1. Introduction

Variability in the outputs of manufacturing processes has been studied for decades. It is investigated using many techniques, such as the design of experiments, and statistical process controls, especially with the help of process capability analysis [

1]. Advances in industrial systems have required process engineers to widely analyze and control each element in their processes [

2]. Using process capability analysis, we can evaluate manufacturing processes and use this information to improve the capabilities of the considered processes to meet the desired specifications.

It is an established fact that most manufacturing products have more than one quality characteristic (QC). Moreover, these QCs are functionally correlated, implying that they should be considered together. Consequently, the product quality evaluation process becomes more complex as the number of QCs increases, leading to increased interest in finding capability indices that can address multivariate non-normal process capabilities. For example, Wang [

3] performs a process capability analysis for a real-world product with seven QCs.

Multivariate process capability analysis is a common topic of interest in the literature. Taam et al. [

4] propose the first multivariate capability index using the concepts of process regions (PRs) and specification regions (SRs). Chen [

5] presents the first multivariate Cp that uses the proportion of non-conformance (PNC). Shahriari et al. [

6] evaluate the performance of multivariate QCs using process capability analysis. Braun [

7] investigates the shapes of the process PRs and SRs to define a new process capability index (PCI). Castagliola et al. [

8] study bivariate process capabilities and derive two indices based on the PNC. Bothe [

9] establishes a method for estimating a multivariate

index. Wang et al. [

10] define a new index from

and

based on a principal component analysis (PCA) decomposition.

The literature includes many other studies in the field of multivariate capability analysis [

3,

11,

12,

13,

14,

15,

16,

17,

18,

19,

20,

21,

22,

23,

24,

25,

26,

27,

28,

29,

30,

31,

32,

33,

34,

35,

36]. PCA was first used in process capability analysis by Wang and Chen [

37]. Chen [

5] presents one of these multivariate PCIs by establishing a comparison between the original PR and SR. Although he compares the PR to the SR, Chen does not consider the position of the PR within the SR in his investigation. Das and Dwivedi [

28] use the g and h multivariate PCI for non-normal data. Their proposed PCI has been compared to other PCIs in the literature, and it performs well. However, the process of finding this PCI requires some complex computations. Ciupke [

22] proposes a multivariate PCI that can be used for normal and non-normal QCs. He suggests the use of one-sided models to determine the PR, which is compared with SR in the evaluation of multivariate non-normal processes. Pan et al. [

20] extend the work of Pan and Lee [

32] to propose a multivariate non-normal PCI. They estimate the original probability density function using a weighted standard deviation. Castagliola [

38] define the traditional PCIs (Cp, and Cpk) based on the PNC.

Many previous studies have been conducted on PCIs in this group. However, most of these studies deal with multivariate normal data [

39,

40]. Nevertheless, some attempts have been made to extend the use of the PNC to non-normal data. Abbasi and Niaki [

41] use the concept of the PNC to develop a multivariate non-normal PCI. They use the root transformation method to normalize non-normal data and then use Monte Carlo simulation to estimate the PNC. Ahmad et al. [

33] investigate multivariate non-normal process capability analysis based on the PNC. They reduce the dimension of the multivariate QCs using the covariance distance (CD). Many studies in the literature consider non-normal PCIs [

8,

11,

42,

43,

44,

45,

46,

47,

48,

49,

50]. Additionally, a few studies focus on multivariate non-normal process capabilities. The number of such studies increases yearly [

3,

11,

25,

27,

44,

51,

52,

53,

54,

55,

56,

57,

58,

59].

Most of existing multivariate PCIs are based on normality theory and treat multivariate QCs as normal data. However, most real-world data on QCs do not follow a normal distribution. Moreover, the proposed non-normal multivariate PCIs in the literature still have many limitations. These limitations relate to the following issues:

Consequently, the provision of a robust multivariate PCI is still a great research opportunity.

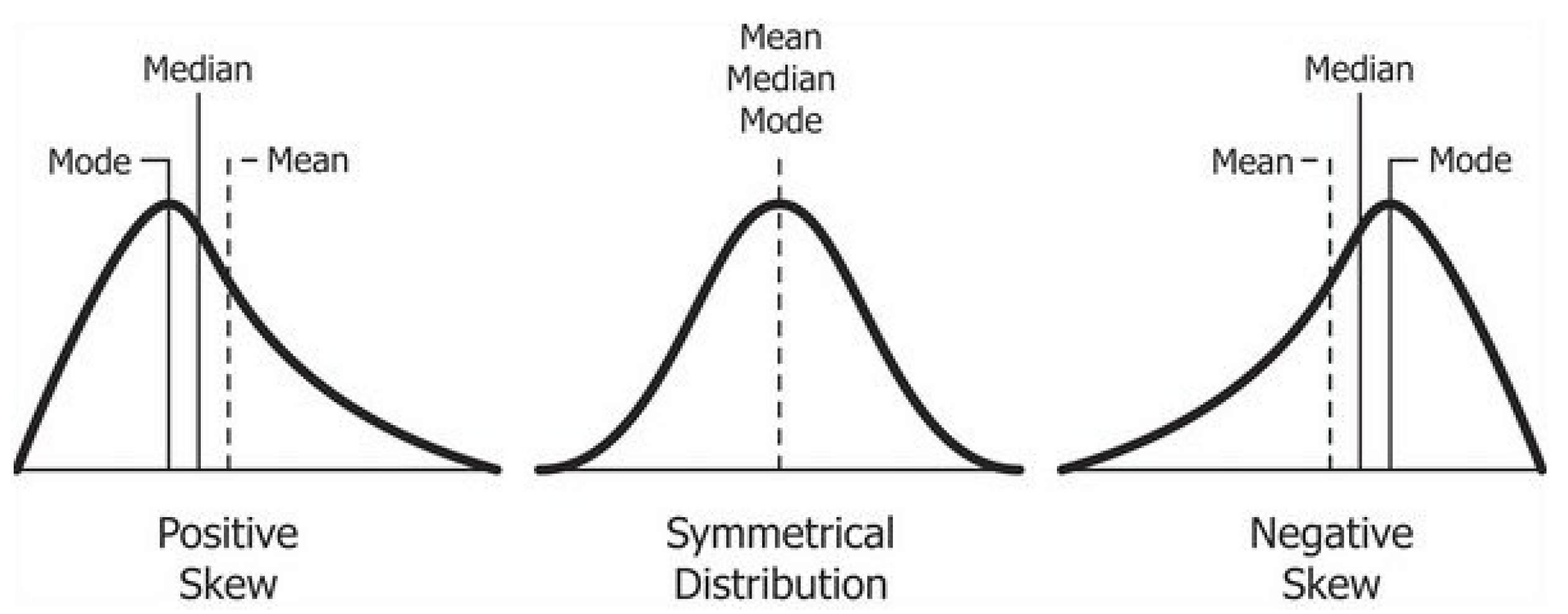

The objective of this study is to provide a multivariate non-normal capability index that takes into account correlations between QCs, regardless of data skewness type. Although, Abbasi and Niaki [

41] propose a methodology for estimating PCIs for multivariate non-normal processes for right-skewed data, it fails to reduce the skewness of left-skewed data. However, in practice, many multivariate manufacturing processes contain positive (right-sided) and negative (left-sided) skewness (

Figure 1).

Owing to the limitations of the proposed methods for estimating multivariate non-normal process capabilities in the literature [

41], carrying out different transformations is an important research opportunity. These transformation techniques, such as the Box–Cox and Johnson transformations [

61,

62], can be used, and their performances can be evaluated.

The rest of this article is organized as follows.

Section 2 provides a theoretical background on process capability analysis. The methodology is presented in

Section 3.

Section 4 presents and discusses the results revealed by applying the implemented methodology. Finally,

Section 5 concludes the study and suggests some directions for future research.

2. Theoretical Background

It is worth noting that process monitoring precedes the use of process capabilities. The stability of a process is usually tested using quality control charts. Montgomery [

63] provides a useful presentation of statistical process controls.

After the stability of a process is determined, its capabilities can be analyzed using different tools, such as histograms, descriptive statistics, and skewness [

63]. The most important method in a capability analysis is called the process capability index (PCI). A PCI is a unitless measure that quantifies the relation between the actual performance of a process and its specified requirements. PCIs are proposed to predict the proportion of products that are not expected to meet a given set of specifications. Generally, the higher the PCI value, the lower the proportion of non-conformance (PNC). Juran and Frank [

64] propose a PCI for process capability assessment with the assumption

, as follows:

where

USL is the upper specification limit of the process,

LSL is the lower specification limit, and

is the standard deviation of the process data. Moreover, if the process data follow a normal distribution

, then we can say that the process is centered at its nominal mean. If its actual mean is defined by

that is,

, then the process is considered capable if

. then we can say that the process is centered at its nominal mean. If its actual mean is defined by.

Such a process results in a percent of non-conforming items of at most 0.27%, that is, 2700 nonconforming items per million items produced in a production process, which is small [

65].

In most cases, the process mean does not equal the nominal mean, but rather, is shifted somewhat. Process capability assessment using the

index does not take into account this shift. Thus, another PCI, called

, was proposed by Kane [

66]. This PCI depends on the minimum assessments of the upper and lower capability indexes

.

where μ and σ are the mean and standard deviation, respectively, of the in-control process.

It is worth noting that

is linked to the PNC [

67]. Suppose that the QC,

X, is normally distributed. Then, the PNC is expressed as:

If

is replaced with the nominal mean

, as stated in Equation (2), the PNC is calculated as:

where

is the cumulative distribution function of the unit Gaussian.

The PNC can also be expressed as the number of defects in terms of parts per million (PPM).

Table 1 shows the number of defects in PPM terms for some

values. The

value can also be used to specify the sigma level of a process. For example, if

, the process is at the six sigma level, and if

, the process is working at the three sigma level [

3].

Process capability analysis is mainly based on probability theory. Consequently, the PCI should be fitted to a specific probability distribution that can be used to estimate its index given its variation [

8]. The traditional PCIs, such as

and

, are used when the QCs are normally distributed. However, in practice, quality specialists should verify the normality assumptions before conducting performance analysis using the traditional PCIs. Clements [

43] developed one of the most famous PCIs that can be used for univariate non-normal QCs.

This PCI uses non-normal quantiles instead of , which were used in Equation (1). Here, qα represents the quantiles of a distribution in the Pearson family for the specified α values.

Multivariate process capability analysis is the process of quantifying multiple QCs of a product using a single PCI. This index can be used to evaluate the quality of a product, as well as the capabilities of a process. Many studies in the literature aim to provide a practical measure of multivariate non-normal process capabilities. This study focuses on providing a multivariate non-normal capability index that takes into account correlations between QCs.

Generally, a multivariate PCI is a single number that can evaluate the quality of a considered product using multiple QCs for that product. Different methods can be used to determine a multivariate PCI, such as:

Computing the ratio of the tolerance limits to the process variation;

Using the PNC for the relevant products;

Exploring global multivariate quality control methods.

3. Research Methodology

This study investigates a multivariate PCI for both right- and left-skewed data. First, the root transformation method, which is proposed in the literature [

41], is validated and adopted for the same non-normal data as in the literature. Then, the performances of the Box–Cox and Johnson transformations for PCI calculations are investigated. The study applies two algorithms for Box–Cox and Johnson transformations to investigate multivariate PCIs for non-normal data. Statistical and heuristic methods are used to identify the best parameters for the transformation techniques.

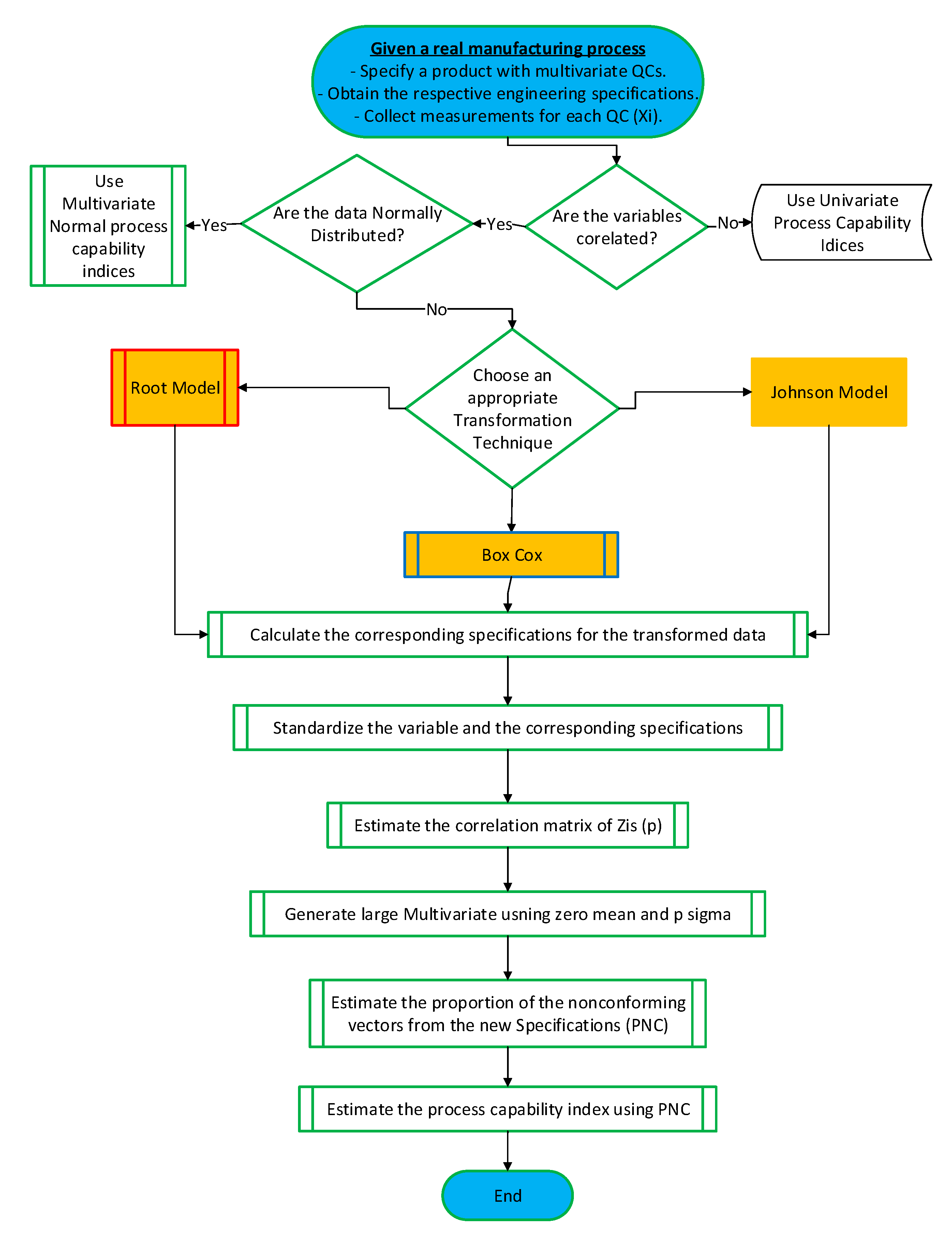

Figure 2 presents a flow chart for the applied methodology.

The methodology in this study consists of several steps that lead to an estimated PCI for multivariate non-normal data as shown in

Table 2. The methodology suggests three types of transformation techniques to normalize the data. Furthermore, the specification limits are transformed using either the same techniques or prediction techniques. Then, the transformed data are standardized

, where Y

i represents the transformed data and

p is the number of QCs. Then, the correlation matrix of

, denoted by

, is estimated in the next step in which a large sample from a multivariate normal distribution with mean zero and covariance

z is generated. Then, based on the transformed specification limits, the PNC of the generated sample is estimated. Finally, Equation (10) is used to estimate the process PCI:

Aside from the model taken from prior studies, the models used follow similar procedures for finding the PCI in the case of multivariate non-normal QCs. However, the three models differ from each other in their skewness reduction methods and in estimating the new specification limits for transformed data. In the next sections, each model is discussed separately.

3.1. Root Transformation

Root transformation, which was proposed by Abbasi and Niaki [

41], consists of three main stages. First, the skewness of the marginal probability distributions of the variables is diminished using a root transformation technique.

A Monte Carlo simulation method is employed to estimate the process PNC;

The relationship between the PNC and PCI is found;

The PCI is estimated using the PNC.

Although this method mentions two-sided specifications, it supposes that the marginal distributions are right-skewed for most non-normal processes, and, thus, only the USL must be defined.

The root transformation technique searches for a proper root (r) of the right-skewed non-normal data such that if the data were raised to the power r

, the skewness in the distribution of the transformed data would be almost zero. The bisection method is employed to find the appropriate value of r. This method is based on the point at which a function changes sign when it passes through zero. By evaluating a function in the middle of an interval and replacing whichever limit has the same sign, the bisection method can halve the size of the interval in different iterations to eventually find the root. For example, to find the root of

in the interval of

, where

, a tolerance

is chosen, and the algorithm in

Figure 3 is then applied:

To estimate a PCI for multivariate non-normal processes, the root transformation technique can first be applied to diminish the skewness in the marginal distributions of the

until the skewness is less than the tolerance or until a specific number of iterations has been performed. The specification limits of the original variables are transformed in the same manner, that is, by raising each specification limit to the power given by the root obtained for its corresponding variable and then standardizing it in the same way as its corresponding variable is standardized. Through this procedure, a new specification limit is obtained for each

. As an example, assume that the upper specification limit of the

original QC (

) is

. Then, the upper specification limit of the

standardized-transformed variable (

) is

which is calculated using Equation (11).

Here,

and

are the estimated mean and standard deviation of the

transformed variable, and

is the root obtained for the

original variable such that the skewness of

is almost zero. If both the upper and lower specification limits are given, the equations for the specification limits change as follows:

3.2. Box–Cox Transformation

In this study, we extend the research in the literature by considering the estimation of λ using a different methodology. Specifically, we use a searching algorithm which finds the argument of minimum skewness over a pre-specified interval for the candidate λ values. Furthermore, this extended method and that of Abbasi and Niaki [

41] are illustrated using real-world datasets with seven QCs that include right- and left-skewed data.

The Box–Cox power transformation [

61] on observations

is given by

where λ is an unknown power transformation parameter and n is the sample size.

Depending on the Box–Cox transformation, a heuristic algorithm is used in this analysis to obtain the best value of λ to effectively reduce the absolute skewness value. The algorithm is provided in

Figure 4. This algorithm starts by ensuring that each element of the dataset is positive. Otherwise, a small constant is added to all observations to shift the dataset to positive values, as originally proposed by Box and Cox [

61]. Then, a sequence of candidate λ values is selected using a fairly precise increment, such as 0.1, 0.02, and so on, in a specified interval. The Box–Cox power transformation given by Equation (13) is applied using all the candidate λ values to obtain as many transformed samples as the number of λ values. The skewness of each of these transformed samples is checked, and the λ value that corresponds to the minimum skewness is selected.

3.3. Johnson Transformation

A Johnson transformation is used to estimate the PCI for multivariate non-normal data. The search for its optimal parameters is conducted in two stages. Initially, the appropriate type of Johnson family distribution for the QC data is determined using the percentile method. Then, the parameters of the selected Johnson distribution are calculated; these parameters serve as an initial solution in the next stage. Typically, the parameters estimated using the percentile method do not work well for skewness reduction. However, they can be used as an initial solution because the optimal parameters are usually close to the parameters estimated using the percentile method. The second stage is called the heuristic method. In this stage, small increments are added to and subtracted from the parameters estimated in the initial solution in a specific number of iterations. Those with the least skewness are the optimal parameters.

3.3.1. Percentile Method

The crucial process in the given non-normal data is to fit to the right family of Johnson distribution. Given any of the transformations described in

Table 3, choose a specific value z > 0 from the standard normal variables. Next, consider four points of

z and

3z, which establishes three equal intervals. Let

be the values corresponding to

under the Johnson transformation. The following steps are used to determine the appropriate type of Johnson transformation:

Step 1: Choose an appropriate value of z;

Step 2: From the normal standard table of normal distribution, obtain the probability distribution ;

Step 3: Find the corresponding quantiles in the sample data;

Step 4: Let ;

Step 5: Define the quantile ratio ;

Step 6: Select the appropriate Johnson system as follows:

In step 1, a value of z > 0 is chosen. This choice should be motivated by the number of data points. In general, for moderate-sized datasets, a value of z less than 1.0 is chosen because a z of 1.0 or higher makes it difficult to estimate the percentile points corresponding to +3z. A more typical choice is using a value of z near 0.5, such as z = 0.524. This choice dictates the use of 3z = 1.572, and these two points require estimating the 70th and 94.2th percentiles. However, the larger the number of observations is, the larger the value of z that can be selected. This analysis subsequently shows that z and the estimated p, m, and n can be used to estimate the distribution parameters. Thus, the choice of z can be motivated by seeking a value which assumes a close match to the data and empirical distribution in the areas of greatest interest. Then, a table of areas for the normal distribution is used to determine the percentages corresponding to . For example, if z = 0.2, then = 0.5793. For each such, the percentile corresponding to is obtained from the data using the relationship and setting = Here, n is the number of data points. Thus, is the ordered observation, where . Because i is not generally an integer, it may be necessary to interpolate. From the values obtained in the previous step, the sample values of m, n, and p can be computed, and the criteria in step 6 can be used to select the appropriate Johnson system.

Johnson Distribution

The formula for transforming non-normal data using the Johnson

Distribution is as follows:

The values of the parameters are presented in such a way as to emphasize their dependence on the ratios

m/p and

n/p. The parameter estimates for the Johnson

distribution are as follows.

Johnson Distribution

The solutions for the

parameters depend on the ratios

p/m and

p/n (as opposed to

m/p and

n/p in the case of the

parameters). The parameter estimates for the Johnson

distribution are as follows.

Johnson Distribution (lognormal)

The parameter estimates for the Johnson

distribution are as follows.

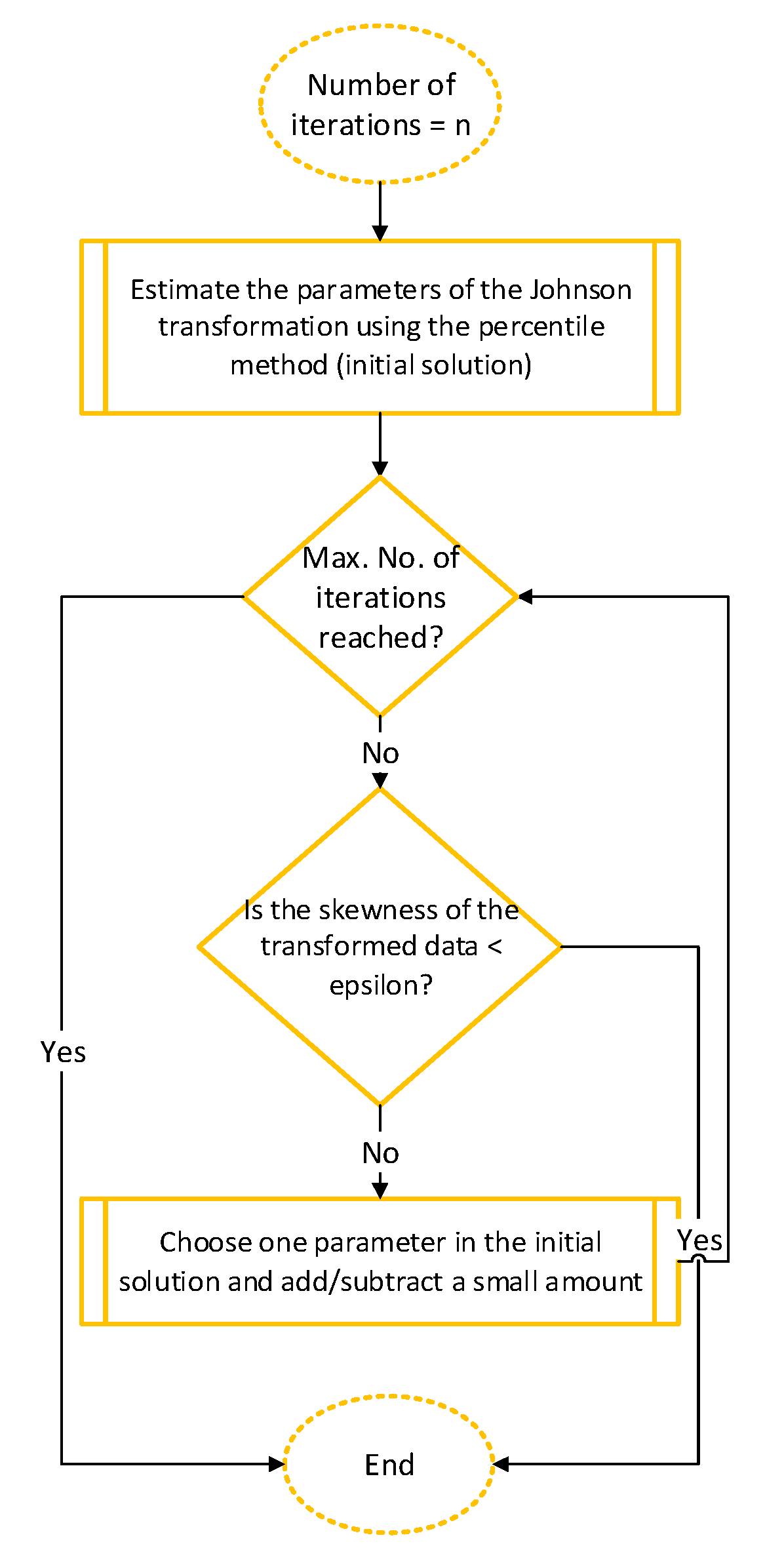

3.3.2. Heuristic Method

In the Johnson transformation, the closeness of the skewness value to zero is a function of the parameter selection. When applying the Johnson family formulas described above, it can be difficult to vary the parameters to achieve zero skewness in the transformed data because the Johnson transformation has four parameters and the trivial solution is time-consuming. Thus, Johnson transformation parameter selection is a complex problem and requires heuristic solutions. Here, we can use an iteration algorithm to search for the best Johnson transformation parameters that bring skewness closest to zero. The implemented algorithm is presented in

Figure 5. This algorithm should specify a specific number of iterations to perform. Then, to speed up the algorithm, the percentile method discussed previously is used to provide an initial solution. Next, the initial parameters are subjected to the addition and subtraction process, and the skewness is evaluated with each addition and subtraction. Finally, the algorithm chooses the parameters with the least absolute value of skewness.

3.4. Application and Comparative Examples

The most important step is presenting applications of these methods and a set of comparisons. To do that, two examples from the literature with known PNCs are presented in this section. The first example is discussed and its statistical properties are shown by Abbasi and Niaki [

41] (Case 1) without presenting the data, and the second example is presented as a real case study by Wang [

3] (Case 2). These two examples are discussed in the next sections.

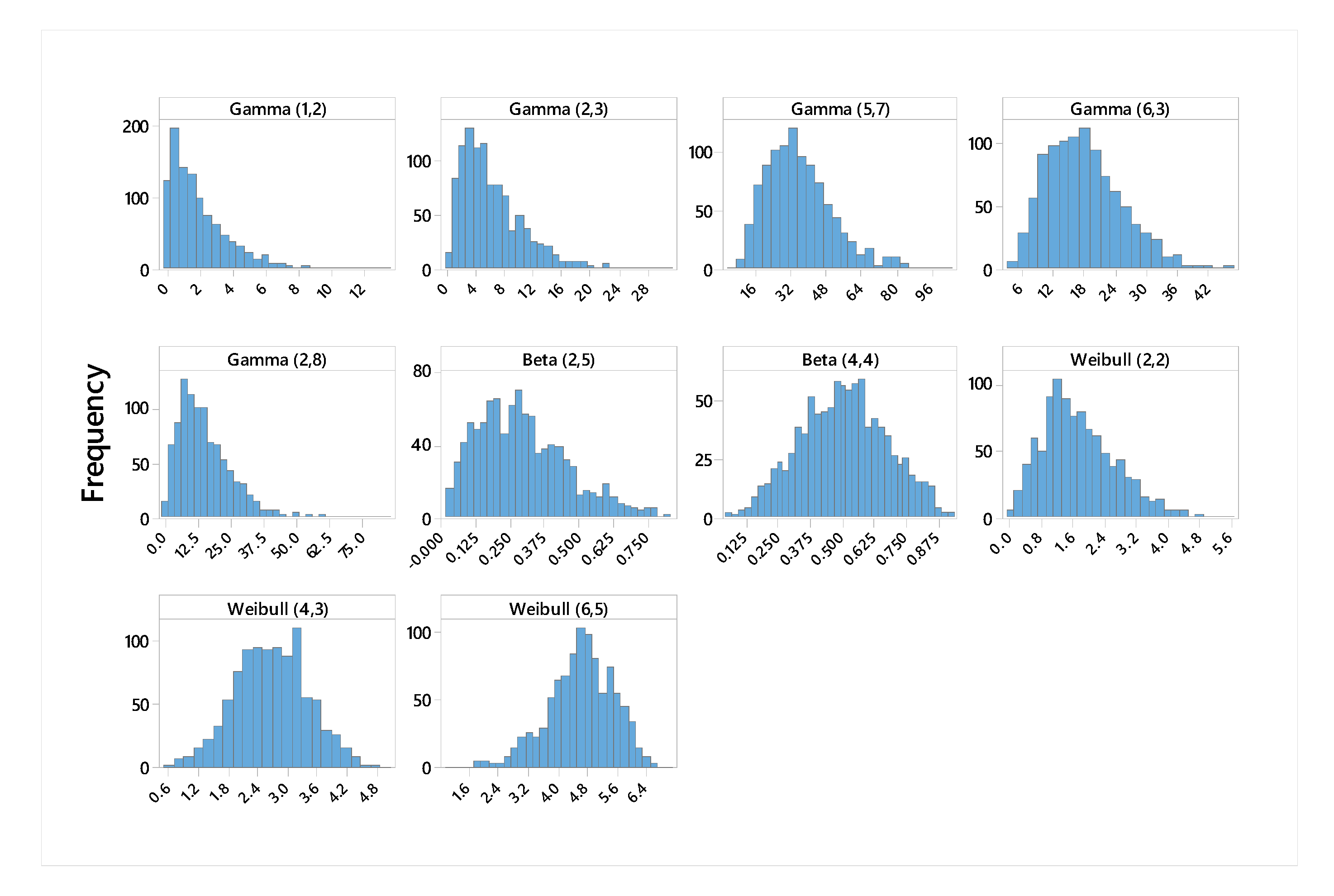

3.4.1. Case 1

This example includes three distributions and four samples. Each sample is generated with four different sample sizes, as shown in

Table 4. The non-normal distributions are the gamma, beta, and Weibull distributions, and the sample sizes are n = 50, 100, 500, and 1000. The USL is also presented for each variable. The shape and scale parameters are denoted by

, respectively. Additionally, the correlation matrix is presented for each sample. Finally, the actual PCI,

, is shown in the last column for each sample.

The data used to simulate this example have specific correlations. Consequently, an algorithm is designed to generate multivariate non-normal data with a specific marginal distribution and the desired correlation data.

Generating Multivariate Correlated Non-Normal Data

Generating multivariate non-normal data with an arbitrary distribution and specific correlations is crucial in the process of validation. Abbasi and Niaki [

41] use three distributions with four samples with different parameters and correlations. Because all these distributions are non-normal, it is necessary to design an algorithm that generates non-normal multivariate data with the desired correlations. The steps below summarize this algorithm.

First, random vectors with a defined mean vector and covariance matrix are generated from a multivariate normal distribution. The number of vectors is equal to the desired sample size n, and each vector has dimensionality 1 by p, where p is the number of variables or QCs. The data generation process depends on the mean vector (1 by p) and the covariance or correlation matrix (p by p). The mean vector is set equal to zero, and the correlation matrix represents the variance–covariance matrix for all variables that must be generated. Each value in the vector is generated depending on the corresponding value in the mean vector. Moreover, the vectors are generated with respect to the covariance matrix. The generated matrix has dimensionality n by p.

Then, for each variable an n by 1 vector is generated using the inverse of the non-normal cumulative distribution function (CDF). The inverse CDF uses the parameters of the corresponding at the values of the CDF of the normal distribution. However, these procedures result in a multivariate non-normal data with a given arbitrary marginal distribution. However, the output correlation between the variables is almost near the desired correlation, and it is almost different each time the previous procedures are run. Consequently, the algorithm is run for several iterations until the difference between desired and output correlations is less than the tolerance . To illustrate this algorithm, the following step-by-step algorithm generates a multivariate beta distribution sample with size . The correlation of the variables equals as follows:

Step 1: ;

Step 2:;

Step 3:;

Step 4:;

Step 5: .

3.4.2. Case 2

A well-known case study from the literature obtained from a manufacturer in Taiwan’s computer industry is also used. This case study is presented by Wang [

10] and contains a sample of 100 parts that were tested for seven QCs of interest to the manufacturer. These seven QCs are X1 (contact gap X), X2 (contact loop Tp), X3 (LLCR), X4 (contact xTp), X5 (contact loop diameter), X6 (LTGAPY), and X7 (RTGAPY), respectively. The specification limits for these seven QCs can be two-sided or one-sided, and they are 0.10 ± 0.04 mm, 0 + 0.50 mm, 11 ± 5 m, 0 + 0.2 mm, 0.55 ± 0.06 mm, 0.07 ± 0.05 mm, and 0.07 ± 0.05 mm, respectively.

5. Conclusion and Recommendations

5.1. Conclusions

This study aimed to identify effective models for estimating multivariate non-normal PCIs. The implementations of various transformation techniques in this study show that the type of transformation is an important factor to consider when designing PCIs. The results indicate that the performances of process capability estimations for multivariate non-normal data differ across different transformation techniques.

Whereas the root transformation limits the estimation of multivariate non-normal process capabilities to right-skewed data, this study implements general transformations for both types of skewness. The study replicated the root transformation model and extended it by applying Box–Cox and Johnson transformations. The results presented show that the Box–Cox and Johnson transformations outperform the root transformation in estimating multivariate process capabilities for right- and left-skewed data. In the first case, the three methods perform similarly. However, the Box–Cox and Johnson methods provide more precise results in case 2.

The research in this study confirms an existing method for multivariate non-normal process capability analysis and further improves its performance because it extends the method to all types of skewness. Furthermore, the improved method is easy for quality practitioners to use.

5.2. Recommendations and Future Research

The implementation of different transformation techniques in this study shows that performance varies from one transformation technique to another. Additionally, differences arise when using the same transformation technique. Consequently, research gaps still exist, and filling these gaps may lead to more precise performance evaluation of multivariate QCs with non-normal distributions. These gaps can be sorted into two main groups. The first group is associated with developing and investigating more transformation techniques that can provide better results than the existing techniques can. In this regard, researchers can also validate other methods for estimating Johnson transformation parameters, such as the method of moments. The second group of research opportunities stems from noting that the performances of specific transformation techniques differ from one QC to another. These differences can be investigated alongside analyses of QC properties. Such studies may conclude that each transformation technique performs well for specific QC data with specific properties. Moreover, research in this field can be conducted using other criteria besides the skewness of QC data. Finally, depending on the outcomes of research into these gaps, a software package can be developed for industry practitioners. This package can optimize performance evaluation for multivariate QC data, which can facilitate the implementation of multivariate PCIs for non-specialists.