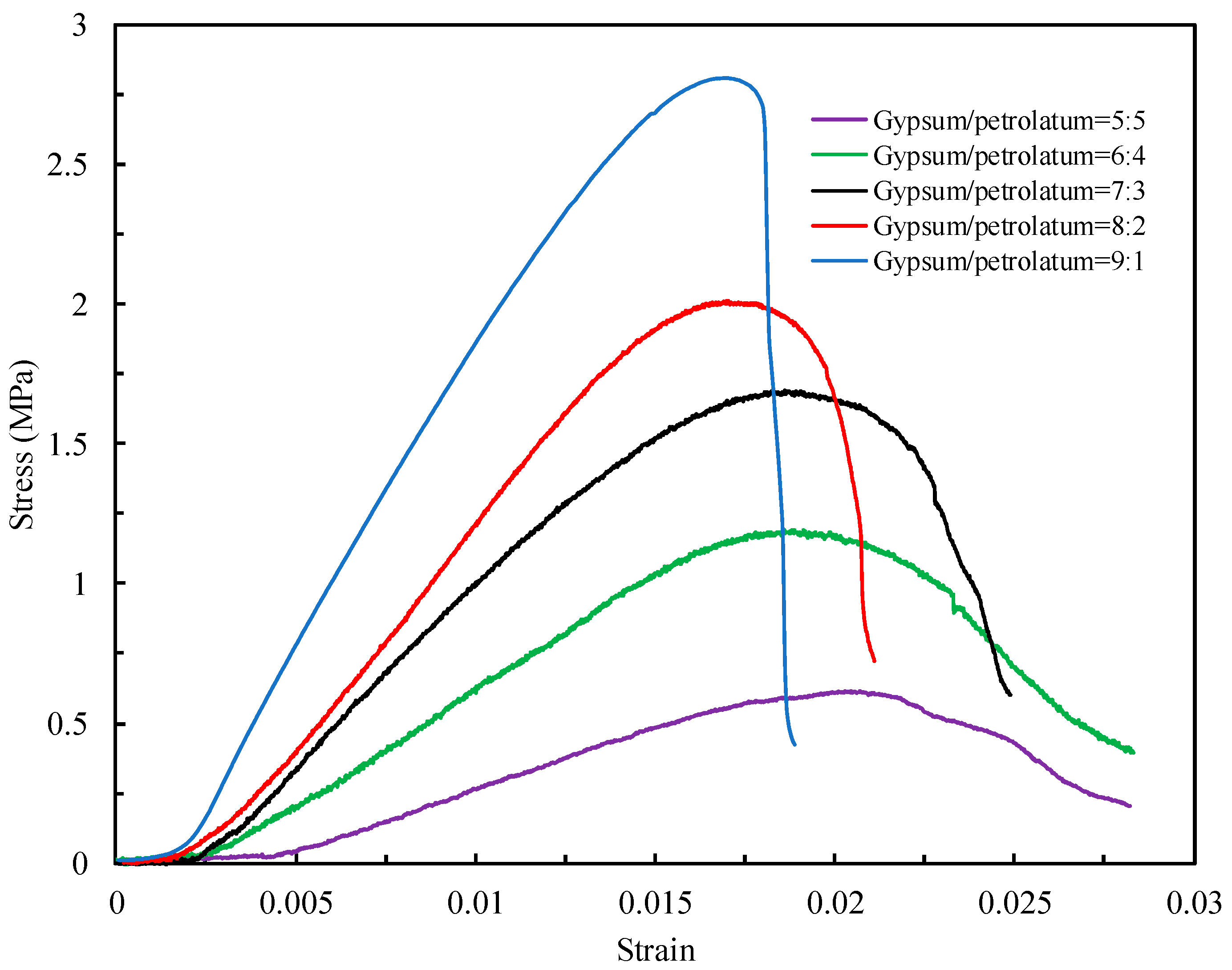

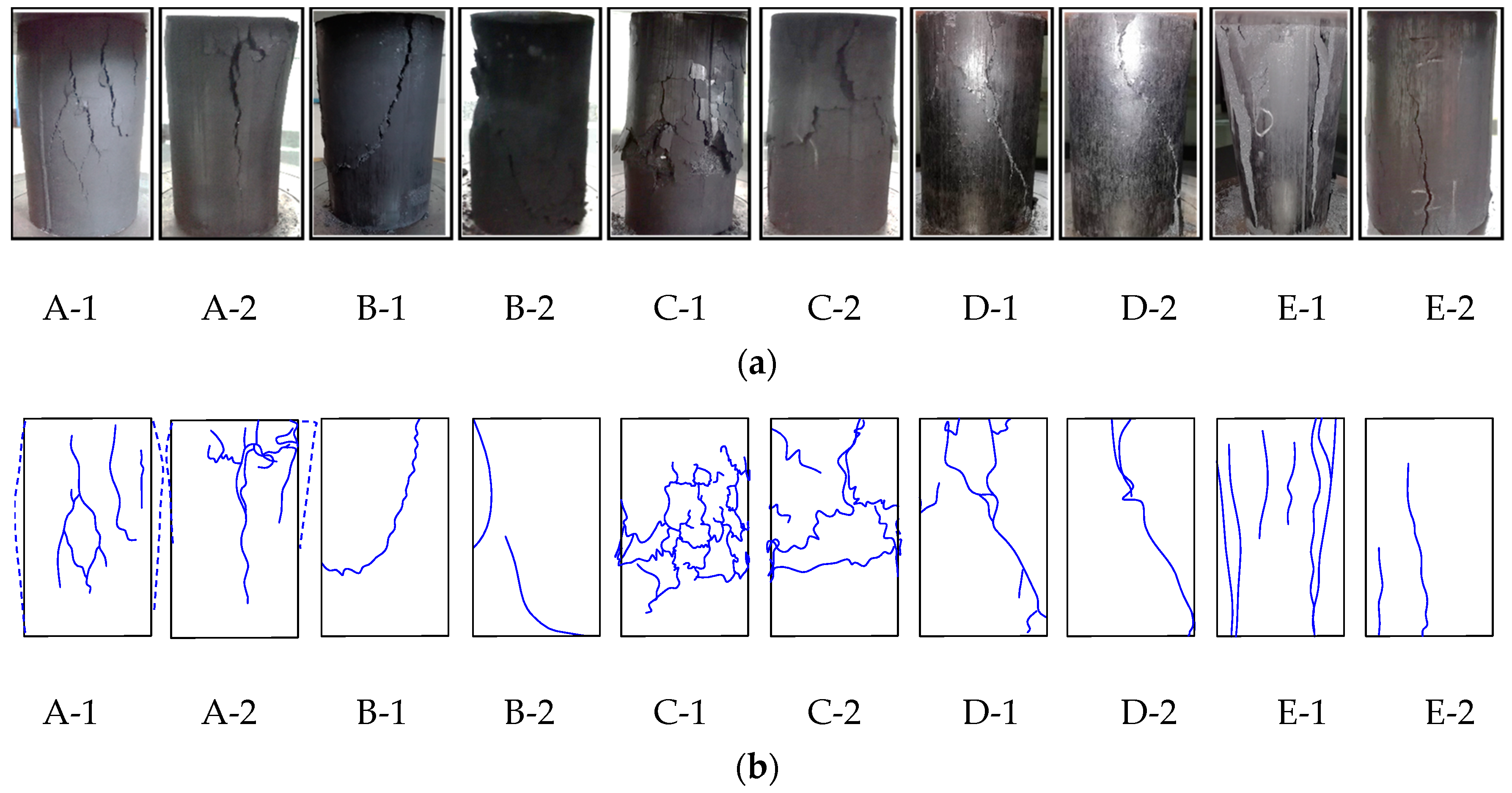

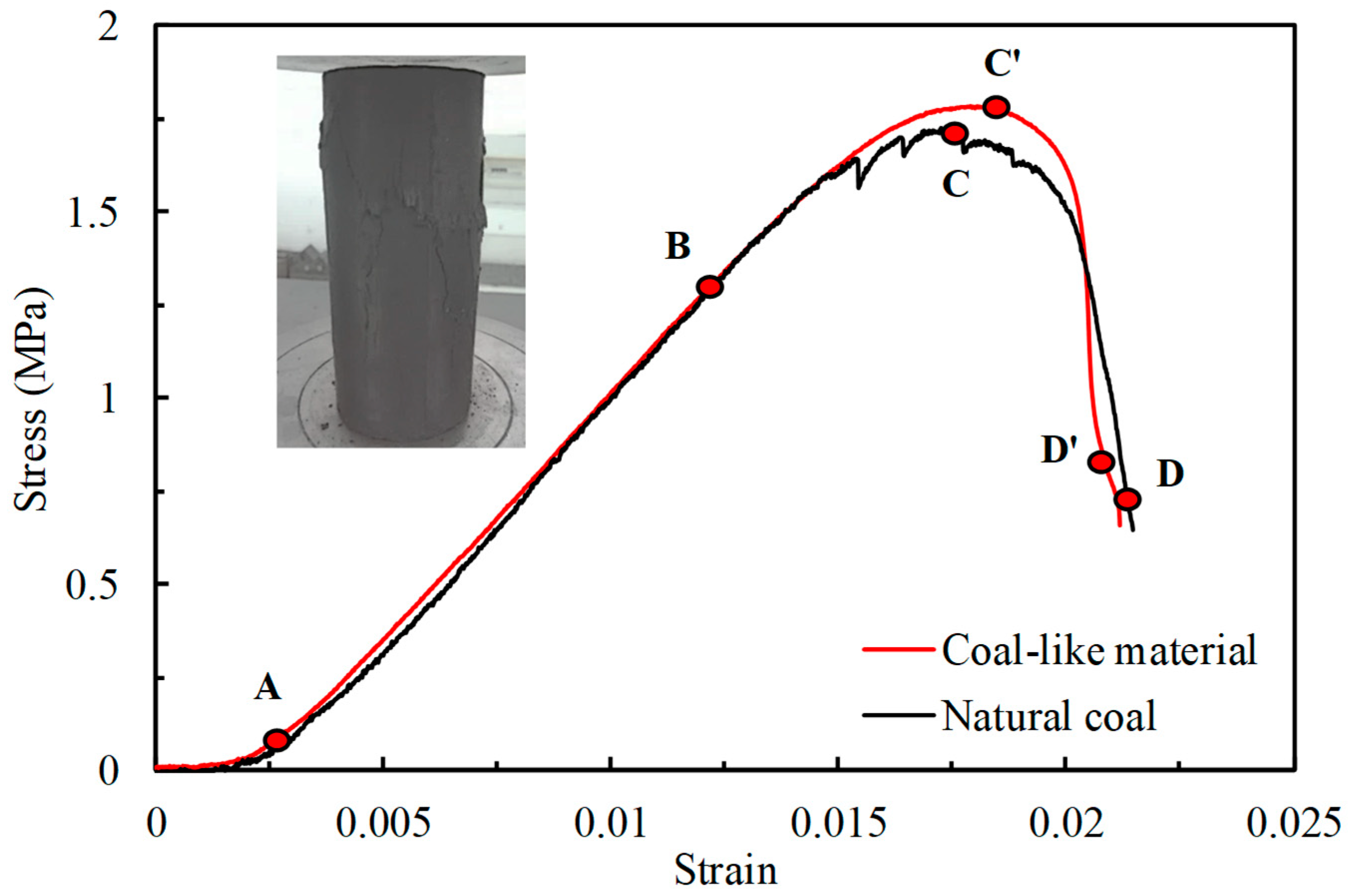

3.2. Deformation Characteristics and Failure Modes of the Coal-Like Samples

3.3. Physicochemical Properties

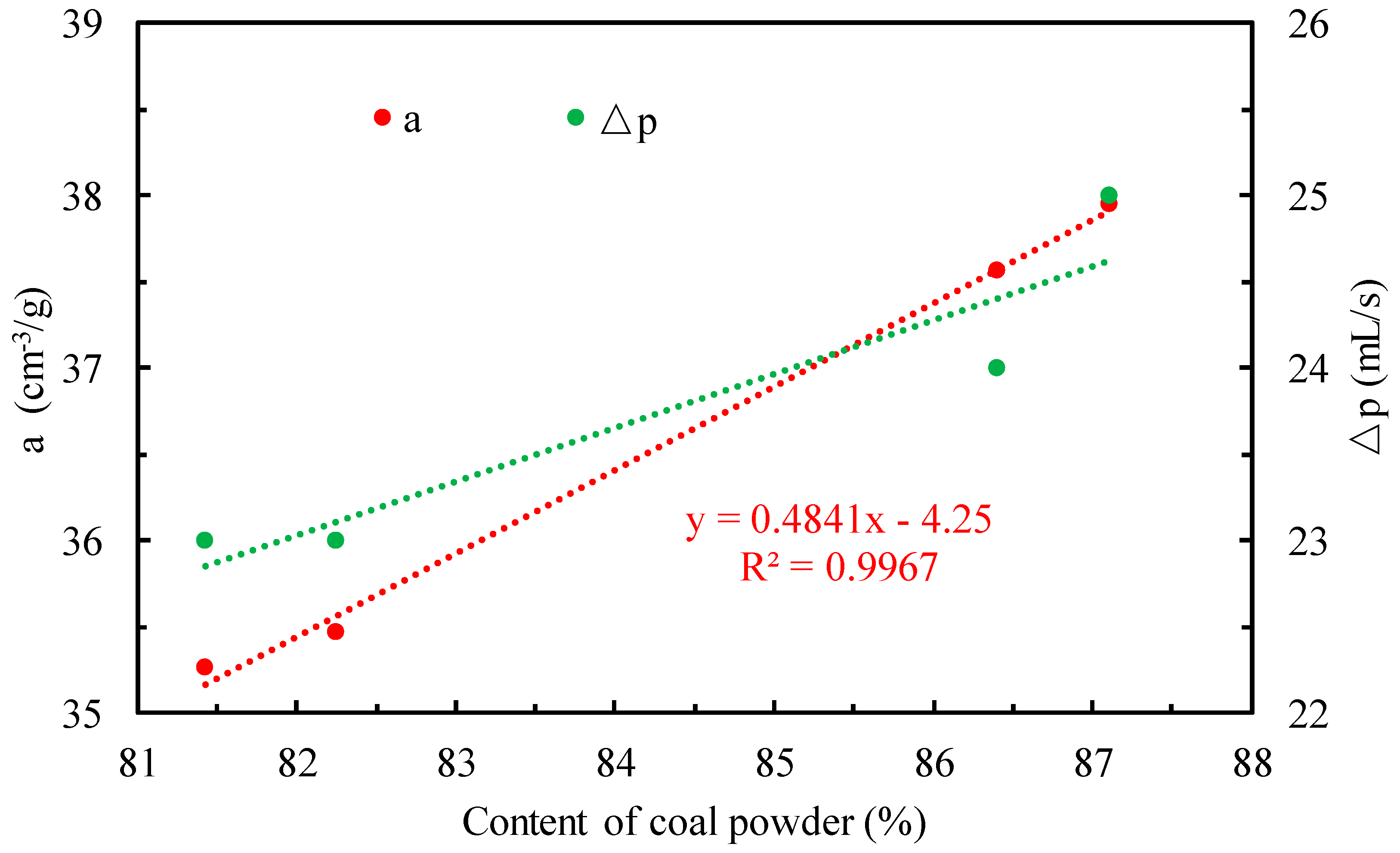

3.3.1. Porosity

3.3.2. Adsorption and Desorption Parameters

3.4. Multivariate Linear Model for Predicting the Mechanical Parameters of Coal-Like Material

3.5. Discussion

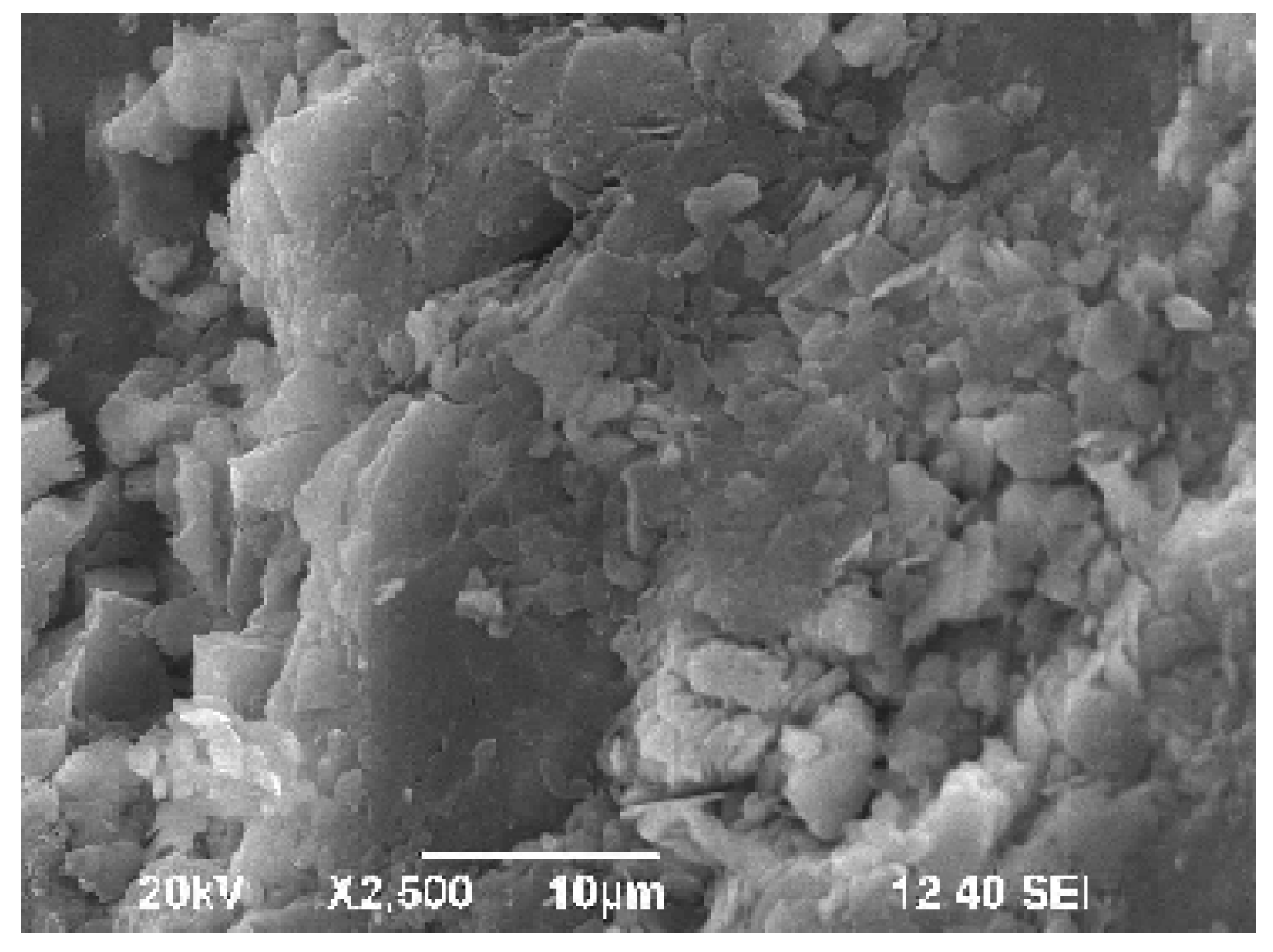

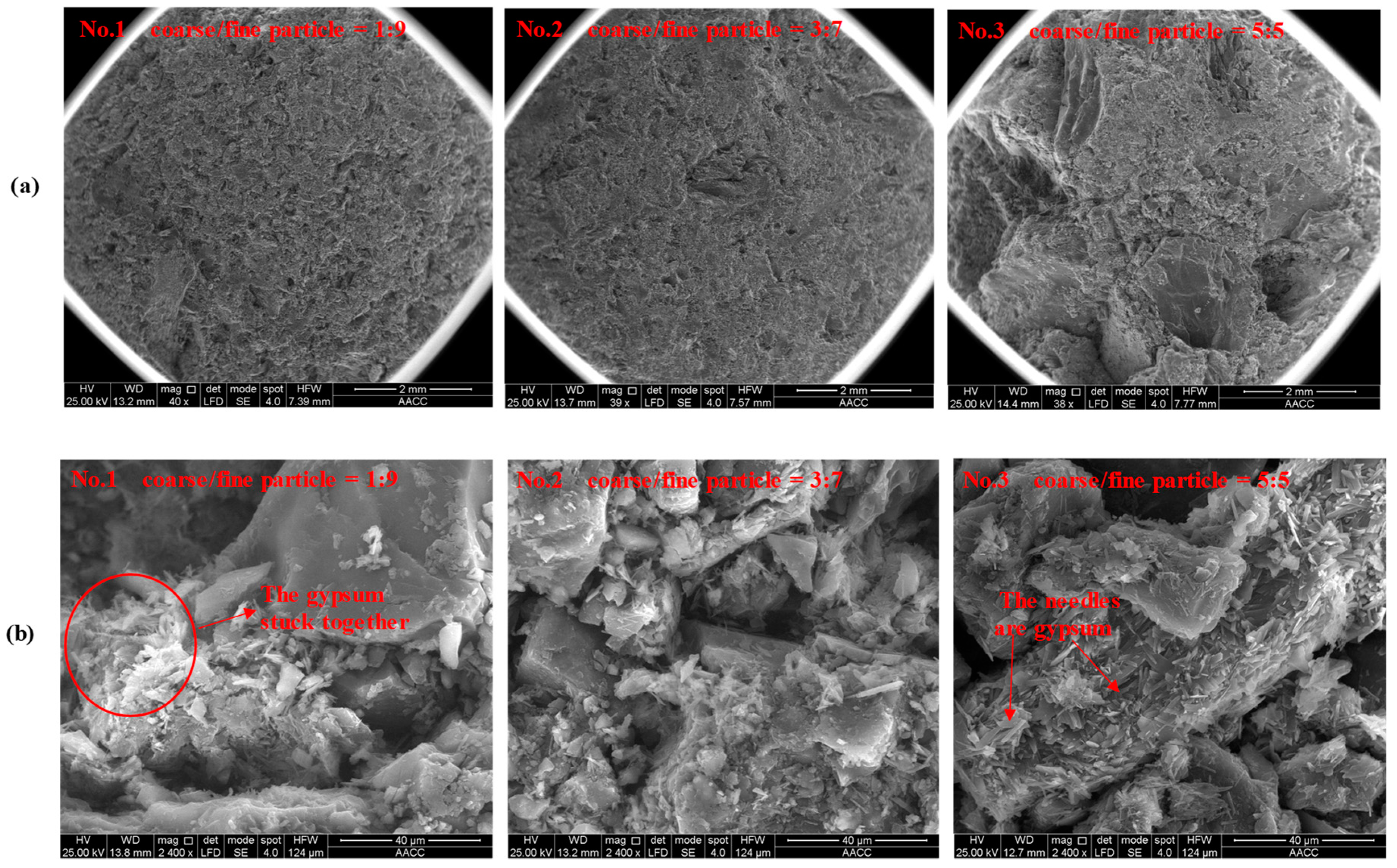

3.5.1. Microscopic Analysis of the Effect of Pulverized Coal Particle Size on Sample Strength

3.5.2. Optimization of Sample Preparation Method and Deformation Characteristic Controlling Binder

3.5.3. Porosity Adjustment Method

3.5.4. Limitation and Future Direction to Improve the Similarity of Solid-Gas Coupling Coal-Like Materials

3.5.5. Application Prospects of Solid-Gas Coupling Coal-Like Materials

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Valliappan, S.; Zhang, W.H. Role of gas energy during coal outbursts. Int. J. Numer. Meth. Eng. 1999, 44, 875–895. [Google Scholar] [CrossRef]

- Lama, R.D.; Bodziony, J. Management of outburst in underground coal mines. Int. J. Coal. Geol. 1998, 35, 83–115. [Google Scholar] [CrossRef]

- Wang, F.; Zhao, X.; Liang, Y.; Li, X.; Chen, Y. Calculation Model and Rapid Estimation Method for Coal Seam Gas Content. Processes 2018, 6, 223. [Google Scholar] [CrossRef]

- Beamish, B.B.; Crosdale, P.J. Instantaneous outbursts in underground coal mines: An overview and association with coal type. Int. J. Coal. Geol. 1998, 35, 27–55. [Google Scholar] [CrossRef]

- Skoczylas, N.; Dutka, B.; Sobczyk, J. Mechanical and gaseous properties of coal briquettes in terms of outburst risk. Fuel 2014, 134, 45–52. [Google Scholar] [CrossRef]

- Zhao, B.; Wen, G.C.; Sun, H.T.; Sun, D.L.; Yang, H.M.; Cao, J.; Dai, L.C.; Wang, B. Similarity criteria and coal-like material in coal and gas outburst physical simulation. Int. J. Coal Sci. Technol. 2018, 5, 167–178. [Google Scholar] [CrossRef]

- Chen, L.; Wang, E.Y.; Ou, J.C.; Fu, J.W. Coal and gas outburst hazards and factors of the No. B-1 Coalbed, Henan, China. Geosci. J. 2018, 22, 171–182. [Google Scholar] [CrossRef]

- Wang, G.; Wu, M.M.; Wang, H.Y.; Huang, Q.M.; Zhong, Y. Sensitivity analysis of factors affecting coal and gas outburst based on an energy equilibrium model. Chin. J. Rock Mech. Eng. 2015, 34, 238–248. (In Chinese) [Google Scholar] [CrossRef]

- Yuan, L. Control of coal and gas outbursts in Huainan mines in China: A review. J. Rock Mech. Geotech. Eng. 2016, 8, 559–567. [Google Scholar] [CrossRef]

- Wang, G.; Li, W.X.; Wang, P.F.; Yang, X.X.; Zhang, S.T. Deformation and gas flow characteristics of coal-like materials under triaxial stress conditions. Int. J. Rock Mech. Min. Sci. 2017, 91, 72–80. [Google Scholar] [CrossRef]

- Peng, S.J.; Xu, J.; Yang, H.W.; Liu, D. Experimental study on the influence mechanism of gas seepage on coal and gas outburst disaster. Saf. Sci. 2012, 50, 816–821. [Google Scholar] [CrossRef]

- Skoczylas, N. Laboratory study of the phenomenon of methane and coal outburst. Int. J. Rock Mech. Min. Sci. 2012, 55, 102–107. [Google Scholar] [CrossRef]

- Hu, Q.T.; Zhang, S.T.; Wen, G.C.; Dai, L.C.; Wang, B. Coal-like material for coal and gas outburst simulation tests. Int. J. Rock Mech. Min. Sci. 2015, 74, 151–156. [Google Scholar] [CrossRef]

- Sun, H.T.; Cao, J.; Li, M.H.; Zhao, X.S.; Dai, L.C.; Sun, D.L.; Wang, B.; Zhai, B.N. Experimental Research on the Impactive Dynamic Effect of Gas-Pulverized Coal of Coal and Gas Outburst. Energies 2018, 11, 797. [Google Scholar] [CrossRef]

- Alexeev, A.D.; Revva, V.N.; Alyshev, N.A.; Zhitlyonok, D.M. True triaxial loading apparatus and its application to coal outburst prediction. Int. J. Coal. Geol. 2004, 58, 245–250. [Google Scholar] [CrossRef]

- Clayton, J.L. Geochemistry of coalbed gas—A review. Int. J. Coal. Geol. 1998, 35, 159–173. [Google Scholar] [CrossRef]

- Prusty, B.K. Sorption of methane and CO2 for enhanced coalbed methane recovery and carbon dioxide sequestration. J. Nat. Gas Chem. 2008, 17, 29–38. [Google Scholar] [CrossRef]

- Jasinge, D.; Ranjith, P.G.; Choi, S.K.; Kodikara, J. Mechanical Properties of Reconstituted Australian Black Coal. J. Geotech. Geoenviron. Eng. 2009, 135, 980–985. [Google Scholar] [CrossRef]

- Jasinge, D.; Ranjith, P.G.; Choi, S.K. Development of a reconstituted brown coal material using cement as a binder. Environ. Earth Sci. 2011, 64, 631–641. [Google Scholar] [CrossRef]

- Jasinge, D.; Ranjith, P.G.; Choi, X.; Fernando, J. Investigation of the influence of coal swelling on permeability characteristics using natural brown coal and reconstituted brown coal specimens. Energy 2012, 39, 303–309. [Google Scholar] [CrossRef]

- Ranjith, P.G.; Shao, S.S.; Viete, D.R.; Jaysinge, D. Carbon Dioxide Storage in Coal: Reconstituted Coal as a Structurally Homogeneous Substitute for Coal. Int. J. Coal Prep. Util. 2012, 32, 265–275. [Google Scholar] [CrossRef]

- Skochinski, A.A. Communication of the Initiation of a Sudden Outburst of Gas and Coal in the Model in Outburst Laboratory of the Institute of Mining of AN, SSSR; Ugol: Novokuznetsk, Russia, 1953; p. 10. [Google Scholar]

- Yin, G.Z.; Huang, Q.X.; Zhang, D.M.; Wang, D.K. Test study of gas seepage characteristics of gas-bearing coal specimen during process of deformation and failure in geostress field. Chin. J. Rock Mech. Eng. 2010, 29, 336–343. (In Chinese) [Google Scholar]

- Jiang, C.B.; Yin, G.Z.; Li, X.Q.; Cai, B. Experimental study of gas permeability of outburst coal briquettes in complete stress-strain process. Chin. J. Rock Mech. Eng. 2010, 29, 3482–3487. (In Chinese) [Google Scholar]

- Cao, S.G.; Li, Y.; Guo, P.; Bai, Y.J.; Liu, Y.B. Comparative research on permeability characteristics in complete stress-strain process of briquettes and coal samples. Chin. J. Rock Mech. Eng. 2010, 29, 899–906. (In Chinese) [Google Scholar]

- Chen, H.D.; Cheng, Y.P.; Zhou, H.X.; Li, W. Damage and Permeability Development in Coal During Unloading. Rock Mech. Rock Eng. 2013, 46, 1377–1390. [Google Scholar] [CrossRef]

- Xu, J.; Geng, J.B.; Peng, S.J.; Liu, D.; Nie, W. Acoustic emission characteristics of coal and gas outburst under different moisture contents. J. China Coal Soc. 2015, 35, 1047–1054. [Google Scholar] [CrossRef]

- Jasinge, D.; Ranjith, P.G.; Kodikara, J.; Al, E. A Comparision of Stress Strain Behavior of Reconstituted and Natural Black Coal. In Proceedings of the Congress of the 11th ISRM of the International Society of Rock Mechanics, Lisbon, Portugal, 9–13 July 2007. [Google Scholar]

- Xu, J.; Ye, G.B.; Li, B.B.; Cao, J.; Zhang, M. Experimental study of mechanical and permeability characteristics of moulded coals with different binder ratios. Rock Soil Mech. 2015, 36, 104–110. (In Chinese) [Google Scholar] [CrossRef]

- Zhang, Q.H.; Yuan, L.; Wang, H.P.; Kang, J.H.; Li, S.C.; Xue, J.H.; Zhou, W.; Zhang, D.M. Establishment and analysis of similarity criteria for physical simulation of coal and gas outburst. J. China Coal Soc. 2016, 41, 2773–2779. (In Chinese) [Google Scholar] [CrossRef]

- Zhang, S.T.; Lin, D.C.; Wang, B.; Cao, J. Experimental study of mixture ratio of similar material for simulation of coal and gas outburst. Coal Sci. Technol. 2015, 43, 76–80. (In Chinese) [Google Scholar] [CrossRef]

- Wang, J.L.; Li, M.; Xu, S.C.; Qu, Z.H.; Jiang, B. Simulation of Ground Stress Field and Advanced Prediction of Gas Outburst Risks in the Non-Mining Area of Xinjing Mine, China. Energies 2018, 11, 1285. [Google Scholar] [CrossRef]

- Yin, W.T.; Fu, G.; Yang, C.; Jiang, Z.G.; Zhu, K.; Gao, Y. Fatal gas explosion accidents on Chinese coal mines and the characteristics of unsafe behaviors: 2000–2014. Saf. Sci. 2017, 92, 173–179. [Google Scholar] [CrossRef]

- Wang, C.J.; Yang, S.Q.; Yang, D.D.; Li, X.W.; Jiang, C.L. Experimental analysis of the intensity and evolution of coal and gas outbursts. Fuel 2018, 226, 252–262. [Google Scholar] [CrossRef]

- Li, H.Y. Major and minor structural features of a bedding shear zone along a coal seam and related gas outburst, Pingdingshan coalfield, northern China. Int. J. Coal. Geol. 2001, 47, 101–113. [Google Scholar] [CrossRef]

- Cao, Y.X.; Mitchell, G.D.; Davis, A.; Wang, D.M. Deformation metamorphism of bituminous and anthracite coals from China. Int. J. Coal. Geol. 2000, 43, 227–242. [Google Scholar] [CrossRef]

- Ju, Y.W.; Jiang, B.; Hou, Q.L.; Tan, Y.J.; Wang, G.L.; Xiao, W.J. Behavior and mechanism of the adsorption/desorption of tectonically deformed coals. Chin. Sci. Bull. 2009, 54, 88–94. [Google Scholar] [CrossRef]

- Ju, Y.W.; Jiang, B.; Hou, Q.L.; Wang, G.L. The new structure-genetic classification system in tectonically deformed coals and its gelological significance. J. China Coal Soc. 2004, 29, 513–517. (In Chinese) [Google Scholar] [CrossRef]

- China National Coal Association. Methods for Determining the Physical and Mechanical Properties of Coal and Rock—Part 7: Methods for Determining the Uniaxial Compressive Strength and Counting Softening Coefficient; GB/T 23561.7-2009; China National Coal Association: Beijing, China, 2009.

- China National Coal Association. Methods for Determining the Physical and Mechanical Properties of Coal and Rock—Part 11: Methods for Determining Shear Strength of Coal and Rock; GB/T 23561.11-2010; China National Coal Association: Beijing, China, 2010.

- Mansouri, H.; Ajalloeian, R. Mechanical behavior of salt rock under uniaxial compression and creep tests. Int. J. Rock Mech. Min. Sci. 2018, 110, 19–27. [Google Scholar] [CrossRef]

- Gao, Y.J. Analysis of the Factors Influencing Briquette Forming and Design of Roll Briquetting Machine. Master’s Thesis, Shanxi University, Taiyuan, China, 2009. (In Chinese with English abstract). [Google Scholar]

- Liu, S.; Liu, W. Experimental Development Process of a New Fluid–Solid Coupling Similar-Material Based on the Orthogonal Test. Processes 2018, 6, 211. [Google Scholar] [CrossRef]

- Brown, E.T. Suggested Method for Determining the Uniaxial Compressive Strength of Rock Materials, Rock Characterization, Testing and Monitoring; ISRM Suggested Methods; Pergamon Press: Oxford, UK, 1981. [Google Scholar]

- Yang, D.D.; Chen, Y.J.; Tang, J.; Li, X.W.; Jiang, C.L.; Wang, C.J.; Zhang, C.J. Experimental research into the relationship between initial gas release and coal-gas outbursts. J. Nat. Gas Sci. Eng. 2018, 50, 157–165. [Google Scholar] [CrossRef]

- Laxminarayana, C.; Crosdale, P.J. Role of coal type and rank on methane sorption characteristics of Bowen Basin, Australia coals. Int. J. Coal. Geol. 1999, 40, 309–325. [Google Scholar] [CrossRef]

- Ruppel, T.C.; Grein, C.T.; Bienstock, D. Adsorption of methane on dry coal at elecated pressure. Fuel 1974, 53, 152–162. [Google Scholar] [CrossRef]

- Jasinge, D.; Ranjith, P.G.; Choi, S.K. Effects of effective stress changes on permeability of latrobe valley brown coal. Fuel 2011, 90, 1292–1300. [Google Scholar] [CrossRef]

- Tang, J.; Jiang, C.L.; Chen, Y.J.; Li, X.W.; Wang, G.D.; Yang, D.D. Line prediction technology for forecasting coal and gas outbursts during coal roadway tunnelling. J. Nat. Gas Sci. Eng. 2016, 34, 412–418. [Google Scholar] [CrossRef]

- Xue, Y.; Gao, F.; Gao, Y.; Chen, H.M.; Liu, Y.K.; Hou, P.; Teng, T. Quantitative evaluation of stress-relief and permeability-increasing effects of overlying coal seams for coal mine methane drainage in Wulan coal mine. J. Nat. Gas Sci. Eng. 2016, 32, 122–137. [Google Scholar] [CrossRef]

| No. | Coal Particle Size (mm) | Compaction Pressure (MPa) | Additives | Molding/Air Curing Time (h) | References |

|---|---|---|---|---|---|

| 1 | 0–0.2 | 2.76–19.90 | None | - | [5,12,22] |

| 2 | 0.25–0.38 | 100 | Water | Molding curing 0.33 h | [23,24,25] |

| 3 | 0–1 | 4–13 | Water | Molding curing 24 h | [20] |

| 4 | 0.18–0.25 | 100 | water | 24 h drying in drying basin | [11] |

| 5 | 0.18–0.25 | 100 | Water | Molding curing 0.5 h | [26] |

| 6 | 0–1.7 | 4 | Water | - | [27] |

| 7 | 0.1–1 | 5.7 | Cement, water | Molding curing 24 h, air curing 96 h | [18,28] |

| 8 | 0–0.8 | 2–6 | Cement, water | Molding curing 14.6–20 h, air curing 96–24 × 28 h | [19] |

| 9 | 0.063–1 | 5 | Phenol-Formaldehyde Resin, potassium hydroxide alkaline aqueous, distilled water | Molding curing 3–26 h, air curing time 144.5–598.5 h | [21] |

| 10 | 0.18–0.25 | 100 | Cement, water | Molding curing 0.17 h, air curing 24 × 28 h | [29] |

| 11 | 0.18–0.38/0.38–0.83 mass ration 1:1 | 25 | Cement, sand, activated carbon, water | Air cured 7 × 24 h | [6,10,13] |

| Type | Name | Remarks |

|---|---|---|

| Aggregate | Coal powder | 1–2 mm and 0–0.5 mm coal particles |

| Binder | Gypsum (The Group of TZU She Tang Gypsum, Taiwan, China) | Particle size 0.048 mm, density 2.3 g/cm3, fast-hardening for 15–45 min |

| Petrolatum (Dezhouchengze Co., LTD, Dezhou, in Shandong Province, China) | Medical grade, density 0.83 g/cm3 | |

| Auxiliary material | Light Calcium carbonate (Darui Chemical Co., LTD, Gaoan, in Jiangxi Province, China) | Ultra-fine, ultra-white, light calcium carbonate, 0.1 μm < particle size ≤ 1 μm, stable performance, density 0.54 g/cm3 |

| Water | Tap water |

| Factor | A-Aggregate/ Binder | B-Coarse/Fine Aggregate | C-Gypsum/ Petrolatum | D-Calcium Carbonate (%) | |

|---|---|---|---|---|---|

| Level | |||||

| 1 | 6:1 | 1:9 | 5:5 | 2 | |

| 2 | 7:1 | 2:8 | 6:4 | 3 | |

| 3 | 8:1 | 3:7 | 7:3 | 4 | |

| 4 | 9:1 | 4:6 | 8:2 | 5 | |

| 5 | 10:1 | 5:5 | 9:1 | 6 | |

| Factor | Aggregate/Binder | Coarse/Fine Aggregate | Gypsum/Petrolatum | Calcium Carbonate (%) | |

|---|---|---|---|---|---|

| Group No. | |||||

| 1 | 6:1 | 1:9 | 5:5 | 2 | |

| 2 | 6:1 | 2:8 | 6:4 | 3 | |

| 3 | 6:1 | 3:7 | 7:3 | 4 | |

| 4 | 6:1 | 4:6 | 8:2 | 5 | |

| 5 | 6:1 | 5:5 | 9:1 | 6 | |

| 6 | 7:1 | 1:9 | 6:4 | 4 | |

| 7 | 7:1 | 2:8 | 7:3 | 5 | |

| 8 | 7:1 | 3:7 | 8:2 | 6 | |

| 9 | 7:1 | 4:6 | 9:1 | 2 | |

| 10 | 7:1 | 5:5 | 5:5 | 3 | |

| 11 | 8:1 | 1:9 | 7:3 | 6 | |

| 12 | 8:1 | 2:8 | 8:2 | 2 | |

| 13 | 8:1 | 3:7 | 9:1 | 3 | |

| 14 | 8:1 | 4:6 | 5:5 | 4 | |

| 15 | 8:1 | 5:5 | 6:4 | 5 | |

| 16 | 9:1 | 1:9 | 8:2 | 3 | |

| 17 | 9:1 | 2:8 | 9:1 | 4 | |

| 18 | 9:1 | 3:7 | 5:5 | 5 | |

| 19 | 9:1 | 4:6 | 6:4 | 6 | |

| 20 | 9:1 | 5:5 | 7:3 | 2 | |

| 21 | 10:1 | 1:9 | 9:1 | 5 | |

| 22 | 10:1 | 2:8 | 5:5 | 6 | |

| 23 | 10:1 | 3:7 | 6:4 | 2 | |

| 24 | 10:1 | 4:6 | 7:3 | 3 | |

| 25 | 10:1 | 5:5 | 8:2 | 4 | |

| No. | Density (g/cm3) | UCS (MPa) | E (MPa) | Cohesion (MPa) | F (°) |

|---|---|---|---|---|---|

| 1 | 1.235 | 0.67 | 39.76 | 0.131 | 17.4 |

| 2 | 1.248 | 1.24 | 76.22 | 0.153 | 23.8 |

| 3 | 1.251 | 1.68 | 91.90 | 0.192 | 27.2 |

| 4 | 1.253 | 1.82 | 141.45 | 0.201 | 32.4 |

| 5 | 1.242 | 1.74 | 152.75 | 0.248 | 35.6 |

| 6 | 1.228 | 0.91 | 35.11 | 0.132 | 18.2 |

| 7 | 1.229 | 1.49 | 108.22 | 0.164 | 20.4 |

| 8 | 1.231 | 1.94 | 163.66 | 0.185 | 27.8 |

| 9 | 1.296 | 2.05 | 181.85 | 0.203 | 32.8 |

| 10 | 1.176 | 0.55 | 32.06 | 0.089 | 28.2 |

| 11 | 1.223 | 1.16 | 63.90 | 0.152 | 18.7 |

| 12 | 1.289 | 1.72 | 111.81 | 0.173 | 21.1 |

| 13 | 1.305 | 2.20 | 196.18 | 0.201 | 30.1 |

| 14 | 1.188 | 0.89 | 63.11 | 0.073 | 23.7 |

| 15 | 1.184 | 0.79 | 49.05 | 0.095 | 28.9 |

| 16 | 1.256 | 1.39 | 64.43 | 0.164 | 21.6 |

| 17 | 1.252 | 1.94 | 163.59 | 0.213 | 24 |

| 18 | 1.172 | 0.99 | 60.69 | 0.068 | 23.4 |

| 19 | 1.171 | 1.13 | 84.24 | 0.089 | 25.6 |

| 20 | 1.212 | 1.04 | 55.07 | 0.119 | 29.8 |

| 21 | 1.238 | 1.61 | 97.41 | 0.191 | 22.4 |

| 22 | 1.181 | 0.77 | 49.24 | 0.061 | 16.8 |

| 23 | 1.218 | 1.23 | 74.83 | 0.078 | 22.2 |

| 24 | 1.211 | 1.38 | 93.58 | 0.108 | 27.4 |

| 25 | 1.209 | 1.27 | 77.25 | 0.128 | 30.6 |

| TDC | 1.280 | 1.72 | 126.35 | 0.17 | 27 |

| Level | Average Density (g/cm3) | Average UCS (MPa) | Average EM (MPa) | Average Cohesion (MPa) | Average IFA (°) | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | A | B | C | D | A | B | C | D | A | B | C | D | A | B | C | D | |

| 1 | 1.246 | 1.236 | 1.190 | 1.250 | 1.43 | 1.15 | 0.77 | 1.34 | 100.41 | 60.12 | 48.97 | 92.66 | 0.185 | 0.154 | 0.084 | 0.141 | 27.28 | 19.66 | 21.90 | 24.66 |

| 2 | 1.232 | 1.240 | 1.210 | 1.239 | 1.39 | 1.43 | 1.06 | 1.35 | 104.18 | 101.82 | 63.89 | 92.49 | 0.155 | 0.153 | 0.109 | 0.143 | 25.48 | 21.22 | 23.74 | 26.22 |

| 3 | 1.238 | 1.235 | 1.225 | 1.226 | 1.35 | 1.61 | 1.35 | 1.34 | 96.81 | 117.45 | 82.53 | 86.19 | 0.139 | 0.145 | 0.147 | 0.148 | 24.50 | 26.14 | 24.70 | 24.74 |

| 4 | 1.213 | 1.224 | 1.248 | 1.215 | 1.30 | 1.45 | 1.62 | 1.34 | 85.60 | 112.84 | 111.72 | 91.36 | 0.131 | 0.135 | 0.170 | 0.144 | 24.88 | 28.38 | 26.70 | 25.50 |

| 5 | 1.211 | 1.205 | 1.267 | 1.210 | 1.25 | 1.08 | 1.91 | 1.35 | 78.46 | 73.23 | 158.36 | 102.76 | 0.113 | 0.136 | 0.211 | 0.147 | 23.88 | 30.62 | 28.98 | 24.90 |

| Range | 0.035 | 0.035 | 0.076 | 0.040 | 0.18 | 0.53 | 1.14 | 0.01 | 25.72 | 57.33 | 109.39 | 11.39 | 0.07 | 0.02 | 0.13 | 0.01 | 3.40 | 10.96 | 7.08 | 1.56 |

| Sample | Apparent Density (g/cm3) | True Density (g/cm3) | Mass Ratio of Coal Powder (%) | Porosity (%) |

|---|---|---|---|---|

| TDC | 1.268 | 1.573 | - | 15.3 |

| No. 4 | 1.241 | 1.558 | 81.43 | 15.7 |

| No. 8 | 1.277 | 1.623 | 82.25 | 16.1 |

| No. 12 | 1.293 | 1.691 | 87.11 | 17.4 |

| No. 17 | 1.240 | 1.591 | 86.40 | 16.9 |

| Sample | a (cm3/g) | b (1/MPa) | Δp (mL/s) |

|---|---|---|---|

| TDC | 39.789 | 1.113 | 27 |

| No. 4 | 35.258 | 1.169 | 23 |

| No. 8 | 35.463 | 1.163 | 23 |

| No. 12 | 37.944 | 1.137 | 25 |

| No. 17 | 37.562 | 1.146 | 24 |

| Sample | Apparent Density (g/cm3) | UCS (MPa) | EM (MPa) | Cohesion (MPa) | IFA (°) | Porosity (%) | a | Δp |

|---|---|---|---|---|---|---|---|---|

| Coal-like material | 1.286 | 1.78 | 131.85 | 0.18 | 25.8 | 17.1 | 38.343 | 25 |

| TDC | 1.280 | 1.72 | 126.35 | 0.17 | 27 | 15.3 | 39.789 | 27 |

| Difference (%) | +0.47 | +3.49 | +4.35 | −5.9 | −4.44 | +11.76 | −3.63 | −7.41 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.; Xie, W.; Su, Z.; Tang, Q. Experimental Development of Coal-Like Material with Solid-Gas Coupling for Quantitative Simulation Tests of Coal and Gas Outburst Occurred in Soft Coal Seams. Processes 2019, 7, 155. https://doi.org/10.3390/pr7030155

Wang X, Xie W, Su Z, Tang Q. Experimental Development of Coal-Like Material with Solid-Gas Coupling for Quantitative Simulation Tests of Coal and Gas Outburst Occurred in Soft Coal Seams. Processes. 2019; 7(3):155. https://doi.org/10.3390/pr7030155

Chicago/Turabian StyleWang, Xingkai, Wenbing Xie, Zhili Su, and Qingteng Tang. 2019. "Experimental Development of Coal-Like Material with Solid-Gas Coupling for Quantitative Simulation Tests of Coal and Gas Outburst Occurred in Soft Coal Seams" Processes 7, no. 3: 155. https://doi.org/10.3390/pr7030155

APA StyleWang, X., Xie, W., Su, Z., & Tang, Q. (2019). Experimental Development of Coal-Like Material with Solid-Gas Coupling for Quantitative Simulation Tests of Coal and Gas Outburst Occurred in Soft Coal Seams. Processes, 7(3), 155. https://doi.org/10.3390/pr7030155