A Holonic-Based Self-Learning Mechanism for Energy-Predictive Planning in Machining Processes

Abstract

:1. Introduction

2. Related Works

2.1. Holonic Manufacturing Systems

- Holon: An autonomous and cooperative building block for transforming, transporting, storing, and validating information and physical manufacturing objects. Basic holons consist of product, resource, and order holons, whereas staff holons assist the basic holons.

- Holarchy: A system of holons that cooperates to achieve a goal. It defines the basic rules for cooperation of holons, thereby limiting their autonomy.

- Autonomy: The capability of a holon to create and control the execution of its own plans and strategies.

- Cooperation: A process whereby a set of holons develops and executes mutually acceptable plans.

- Automation: The low- and (or) high-level control architecture to synchronize physical and software control units for flexibility at the machine or shop floor levels.

- Task allocation: Task assignment involving the distribution of tasks to available resources with the use of Contract Net Protocol (CNP), a negotiation procedure between a manager and a set of candidate contractors about the assignment of a task [18]. Task allocation can be a part of planning and scheduling in some sense.

- Fault-tolerance: Detection of failure, diagnosis of failure, and determination of reasonable recovery actions.

- Real-time control: The system control that reacts within precise time constraints, being classified into hard (missing deadline results in catastrophic consequences) or soft (meeting deadline is desirable but missing a deadline will not cause serious damage).

- Planning and scheduling (the application of the present work): Optimal planning and scheduling of available resources in the production or process level.

2.2. Learning-Based Analytics

3. Self-Learning Factory and Hybrid Learning

3.1. Self-Learning Factory

3.2. Hybrid Learning

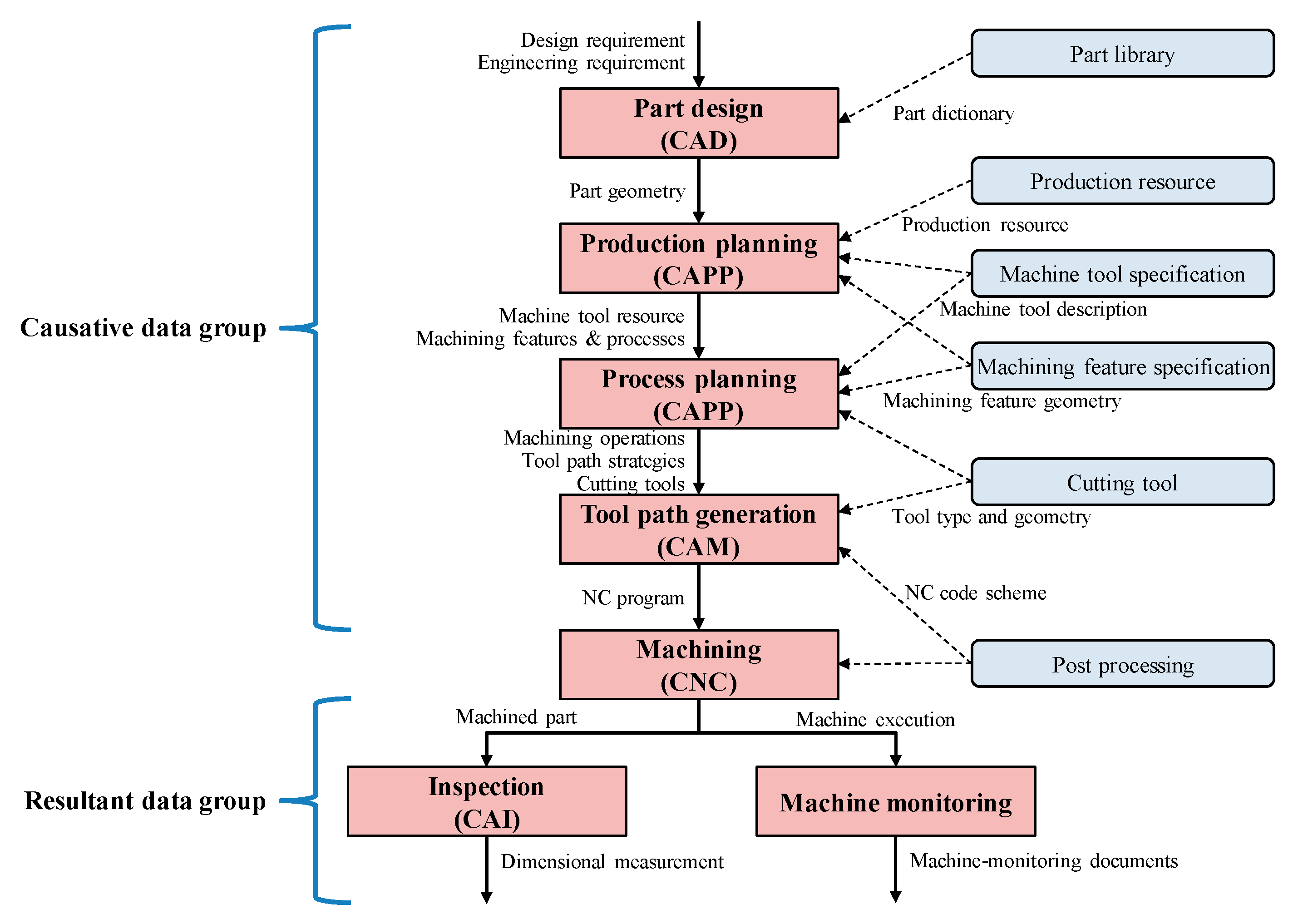

4. Mechanism

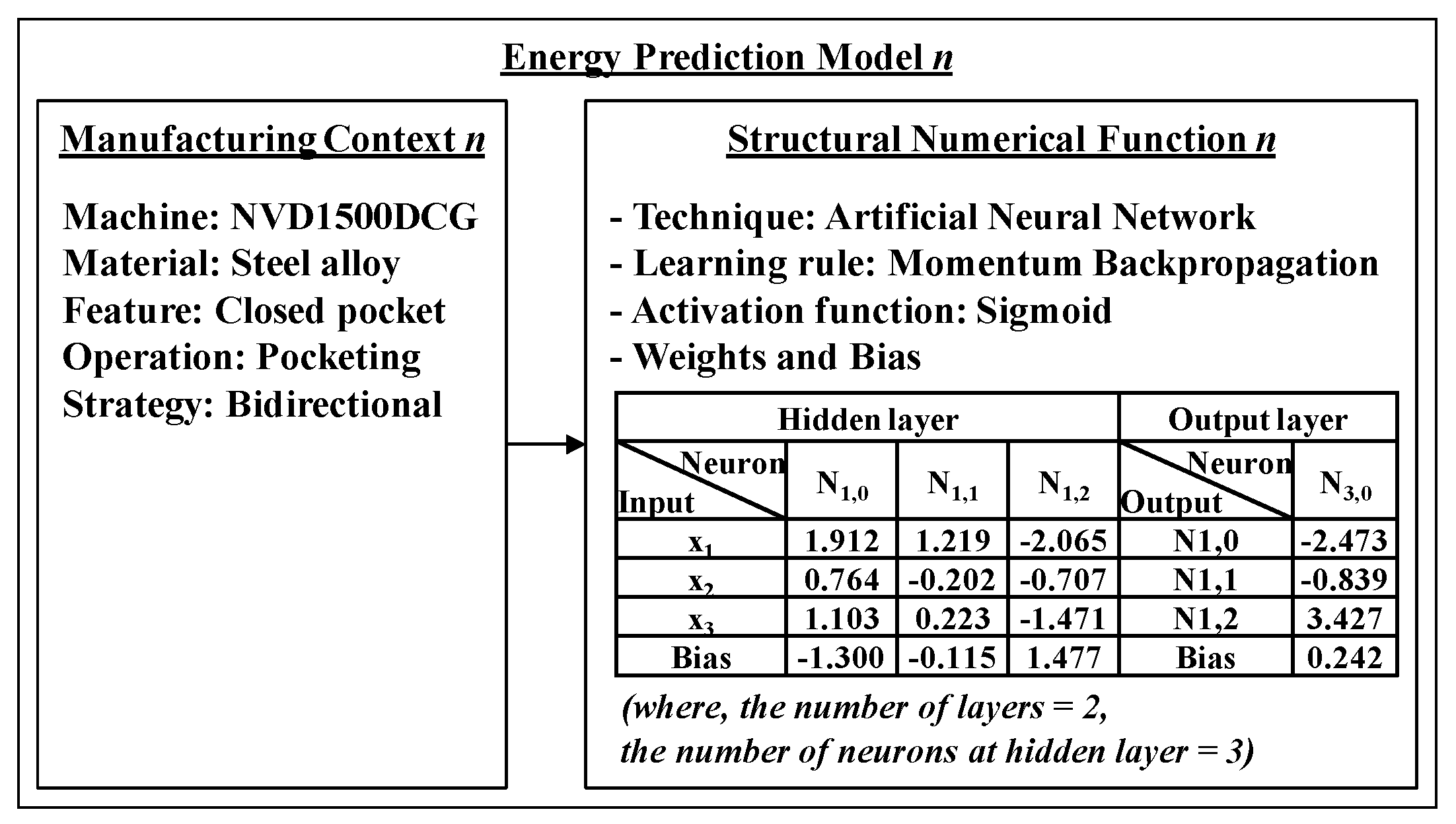

4.1. Modeling Method

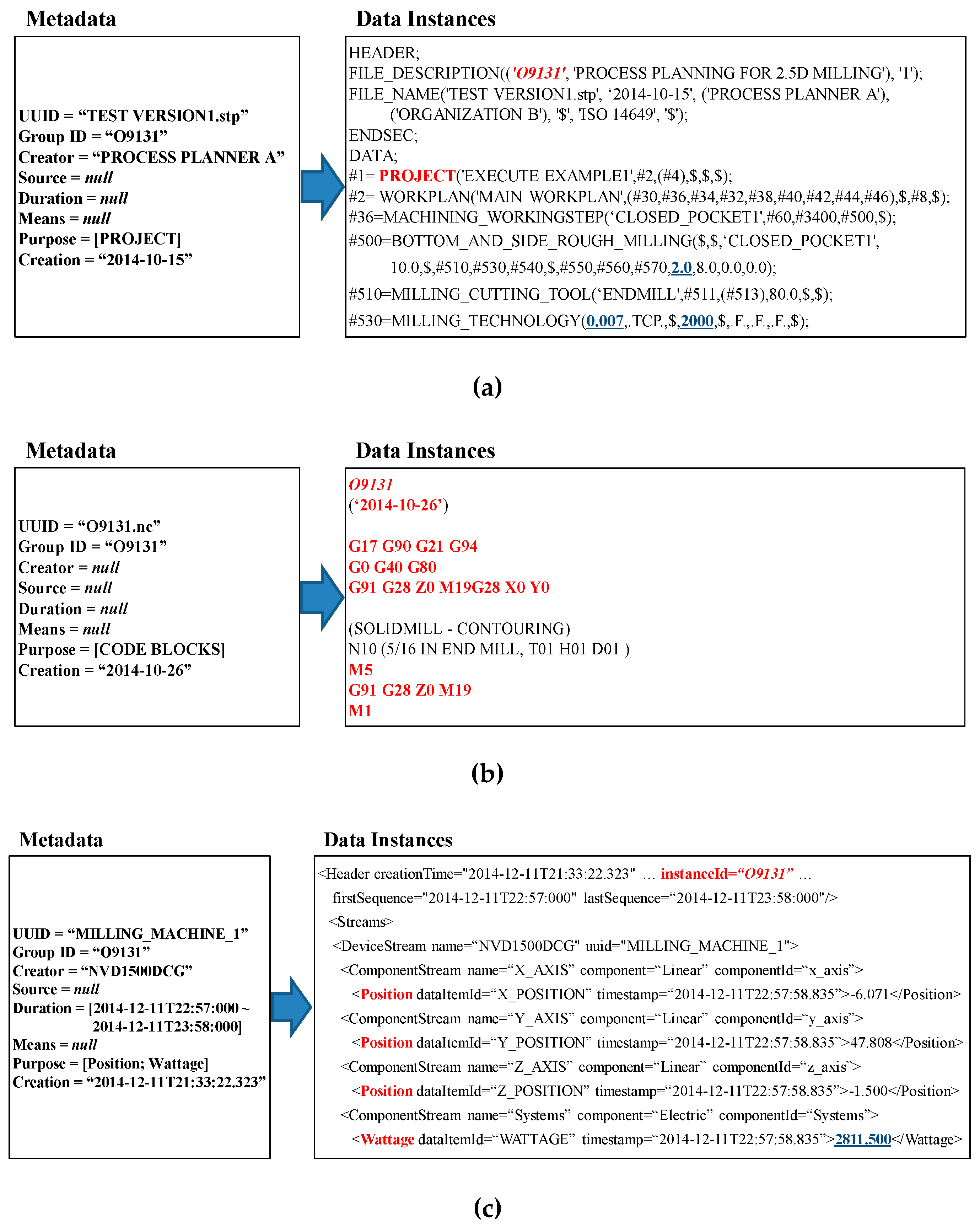

4.1.1. Machine-Learning Method

- UUID: Universally Unique Identifier.

- Group ID: an identifier for grouping instances.

- Creator: an identifier indicating who creates instances.

- Source: an identifier indicating where instances are stored.

- Duration: a period of time for gathering instances.

- Means: an identifier indicating how instances are obtained.

- Purpose: data attributes to be requested.

- Creation: a timestamp of data creation.

- Machine: an identifier for the machine tool that creates a model.

- Material: an identifier for a workpiece material.

- Feature: an identifier for a machining feature.

- Operation: an identifier related to a machining operation.

- Strategy: an identifier related to a machining strategy that identifies the tool path pattern.

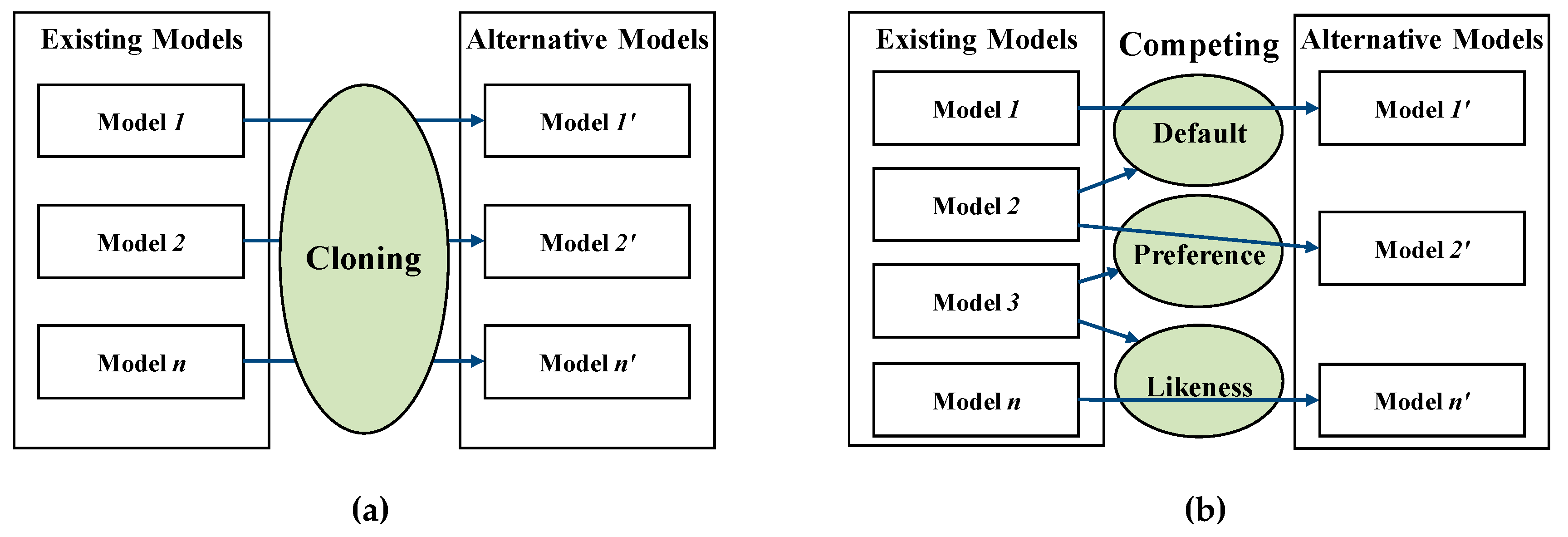

4.1.2. Transfer Learning Method

4.2. System Architecture

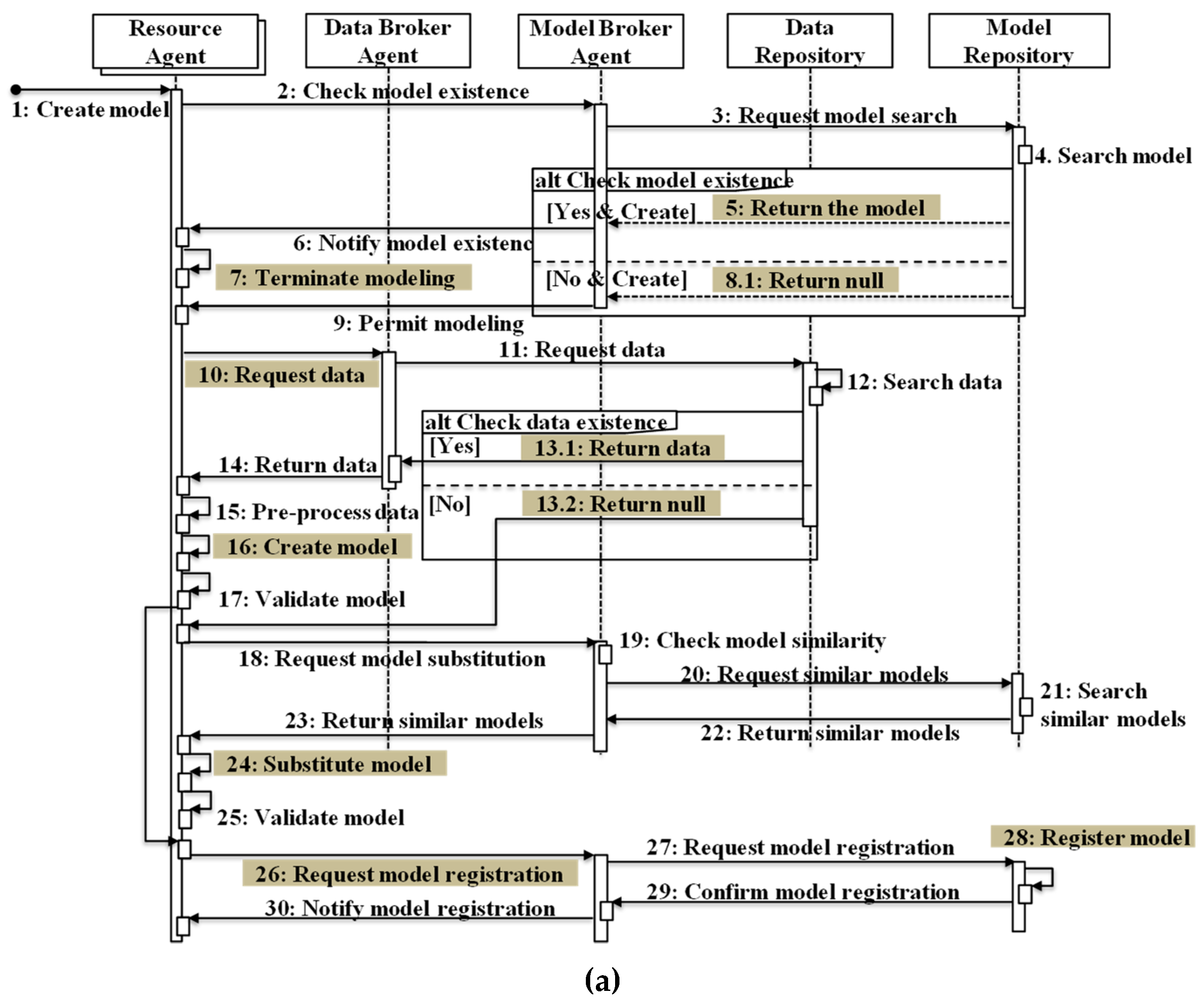

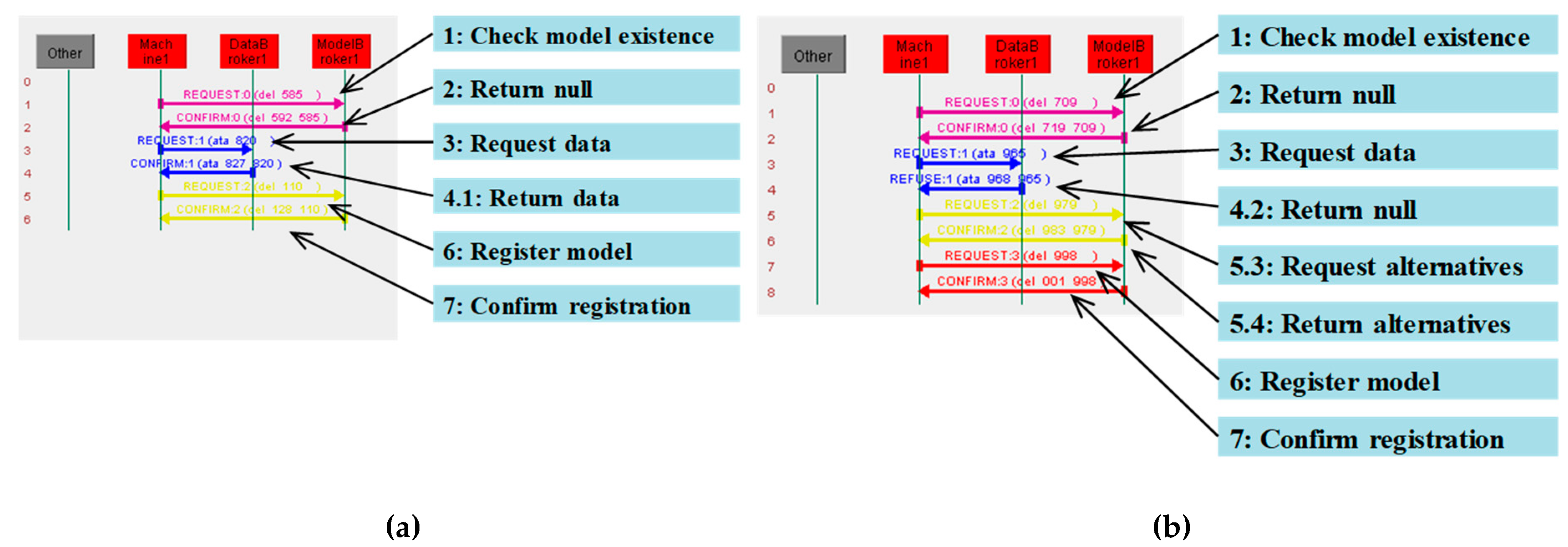

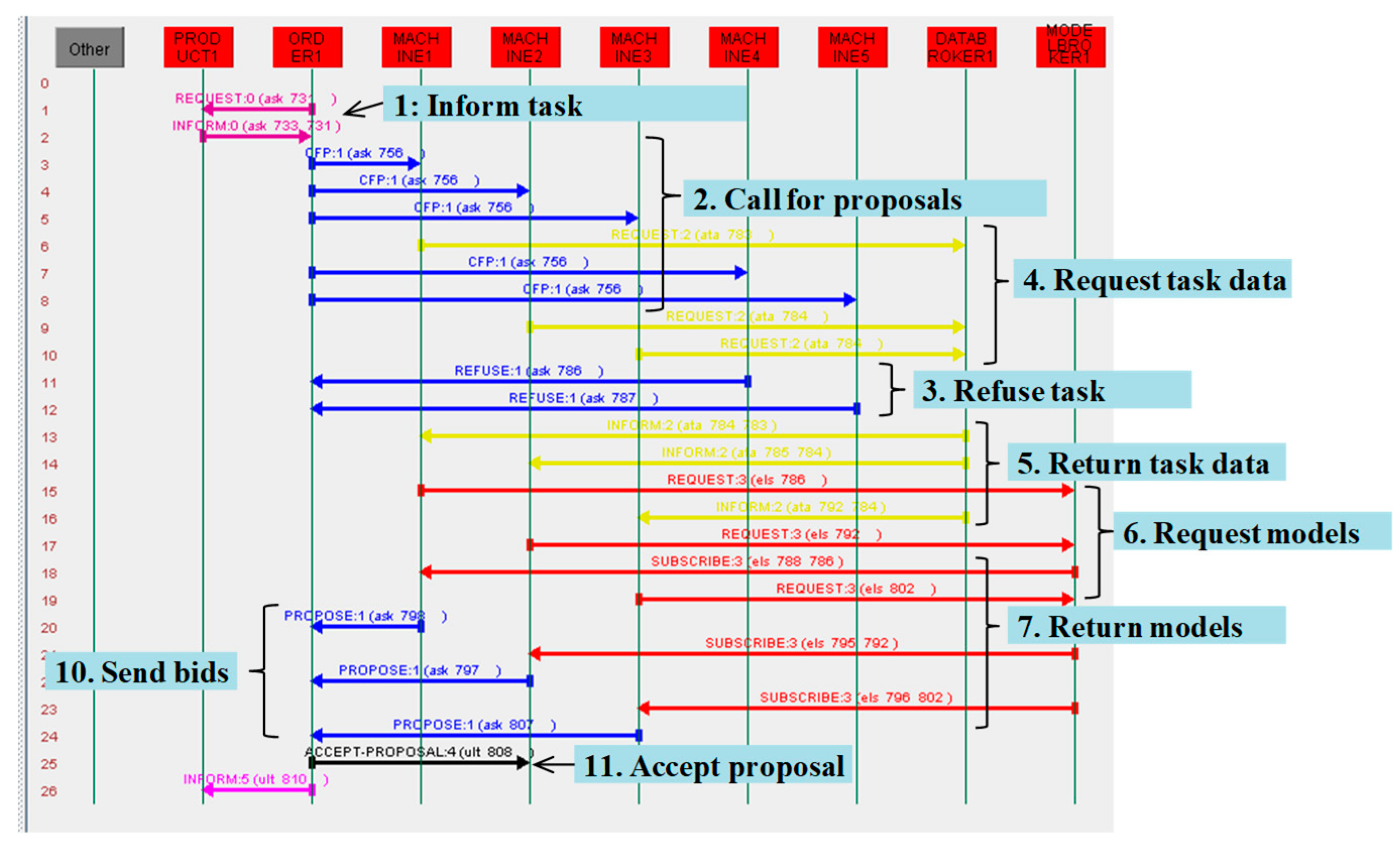

4.3. Operational Procedure

5. Implementation

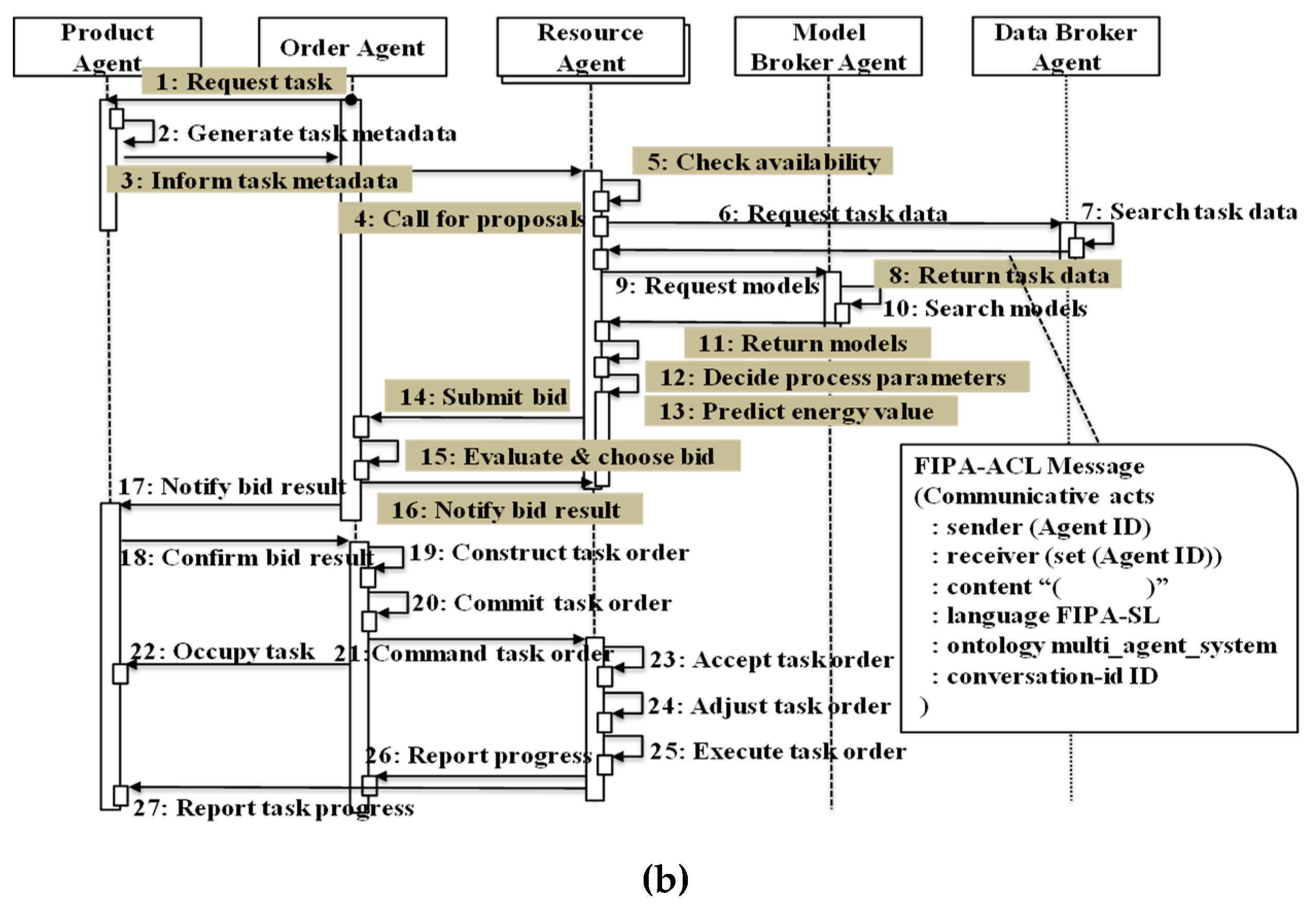

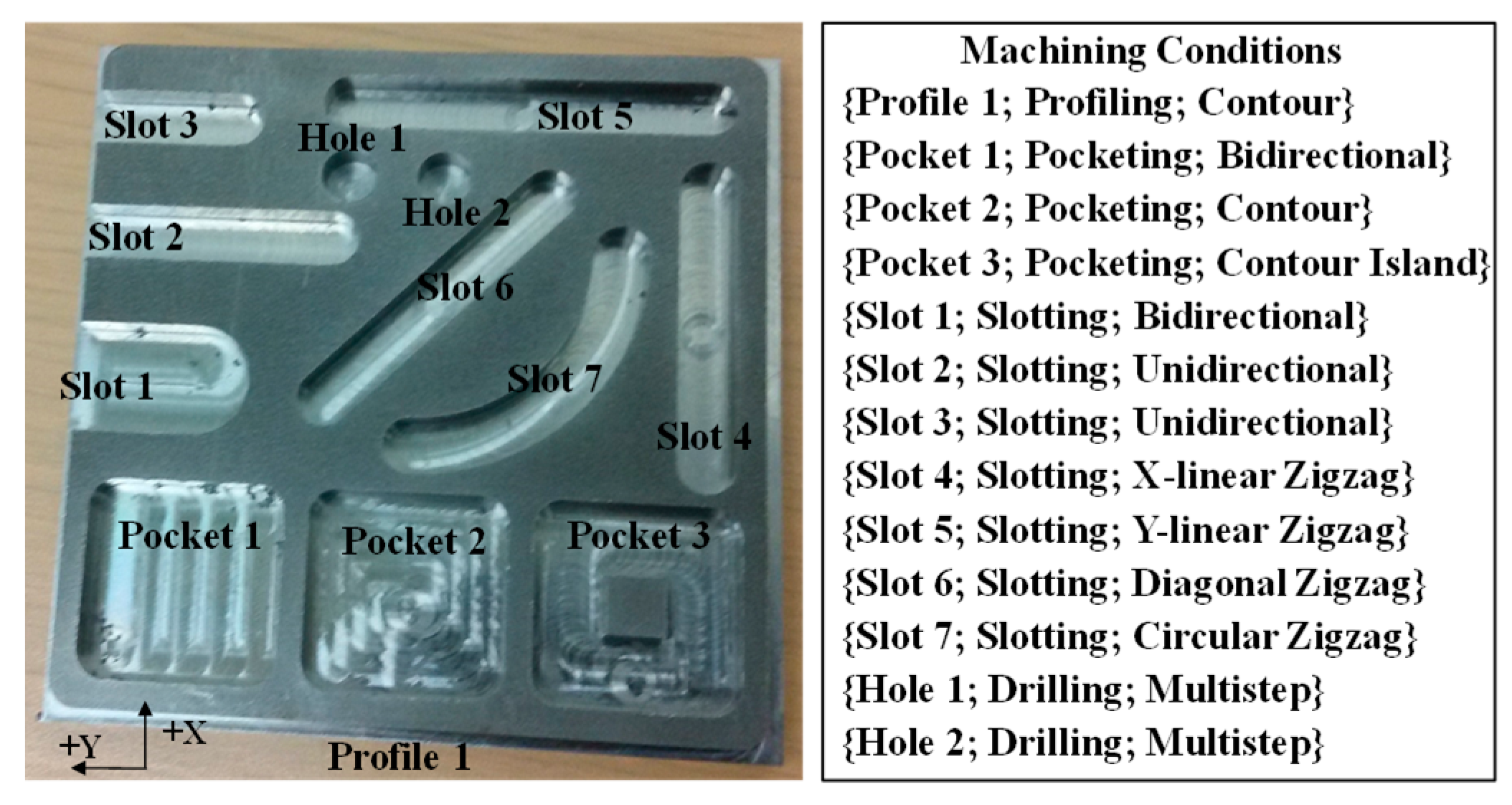

5.1. Implementation Scenarios

5.2. Prototype Implementation

5.3. Discussion

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Davis, J.; Edgar, T.; Porter, J.; Bernaden, J.; Sarli, M. Smart manufacturing, manufacturing intelligence and demand-dynamic performance. Comput. Chem. Eng. 2012, 47, 145–156. [Google Scholar] [CrossRef]

- Zuehlke, D. SmartFactory—Towards a factory-of-things. Annu. Rev. Control 2010, 34, 129–138. [Google Scholar] [CrossRef]

- Rajkumar, R.; Lee, I.S.; Sha, L.; Stankovic, J. Cyber-physical systems: The next computing revolution. In Proceedings of the 47th ACM/IEEE Design Automation Conference, Anaheim, CA, USA, 13–18 June 2010; pp. 731–736. [Google Scholar]

- Monostori, L.; Kadar, B.; Bauernhansl, T.; Kondoh, S.; Kumara, S.R.T.; Reinhart, G.; Sauer, O.; Schuh, G.; Sihn, W.; Ueda, K. Cyber-physical systems in manufacturing. CIRP Ann. 2016, 65, 621–641. [Google Scholar] [CrossRef]

- Schuh, G.; Anderl, R.; Gausemeier, J.; ten Hompel, M.; Wahlster, W. Industrie 4.0 Maturity Index—Managing the Digital Transformation of Companies; ACATECH Study; Herbert Utz Verlag: Munich, Germany, 2017. [Google Scholar]

- Shen, W.; Maturana, F.; Norrie, D.H. Enhancing the performance of an agent-based manufacturing system through learning and forecasting. J. Intell. Manuf. 2000, 11, 365–380. [Google Scholar] [CrossRef]

- Brussel, H.V.; Wyns, J.; Valckenaers, P.; Bongaerts, L.; Peeters, P. Reference architecture for holonic manufacturing systems: PROSA. Comput. Ind. 1998, 37, 255–274. [Google Scholar] [CrossRef]

- Shen, W.; Hao, Q.; Yoon, H.J.; Norrie, D.H. Applications of agent-based systems in intelligent manufacturing: An updated review. Adv. Eng. Inform. 2006, 20, 415–431. [Google Scholar] [CrossRef]

- Priore, P.; De la Fuente, D.; Puente, J.; Parreno, J. A comparison of machine-learning algorithms for dynamic scheduling of flexible manufacturing systems. Eng. Appl. Artif. Intell. 2006, 19, 247–255. [Google Scholar] [CrossRef]

- Pan, S.J.; Yang, Q. A survey on transfer learning. IEEE Trans. Knowl. Data Eng. 2010, 22, 1345–1359. [Google Scholar] [CrossRef]

- Manufacturing Energy Consumption Survey. Available online: https://www.eia.gov/consumption/manufacturing/data/2014/index.php (accessed on 24 September 2019).

- Hu, S.; Liu, F.; He, Y.; Hu, T. An on-line approach for energy efficiency monitoring of machine tools. J. Clean. Prod. 2012, 27, 133–140. [Google Scholar] [CrossRef]

- Kara, S.; Li, W. Unit process energy consumption models for material removal processes. CIRP Ann. 2011, 60, 37–40. [Google Scholar] [CrossRef]

- Shin, S.J.; Woo, J.Y.; Rachuri, S.; Meilanitasari, P. Standard data-based predictive modeling for power consumption in turning machining. Sustainability 2018, 10, 598. [Google Scholar] [CrossRef]

- Babiceanu, R.F.; Chen, F.F. Development and applications of Holonic manufacturing systems: A survey. J. Intell. Manuf. 2006, 17, 111–131. [Google Scholar] [CrossRef]

- Monostori, L.; Vancza, J.; Kumara, S.R.T. Agent-based systems for manufacturing. CIRP Ann. 2006, 55, 697–720. [Google Scholar] [CrossRef]

- Leitão, P. Agent-based distributed manufacturing control: A state-of-the art survey. Eng. Appl. Artif. Intell. 2009, 22, 979–991. [Google Scholar] [CrossRef]

- Odell, J.J.; Van Dyke Parunak, H.; Bauer, B. Representing Agent Interaction Protocols in UML. In Agent-Oriented Software Engineering; Ciancarini, P., Wooldridge, M.J., Eds.; Springer: Berlin, Germany, 2000; pp. 121–140. [Google Scholar]

- Alotaibi, A.; Lohse, N.; Vu, T.M. Dynamic Agent-based Bi-objective Robustness for Tardiness and Energy in a Dynamic Flexible Job Shop. Procedia CIRP 2016, 57, 728–733. [Google Scholar] [CrossRef] [Green Version]

- Marchiori, F.; Belloni, A.; Beninie, M.; Cateni, S.; Colla, V.; Ebeld, A.; Lupinelli, M.; Nastasi, G.; Neuer, M.; Pietrosanti, C.; et al. Integrated dynamic energy management for steel production. Energy Procedia 2017, 105, 2772–2777. [Google Scholar] [CrossRef]

- Giret, A.; Trentesaux, D.; Salido, M.A.; Garcia, E.; Adam, E. A holonic multi-agent methodology to design sustainable intelligent manufacturing control systems. J. Clean. Prod. 2017, 167, 1370–1386. [Google Scholar] [CrossRef]

- Lind, M.; Roulet-Dubonnet, O. Holonic shop-floor application for handling, feeding and transportation of workpieces. Int. J. Prod. Res. 2011, 49, 1441–1454. [Google Scholar] [CrossRef] [Green Version]

- Adam, E.; Berger, T.; Sallez, Y.; Trentesaux, D. Role-based manufacturing control in a holonic multi-agent system. Int. J. Prod. Res. 2011, 49, 1455–1468. [Google Scholar] [CrossRef]

- Barbosa, J.; Leitão, P.; Adam, E.; Trentesaux, D. Dynamic self-organization in holonic multi-agent manufacturing systems: The ADACOR evolution. Comput. Ind. 2015, 66, 99–111. [Google Scholar] [CrossRef] [Green Version]

- Wang, K.; Choi, S.H. A holonic approach to flexible flow shop scheduling under stochastic processing times. Comput. Oper. Res. 2014, 43, 157–168. [Google Scholar] [CrossRef]

- Hsieh, F.S.; Lin, J.-B. A self-adaptation scheme for workflow management in multi-agent systems. J. Intell. Manuf. 2016, 27, 131–148. [Google Scholar] [CrossRef]

- Leitão, P. A holonic disturbance management architecture for flexible manufacturing systems. Int. J. Prod. Res. 2011, 49, 1269–1284. [Google Scholar] [CrossRef]

- Silva, R.; Blos, M.; Junqueira, F.; Filho, D.S.; Miyagi, P. A service-oriented and holonic control architecture to the reconfiguration of dispersed manufacturing systems. In Proceedings of the 5th Doctoral Conference on Computing, Electrical and Industrial Systems (DoCEIS), Costa de Caparica, Portugal, 7–9 April 2014. [Google Scholar]

- Jovanovic, M.; Zupan, S.; Prebil, I. Holonic control approach for the “green”-tyre manufacturing system using IEC 61499 standard. J. Manuf. Syst. 2016, 40, 119–136. [Google Scholar] [CrossRef]

- Indriago, C.; Cardin, O.; Rakoto, N.; Castagna, P.; Chacon, E. H2CM: A holonic architecture for flexible hybrid control systems. Comput. Ind. 2016, 77, 15–28. [Google Scholar] [CrossRef]

- Nejad, H.T.N.; Sugimura, N.; Iwamura, K. Agent-based dynamic integrated process planning and scheduling in flexible manufacturing systems. Int. J. Prod. Res. 2011, 49, 1373–1389. [Google Scholar] [CrossRef]

- Quintanilla, F.G.; Cardin, O.; L’Anton, A.; Castagna, P. A Petri net-based methodology to increase flexibility in service-oriented holonic manufacturing systems. Comput. Ind. 2016, 76, 53–68. [Google Scholar] [CrossRef]

- Nouri, H.E.; Driss, O.B.; Ghédira, K. Simultaneous scheduling of machines and transport robots in flexible job shop environment using hybrid metaheuristics based on clustered holonic multiagent model. Comput. Ind. Eng. 2016, 102, 488–501. [Google Scholar] [CrossRef]

- Pascal, C.; Panescu, D. On rescheduling in holonic manufacturing systems. Comput. Ind. 2019, 104, 34–46. [Google Scholar] [CrossRef]

- Monostori, L.; Brussel, H.V.; Westkampfer, E. Machine learning approaches to manufacturing. CIRP Ann. 1996, 45, 675–712. [Google Scholar] [CrossRef]

- Wuest, T.; Weimer, D.; Irgens, C.; Thoben, K.D. Machine learning in manufacturing: Advantages, challenges, and applications. Prod. Manuf. Res. 2016, 4, 23–45. [Google Scholar] [CrossRef]

- Monostori, L. AI and machine learning techniques for managing complexity, changes and uncertainties in manufacturing. Eng. Appl. Artif. Intell. 2003, 16, 277–291. [Google Scholar] [CrossRef]

- Kadar, B.; Monostori, L. Approaches to Increase the Performance of Agent-Based Production Systems; Engineering of Intelligent Systems; Springer: Heidelberg, Germany, 2001; pp. 612–621. [Google Scholar]

- Liu, Z.; Guo, Y. A hybrid approach to integrate machine learning and process mechanics for the prediction of specific cutting energy. CIRP Ann. 2018, 67, 57–60. [Google Scholar] [CrossRef]

- Garg, A.; Lam, J.S.L.; Gao, L. Energy conservation in manufacturing operations: Modelling the milling process by a new complexity-based evolutionary approach. J. Clean. Prod. 2015, 108, 34–45. [Google Scholar] [CrossRef]

- Bhinge, R.; Park, J.; Law, K.H.; Dornfeld, D.A.; Helu, M.; Rachuri, S. Toward a Generalized Energy Prediction Model for Machine Tools. J. Manuf. Sci. Eng. 2017, 139, 041013. [Google Scholar] [CrossRef]

- Bang, S.H.; Ak, R.; Narayanan, A.; Lee, Y.T.; Cho, H.B. A survey on knowledge transfer for manufacturing data analytics. Comput. Ind. 2019, 104, 116–130. [Google Scholar] [CrossRef]

- Chen, G.; Li, Y.; Liu, X. Pose-dependent tool tip dynamics prediction using transfer learning. Int. J. Mach. Tools Manuf. 2019, 137, 30–41. [Google Scholar] [CrossRef]

- Shin, S.J.; Woo, J.Y.; Rachuri, S. Energy efficiency of milling machining: Component modeling and online optimization of cutting parameters. J. Clean. Prod. 2017, 161, 12–29. [Google Scholar] [CrossRef]

- Lee, J.; Lapira, E.; Bagheri, B.; Kao, H. Recent advances and trends in predictive manufacturing systems in big data environment. Manuf. Lett. 2013, 1, 38–41. [Google Scholar] [CrossRef]

- Li, L.; Liu, F.; Chen, B.; Li, C.B. Multi-objective optimization of cutting parameters in sculptured parts machining based on neural network. J. Intell. Manuf. 2015, 26, 891–898. [Google Scholar] [CrossRef]

- Aramcharoen, A.; Mativenga, P.T. Critical factors in energy demand modelling for CNC milling and impact of toolpath strategy. J. Clean. Prod. 2014, 78, 63–74. [Google Scholar] [CrossRef]

- Han, S.H.; Choi, Y.; Yoo, S.B.; Park, N.K. Collaborative engineering design based on an intelligent STEP database. Concurr. Eng. Res. Appl. 2002, 10, 239–249. [Google Scholar] [CrossRef]

- Xu, X.W.; Wang, H.; Mao, J.; Newman, S.T.; Kramer, T.R.; Proctor, F.M.; Michaloski, J.L. STEP-compliant NC research: The search for intelligent CAD/CAPP/CAM/CNC integration. Int. J. Prod. Res. 2005, 43, 3703–3743. [Google Scholar] [CrossRef]

- Vijayaraghavan, A.; Dornfeld, D. Automated energy monitoring of machine tools. CIRP Ann. 2010, 59, 21–24. [Google Scholar] [CrossRef] [Green Version]

- MIT Critical Data. Secondary Analysis of Electronic Health Records; Springer International Publishing: Cham, Switzerland, 2016; pp. 115–141. [Google Scholar]

- Nannapaneni, S.; Mahadevan, S.; Rachuri, S. Performance evaluation of a manufacturing process under uncertainty using Bayesian networks. J. Clean. Prod. 2016, 113, 947–959. [Google Scholar] [CrossRef] [Green Version]

- Shin, S.J.; Woo, J.; Rachuri, S.; Seo, W. An energy-efficient process planning system using machine-monitoring data: A data analytics approach. Comput. Aided Des. 2019, 110, 92–109. [Google Scholar] [CrossRef]

- Witten, I.H.; Frank, E. Data Mining—Practical Machine Learning Tools and Techniques; Elsevier: San Francisco CA, USA, 2005. [Google Scholar]

- Zhong, E.; Fan, W.; Yang, Q.; Verscheure, O.; Ren, J. Cross validation framework to choose amongst models and datasets for transfer learning. In Machine Learning and Knowledge Discovery in Databases; Springer: Heidelberg, Germany, 2010; pp. 547–562. [Google Scholar]

- Bellifemine, F.; Caire, G.; Greenwood, D. Developing Multi-Agent Systems with JADE; John Wiley & Sons, Ltd.: Chichester, UK, 2007. [Google Scholar]

- Larek, R.; Brinksmeier, E.; Meyer, D.; Pawletta, T.; Hagendorf, O. A discrete-event simulation approach to predict power consumption in machining processes. Prod. Eng. Res. Dev. 2011, 5, 575–579. [Google Scholar] [CrossRef]

- Shin, S.J.; Woo, J.; Kim, D.B.; Kumaraguru, S.; Rachuri, S. Developing a virtual machining model to generate MTConnect machine-monitoring data from STEP-NC. Int. J. Prod. Res. 2016, 54, 4487–4505. [Google Scholar] [CrossRef]

| Application | Citation | Objective | Holon Characteristics (Basic/Staff Holon) |

|---|---|---|---|

| Automation | [22] | A logic control system that supports autonomous and cooperative actions on Automated Guided Vehicles (AGV) | - Resource (B) 1: the set of devices consisting of robots, workpiece suppliers, and conveyors - Order (B): contains the data relevant to top-level holon orders - Product (B): represents the abstraction of constituent parts - Scheduling (S) 1: provides scheduling data to other holons - Traffic controller (S): surveys AGV traffic and advises AGV holons to sort out conflicts and avoid congestion |

| [23] | An adaptive control system that operates using a role-based mechanism to maintain performance even when faced with perturbations | - Holon agent (B): a resource or an intelligent product, which can inform, communicate, decide and act independently - Optimization mechanism (S): a societal or environmental optimization mechanism to ensure global performance | |

| [24] | A high-level architecture with integration of both behavioral and structural self-organization for adaptive production control | - Product (B): represents products and the knowledge for production - Task (B): manages real-time execution of orders - Operational (B): represents resources (e.g., robots and operators) - Supervisor (S): introduces optimization into the system | |

| Task allocation | [25] | A machine allocation algorithm that employs the genetic algorithm control for schedule generation and the shortest processing time-based Contract Net Protocol (CNP) for schedule negotiation | - Job (B): represents single jobs - Machine (B): represents machines - Job management (S): manages job holons and informs decomposition into decomposition holons - Decomposition (S): allows for cluster generation and scheduling assignment - Cluster (S): groups a number of machine holons - Genetic Algorithm (S): determines job process sequences in a meta-heuristic method |

| [26] | A software design methodology that formulates workflow adaptation problems based on the CNP | - Task (B): represents tasks to be processed - Actor (B): represents workers or customers in the system | |

| Fault-tolerance | [27] | A distributed architecture that performs disturbance handling and predicts mean time between failures | - Resource (B): monitors the device’s status for predictive maintenance - Quality control (S): performs detection through quality verification - Task (S): monitors production orders - Supervisor (S): performs meta-monitoring by aggregating the information under holon clusters |

| [28] | A service-oriented architecture that operates mechanisms for fault treatment with reconfiguration of dispersed manufacturing | - Product (B): manages requests of products, searches for corresponding holons, and creates a work order - Task (B): manages recipes - Operation (B): represents equipment and humans - Supervisor (S): coordinates the services of all holons | |

| Real-time control | [29] | An adaptive control and distributed approach using IEC 61499 function blocks in machining groups | - Product (B): requests manufacturing to planning holons - Planning (B): assigns product operations into machines - Main Control (B): sequences operations and calculates the processing time of production - Operation (B): consists of: control layers to encapsulate agent and function blocks, interface layers to contain virtual simulation and a logical adapter, and machine layers to encapsulate a real machine and its virtual model |

| [30] | A holonic hybrid control system that interacts discrete planning and continuous processes | - Product (B): stores and communicates recipes of products - Order (B): determines future planning and holarchy of the system - Resource (B): performs device online control | |

| Planning/scheduling | [31] | An integrated planning and scheduling algorithm that dynamically generates optimal process plans and schedules | - Job (B): represents jobs to be manufactured - Machine tool (B): represents machine tools - Machining process (B): represents machining processes by machine tools - Production engineering (S): initializes the basic holons and modifies job specifications for disturbance handling - Job order (S): represents manufacturing tasks - Coordination (S): determines suitable assignment of job holons using mathematical models |

| [32] | A Petri-net based methodology that computes sequential flexibility for dead-lock free planning and scheduling | - Product (B): possesses product’s process information - Resource (B): provides manufacturing capability - Order (B): coordinates the execution of production plans - Directory facilitator (S): provides static information on the system as an information server | |

| [33] | A hybrid metaheuristic-based holonic multi-agent model for flexible job shop scheduling and robot routing | - Robot-system (B): represents robots used for operation - Order-system (B): executes orders within each job - Machine-system (B): represents machine system tools - Scheduler (B): prepares the best promising reasons of the search space - Cluster (B): guides the search to the global optimum solution of the problem | |

| [34] | A rescheduling mechanism for unpredicted orders and unavailable resource appearance | - Product/Order (B): issues goals according to orders to be solved as managers - Resource (B): represents machines to carry out operations - Contractor (S): performs negotiations among resource holons within the CNP |

| Strategy. | Unidirectional x-axis down Milling | Unidirectional x-axis up Milling | Bidirectional x-axis | Unidirectional y-axis | Contour | Spiral |

|---|---|---|---|---|---|---|

| Unidirectional x-axis down milling | High | Low | High | Low | Low | |

| Unidirectional x-axis up milling | High | Low | High | Low | Low | |

| Bidirectional x-axis | Low | Low | Low | High | High | |

| Unidirectional y-axis | High | High | Low | Low | Low | |

| Contour | Low | Low | High | Low | High | |

| Spiral | Low | Low | High | Low | High |

| Manufacturing Context | x Variables | y Variable | ||||||

|---|---|---|---|---|---|---|---|---|

| Machine | Material | Feature | Operation | Strategy | Feedrate | Spindle speed | Cutting depth | Energy |

| NVD1500DCG | Steel alloy | Closed pocket | Pocketing | Bi-directional | 0.333 | 0.5 | 1 | 0.188 |

| 0.667 | 0 | 0 | 0.546 | |||||

| 0.667 | 1 | 0 | 0.227 | |||||

| 0.667 | 1 | 1 | 0.000 | |||||

| Contour | 0.333 | 0.5 | 0 | 0.796 | ||||

| 1 | 0.5 | 0 | 0.256 | |||||

| 0.333 | 0.5 | 1 | 0.269 | |||||

| 0.667 | 0 | 0 | 0.386 | |||||

| Trial | Feedrate (mm/tooth) | Spindle Speed (RPM) | Cutting Depth (mm) |

|---|---|---|---|

| 1 | 0.0127 | 1500 | 1.5 |

| 2 | 0.0127 | 2000 | 1.5 |

| 3 | 0.0127 | 1750 | 1 |

| 4 | 0.0229 | 1750 | 1 |

| 5 | 0.0127 | 1750 | 2 |

| 6 | 0.0178 | 1500 | 1 |

| 7 | 0.0178 | 2000 | 1 |

| 8 | 0.0178 | 2000 | 2 |

| 9 | 0.0178 | 1750 | 1.5 |

| 10 | 0.0076 | 1750 | 1.5 |

| 11 | 0.0152 | 1750 | 1.5 |

| 12 | 0.0127 | 1750 | 1.5 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shin, S.-J.; Kim, Y.-M.; Meilanitasari, P. A Holonic-Based Self-Learning Mechanism for Energy-Predictive Planning in Machining Processes. Processes 2019, 7, 739. https://doi.org/10.3390/pr7100739

Shin S-J, Kim Y-M, Meilanitasari P. A Holonic-Based Self-Learning Mechanism for Energy-Predictive Planning in Machining Processes. Processes. 2019; 7(10):739. https://doi.org/10.3390/pr7100739

Chicago/Turabian StyleShin, Seung-Jun, Young-Min Kim, and Prita Meilanitasari. 2019. "A Holonic-Based Self-Learning Mechanism for Energy-Predictive Planning in Machining Processes" Processes 7, no. 10: 739. https://doi.org/10.3390/pr7100739

APA StyleShin, S.-J., Kim, Y.-M., & Meilanitasari, P. (2019). A Holonic-Based Self-Learning Mechanism for Energy-Predictive Planning in Machining Processes. Processes, 7(10), 739. https://doi.org/10.3390/pr7100739