Availability Assessment of IMA System Based on Model-Based Safety Analysis Using AltaRica 3.0

Abstract

1. Introduction

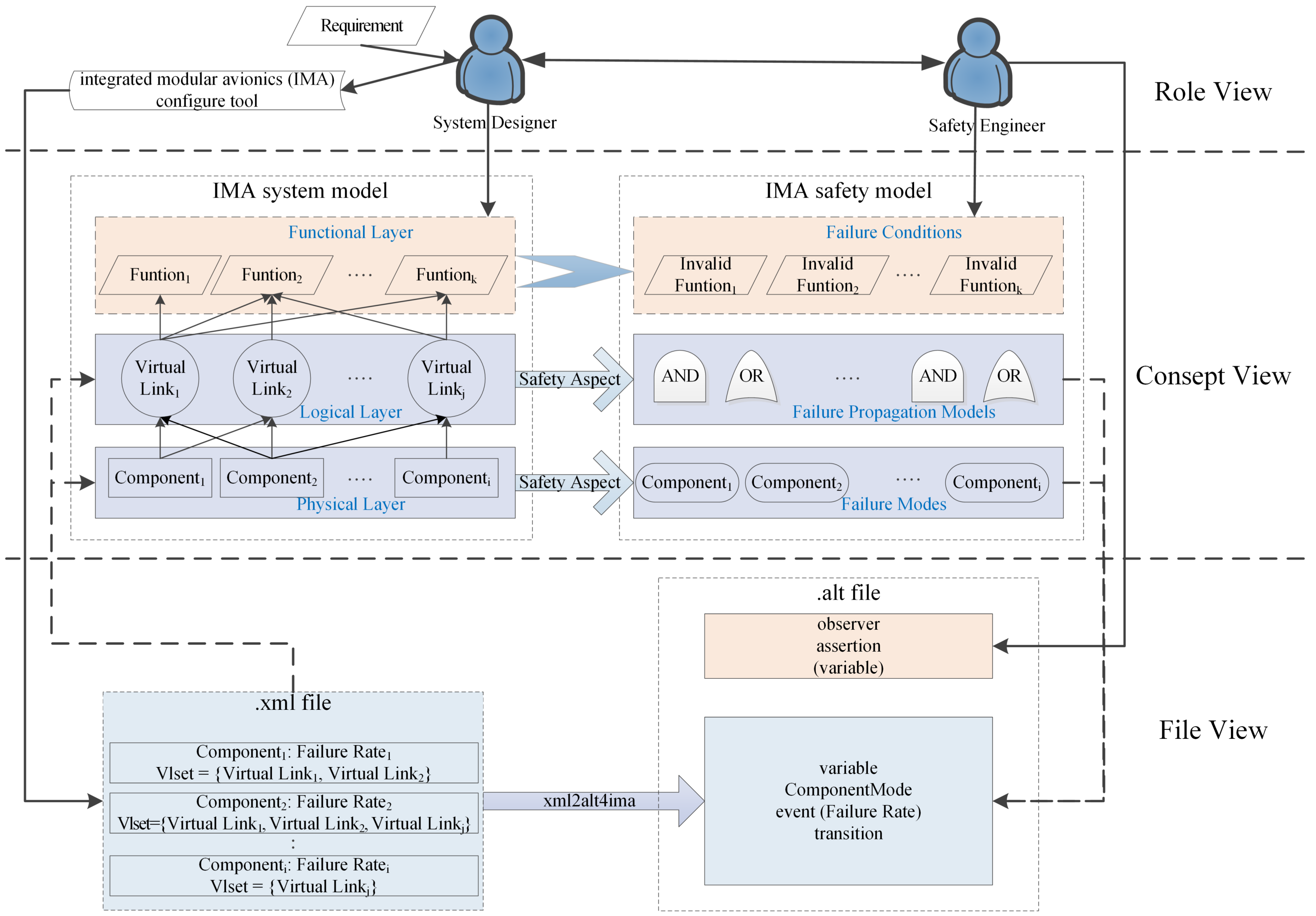

2. Assessment Method

- Step 1. Define the failure condition of the IMA system and their safety requirements.The failure condition means an unexpected state. It is always a logical combination of some unexpected states. For the IMA system, it means an invalid function.

- Step 2. Utilize the special generation tool (xml2alt4ima) to generate an alt file based on the configuration xml file.The xml2alt4ima tool is designed to aid the construction of the alt file according to the xml configure file.

- Step 3. Manually add the observer, assertion, and variables if needed.Complete the alt file manually. The observer is used to represent the failure condition and complex function. The assertion contains some sentences to represent the logical relationship. Variables provide assistance in understanding the logical relationship between the failure condition and failure mode. In addition, we need to add a variable named “failed”, which is used to represent the top event of the fault tree.

- Step 4. Utilize the AltaRica 3.0 assessment tool to compile the alt file, and obtain the cut set, probability, contribution, and so on.The AltaRica 3.0 compiler can explain the meaning of the alt file. We recommend the free OpenAltaRica tool [22], which integrates many analysis functions.

| Algorithm 1 The algorithm to generate the alt file from the configuration xml file of the IMA system. |

| Input: xml file, including m (m≥1) components with failure rate and configured VLs; |

| Output: alt file, including file structure, event, transition and required variable; |

| 1: Begin initialization |

| 2: Define the domain of ComponentMode for all components |

| 3: End initialization |

| 4: m⇐ the quantity of the components in the xml file |

| 5: For component i (1≤i≤m) |

| 6: ⇐ the failure rate of component i |

| 7: Define the state of component i based on ComponentMode |

| 8: Define the event for component i with |

| 9: Define the transition of component i based on event |

| 10: n ⇐ the quantity of the VLs configured in component i |

| 11: For VL j (1≤j≤n) |

| 12: Define variables for VL j configured in component i |

| 13: p ⇐ he quantity of components in the actual path through VL j |

| 14: For component k (1≤k≤p) |

| 15: Add action for VL j in the transition configured in component i |

| 16: End component k |

| 17: End VL j |

| 18: End component i |

| 19: Delete redundant variables for VL |

| 20: Begin modification |

| 21: Add assertion for the failure condition |

| 22: Add block for the whole model |

| 23: End modification |

3. Case Study

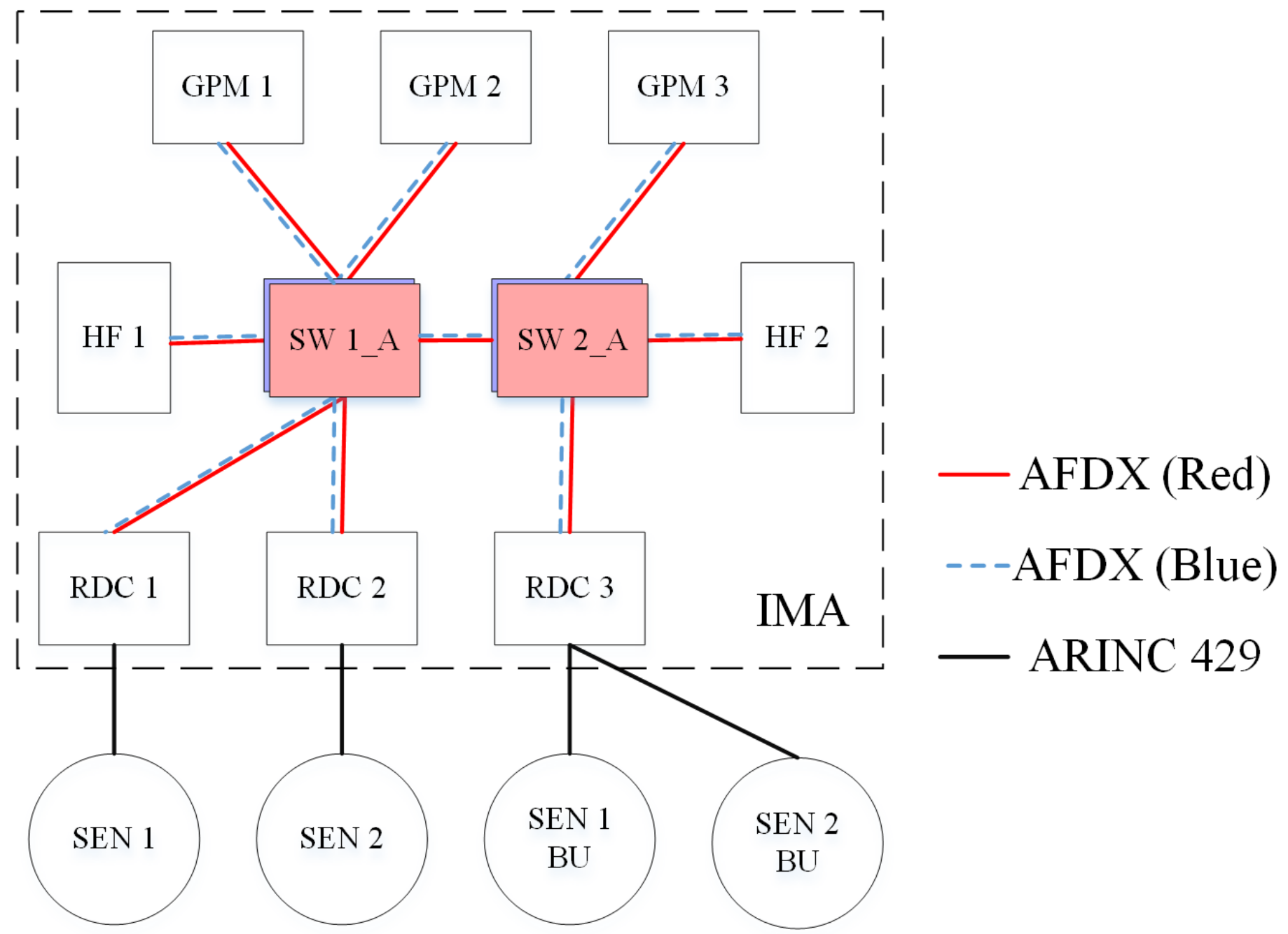

3.1. IMA System Model

3.2. Assumption and Failure Definition

- Faults are modeled as statistically independent distributed events;

- The failure rate of each component is a constant;

- A fault occurs instantaneously and at most one fault event in a minimum time slice;

- The system and its components have two states: normal and failure;

- The system and its components are unrepairable while in use;

- The cable between two components keeps working.

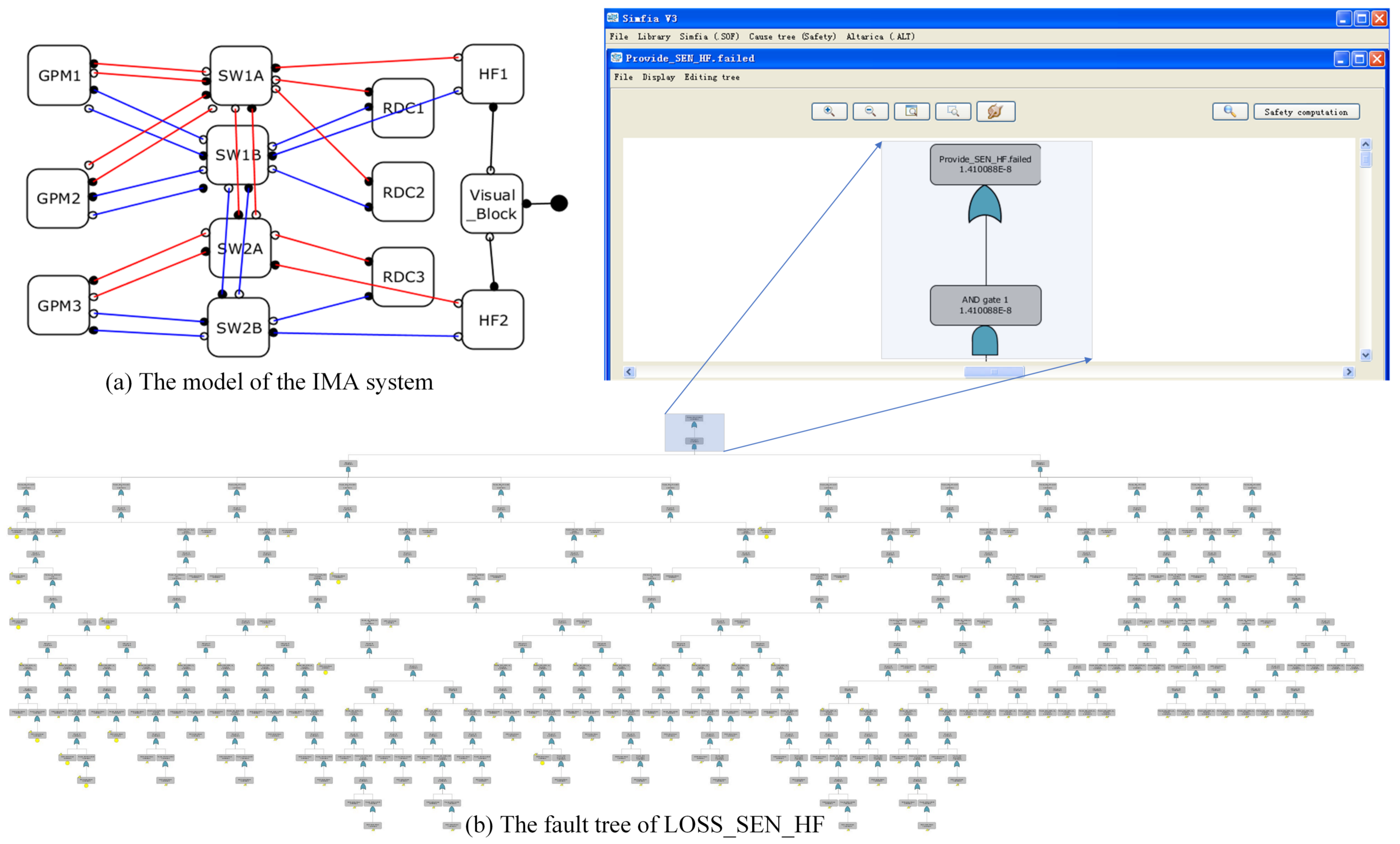

3.3. Results

3.4. Optimization of the IMA System

3.5. Efficiency of Safety Assessment Process

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| IMA | Integrated Modular Avionics |

| AFDX | Avionics Full Duplex Switched Ethernet |

| VL | Visual Link |

| FTA | Fault Tree Analysis |

| MBSA | Module Based Safety Analysis |

| ARP | Aerospace Recommended Practice |

| GTS | Guarded Transition Systems |

| FPM | Failure Propagation Model |

| CARERI | China National Aeronautical Radio Electronics Research Institute |

| ICD | Interface Control Document |

| GPM | General Processing Module |

| RDC | Remote Data Concentrator |

| HF | Hosted Function |

| SW | Switch |

| SEN | Sensor |

| BU | Backup |

| ARINC | Aeronautical Radio Inc. |

| MTBF | Mean Time Between Failure |

| LRU | Line Replaceable Unit |

| DAL | Development Assurance Level |

| KB | Kilo Byte |

| OPSA | Open Probabilistic Safety Assessment |

References

- Windsor, J.; Deredempt, M.H.; de Ferluc, R. Integrated modular avionics for spacecraft spacecraft-user requirements, architecture and role definition. In Proceedings of the IEEE/AIAA 30th Digital Avionics Systems Conference (DASC 2011), Seattle, WA, USA, 16–20 October 2011; pp. 8A6:1–8A6:16. [Google Scholar]

- DO297. Integrated Modular Avionics; RTCA, Inc.: Washington, DC, USA, 2005. [Google Scholar]

- Watkins, C.B.; Walter, R. Transitioning from federated avionics architectures to integrated modular avionics. In Proceedings of the IEEE/AIAA 26th Digital Avionics Systems Conference (DASC 2007), Dallas, TX, USA, 21–25 October 2007; pp. 2.A.1:1–2.A.1:10. [Google Scholar]

- Itier, J.B. A380 Integrated Modular Avionics. Available online: http://www.artist-embedded.org/docs/Events/2007/IMA/Slides/ARTIST2_IMA_Itier.pdf (accessed on 21 December 2018).

- Alena, R.L.; Ossenfort, J.P.; Laws, K.I.; Goforth, A.; Figueroa, F. Communications for Integrated Modular Avionics. In Proceedings of the 2007 IEEE Aerospace Conference, Big Sky, MT, USA, 3–10 March 2007; pp. 1–18. [Google Scholar]

- ARP4754A. Guidelines for Development of Civil Aircraft and Systems; SAE International: Warrendale, PA, USA, 2010. [Google Scholar]

- Güdemann, M. Qualitative and Quantitative Formal Model-Based Safety Analysis: Push the Safety Button. Ph.D. Thesis, Otto von Guericke University Magdeburg, Magdeburg, Germany, 2011. [Google Scholar]

- Hönig, P.; Lunde, R.; Holzapfel, F. Model Based Safety Analysis with smartIflow. Information 2017, 8, 7. [Google Scholar] [CrossRef]

- Morel, M. Model-Based Safety Approach for Early Validation of Integrated and Modular Avionics Architectures. In Proceedings of the 4th International Model-Based Safety and Assessment (IMBSA 2014), Munich, Germany, 27–29 October 2014; pp. 57–69. [Google Scholar]

- Issad, M.; Kloul, L.; Rauzy, A. A Model-Based Methodology to Formalize Specifications of Railway Systems. In Proceedings of the 4th International Model-Based Safety and Assessment (IMBSA 2014), Munich, Germany, 27–29 October 2014; pp. 28–42. [Google Scholar]

- Papadopoulos, Y.; Grante, C. Evolving car designs using model-based automated safety analysis and optimisation techniques. J. Syst. Softw. 2005, 76, 77–89. [Google Scholar] [CrossRef]

- Lisagor, O.; Kelly, T.; Niu, R. Model-based safety assessment: Review of the discipline and its challenges. In Proceedings of the IEEE 9th International Conference on Reliability, Maintainability and Safety (ICRMS 2011), Guiyang, China, 12–15 June 2011; pp. 625–632. [Google Scholar]

- ARP 4761A (Draft) Associated Appendix. Model Based Safety Analysis; SAE International: Warrendale, PA, USA. (In Press)

- Prosvirnova, T.; Batteux, M.; Brameret, P.A.; Cherfi, A.; Friedlhuber, T.; Roussel, J.M.; Rauzy, A. The altarica 3.0 project for model-based safety assessment. In Proceedings of the 4th IFAC Workshop on Dependable Control of Discrete Systems (DCDS 2013), York, UK, 4–6 September 2013; pp. 1–7. [Google Scholar]

- Prosvirnova, T. Altarica 3.0: A Model-Based Approach for Safety Analyses. Ph.D. Thesis, Ecole Polytechnique, Palaiseau, France, 2014. [Google Scholar]

- Mortada, H.; Prosvirnova, T.; Rauzy, A. Safety assessment of an electrical system with AltaRica 3.0. In Proceedings of the 4th International Model-Based Safety and Assessment (IMBSA 2014), Munich, Germany, 27–29 October 2014; pp. 181–194. [Google Scholar]

- Brameret, P.A.; Rauzy, A.; Roussel, J.M. Automated generation of partial Markov chain from high level descriptions. Reliab. Eng. Syst. Saf. 2015, 139, 179–187. [Google Scholar] [CrossRef]

- Li, S.; Duo, S. A practicable mbsa modeling process using Altarica. In Proceedings of the 4th International Model-Based Safety and Assessment (IMBSA 2014), Munich, Germany, 27–29 October 2014; pp. 1–13. [Google Scholar]

- Gu, Q.; Wang, G.; Zhai, M. Model-based safety analysis for integrated avionics system. In Proceedings of the 14th AIAA Aviation Technology, Integration, and Operations Conference (ATIO 2014), Atlanta, GA, USA, 16–20 June 2014; pp. 2226:1–2226:8. [Google Scholar]

- Joshi, A.; Miller, S.P.; Whalen, M.; Heimdahl, M.P.E. A proposal for model-based safety analysis. In Proceedings of the 24th IEEE Digital Avionics Systems Conference (DASC 2005), Washington, DC, USA, 30 October–3 November 2005; pp. 13:1–13:12. [Google Scholar]

- Design Assurance Guidance for Airborne Electronic Hardware; DO254; RTCA, Inc.: Washington, DC, USA, 2005.

- OpenAltaRica web page. Available online: http://openaltarica.fr/ (accessed on 21 December 2018).

- Ananda, C.M.; Venkatanarayana, K.G.; Preme, M.; Raghu, M. Avionics systems, integration, and technologies of the light transport aircraft. Def. Sci. J. 2011, 61, 289–298. [Google Scholar] [CrossRef]

- Moir, I.; Seabridge, A.; Jukes, M. Civil Avionics Systems; John Wiley & Sons Ltd.: West Sussex, UK, 2013; ISBN 978-1-118-34180-3. [Google Scholar]

- Tu, J.; Cheng, R.; Tao, Q. Reliability analysis method of safety critical avionics system based on dynamic fault tree under fuzzy uncertainty. Mt. Reliab. 2015, 17, 156–163. [Google Scholar] [CrossRef]

- Dugan, J.B.; Bavuso, S.J.; Boyd, M.A. Dynamic fault-tree models for fault-tolerant computer systems. IEEE Trans. Reliab. 1992, 41, 363–377. [Google Scholar] [CrossRef]

- Jukes, M. Aircraft Sisplay Systems; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2004; ISBN 978-1-56347-657-0. [Google Scholar]

- RDC booklet of Flight Data Systems. Available online: https://www.flightdata.aero/static/uploads/files/fds-rdc-final-wfvctuhozukm.pdf (accessed on 21 December 2018).

- Guidelines and Methods for Conducting the Safety Assessment Process on Civil Airborne Systems and Equipment; ARP4761; SAE International: Warrendale, PA, USA, 1996.

- Aupetit, B.; Batteux, M.; Rauzy, A.; Roussel, J.M. Improving performances of the altarica 3.0 stochastic simulator. In Proceedings of the 25th European Safety and Reliability Conference (ESREL 2015), Zurich, Switzerland, 7–10 September 2015; pp. 1815–1823. [Google Scholar]

- Open-PSA Format Web Page. Available online: http://www.open-psa.org/ (accessed on 21 December 2018).

- Yakymets, N.; Jaber, H.; Lanusse, A. Model-based system engineering for fault tree generation and analysis. In Proceedings of the 1st International Conference on Model-Driven Engineering and Software Development (MODELSWARD 2013), Barcelona, Spain, 19–21 February 2013; pp. 210–214. [Google Scholar]

| Component | Mean Time Between Failure (MTBF) | Failure Rate per Flight Hour |

|---|---|---|

| Sensor (SEN) | 20,000 h | |

| Switch (SW) | 100,000 h | |

| Remote data concentrator (RDC) | 14,000 h | |

| Hosted function (HF) | 16,000 h | |

| General processing module (GPM) | 50,000 h |

| Rank | Minimal Cut Set | Probability |

|---|---|---|

| 1 | rdc1_f, rdc3_f | |

| 2 | rdc2_f, rdc3_f | |

| 3 | hf1_f, hf2_f | |

| 4 | gpm1_f, gpm2_f, gpm3_f | |

| 5 | rdc1_f, sw2A_f, sw2B_f | |

| 6 | rdc2_f, sw2A_f, sw2B_f | |

| 7 | rdc3_f, sw1A_f, sw1B_f | |

| 8 | hf1_f, sw2A_f, sw2B_f | |

| 9 | hf2_f, sw1A_f, sw1B_f | |

| 10 | gpm3_f, sw1A_f, sw1B_f | |

| 11 | hf2_f, rdc1_f, sw1A_f, sw2B_f | |

| ⋮ | ⋮ | ⋮ |

| Configuration | Probability of LOSS_SEN_HF |

|---|---|

| without GPM1 | |

| without GPM2 | |

| without GPM3 |

| Main Steps | MBSA | Simfia | Relex |

|---|---|---|---|

| 1. Definition of components | [auto] Define the ComponentMode by xml2alt4ima [source] system model (xml file) | [manually] Create the blocks as the components of system | [manually] Define the basic event of the fault tree |

| 2. Configuration of components | [auto] Get the failure rate for every component; Define the event with corresponding failure rate by xml2alt4ima [source] system model (xml file) | [manually] Set the failure rate for every block; Create the connector to link the blocks; Set the state types of IN/OUT port of each connector | [manually] Set the failure rate for every basic event; Define the gate; Set the gate type |

| 3. Modeling of logical causes | [auto] Add the transition as the relationship between Visual Links and Components by xml2alt4ima [source] system model (xml file) | [manually] Set the logical causes of every state type of each OUT connector | [manually] Connect the gate with other gates and basic events |

| 4. Definition of failure condition | [manually] Add an observer for the failure condition | [manually] Define a new block for the failure condition | [manually] Define the gate as the top event of the fault tree |

| 5. Configuration of failure condition | [manually] Build the assertion as the relationship between Failure condition and Visual Links | [manually] Create the connector to link the new blocks; Set the state types of IN/OUT port of each connector; Set the logical causes of every state type of each OUT connector | [manually] Connect the top event gate with other gates and basic events |

| 6. Obtain the fault tree | [auto] Generated by OpenAltaRica [source] safety model (alt file) | [auto] Generate the fault tree [source] safety model | [manually] Build the fault tree from top to down |

| 7. Obtain the cut set of failure condition | [auto] Obtain the cut set of failure condition [source] fault tree (opsa file) | [auto] Obtain the cut set of failure condition [source] safety model | [auto] Obtain the cut set of failure condition [source] fault tree |

| 8. Calculate the availability | [auto] Calculate the availability [source] fault tree (opsa file) | [auto] Calculate the availability [source] safety model | [auto] Calculate the availability [source] fault tree |

| Case 1 | Case 2 | Case 3 | |||||||

|---|---|---|---|---|---|---|---|---|---|

| MBSA | Simfia | Relex | MBSA | Simfia | Relex | MBSA | Simfia | Relex | |

| Quantity of components in model | 10 Components | 12 Components | 15 Components | ||||||

| Time for modeling | ≈1 h | ≈4 h | ≈6 h | ≈1 h | ≈6 h | ≈10 h | ≈1 h | ≈8 h | ≈12 h |

| Time for generating fault tree | <1 min | <10 s | none | <10 min | < 10 s | none | <1 h | <1 min | none |

| Quantity of gates and basic events | 1254 | 167 | 84 | 5828 | 232 | 115 | 45,844 | 282 | 136 |

| Time for calculating the cut set | <1 min | <10 s | <10 s | 1 min | <10 s | <10 s | 1 min | <10 s | <10 s |

| Time for remodeling e | ≈40 min | ≈1 h | ≈3 h | ≈1 h | ≈2 h | ≈5 h | ≈1 h | ≈3 h | ≈6 h |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dong, H.; Gu, Q.; Wang, G.; Zhai, Z.; Lu, Y.; Wang, M. Availability Assessment of IMA System Based on Model-Based Safety Analysis Using AltaRica 3.0. Processes 2019, 7, 117. https://doi.org/10.3390/pr7020117

Dong H, Gu Q, Wang G, Zhai Z, Lu Y, Wang M. Availability Assessment of IMA System Based on Model-Based Safety Analysis Using AltaRica 3.0. Processes. 2019; 7(2):117. https://doi.org/10.3390/pr7020117

Chicago/Turabian StyleDong, Haiyong, Qingfan Gu, Guoqing Wang, Zhengjun Zhai, Yanhong Lu, and Miao Wang. 2019. "Availability Assessment of IMA System Based on Model-Based Safety Analysis Using AltaRica 3.0" Processes 7, no. 2: 117. https://doi.org/10.3390/pr7020117

APA StyleDong, H., Gu, Q., Wang, G., Zhai, Z., Lu, Y., & Wang, M. (2019). Availability Assessment of IMA System Based on Model-Based Safety Analysis Using AltaRica 3.0. Processes, 7(2), 117. https://doi.org/10.3390/pr7020117