1. Introduction

The global economy is rapidly changing, and technological innovation has become more important due to the trajectory of technology, short product life cycles, and globalization. It is necessary to develop new models of planning in project management and transferring technologies to achieve sustainability in global markets. For the automobile industry, acquiring innovative technologies can be a source of a firm’s long-term success. The technology strategy has become one of the most significant factors for a firm to consider when making a business decision. There are two ways to obtain technology to increase a firm’s competitiveness: self-research and development (R&D) and technology transfer.

Parker, D., et al., 1998, suggested that technology transfer is a strategic component of innovation activity [

1]. According to the efficient implementation of technologies, the transmission mechanism industry can intensify the implementation and development processes of high-tech innovations in production activities and gain additional competitive advantages. Effective technology transfer accelerates innovation processes at regional, national and transnational levels [

2,

3]. The study of the process of technological transfer is necessary to evaluate benefits of technology transfer and ways to achieve these benefits. Dyer (1998) and Stuart (1988) have studied the relationship characteristics between alliance partners, including the effects of the relative position and reputation of each partner firm, the strategic similarity of the firms, and their former relationship [

4,

5,

6].

The commercialization of technology in developed and innovation-driven countries (USA, Germany, South Korea, etc.) is the foundation of global competitiveness, which actualizes the need for significant efforts to support and develop the production of knowledge, high technology, and innovation in various fields of activity. One of the catalyzers for the development of innovation is scientific activity, as a basis for the development of knowledge and the creation of high technology. Many empirical studies have examined how technology transfer influences investment in self-R&D expenditure. Most authors (Odagiri, 1983; Braga and Wilmore, 1991; Deolalikar and Evenson, 1993; Zhao, 1995; Hu et al., 2005) show that a complementary relationship exists between technology transfer and self-R&D, confirming that there is a positive effect [

7,

8,

9,

10,

11].

In global practice, the construction of infrastructure for support innovation is carried out within a number of organizational forms, such as “Technopolice”, zones for the development of innovative and high technologies, science and technology parks, innovation and technology centers, centers for the commercialization of technologies, and business incubators [

12].

To create a mechanism for the optimal interaction of organizations in national and transnational dimensions, modeling should be defined which allows the implementation of the process of technology transfer in the most efficient way. The peculiarity of these parameters is that goals and objectives of each of the participants in the process of technology transfer should be determined well.

In global markets, the technology-transfer process has many risks; for example:

Differences in industry standards;

Different levels of infrastructure;

Unstable logistic systems;

Fluctuations in investment;

Problem with intellectual property rights and technological protection;

Difference in legal and economic national levels;

Difference in competencies and innovation development, etc.

The selection of a technology transfer implementation mechanism should be based on an analysis of the technology itself, the specifics of the future cooperation strategy with its developer, investment opportunities, and the technical ability of organizations in the implementation of innovative technology. When choosing a transfer method, it should be understood that the more complex and larger the scale of technology, the closer an interaction should be organized between its buyers and creators.

Global experience in technology transfer indicates that technological intermediation is necessary to reduce barriers to ways to transfer information awareness technologies, technology management, financing innovative projects, etc. In this case, project management can help global managers to improve technology transfer processes; all the steps of the technology transfer process could be recognized as operations of the project, and so managers may evaluate resources, build an effective network for transfer, and arrange control over the process of technology transfer. For example, Hu et al. (2005) explain the impact of project management tools on effectiveness of R&D in technology transfer process; they confirm that optimization and an effective planning process may reduce R&D transfer risks and create effective transfer process [

11]. Rodgers et al. (1982) discussed the influence of project management tools on communication process in a technology-transfer model [

12].

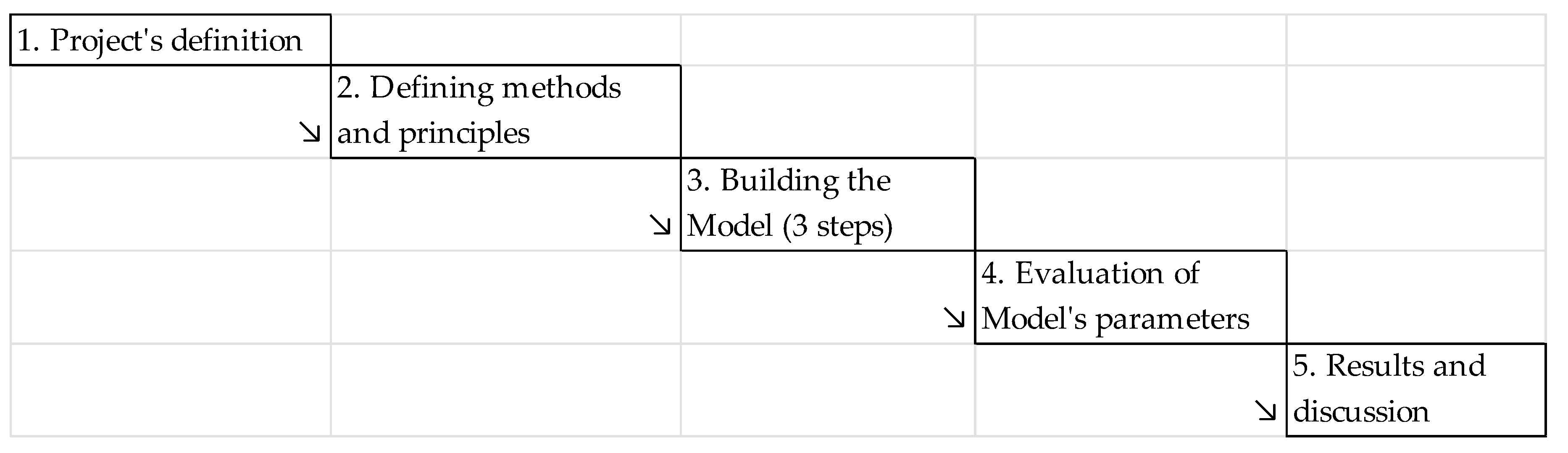

So, three research questions were submitted during the survey to improve the clarity of tasks.

How could project management be used for technology transfer process?

How do Gantt Charts and Critical Path Analysis flow diagrams impact technology transfer projects?

Which results could be achieved in the application of project management tools for technology transfer models?

Research into the transfer of R&D results also emphasizes the role of intermediaries in the innovation process; i.e., technology transfer entities (

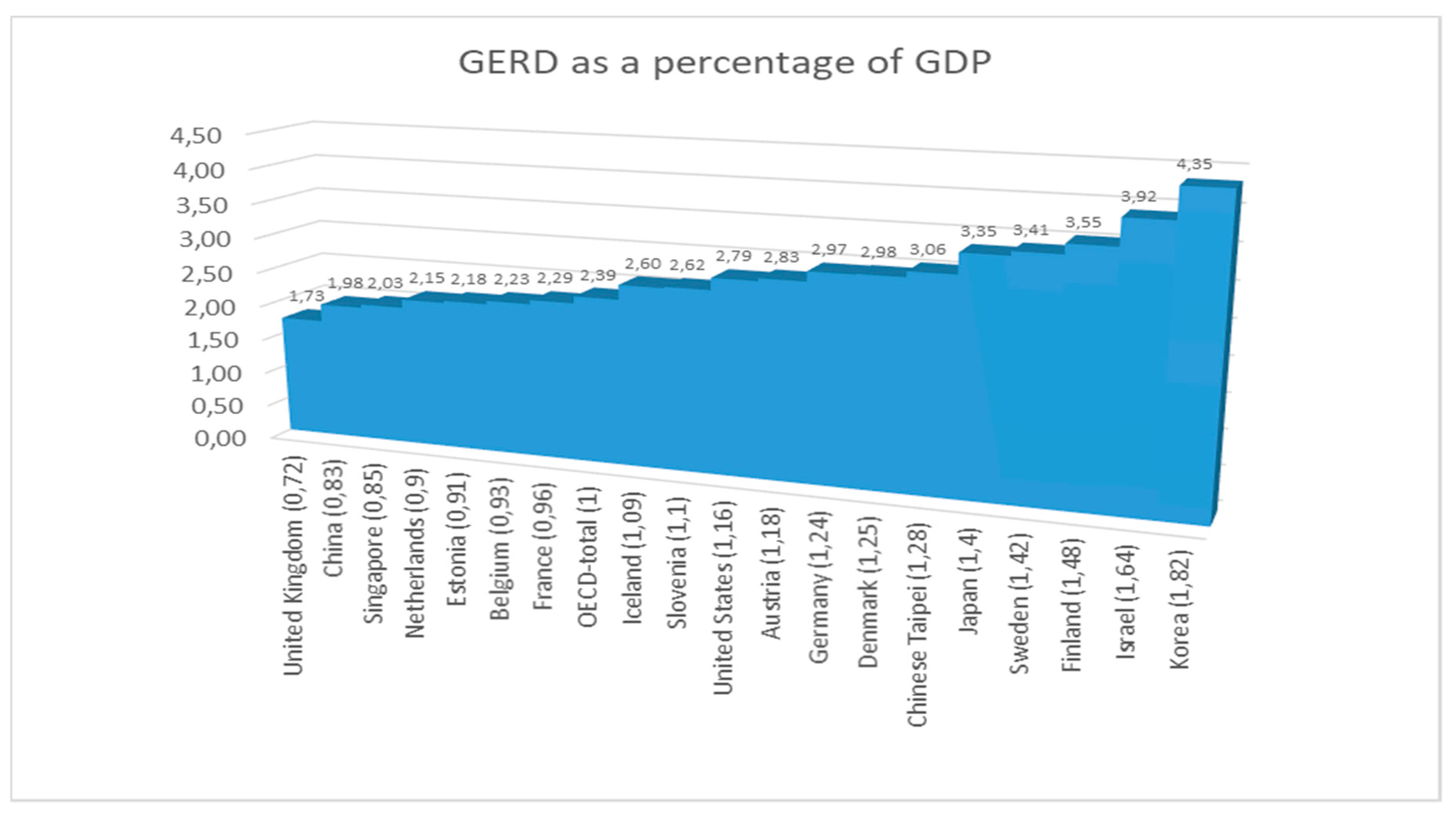

Figure 1).

Figure 1 shows the gross domestic expenditure on research and development (GERD) against the economic scales of each country. It presents the R&D investment amount against the gross domestic product (GDP), based on the data given by the Organization for Economic Cooperation and Development (OECD) in July 2017. When the OECD average was taken as “1”, Korea invested 1.8 times more than the average of OECD and comparatively small countries, such as Israel, Finland, Sweden, and Korea, showed high percentages of R&D investment against their GDPs [

13]. Data subjects build communication between users and technology providers, help create connections in networks and systems through communication between organizations, and encourage interaction within the system and help accomplish search tasks, evaluation, and the dissemination of innovation. The main partners in the technology transfer process in global markets are the headquarters, subsidiary, cluster center, technology broker, consulting agency, training and competence center, R&D center, and financial agency.

Technology intermediaries can act with specialized government agencies, transfer centers technologies, non-governmental organizations, innovation relay centers, departmental university technology transfer, regional technology centers, research and technology organizations, international transfer networks technology, and so on, Korean corporations (such as Samsung; Hyundai; etc.) are currently trying to develop an innovative ecosystem in global markets, which will help them to produce and transfer more innovations and innovative technologies [

14]. The aim of this strategy is to increase global competitiveness and achieve continuous improvement. For example, the Hyundai corporation developed very quickly in the automobile industry—not only in domestic but also in foreign markets—using a technology transfer strategy. For example, Hyundai built its first automobile factory in Russia in 2007, and in 2019, it opened the Global Training Center in Moscow [

15]. This is a good example of the development concept for innovation transfer in a global environment.

An effective planning process plays a main role in the technology transfer process, because it may prevent the risks and problems which were discussed earlier and encourage a more competitive strategy. For this reason, the planning process and its impact on the technology transfer process are discussed in this paper.

2. Theory Framework

2.1. Project Management for Technology Transfer. Technology Transfer Models

There are many definitions of technology transfer by various researchers. Foster (1971) refers to two different methods of technology transfer [

16]: horizontal technology transfer is the transfer of technological knowledge or innovation between projects, organizations, industries, and nations; vertical technology transfer is the transfer of technological knowledge or innovation, from basic to advanced research, from development through to commercialization. Camp and Sexton (1992) define technology transfer as the path of technological knowledge, ideas, and research results from the initial conceiving organization to the user organization, focusing on licensing-in and technological cooperation [

17]. Both approaches to technology transfer involve acquiring innovation from an outside source as well as sharing technological knowledge of their products or processes. Therefore, Camp and Sexton’s definition of technology transfer is based upon Foster’s definition of horizontal technology transfer.

Most of the technology transfer models are based on a project management approach, which means that all the operations in transfer are considered as steps in a project. For example, concerning the content found in the literature, the findings can be divided into three groups. The first refers to papers that present models of technological transfer (Bozeman et al., 2015; Malik, 2002) [

18,

19].

The second group of findings is characterized by case studies where the authors present their experiences in transferring a technology (Burnside and Witkin, 2008; Gorschek et al., 2006) [

20,

21]. Although these papers do not present a model; it is possible to describe the technology transfer process as the elements that are necessary to transfer a technology. This group describes the basic elements that must exist in a technology transfer. It should be noted that in this group a contribution is made in the division of transfer modalities and a mapping between the state of technology and the transfer mechanism.

The third group of findings presents the complementary elements in technology transfer process (Waroonkun and Stewart, 2008; Khabiri et al., 2012) [

22,

23]. These elements are not fundamental to the transfer models; however, they are very helpful for the transfer process as a project to be carried out in the best way.

All of these groups should be evaluated for technology transfer process, so the most popular qualitative technology transfer models are presented in

Table 1.

There are also other non-qualitative models of technology transfer. For example, according to Devine et al., there are three mostly accepted models of technology transfer. They are the most accepted by managers of international corporations according to their corporate goals. For example, first model is the Appropriability Model. It emphasizes the importance of the quality of research and competitive market pressures in achieving technology transfer. This model assumes that good technologies take care of themselves and are successful, but this is seldom true in the real world. So, this model solves the problem of technology customization during the technology-transfer process [

29].

The second model is the Dissemination Model. It focuses on the diffusion of innovation. The goal is to disseminate innovations to individual users. So, this model follows a corporate goal of business diversification [

30].

The third model is the Knowledge Utilization Model, which emphasizes the importance of (1) interpersonal communication between researchers and users; and (2) organizational barriers and facilitators of transfer. So, this model tries to prevent and manage technology transfer risks of communication as a corporate goal.

Radosevich and Radosevich and Smith studied a model for entrepreneurship infrastructure development in the creation of a technopolis [

29,

30]. In their study, they analyzed how to commercialize technologies that are developed by public sector institutions. The two primary modes of commercialization are transferring the technology to an existing firm—i.e., the inventor–entrepreneur model—or working with a new entrepreneurial effort—i.e., the external entrepreneur model [

31].

Jolly (1997) introduced the process perspective into technology commercialization [

32]. He argues that technology commercialization is about performing successfully in a range of activities, each adding value to the technology as it progresses along the commercialization process. Five of these activities constitute the key subprocesses involved in bringing new technologies to market: imagining a techno-market insight; incubating the technology to define its commercializability; demonstrating it contextually in production and/or processes; promoting the latter’s adoption; and sustaining commercialization. As important as these subprocesses are the four bridges between them. These bridges are:

Between bringing new technologies to market and imagining a techno-market insight—the bridge is market-push strategy;

Between incubating the technology to define its commercializability and demonstrating it contextually in production and/or processes—the bridge is market research;

Between demonstrating it contextually in production and/or processes and promoting the latter’s adoption—the bridge is R&D and design concept’s improvement;

Between promoting the latter’s adoption and sustaining commercialization—the bridge is market-pull strategy.

To overcome the limitations of the above-mentioned models, the following four levels of technology transfer are suggested based on Gibson and Smilor’s four-level technology transfer model [

33]. At Level I—technology creation—individuals conduct state-of-the-art research or develop the best practices into knowledge and announce these results by such varied means as research publications, videotapes, teleconferences, news, personal communications, and anecdotes. Level II—technology transfer—calls for the beginnings of shared responsibility between technology developers and users. Success occurs when technology is transferred across personal, functional, or organizational boundaries, and it is accepted and understood by designated users. In Level III transfer, success is marked by the timely and efficient implementation of technology. Technology implementation can occur within the user organization in terms of manufacturing or other processes, or it can occur in terms of services or best practices. Level IV transfer—technology utilization—centers on commercialization. Level IV builds cumulatively on the successes achieved in attaining the objectives of the three previous stages, but market strength is required. Success is measured in terms of the return on investment (ROI) or market share.

Gibson et al. introduce two basic kinds of technology transfer—from research to commercial application—which directly impact the creation of wealth and high-value jobs: (1) the transfer of creative and innovative technologies to established firms; and (2) the spinning-out of technologies into start-up companies [

34].

As it is important to adapt project management tools to the technology transfer process, we here present a comparison of the most useful of them (

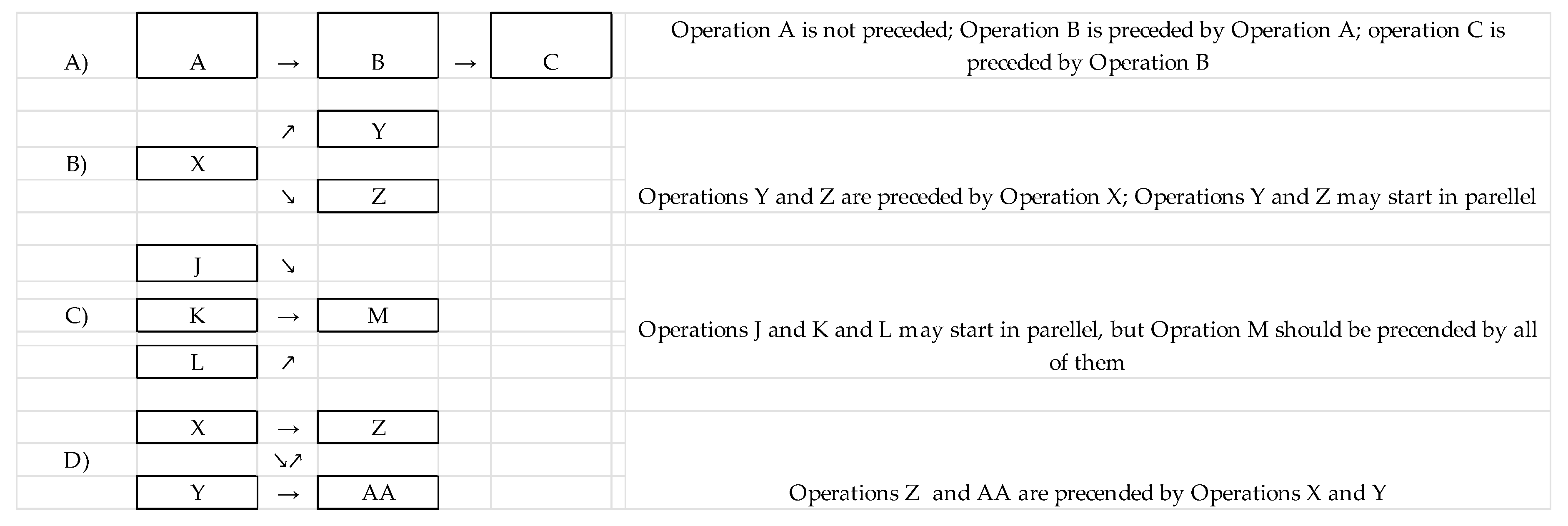

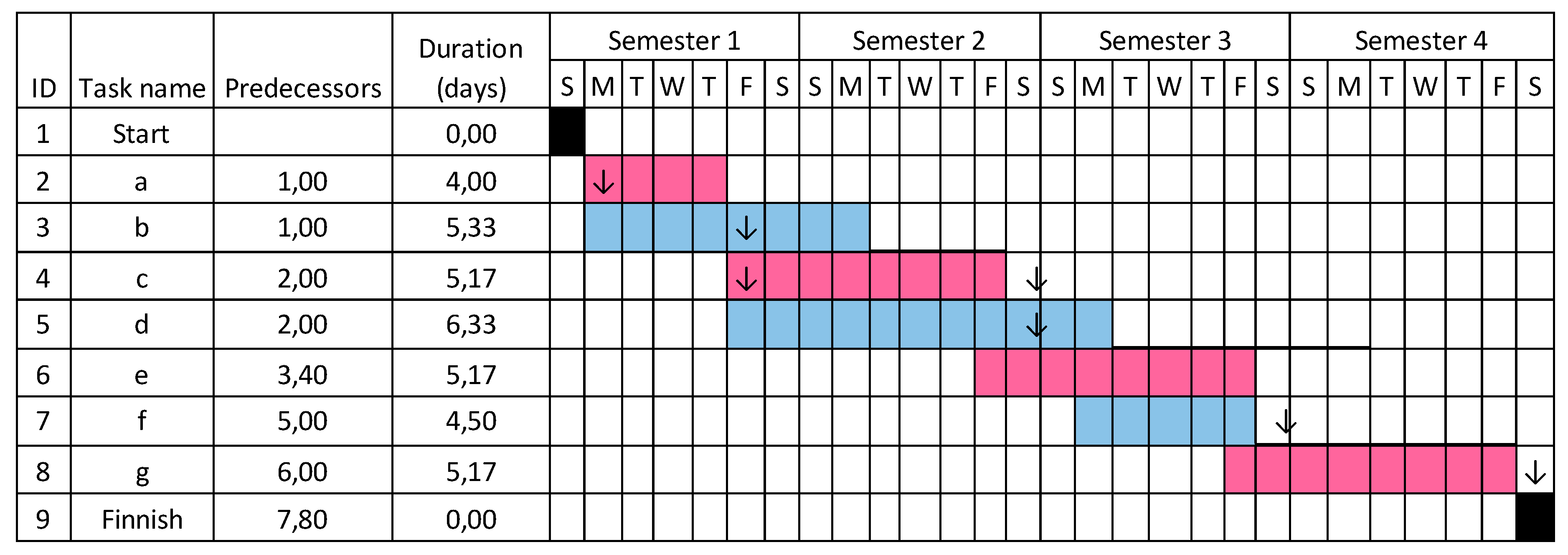

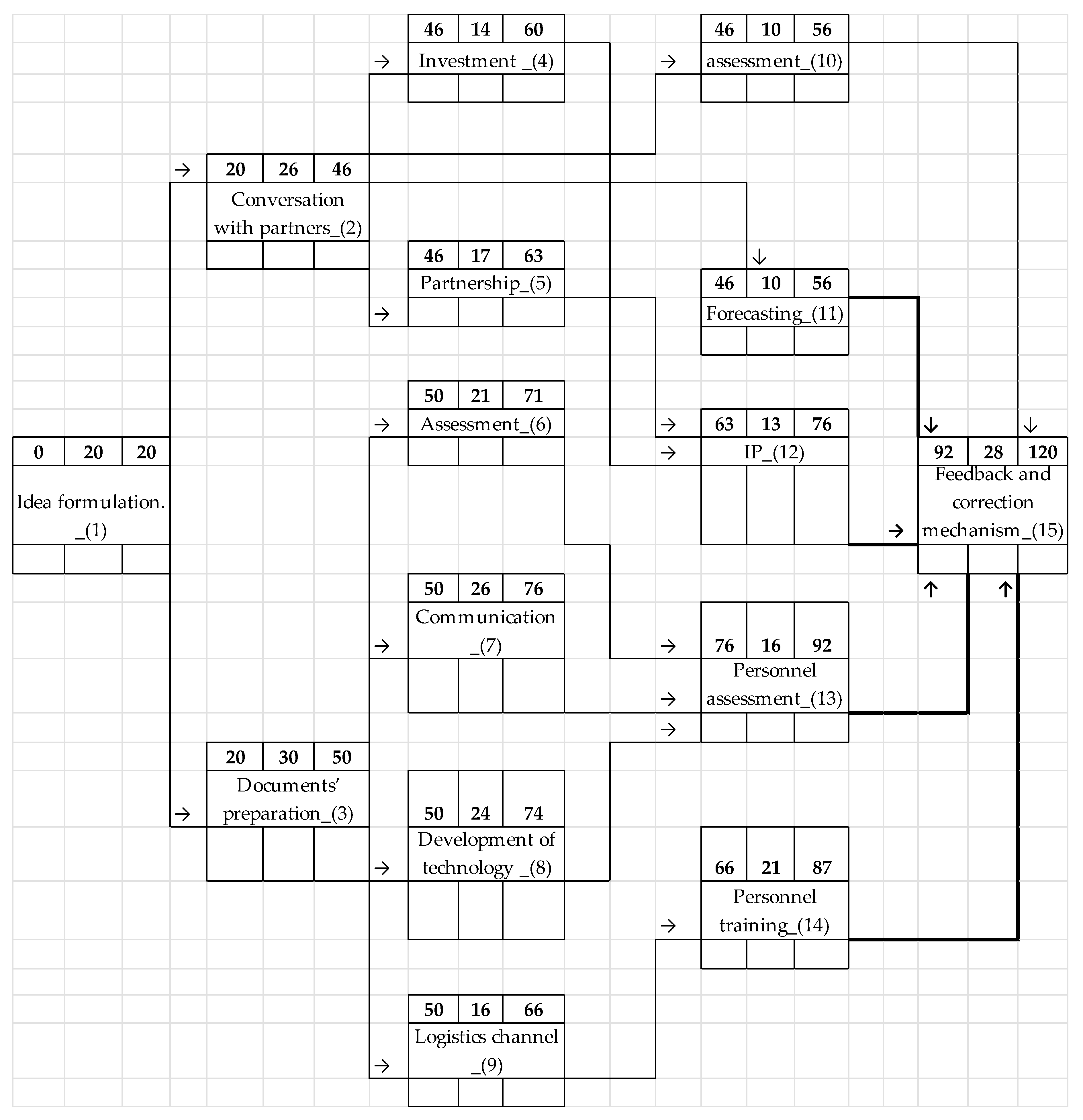

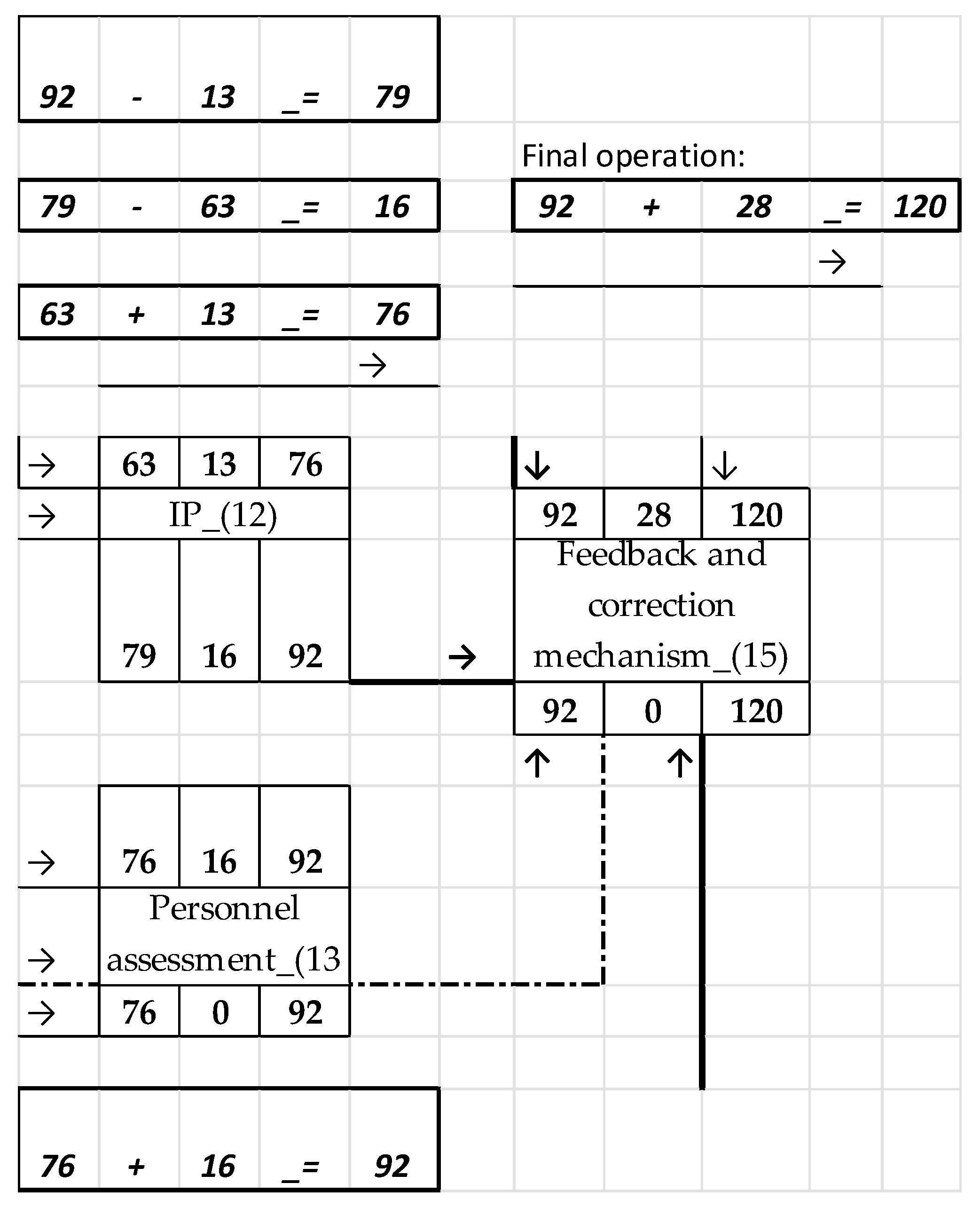

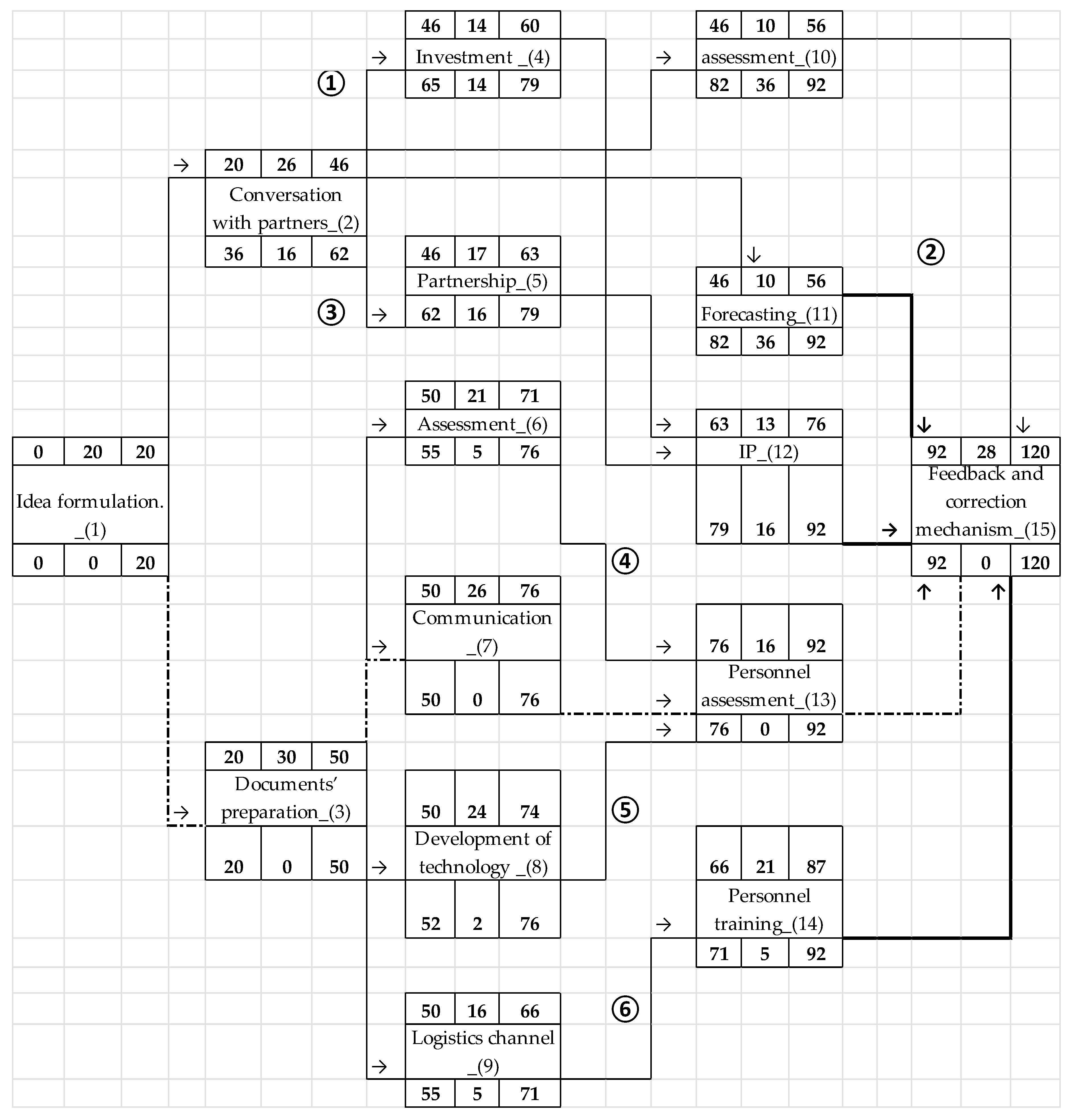

Table 2). Technology transfer process requires more significant efforts for risk’s prevention. For example, identifying and sequencing parallel and interdependent activities and stages may help to achieve a partner’s goal during the transfer process. Critical Path Analysis flow diagrams method helps us to manage this risk. On another hand, the Gantt Chart method helps manager to arrange monitoring, forecasting, reporting an international transfer process.

Fishbone diagrams are also useful for brainstorming and identifying causal factors which might otherwise be forgotten. For complex proposals, or when you lack experience in the issues, it is important to involve others in the brainstorming process. Thereafter, it is a question of putting the issues in the right order, and establishing relationships and links between each issue. Complex projects will have a number of activities running in parallel. Some parts of the plan will need other parts of the plan to be completed before they can begin or progress. Such “interdependent” parts of a project need particularly careful consideration and planning. Sometimes, they will require a feasibility stage before the completion of a detailed plan. Thus, Gantt Charts and Critical Path Analysis flow diagrams are two commonly used tools for detailed project management planning, enabling scheduling, costing and budgeting and other financials, and project management and reporting.

2.2. Gantt Charts (GC) and Critical Path Analysis (CPA) Flow Diagrams

A Gantt Chart (GC) planning method (hereafter called a network diagram) is a popular type of chart (invented by Henry Gantt) used to plan and monitor the implementation of a project. A GC is a type of bar chart that illustrates a project schedule and is named after its inventor, Henry Gantt (1861–1919), who designed such a chart between 1910–1915 [

35]. Modern GCs also show the dependency relationships between activities and the current schedule status. They are usually created initially using an early start time approach, where each task is scheduled to start immediately when its prerequisites are complete. This method maximizes the float time available for all tasks. This interactive network diagram is presented in almost all project management systems. A GC method helps to follow these steps of project management:

understand scope and stages in technology transfer, and its success criteria including;

forming the transfer team and developing the project charter;

consolidating knowledge for transfer and developing a technology transfer proposal;

identifying risks, conducting risk assessments and developing technology transfer plan;

executing the transfer;

finalizing the transfer and performing the review.

GC presents the systematic (step-by-step and planned) procedure that is followed in order to pass the documented knowledge and experience gained during development and/or commercialization to an appropriate, responsible, and authorized party. Technology transfer embodies both the transfer of documentation and the demonstrated ability of a receiving unit to effectively perform the critical elements of transferred technology, to the satisfaction of all parties and any, or all, applicable regulatory bodies.

The network diagram shows the tasks and stages of the project, considering their length over time. The tasks in the diagram can be dependent on each other (for example, one task can only begin after the completion of another). In addition, the percentage of completion of each task and the person responsible for its implementation can be displayed.

Critical Path Analysis (CPA) was developed in the 1950s to control large defense and technology projects and has been used routinely since then. As with GC, CPA helps managers to plan all tasks that must be completed as part of a project [

35]. It acts as the basis both for the preparation of a schedule and for resource planning. During the management of a project, it allows managers to monitor the achievement of project goals. which helps users to see where remedial action needs to be taken to get a project back on course.

Critical path analysis is a project-management technique that lays out all of the activities needed to complete a task, the time it will take to complete each activity and the relationships between the activities. Also called the “critical path method”, critical path analysis can help predict whether a project can be completed on time and can be used to reorganize the project both before starting it, and as it progresses, to keep the project’s completion on track and ensure that deliverables are ready on time. Either manually or using computer software, the project manager first lists each activity, the order it must be completed in and how long it is expected to take, and then diagrams the process. This method impacts on effectiveness of communication and tasks between different steps of transfer project.

Within a project, it is likely that a manager will display a final project plan as a GC (using Microsoft Project or other software for projects of medium complexity or an Excel spreadsheet for projects of low complexity). The benefit of using CPA within the planning process is that it helps develop and test a plan to ensure that it is robust [

36]. CPA formally identifies tasks which must be completed on time for the whole project to be completed on time. It also identifies which tasks can be delayed if resources need to be reallocated to catch up on missed or overrunning tasks.

Clark, W. (1922) tells that networking is convenient for managing project time. By setting the planned duration of each task and the relationship between tasks, the manager can easily get the theoretical duration of the project (critical path) [

37]. Furthermore, if a manager is looking at the network diagram during the implementation of the project, they can quickly assess the extent to which the planned deadlines are being achieved to make appropriate adjustments.

Tsinarakis (2018), Haji and Darabi (2007) discuss other approaches of project management (simulation; lean concept; waterfall; scrum, Petri net (1996), etc.), but they have more limitations for practical application in comparison with the Gantt Chart and Critical Path Analysis [

38,

39,

40].

5. Discussion

The combination of Gantt Charts and Critical Path Analysis flow diagrams methods obtained significant success in that it improved the planning process for technology transfer projects, helped managers to understand another aspect of a sustainable project’s development: how risk-management tools impact the technology transfer project’s planning process.

Some limitations of this research were investigated.

- 1.

This research is based on one project: technology knowledge transfers between a headquarters and subsidiary (South Korea–Russia).

The critical path indicators and operations may have different variations depending on type and area of project. For example, some external factors (partnership communication process; standards change in industry, so on) and internal factors (access to resources; management style; corporate goals; so on) may affect the decision-making process in the project management system.

- 2.

The period of the survey is only from January 2019 until now.

The project which is the object of this survey has been started from the beginning of running year (2019) and will be continued until 2025. So, we calculated the critical path way of the project to optimize all the resources and improve effectiveness. But there could be unexpected influences in future (from 2020 till 2025) in internal and external environments, which is why we discuss risk-analysis in the discussion section. Unfortunately, we cannot arrange forecasting now which refers to any possible changes in this project of technology transfer. Using Critical Path Analysis within the planning process helped us develop and test a plan (292 weeks) to ensure that it is robust. Critical Path Analysis formally identifies the tasks which must be completed on time for the whole project to be completed on time. We obtained 292 weeks of transfer project duration, because we calculated all the requirement indicators, including parallel, crushing operations and critical path way.

- 3.

The scope of this survey is focused on the automobile industry.

The Korean automobile industry develops very fast and manage a lot of changes. For example, it is necessary to adapt Korean technologies to local markets, share knowledge, communicate with local suppliers and compete with other global transport companies. All these factors dictate the special corporate goals and define the steps of the transfer project. In another industry there are other trends and changes, so the project management results vary.

To manage these limitations in future it is useful to study risk management tools in technology transfer process.

The risk evaluation problem should be investigated in future research, because some questions and uncertainties in the current survey have been raised:

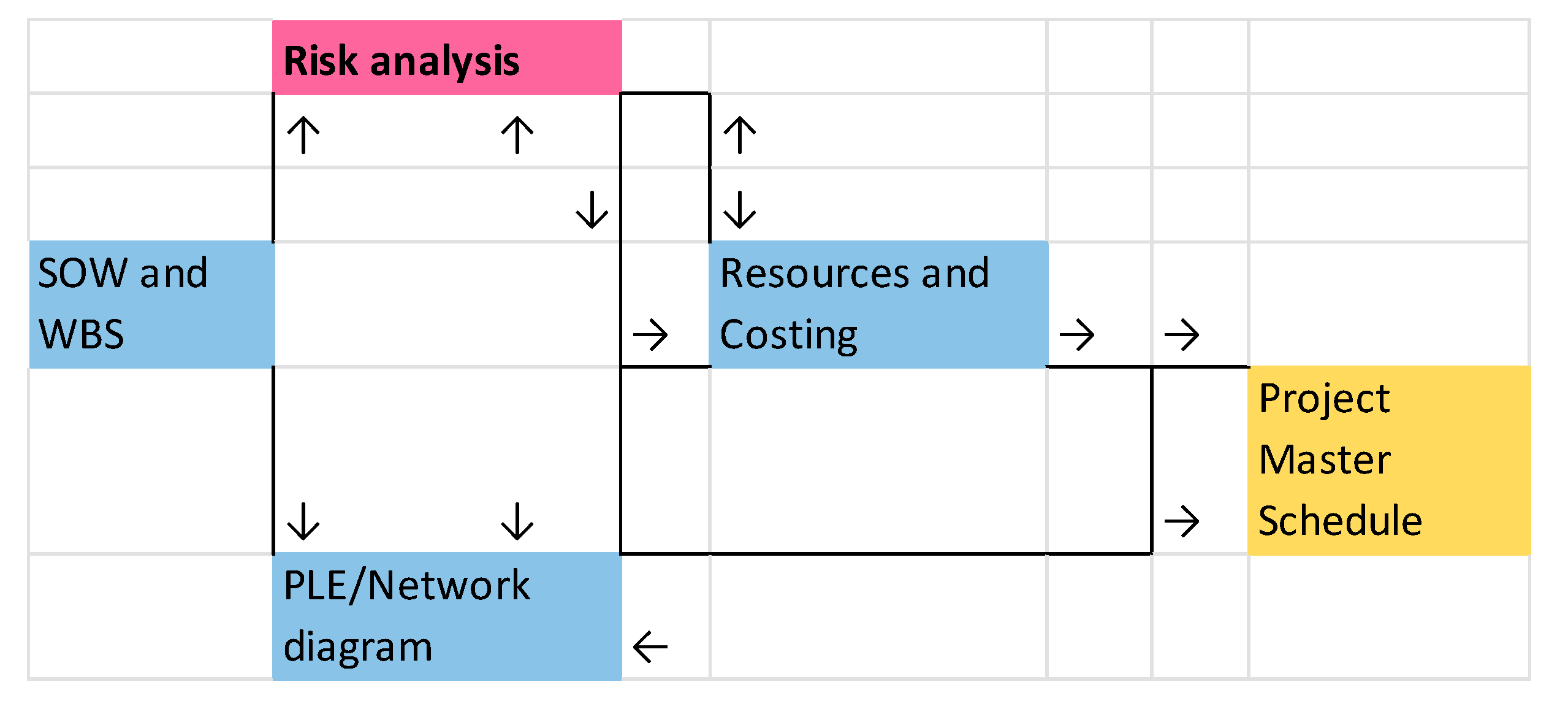

Critical path analysis and a model parameters evaluation are included in the project’s planning process, but there is nothing about risk analysis;

Risk factors may have a negative impact on project management, and they should be submitted in the Gantt Chart model;

Different risk management tools should be estimated, and only one tool (or sustainable combination of the tools) should be chosen.

Abba, W.F. (1995) stated that there should be an application of integrated (comprehensive) risk analysis and the optimization of the project network schedule [

61]. Integral risk analysis implies the structuring of possible risk events, allocation of macro and micro risks, qualitative and quantitative assessment of identified risks, and the development of regulations for activities related to risk management (

Figure 9).

In the network graph, the parameters of time and cost of work and risk factor parameters are introduced, with the last parameter determined by constructing risk matrices. The network diagram model is a non-linear optimization task according to the criteria of the minimum time, cost and risk of the project. The application of the proposed methodology, as its testing on a real project to create technological innovation for automobile industry shows, can significantly improve project performance and thereby increase the chances of its successful implementation.

It is necessary to emphasize that a technology-transfer process differs in some subjects; for example, the receiver can often become the sender and vice versa for a single transfer. In the specific case of the collaboration between a headquarter and a subsidiary, there is a process of validation and learning that is cyclical. Considering the Heslop, L. A. (2001) [

63] model, the “message”—which for the technology transfer process is technology, scientific knowledge, or any research result—can be presented in different ways of project management and the transfer process can be performed by different mechanisms, which are known as transfer mechanisms (Heinzl et al. 2013) [

64].

It should be noted that authors such as Shvetsova O. (2018); Bozeman (Bozeman 2000; Bozeman et al. 2015), Rubiralta (2004), Malik (2002), Waroonkun and Stewart (2008), and Khakbaz, P. P. (2012) did not differentiate between the strategy and risk-management mechanism for the technology transfer processes [

65,

66,

67]. However, other authors such as Landau (Landau et al. 1982) (who separated the middle element of the package from the marketing mechanism), Mayer and Blaas (2002) (who separated what the initiative business unit sends and what the accepter business unit receives), and Hoffmann (Hoffmann et al. 2009) (for whom, according to the level of the object, the headquarter uses a different strategy and the transfer is performed in a different mechanism) differentiated the strategies from the mechanisms [

67,

68,

69].

Berg H. P. (2010) suggested that risk in project management is often understood as the probability of not receiving a planned result at a given level of quality and on time [

70]. The nature of the risks is quite diverse, but an analysis of the reasons for the unsuccessful implementation of projects showed that the main one is a lack of resources or time. A very important aspect of the problem is the consideration of two types of project risk influence: temporary (risk of failure to complete operation on time), and cost (risk of exceeding the cost of operation). Selig, G. J. (2008) suggested that the presence of a significant number of operations with temporary and cost risks leads to risk for the entire project or program (exceeding the project implementation deadlines, or the costs of its implementation) [

71]. Resource support parameters and time limits, as a rule, are placed at the stage of pre-project preparation, thereby confirming the position that the reasons for successful or unsuccessful project implementation are present at the preliminary planning stage; thus, at the planning stage, it is necessary to provide for the necessary compensation measures and take adequate organizational and managerial decisions, but for these purposes, it is necessary to have information about the nature of potential risks. This makes it necessary to evaluate the risks that arise during the implementation of the project at the planning stage to estimate—preferably quantitatively—their impact on results and the necessary compensation for adverse conditions. The whole range of measures for the accounting and assessment of and compensation for project risks is implemented within the framework of the risk-management methodology [

71]. The methods of accounting and risk assessment are quite diverse, and the success of their application largely depends on the correct classification, which involves considering the nature of the risk.

6. Conclusions

During this research, the authors chose the case study of the Korean automobile industry as an excellent example of technology transfer in global markets. A single project of technology transfer was discussed: technology knowledge transfers from a Korean headquarters to a Russian manufacturing subsidiary (Hyundai Motor Corporation). The quantitative data were collected through the open resources of the Corporation; the qualitative data were analyzed through a case study and model parameter evaluation.

A significant result of the combination of Gantt Charts and Critical Path Analysis flow diagrams methods, which improved the planning process of the technology-transfer project, was found from this survey.

The authors examined the practical mechanisms for compiling a network schedule and calculating the main parameters of the time duration of the project. Thus, the authors came close to exploring the possibilities of an analysis carried out in order to optimize the network model and formulate an action plan directly to improve its quality for a sustainable project planning process. This topic takes up little space in the project manager’s complex of knowledge and is not particularly difficult to grasp. In any case, each planning manager must be able to reproduce the visualization of the schedule and perform the associated calculations at a good professional level.

Therefore, the authors explained the significant task and risk of technology transfer in each step to exclude the trivial application of CPA and GC methods:

Defining the scope of the study and design steps of the project—(a) defined scope of market segment, industry standards and market barriers; (b) made a consideration about scope of the technology transfer (what exactly we needed to transfer); risks of this stage, which were managed by CPA and GC methods: strategy uncertainty avoidance; partnership considerations for long-term period.

Defining the model’s parameters, principles and methods for planning—checked the priority of CPA and GC methods; applied for the technology (computer model). Risks of this stage, which were managed by CPA and GC methods: planning mistakes can be excluded; evaluation of resource capacity can be arranged.

Using a three-step approach to build the model of technology transfer using the project management concept—identified all the resources, applied for three step process with problem markers interruptions. Risks of this stage, which were managed by CPA and GC methods, were: correction of the technology transfer project schedule; contribution with correction markers into the optimization of planning process.

Finding and evaluating additional model parameters to increase effectiveness—managed the appropriate resources for technology replacement and knowledge improvement. Risks of this stage, which were managed by CPA and GC methods, were: correction of the resources and capabilities in technology transfer project schedule; contribution with correction markers into the optimization of resource planning process.

Arranging results discussion and determining the area of investigation of future projects—further considerations within partnership and technology delivery. Risks of this stage, which were managed by CPA and GC methods, were: correction of the future considerations in project schedule; contribution with correction markers into the optimization of future planning process and partnership.

The main results of this research are as follows:

Hypothesis “The combination of Gantt Charts and Critical Path Analysis flow diagrams methods improves the planning process for a technology transfer project” is proved by this study.

It is useful to apply project management tools for technology transfer models;

Gantt Charts and Critical Path Analysis flow diagrams have a sustainable impact on technology transfer projects;

The critical path and operation reserves in a network diagram help to optimize the planning process for technology transfer.

For future research, it will be necessary to investigate the correlation between risk-management tools and project management tools for sustainable technology transfer in the automobile industry.